Patents

Literature

43 results about "Glove liner" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

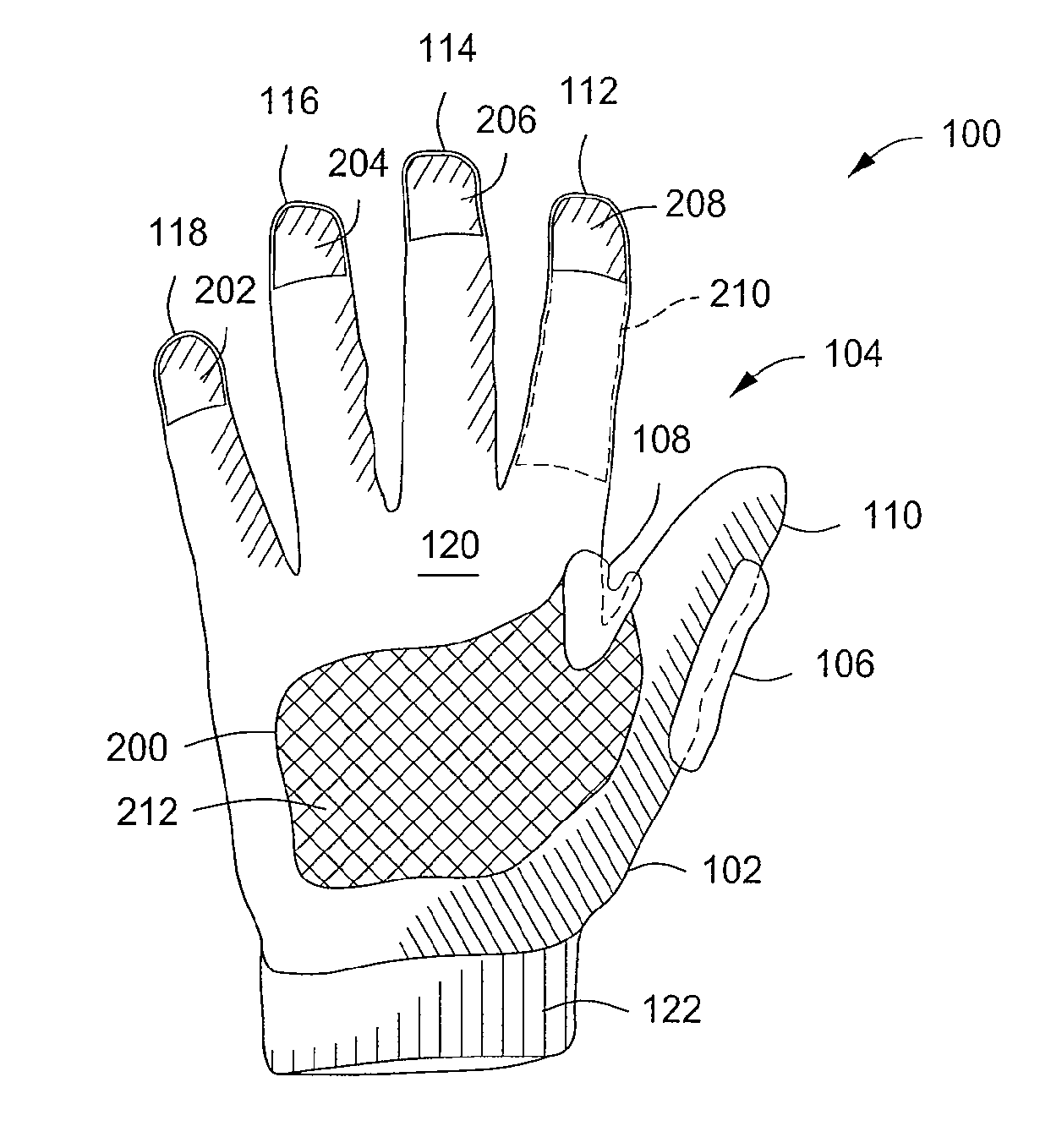

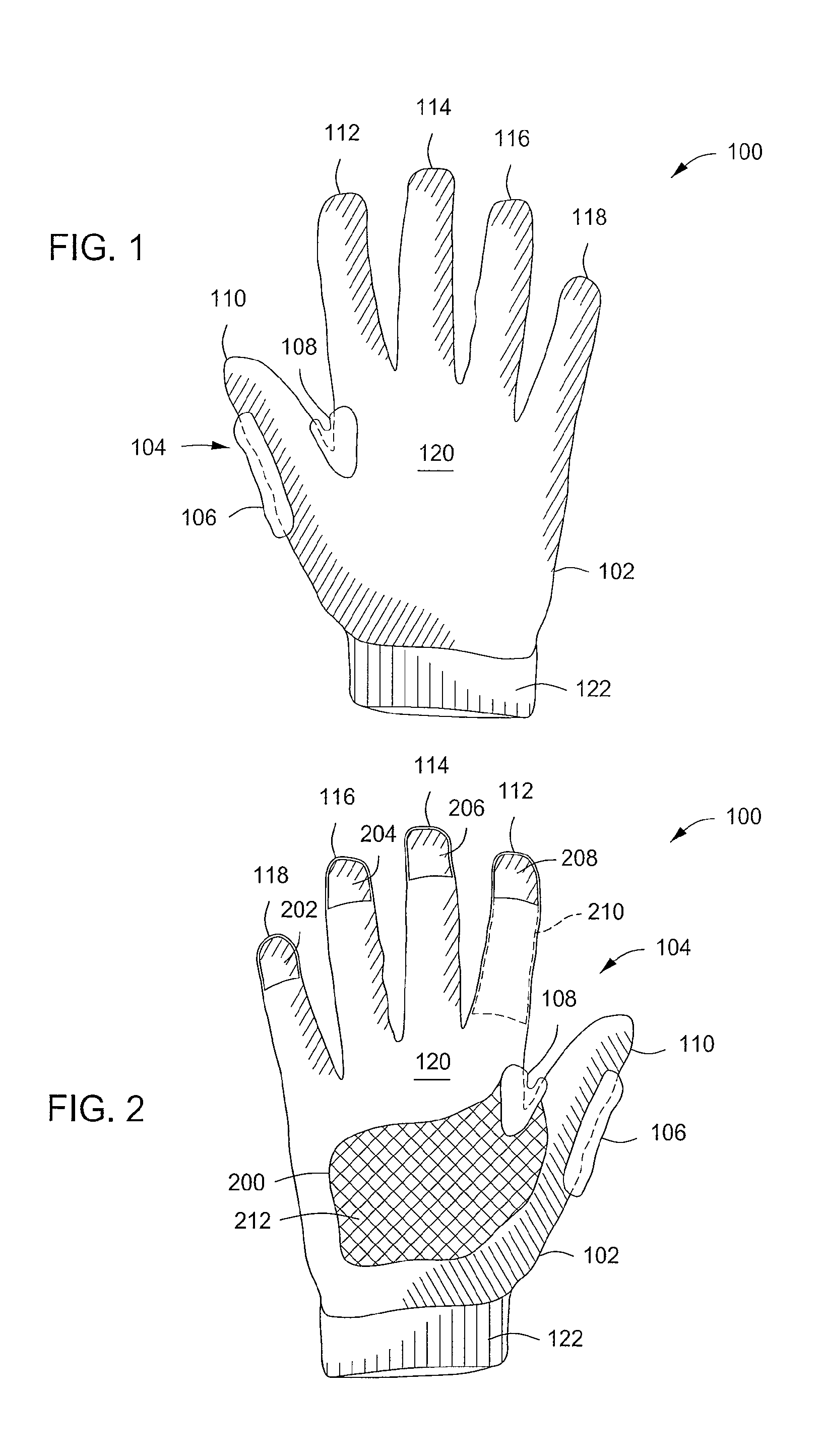

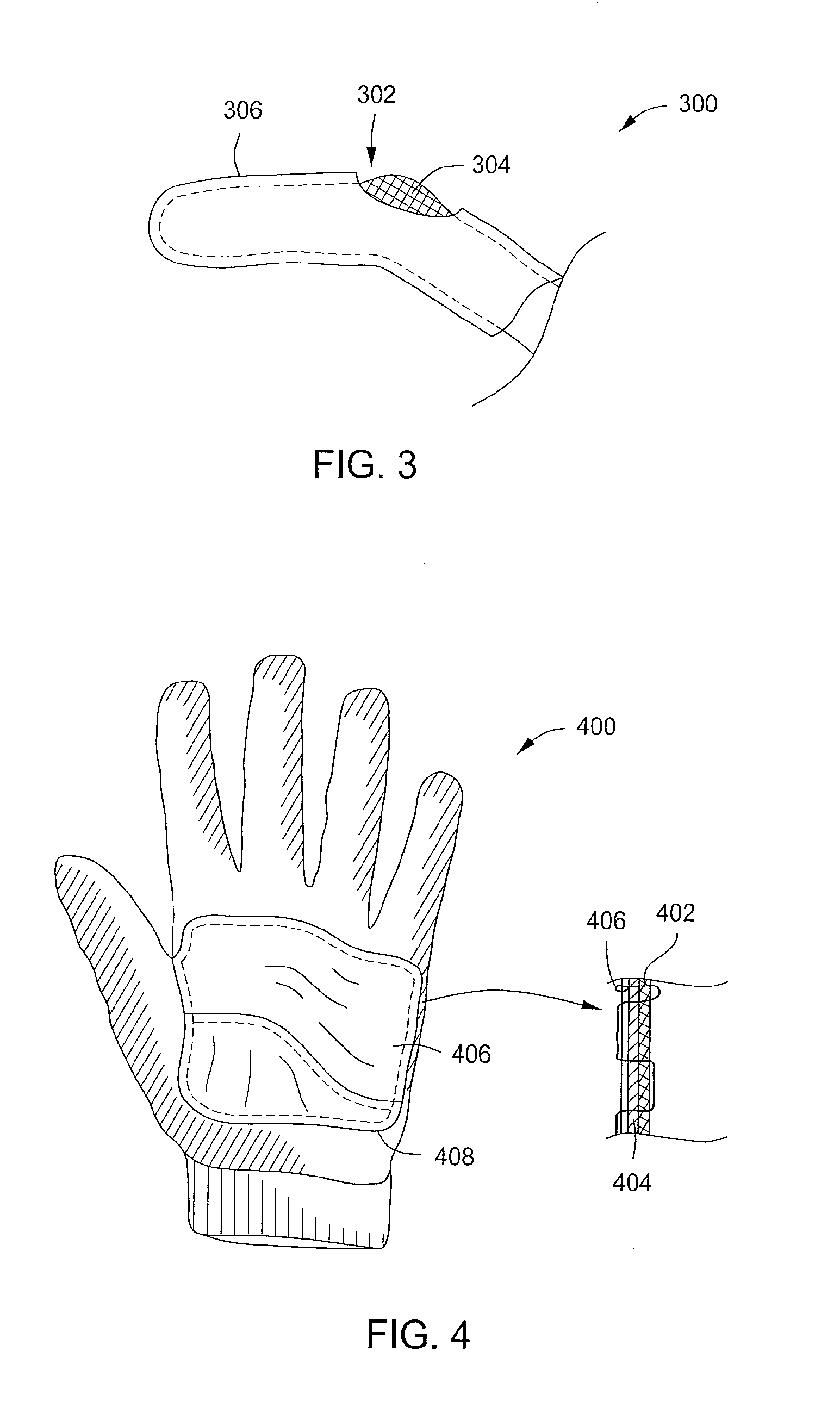

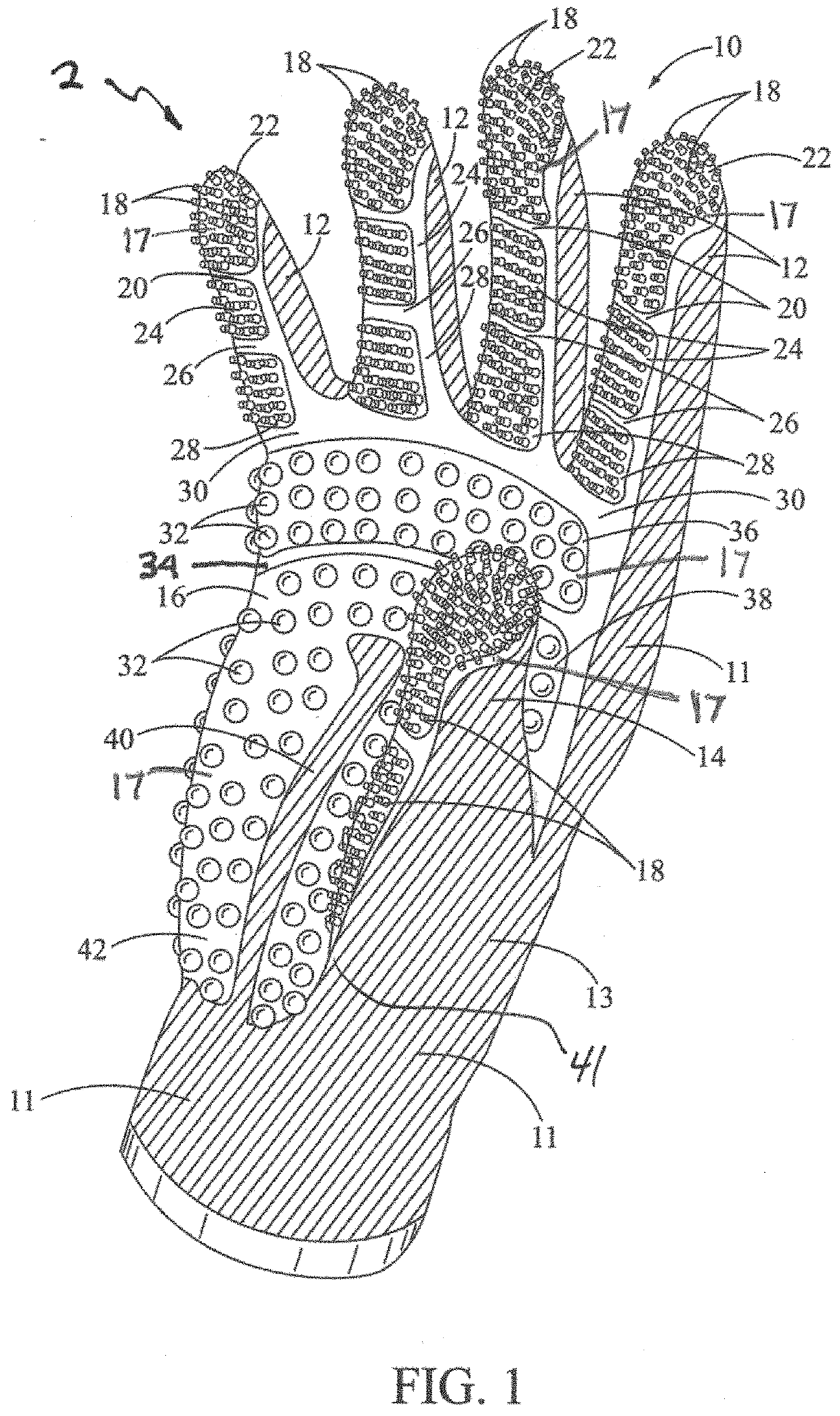

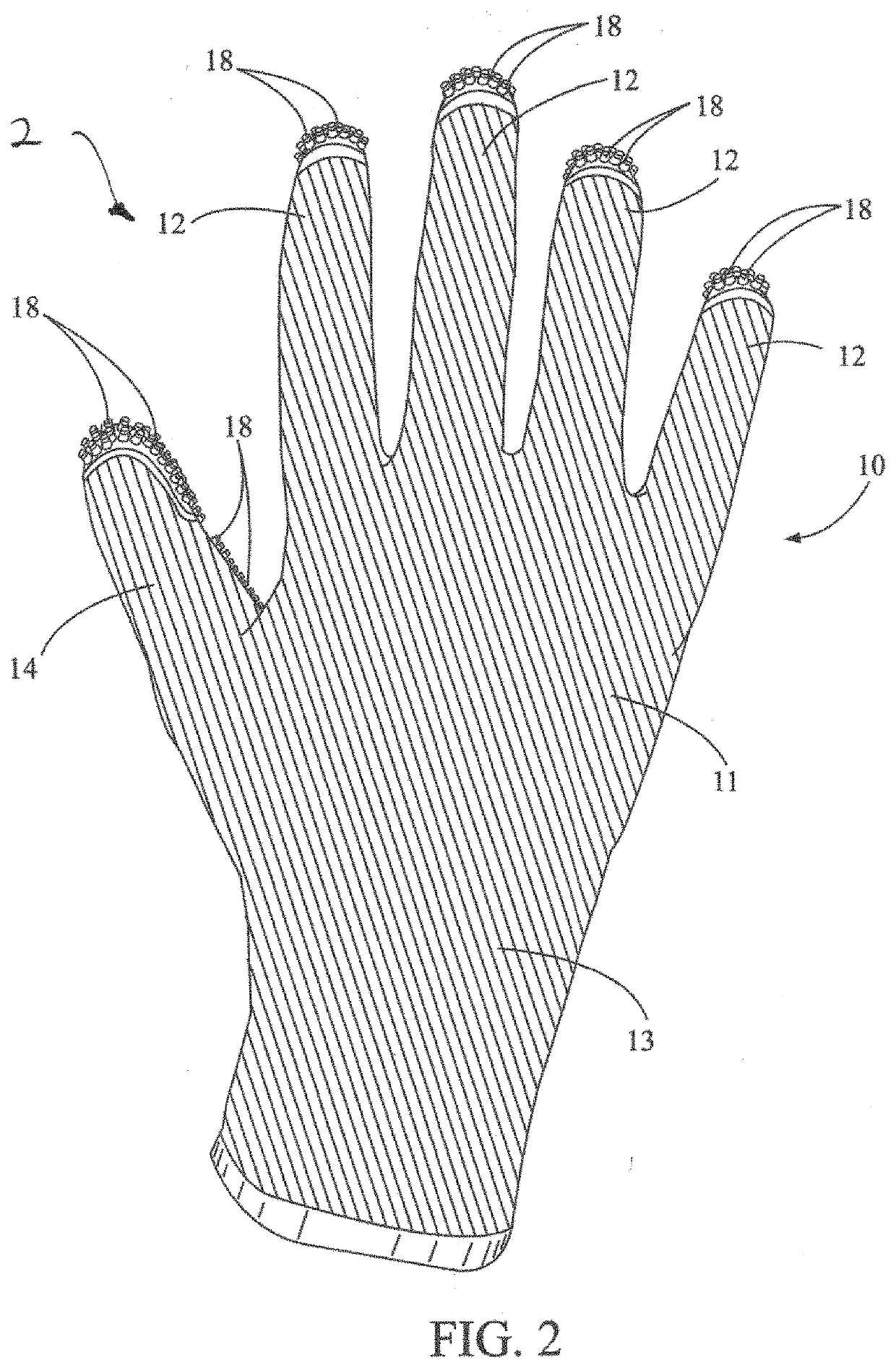

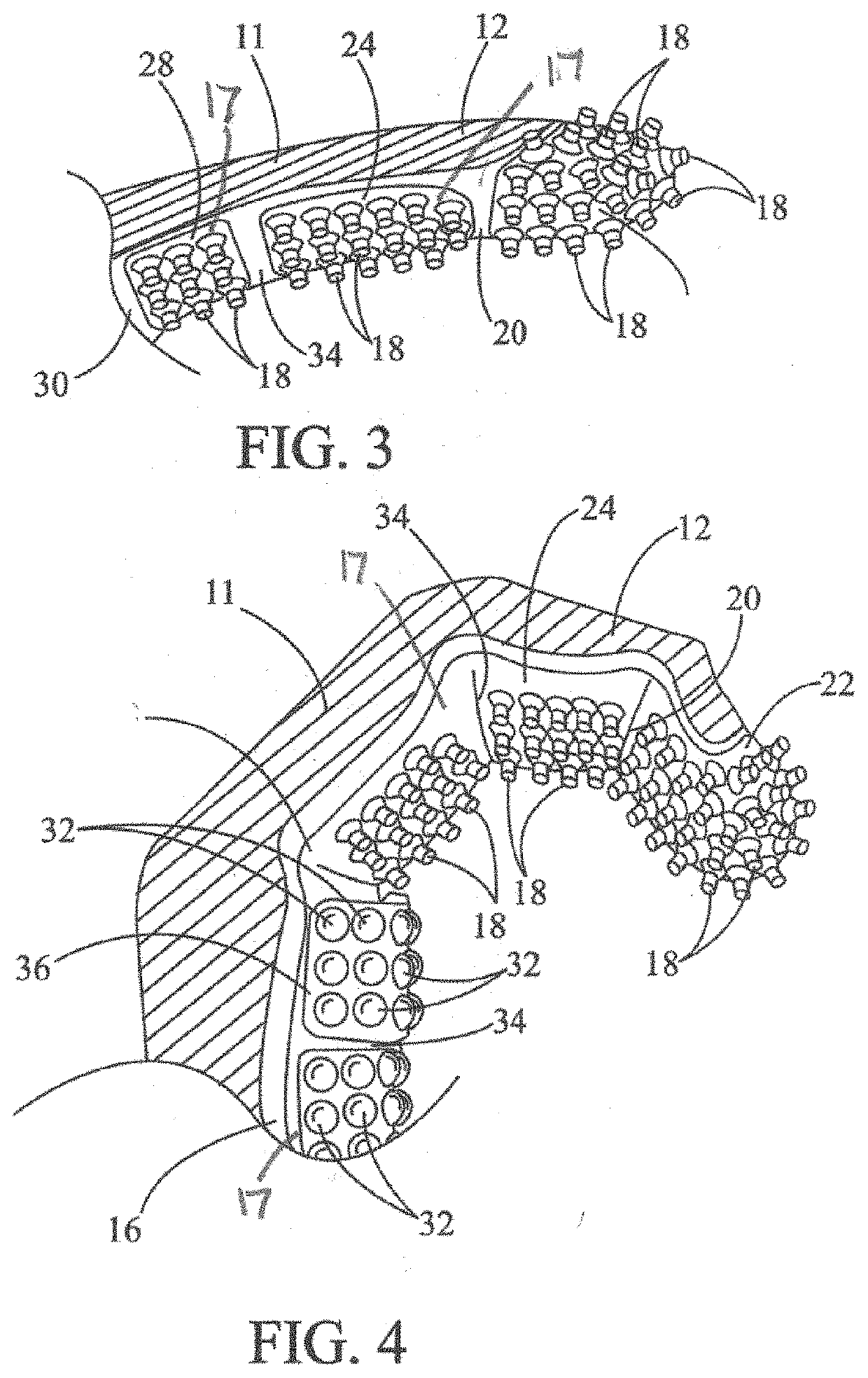

Glove having injection molded components

A glove having a glove liner adorned with at least one injection-molded component that provides the glove with specific characteristics tailored to a specific glove application. The liner may comprise a fabric and / or an elastomeric material. The position, composition, and / or contour of the injection-molded components define the characteristics of the glove.

Owner:ANSELL

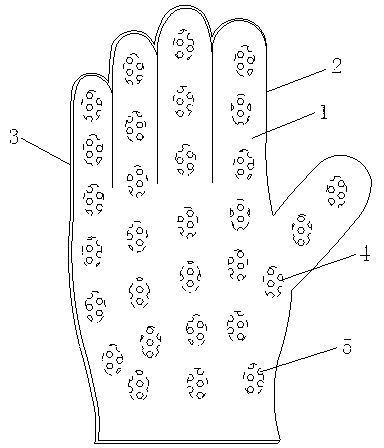

Latex dispensing glove and preparation method thereof

ActiveCN103981723AResistant to chemically aggressive mediaOil resistantSynthetic fibresVegetal fibresFiberPolymer science

The invention relates to a latex dispensing glove and a preparation method thereof. The glove includes a glove liner and an outer glue dipping layer. The glove liner is knitted from nylon, terylene, cotton or rayon fiber through seamless knitting, the outer glue dipping layer is a latex outer glue dipping layer, and the surface of the outer glue dipping is distributed with friction substances made of a polymer material; and the latex outer glue dipping layer consists of the following components: oil and solvent resistant rubber or polymer alloy material or electrostatic material or high temperature resistant material, a curing agent and san accelerator. According to the invention, friction substances made of the polymer material on the glove surface isolate the contact between glove and a held object to give more secure and reliable protection on the hand, and also increase the frictional force between the glove and the held object, so that the glove is safe and convenient for application, and can be used for hand protection under different conditions.

Owner:ZHEJIANG KANG LONG DA SPECIAL PROTECTION TECH CO LTD

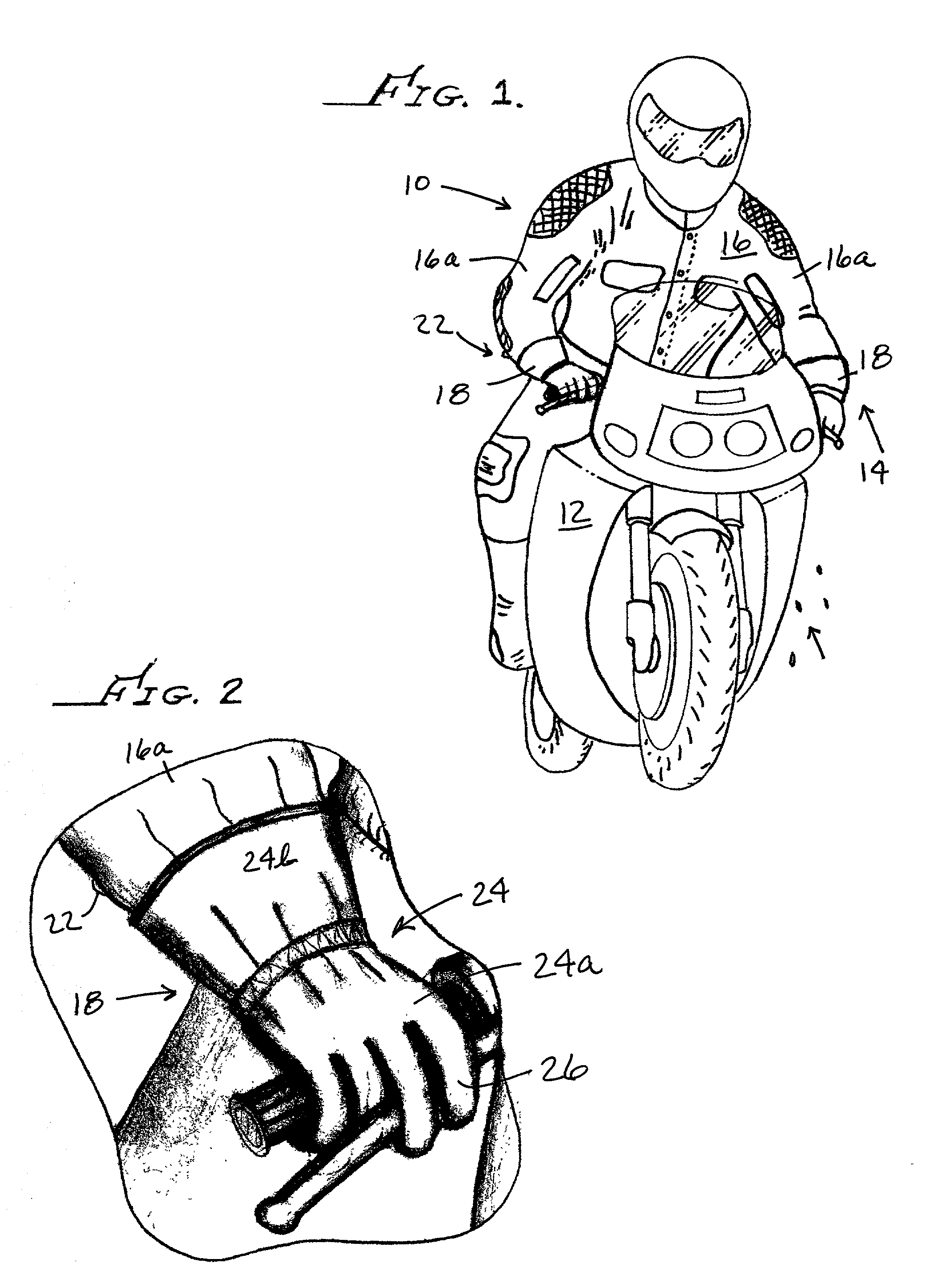

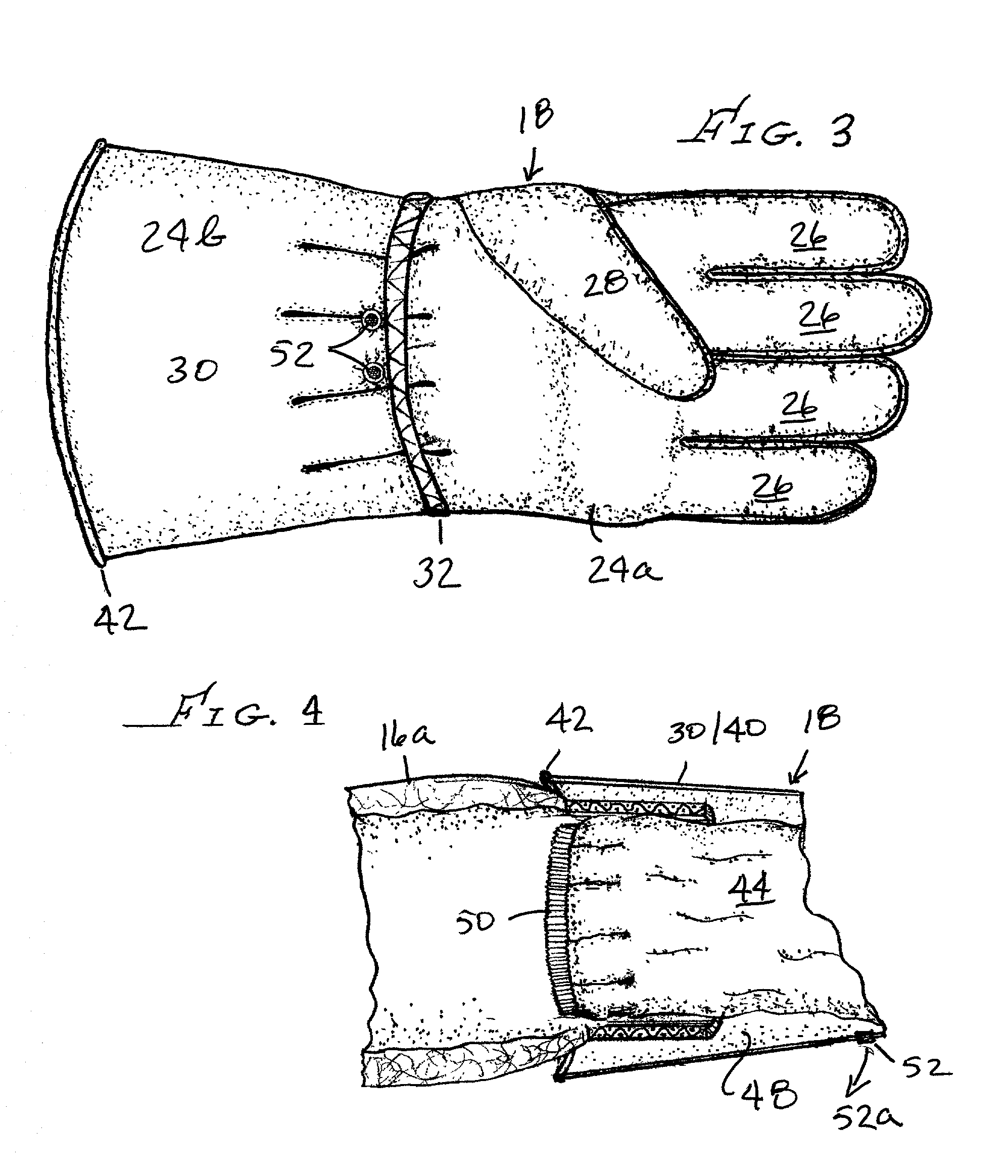

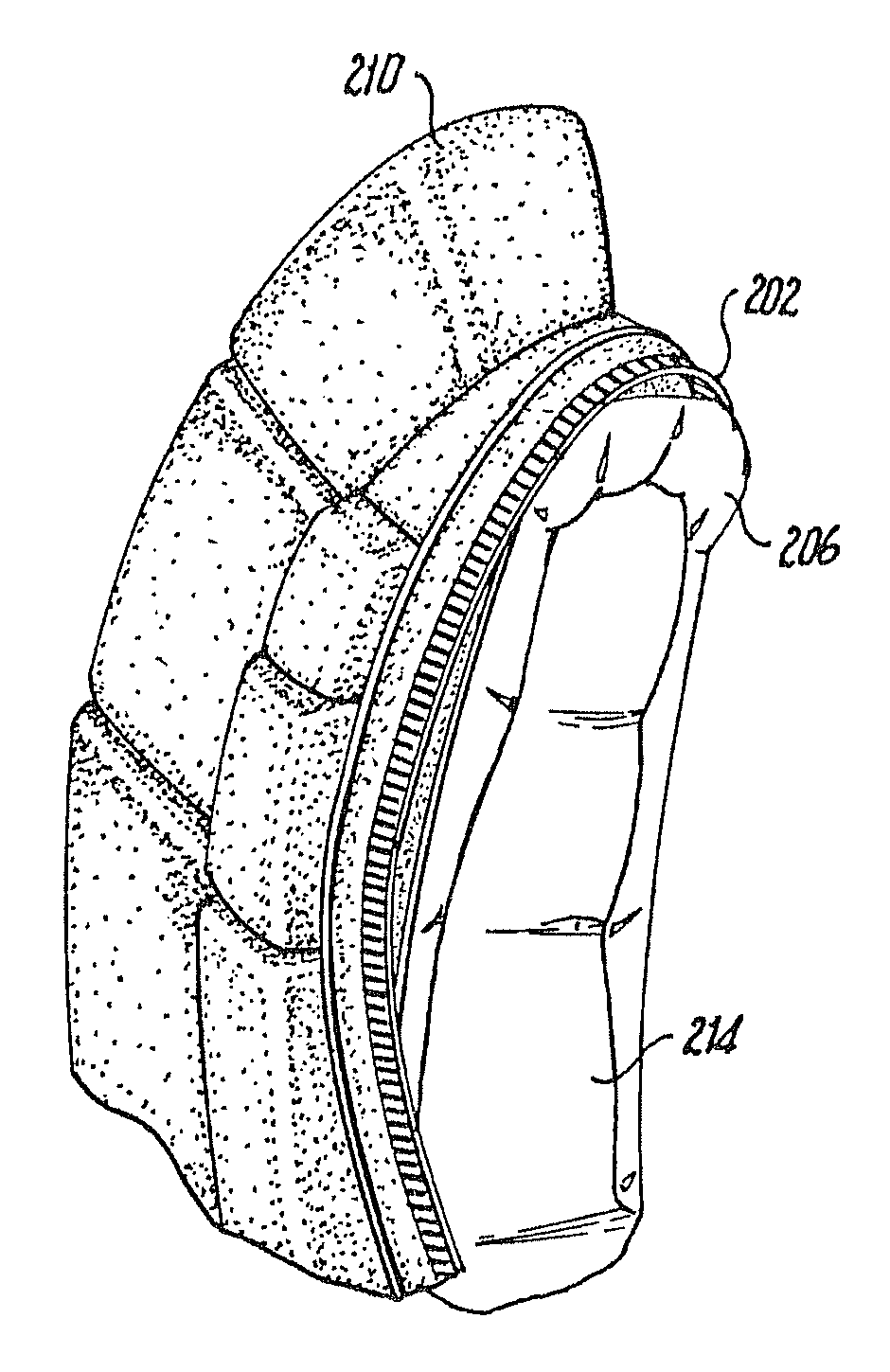

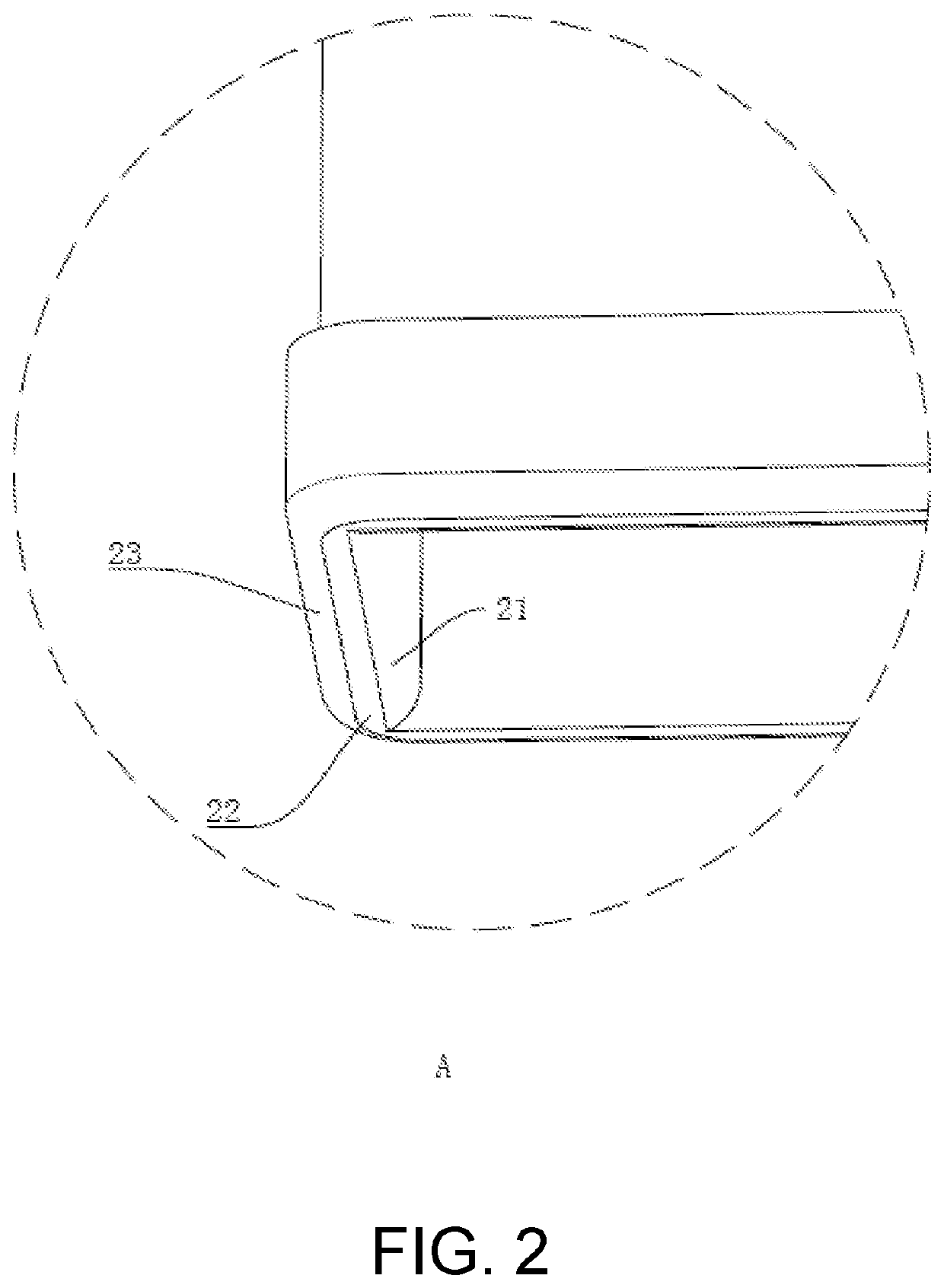

Foul-weather sport glove and method

A weather-resistant glove for wear particularly by operators and passengers of open-air sport motor vehicles includes an outer glove shell and in inner glove liner, each having an elongate gauntlet cuff portion. The gauntlet cuff portion has an inner gauntlet and an outer gauntlet cooperatively defining a water catch basin, from which a drain opens outwardly of the glove at or near the lowest point of this basin while the user's hands are in a typical downwardly angled position on the sport motor vehicle. Water dribbling along a leeward side of the user's arms and into the gauntlets of the gloves will be caught in the water catch basins and is then drained outwardly of the glove without wetting the user's hands.

Owner:INTERSPORT FASHIONS WEST

Butyl blending emulsion chemical protective glove and preparation method thereof

ActiveCN103965554AKeep airtightCorrosion resistance hasGlovesProtective garmentPolymer scienceVulcanization

The invention discloses a butyl blending emulsion chemical protective glove and a preparation method thereof. The butyl blending emulsion chemical protective glove comprises a glove liner and a macromolecule blending emulsion material outer gumming layer, wherein the macromolecule blending emulsion material outer gumming layer comprises the components of a macromolecule blending alloy material main body, a vulcanizer, a promoter and a vulcanization activator according to the mass ratio of 100 to 0.5-5 to 0-2 to 1-3; the macromolecule blending alloy material main body comprises 60 to 100 percent of butyl rubber and 0 to 40 percent of other high polymer materials; the high polymer materials are PVC, PE, phenolic aldehyde or nitrile rubber. The butyl blending emulsion chemical protective glove overcomes defects in binding power and tear resistance, has excellent performances of chemical corrosion prevention, solvent resistance and oil resistance, has an excellent water resisting property and an electrical insulating property, and also has wear resisting, cut preventing and puncture resisting properties and the like; the preparation process is accomplished through mechanized linkage and flow production; the production is feasible, the technology is reasonable, the cost is reasonable, and the butyl blending emulsion chemical protective glove and the preparation method are applicable to industrialized scale production.

Owner:ZHEJIANG KANG LONG DA SPECIAL PROTECTION TECH CO LTD

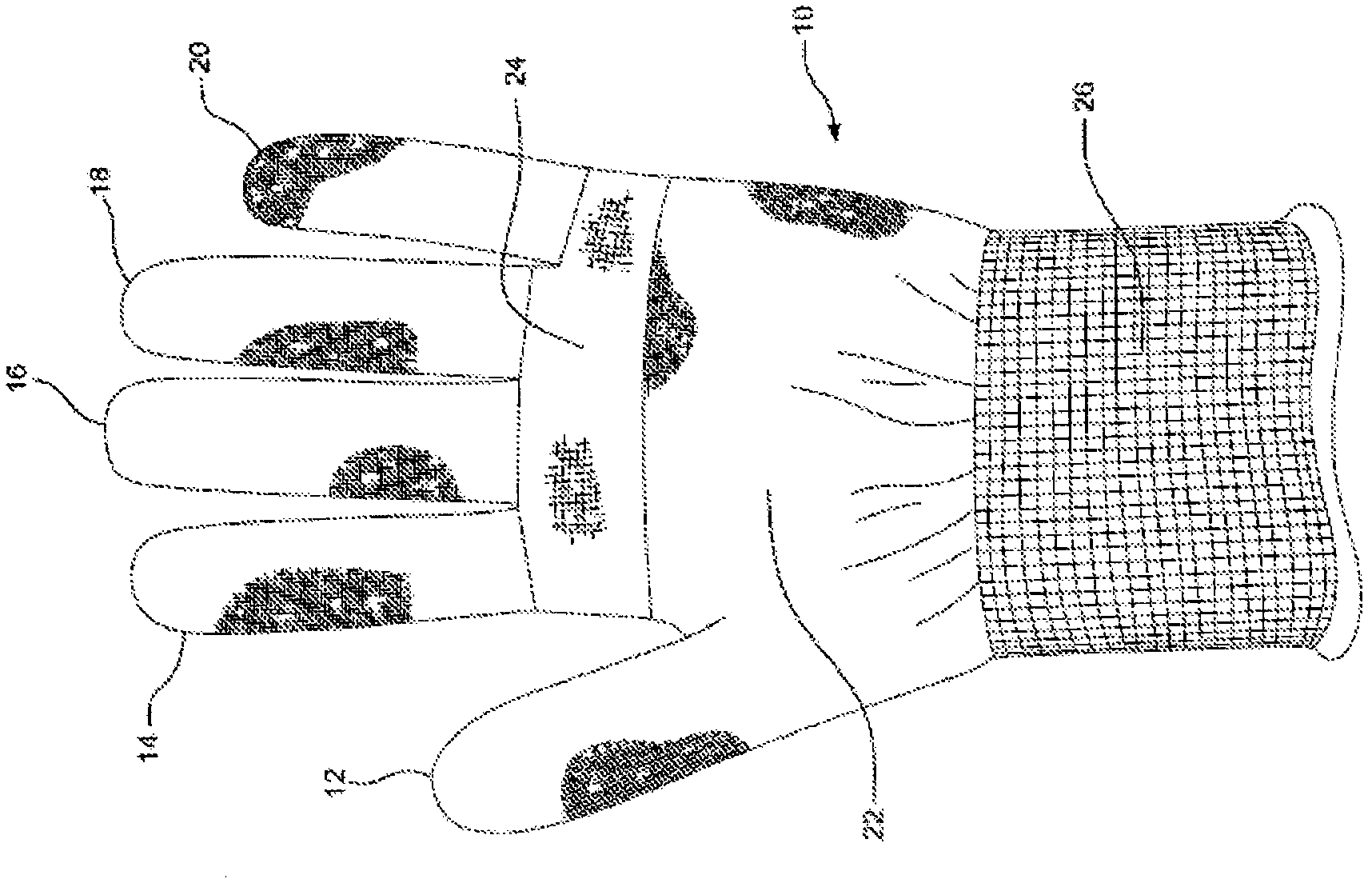

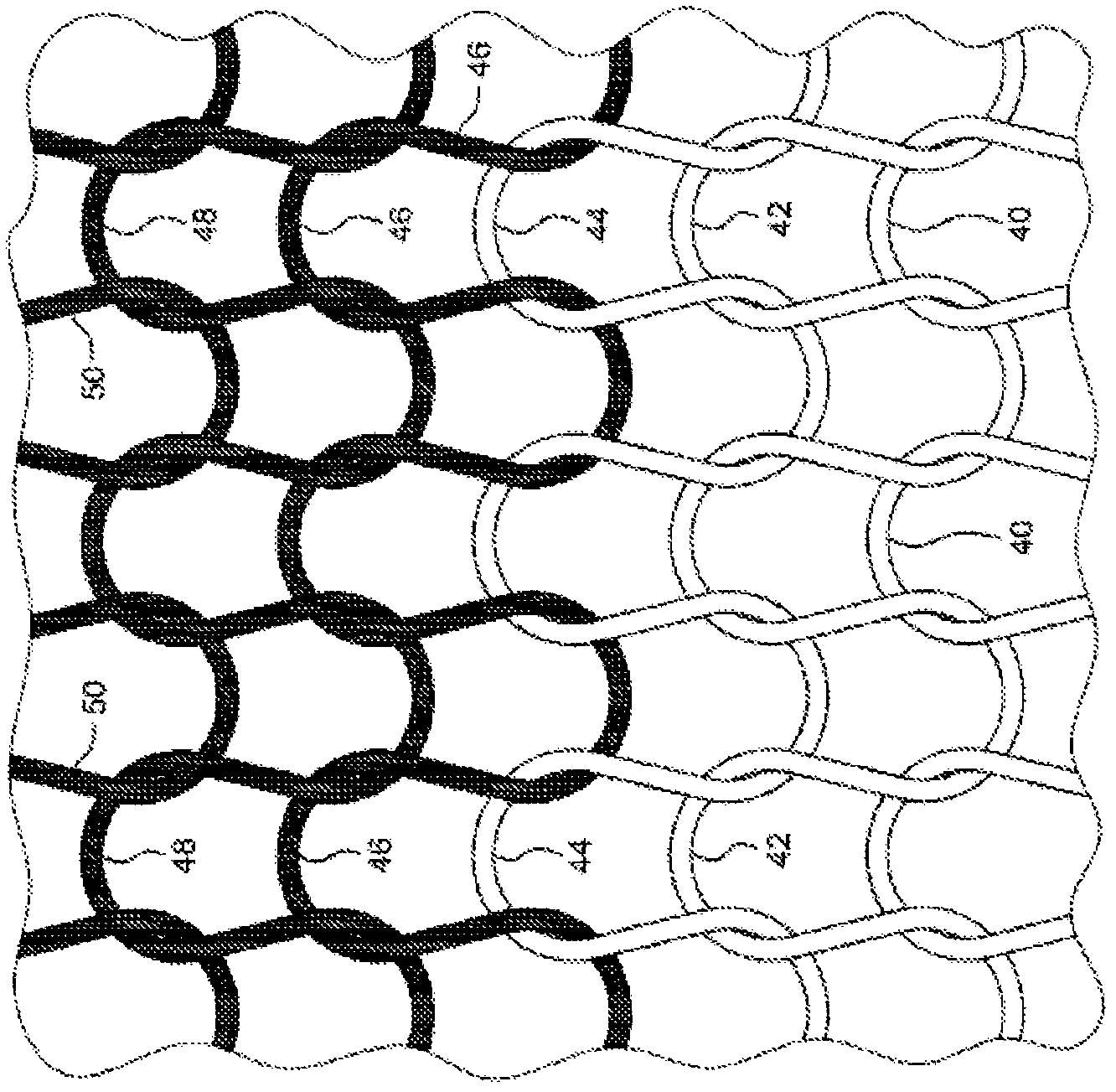

Knitted gloves having a single layer with a plurality of yarns

A seamless, single layer, multi-yarn glove or glove liner is disclosed. The glove or glove liner includes a first type of yarn and a second type of yarn that is different from the first type of yarn. The glove or glove liner has a single layer that includes the first type of yarn and the second type of yarn knitted together to form a hand-like structure that includes a thumb section, a plurality of finger sections and a palm section. The first type of yarn is different that the second type of yarn. For example, the first type of yarn may be a cut resistant yarn and the second type of yarn may be an inexpensive elastic yarn such as Spandex. Gloves suitable for use by carpenters, electricians, HVAC handlers, laborers, masons, and plumbers are also provided. Methods of using these gloves are also provided.

Owner:ANSELL

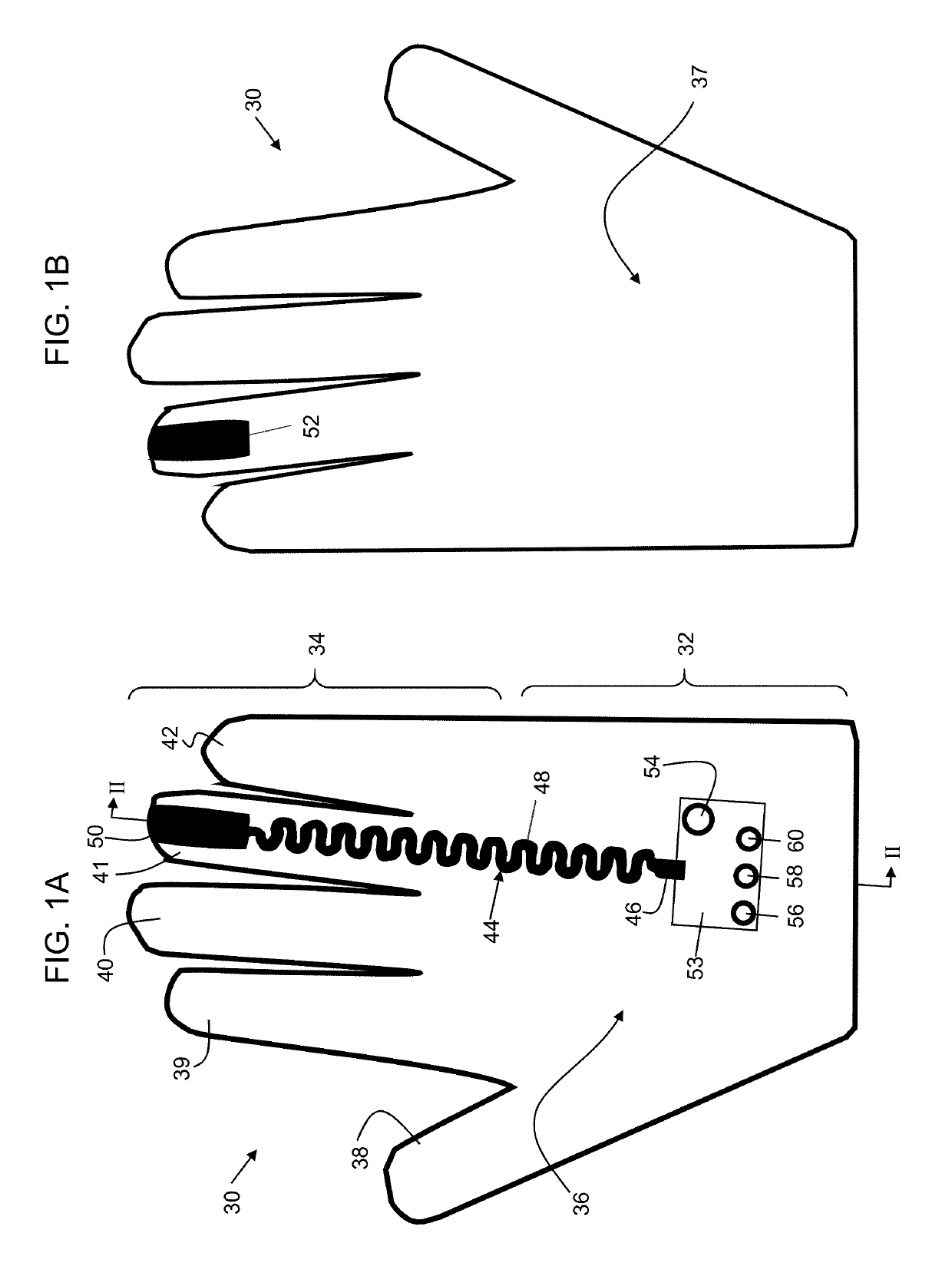

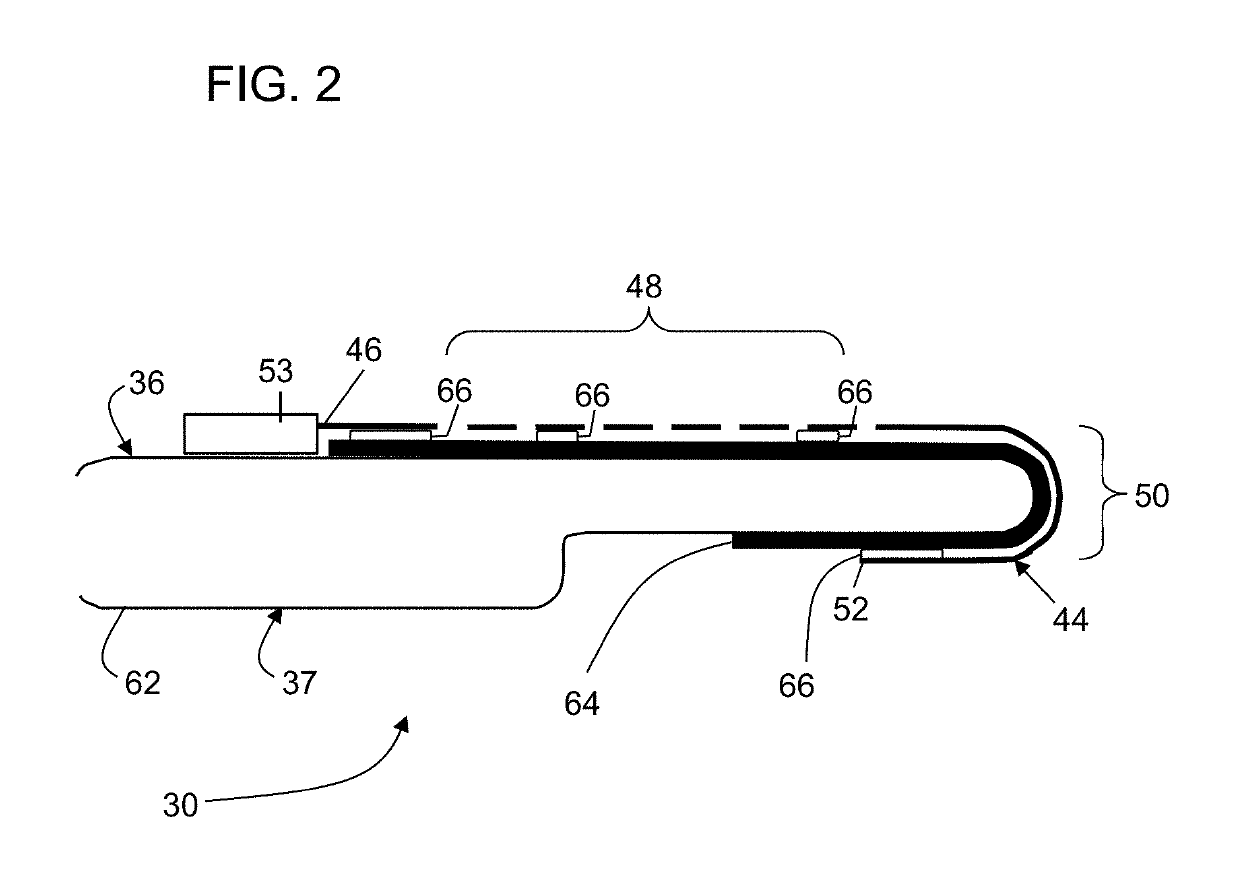

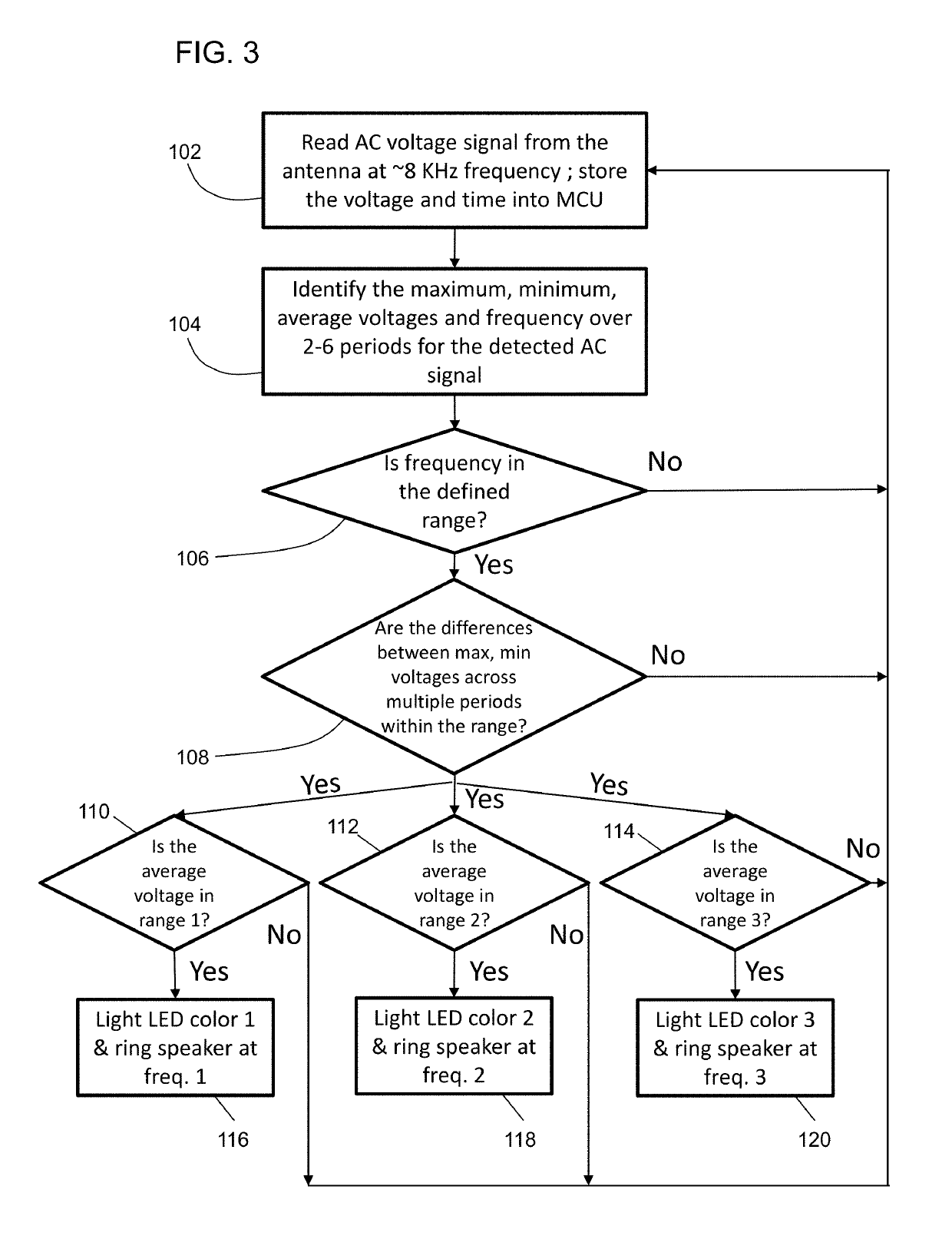

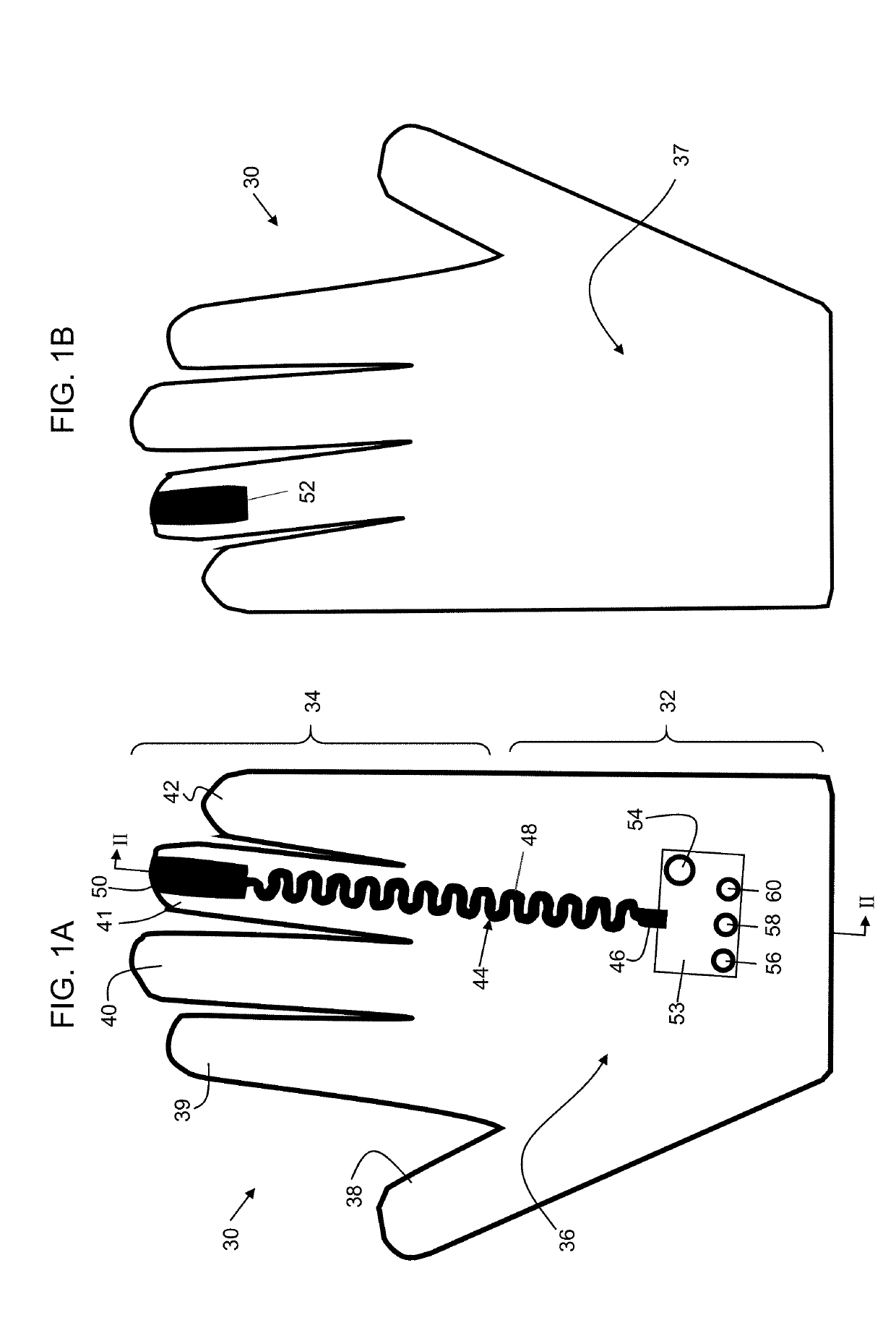

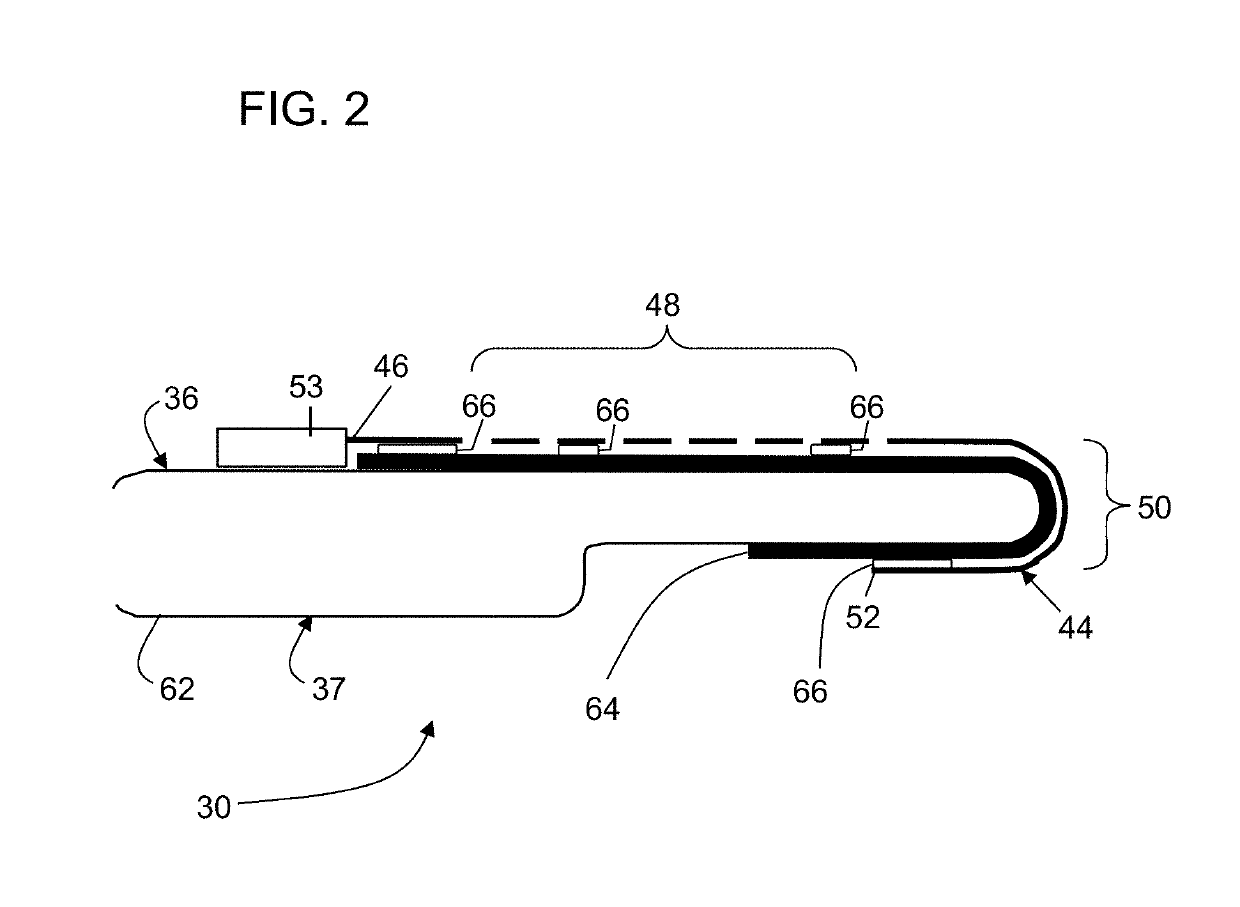

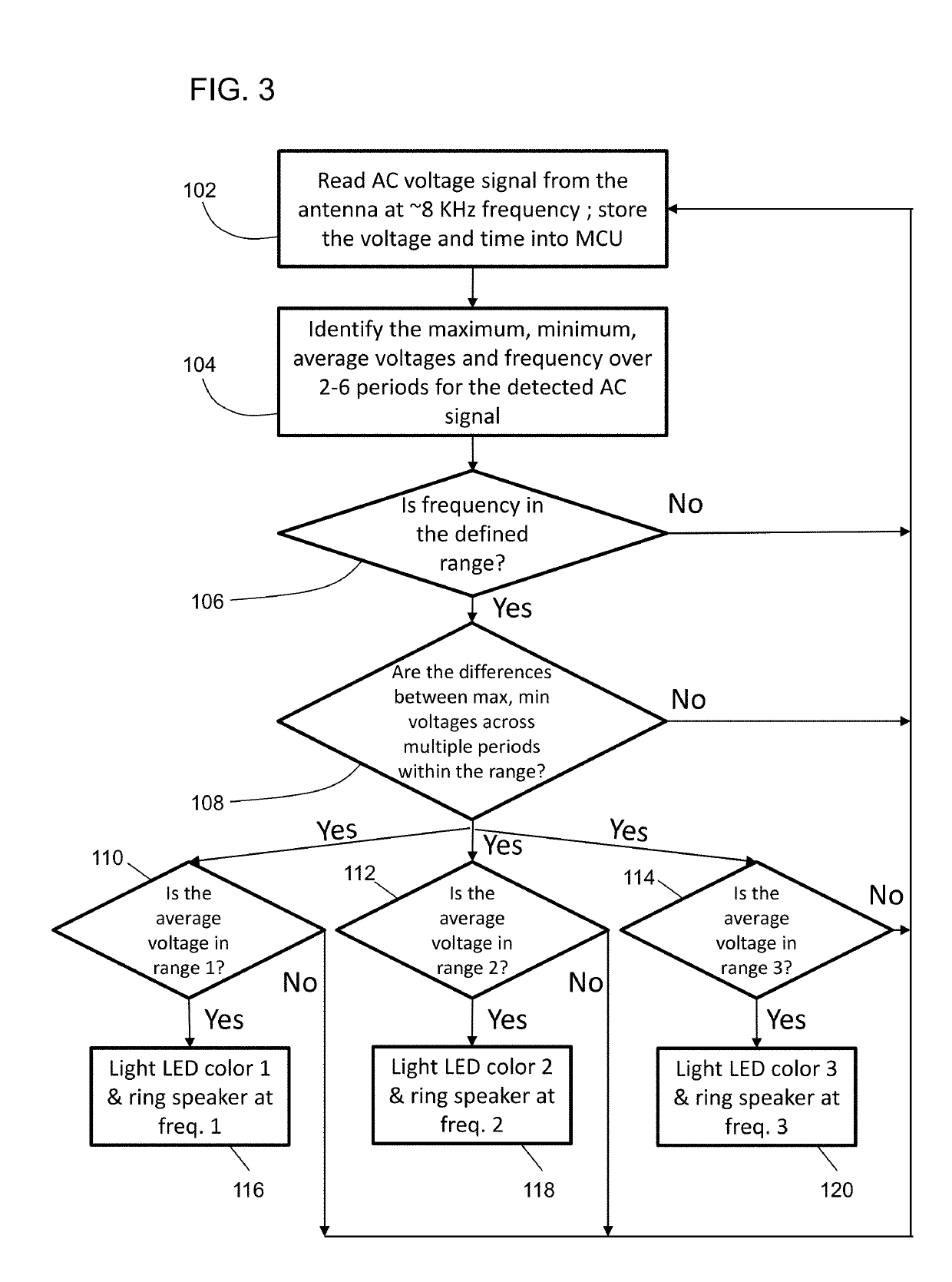

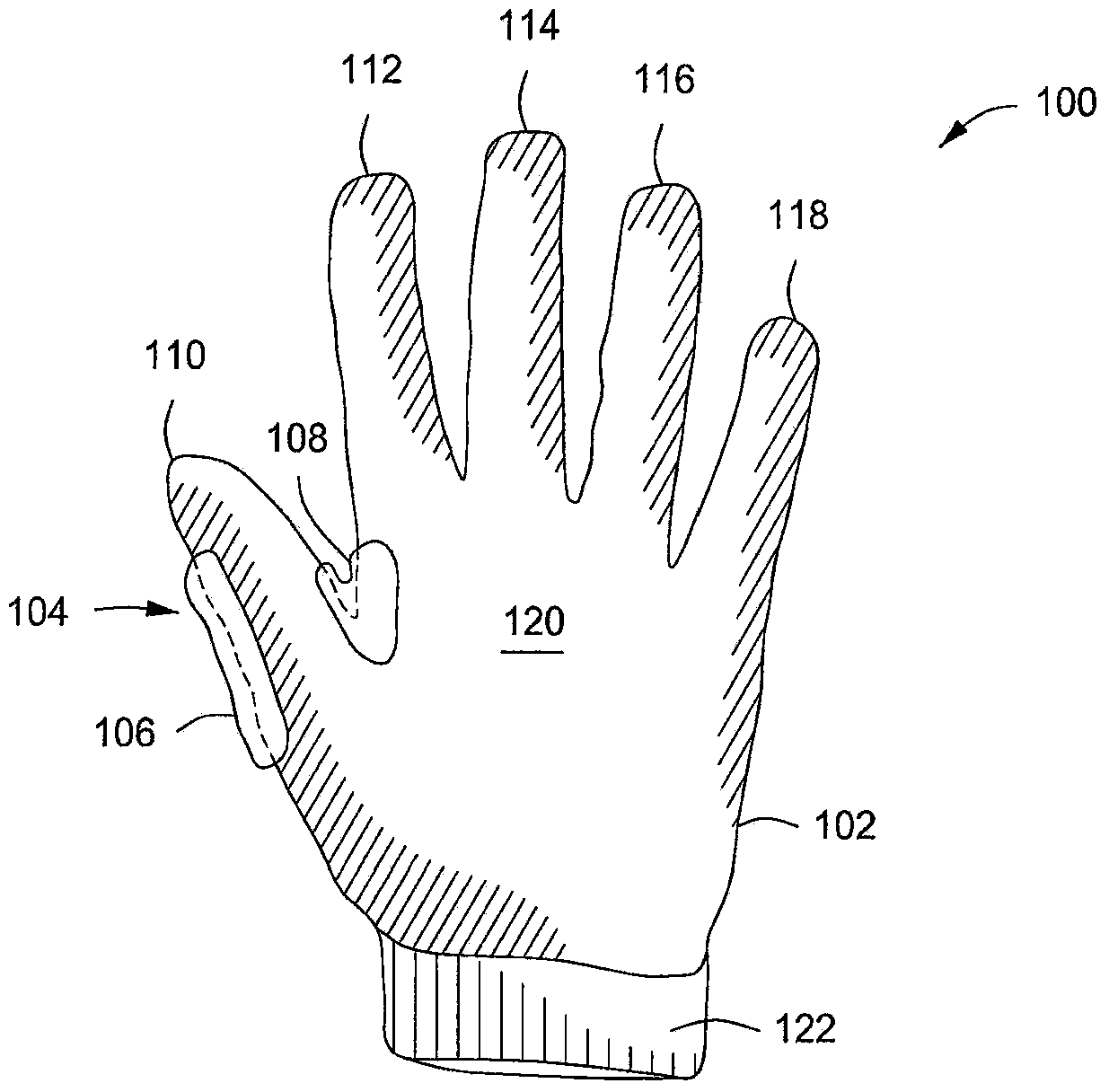

Voltage detecting glove

A voltage detecting glove comprises a glove liner and an outer glove shell. A conductive antenna is disposed inside the outer glove shell but separated from the glove liner by a buffer. The antenna is connected to electronic circuitry configured to sense a voltage indicative of the proximity of the antenna to an AC electric field resulting from energized AC source, and to activate an alarm if the strength of the field exceeds a preselected threshold limit.

Owner:DUPONT SAFETY & CONSTR INC

Voltage detecting glove

A voltage detecting glove comprises a glove liner and an outer glove shell. A conductive antenna is disposed inside the outer glove shell but separated from the glove liner by a buffer. The antenna is connected to electronic circuitry configured to sense a voltage indicative of the proximity of the antenna to an AC electric field resulting from energized AC source, and to activate an alarm if the strength of the field exceeds a preselected threshold limit.

Owner:DUPONT SAFETY & CONSTR INC

Glove having injection molded components

A glove having a glove liner adorned with at least one injection-molded component that provides the glove with specific characteristics tailored to a specific glove application. The liner may comprise a fabric and / or an elastomeric material. The position, composition, and / or contour of the injection-molded components define the characteristics of the glove.

Owner:ANSELL

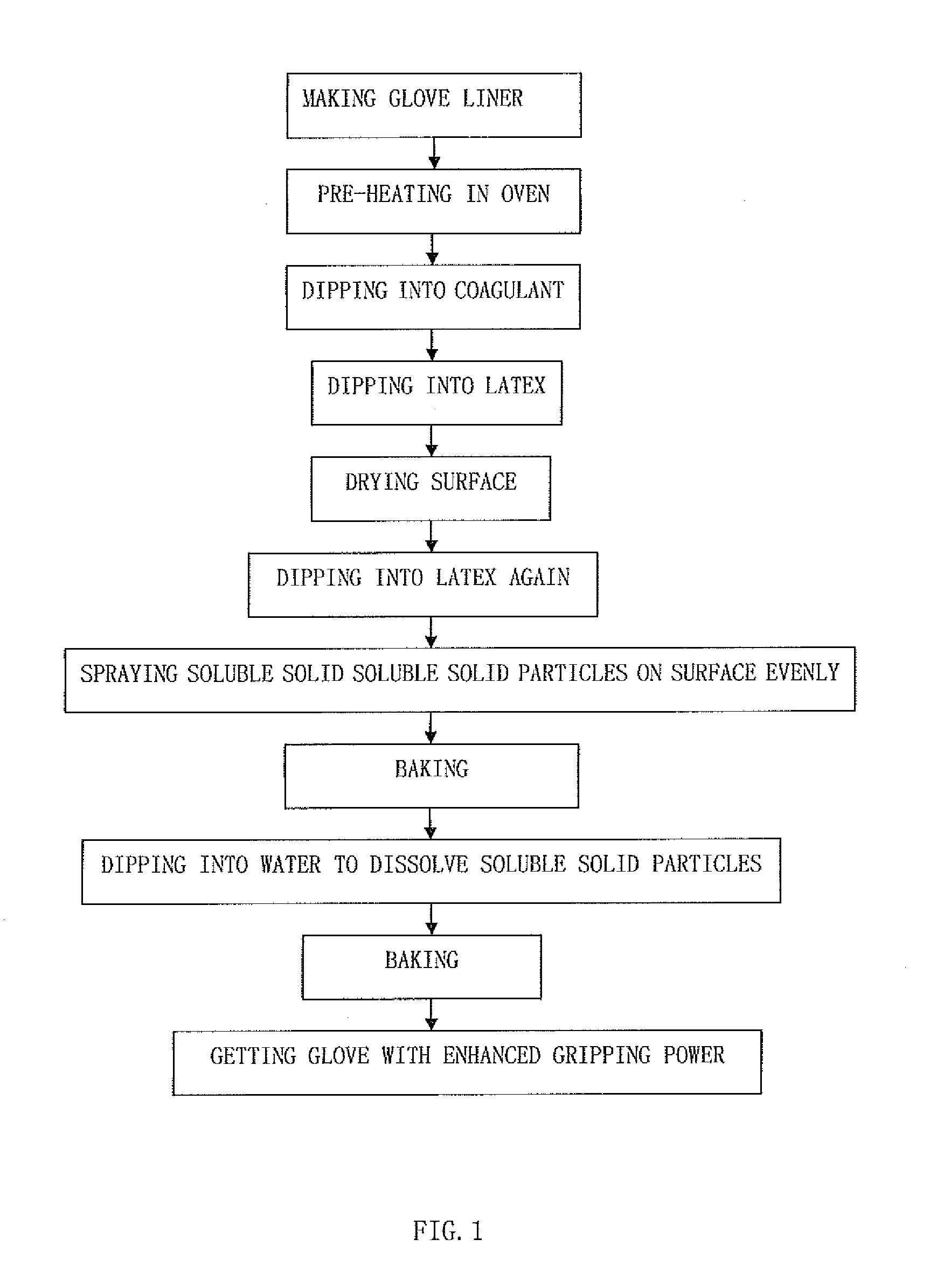

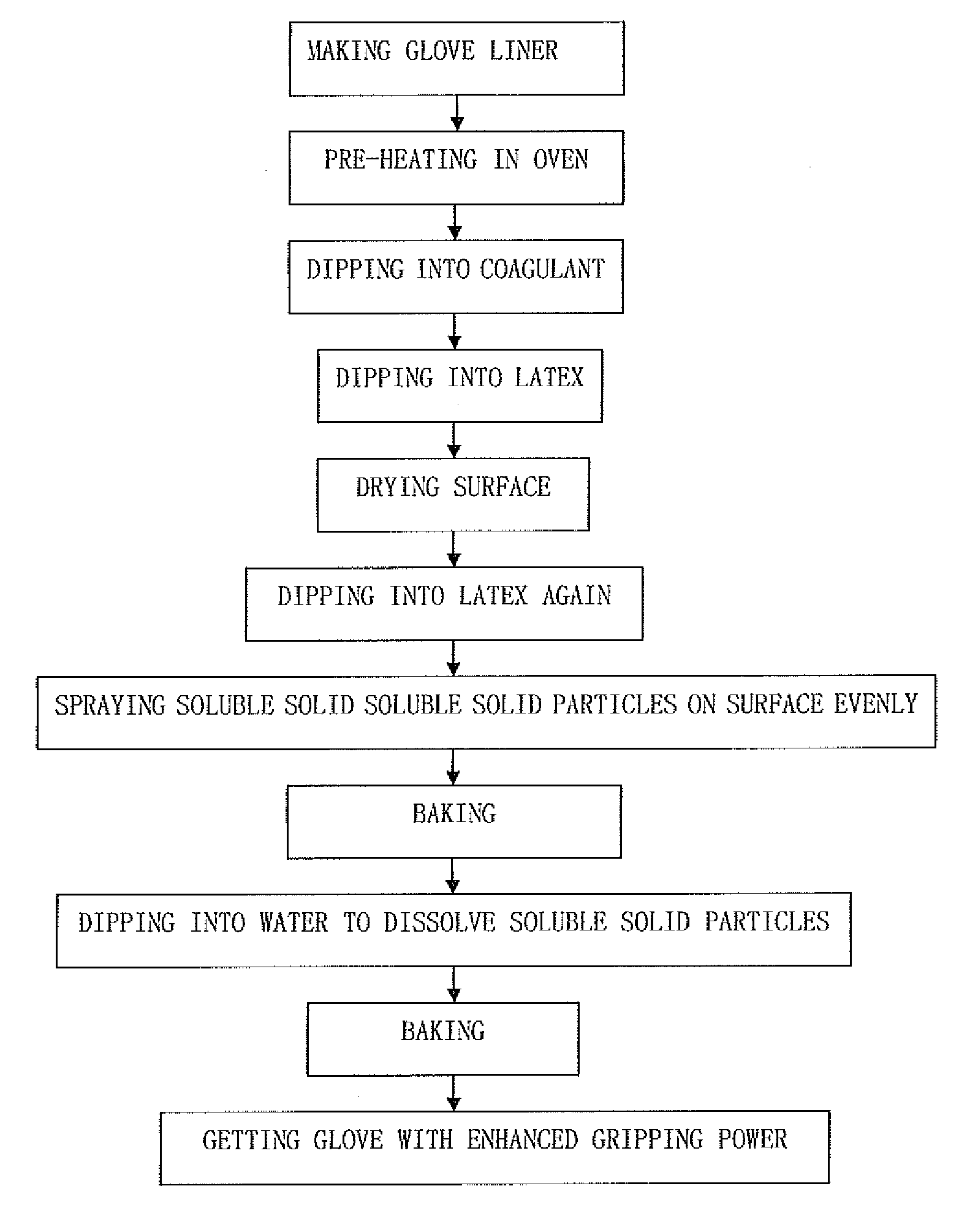

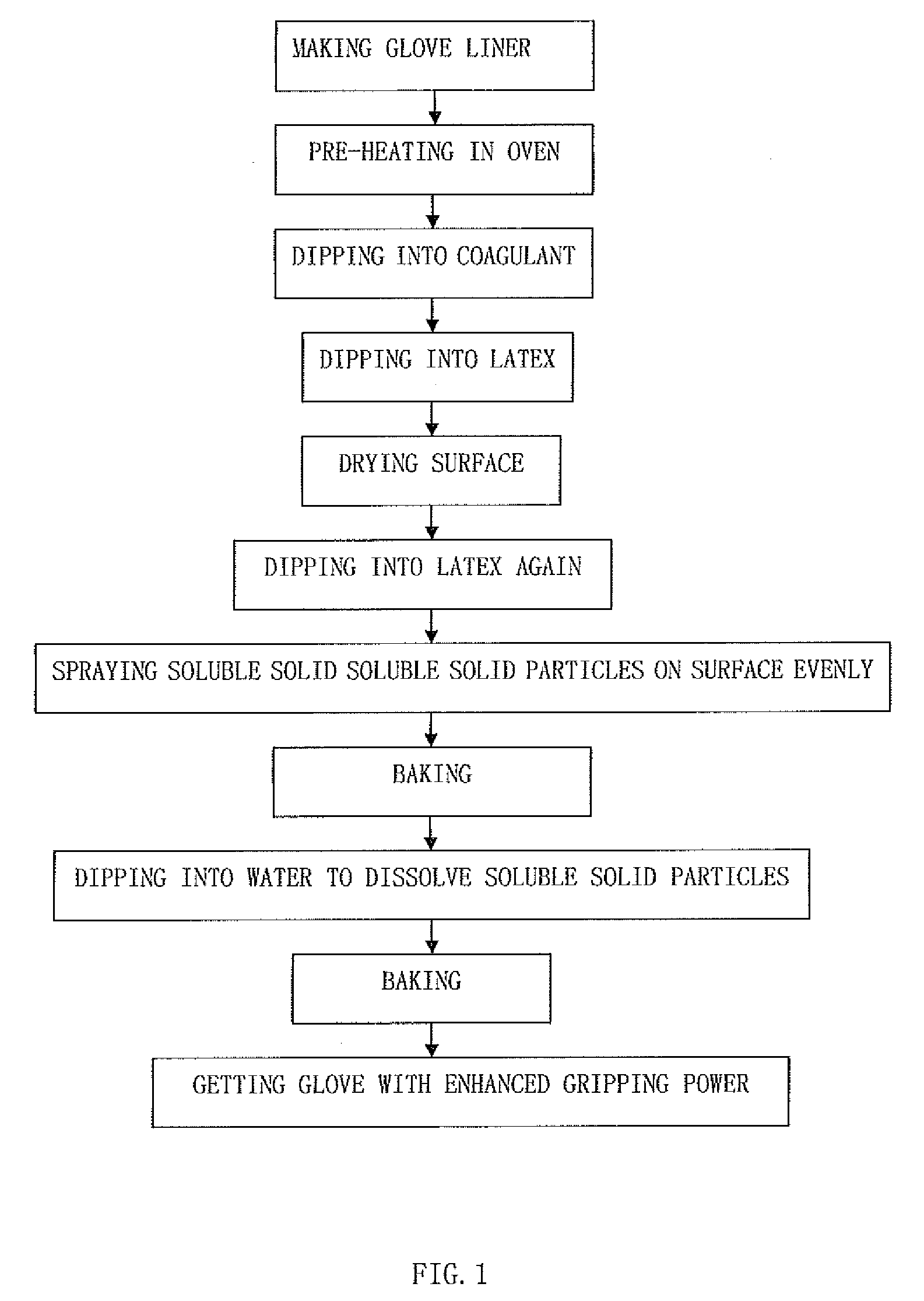

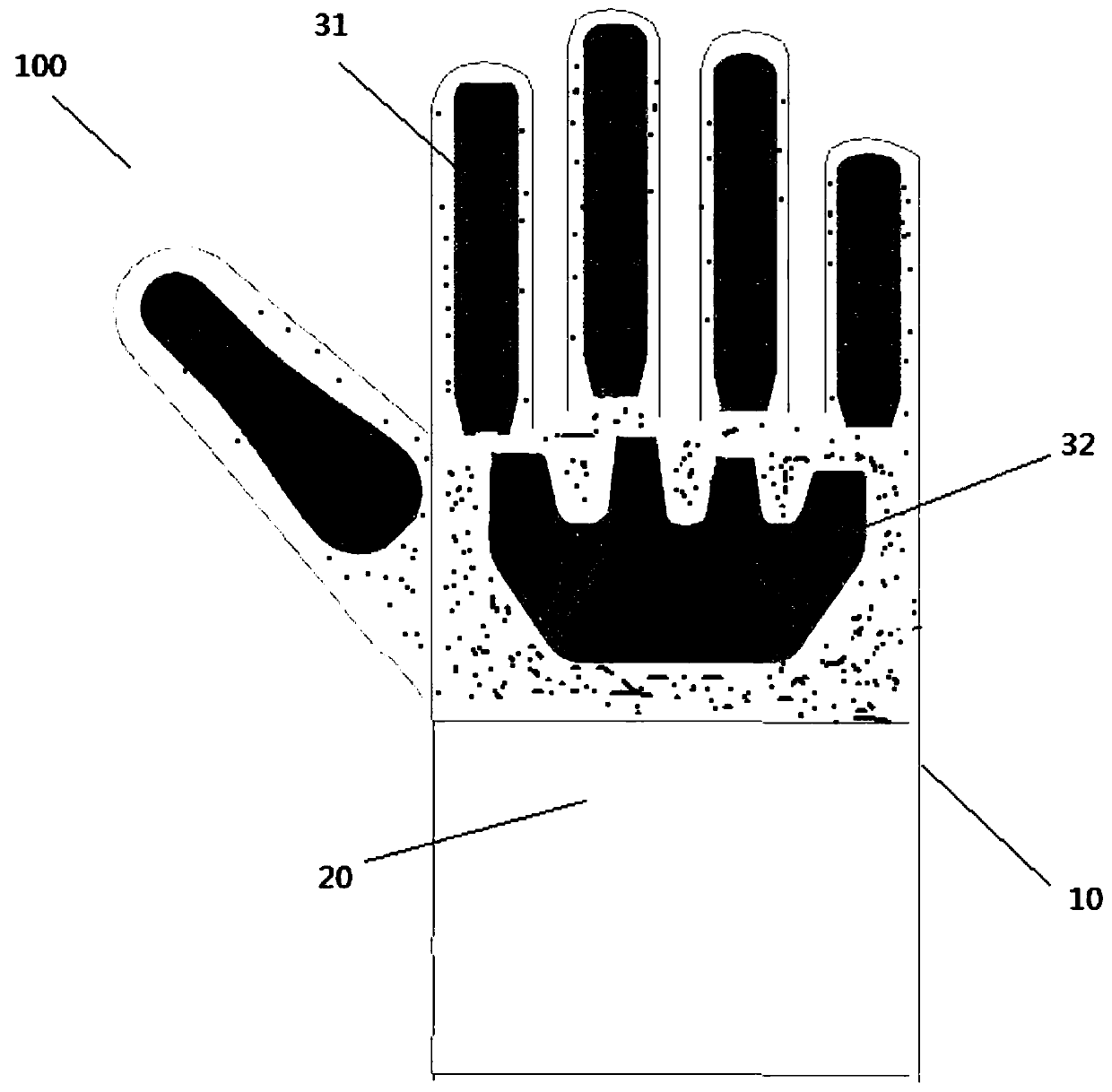

Method for making gloves with enhanced gripping power

ActiveUS20120216377A1Improve gripIncrease elasticityDomestic articlesCoatingsEngineeringSolid particle

A method for making gloves with enhanced gripping power, comprises: step 1, making a glove liner; step 2, covering a hand former with the glove liner and putting it into an oven for pre-heating; step 3, dipping the hand former into a coagulant completely; step 4, dipping the hand former into a latex; step 5, drying the surface; step 6, dipping the hand former into the latex again; step 7, spraying soluble solid particles on the surface evenly; step 8, baking; step 9, dipping the hand former into water to dissolve the soluble solid particles; step 10, baking; getting a glove with enhanced gripping power. The glove made by the method has good flexibility, can prevent oil permeability and has good slip-proof effect.

Owner:LIN CHARLES

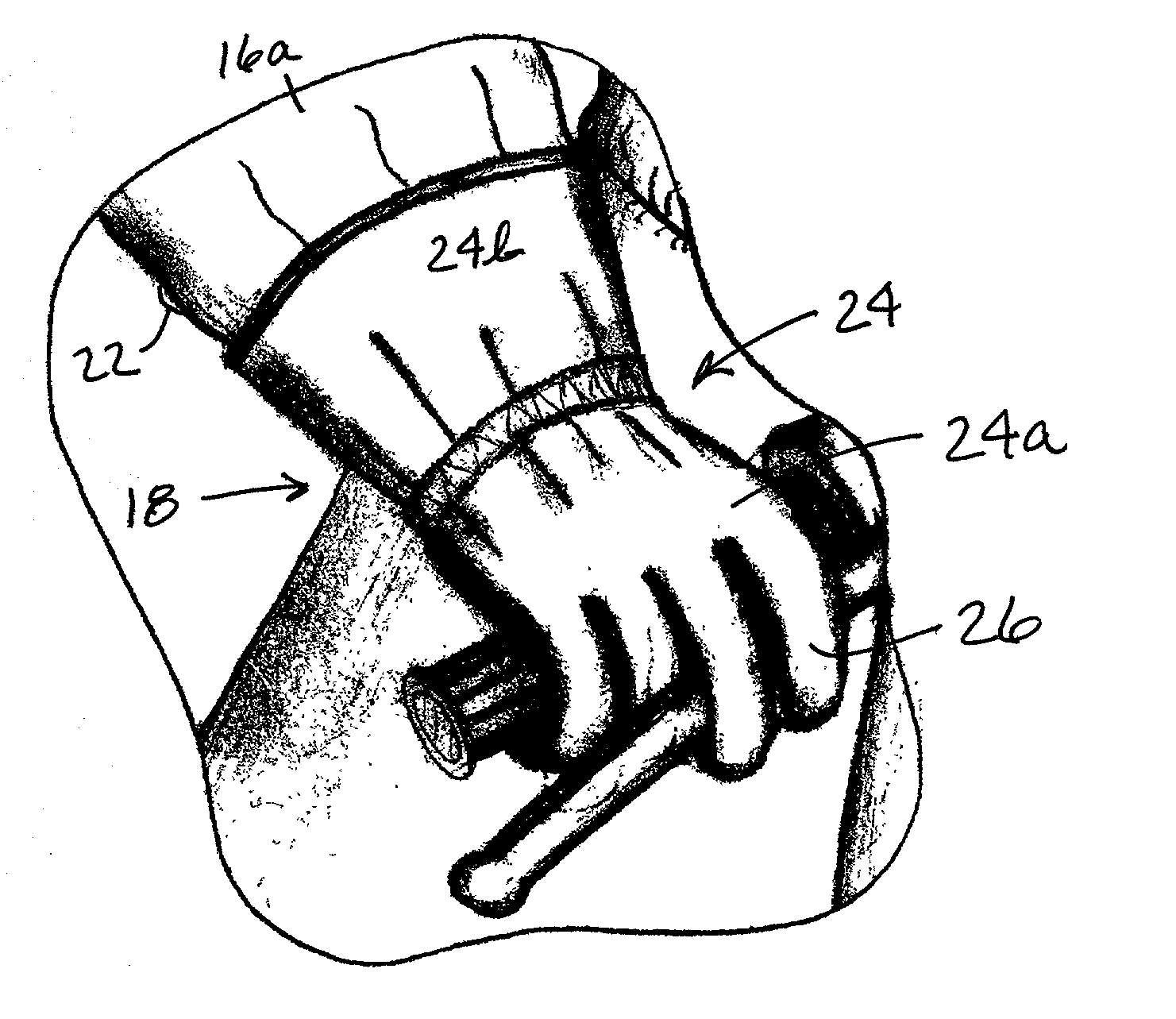

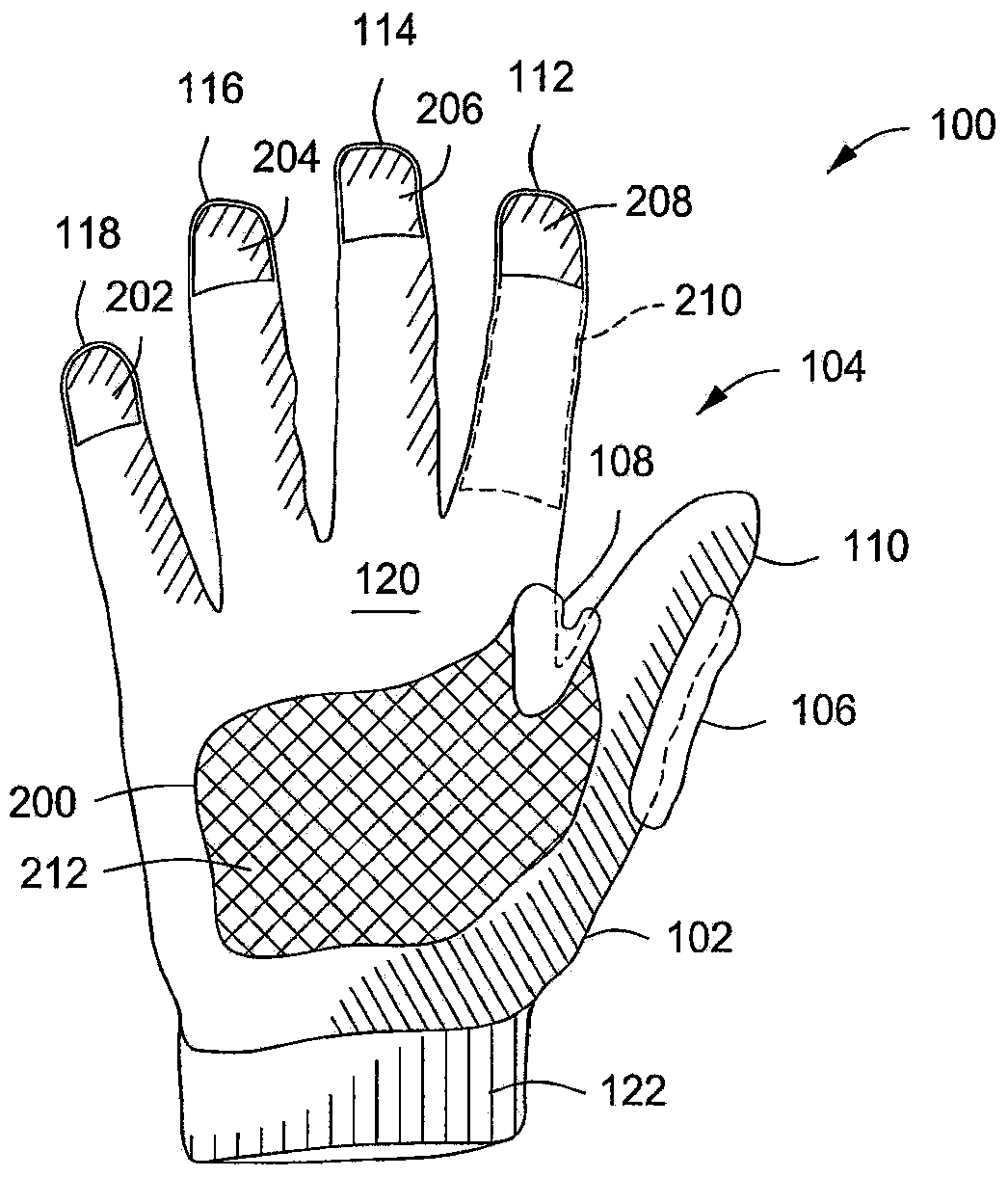

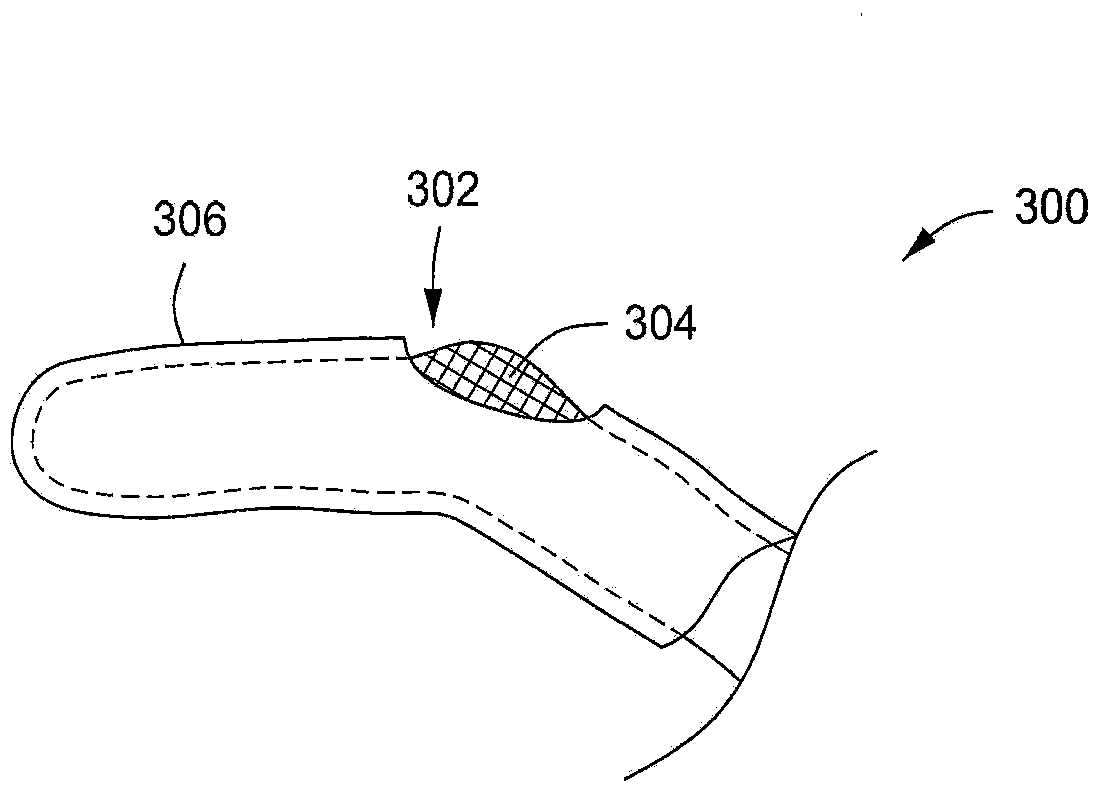

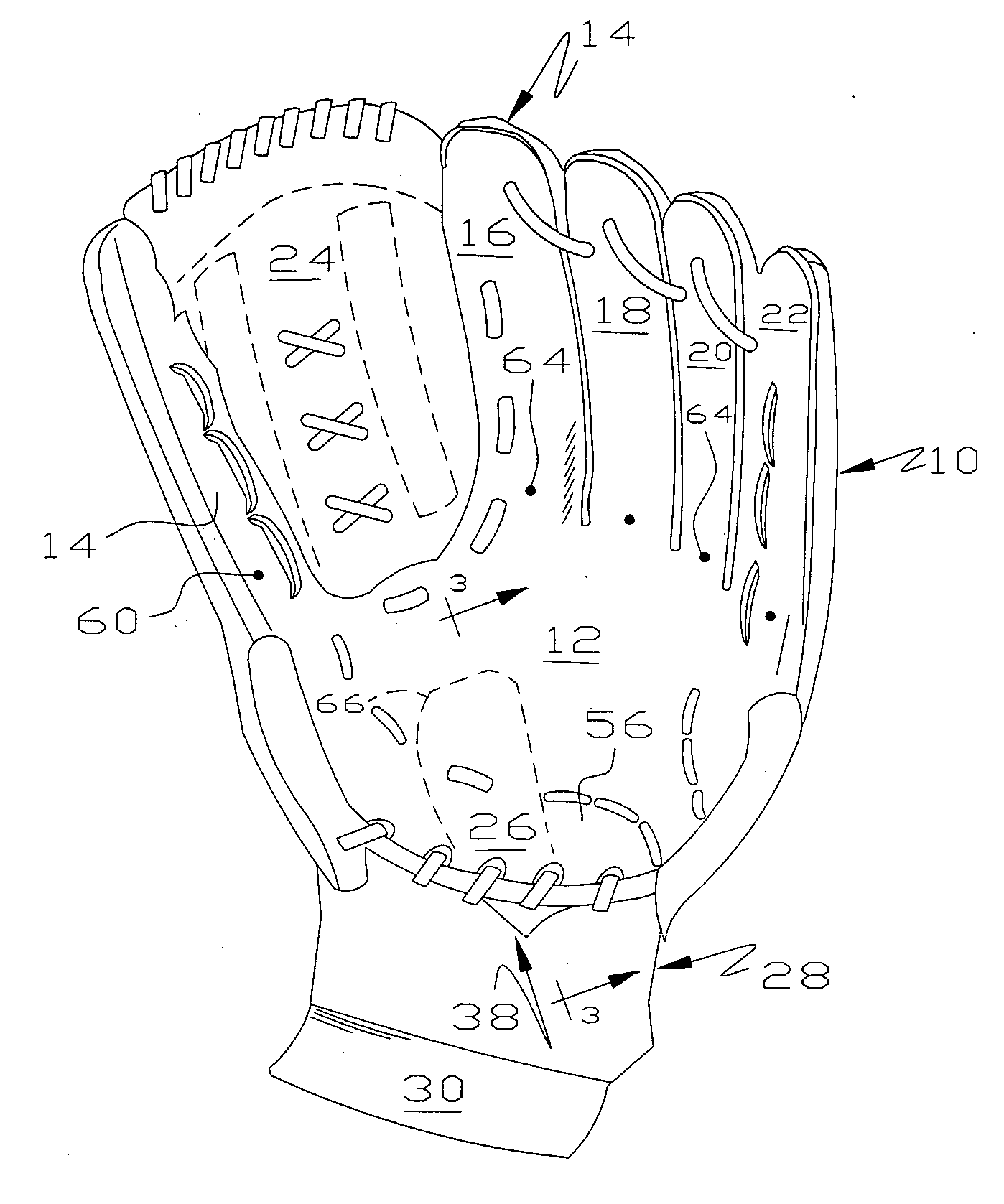

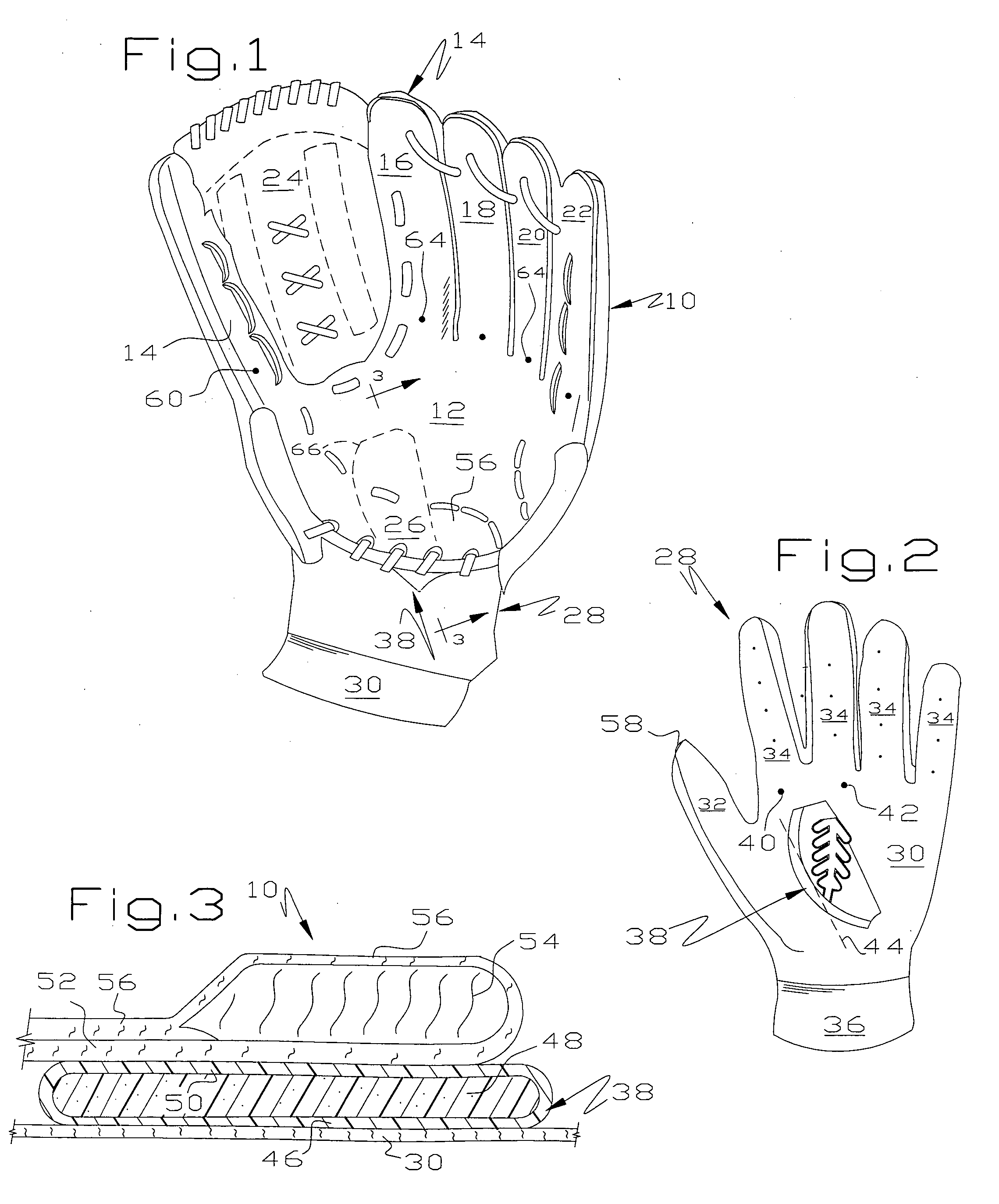

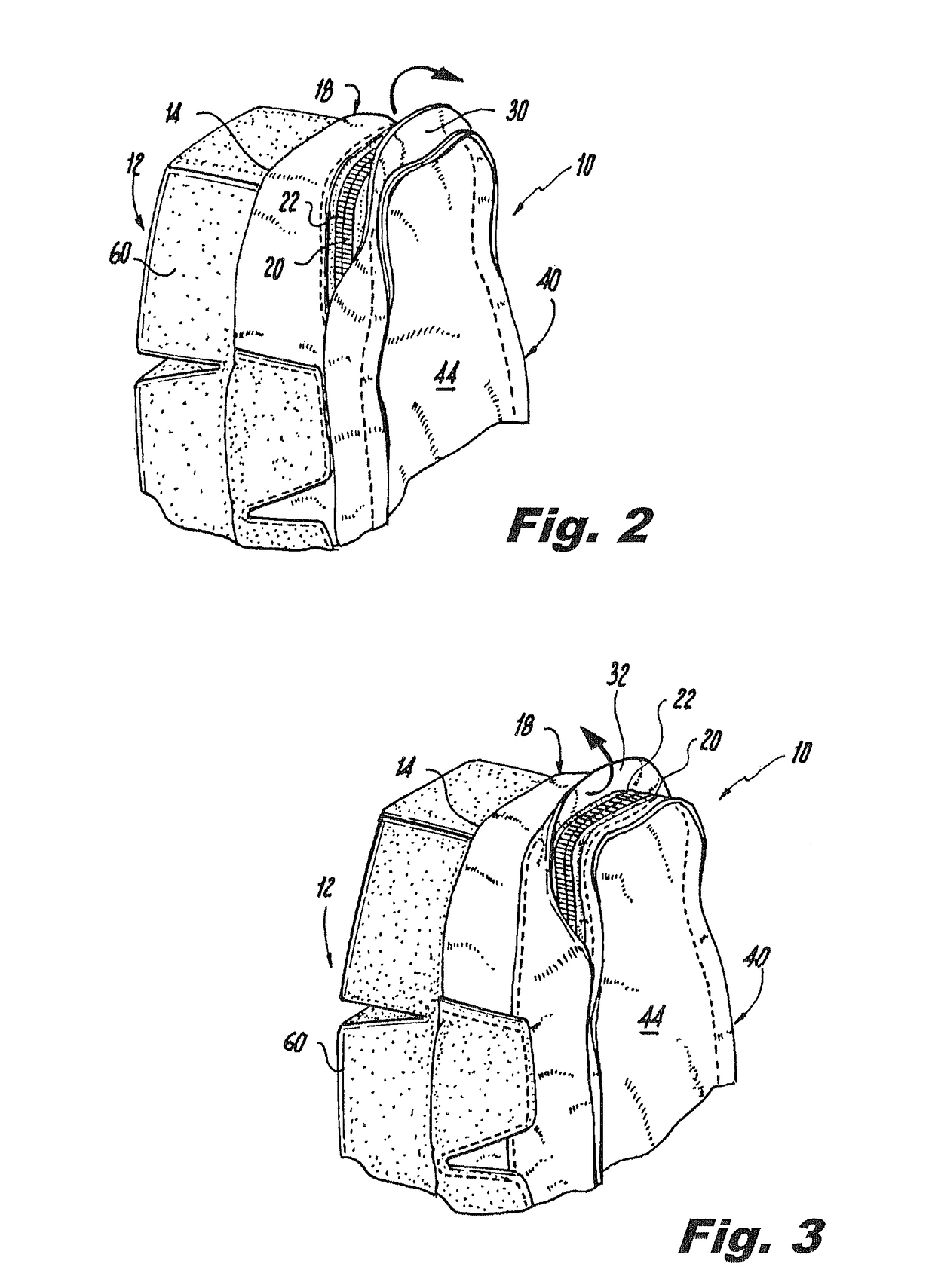

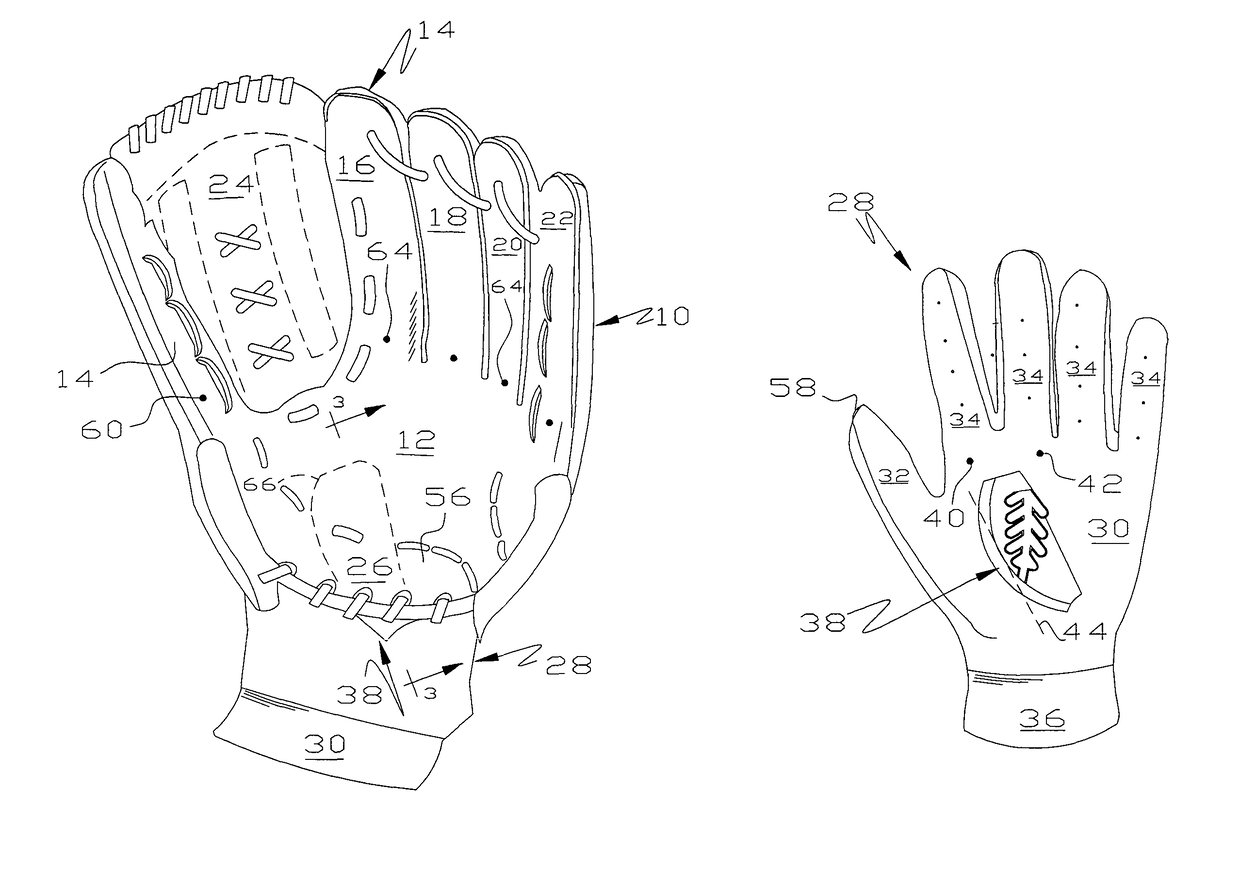

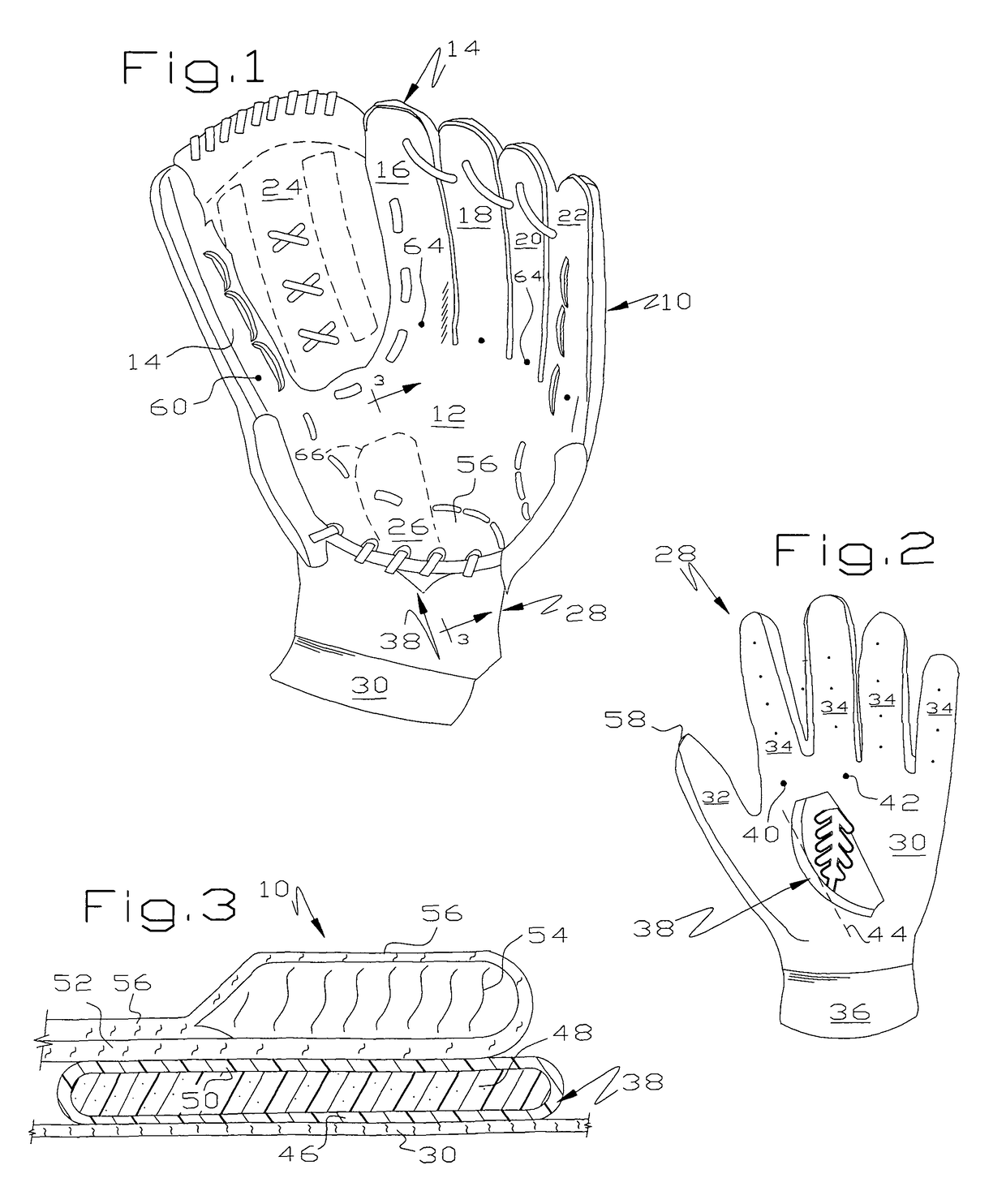

Baseball glove and liner

ActiveUS20140208478A1Improve abilitiesEasy to catchSport apparatusProtective garmentEngineeringMechanical engineering

A glove liner includes a pad running diagonally across the palm of the hand. When the glove liner is inserted into a baseball fielder's glove, the pad underlies a heel of the glove and / or a palm of the glove and promotes catching a baseball in the webbing or pocket of the fielder's glove.

Owner:SALINAS JOSE A

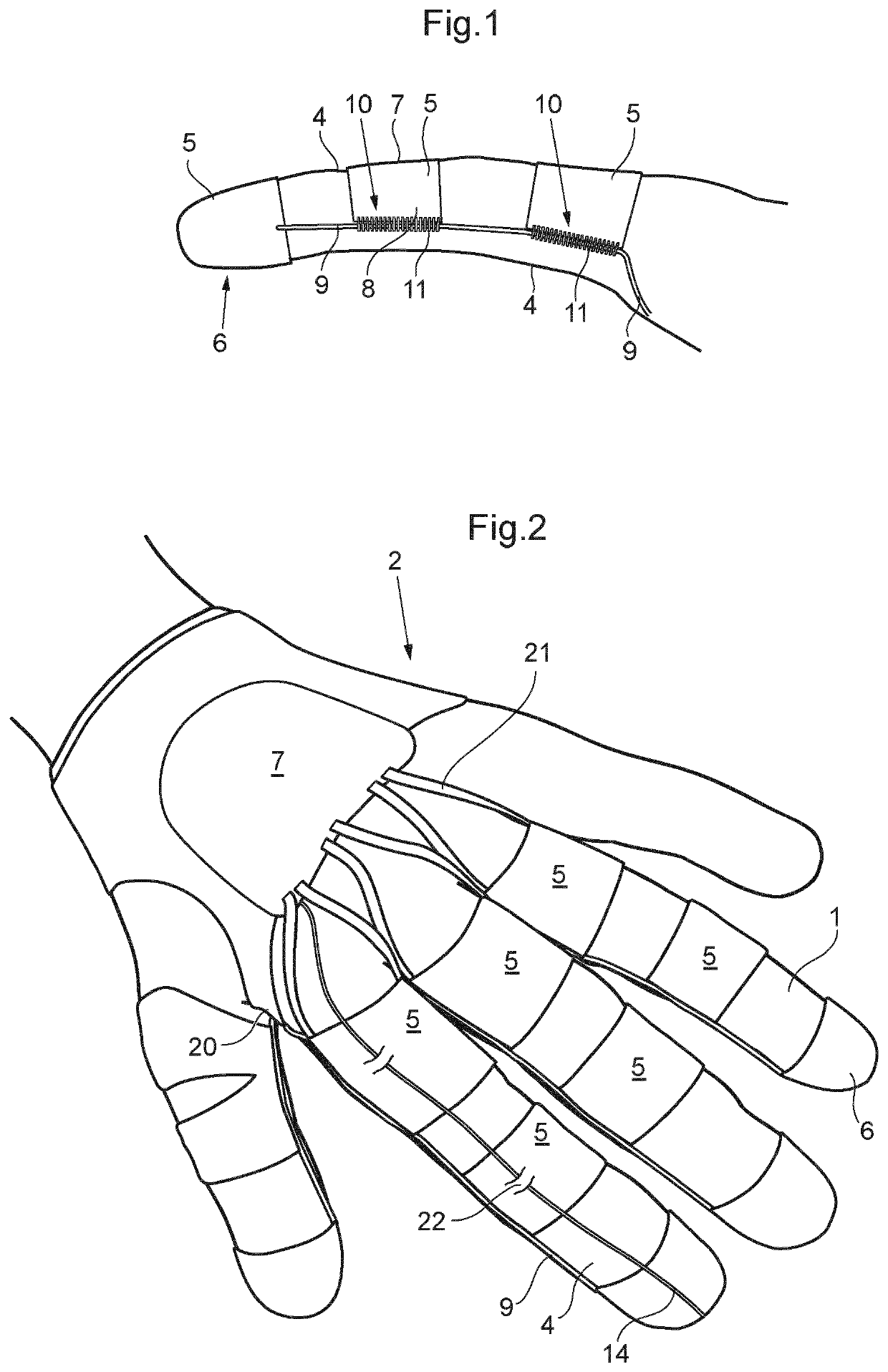

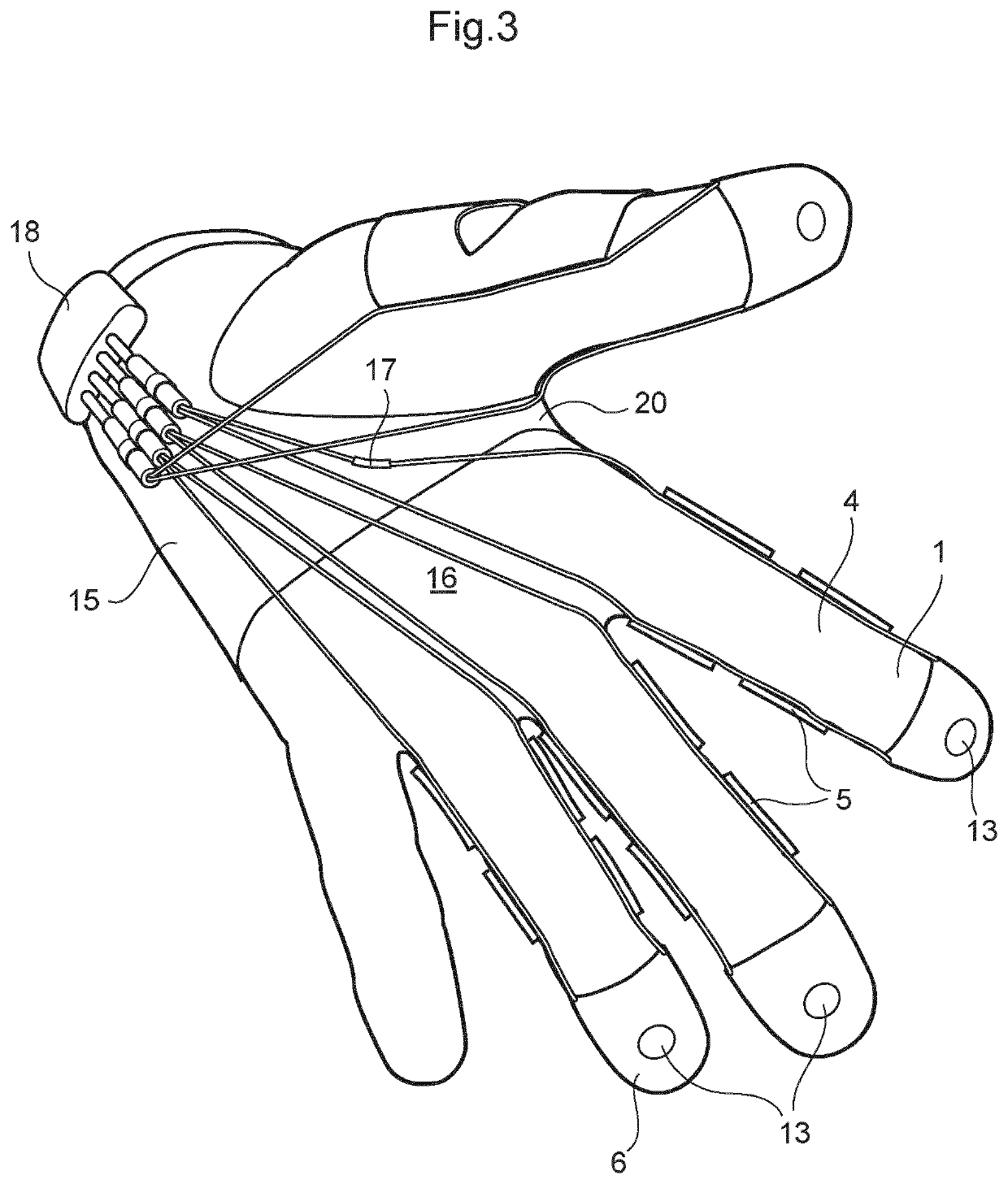

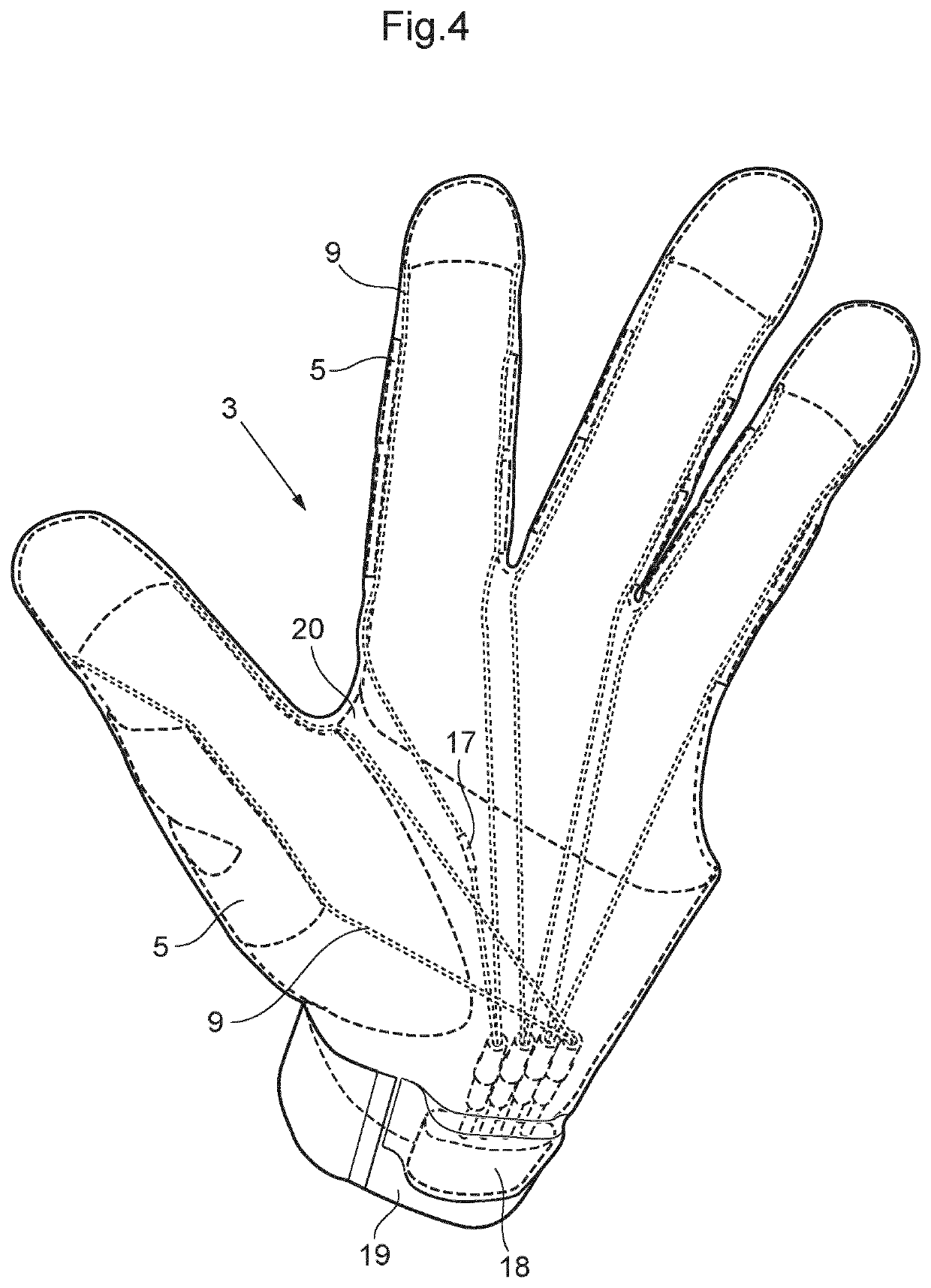

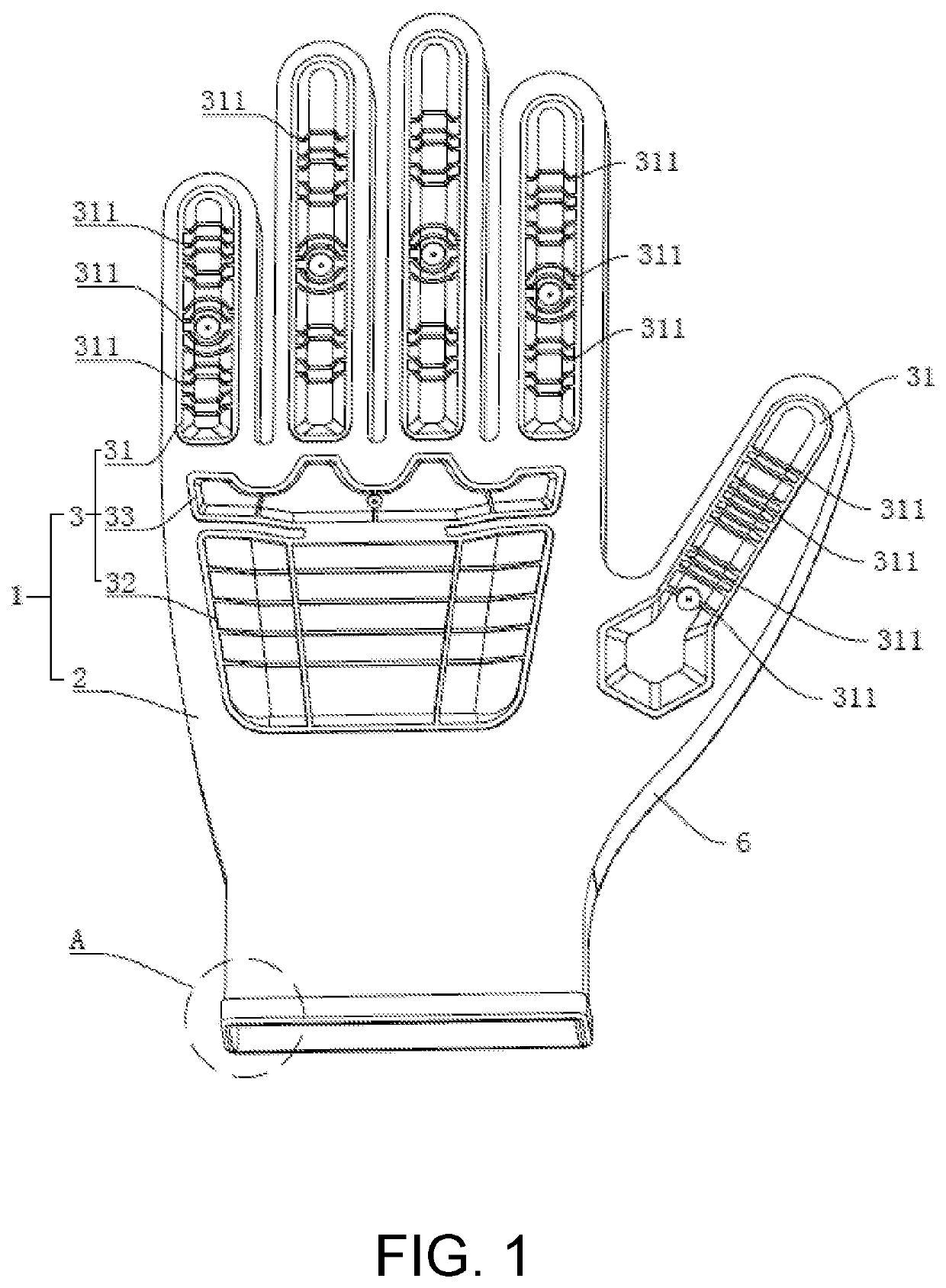

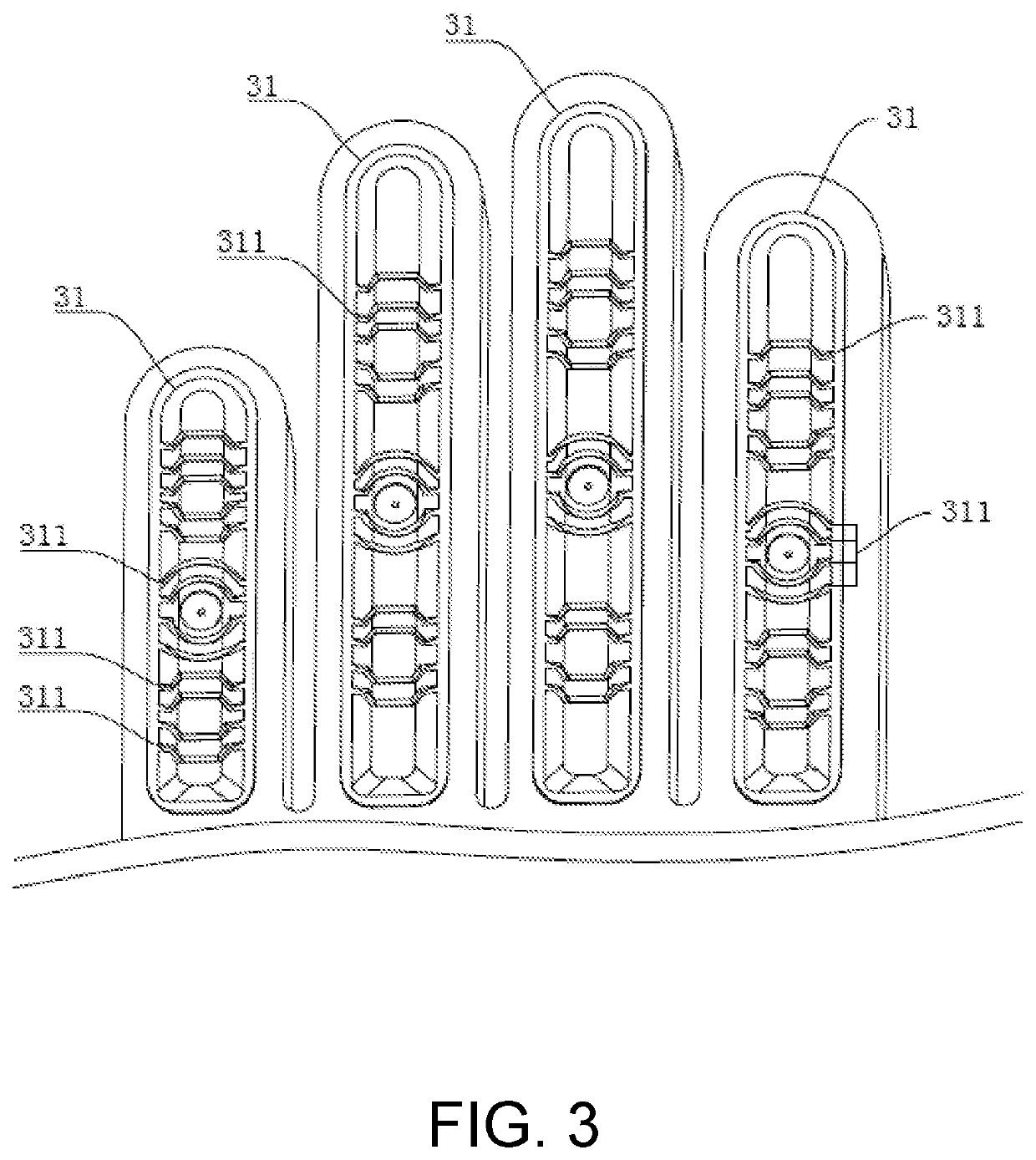

Finger glove liner and strengthening finger glove with liner

PendingUS20210161696A1Less different sizeSimple methodGymnastic exercisingGlovesPolymer scienceEngineering

A finger glove liner (2) comprising at least one finger portion (1), for arrangement inside an outer finger glove, making up a grip strengthening finger glove (3) is provided. The finger glove liner (2) is made of a stretchable material (4) in order to suit more than one size of hands, wherein at least one patch (5) of material, which has attached thereto at least an artificial tendon (9), is arranged at the outside of the finger glove liner (2).

Owner:BIOSERVO TECH AB

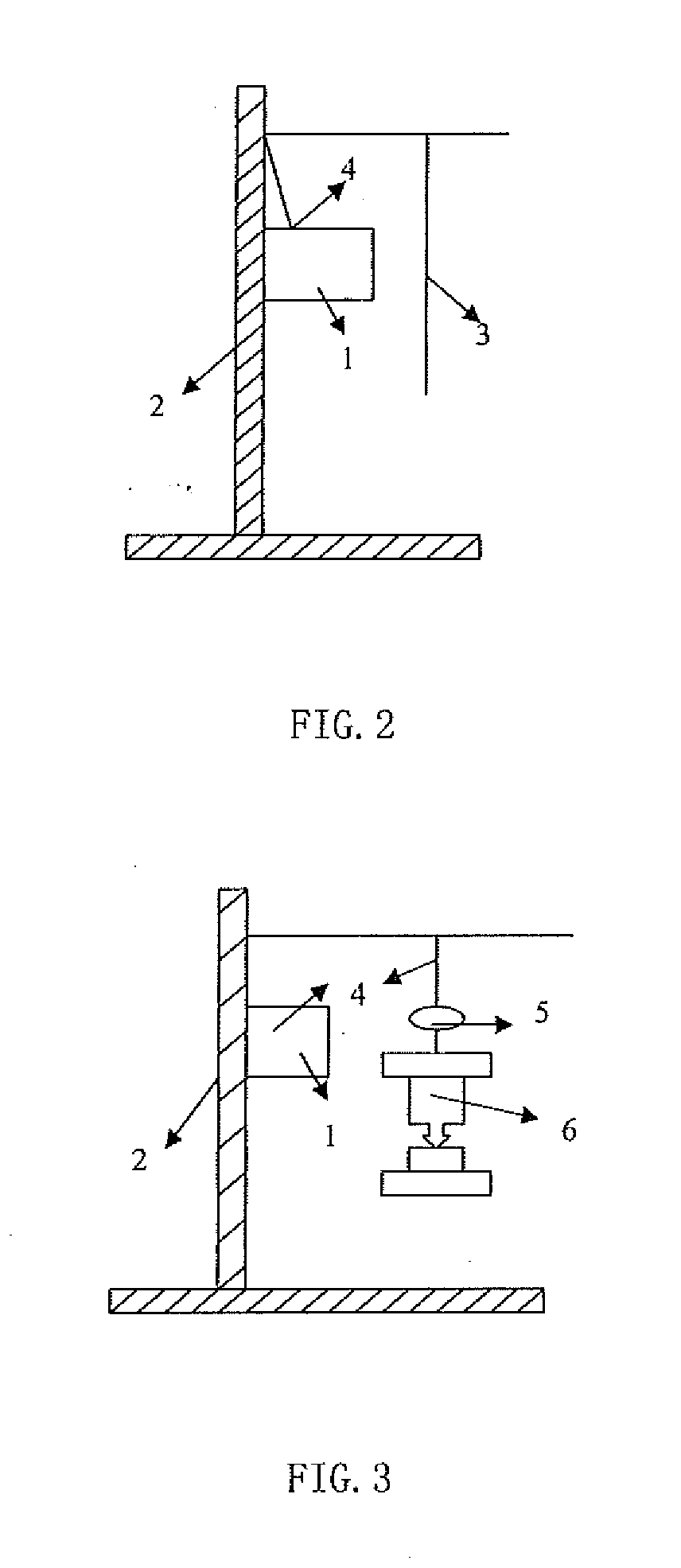

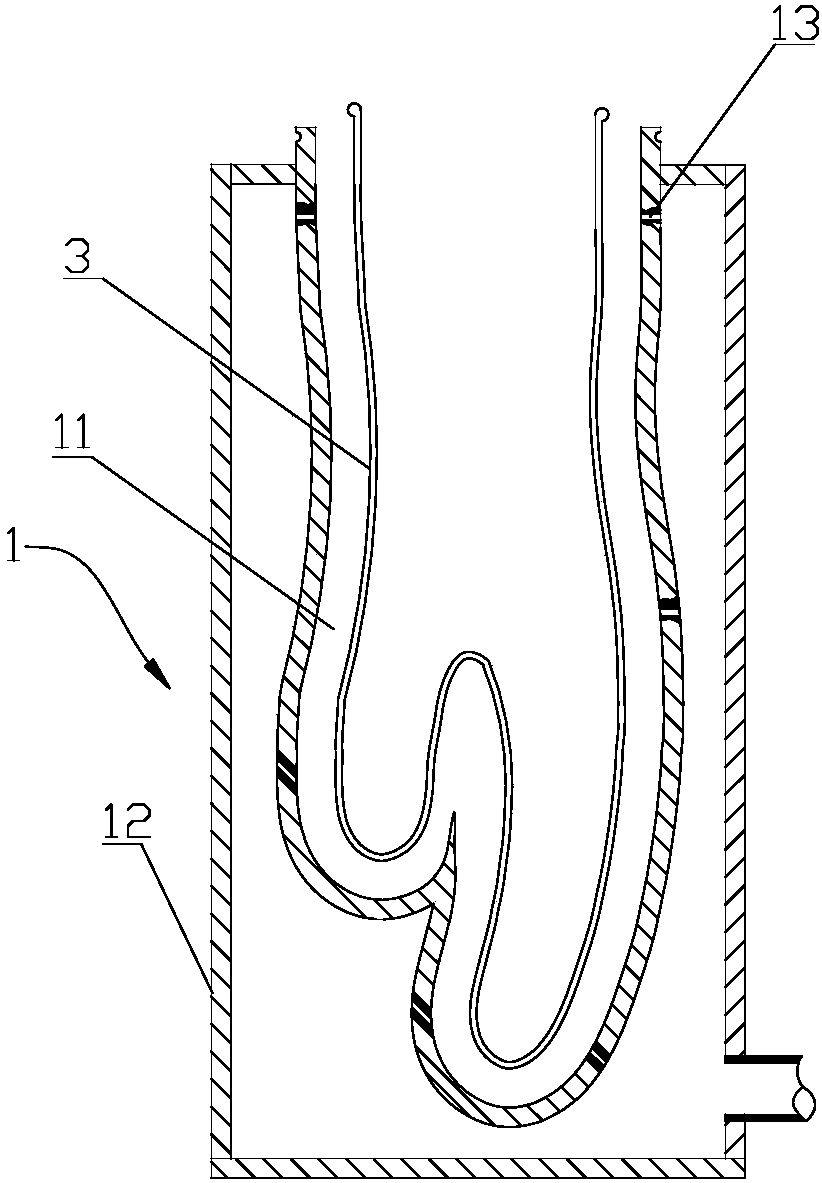

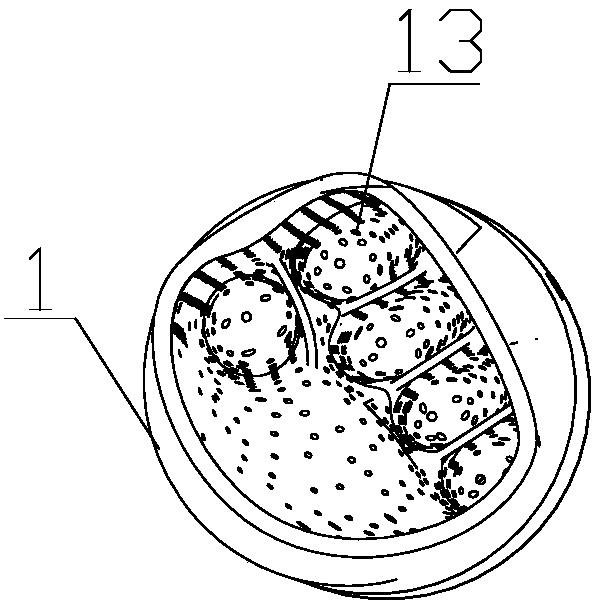

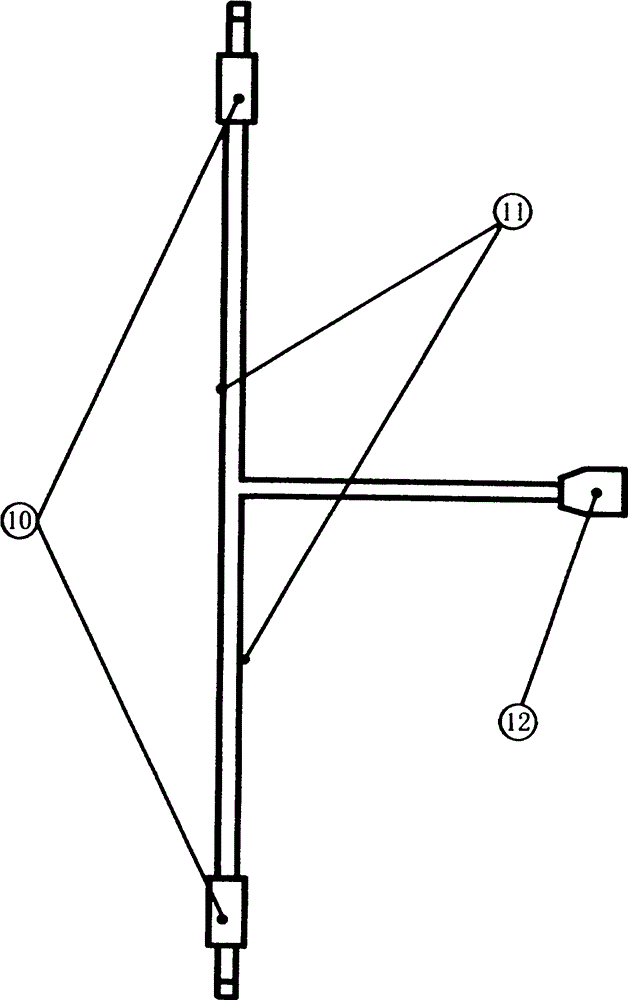

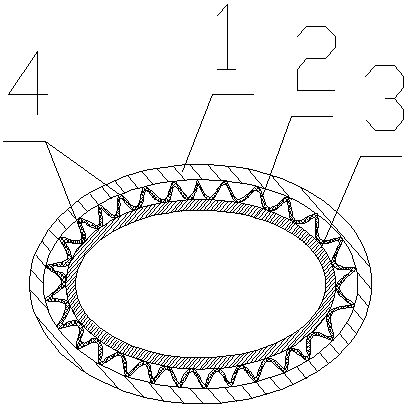

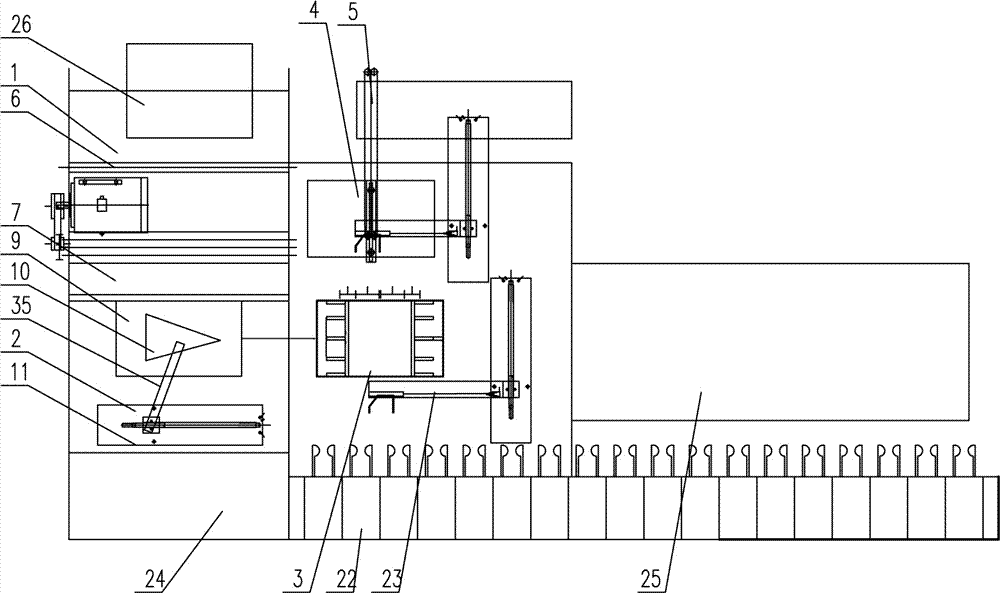

Processing device and processing method of gloves with linings

The invention belongs to the technical field of rubber products, and particularly relates to a processing device and a processing method of gloves with linings. The processing device of the gloves with the linings comprises an expansion mechanism and a glove mold, the expansion mechanism comprises a vacuum absorption cavity, the shape of the vacuum absorption cavity is matched with that of each rubber glove and used for restraining expansion of the gloves, the linings of the rubber gloves are arranged on the glove mold in a sleeved manner, the glove mold drives the linings to enter expanded rubber gloves, the shape of the glove mold is matched with that of the vacuum absorption cavity, and the size of the glove mold is smaller than that of the vacuum absorption cavity. By the aid of the device or the method, the problems of low production efficiency and poor quality of the gloves with the linings in the prior art can be solved.

Owner:李振华

Gardening glove and method of manufacturing the same

PendingUS20210127635A1Ease in gripping and flexingEasy to takeBrush bodiesGlovesEngineeringHot liquids

A gardening glove consisting of a glove liner defining a plurality of fingers, a thumb, and a palm is provided. The glove liner is placed on a first glove mandrel and received inside an injection mold configured to inject hot liquid PVC material on the glove liner's palm, fingers, and thumb, creating patterns of raised nodules that facilitate digging, for example.

Owner:HANDSON EQUINE LLC

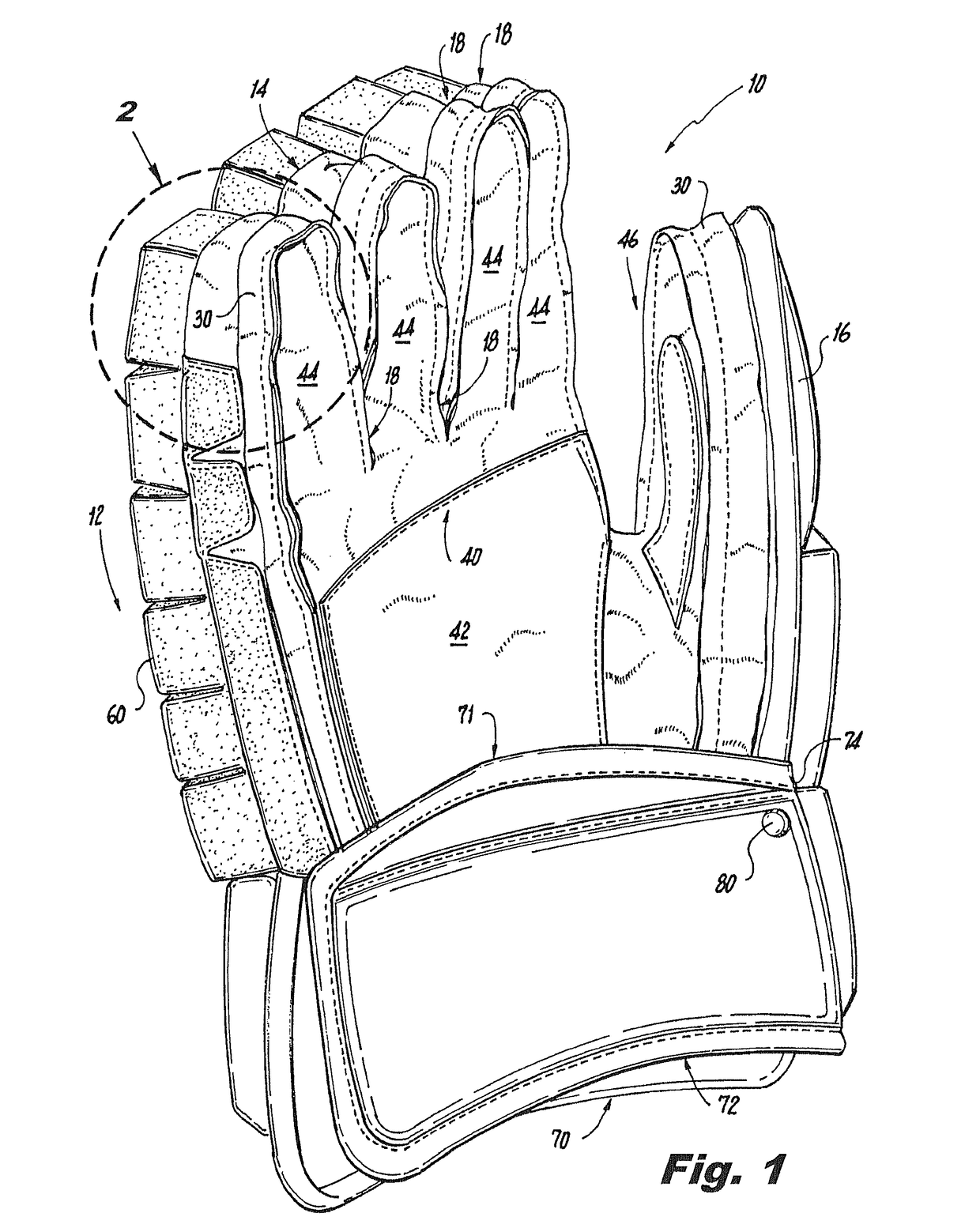

Sports glove with protective interior barriers for fingertips and wrist

ActiveUS9914042B2Quick and economical replacementComfortable internal padded finger stallsGlovesProtective garmentFinger-stallEngineering

A sports glove such as those for hockey, lacrosse, cricket, baseball and the like is formed as a palm and a separate back with a continuous peripheral closure for attachment of the two parts. The fingers inside the finger stalls are protected from contact with the closure material which is typically a metallic or plastic zipper, wherein carefully proportioned padding inside the finger stalls insulates each finger side and distal end from contact with the closure thus offering adequate protection. Furthermore, a pivotable inside wrist cuff flap is provided which creates a smooth transition of inside glove liner material protecting the palm and inside wrist from contact with hook and loop closure materials in the area as the hand is inserted into the glove.

Owner:CHORNE ROBERT

Labor protection glove and production method thereof

InactiveUS20210085001A1Good flexibilityImprove wear resistanceGlovesProtective garmentSkin contactMoisture absorption

A labor protection glove includes a glove body including a glove liner and a back rubber protection layer disposed on a surface of a back of the glove liner. The glove liner includes a skin contact layer, a moisture absorption layer disposed outside the skin contact layer and a wear-resistant layer disposed outside the moisture absorption layer. The back rubber protection layer includes a finger rubber layer disposed at a back of a finger of the glove, a palm-back rubber layer disposed at a back of a palm of the glove body, and a root knuckle rubber layer disposed between the finger rubber layer and the palm-back rubber layer for protecting a knuckle. The finger rubber layer and the root knuckle rubber layer are independently formed by injection molding.

Owner:NANTONG YUANFA INT TRADE CO LTD

A kind of latex dispensing glove and preparation method thereof

ActiveCN103981723BResistant to chemically aggressive mediaOil resistantSynthetic fibresVegetal fibresPolyesterFiber

The invention relates to a latex dispensing glove and a preparation method thereof, comprising a glove liner and an outer dipping layer, wherein the glove liner is a glove liner seamlessly woven with nylon, polyester, cotton or rayon fibers, and the outer dipping layer is latex outer dipping The outer surface of the latex outer dipping layer is covered with polymer material friction objects; the latex outer dipping layer is composed of the following components: oil-resistant and solvent-resistant rubber or polymer alloy materials or anti-static materials or high-temperature resistant materials, Vulcanizing agents and accelerators. The present invention is covered with polymer material friction materials on the outside of the glove, which isolates the contact between the glove and the object to be held, making the protection of the hand safer and more reliable, and also increases the friction between the glove and the object to be held, making it safe. Easy to apply and can be used for hand protection in a variety of environments.

Owner:ZHEJIANG KANG LONG DA SPECIAL PROTECTION TECH CO LTD

High-temperature-resistant, flame-retardant, anti-cutting and anti-chopping glove and preparation method thereof

The invention provides a high-temperature-resistant, flame-retardant, anti-cutting and anti-chopping glove and a preparation method thereof. The high-temperature-resistant, flame-retardant, anti-cutting and anti-chopping glove includes an outer protective sleeve and a glove liner arranged in the outer protective sleeve; the outer protective sleeve is formed by warp-and-weft weaving of covering yarn, the covering yarn is formed by winding an outer bag part closely around a yarn core, the outer bag part is formed by warp-and-weft weaving of aramid fibers, the outer surface of the outer bag part is provided with a high-temperature-resistant latex coating, the inner side of the outer protective sleeve is compounded with a metal wire woven layer, the yarn core is made from glass long fibers, the glove liner is of a two-layer structure made of high-temperature-resistant silica gel, an empty cavity of the glove liner is filled with inert gas, the glove liner is fixedly connected with the inner side wall of the protective sleeve and has good high-temperature-resistant and anti-slipping effects so that hands of a user can be protected and prevented from burning, through the arrangement of metal wires, the glove has good anti-cutting and anti-chopping effects, and the service life of the glove is improved.

Owner:许锰镑

Butyl blended emulsion chemical-resistant gloves and preparation method thereof

ActiveCN103965554BKeep airtightCorrosion resistance hasGlovesProtective garmentPolymer sciencePolymer alloy

The invention relates to a butyl blend emulsion chemical-resistant glove and a preparation method thereof, comprising a glove liner and an outer dipping layer of a blended emulsion material, and the outer dipping layer of a polymer blend material is composed of the following components: polymer blending Gold material main body, vulcanizing agent, accelerator and vulcanization activator, the mass part ratio is: polymer blend alloy material main body: vulcanizing agent: accelerator: vulcanization activator=100:0.5-5:0-2:1-3 ; The main polymer alloy material includes 60%-100% butyl rubber and 0%-40% other polymer materials; other polymer materials are PVC, PE, phenolic or nitrile rubber. The invention solves the disadvantages of cohesive force and tearing performance, has anti-chemical corrosion, solvent resistance, oil resistance, good water resistance and electrical insulation, and has various properties such as abrasion resistance, cutting resistance, and puncture resistance. Excellent performance, the preparation process is mechanized and linked, and the flow operation is completed; the production is feasible, the technology is reliable, the cost is reasonable, and it is suitable for industrial scale production.

Owner:ZHEJIANG KANG LONG DA SPECIAL PROTECTION TECH CO LTD

Super-absorbent fiber material for processing disposable medical glove liner and manufacturing method thereof

InactiveCN111364120AAbsorbentHas one-way moisture permeabilityOrganic chemistryConjugated cellulose/protein artificial filamentsFiberSpinning

The invention discloses a super-absorbent fiber material for processing a disposable medical glove inner and a manufacturing method thereof, and relates to the technical field of medical materials. According to the super-absorbent fiber material for processing the disposable medical glove inner and the manufacturing method thereof, a composite fiber material with a skin-core structure is manufactured and obtained by utilizing a core-layer spinning solution and a skin-layer spinning solution, the manufactured fiber material has good water absorption and water locking properties, moisture emitted by a human skin can be instantly absorbed, the fiber material is suitable for being used as a disposable medical glove inner processing material, the prepared glove inner can obviously improve the wearing comfort of a glove, the biodegradability is realized, and the pollution to the environment after the disposable medical glove are discarded is reduced.

Owner:张慧芬

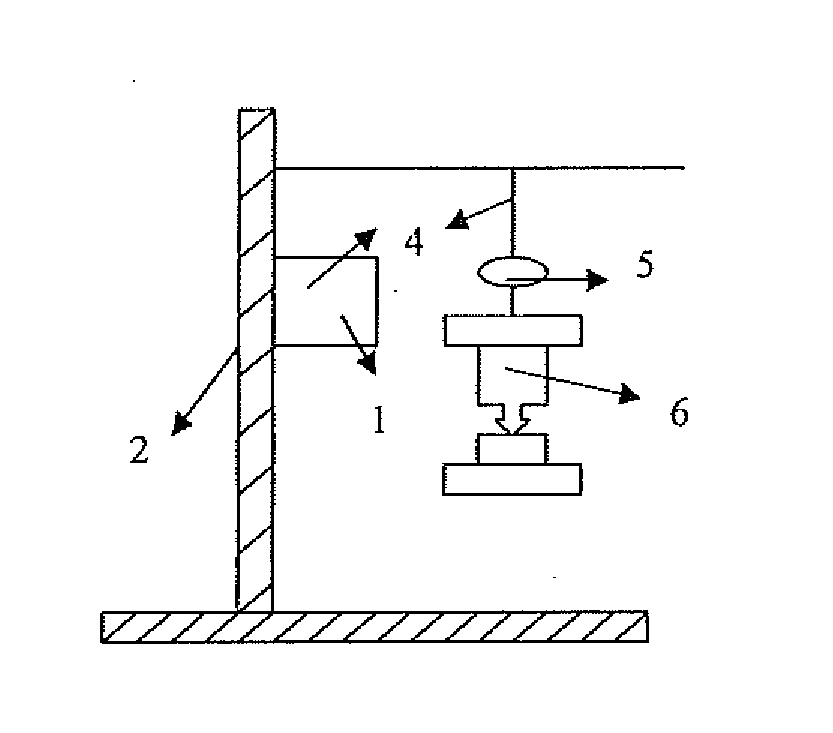

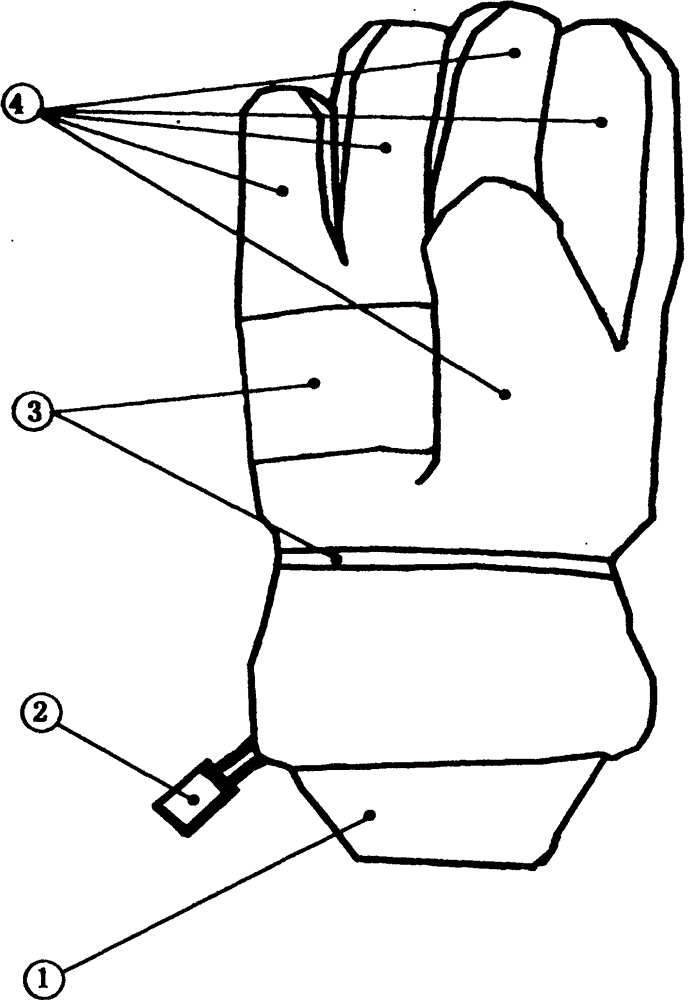

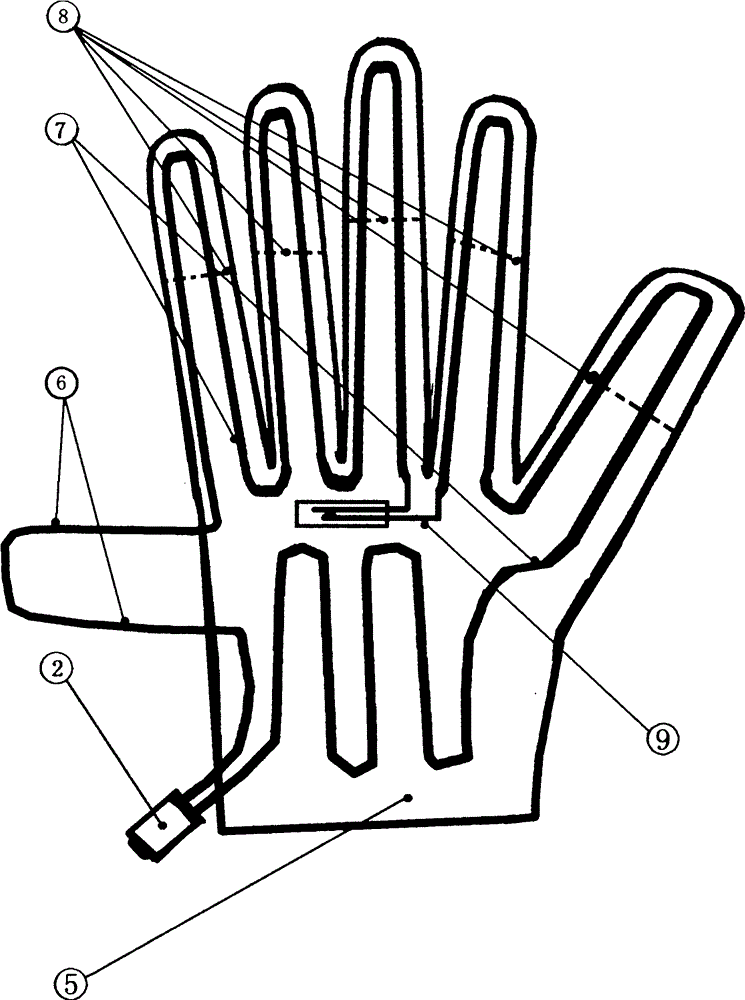

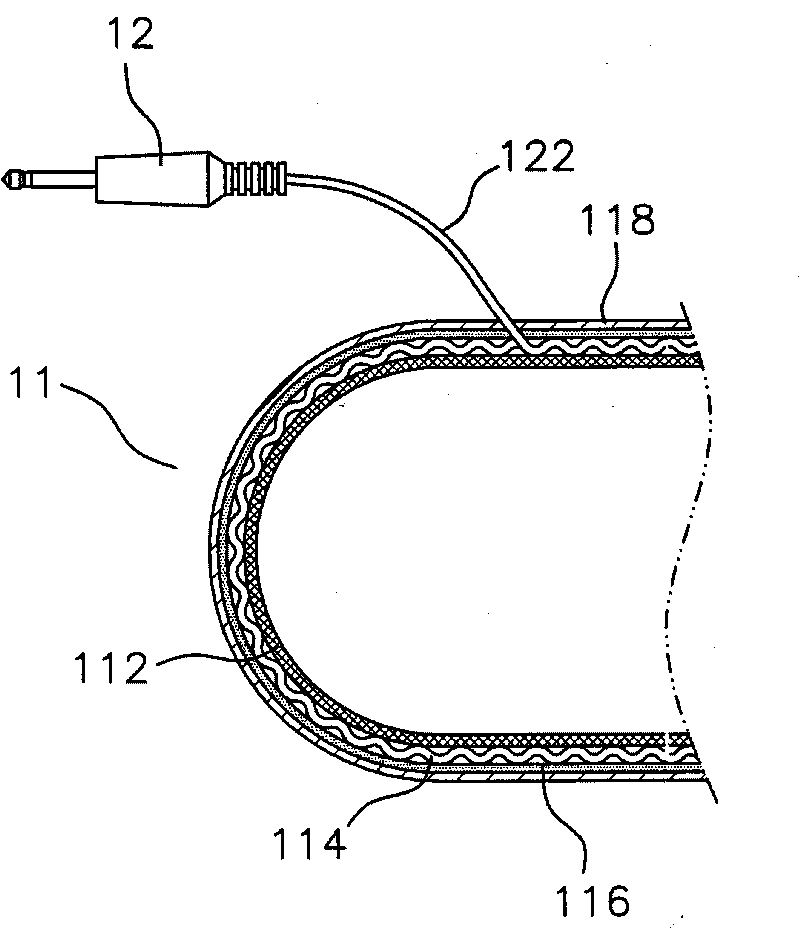

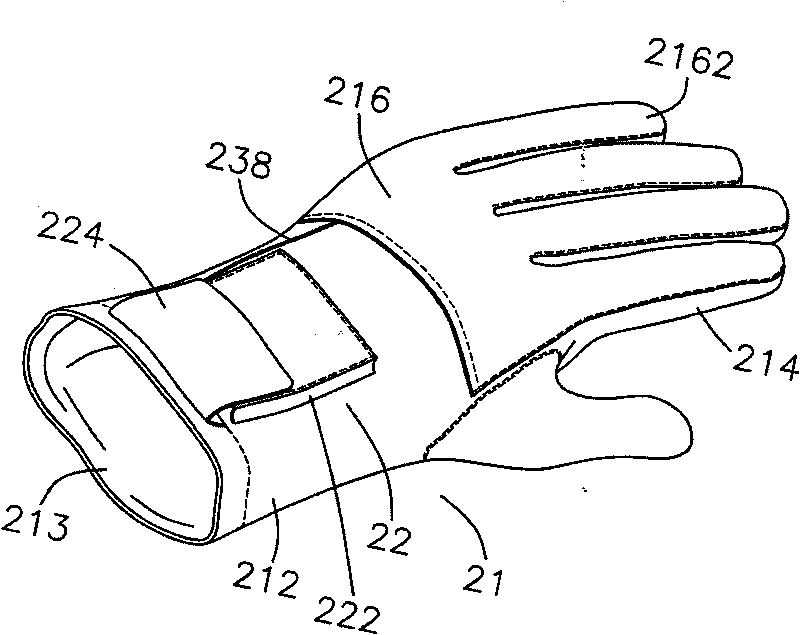

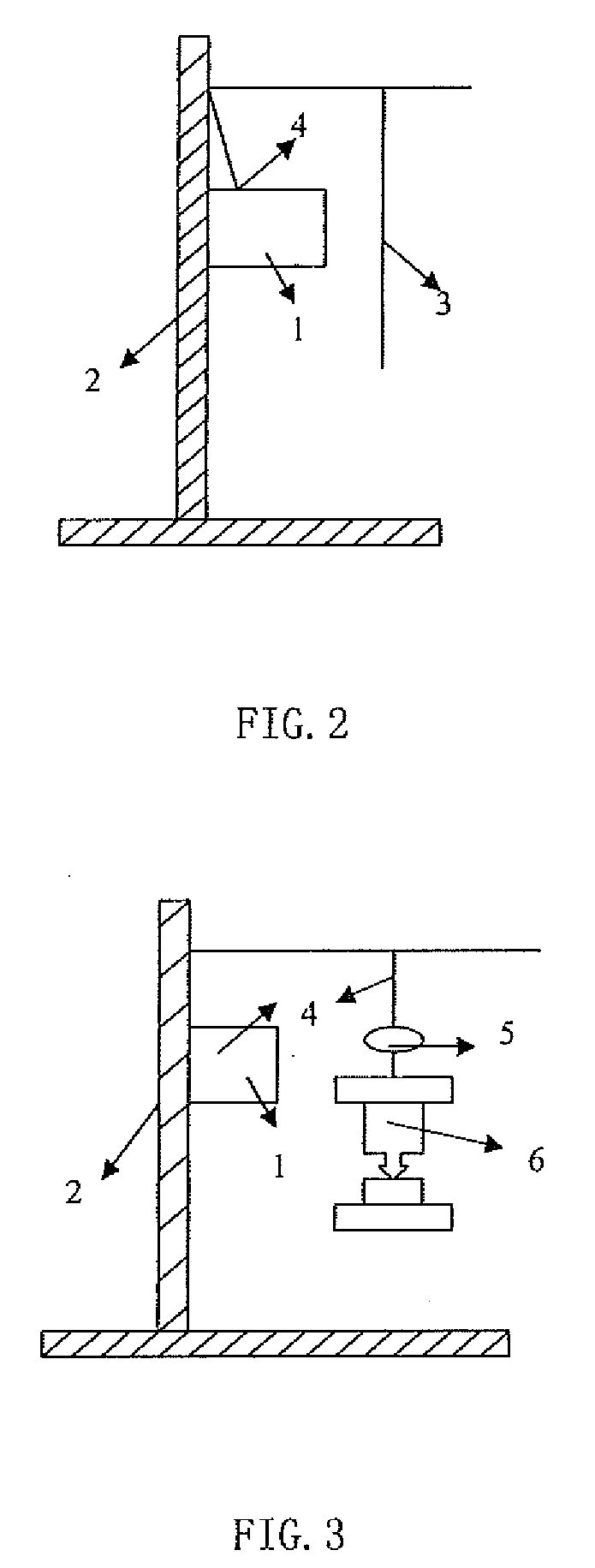

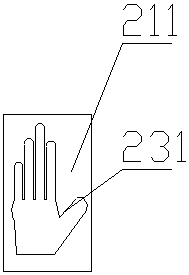

Electric motorcycle heating glove capable of achieving constant temperature automatically

Disclosed is an electric motorcycle heating glove capable of achieving constant temperature automatically. A pair of common warming gloves (as shown in figure 1) is adopted, a heating element (as shown in figure 2) which takes double-layer lengthened finger non-woven fabric as base fabric and sandwiches a far-infrared carbon fiber heating wire in the base fabric is placed in an interlayer of each of glove backs, glove palms and finger portions, the finger heating wires (7) on the heating elements are set in right positions, and a heating wire lead socket (2) is placed outside a glove mouth of each glove. A temperature control switch (9) is mounted in the middle of the glove back of a glove liner of each glove, and a lead of each temperature control switch (9) is serially connected to the corresponding carbon fiber heating wires. When the temperature of each glove is higher than that controlled by the corresponding temperature control switch (9), the corresponding temperature control switch (9) can be disconnected with a heating power supply automatically, so that the temperature cannot rise; when the temperature of each glove is lower than that controlled by the corresponding temperature control switch (9), the corresponding temperature control switch (9) can be connected with the heating power supply automatically so as to achieve heating again.

Owner:华洪林

Magnet therapy massage gloves

InactiveCN103284359ASimple structurePromote circulationElectrotherapyGlovesSurface layerHand disease

The invention discloses a pair of magnetic therapy massage gloves. Each glove comprises a glove body, a glove surface layer and a glove liner layer, wherein magnet therapy massage cushions are fixedly arranged at all parts between the glove surface layer and the glove liner layer. According to the magnet therapy massage gloves, the structure is simple; the magnet therapy massage cushions are arranged between the glove surface layer and the glove liner layer; the design of the gloves is adopted in order to save materials and costs; magnets are arranged, so that hands can be massaged, hand diseases can be prevented and treated, blood circulation is promoted, and working pressure and fatigue are relieved.

Owner:NANTONG HUAHAN HOME TEXTILE FABRICS DESIGN

Boxing glove with negative Poisson's ratio effect and design method thereof

PendingCN109821224AStrong rebound toughnessImprove energy absorptionSport apparatusDomestic articlesEngineeringDesign methods

The invention discloses a boxing glove with a negative Poisson's ratio effect and a design method thereof. The boxing glove is characterized by a concave structure design of liner polyurethane foam. The method comprises the steps of firstly, based on human hand shapes and existing boxing glove bodies, establishing a suitable boxing glove liner model and determining a basic size; then, placing thepolyurethane foam in an aluminum mold and conducting compression, heating, cooling and relaxation treatment on the polyurethane foam to obtain negative Poisson's ratio polyurethane foam with special concave structures; secondly, according to existing international boxing glove weight regulations, designing the thickness and distribution of the negative Poisson's ratio polyurethane foam in a liner,and conducting stress analysis by using relevant software to further determine the optimal thickness of the foam and the distribution in the liner. The boxing glove designed by the method has many advantages of the negative Poisson's ratio effect, and is proved to have strong novelty and practicability.

Owner:NANJING UNIV OF TECH

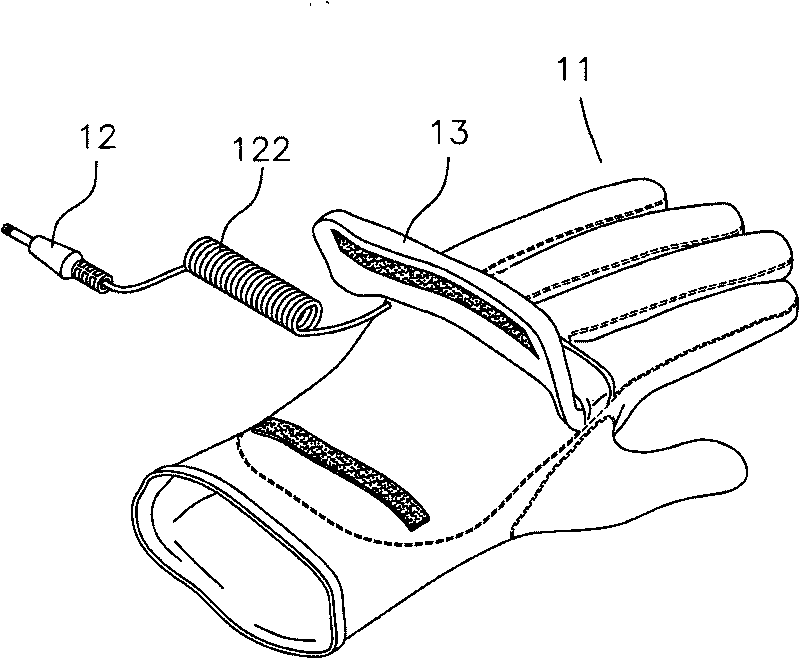

Glove liner with electric heating equipment

InactiveCN101731773AImprove convenienceEasy to cleanOhmic-resistance heating detailsProtective garmentGlove linerElectric heating

The invention relates to a glove liner with electric heating equipment, which comprises a lining, an accommodating bag and the electric heating equipment, wherein the lining is an integral palm-shaped sleeve body consisting of a palm sleeve part and a plurality of fingerstall parts; one end of the palm sleeve part is provided with a linking, while the other end is communicated with the fingerstall parts; the outside of the lining is provided with an outer bag which is provided with a plurality of sub-bags extending to the outside of each fingerstall part; the accommodating bag is arranged outside of the lining, and consists of a bag body and a cover plate; the electric heating equipment consists of an electric heating piece, a power supply and a controller; the electric heating piece, the power supply and the controller are conducted by a lead, so that the electric heating piece is heated to generate heat; the surface of a flexible insulation sheet body is provided with an electric heating loop to form the electric heating piece; a plurality of sub-pieces convexly extend out of the electric heating piece, and the electric heating loop extends to the sub-pieces; the electric heating piece is arranged in the outer bag, and each sub-piece is inserted into each sub-bag; and the power supply and the controller are arranged in the bag body and are covered at a bag opening through the cover plate, so that the lining and the electric heating equipment are easy to separate and assemble, the lining is convenient to clean and the electric heating equipment is convenient to maintain.

Owner:陈树炼

Method for manufacturing bacteriostatic and moisture-proof work-protective gloves

InactiveCN111321603AGood flexibilityReduce volumeWeft knittingLamination ancillary operationsYarnFiber

The invention discloses a method for manufacturing bacteriostatic and moisture-proof work-protective gloves and belongs to the technical field of gloves, wherein the work-protective gloves are manufactured through the following steps of first twisting composite fibers to form silk yarns, then knitting the silk yarns into a hydrophobic inner liner I, a hydrophilic inner liner II and a hydrophobic inner liner III respectively, afterwards, flatly laying the inner liner I, the inner liner II and the inner liner III and sequentially laminating the inner liner I, the inner liner II and the inner liner III to form a composite layer, and processing the composite layer to form a glove liner, wherein the inner liner I is located on the inner side, the inner liner II is located on the interlayer, andthe inner liner III is located on the outer side, then coating the outer surface of the glove liner with a modified nitrile latex layer, and finally coating the surface layer of the modified nitrilelatex layer with a layer of PVC particles. Nitrile and PVC gloves are produced in a composite way, so that the surfaces of the produced gloves have high strength, and the insides have good flexibilityand softness.

Owner:ZHEJIANG EAST ASIA GLOVE CO LTD

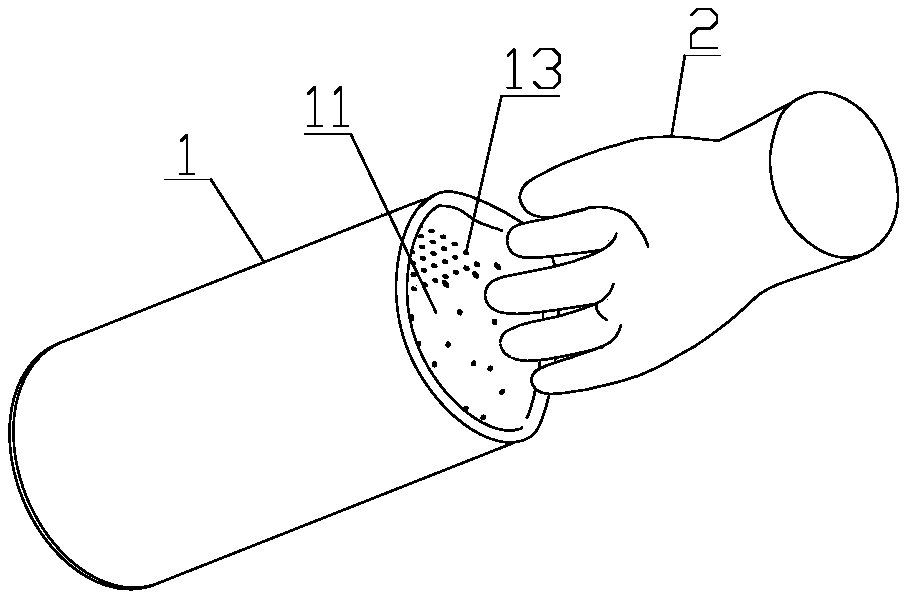

Method for making gloves with enhanced gripping power

ActiveUS8956561B2Improve gripIncrease elasticityCeramic shaping apparatusDomestic articlesSolid particleEngineering

A method for making gloves with enhanced gripping power, comprises: step 1, making a glove liner; step 2, covering a hand former with the glove liner and putting it into an oven for pre-heating; step 3, dipping the hand former into a coagulant completely; step 4, dipping the hand former into a latex; step 5, drying the surface; step 6, dipping the hand former into the latex again; step 7, spraying soluble solid particles on the surface evenly; step 8, baking; step 9, dipping the hand former into water to dissolve the soluble solid particles; step 10, baking; getting a glove with enhanced gripping power. The glove made by the method has good flexibility, can prevent oil permeability and has good slip-proof effect.

Owner:LIN CHARLES

Anti-cutting and anti-impact glove

The invention discloses an anti-cutting and anti-impact glove. The anti-cutting and anti-impact glove comprises a glove liner, a rubber layer coated on the glove liner, and a joint anti-collision component. The joint anti-collision component comprises finger anti-collision blocks arranged at the five finger positions of the glove liner and a hand back anti-collision block arranged at the hand backposition, wherein the finger anti-collision block are composed of connection bars with radian and a plurality of blocks arranged on the surface of the connection bars, the backs of the connection bars are fixed on the surface of the five finger positions of the glove liner coated with glue through an adhesive, the length direction of the connection bars extends in the length direction of each finger, the hand back anti-collision block is fixed on the surface of the central position of the back of the hand of the glove liner coated with glue through an adhesive, and comprises a trapezoidal back of the hand and four knuckle parts covering the metacarpophalangeal joint extending from the lower bottom edge of the back of the hand.

Owner:江苏瑞斯达安全防护用品有限公司

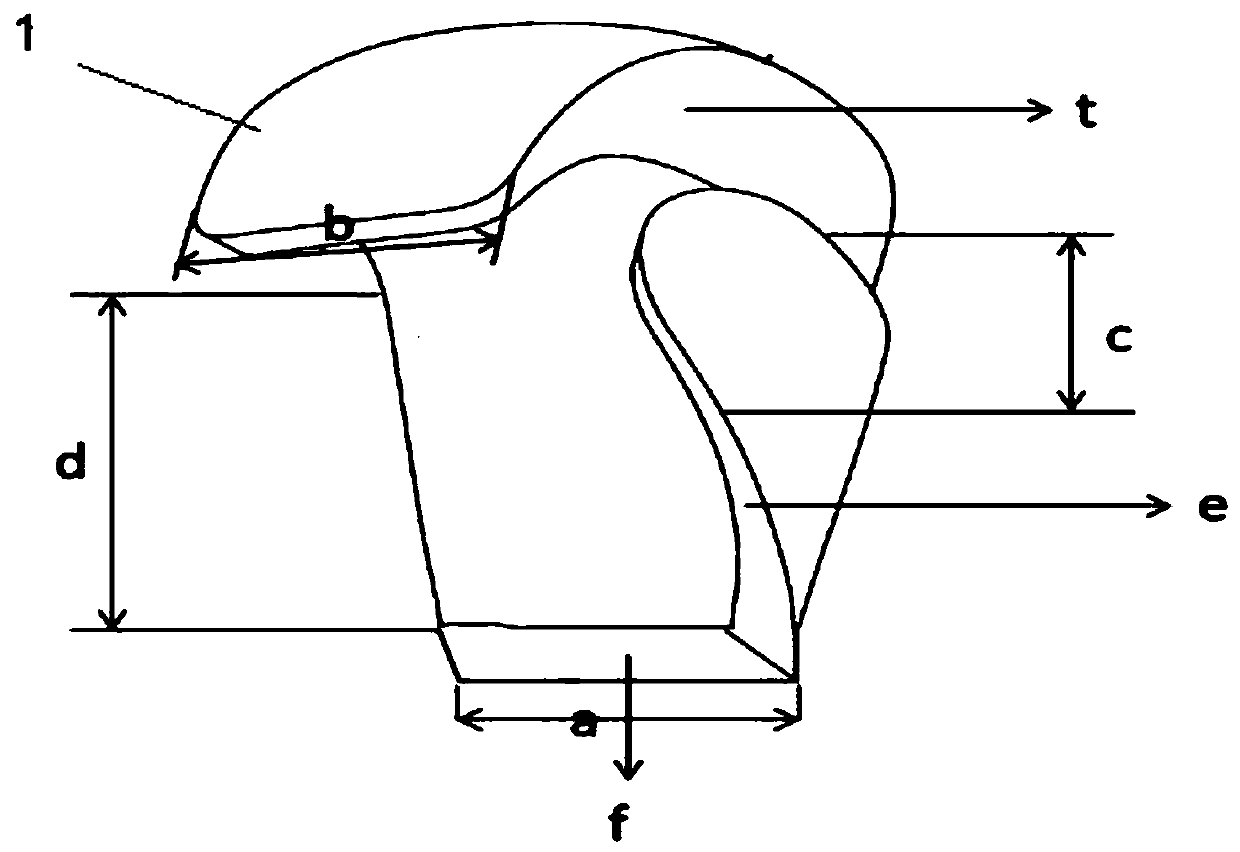

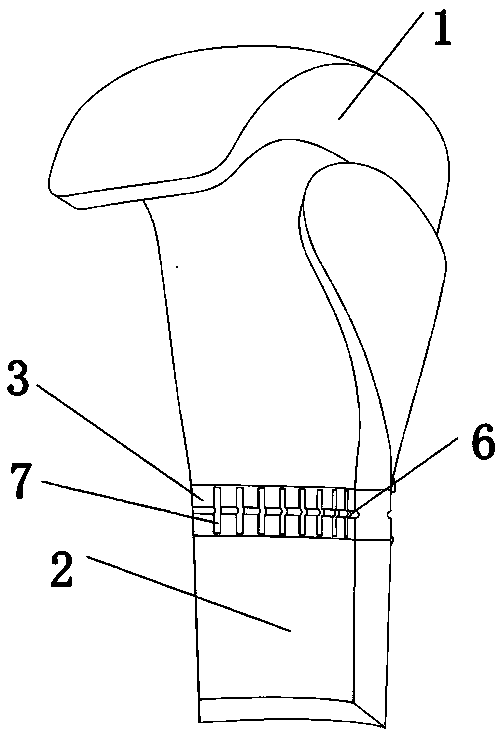

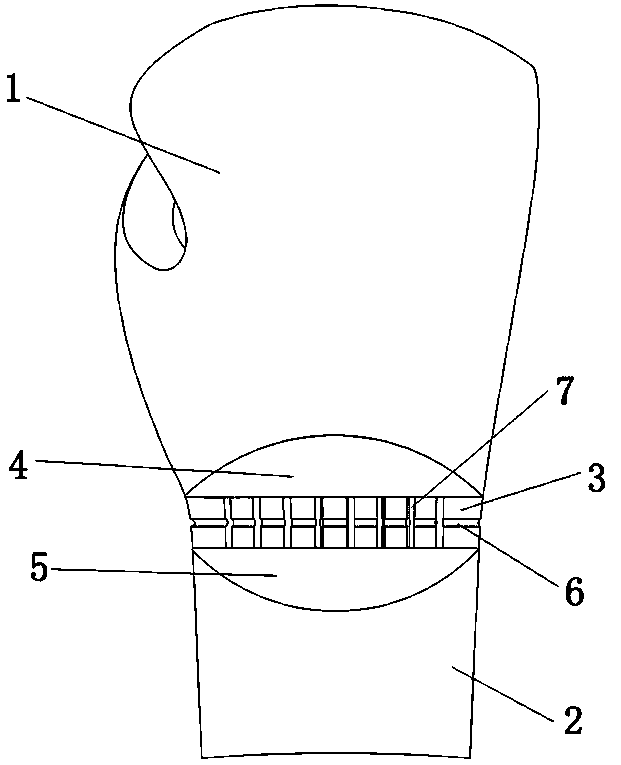

Manufacturing methods of joint type wristband type boxing glove and glove liner thereof as well as boxing glove and glove liner thereof

The invention relates to manufacturing methods of a joint type wristband type boxing glove and a glove liner thereof as well as a boxing glove and a glove liner thereof. The glove liner comprises a body part, a wristband part and a joint type elastic protective block which is connected between the body part and the wristband part; the upper end surface of the elastic protective block is adhered tothe lower end surface of the body part; the lower end surface of the elastic protective block is adhered to the upper end surface of the wristband part; sunken parts convenient for bending of a wristjoint are arranged on the front face and the back face of the elastic protective block respectively; and a plurality of strip through holes are formed in the elastic protective block at intervals. The joint type elastic protective block can ensure the flexibility of the movement of the wrist joint and can also have very good protection effect to the wrist joint; and the structure, the size and the material of the elastic protective block are all specially designed, the whole design accords with the requirements for human engineering, and the glove has a wide market prospect.

Owner:石家庄市五龙体育器材有限公司

A kind of waterproof breathable glove and its manufacturing method

The present invention specifically relates to a waterproof and breathable glove and a manufacturing method thereof. The waterproof and breathable glove at least includes a functional layer, an inner lining, and an inner layer from the outside to the inside, wherein the inner lining is a waterproof and breathable polyurethane film, and the upper and lower sides of the inner lining are Both sides are coated with dots of glue, and the lining is wavy between the functional layer and the inner layer. The manufacturing method includes A. manufacturing of inner lining; B. manufacturing of functional layer; C. manufacturing of inner layer; D. bonding of functional layer, inner lining and inner layer; E. cooling process. The glove is provided with the polyurethane film of the inner liner, so that it has waterproof and breathable characteristics, and in the manufacturing method, the functional layer, the inner layer and the inner liner are bonded by adjusting the volume of the second glove model and the third glove model. When people wear gloves, the functional layer and the inner layer of the gloves are in a semi-tight state, and the inner lining is in a compressed state, thereby improving the durability of the gloves.

Owner:HAINING RANDY SOCKS

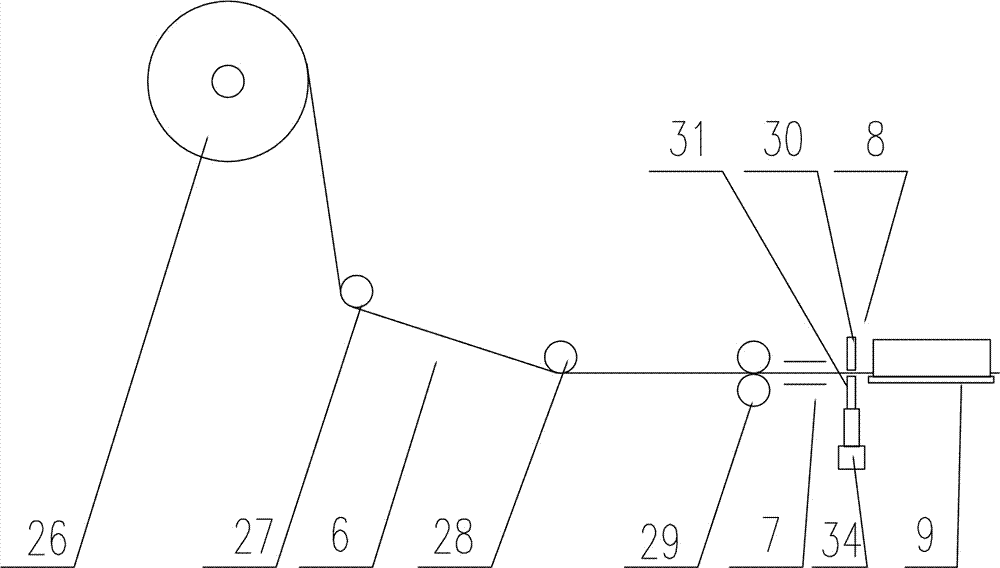

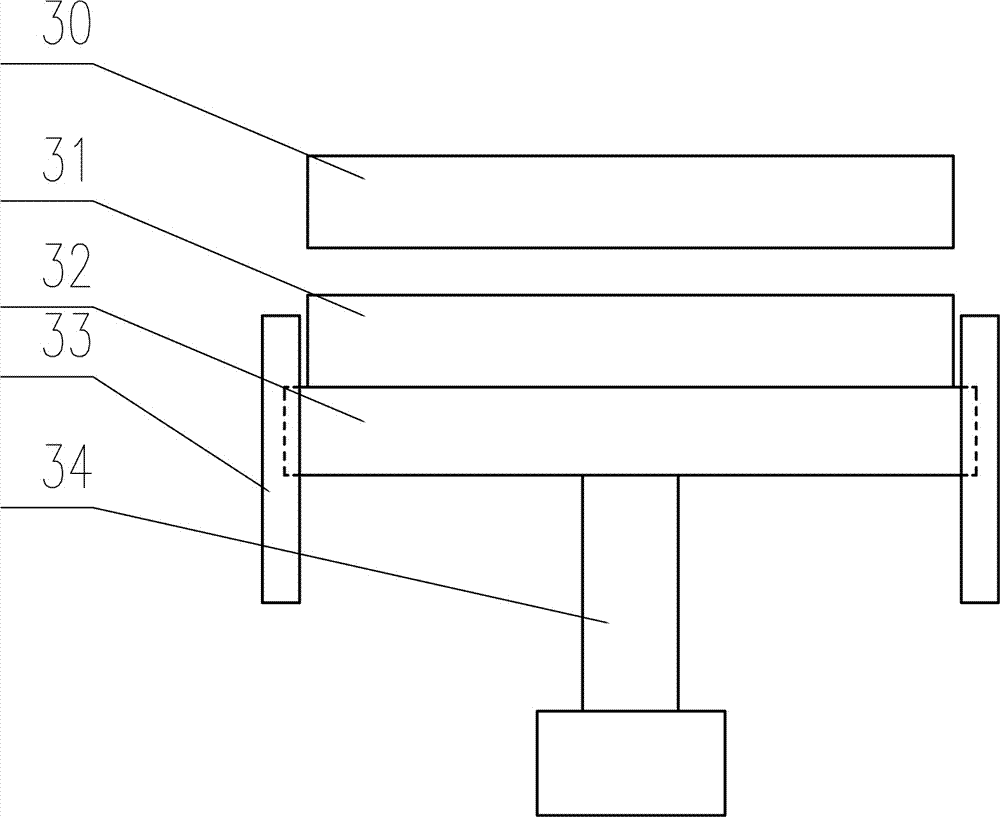

An origami machine for lining paper packaging of medical gloves

Owner:宜昌麦迪科机电设备有限责任公司

Baseball glove and liner

A glove liner includes a pad running diagonally across the palm of the hand. When the glove liner is inserted into a baseball fielder's glove, the pad underlies a heel of the glove and / or a palm of the glove and promotes catching a baseball in the webbing or pocket of the fielder's glove.

Owner:SALINAS JOSE A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com