Labor protection glove and production method thereof

a glove and glove technology, applied in the field of labor protection gloves, can solve the problems of reducing the shock-proof and impact-resistance effect of the glove back, impaired hand flexibility, etc., and achieves the effects of high wear resistance, good softness and comfor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

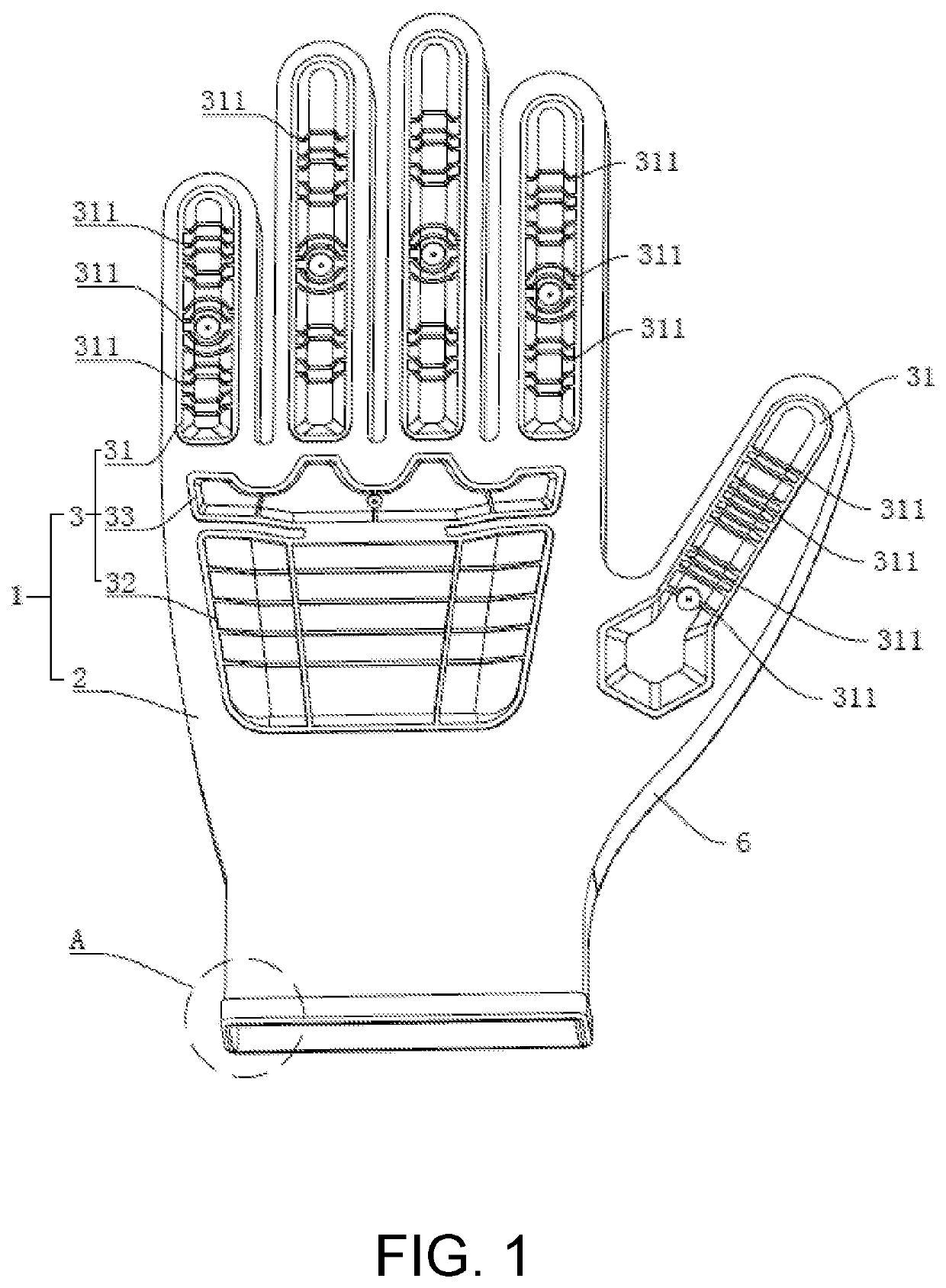

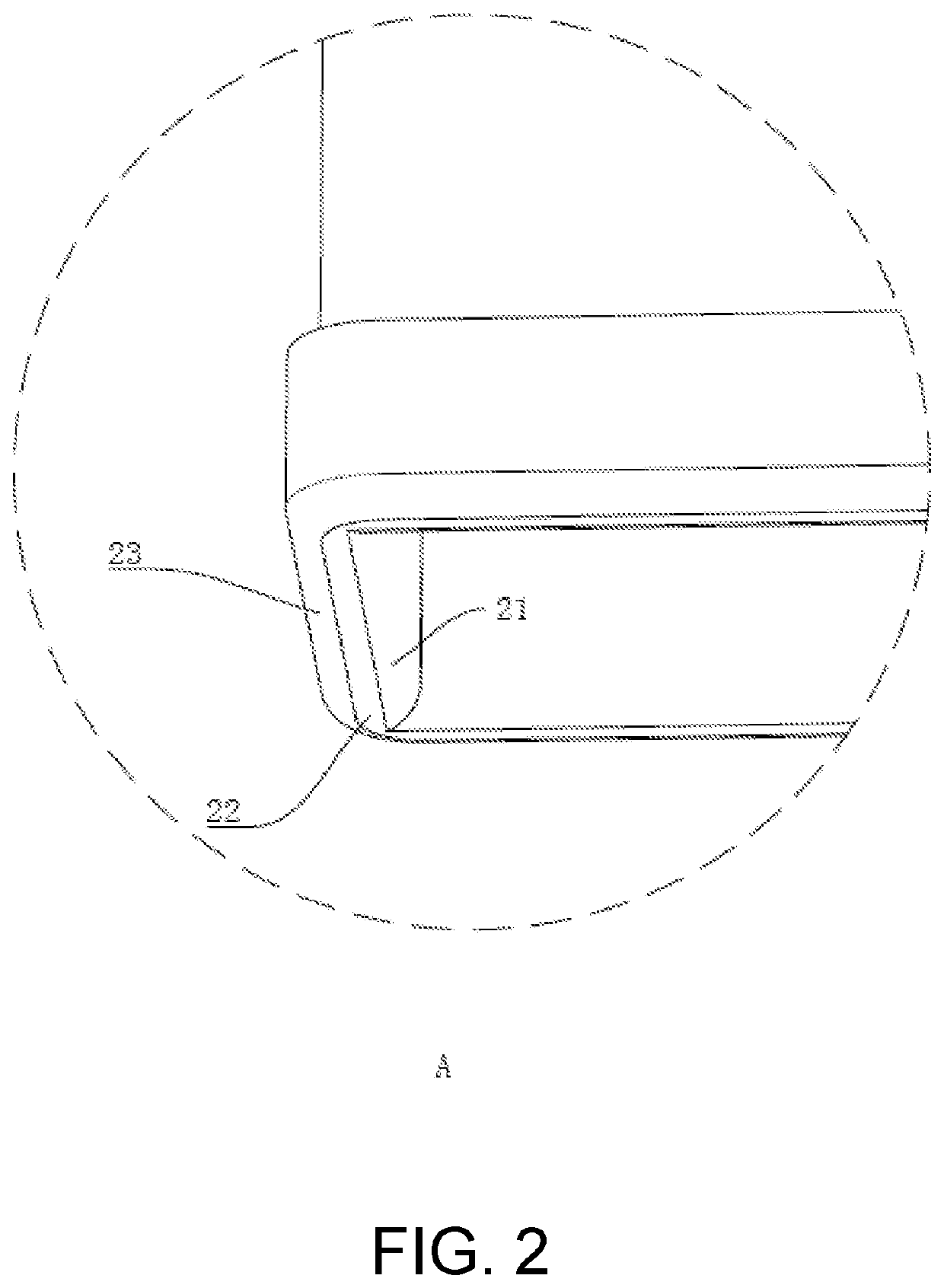

[0042]A highly soft and anti-shock labor protection glove, as shown in FIG. 1 and FIG. 2, includes a glove body 1. A wear-resistant rubber layer 6 is disposed at one side of a palm of the glove body 1 by dipping. The glove body 1 includes a glove liner 2 and a back rubber protection layer 3 disposed on a surface of a back of the glove liner 2. The glove liner 2 includes a skin contact layer 21 woven by at least one of cotton, spandex, polyester and aramid, a moisture absorption layer 22 sewn outside the skin contact layer 21 and woven by a blend of cotton, spandex and bamboo charcoal fiber, and a wear-resistant layer 23 sewn outside the moisture absorption layer 22 and woven by at least one of polyester, nylon and aramid.

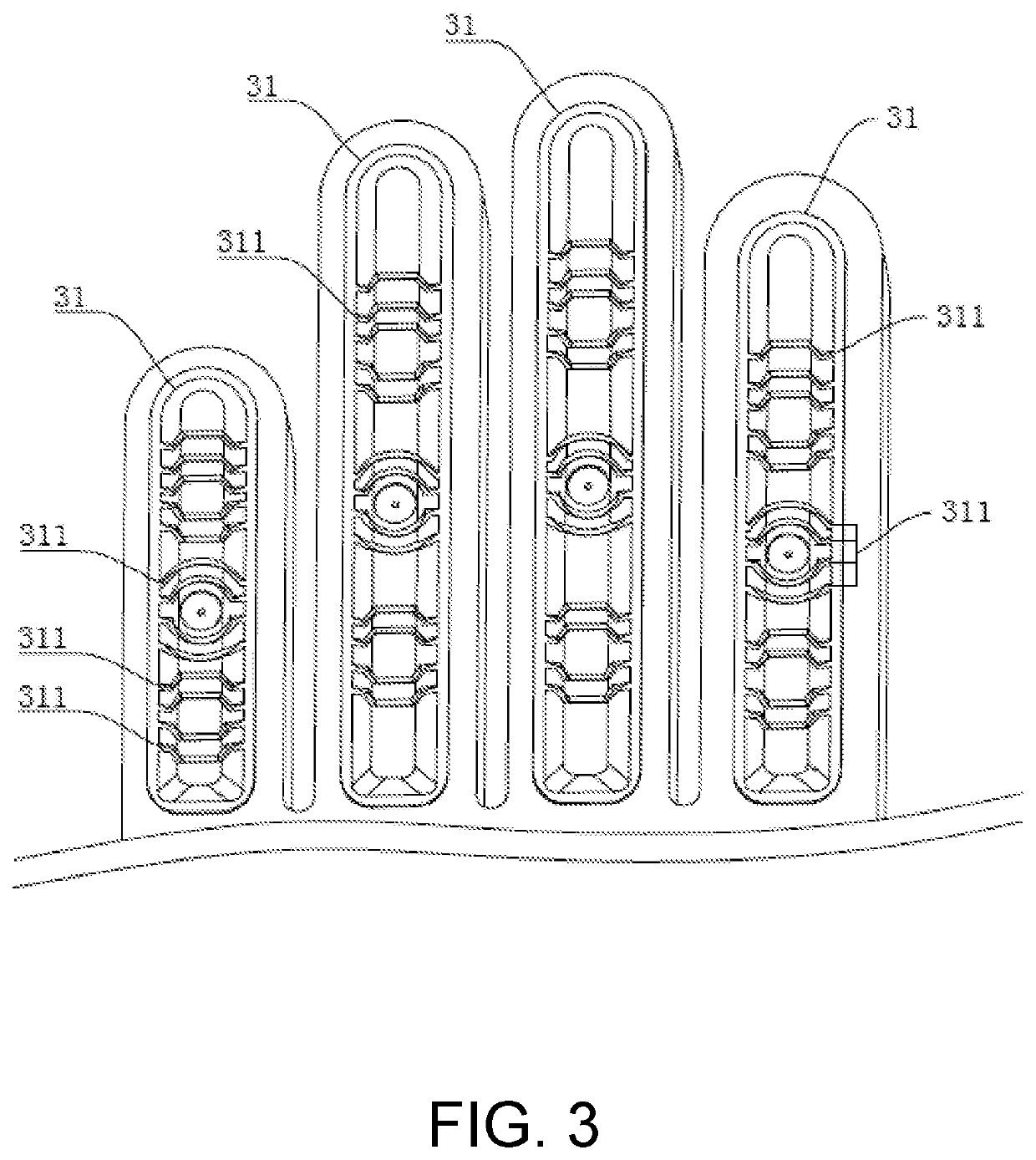

[0043]As shown in FIG. 1, FIG. 3 and FIG. 4, the back rubber protection layer 3 includes a finger rubber layer 31 disposed at a back of fingers of the glove, and a plurality of grooves 311 are disposed at a surface of the finger rubber layer 31 for increasing flexib...

embodiment 2

[0046]A production method of a labor protection glove includes the following steps.

[0047]Step 1, preparing the glove liner 2: weaving the skin contact layer 21 and the moisture absorption layer 22 to form the glove liner 2.

[0048]Step 2, sewing the wear-resistant layer 23: sewing the wear-resistant layer 23 on an outer surface of the glove liner 2.

[0049]Step 3, preparing the back rubber protection layer 3: wearing the glove liner 2 on a hand model, placing the hand model with the glove liner 2 into a rubber-injecting mould of an integrated injection molding machine, closing the rubber-injecting mould, injecting rubber into rubber-injecting holes located above the fingers of the glove while injecting molten rubber into rubber-injecting holes located at root knuckles, and cooling to integrally forming the root knuckle rubber layer 33 and the palm-back rubber layer 32, so as to provide the back rubber protection layer 3 via rubber injection, wherein a rubber-injecting temperature is in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com