Knitted gloves having a single layer with a plurality of yarns

A yarn and glove technology, applied in gloves, weft knitting, knitting, etc., can solve the problem of low air permeability of gloves and optimal air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

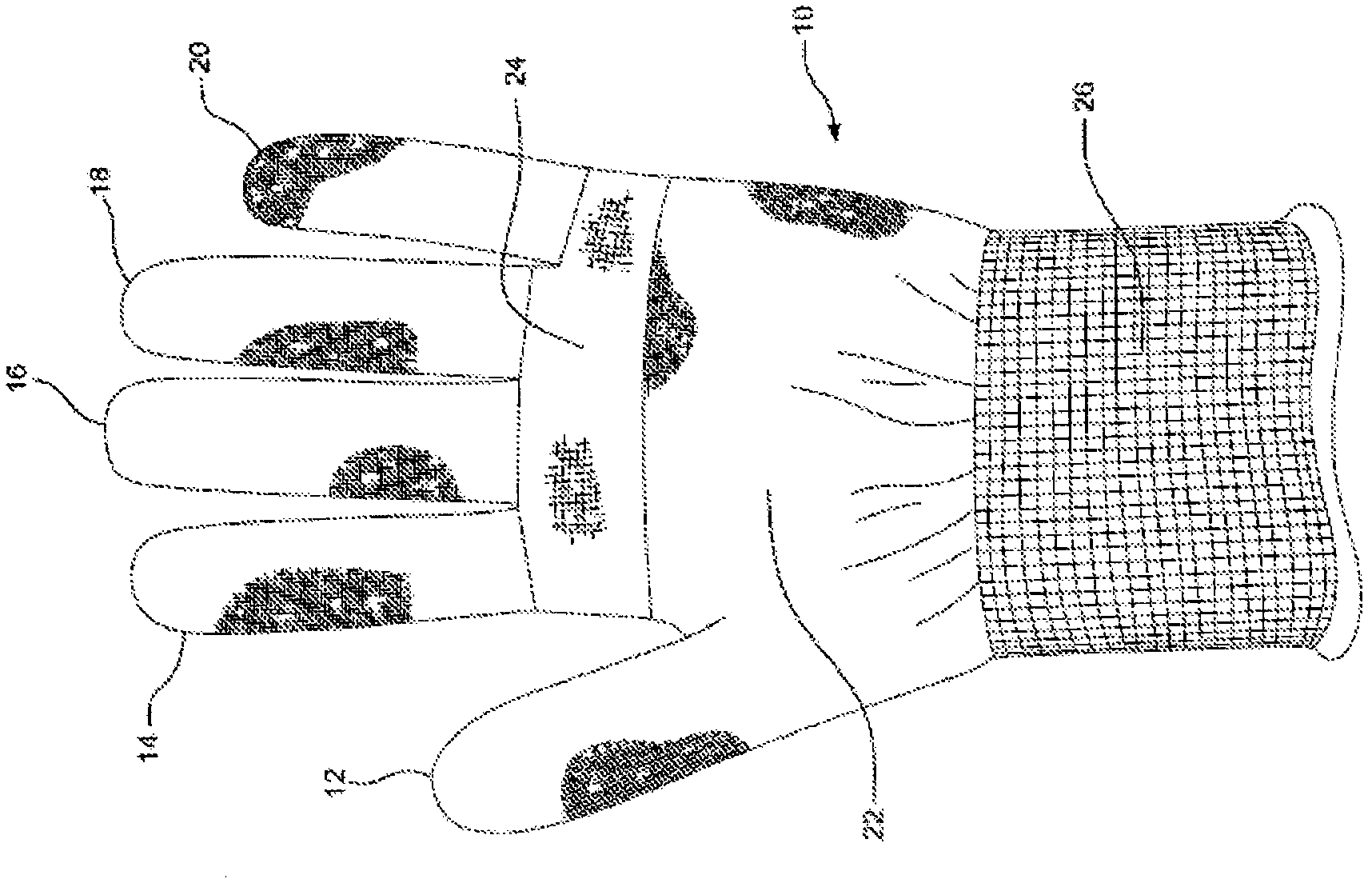

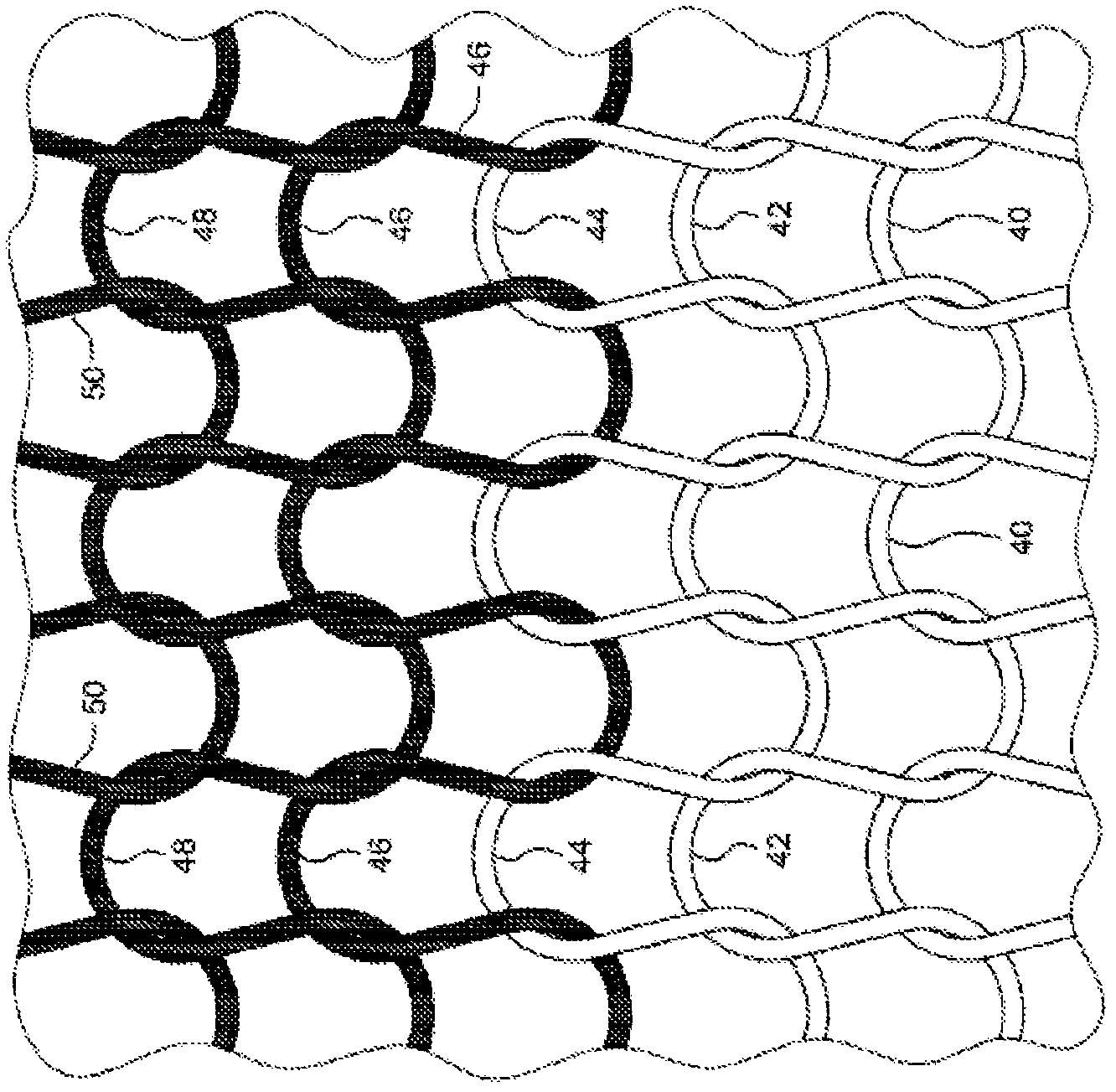

Embodiment 1

[0153] Preferred woodworking gloves are described below. 9 parts including parts 1, 2, 3, 4, 5., 5, 6, 7 and 8 are used with Figure 13 15-pin Dyneema in the first color in the style shown yarn and has Figure 13 15-pin Dyneema in the second color in the style shown The yarn is woven in a single layer. Then, the woven single-layer glove liner with two different types of yarns was placed on the former and immersed in a solution containing soft water, calcium nitrate and dipentyl sulfosuccinate sodium salt (surfactant AY 65%). coagulant. Then, after further processing, the glove liner is dipped into a coating of aqueous latex compound including Synthomer 6322 (an aqueous dispersion of butadiene acrylonitrile copolymer), Darvan WAQ 50% (sodium lauryl sulfate and water), MB-2ES, zinc oxide, Akrosperse E-98 blue pigment, Acrysol RM-5000 (solvent-free hydrophobically modified polyethylene oxide polyurethane) and MHPC-50 (Culminal methyl hydroxypropyl cellulose). Latex comp...

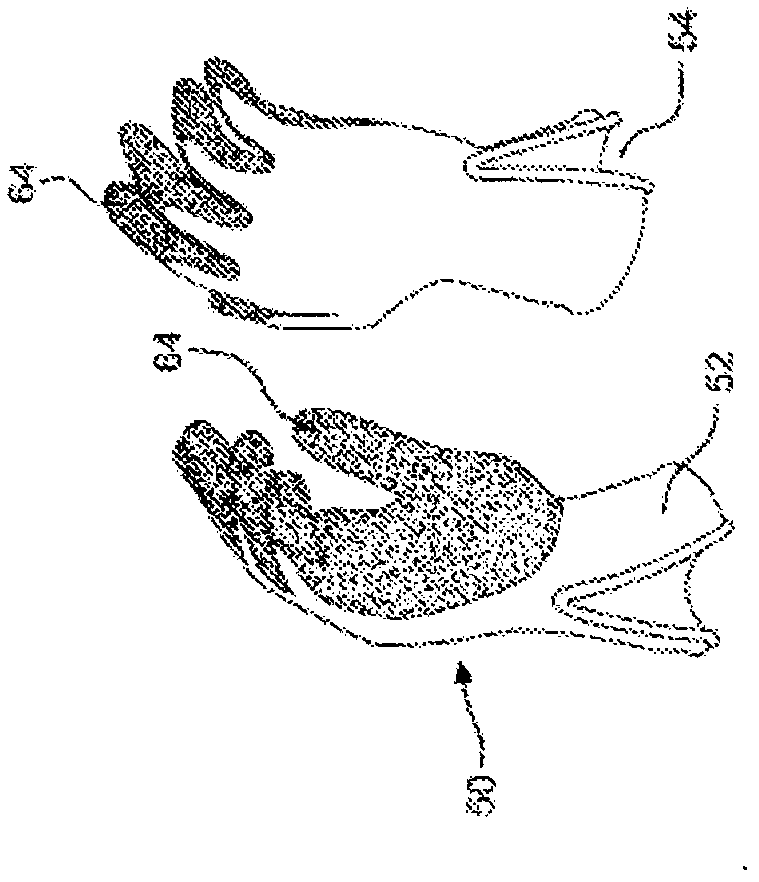

Embodiment 2

[0187] Preferred electrician's gloves are described below. 8 parts including parts 1, 2, 3, 4, 5., 5, 6 and 7 are used with Figure 22 15-pin Dyneema in the first color in the style shown yarn and has Figure 22 15-pin Dyneema in the second color in the style shown The yarn is woven in a single layer. Weave areas of reinforcement into parts 1, 2, 3, 4, and 6 using nylon braiding. Then, the woven glove liner with two different types of yarns was laid out on a former designed to be dipped in the palm and dipped in a mixture of soft water, calcium nitrate and dipentyl sulfosuccinate sodium salt (AY 65% surfactant) coagulant. Then, after further processing, the glove liner is dipped into a coating of aqueous latex compounds including Synthomer 6322 (aqueous dispersion of butadiene acrylonitrile copolymer), Darvan WAQ 50% (sodium lauryl sulfate and water), MB-2ES, zinc oxide, Akrosperse E-98 blue pigment, Acrysol RM-5000 (solvent-free hydrophobically modified polyethylene o...

Embodiment 3

[0189] Preferred electrician's gloves are described below. 9 parts including parts 1, 2, 3, 4, 5., 5, 6, 7 and 8 use a 15-pin Dyneema with the first color in the pattern shown in Figure 8 yarn and 15 stitches of Dyneema with the second color in the pattern shown in Figure 8 The yarn is woven in a single layer. Weave areas of reinforcement into parts 1, 2, 3, 4, 6, and 8 using nylon braiding. Then, a woven glove liner with two different types of yarns was placed on the former and immersed in a coagulant comprising soft water, calcium nitrate and dipentyl sulfosuccinate sodium salt (surfactant AY 65%). Then, after further processing, the glove liner is dipped into a coating of aqueous latex compounds including Synthomer 6322 (aqueous dispersion of butadiene acrylonitrile copolymer), Darvan WAQ 50% (sodium lauryl sulfate and water), MB-2ES, zinc oxide, Akrosperse E-98 blue pigment, Acrysol RM-5000 (solvent-free hydrophobically modified polyethylene oxide polyurethane), and M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com