Rope-driven joint module

A joint module and drive module technology, which is applied in the directions of manipulators, joints, program-controlled manipulators, etc., can solve the problems of failure to achieve modularization, uncompact structure, and insufficient use of rope drive, and achieve a simple and compact overall structure. Achieving dexterous, lightweight effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

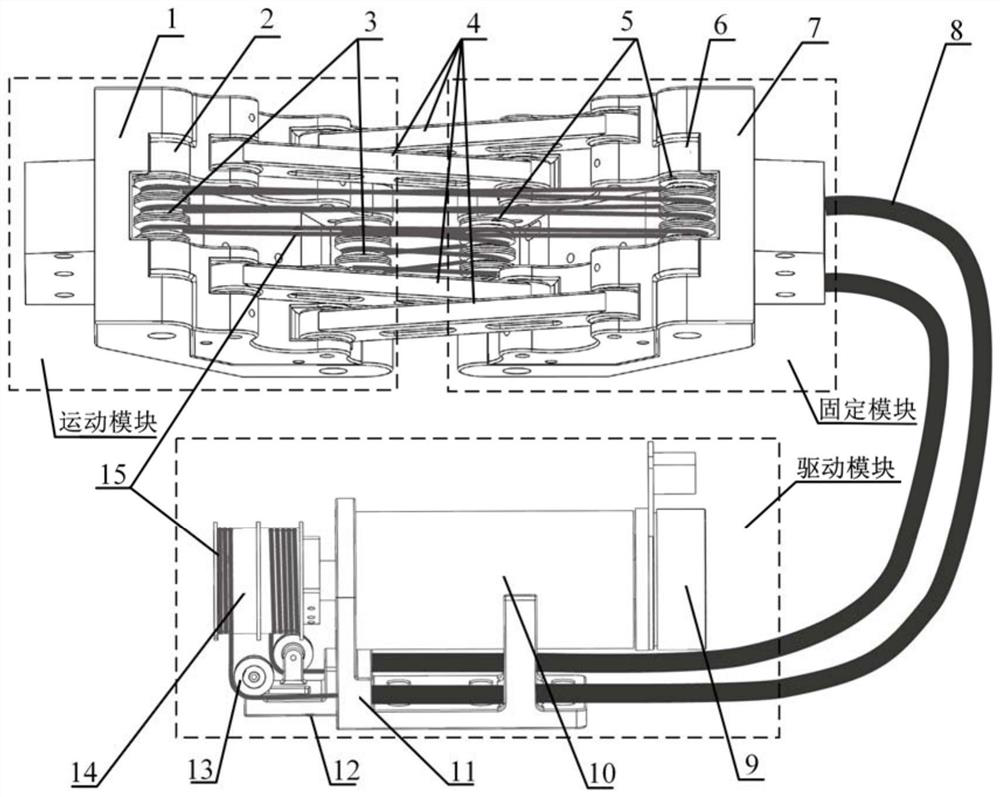

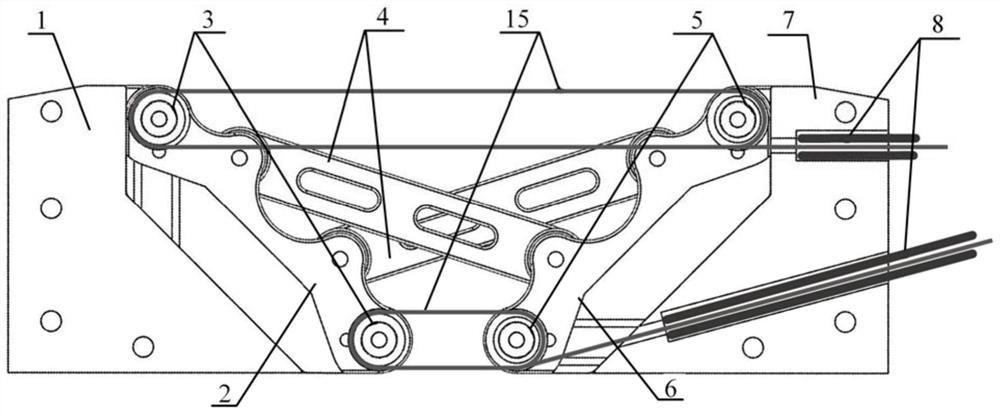

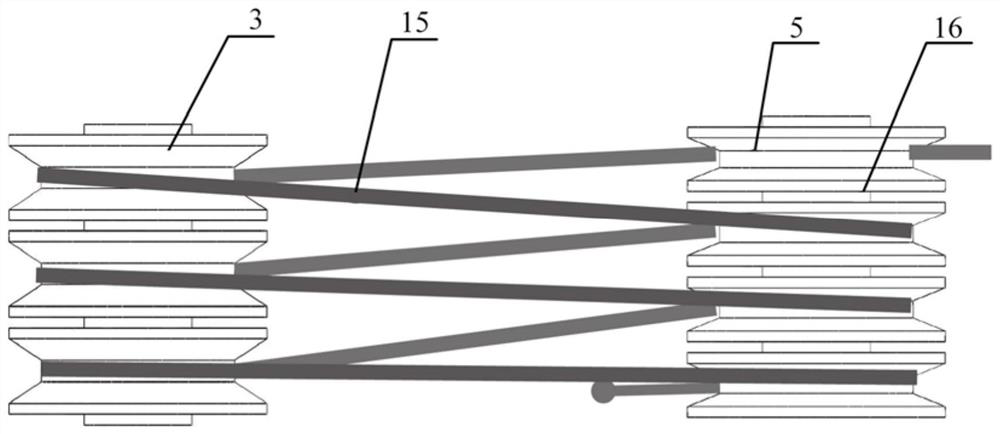

[0035] like Figure 1-3As shown, a kind of rope-driven joint module includes a motion module, a fixed module, a drive module, a connecting rod 4 and a rope 15; the motion module includes a motion base 2 and a movable pulley block movably connected thereto; the fixed module includes a fixed base 6 and The fixed pulley block that is movably connected with it; the two ends of the connecting rod 4 are respectively connected to the motion base 2 and the fixed base 6 in rotation, the movable pulley block is arranged on the motion base 2, and the fixed pulley block is arranged on the fixed base 6; the motion module and The fixed module is connected with the driving module through a rope 15 .

[0036] In the present invention, the fixed module and the moving module are connected through the connecting rod 4, the connecting rod 4 can swing around the fixed module and the moving module at the same time, the fixed module and the moving module can rotate around the connecting rod 4, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com