Glove having injection molded components

a technology of injection molding and components, applied in the field of gloves, can solve the problems of lack etc., and achieve the effects of grip, flexibility, dexterity, and tactility characteristics of gloves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

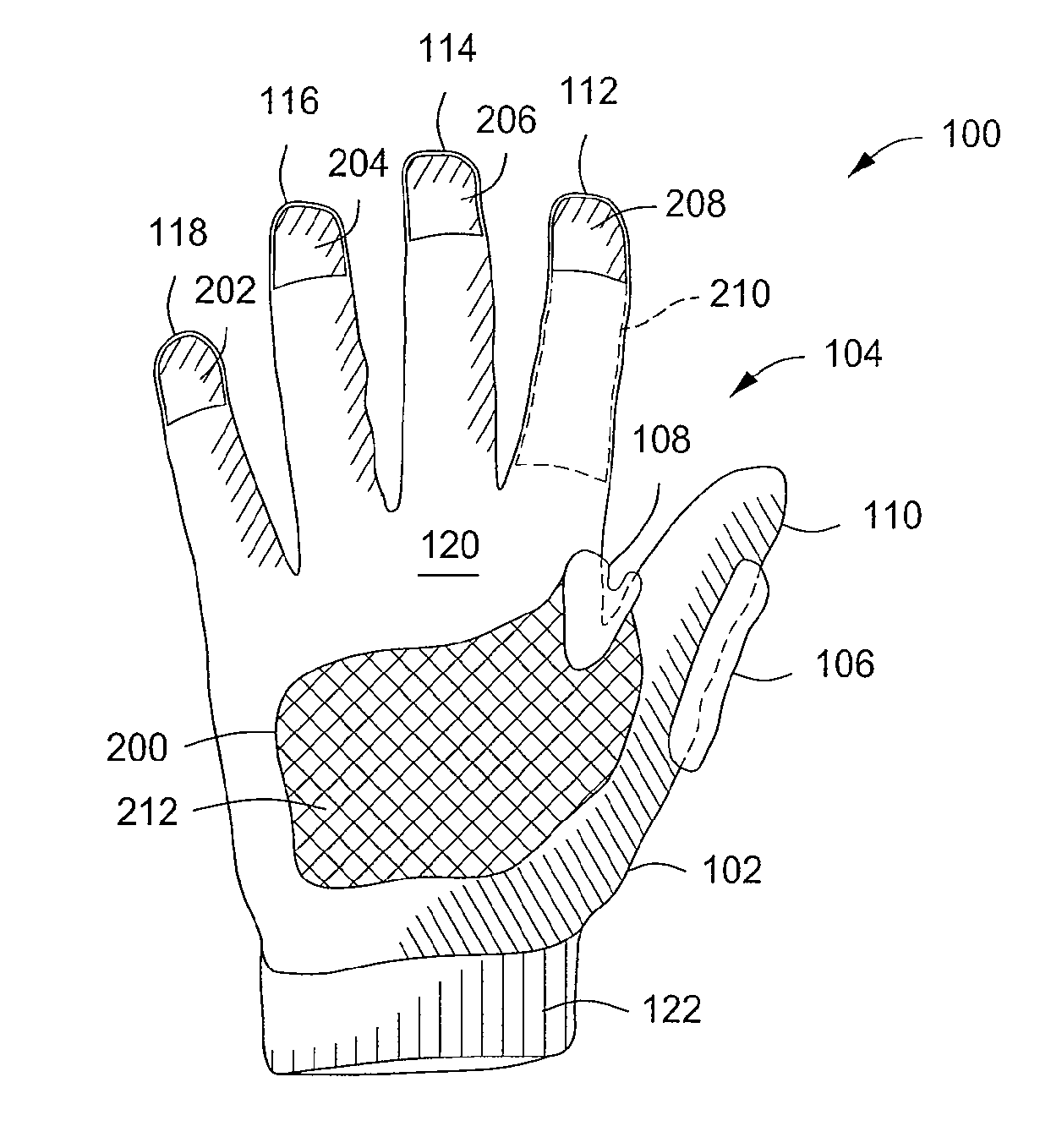

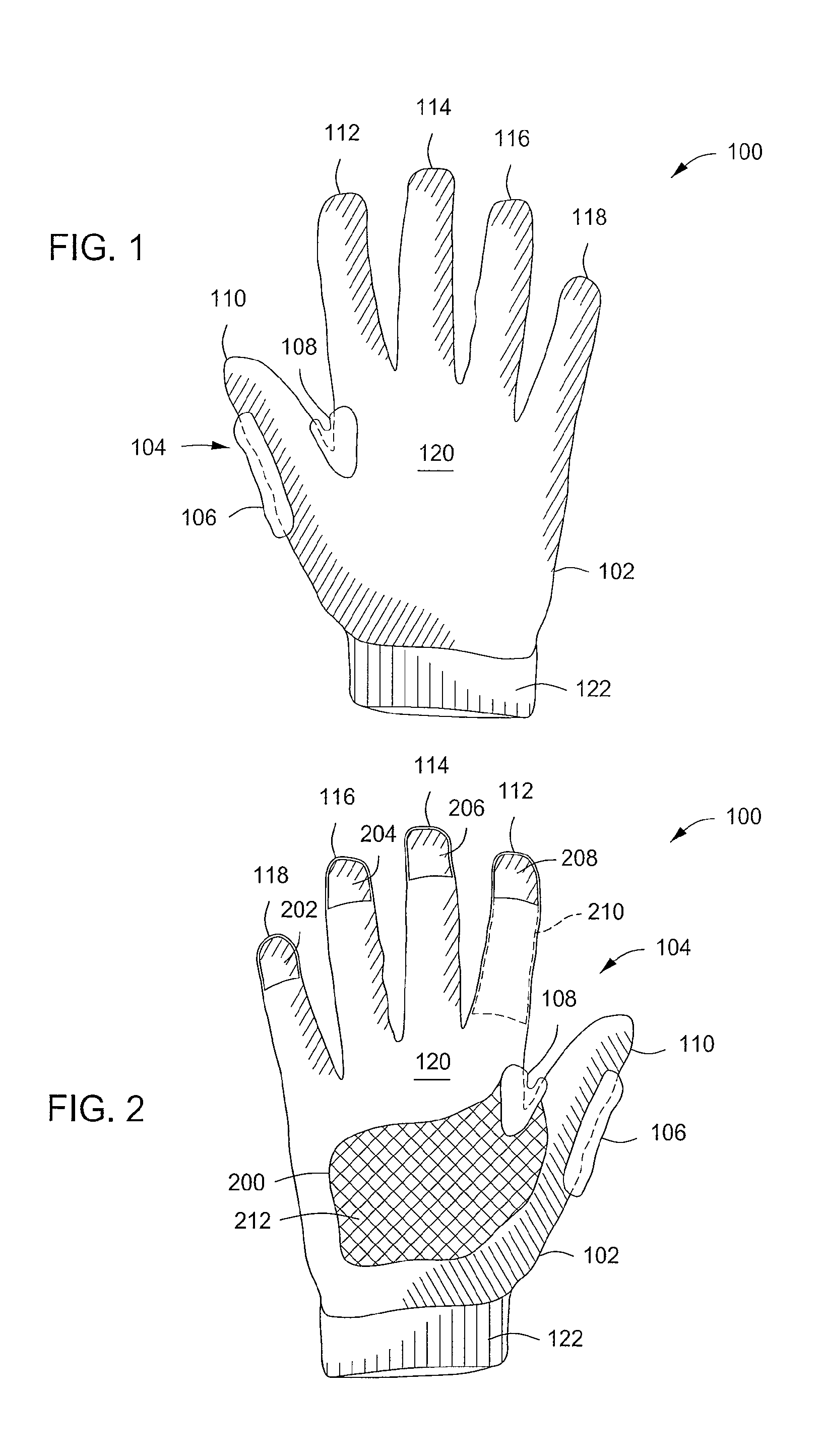

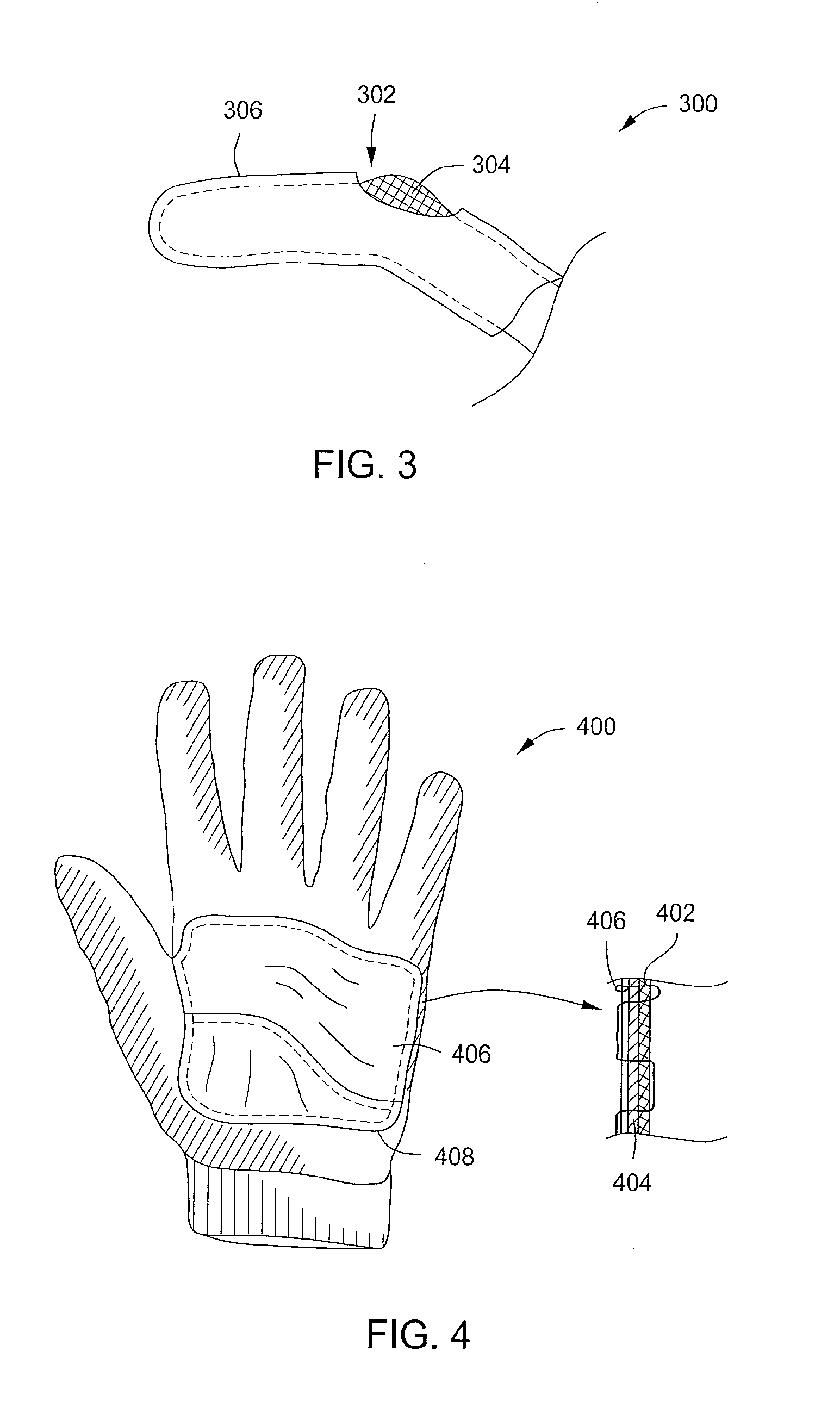

[0020]Embodiments of the present invention comprise a glove having a liner adorned with at least one injection molded component adhered thereto to form an application specific glove. The liner may be fabric and / or an elastomeric material (e.g., natural or synthetic rubber). The at least one injection molded component may be fabricated from an elastomeric material such as silicone, thermoplastic vulcanizate, thermoplastic rubber, thermoplastic elastomer, and the like, or blends or alloys thereof. In some embodiments, the injection molded components comprise thermoplastic polyolefins, such as polyethylene, polypropylene, and the like. In some embodiments, the injection molded components comprise engineered resins, such as nylons, acrylonitrile-butadiene-styrene, saturated styrene block copolymer thermoplastic elastomers (SEBS), polyurethanes, thermoplastic polyurethane alloys, modified-styrenics, styrene-butadiene-styrene, and polybutylene terephthalate resins, and blends and / or alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Composition | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com