Anti-slip breathable operating gloves and preparation method thereof

A glove and anti-slip technology, applied in gloves, protective clothing, clothing, etc., can solve the problems of poor wear resistance, airtight coating, lack of softness, etc., and achieve both softness, wear resistance, and good air permeability , the effect of good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

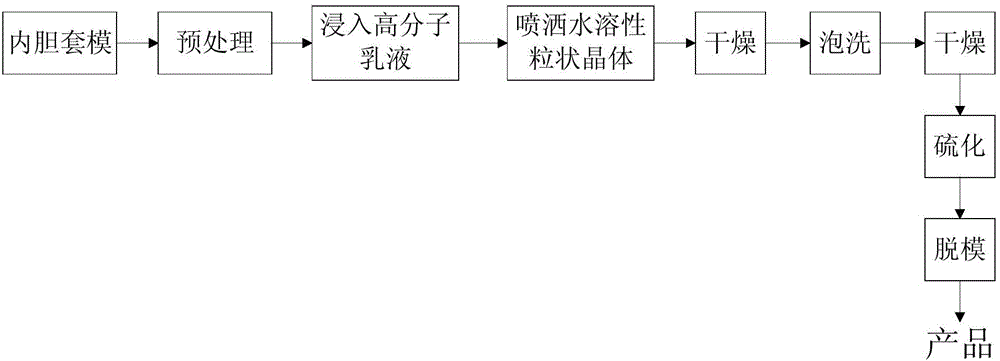

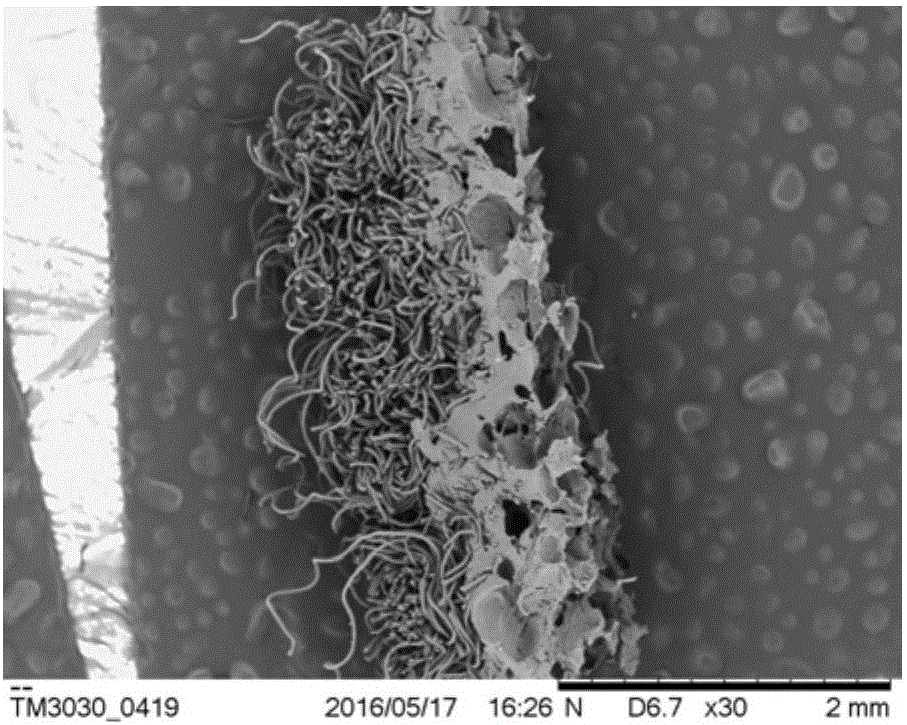

[0068] Such as figure 1 and figure 2 As shown, the specific embodiment part of the present invention provides a kind of preparation method of non-slip breathable work gloves, and described method comprises the following steps:

[0069] (1) preparing polymer emulsion;

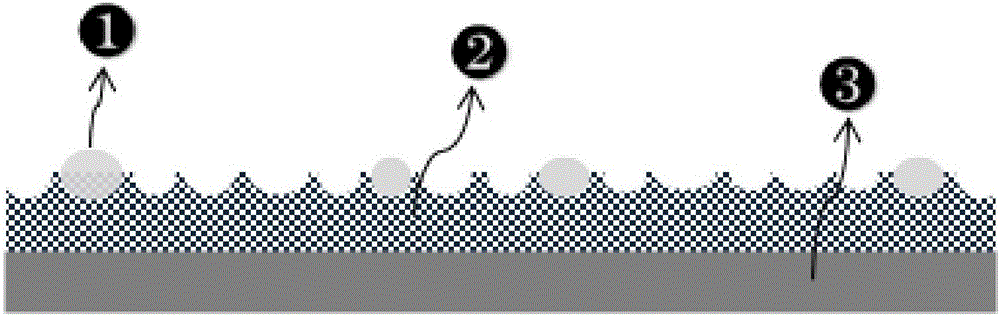

[0070] (2) Put the glove liner 3 on the mold, and after pretreatment, immerse the glove liner 3 in the prepared polymer emulsion to form the polymer coating 2;

[0071] (3) Sprinkle water-soluble granular crystals 1 on the surface of the unsolidified polymer coating 2, then perform drying treatment, and then dissolve the water-soluble granular crystals 1 on the surface of the polymer coating with water;

[0072] (4) The glove liner 3 treated in step (3) is dried, vulcanized and demoulded to obtain a glove product.

Embodiment 1

[0074] This embodiment provides a preparation method of non-slip breathable work gloves, the process of the method is as follows:

[0075] (1) Preparation of polymer emulsion:

[0076] Add KOH, sodium dodecylbenzenesulfonate, sulfur, zinc diethyldithiocarbamate (ZDC), ZnO, antioxidant 2246, tea Saponin, citric acid ester, black pigment, stir evenly to obtain a compound emulsion, let it stand for 18-20 hours, then pass gas into the emulsion, and perform foaming, so that the amount of generated bubbles is controlled by 5-30% of the volume of the emulsion, and the foam is uniform , then add sodium polyacrylate to the emulsion to thicken the emulsion to 800 ± 50mPa·s (using a rotor viscometer: No. 3 rotor, 60 rotation speed measurement), to obtain a polymer emulsion;

[0077] Table 1: Raw material ratio table of polymer emulsion in Example 1

[0078] Element

Solid content (wt%)

Weight percent (wt%)

Nitrile Latex

45

82.5

KOH

0.8

...

Embodiment 2

[0093] This embodiment provides a preparation method of non-slip breathable work gloves, the process of the method is as follows:

[0094] (1) Preparation of polymer emulsion:

[0095] Add KOH, sodium dodecylbenzenesulfonate, sulfur, zinc dimethyl dithiocarbamate, ZnO, antioxidant 2246, tea saponin, Citrate, black pigment, stir evenly to obtain a compound emulsion, let it stand for 12-16 hours, then pass gas into the emulsion, and perform foaming, so that the amount of bubbles generated is controlled by 15-20% of the emulsion volume, foam evenly, and then pour into the emulsion Sodium polyacrylate is added to the emulsion to thicken the emulsion to 300±50mPa·s (measured with a rotor viscometer: No. 3 rotor, 60 rotation speed) to obtain a polymer compound emulsion;

[0096] Table 2: Raw material ratio table of polymer emulsion in Example 2

[0097] Element

Solid content (wt%)

Weight percent (wt%)

Nitrile Latex

45

80

KOH

-

0.5

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com