Robot system oriented to various operations of high-voltage line and operation method

A robot system and robot technology, applied in the field of robot systems, can solve problems such as unfavorable work efficiency and utilization rate of robot systems, high safety, hidden dangers, etc., and achieve the effects of simple structure, improved utilization rate, and widespread promotion significance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

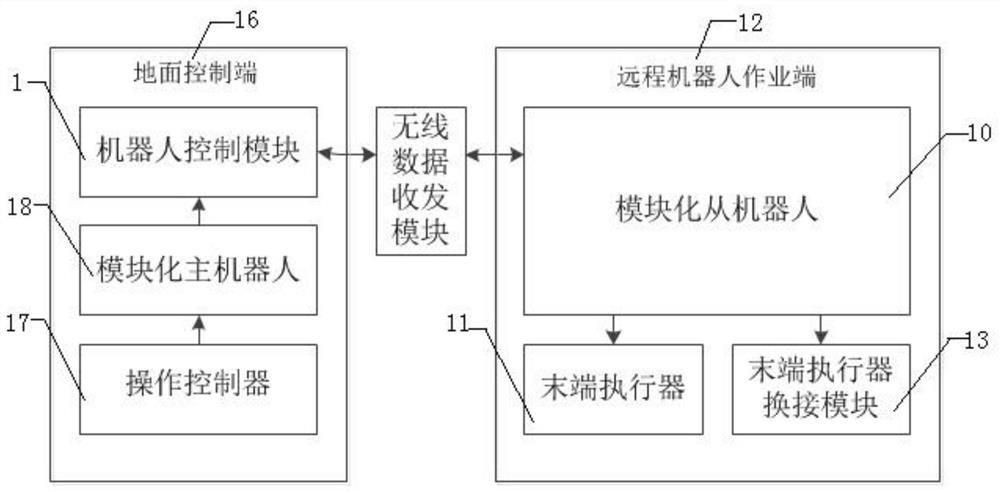

[0047] A robot system for various operations on high-voltage lines, such as figure 1 As shown, it includes: ground control terminal 16, remote robot operation terminal 12 and its power supply;

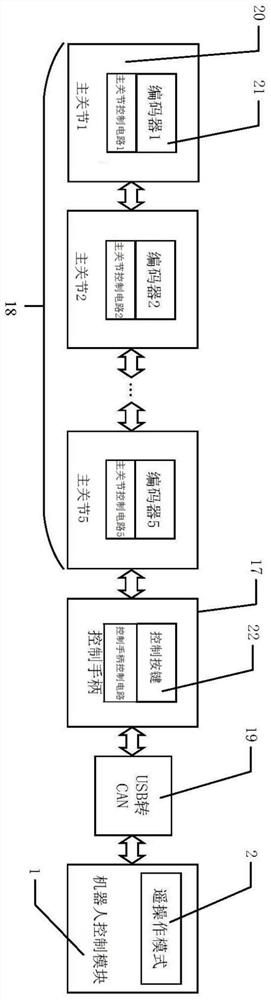

[0048] Wherein the ground control terminal 16 is an end for the operator to operate and control on the ground, which includes an operation controller 17, a modular main robot 18, and a robot control module 1 connected in two directions in sequence;

[0049] Wherein the remote robot working end 12 is one end of the robot system working at high altitude, which includes a modular slave robot 10 with the same structure as the modular master robot 18, an end effector 11 connected to the modular slave robot 10, an end effector switch Connect module 13;

[0050] The robot control module 1 of the ground control terminal 16 communicates with the modular slave robot 10 of the remote robot operation terminal 12 through a wireless data transceiver module.

[0051] The working process of the robo...

Embodiment 2

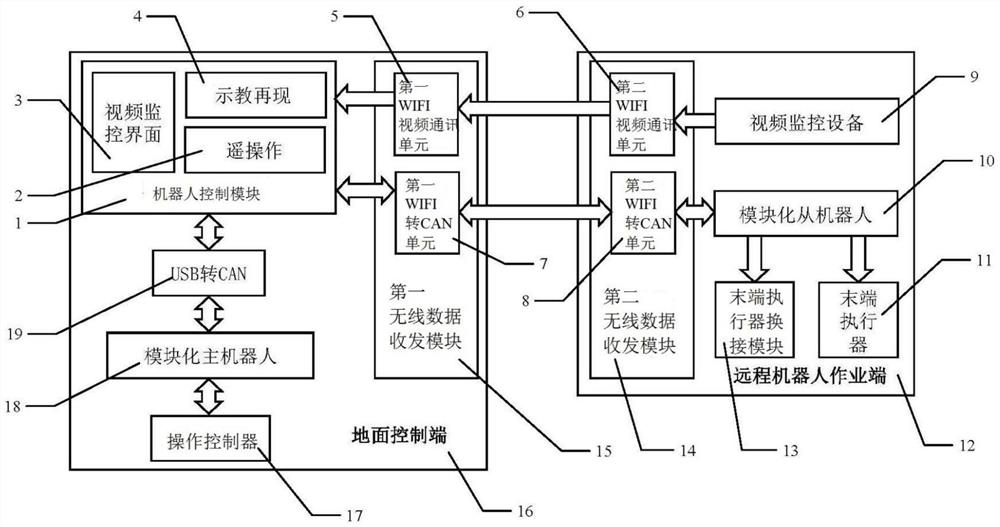

[0055] A robot system for various operations on high-voltage lines, such as figure 2 As shown, it includes: a ground control terminal 16, a remote robot operation terminal 12 and its power supply, a first wireless data transceiver module 15, and a second wireless data transceiver module 14;

[0056] The ground control terminal 16 and the remote robot operation terminal 12 adopt wireless communication technology for signal transmission; wherein, the control signal is two-way transmission, that is, the ground control terminal 16 controls the remote robot operation terminal 12 to perform tasks, and the remote robot operation terminal 12 feeds back to each part of the robot. The joint connection state information and the motion parameters of the joints are sent to the ground control terminal 16; the video signal adopts one-way transmission, and is transmitted back to the ground control terminal 16 by the remote robot control terminal.

[0057] 1. The first wireless data transceiv...

Embodiment 3

[0097] This embodiment provides an operation method for a robot system for multiple operations on high-voltage lines, including the following steps:

[0098] S1. Start the robot system for multiple operations on high-voltage lines;

[0099] S2. The video monitoring equipment monitors the position and posture of the modular slave robot and the end effector in the remote robot operation end in real time, and the video monitoring is performed by the second WIFI video communication unit and the first WIFI video communication unit The monitoring video of the equipment is sent back to the robot control module at the ground control end;

[0100] S3. In the case where the robot control module selects the teaching reproduction function, the robot control module transmits the joint teaching signal to the module of the remote robot working end through the first WIFI to CAN unit and the second WIFI to CAN unit from the robot;

[0101] When the robot control module selects the teleoperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com