Air-cooled cylindrical power battery pack containing bionic surface microstructure heat dissipation piece

A power battery pack and power battery technology, which is applied to secondary batteries, circuits, electrical components, etc., can solve the problems of low cooling efficiency of the air-cooled system, restricting development and application, and poor heat transfer performance, so as to reduce the temperature rise of the battery, Enhance thermal stability and save energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

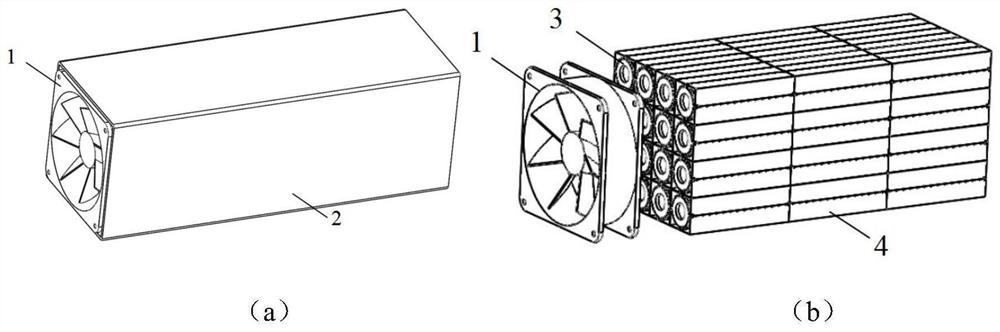

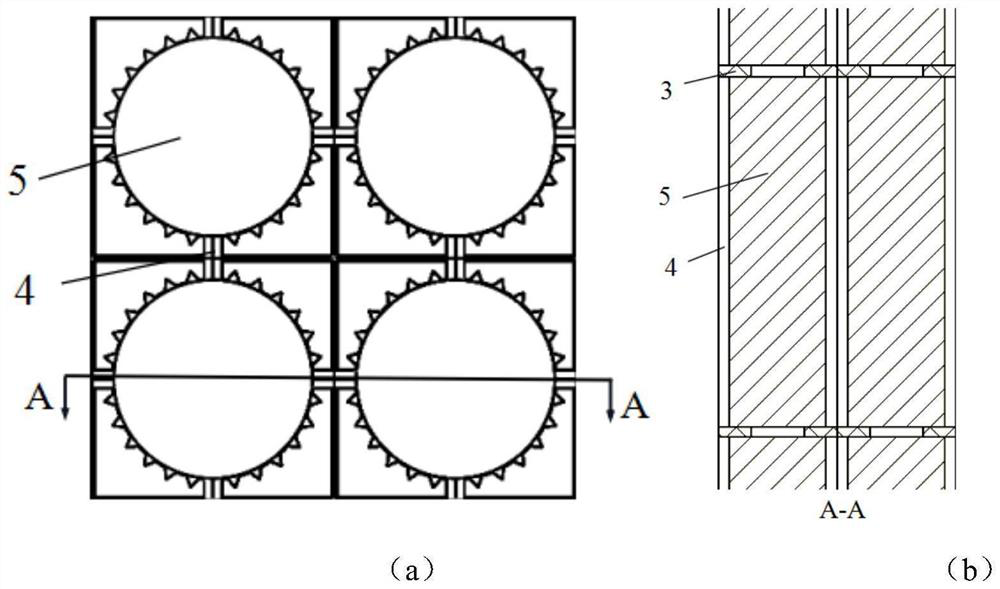

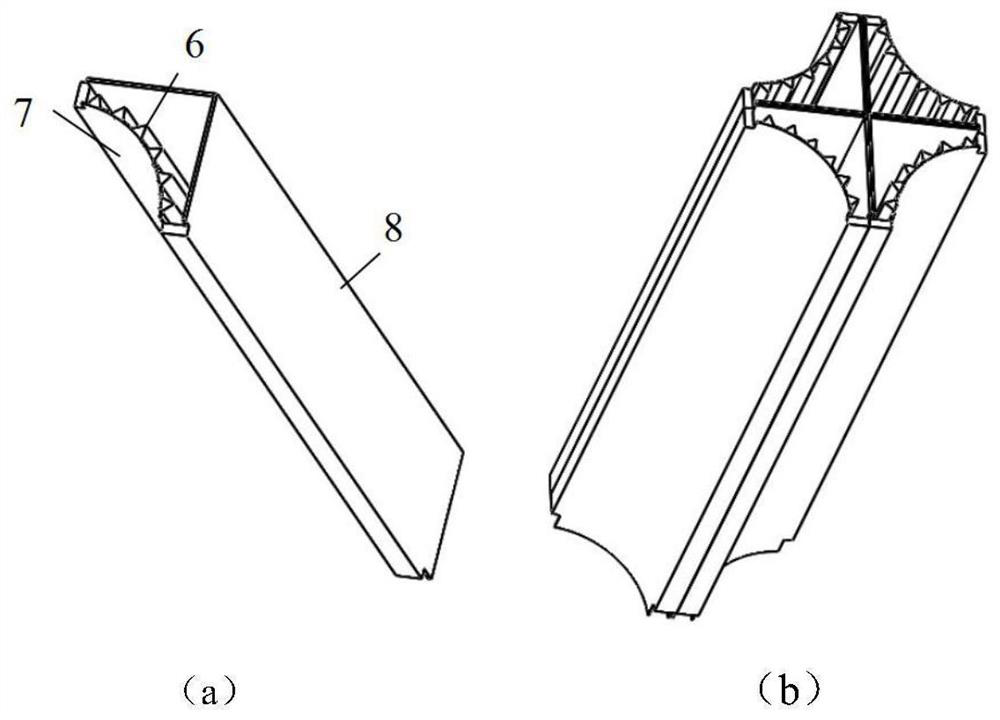

[0027] An air-cooled cylindrical power battery pack containing a bionic surface microstructure heat sink, including a fan 1, a casing 2, an insulating fixing frame 3, a bionic surface microstructure heat sink 4, and a cylindrical power battery 5. The outside air is driven by the fan 1, enters the battery module, passes through the multi-layer cylindrical power battery 5, and flows out from the other end of the battery pack. The bionic surface microstructure heat sink 4 has an arc surface 7 and a right-angle surface 8, the diameter of the arc surface 7 is the same as that of the cylindrical power battery 5, the outer side of the arc surface 7 is in contact with the surface of the cylindrical power battery 5, and the gap is eliminated with heat-conducting glue in the middle Air, increasing thermal conductivity. The four bionic surface microstructure heat sinks 4 are in contact with each other through the right-angled surface 8, and after being combined, they are embedded in the ...

Embodiment 2

[0031] The present invention is effective for heat dissipation of cylindrical power battery packs, and the 18650 type cylindrical battery 5 in the present invention can also be 26650, 26650, 32650 and other cylindrical batteries. At the same time, the present invention is also applicable when the distribution distance and arrangement of the batteries are changed.

Embodiment 3

[0033] The cross-section of the biomimetic surface microstructure 6 can be rectangular, triangular, trapezoidal or oval, the height of the biomimetic surface microstructure 6 is 0.4-1.4 mm, and the interval s of the biomimetic surface microstructure 6 is twice the height h. The three-layer bionic surface microstructure heat sink is assembled in the axial direction. After being installed in the battery pack, the overall axial length L is 41-201mm. According to the use of the battery module, when the inlet wind speed is 0.8m / s, the cross-sectional shape, height and overall length of the biomimetic surface microstructure 6 can be changed accordingly.

[0034] When the cross-sectional shape and overall length of the biomimetic surface microstructure 6 are triangular and 201 mm, respectively, the maximum temperature and maximum temperature difference of the battery module gradually decrease with the increase of the height of the microstructure. When the microstructure height increa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com