Patents

Literature

67results about How to "Flexible size change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

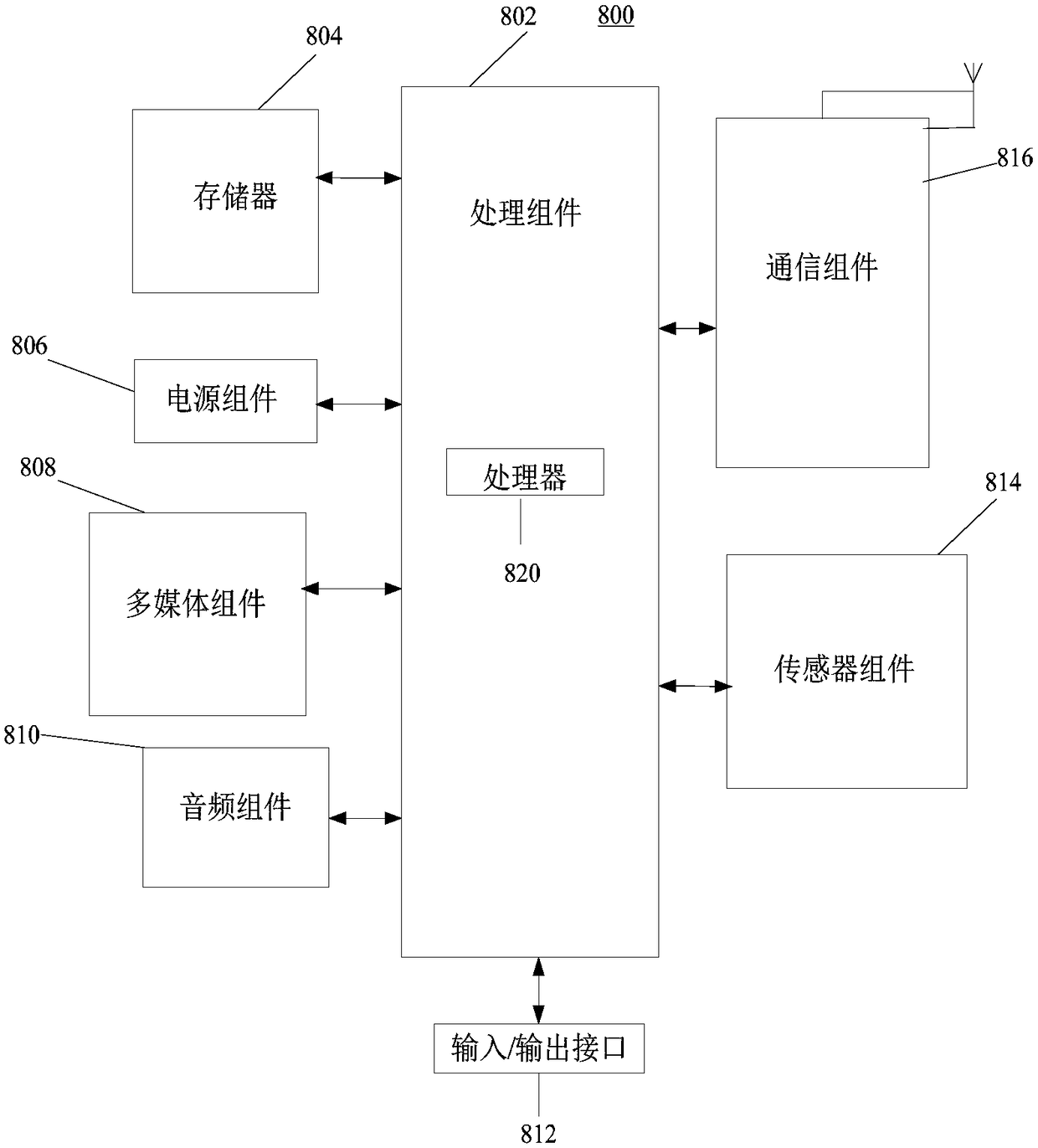

Electronic equipment and flexible connecting mechanism

ActiveCN106884867AReduced support areaIncrease the support areaDigital data processing detailsCasings/cabinets/drawers detailsEngineeringElectric equipment

The invention discloses a flexible connecting mechanism which comprises a fixed supporting piece, mobile supporting pieces slidably or rotatably connected with the fixed supporting piece and a flexible piece. The flexible piece can be bent and can cover on the fixed supporting piece and the mobile supporting pieces, and at least one end of the flexible piece is slidably connected with the fixed supporting piece or the mobile supporting pieces. According to the flexible connecting mechanism, the area of supporting to the flexible piece can be changed through relative sliding or rotating of the fixed supporting piece and the mobile supporting pieces, and when the flexible piece is a flexible screen or is used for arranging a part of the flexible screen, the display area can be changed by changing the supporting area so that the size of the screen of electronic equipment can be flexibly changed according to different use needs, and the diversified use needs of a user are met. The invention further provides the electronic equipment provided with the flexible connecting mechanism.

Owner:LENOVO (BEIJING) CO LTD

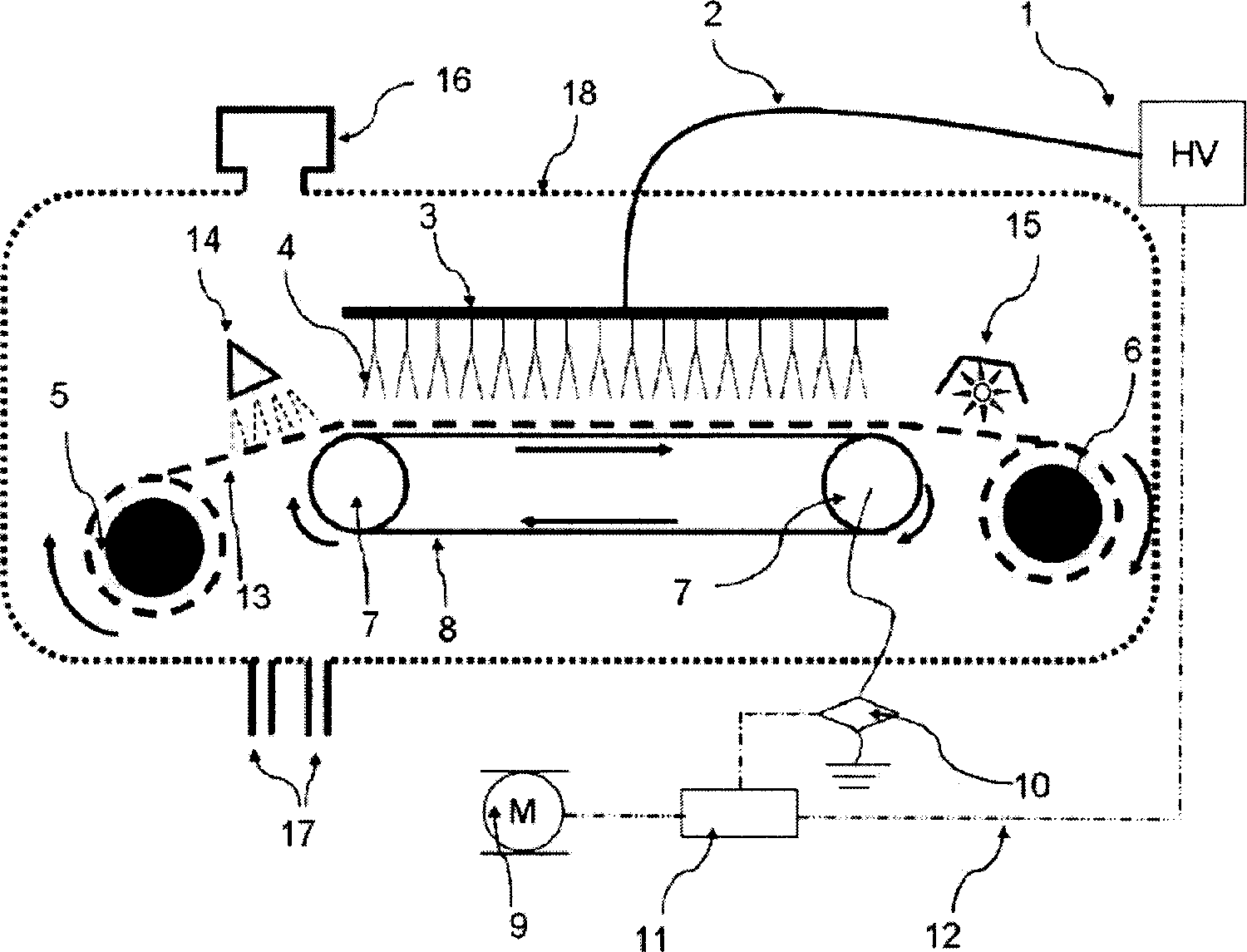

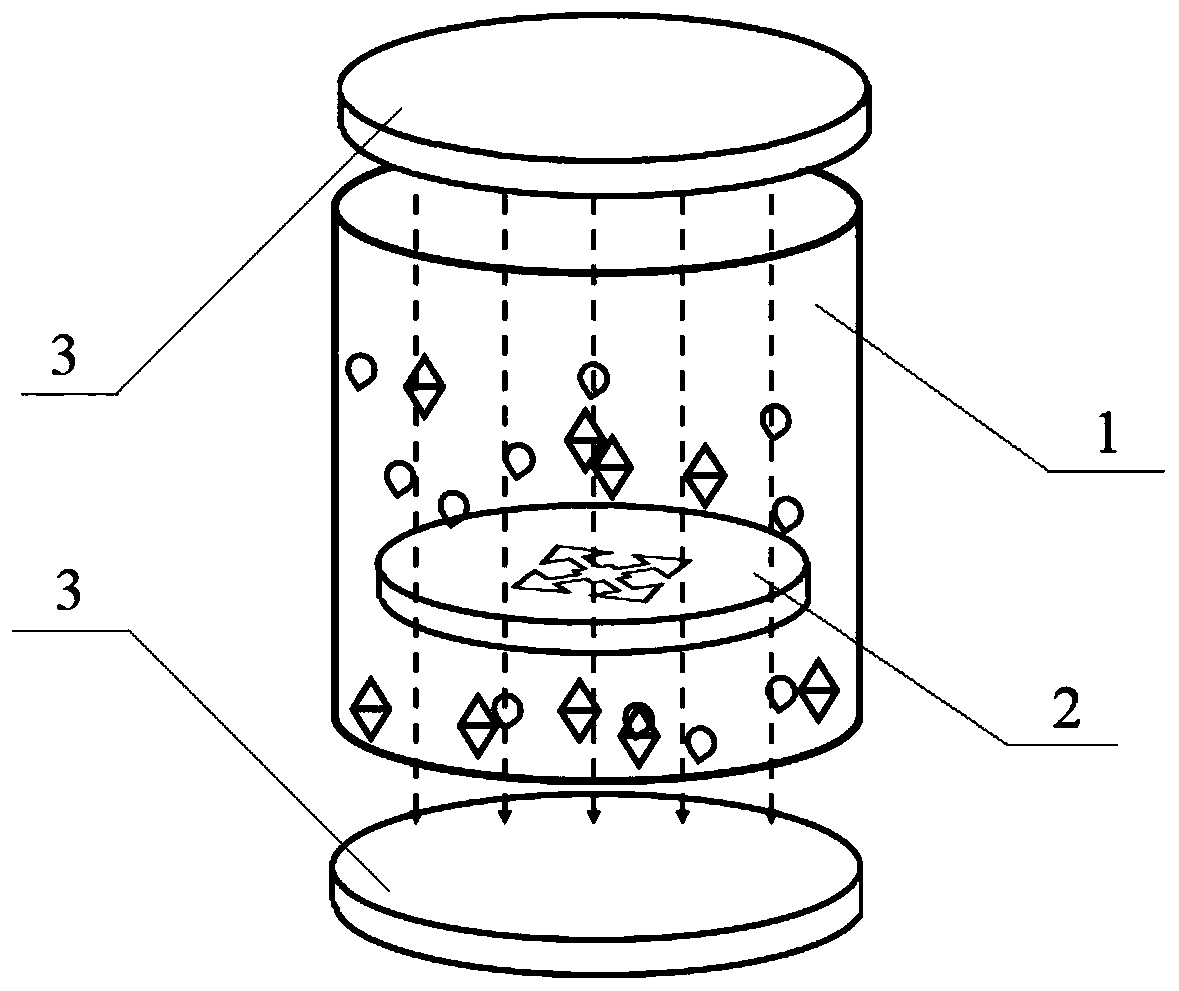

Modifying treating device for corona discharge low temperature plasma fabric surface

InactiveCN1900408ASimple structureUniform and strong dischargeUltrasonic/sonic fibre treatmentAutomatic controlControl system

The present invention relates to low temperature plasma fabric modifying processing unit, in particular relating to corona discharge low temperature plasma fabric modifying processing unit. It features utilizing ultrathin flake electrode array trigering strong corona discharge to generate activity plasma zone, through regulating discharge gas component to generate plasma zone having different modifying effect, to make fabric continuously to obtain processing through said activity plasma zone. Said device mainly consists of material feed system, electrode system, humidity regulating device, infra-red drying device, leak-tight system, power supply and automatic control system.

Owner:DALIAN UNIV OF TECH

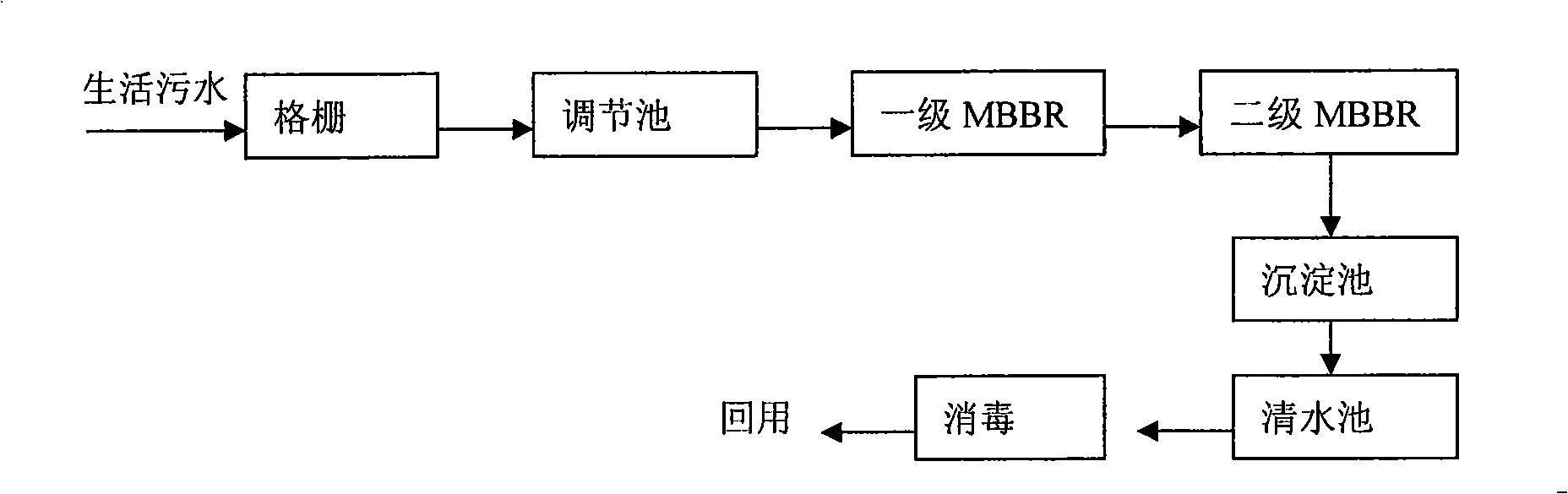

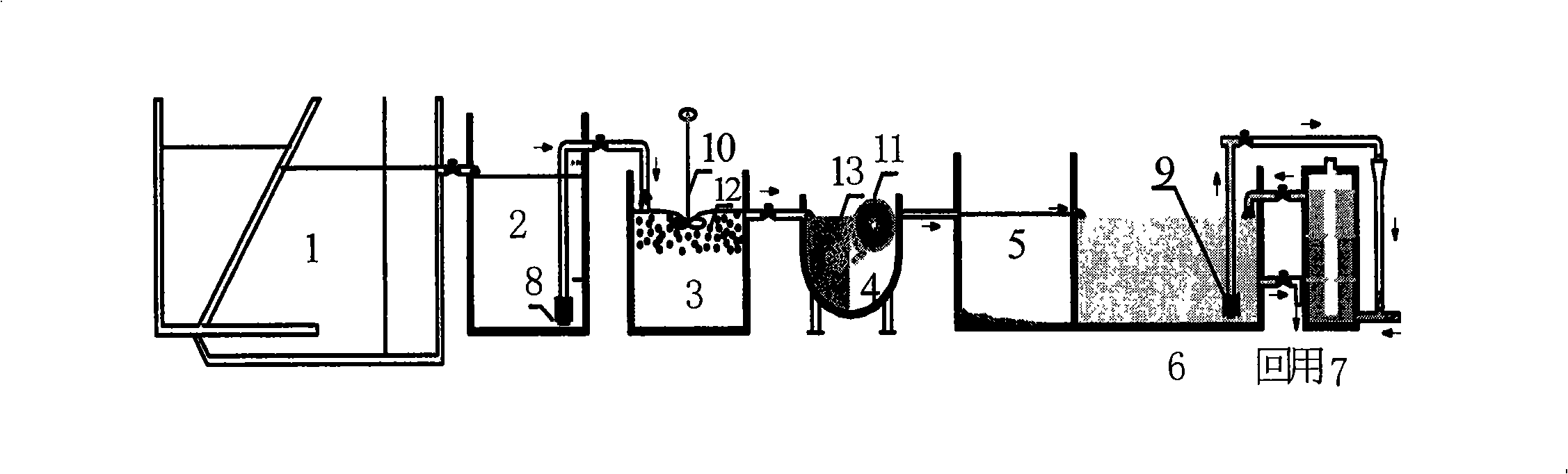

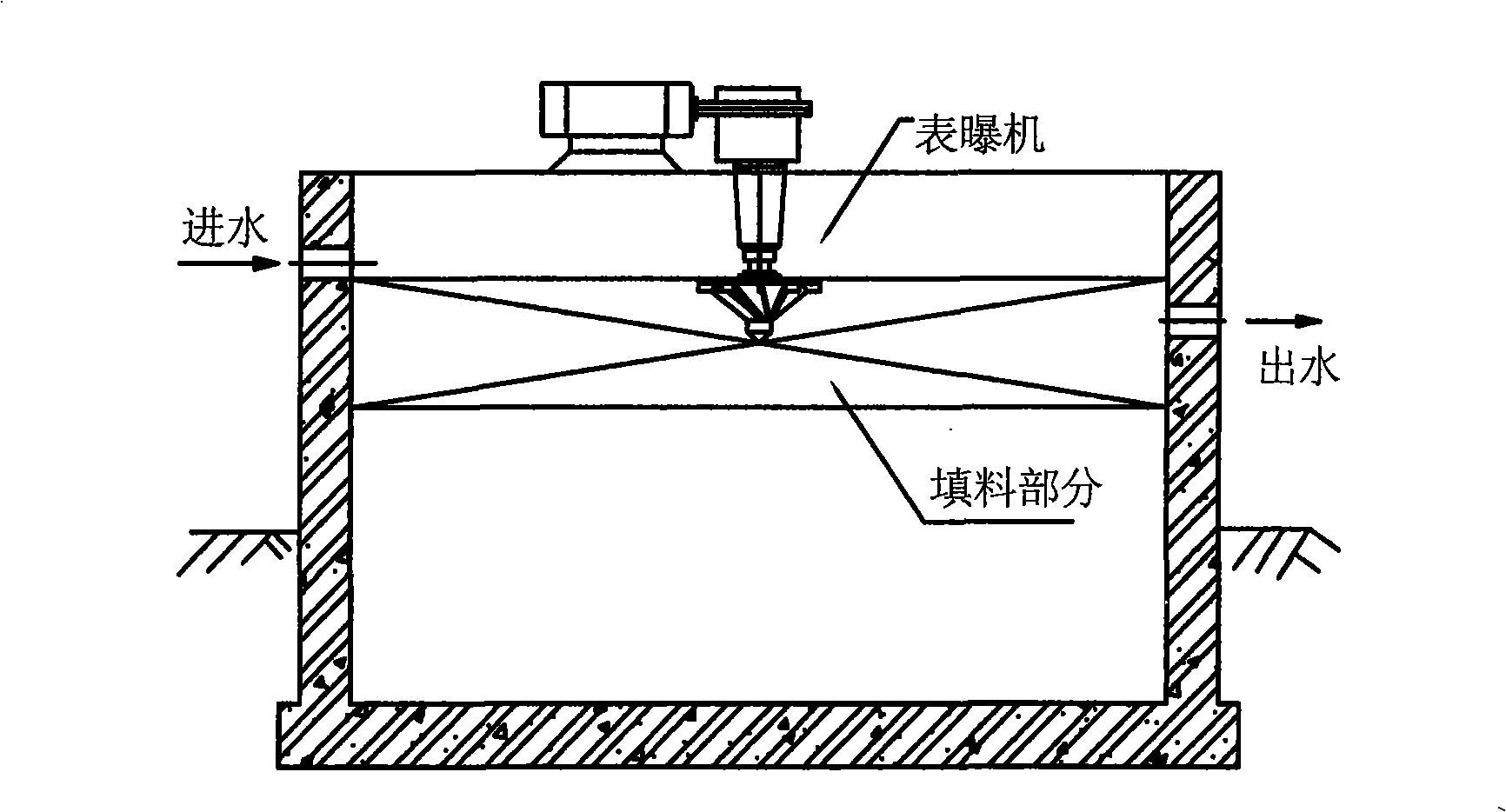

Water treatment system in two-stage moving bed biomembrane reactor

InactiveCN101402487AEasy to handleStrong resistance to shock loadsSustainable biological treatmentBiological water/sewage treatmentAutomatic controlSludge

The invention belongs to the field of water treatment, and relates to a two-stage moving bed biomembrane reactor medium water treatment system. The two-stage moving bed biomembrane reactor medium water treatment system is characterized in that the whole process adopts a programmable PLC automatic control system; the main treatment structure is two-stage cascade connected moving bed biomembrane reactors; and the concrete process flow is as follows: domestic sewage or sewage with similar water quality enters a regulating pond through grates and then enters a first-stage MBBR reactor and a second-stage MBBR reactor in turn by pump lifting; and then the water is outputted into a depositing pond, enters a clear water pond and is reused for flushing toilet or as landscape water after cyclic ultraviolet sterilization. The two-stage moving bed biomembrane reactor medium water treatment system has the advantages that: 1 the system has good medium water treatment effects, stronger resistance to shock load and stable outputted water quality; 2 the system has simple and convenient operating management, a small floor area, convenient maintenance and little excessive sludge; and the system adopts the PLC automatic control system with high automatic degree; 3 the system adopts a mechanical aeration mode, thereby bringing about low energy consumption and good oxygenation performance without an independent blower; 4 the system adopts a cyclic ultraviolet sterilization mode without any medicament added during the whole process, thereby avoiding the secondary pollution; and 5 the system has a wide application range.

Owner:UNIV OF SCI & TECH BEIJING

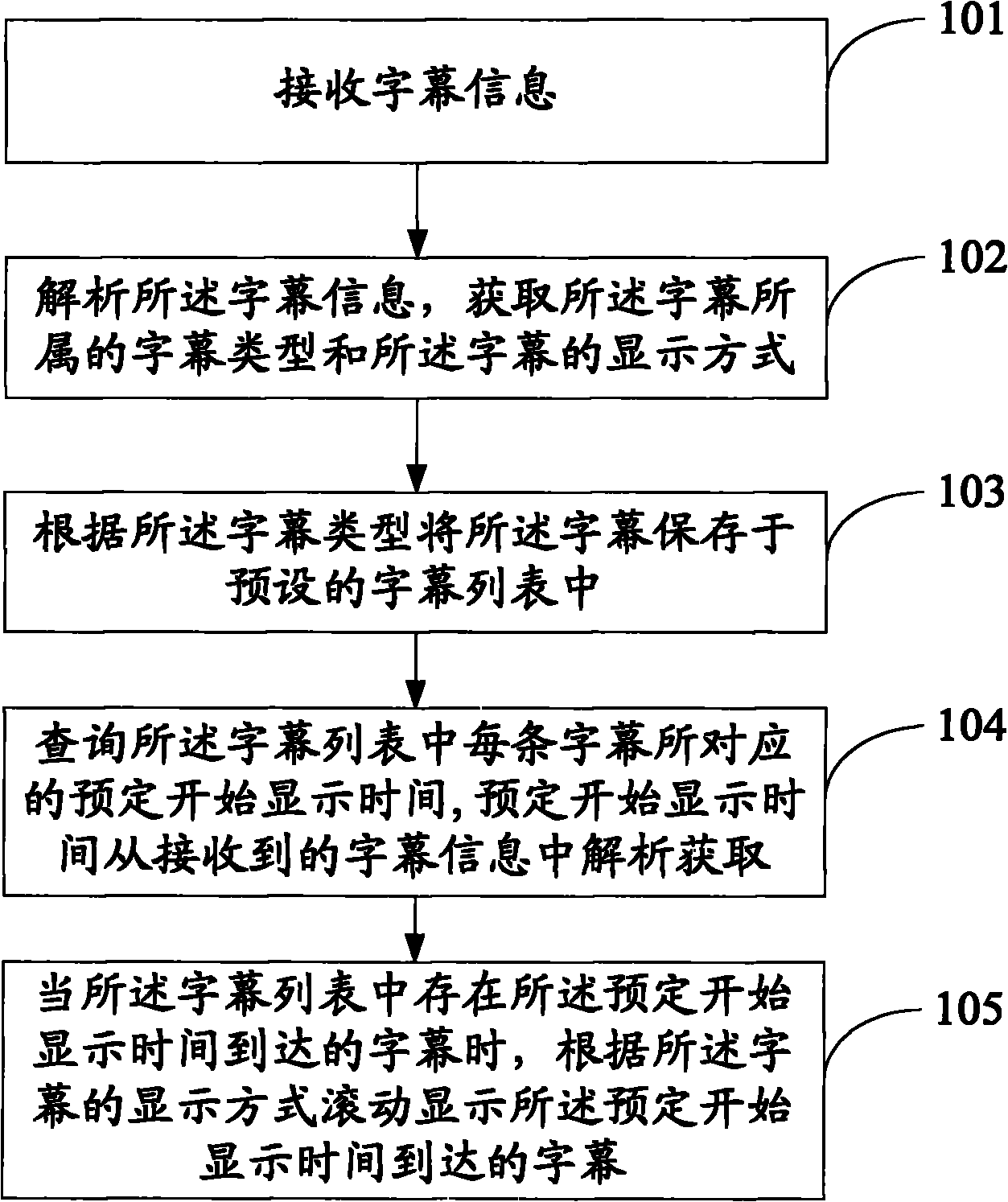

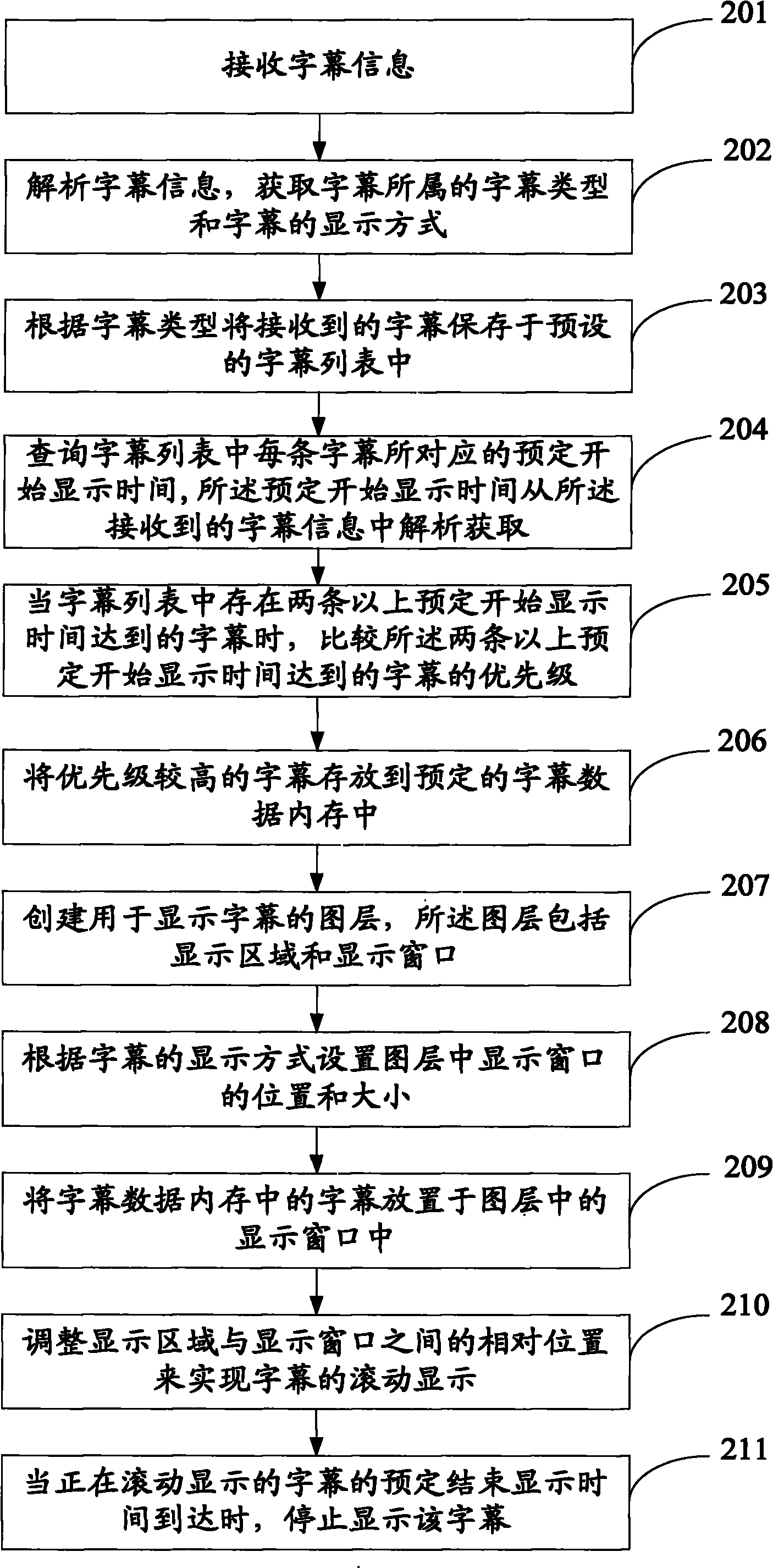

Method and device for displaying rolling subtitles

InactiveCN102158666AIncrease flexibilityAchieve diversificationTelevision system detailsColor television detailsStart timeDual mode

The embodiment of the invention discloses a method and device for displaying rolling subtitles, relating to the technical field of mobile multimedia and solving the problem of affecting user experience because the traditional rolling subtitle display mode based on a digital TV set box is single and has poorer display flexibility. The technical scheme provided by the invention comprises the following steps of: receiving subtitle information; analyzing the subtitle information to obtain a subtitle type and a display mode of the subtitles; according to the subtitle type, storing the subtitles into a preset subtitle list; inquiring preset display starting time corresponding to each subtitle in the subtitle list; and when the subtitle list has the subtitles reaching the preset display starting time, displaying the subtitle reaching the preset display starting time in a rolling mode according to the subtitle displaying mode. The technical scheme provided by the invention can be applied to the rolling subtitle displaying technology of the digital TV set box, an IPTV (Internet Protocol Television) set box and a dual-mode sex box.

Owner:QINGDAO HISENSE MEDIA NETWORKS CO LTD

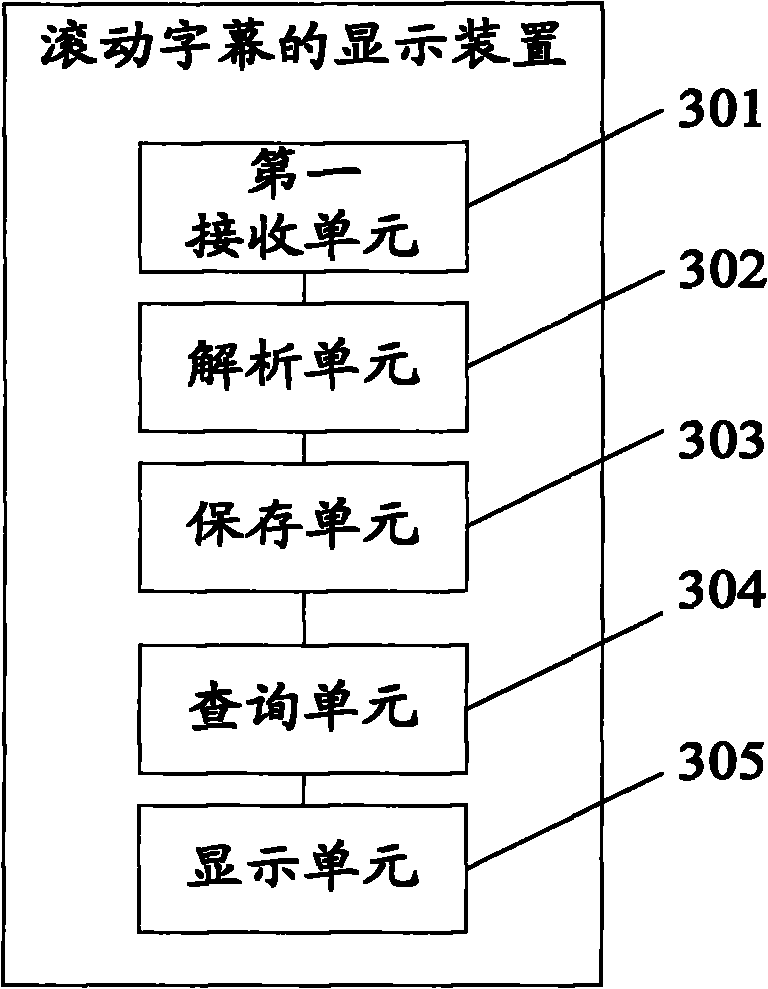

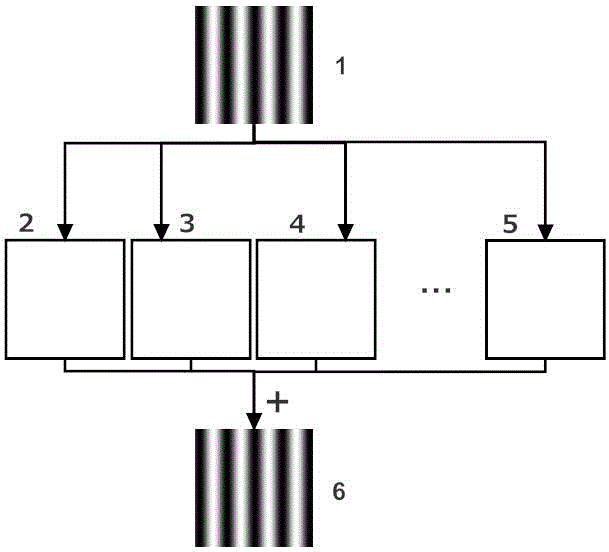

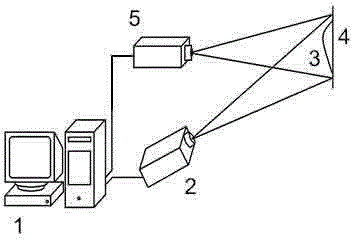

Method for generating light field with sine structure by means of space-time binary encoding

ActiveCN104567730AImprove sinusoidalityHigh-speed and high-precision 3D surface shape measurementUsing optical meansNon linear responseGray level

The invention belongs to the three-dimensional sensing technology and discloses a method for generating a light field with a sine structure by means of space-time binary encoding. According to the method, a standard sine fringe pattern 1 generated by a computer is equally divided into 2<n> (n>=2) sections according to gray-level distribution, then time and space encoding is conducted on each section by means of two-dimensional error diffusion to obtain 2<n> (n>=2) binary fringe patterns (2, 3, 4, ..., 5), and then linear superposition is conducted on the binary fringe patterns after the binary fringe patterns are projected and acquired through an imaging system, so that a high-quality sine fringe 6 is obtained. The projected binary fringe patterns are not affected by the non-linear response of a digital projector, the high-speed binary pattern switching function of the digital projector is fully utilized, and the speed and precision of three-dimensional surface measurement are improved.

Owner:SICHUAN UNIV

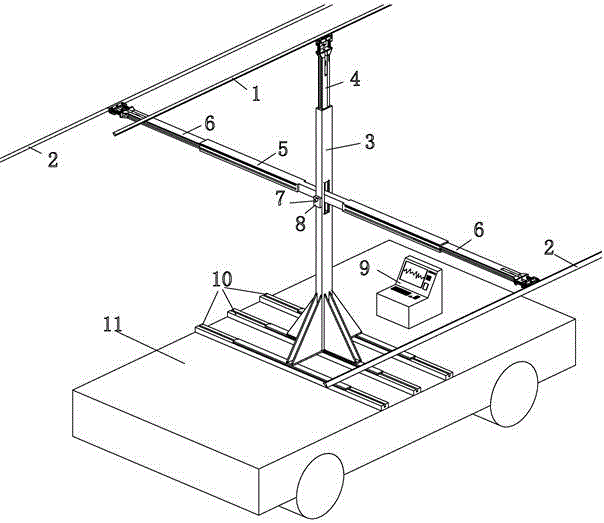

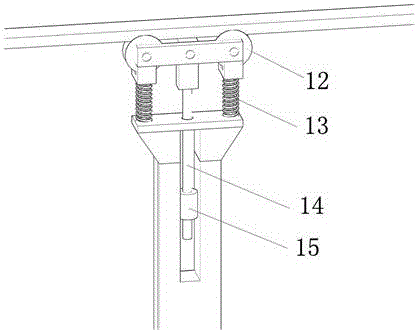

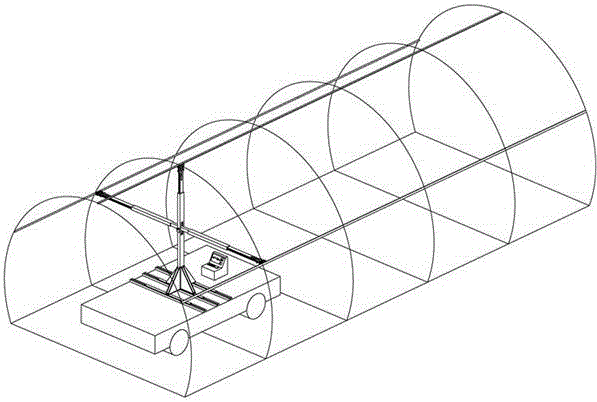

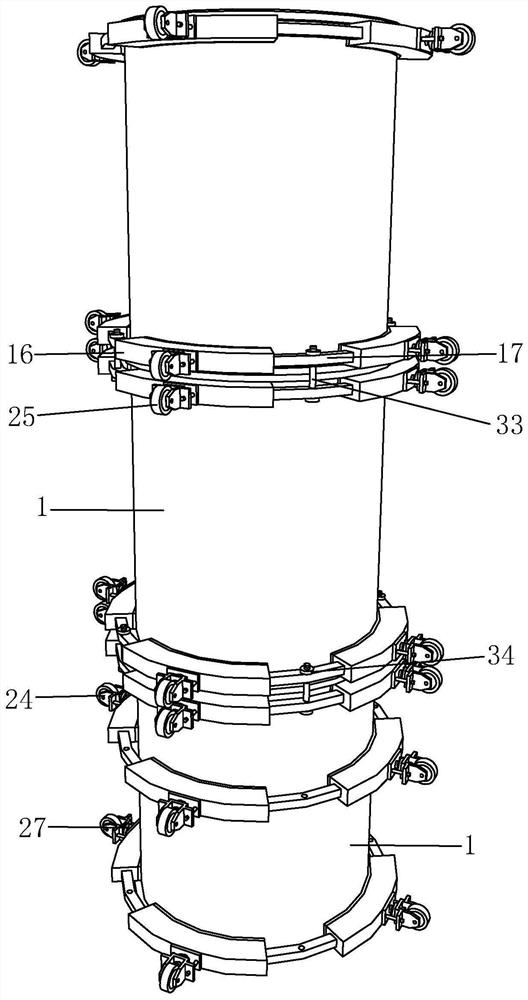

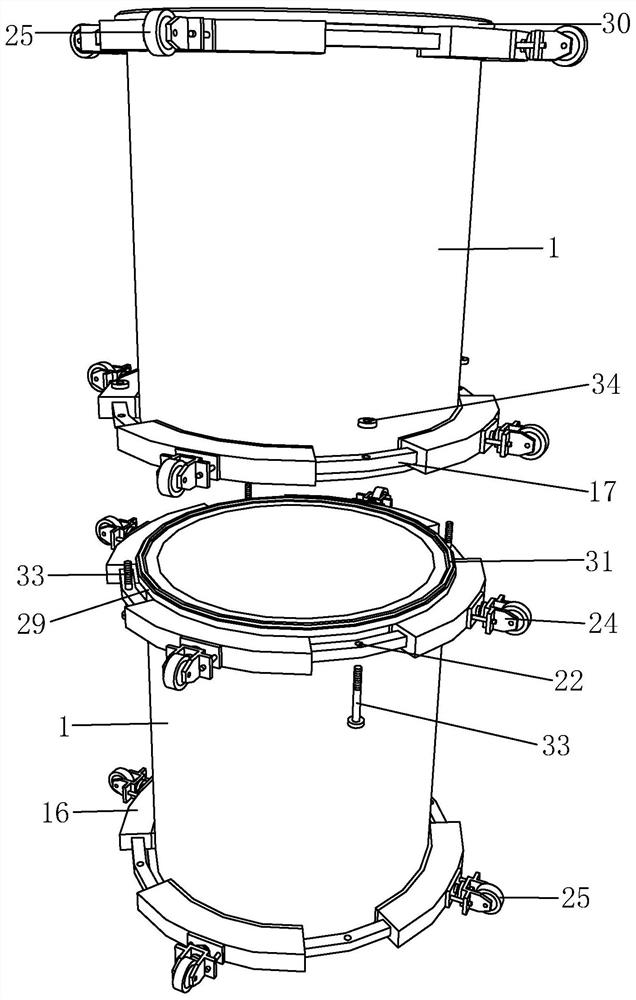

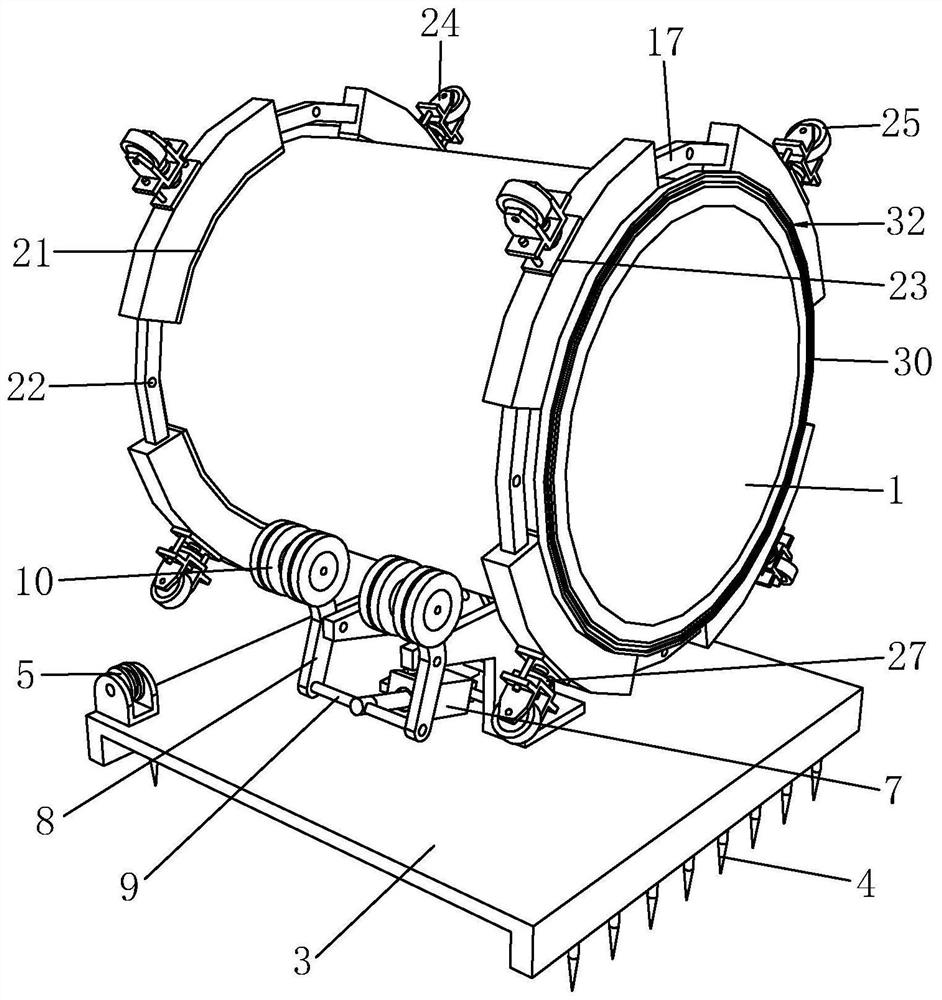

Tunnel monitoring device

ActiveCN106352844ARealize real-time monitoringEasy to operateMeasurement devicesSize changeEngineering

The invention discloses a tunnel monitoring device. The tunnel monitoring device comprises a track device, an elastic dynamical displacement monitoring device, a fixed support device, a data processing device and an advancing device, wherein the track device fits a tunnel wall, and can be deformed together with the tunnel wall; the elastic dynamic displacement monitoring device advances on the track device, and can convert the deformation of the tunnel wall into displacement data and transmit the displacement data to the data processing device; the elastic dynamic displacement monitoring device is fixedly connected with the fixed support device; the fixed support device is connected with the advancing device. By adopting the tunnel monitoring device, real-time monitoring of tunnel deformation continuous full coverage is realized. The tunnel monitoring device has the advantages of prevention of leakage points for monitoring, higher universality, easiness and convenience in operation and flexible size change, is suitable for different tunnel sections and can be used repeatedly.

Owner:SHIJIAZHUANG TIEDAO UNIV

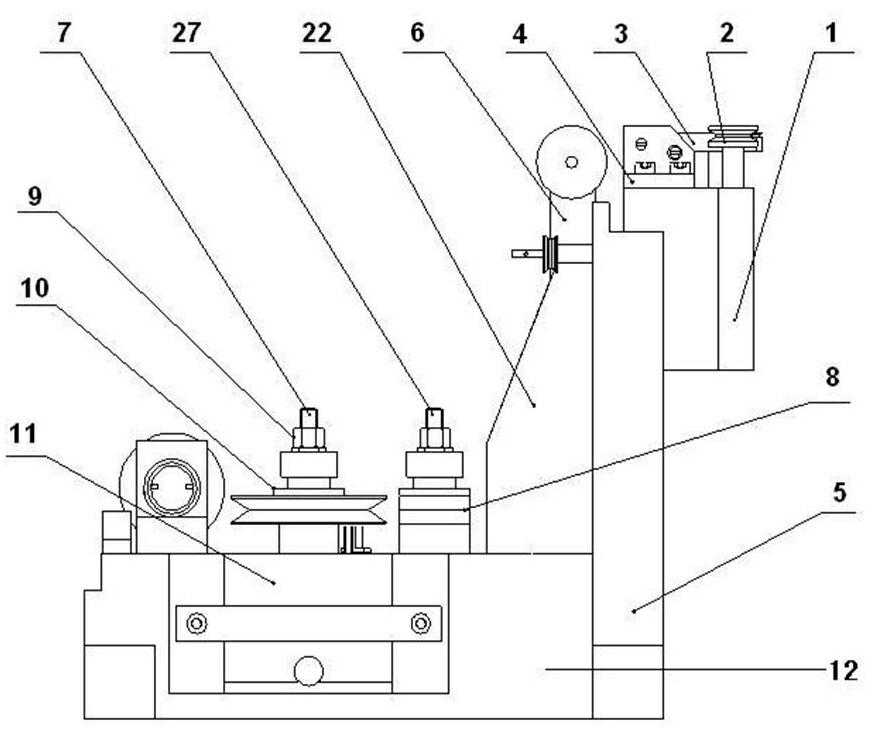

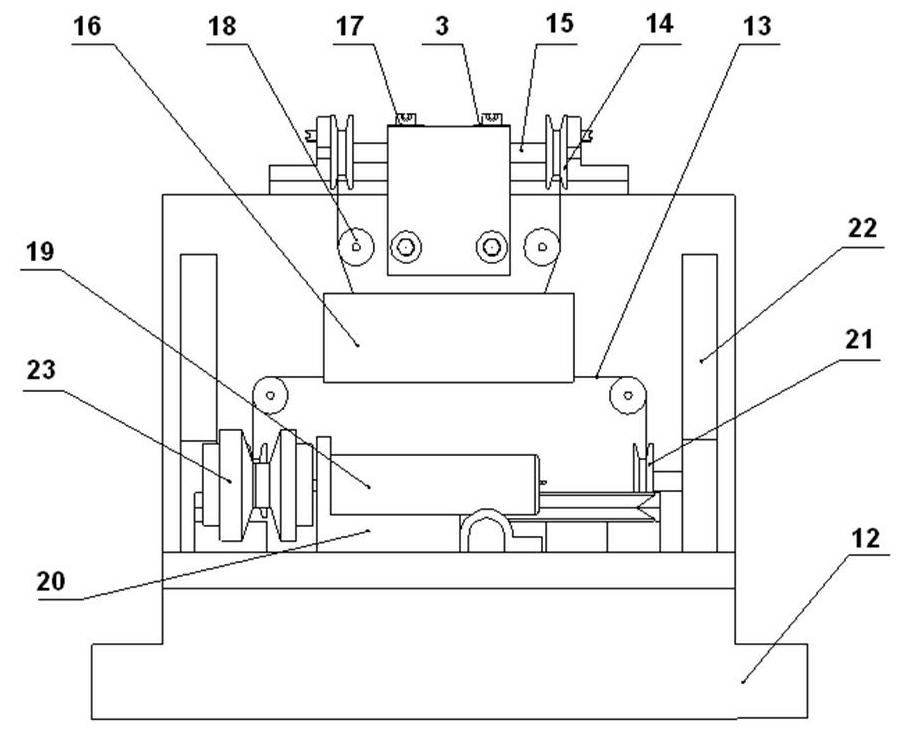

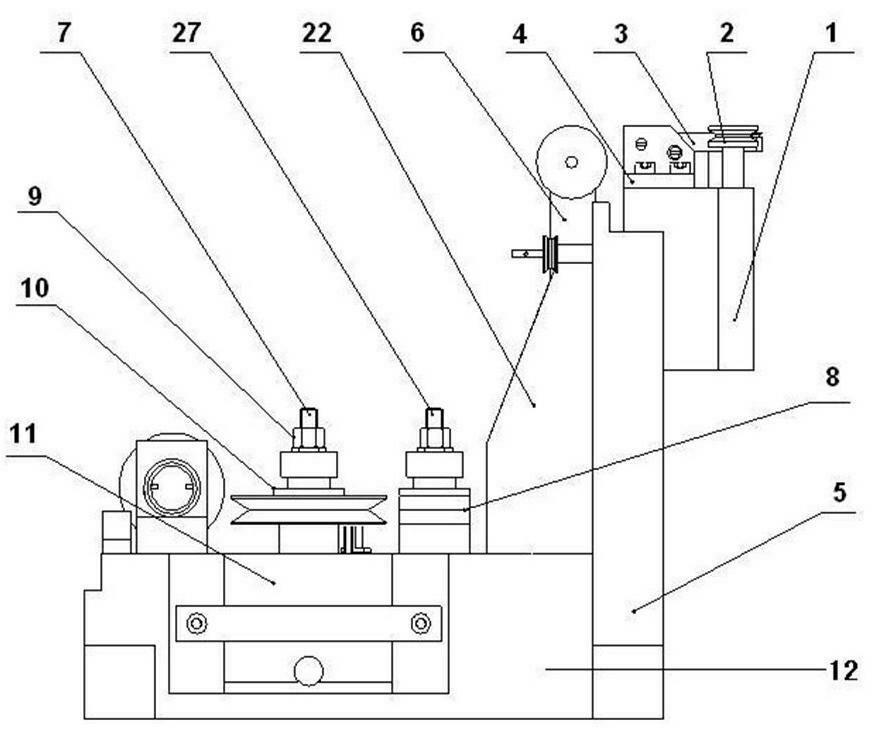

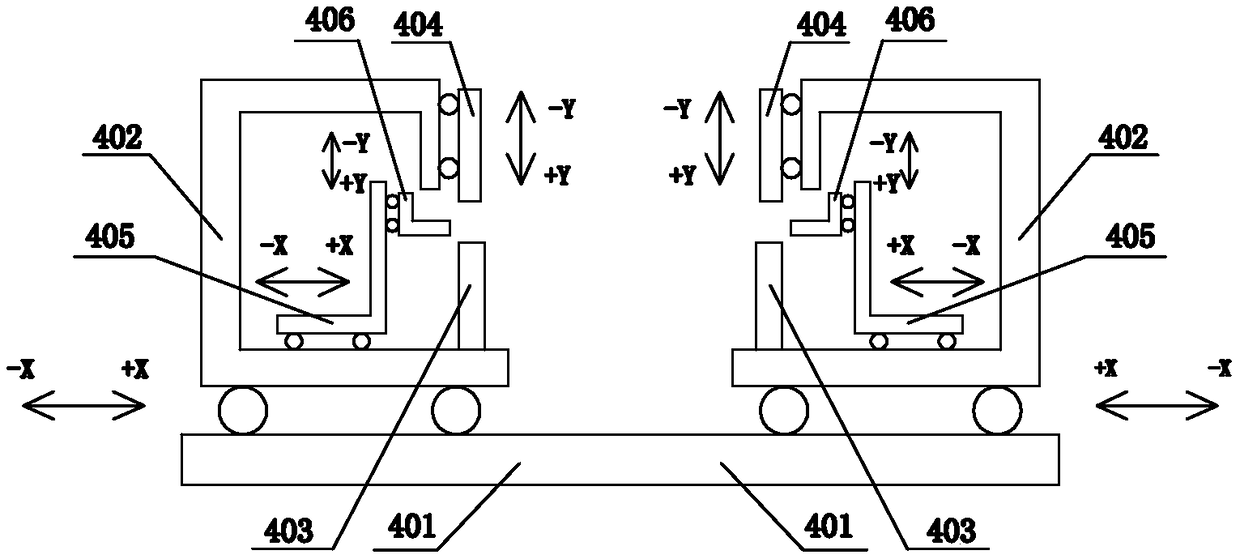

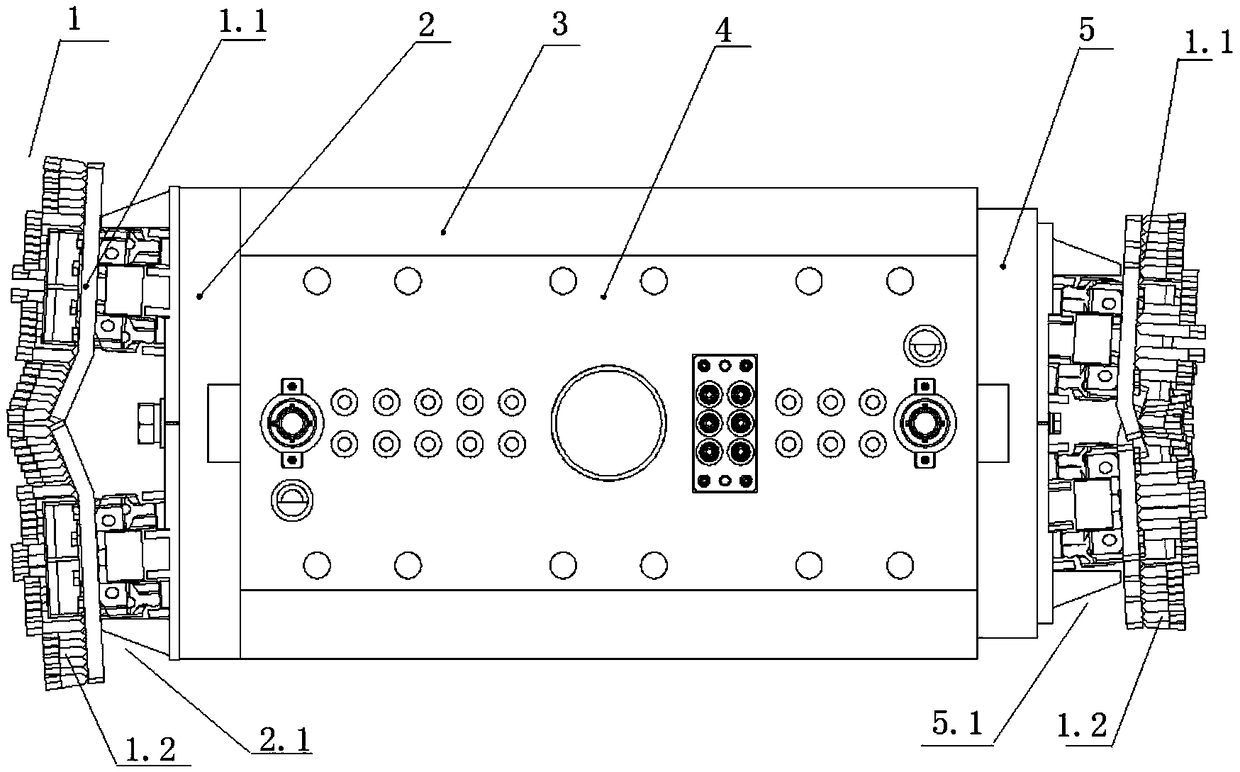

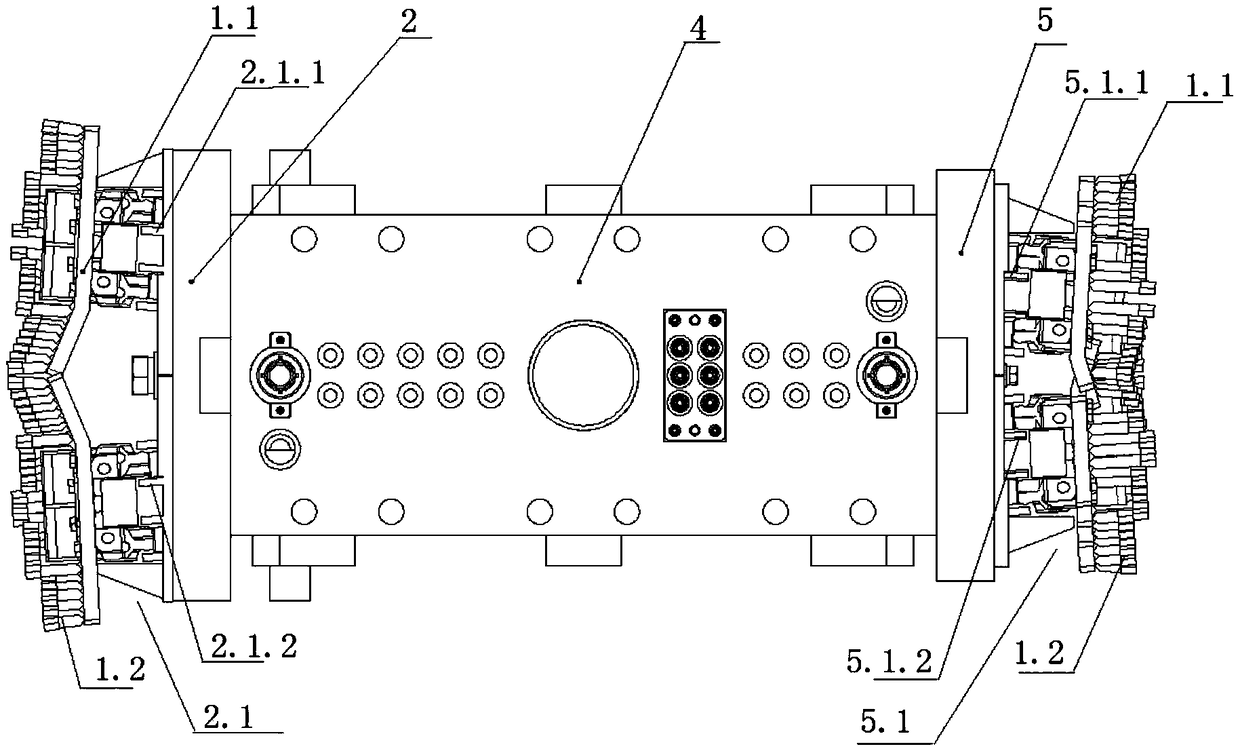

Miniaturized bifunctional line electrode grinding device

InactiveCN102601707AImprove dynamic characteristicsExpansion of comprehensive processing capabilitiesGrinding machine componentsGrinding machinesElectric dischargeMiniaturization

The invention discloses a miniaturized bifunctional line electrode grinding device. A motor assembly, a wire winding wheel, a wire discharging wheel, a damper and a damping fin in the line electrode grinding device are arranged on a bottom supporting plate, and a left grinding head, a right grinding head, a shock absorber, a guide wheel and a transition wheel are arranged on a vertical supporting plate. An electrode wire is wound on the left grinding head and the right grinding head after being led out by the wire discharging wheel and passing through a middle transition device and then passes through corresponding transition devices, and finally, wire winding is realized by the wire winding wheel, so that the whole wire moving process is finished. The motor assembly drives the wire winding wheel to rotate to realize the wire moving function of the electrode wire. All the devices provided by the invention are arranged reasonably, the device can be miniaturized and lightened, and the dynamic characteristic of a workbench can be improved. The spatial size of an electric discharge machining region arranged between the left grinding head and the right grinding head provided by the invention can be flexibly adjusted, the machining requirements of a microarray tool electrode and a non-microarray tool electrode can be met, and the function of a micro-electric machining system is remarkably expanded.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

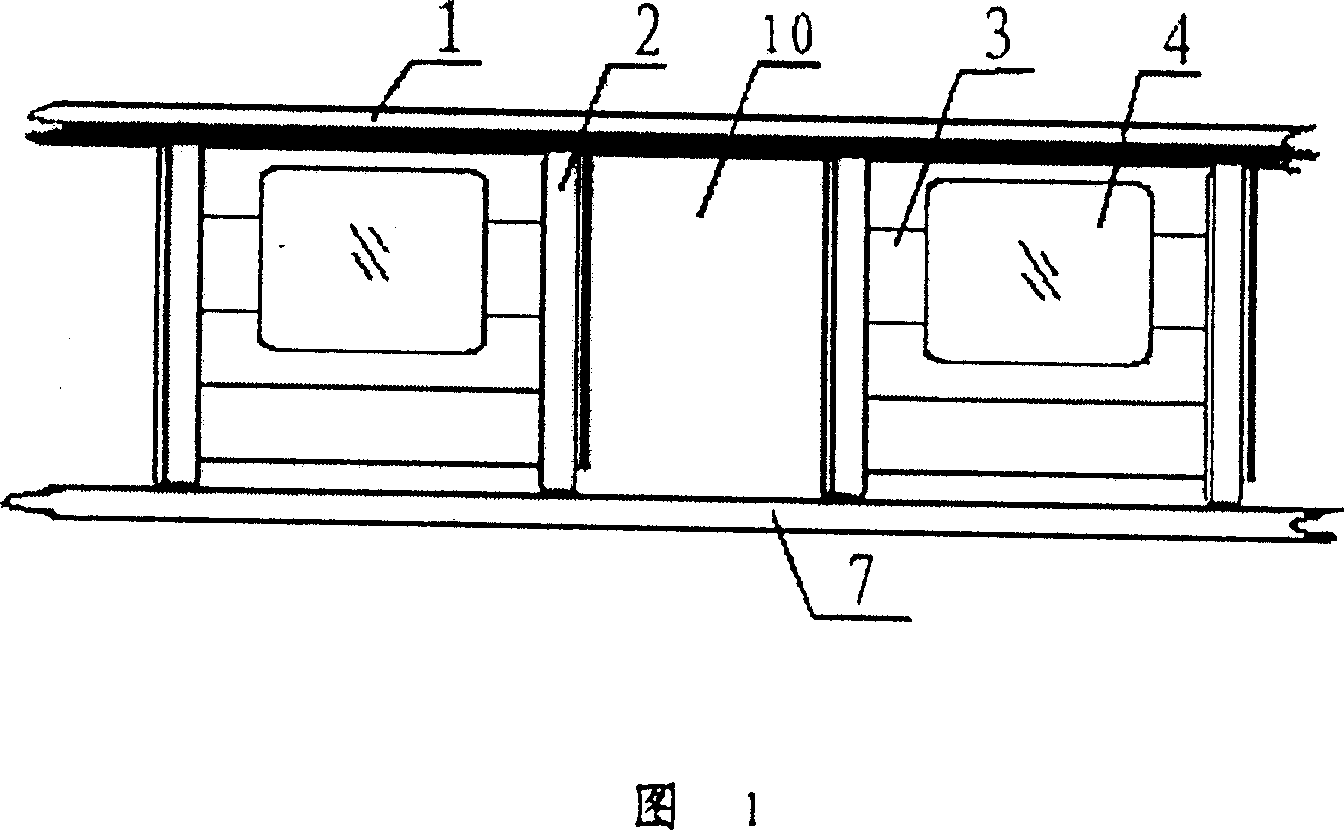

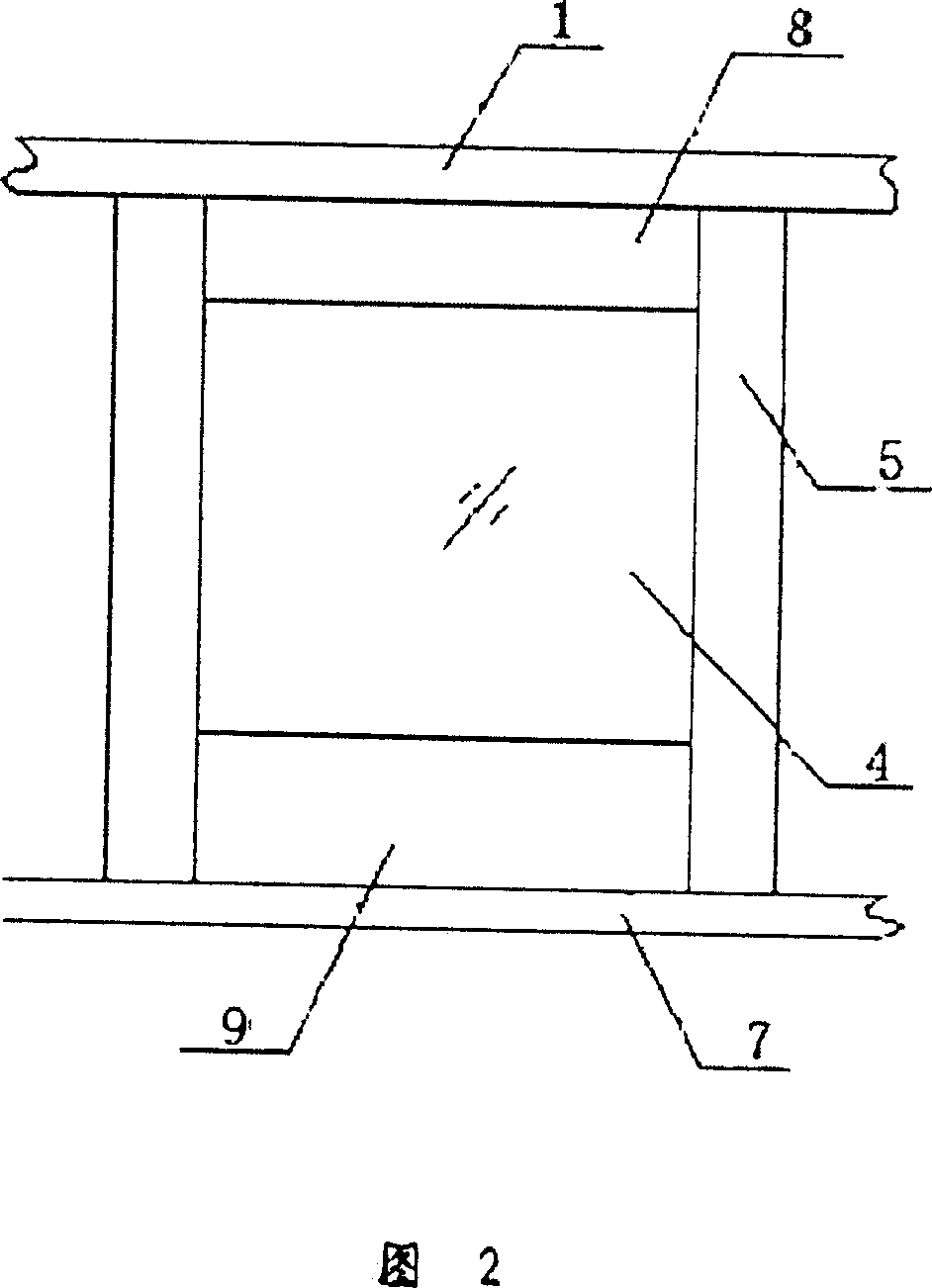

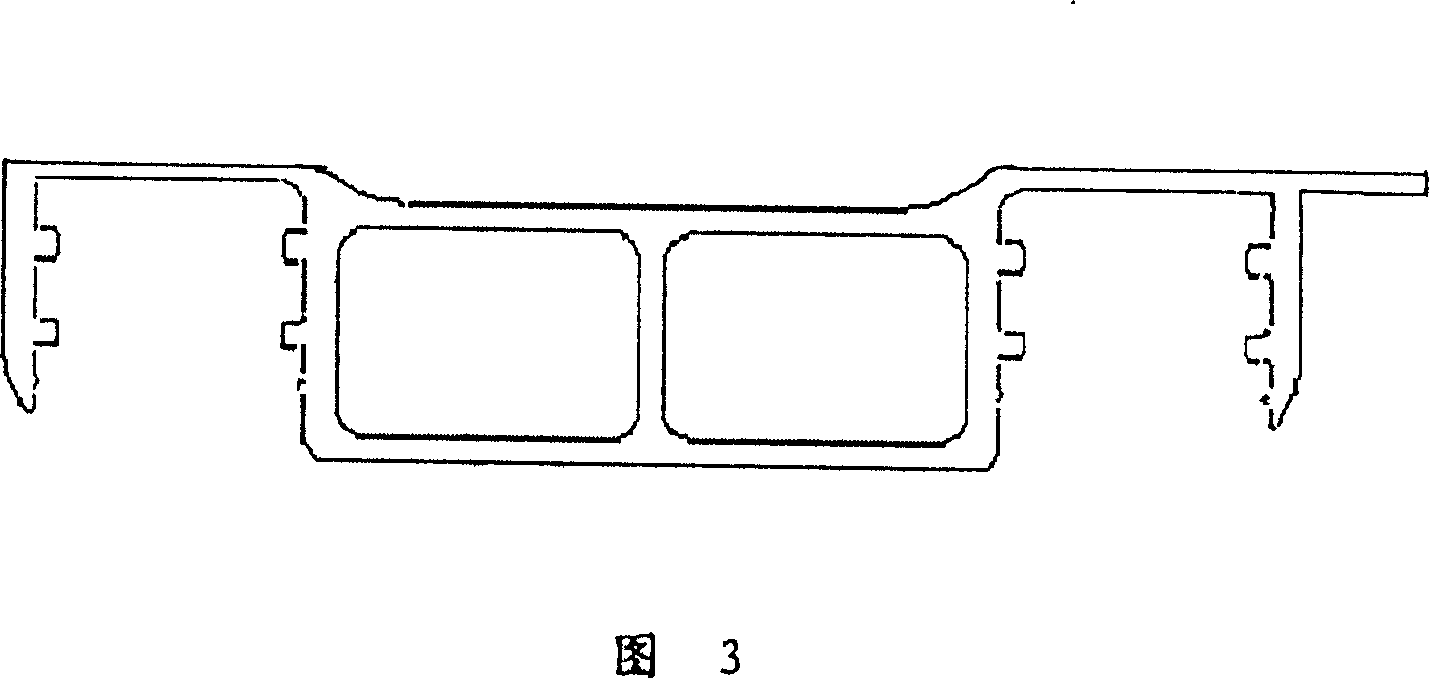

Novel sidewall for underground vehicle

ActiveCN101032966AIncrease the effective areaBright lightAxle-box lubricationMaterial based railway technolgyEngineeringWall plate

Owner:CRRC NANJING PUZHEN CO LTD

High-performance nano silicon carbide ceramic as well as preparation method and application thereof

The invention belongs to the field of non-oxide ceramic materials, and discloses high-performance nano silicon carbide ceramic as well as a preparation method and application thereof. The preparationmethod of the silicon carbide ceramic comprises the following steps of: ball-milling and mixing polycarbosilane serving as a precursor and a sintering aid Al2O3-CeO2, heating to 200-400 DEG C in a protective atmosphere, keeping the temperature, heating to 500-1200 DEG C, and cracking the mixture to obtain mixed powder; and carrying out ball milling and granulation on the mixed powder, putting thegranules into a graphite mold, applying pressure of 1-20 MPa, and sintering at 1200-1450 DEG C in a protective atmosphere. Through the size effect, the thickness of the sample is controlled, so that the density of the sample is 97% or above, the Vickers hardness is 25-35 GPa, the bending strength is 700-1200 MPa, the breaking tenacity is 6-12 MPa.m<1 / 2>, and the high-temperature strength at 1200 DEG C is 800-1300 MPa. The ceramic can be widely applied to the field of nuclear energy.

Owner:GUANGDONG UNIV OF TECH

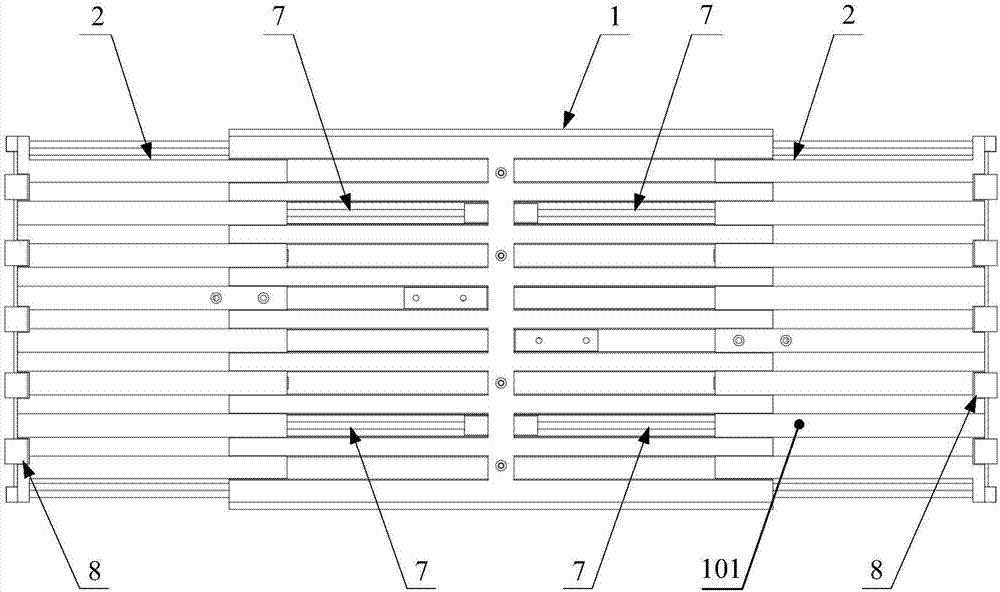

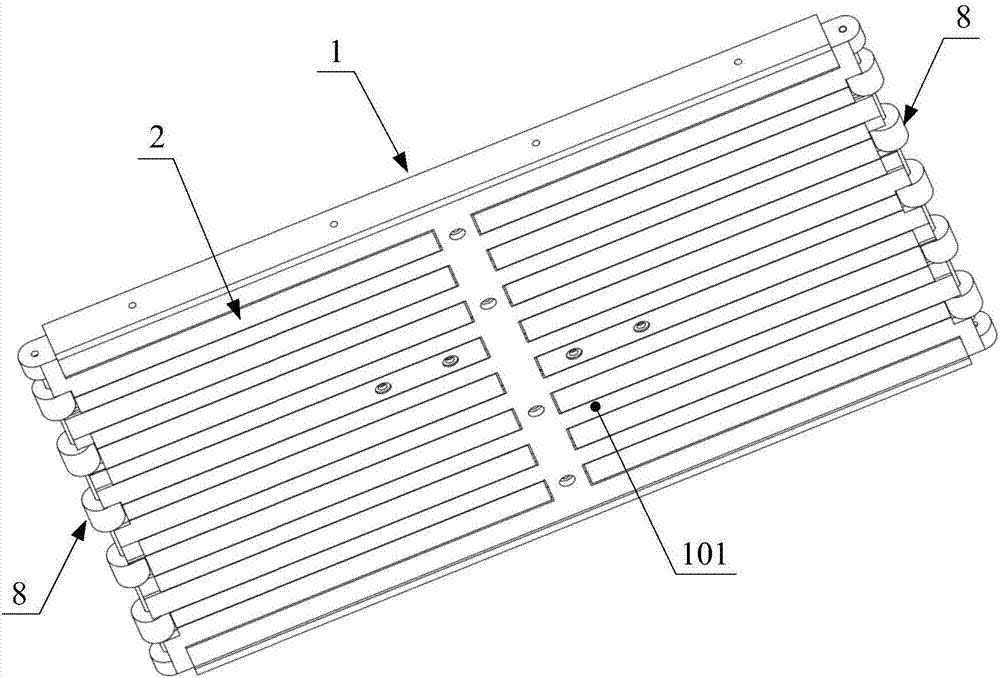

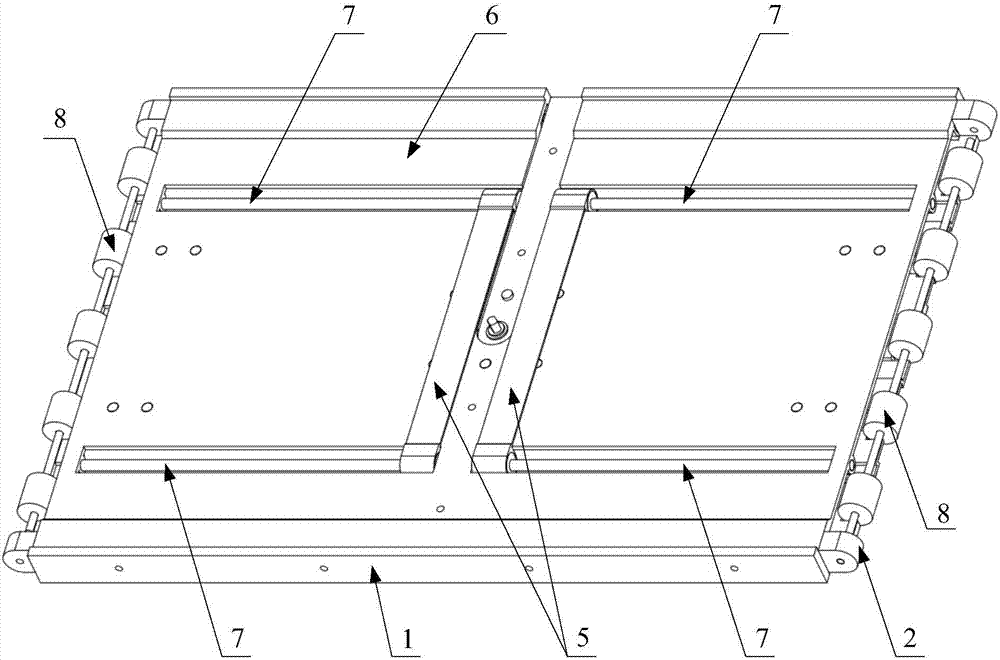

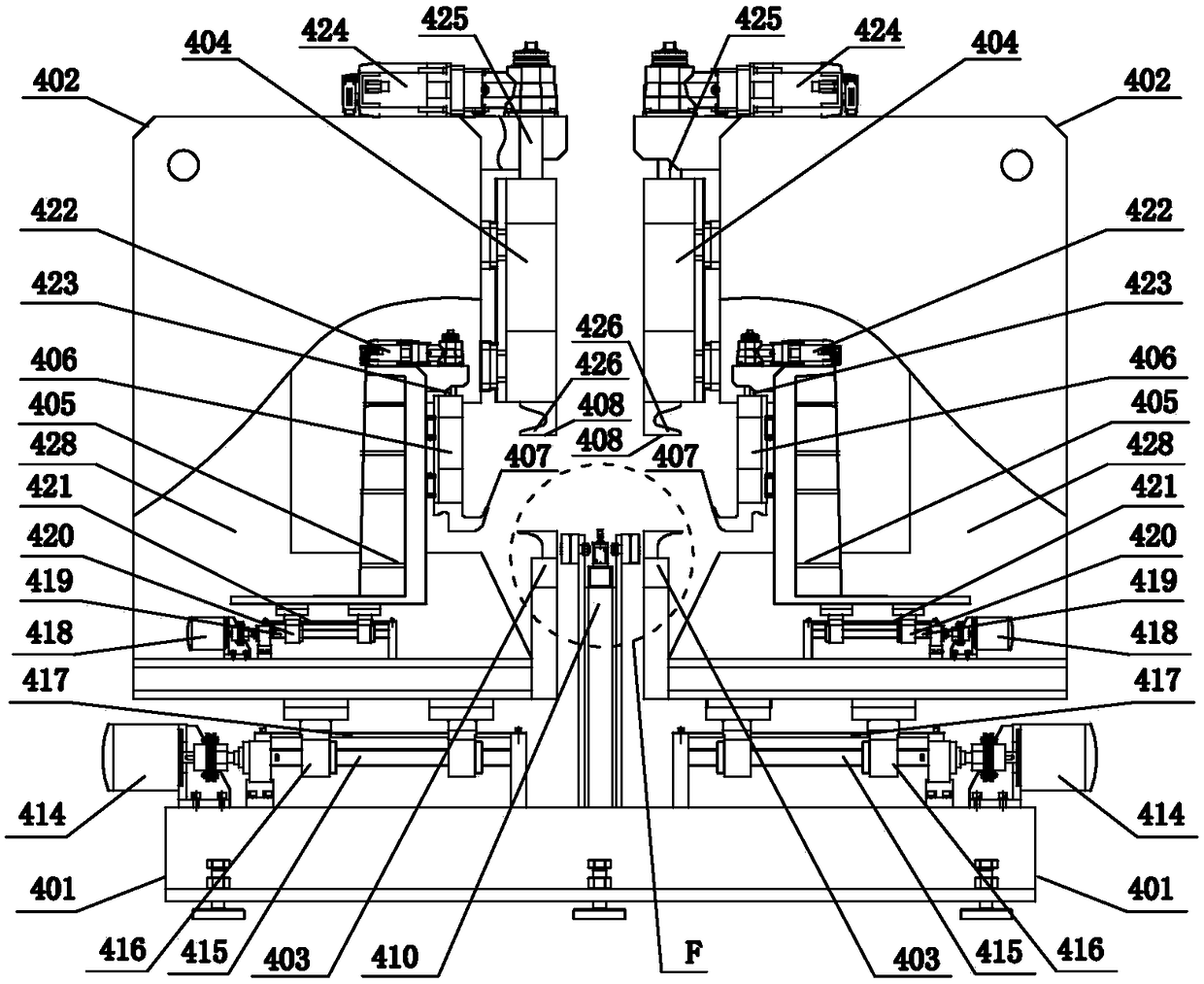

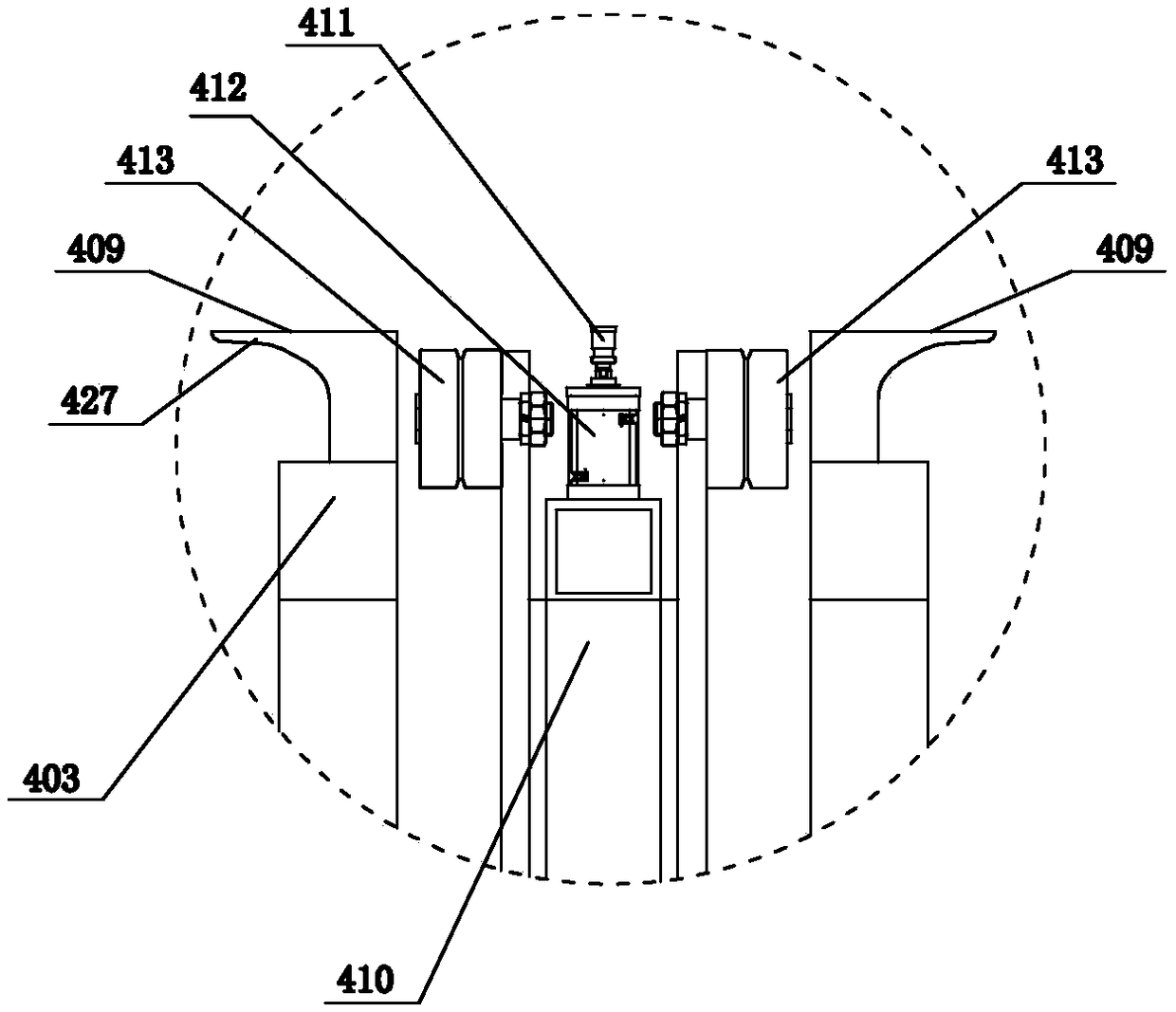

Flexible bending machine

PendingCN109351816AApplicable production needsFlexible size changeMetal-working feeding devicesPositioning devicesEngineeringLower face

The invention discloses a flexible bending machine. The flexible bending machine comprises a base, a conveying table and two shoulder bases; the conveying table is arranged in the middle of the upperface of the base, the two shoulder bases are symmetrically arranged on the two sides of the conveying table, and can move in the width direction of the base, a supporting frame, a pressing frame and abending frame are arranged on each shoulder base, the supporting frames are fixed to the side faces of the shoulder bases, supporting planes are arranged on the supporting frames, the pressing framescan move up and down relative to the shoulder bases, a pressure application plane is arranged on the lower face of each pressing frame, the pressure application planes correspond to the supporting planes up and down, the bending frames are located on the side edges, back onto the conveying table, of the supporting frames, the bending frames can move up and down relative to the shoulder bases, andcan move in the width direction of the shoulder bases, and bending protruding sides facing the supporting planes are arranged on the bending frames. Plates of different thicknesses, different sizes and different materials can be bent, and the bending size and shape can be flexibly changed.

Owner:CHINA NAT ELECTRIC APP RES INST +1

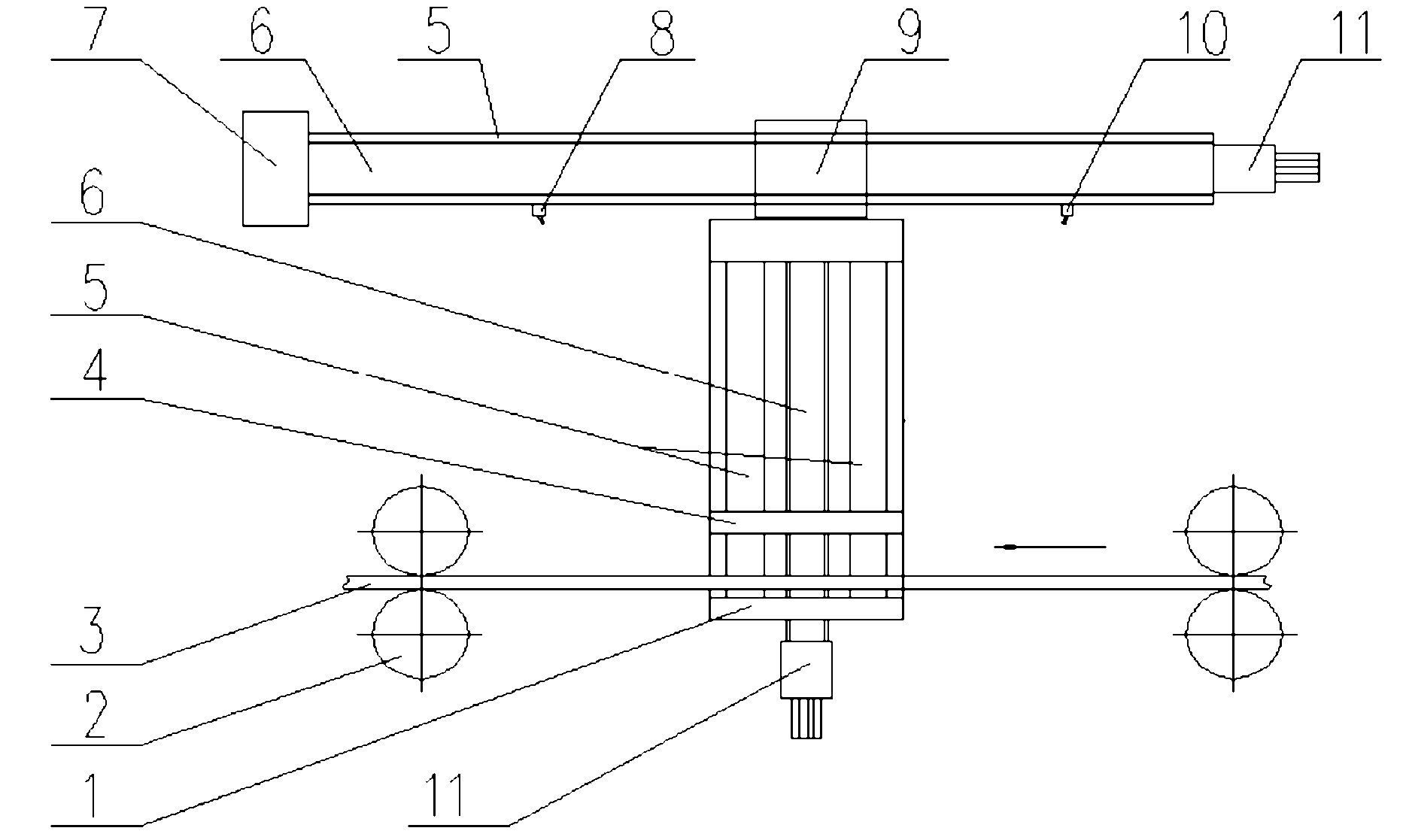

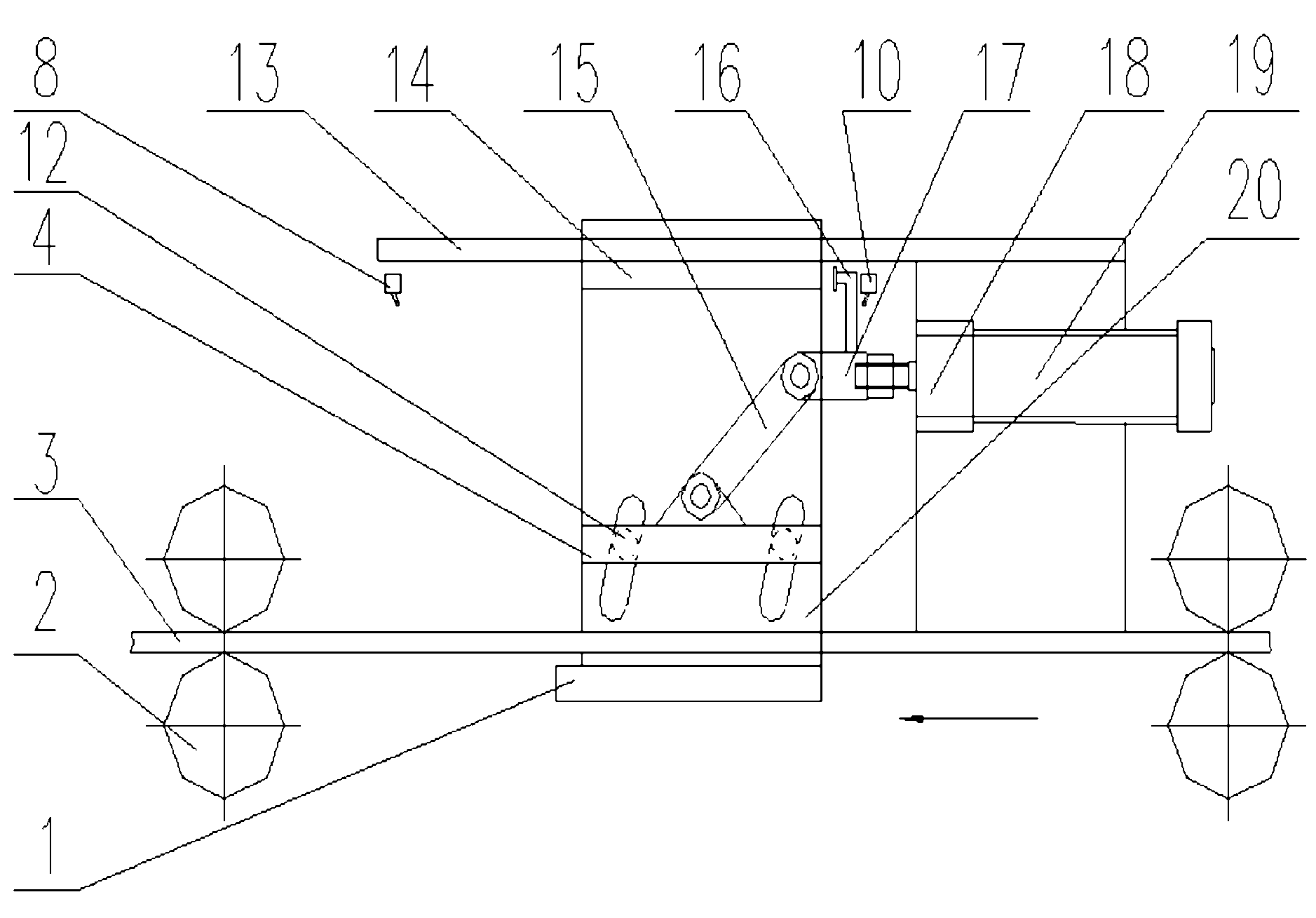

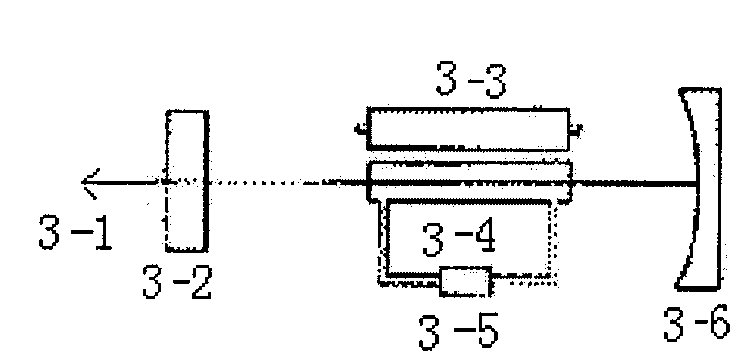

Continuous processing method for diffuser plate with surface microstructure

ActiveCN102248743ASimple processing methodEasy to operateLamination ancillary operationsLaminationMaterials scienceLight source

The invention relates to a continuous processing method for a diffuser plate with a surface microstructure and belongs to the field of continuous pressing. A microstructure is formed on the diffuser plate. After the diffuser plate is pressed, the microstructure on a mould is precisely copied onto the diffuser plate and a light source is uniformly scattered after passing through the diffuser plate, namely after the light source enters into the diffuser plate, the diffuser plate can homogenize the light source under the effect of the scattering of the microstructure. Two devices are used for realizing the continuous processing of the diffuser plate. In a first scheme, the device is composed of upper and lower moulds, a motor, a screw rod, and the like, wherein the screw rod is used for controlling the opening / closing and the left and right moving of the moulds. The first scheme has the advantage of stable and precise motion. In a second scheme, the device is composed of upper and lower moulds, a cylinder, a connecting rod, a rail, a sliding block, and the like, wherein the cylinder is used for pushing the connecting rod to control the upper mould to move up and down so as to finish the mould opening / closing operation, and the sliding block slides on the rail so as to move the moulds left and right. The second scheme has the advantages that the structure is simple, the operation is flexible and the cost is low.

Owner:BEIJING UNIV OF CHEM TECH

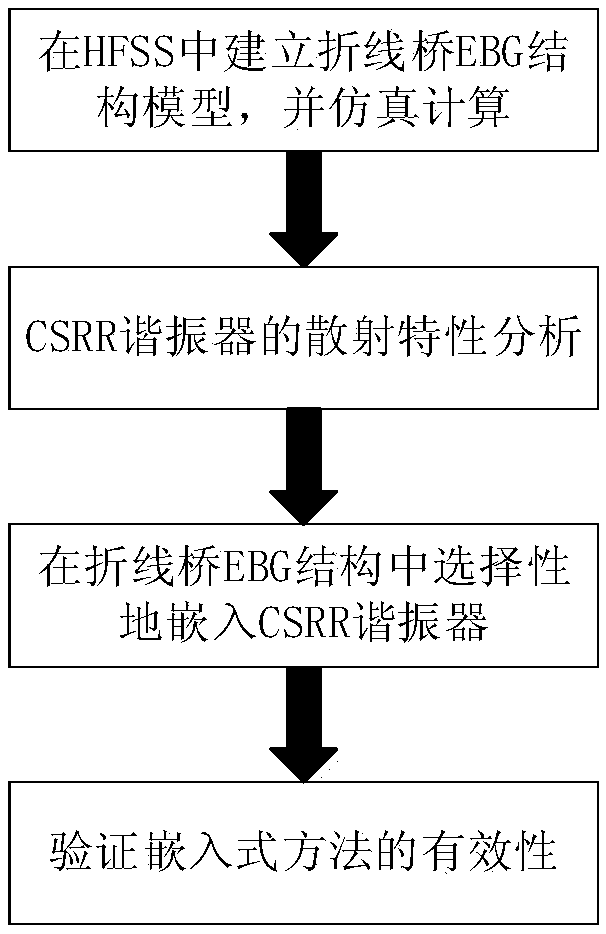

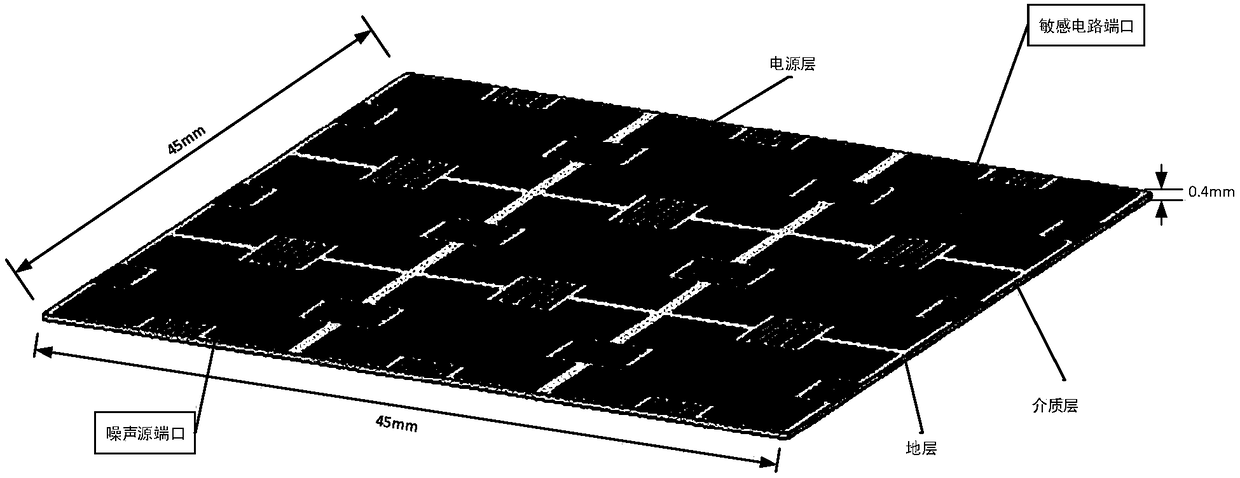

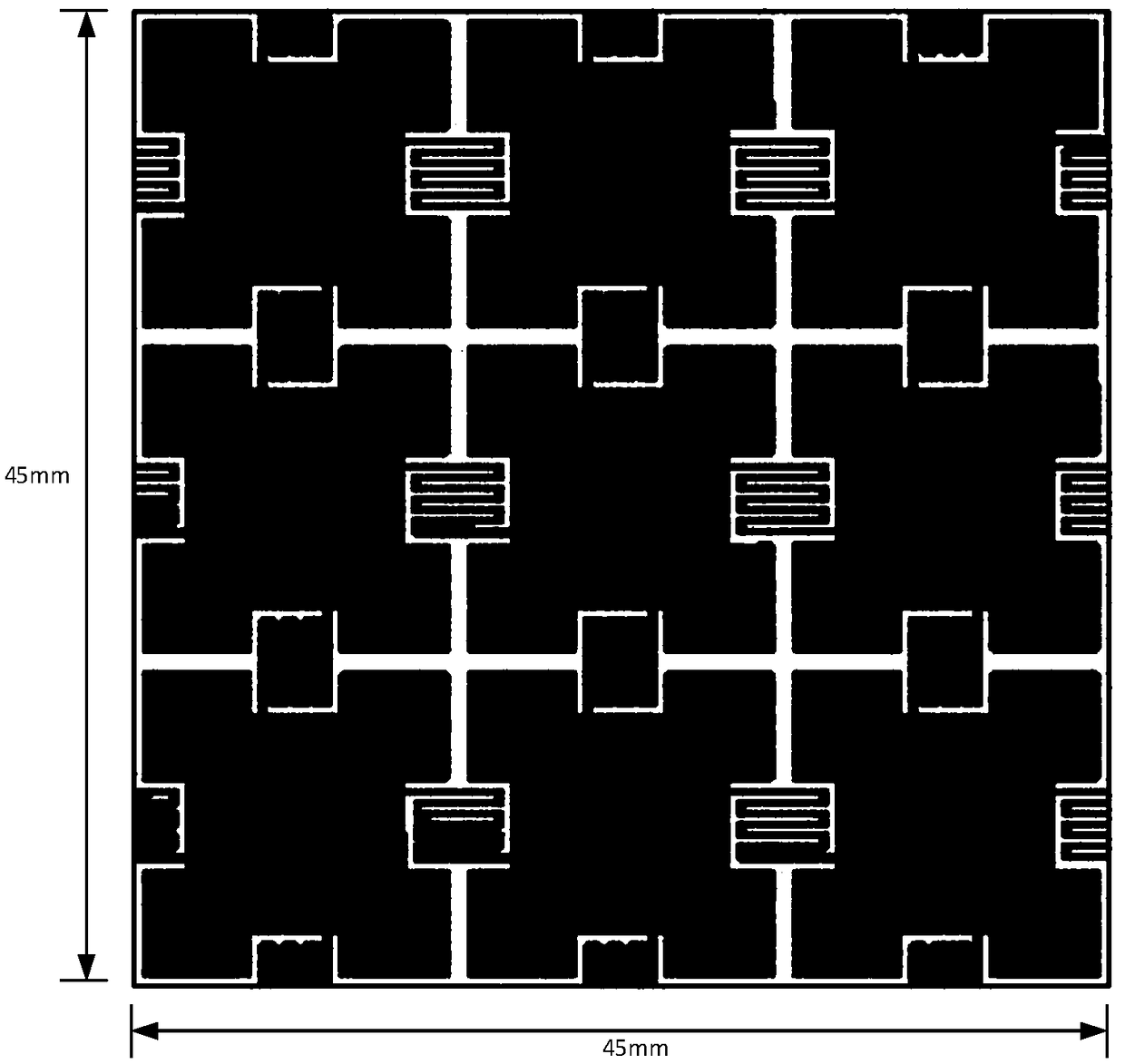

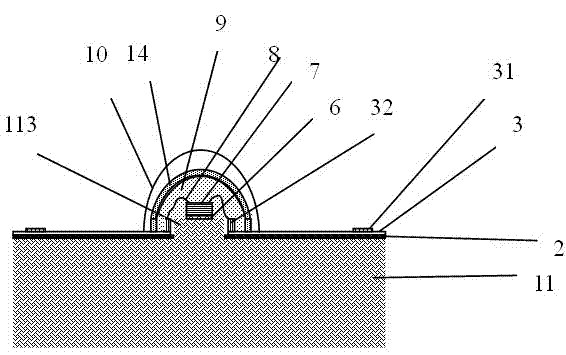

Selective embedding method based on planar electromagnetic band gap structure

InactiveCN108182321ASuppress noiseSSN noise suppressionDesign optimisation/simulationCAD circuit designBroadbandElectromagnetic band gap

The invention discloses a selective embedding method based on a planar electromagnetic band gap structure, and is used for enhancing the effect of inhibiting simultaneous switching noise. Firstly, a new EBG structure is designed on the basis of a broken line-shaped periodic bridge, then the scattering properties of a split ring resonator is analyzed, and meanwhile, a complementary split ring resonator (CSRR) is embedded into a special unit of the EBG structure, wherein the special unit is a unit where a noise source port and a sensitive circuit port are positioned. The research shows that thestructure can achieve more than -40 dB of inhibition on SSN noise in ultra-broadband of 0.9 GHz-36 GHz. by means of the method, the bandwidth of the EBG structure can be effectively broadened, the inhibition depth is enhanced, an equivalent circuit model of the structure is extracted, the circuit performance is analyzed, and the structural design is guided.

Owner:BEIHANG UNIV

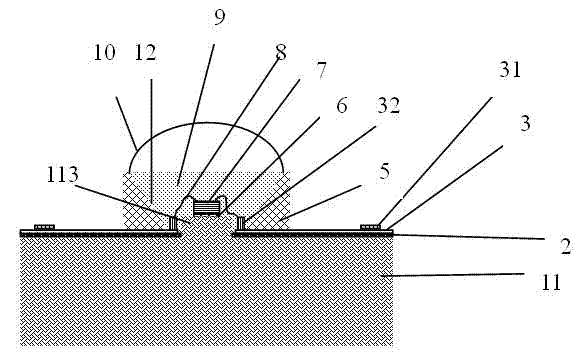

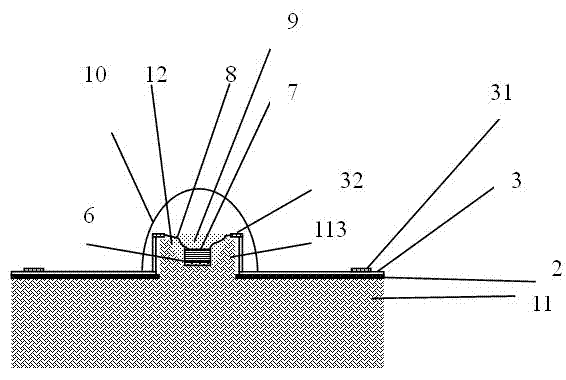

High-power LED packaging structure

InactiveCN102364709AShort leadFlexible size changeSolid-state devicesSemiconductor devicesHeat resistanceJunction temperature

The invention discloses a high-power LED packaging structure which is characterized by comprising a heat radiating substrate, an LED chip, a lens and a circuit layer, wherein the upper surface of the heat radiating substrate is provided with a bulge; the LED chip is installed on the bulge on the upper surface of the heat radiating substrate; the circuit layer is stuck to the upper surface of the heat radiating substrate through a bonding layer and is provided with an internal electrode and an external electrode connected with a power supply, the internal electrode is arranged at the edge of a hole, and a lead of the LED chip is connected with the internal electrode; the lens is arranged above the LED chip; and the structure ensures that the LED chip directly radiates heat to the air through the substrate which simultaneously has a heat sink function so that the junction temperature of an LED can be effectively reduced. The packaging structure reduces the heat resistance of the entire heat transferring process, can be used for heat radiation of high-power LEDs and realization of efficient illumination and is simple in process and easy to manufacture.

Owner:SOUTH CHINA NORMAL UNIVERSITY

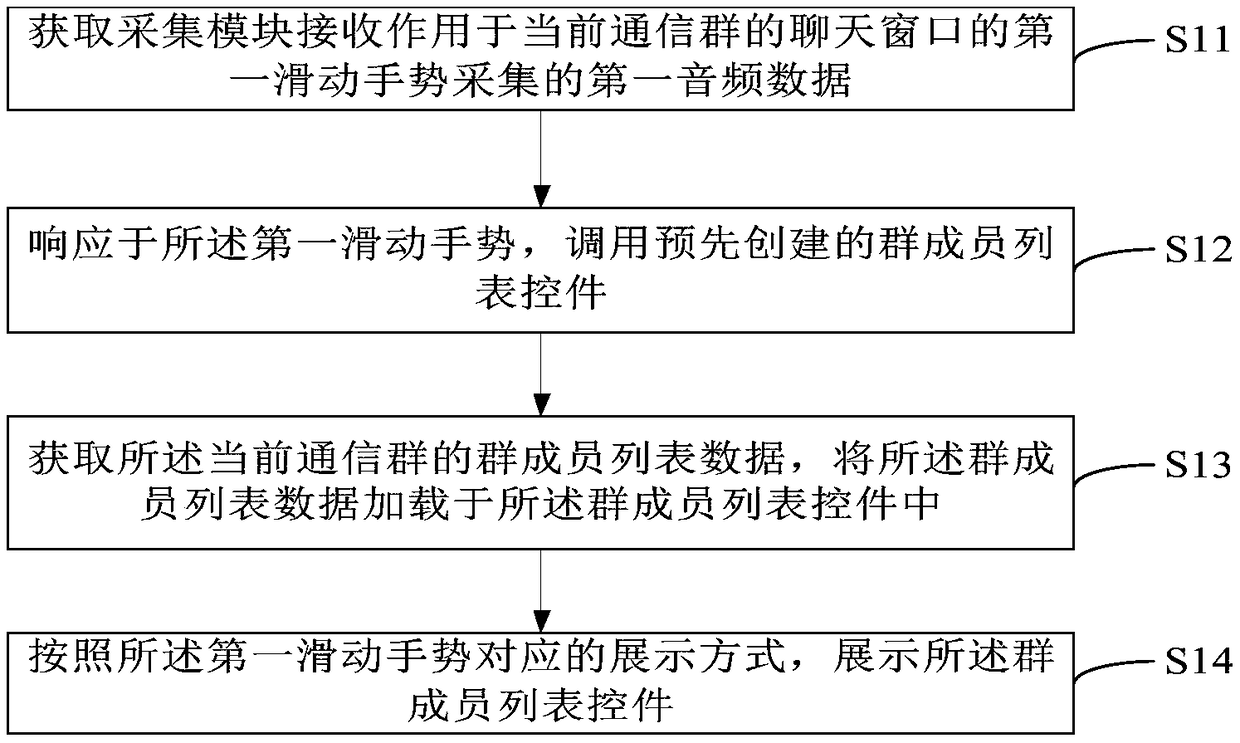

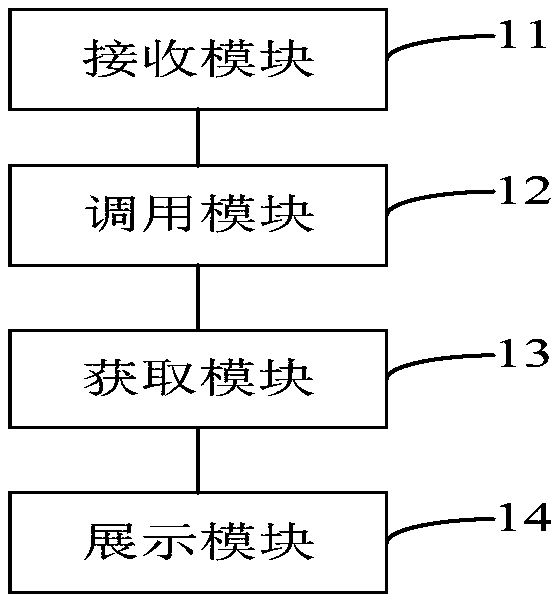

Method and device for displaying group member list in instant messaging application and mobile terminal

InactiveCN109165068AEasy accessImprove experienceExecution for user interfacesData switching networksComputer terminalInstant messaging

The invention provides a method for displaying a group member list in an instant messaging application, the method comprising the following steps: receiving a first sliding gesture acting on a chat window of a current communication group; calling a pre-created group member list control in response to the first sliding gesture; acquiring group member list data of the current communication group andloading the group member list data in the group member list control; displaying the group member list control in a presentation manner corresponding to the first sliding gesture. The invention can quickly display the group member list of the communication group based on the sliding gesture, is convenient for the user to quickly view the group member list when chatting, and improves the user experience.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

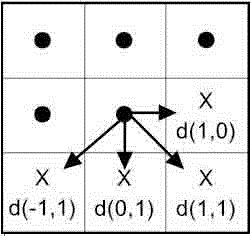

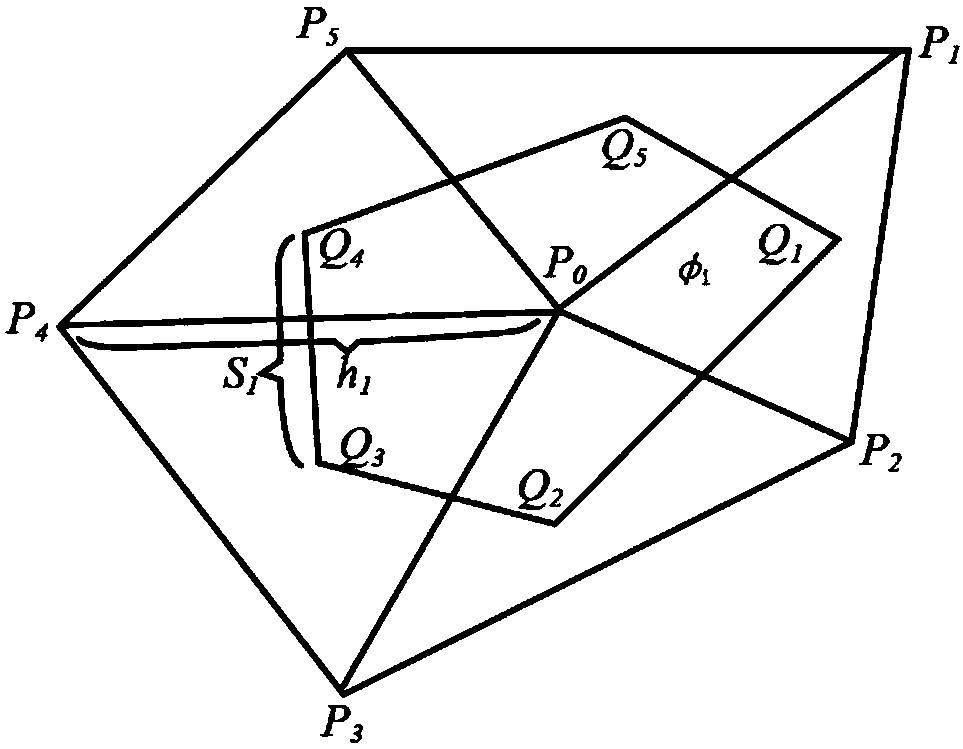

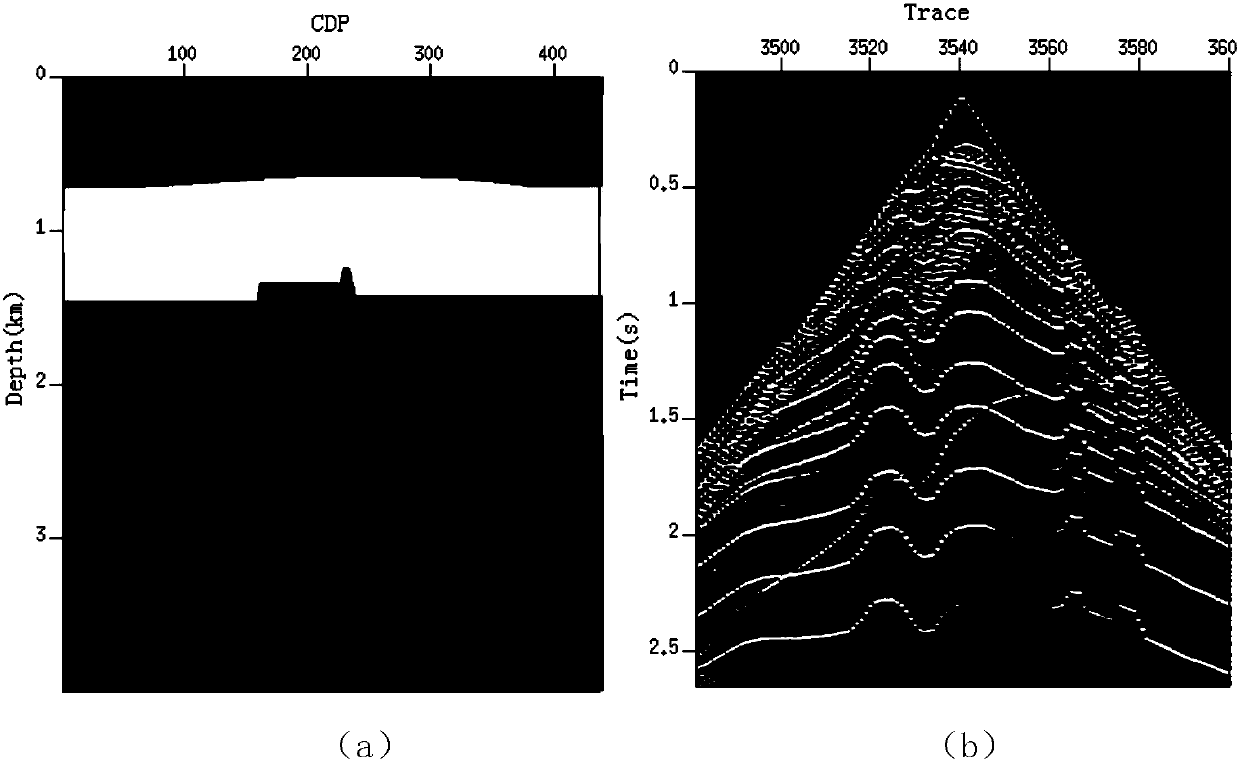

Triangular grid reverse time migration method under mountainous terrain conditions

InactiveCN107942388AFlexible size changeIncrease flexibilitySeismic signal processingDual unitReverse time

The invention relates to a triangular grid reverse time migration method under mountainous terrain conditions. The triangular grid reverse time migration method is characterized in that the process ofmodel subdivision is that a geological region involved in the migration is subdivided using triangular grids, with no overlapping or and blank regions among the triangular grids; after the subdivision is completed, the model becomes an aggregation of a large number of triangular grids, each node may be the common vertex of multiple triangles; multiple triangular grids with the common vertex constitute a computing unit which is a polygon; and the center of gravity is obtained for each triangle in the computing unit, and the centers of gravity of the triangles are connected to form a new polygon, and the new polygon is a dual unit of the computing unit.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

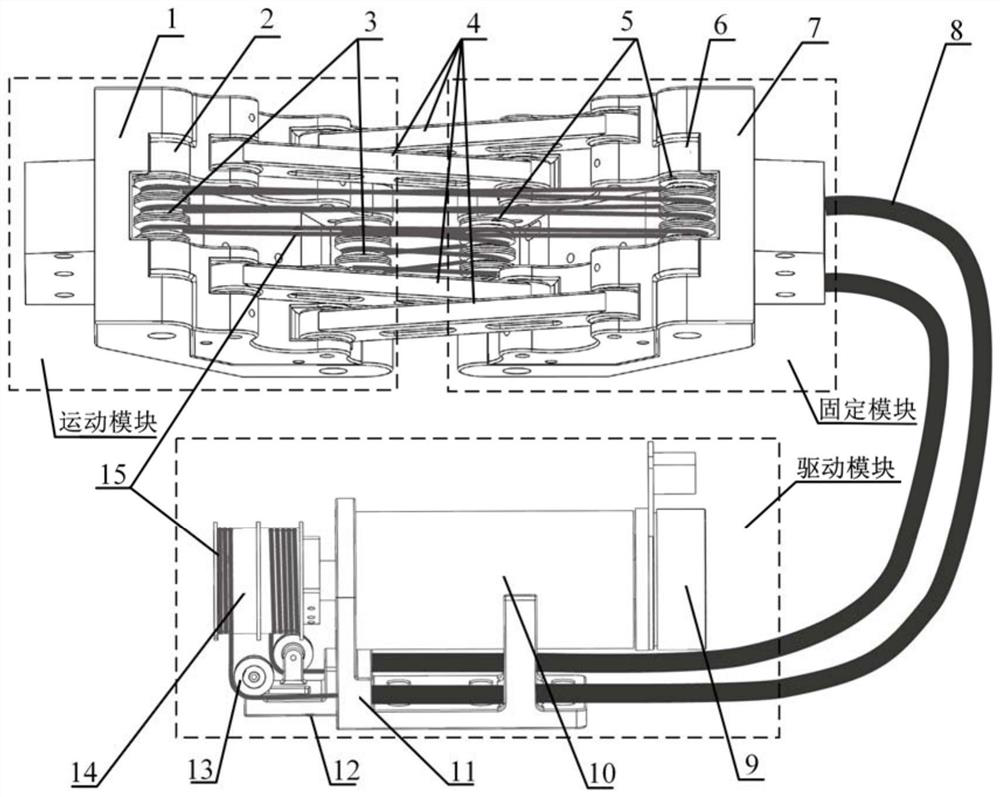

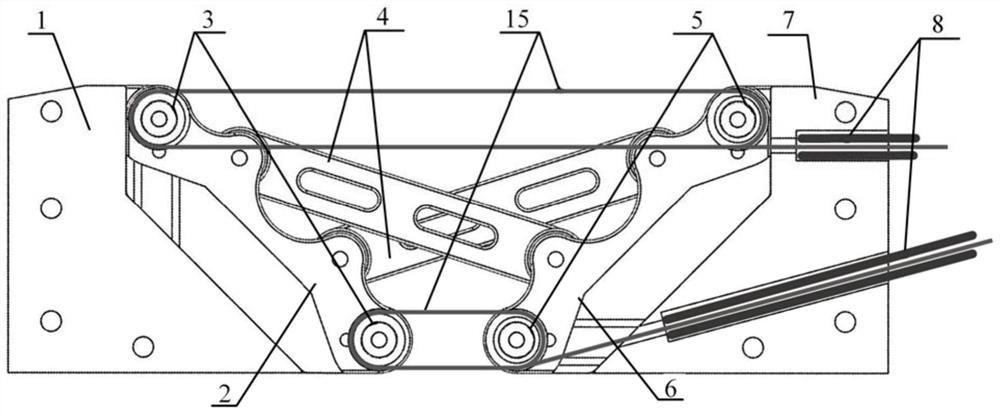

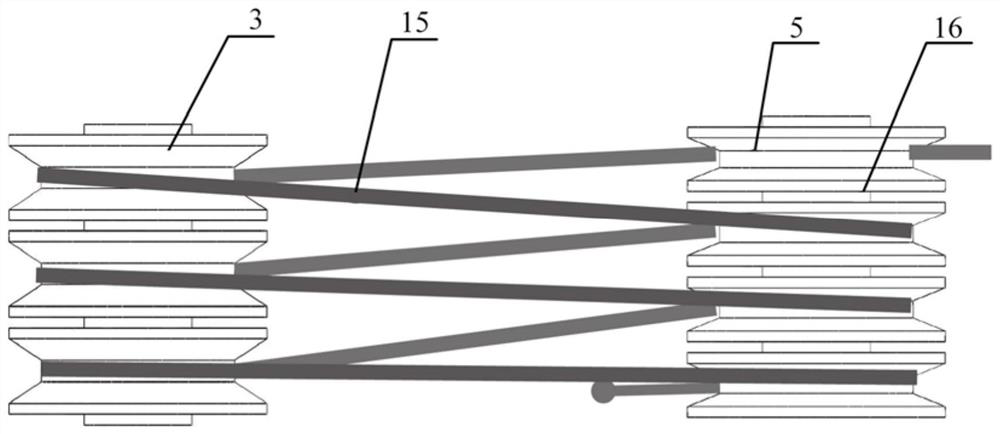

Rope-driven joint module

ActiveCN112454345AFlexible size changeDexterityProgramme-controlled manipulatorJointsRobotic armControl engineering

The invention relates to the technical field of robot joint design, in particular to a rope-driven joint module. The joint module comprises a moving module, a fixed module, a driving module, a connecting rod and a rope; the moving module comprises a moving base and a movable pulley block movably connected with the moving base; the fixed module comprises a fixed base and a fixed pulley block movably connected with the fixed base; the two ends of the connecting rod are rotationally connected with the moving base and the fixed base, the movable pulley block is arranged on the moving base, and thefixed pulley block is arranged on the fixed base; and the moving module and the fixing module are connected with the driving module through the rope. The rope-driven joint module is a one-degree-of-freedom rope-driven joint module which is high in rigidity, low in rotational inertia, small in size, light in weight and low in cost, and the safety and high efficiency of a bionic mechanical arm canbe effectively improved.

Owner:GUANGDONG UNIV OF TECH

Construction method for internally penetrating steel pipes for top pipe of water diversion project

ActiveCN113339585AFlexible height changeStrong penetrating powerPipe laying and repairArchitectural engineeringWater diversion

The invention discloses a construction method for internally penetrating steel pipes for a top pipe of a water diversion project. The construction method comprises the following steps that (a) construction preparation is conducted; (b) the first steel pipe is in place; (c) the first steel pipe is positioned; and (d) the pipes are penetrated one by one. According to the construction method, the construction difficulty is low, the efficiency is high, flexibility and applicability are achieved, the front and back steps are orderly, control is convenient, the construction quality is ensured, steel pipe pushing is convenient and fast, the equipment input cost is low, the front steel pipe and the back steel pipe are connected firmly, the structure is stable, the sealing performance is high, and the service life is long.

Owner:ZHEJIANG JIANGNANCHUN CONSTR GRP

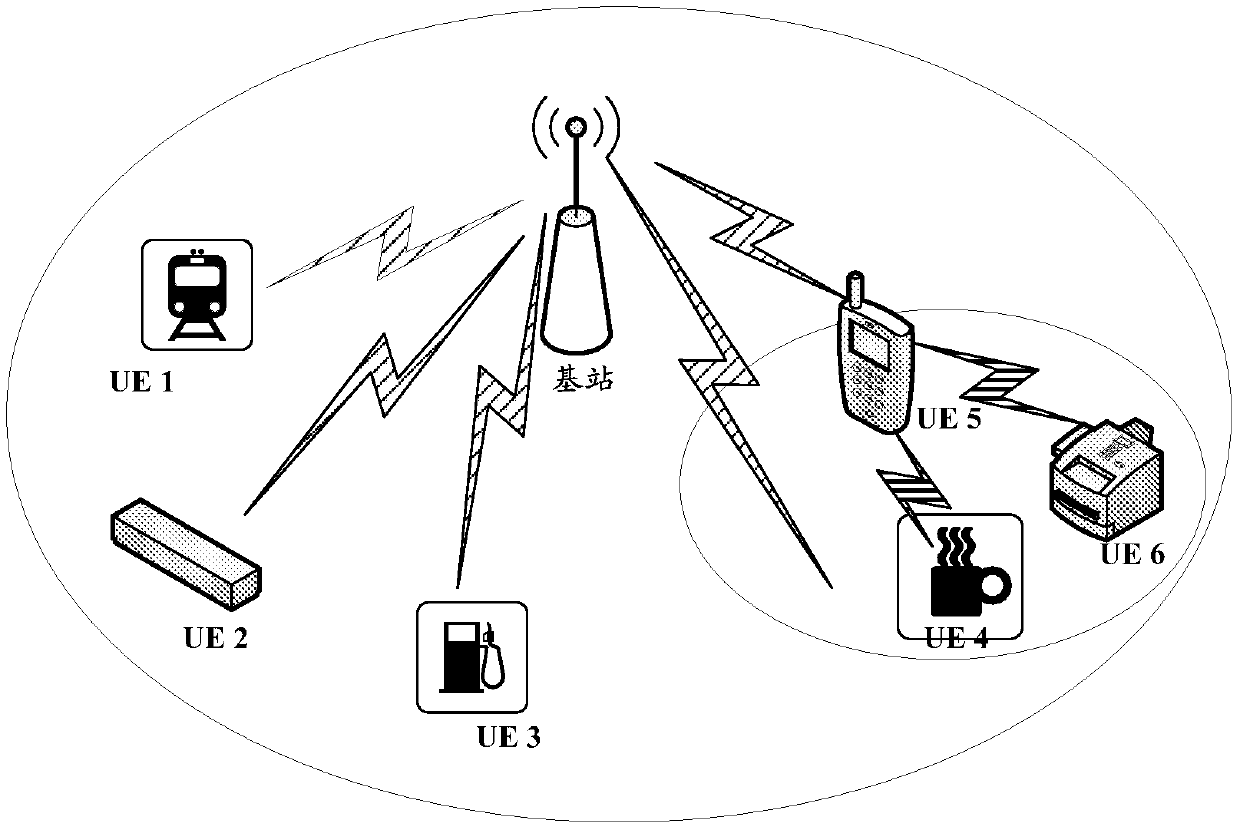

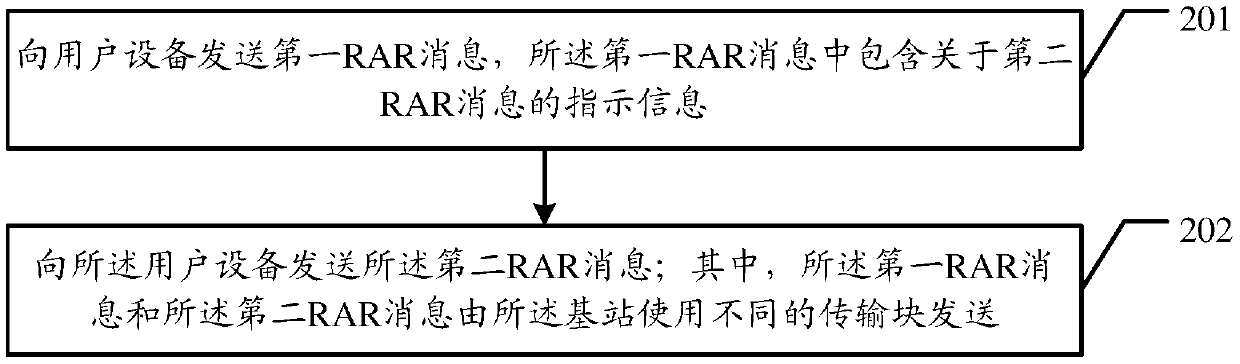

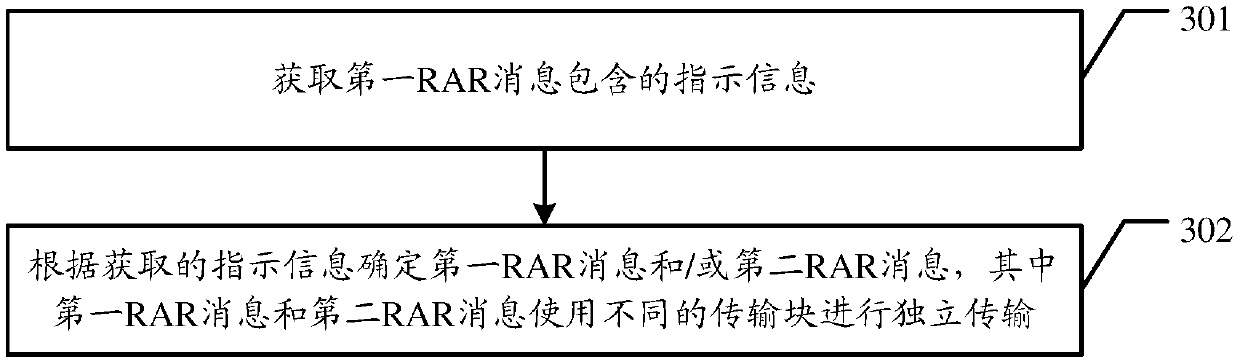

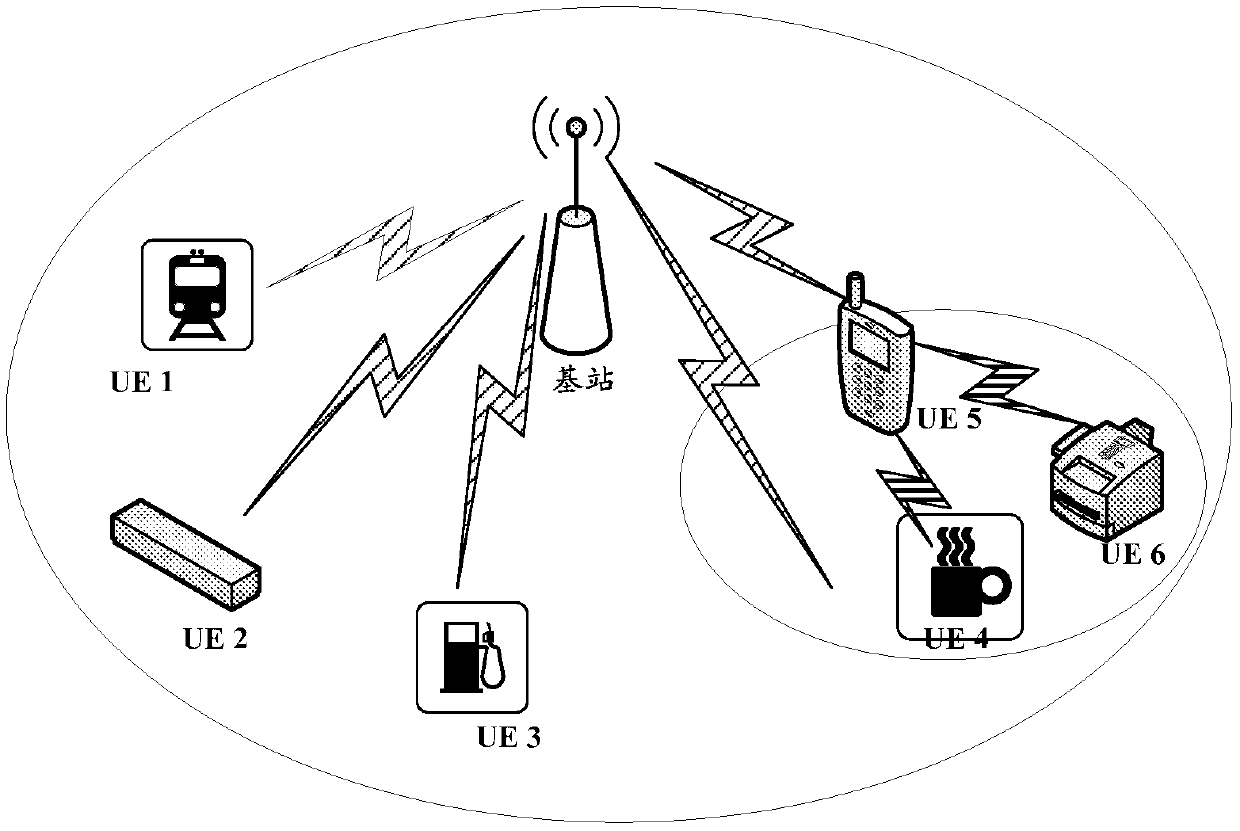

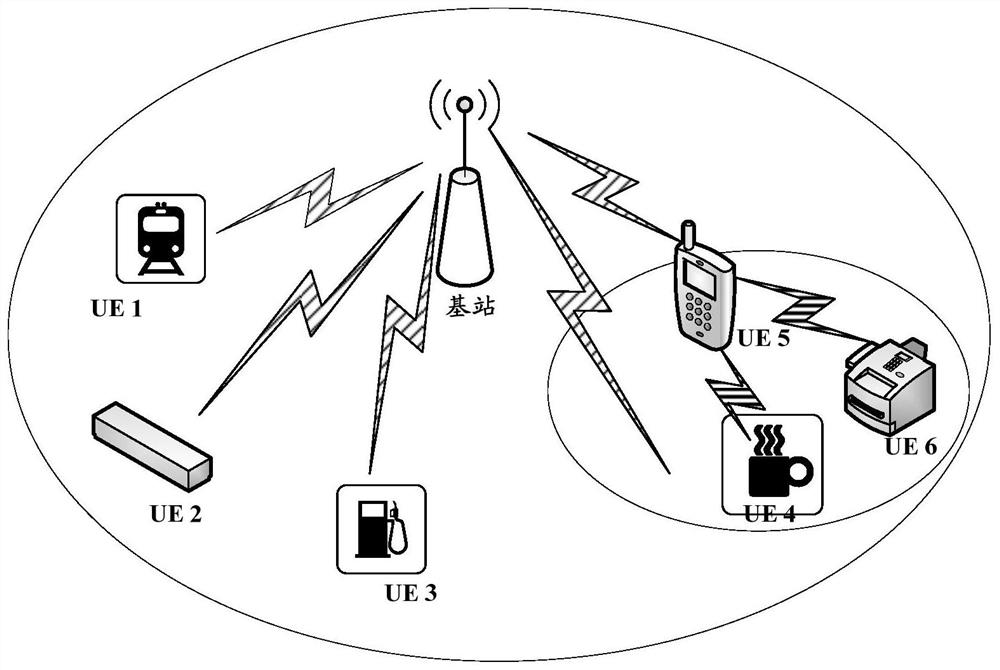

A transmission method, base station, and user equipment of a random access response message

ActiveCN106664720BFlexible size changeReduce detection power consumptionWireless communicationTelecommunicationsComputer science

A method, base station, and user equipment for transmitting random access response (RAR) messages. The method for transmitting the RAR messages comprises: transmitting a first RAR message to a user equipment, where the first RAR message comprises indication information related to a second RAR message; transmitting the second RAR message to the user equipment, where the first RAR message and the second RAR message are transmitted by the base station using different transmission blocks.

Owner:HUAWEI TECH CO LTD

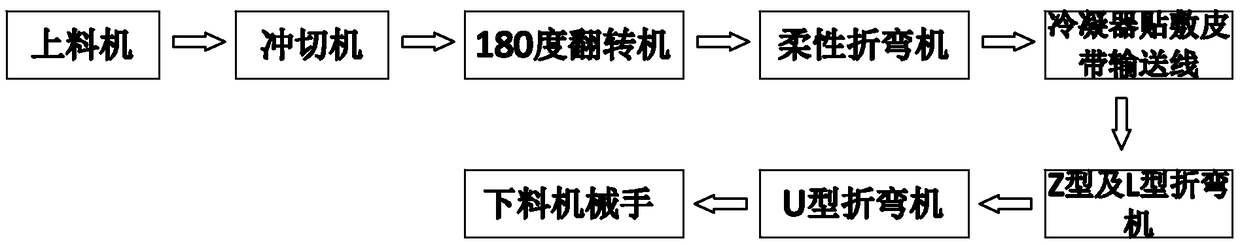

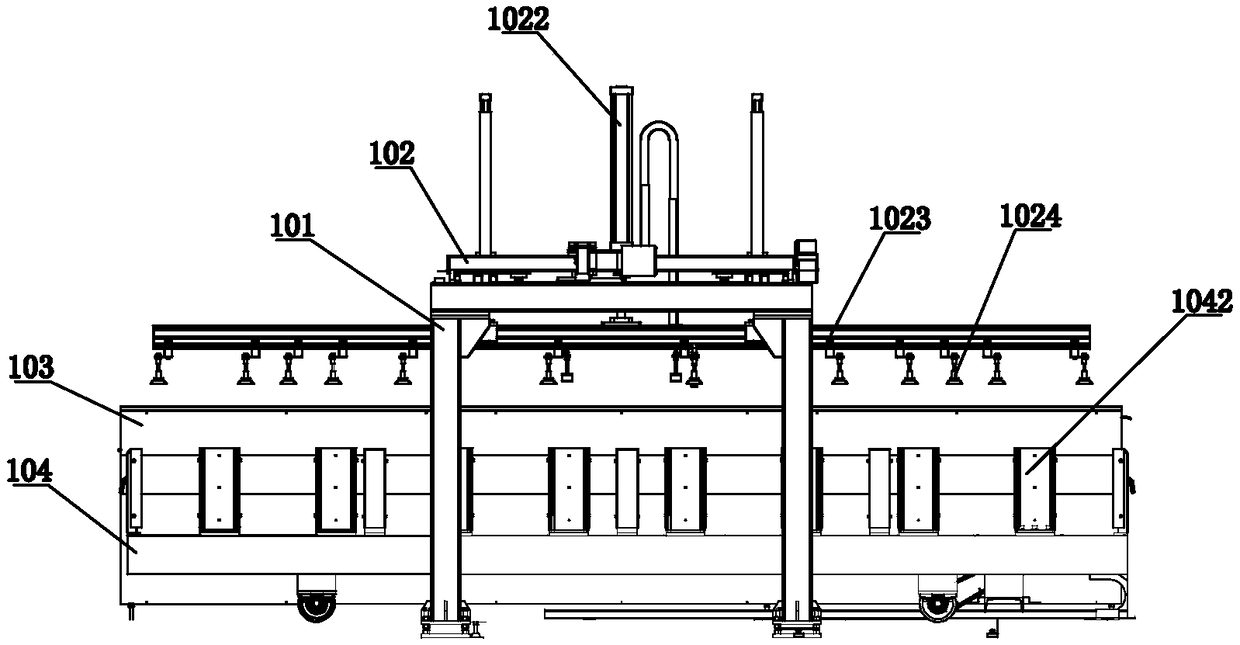

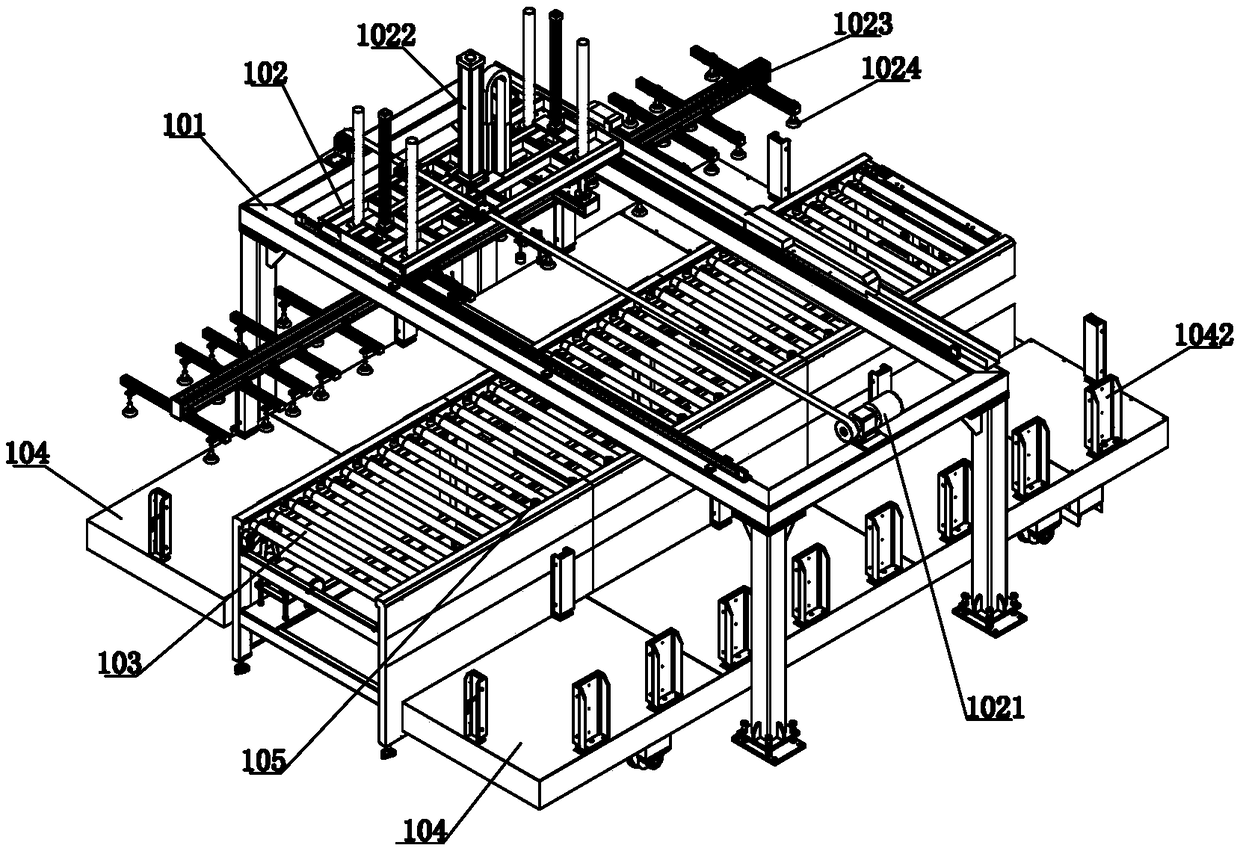

Flexible production line for refrigerator shell

PendingCN109433914AMeet production needsFlexible size changeMetal-working feeding devicesPositioning devicesProduction linePunching

The invention discloses a flexible production line for a refrigerator shell. A feeding machine, a punching machine, a 180-degree overturning machine, a flexible bending machine, a condenser attachingbelt conveying line, Z-shaped and L-shaped bending machines, a U-shaped bending machine and a discharging manipulator are arranged on the production line sequentially, wherein the flexible bending machine comprises a base, a conveying table and two shoulder seats, the conveying table is arranged on the base, the two shoulder seats are symmetrically arranged on two sides of the conveying table, andmaterial supporting frames, material pressing frames and bending frames are arranged on the shoulder seats. The material supporting frames are fixed to the side surfaces of the shoulder seats, supporting planes are arranged on the material supporting frames, the supporting planes correspond to the conveying surface of the conveying table, the material pressing frames can move up and down relativeto the shoulder seats, pressing planes are arranged below the material pressing frames, the pressing planes correspond to the supporting planes up and down, the bending frames are positioned on the side edges, facing away from the conveying table, of the material supporting frames, the bending frames can move up and down or move in the width direction of the shoulder seats, and bending convex edges are arranged on the bending frames. The flexible production line for the refrigerator shell can machine the refrigerator shell with different structures.

Owner:CHINA NAT ELECTRIC APP RES INST +1

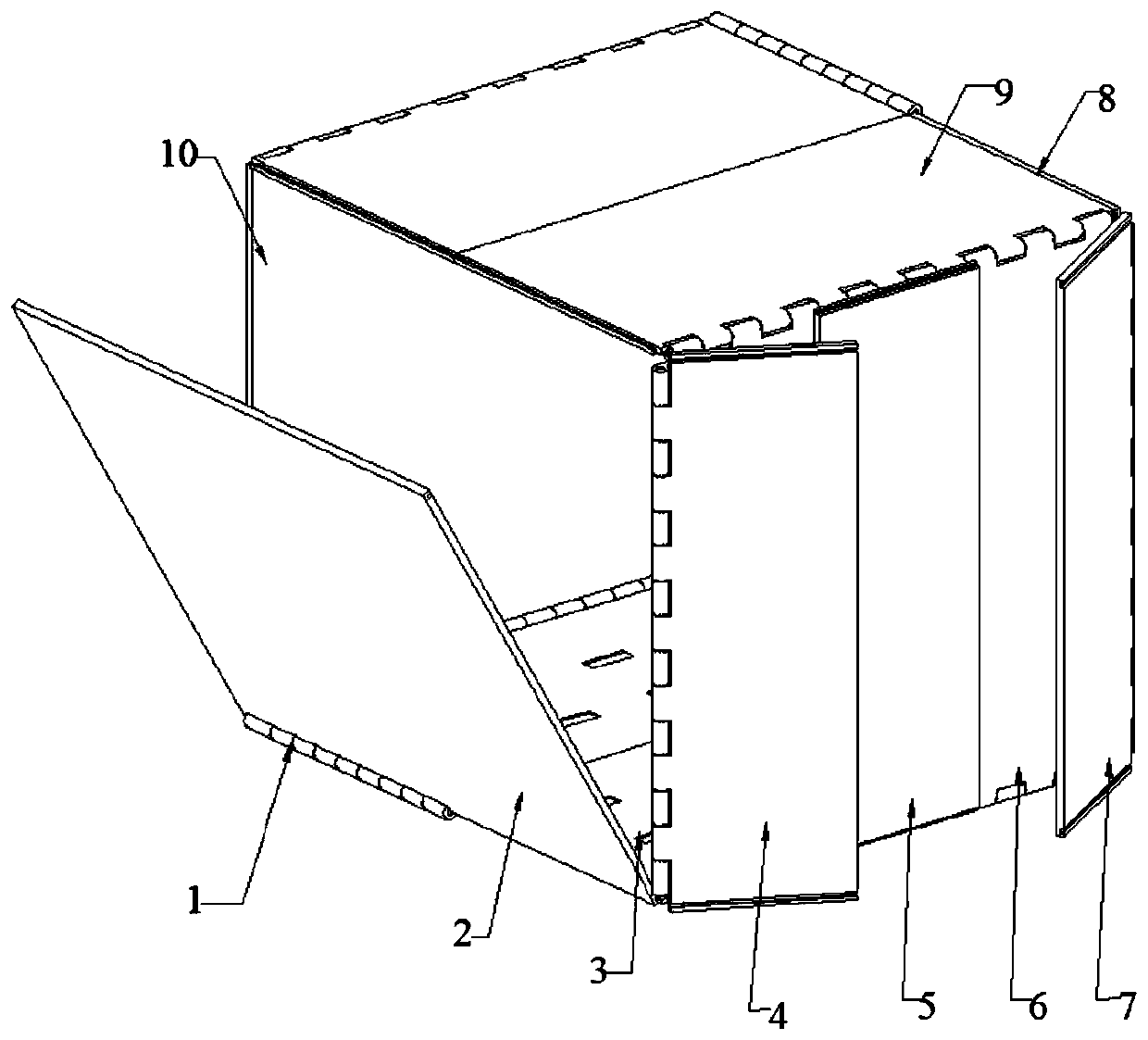

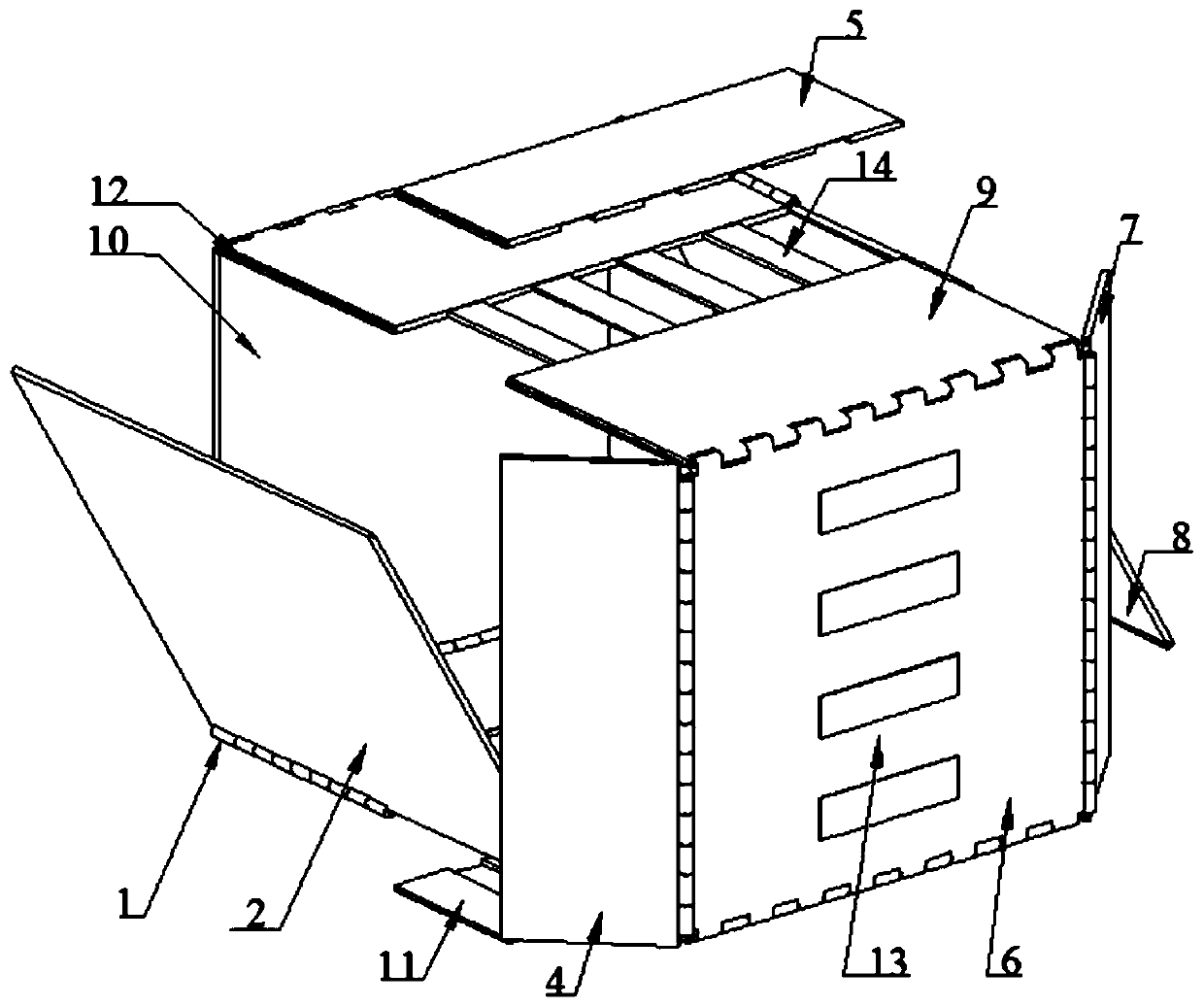

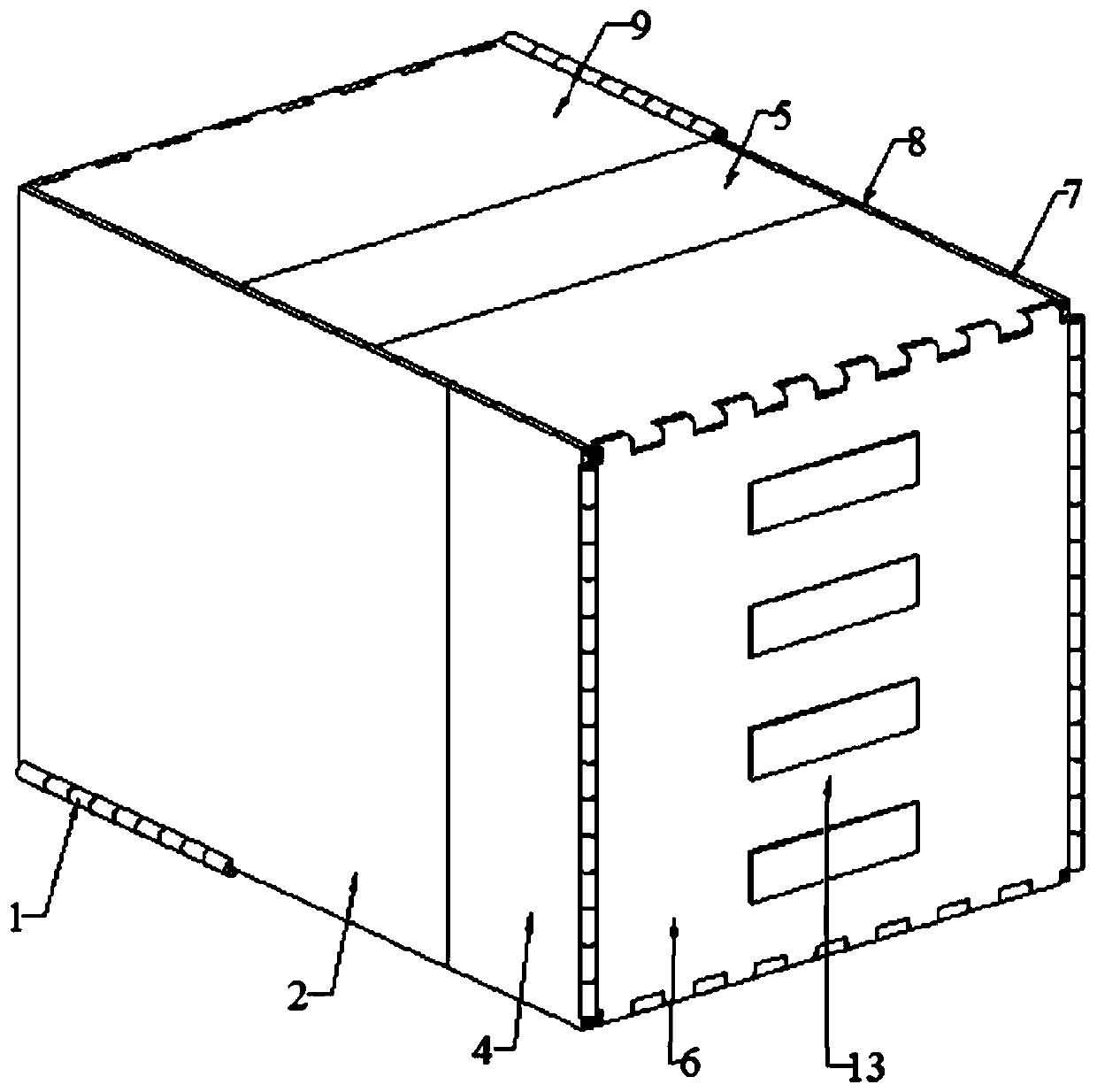

Variable-size environment-friendly packaging box and using method thereof

PendingCN110893930AVerify mechanical reliabilityHigh number of reusesVariable capacity containersStructural engineeringMechanical engineering

The invention discloses a variable-size environment-friendly packaging box and a using method thereof. The packaging box comprises a box body frame, a front panel and a rear panel; the box body framecomprises a top panel, a bottom panel, a left supporting panel and a right supporting panel; each of the top panel and the bottom panel comprises two splicing panels connected through a sliding rail;each of the front panel and the rear panel comprises a main board and a splicing board, and the main board and the splicing board are connected with the box body frame; and the box body frame is sealed through the main board, or the front side and the rear side of the box body frame are sealed by the main board and the splicing board, and the top and the bottom of the box body frame are sealed byfilling the top and bottom splicing panel. According to the packaging box, the functions of repeated disassembly, repeated use and convenient recycling are achieved, the size of the box body in the original form can be increased by stretching of the space of the box body, the size of the box body of the packaging box can be flexibly changed, and therefore commodities of different specifications can be packaged.

Owner:SHAANXI UNIV OF SCI & TECH

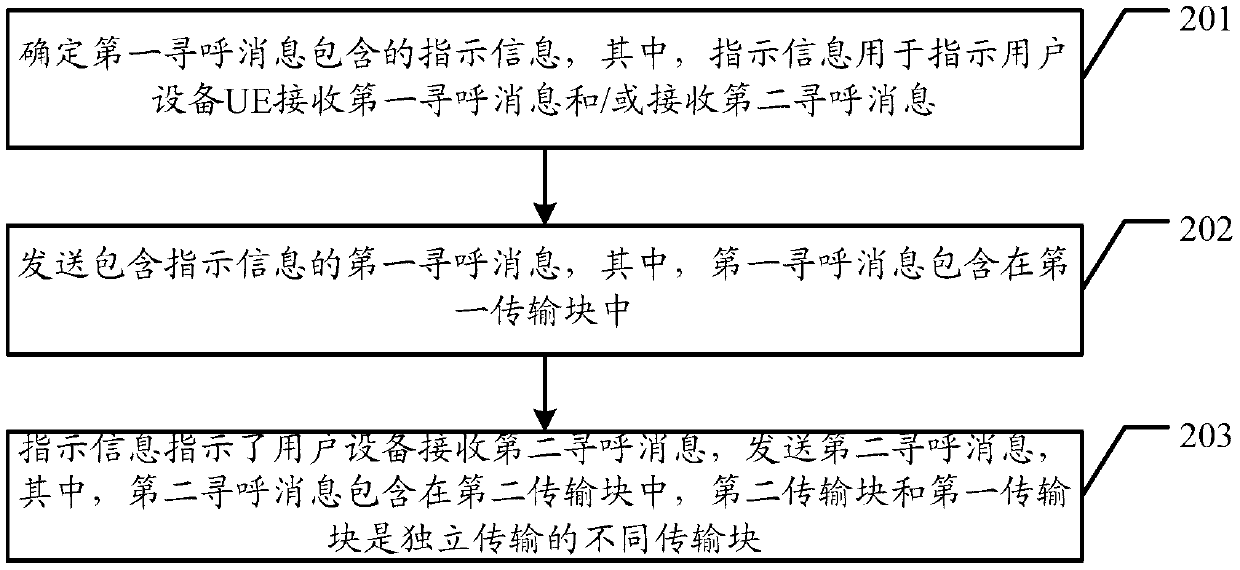

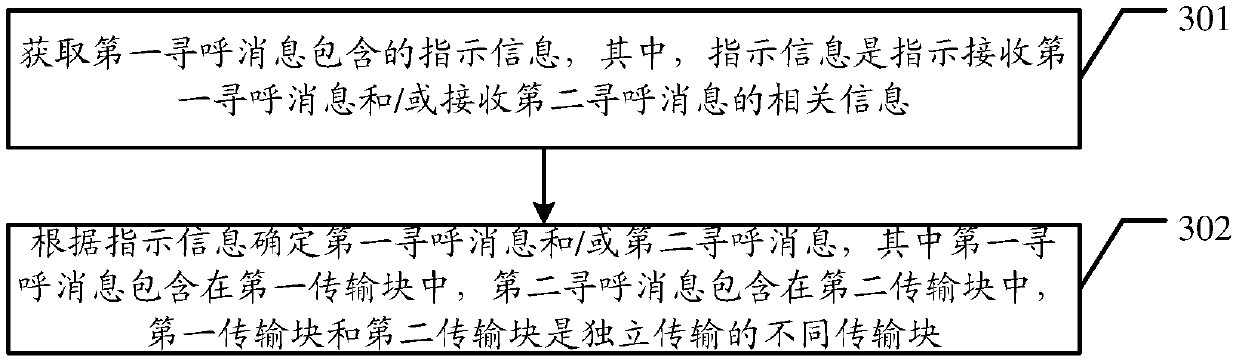

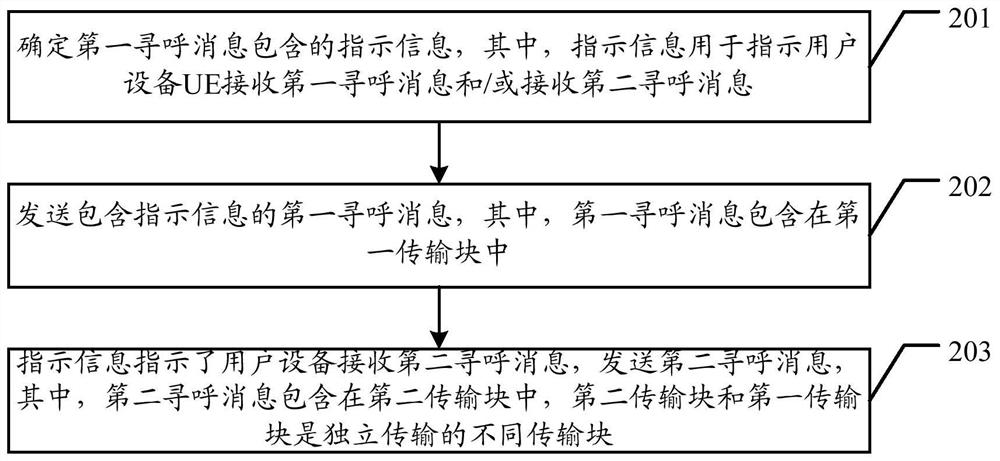

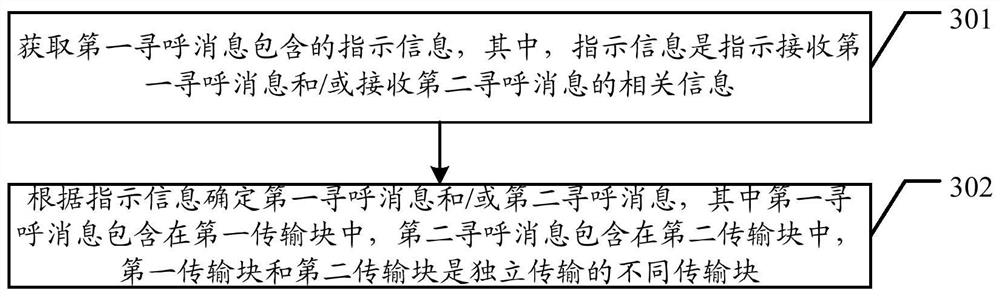

A method for transmitting paging message, base station and user equipment

ActiveCN107211390BReduce detection power consumptionFlexible size changeWireless communicationPagingUser equipment

A method for transmitting a paging message, a base station, and user equipment, wherein a method for transmitting a paging message includes: determining indication information contained in a first paging message, wherein the indication information is used to instruct a user equipment UE to receive The first paging message and / or receiving the second paging message; sending the first paging message including the indication information, wherein the first paging message is included in the first transmission block; the indication information indicates For the user equipment to receive the second paging message and send the second paging message, wherein the second paging message is included in a second transmission block, and the second transmission block and the first A transport block is a distinct transport block that is transmitted independently.

Owner:HUAWEI TECH CO LTD

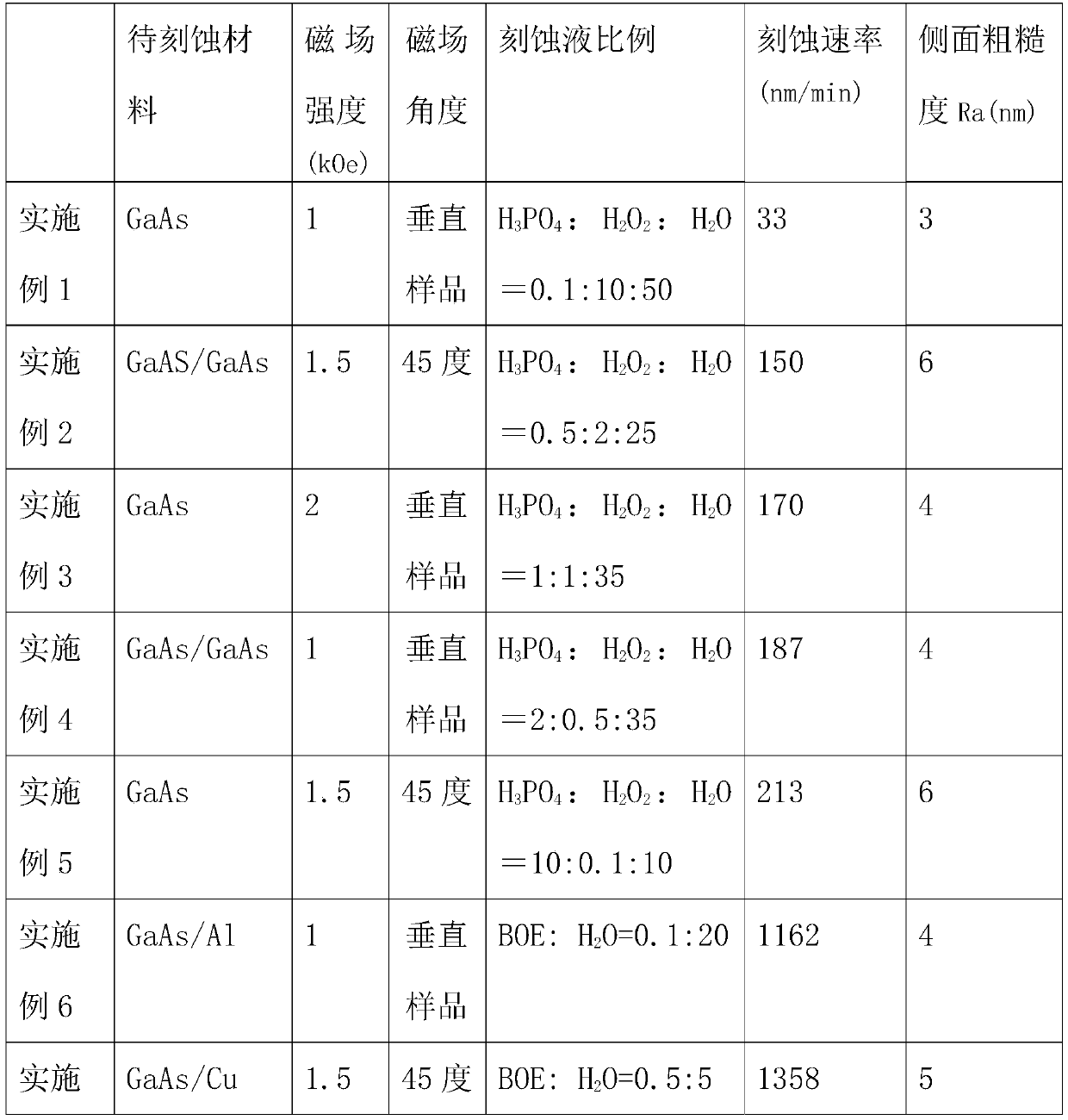

Magnetic field assisted chemical etching device and method

InactiveCN109860039AReduce side damageLow costSemiconductor/solid-state device manufacturingGraphicsSemiconductor materials

The invention provides a magnetic field assisted chemical etching method. The method includes the following steps: S1, performing gluing and photo etching processing on a semiconductor material so that a to-be-etched material can be obtained; and S2, putting the to-be-etched material into an etching liquid, and performing etching under a magnetic field with the intensity being 1 kOe - 2 kOe. A magnetic field assisted chemical etching device is also provided. The device includes a solution bottle and a magnetic field excitation device; the solution bottle is used for accommodating the etching liquid and the to-be-etched material; and the magnetic field excitation device is arranged at the external of the solution bottle and used for providing a stable magnetic field. Through the addition ofconventional chemical etching and the magnetic field, anions and cations in the etching solution can move along a certain direction, so that directional etching can be realized, damages to the side surfaces of retained graphics can be reduced, the moving ions can be accelerated, and etching rates can be enhanced; and the method is simple in operation, low in cost and wide in application range, and can realize the directional chemical etching of all common semiconductor chips at the present stage.

Owner:SUZHOU JUZHEN PHOTOELECTRIC

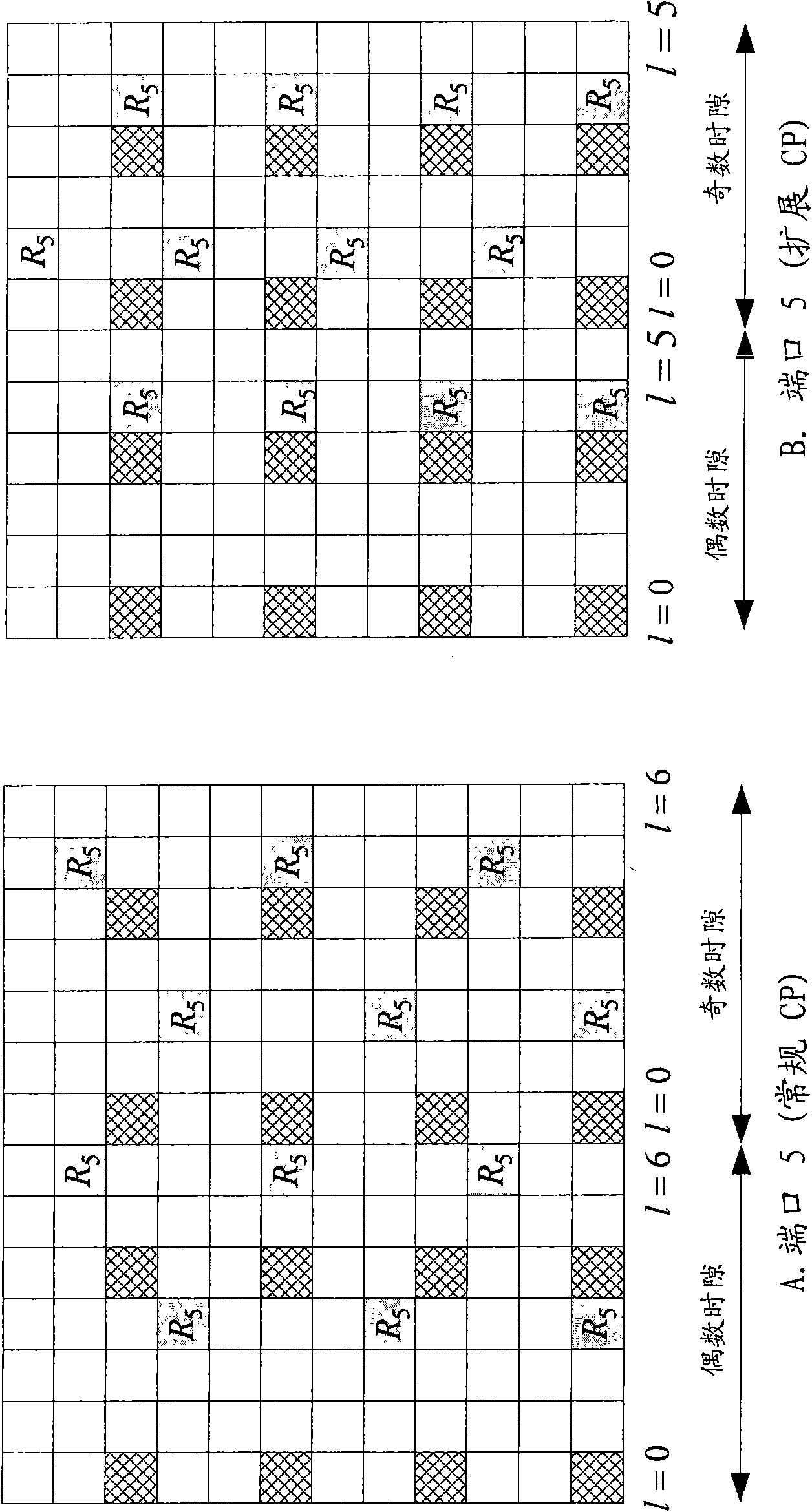

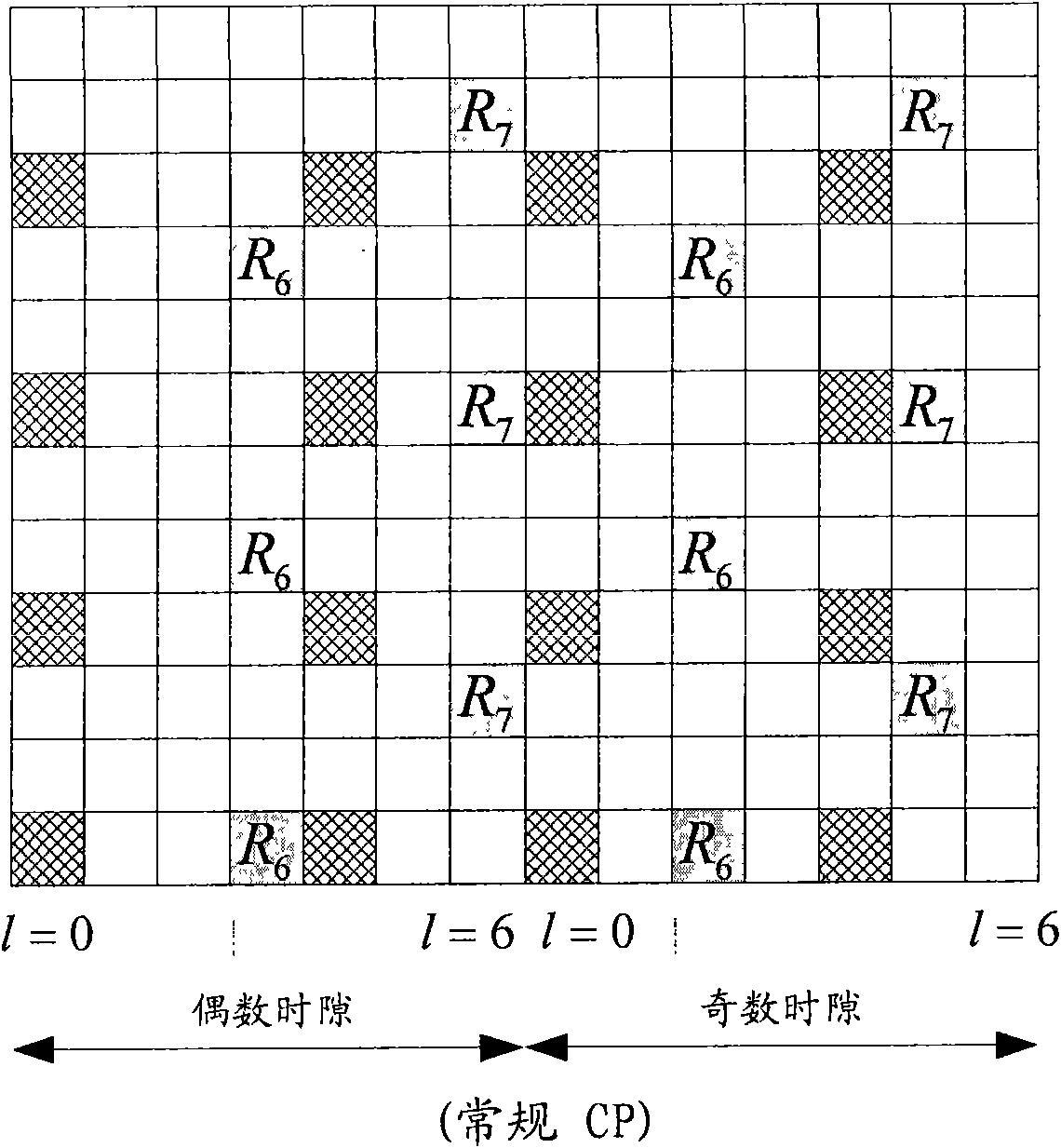

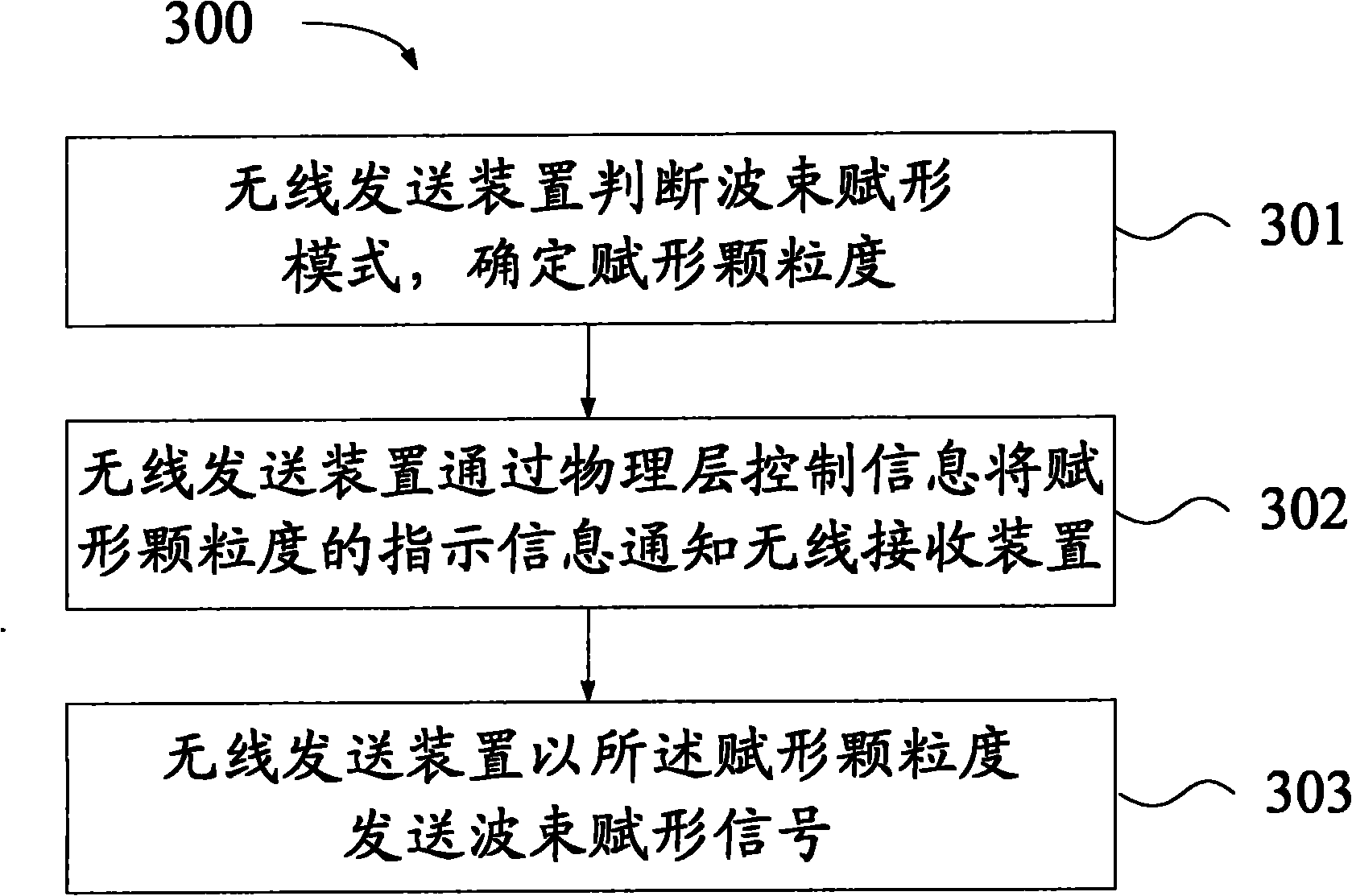

Indication method, system and device of beam-forming granularity

ActiveCN101771452AImprove demodulation performanceFlexible changeSpatial transmit diversityEngineeringBeamforming

The invention provides an indication method, a system and a device of beam-forming granularity. A wireless transmitting device judges a beam-forming mode to be adopted and confirms the beam-forming granularity of a beam-forming signal to be sent; the wireless transmitting device informs a wireless receiving device with the indication information of the beam-forming granularity by the control information of a physical layer; and the wireless transmitting device sends the beam-forming signal to the wireless receiving device based on the beam-forming granularity. By adopting the method, the system and the device of the invention, the indication problem of the beam-forming granularity during beam-forming transmission is effectively solved, and the demodulation performance of the system is improved.

Owner:DATANG MOBILE COMM EQUIP CO LTD

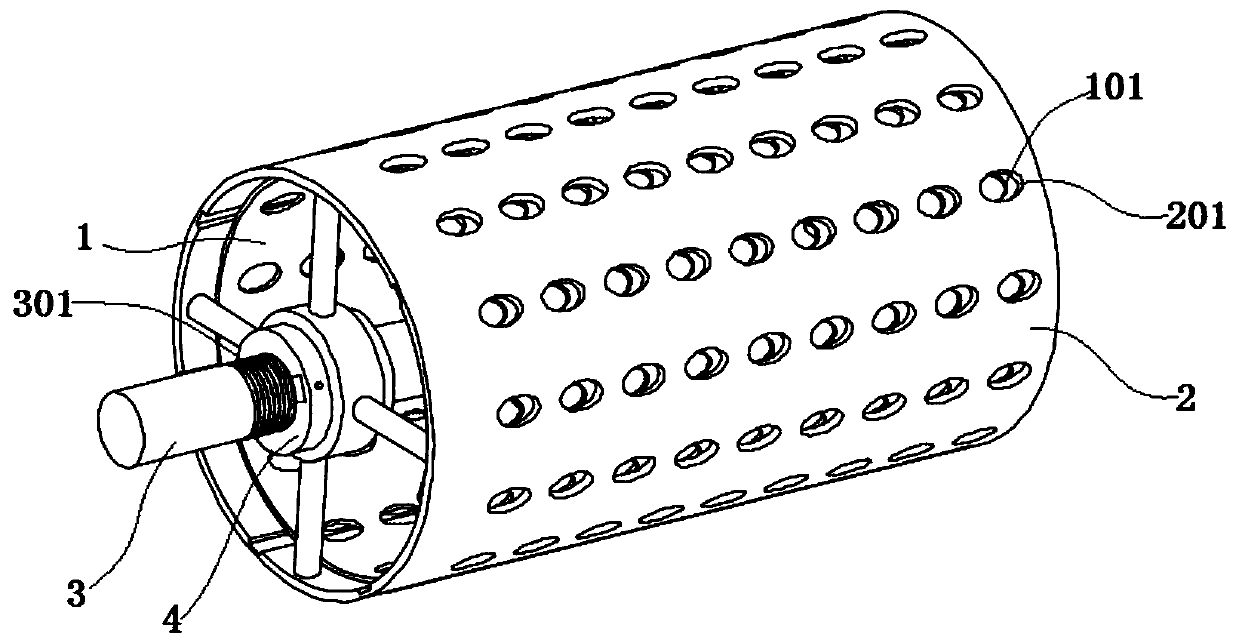

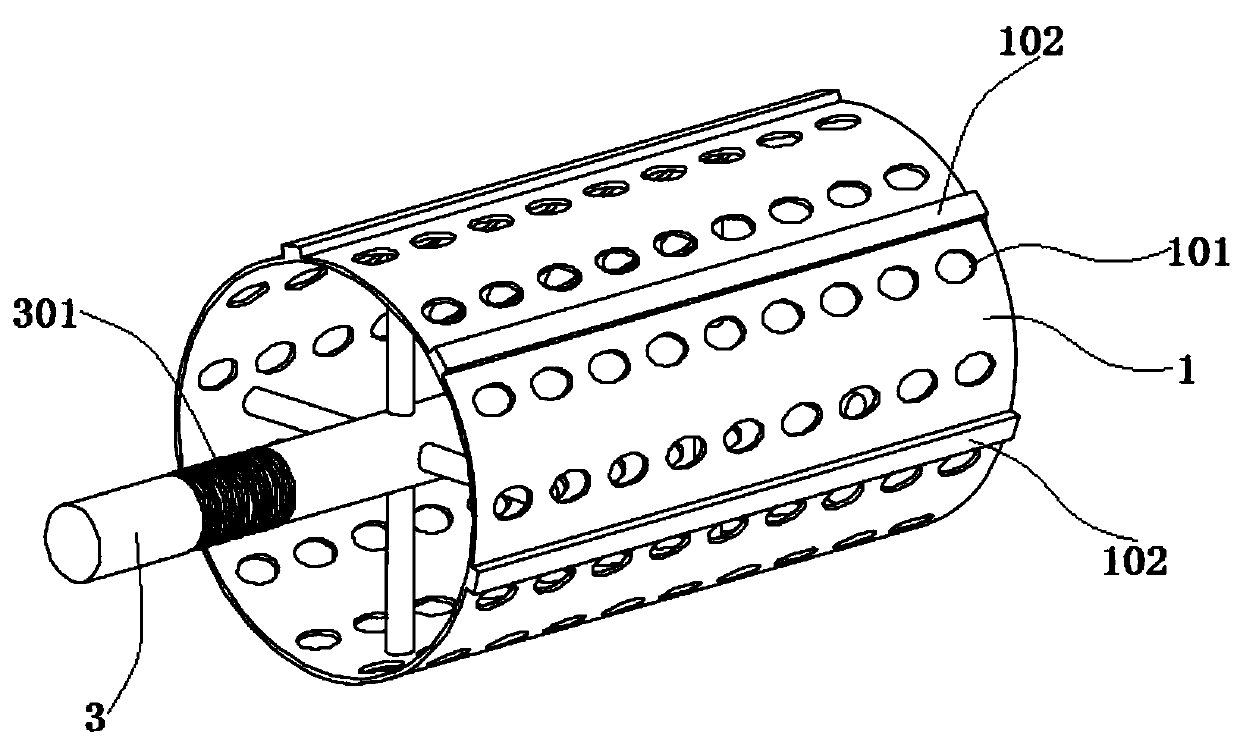

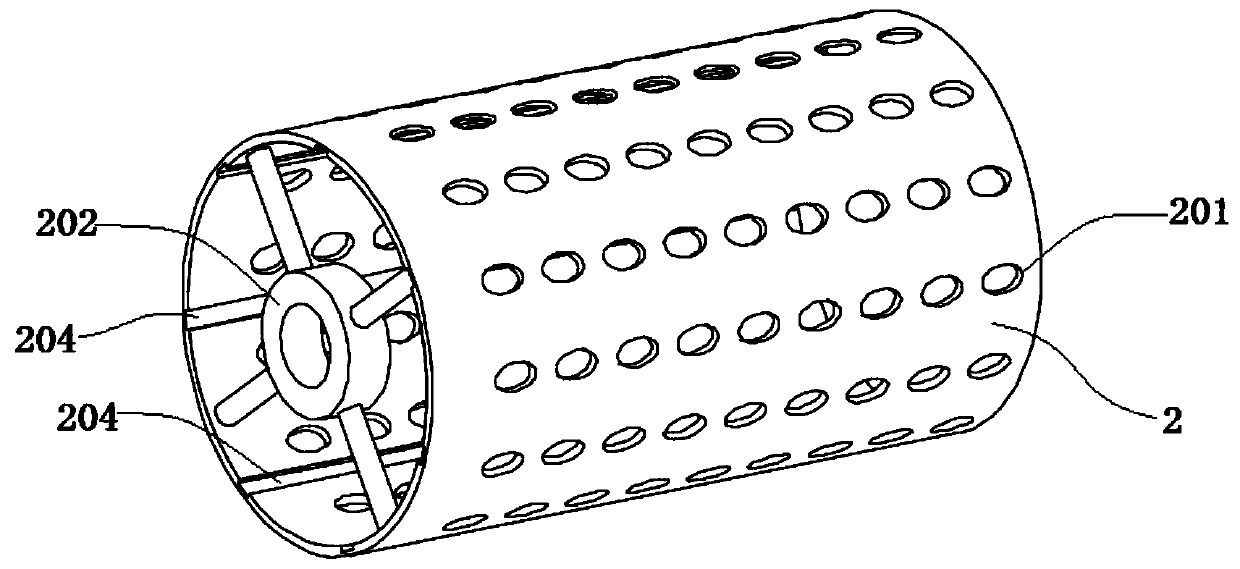

Screening device for wear-resisting ball machining

InactiveCN111330833AFlexible Mesh SizeChange mesh sizeSievingScreeningScreens (device)Structural engineering

The invention discloses a screening device for wear-resisting ball machining, and relates to the technical field of wear-resisting ball production. The screening device for wear-resisting ball machining comprises an inner roller screen and an outer roller screen; the inner surface of the inner roller screen is fixedly connected with a transmission shaft through a connecting rod; first screen holesare arrayed in the peripheral side surface of the inner roller screen; external threads are arranged on the peripheral side of the transmission shaft; the inner surfaces of the two ends of the outerroller screen are fixedly connected with a first connecting sleeve and a second connecting sleeve through connecting rods correspondingly; and the first connecting sleeve is connected with the transmission shaft through an adjusting sleeve. According to the screening device for wear-resisting ball machining, the inner roller screen and the outer roller screen which can be in sliding fit with eachother are arranged, and the size of a screen mesh is changed through utilizing mutual dislocation between the first screen holes and second screen holes, so that the problems that screen equipment cannot adapt to screening of multi-size wear-resisting balls and consequently is poor in adaptability are solved; and meanwhile, through mutual dislocation adjustment between the first screen holes and the second screen holes, the wear-resisting balls clamped in the screen holes can be effectively removed, and the problems that the production efficiency and the production cost are influenced due to the fact that manual cleaning is needed can be solved.

Owner:合肥新士鑫机械科技有限公司

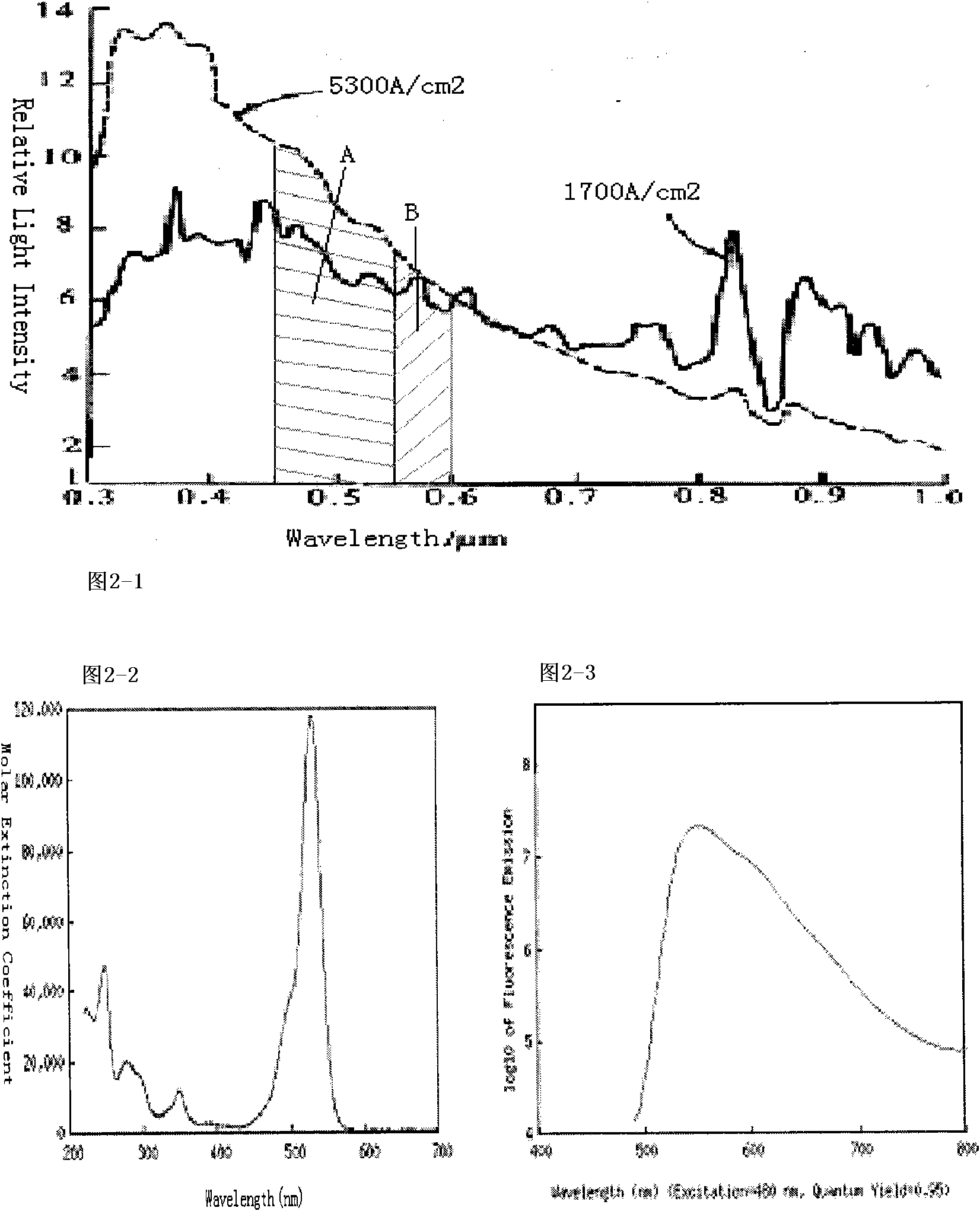

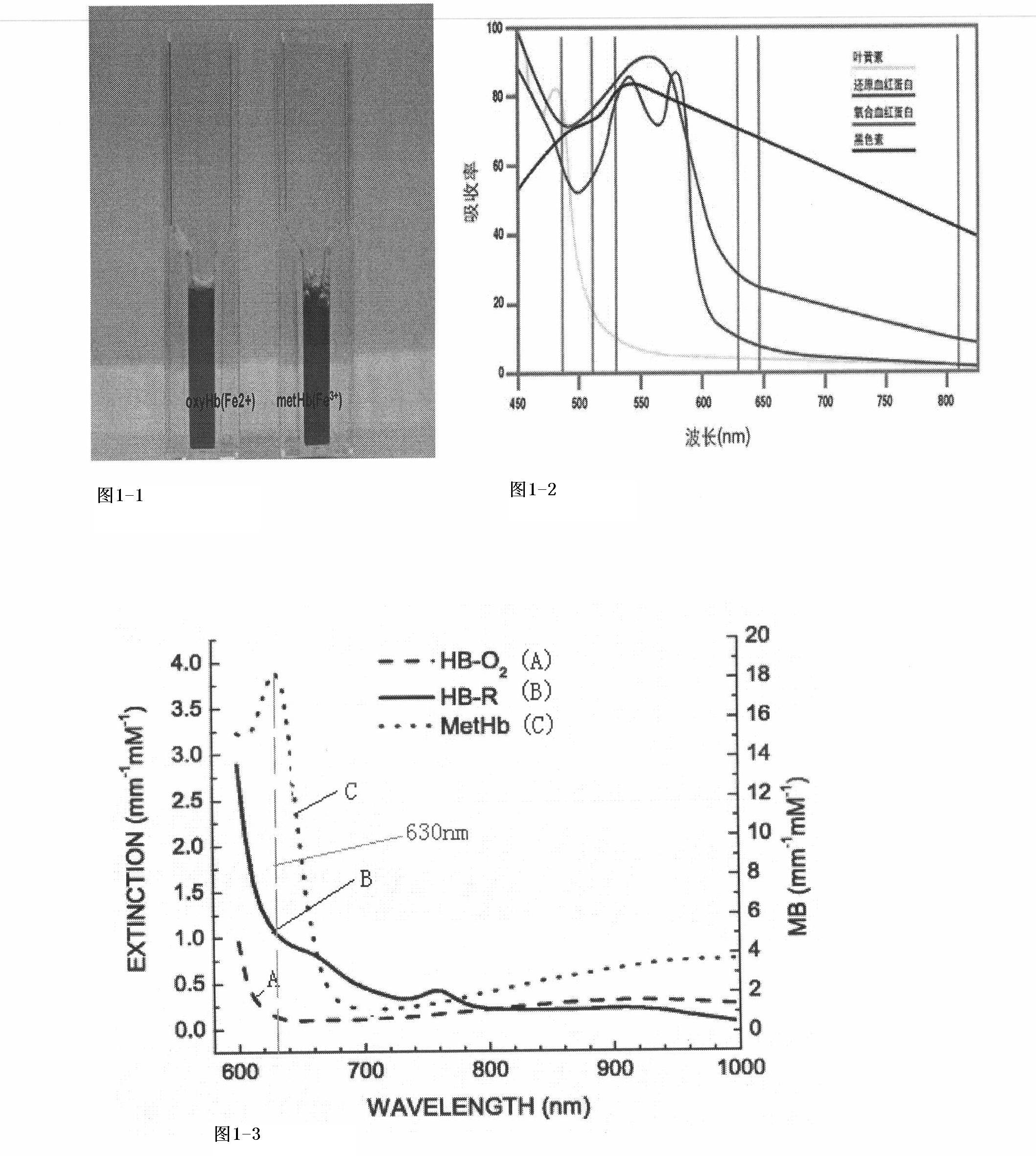

Dermovascular disease therapeutic instrument adopting dye conversion

ActiveCN102488972AAvoid replacementChange sizeLight therapyTherapeutic effectNear infrared radiation

The invention relates to a therapeutic instrument for dermovascular diseases. The dye conversion function is utilized. The utilization rate of the spectral radiation of the xenon lamp is increased. By changing the discharge current density of the xenon lamp, the spectral distribution of the radiation of the xenon lamp is changed; and by utilizing stronger near-infrared radiation, the treatment effect of deep angionosis can be enhanced. Compared with the existing photon machine used for treating angionosis at home and abroad, the treatment function is greatly increased. Compared with the dye and YAG dual-wavelength laser all-in-one machine abroad, the energy utilization rate is high, namely energy is saved, the structure is simple, and the cost is greatly reduced. Therefore, the therapeutic instrument has very high international competitiveness.

Owner:永清马文光电科技有限公司

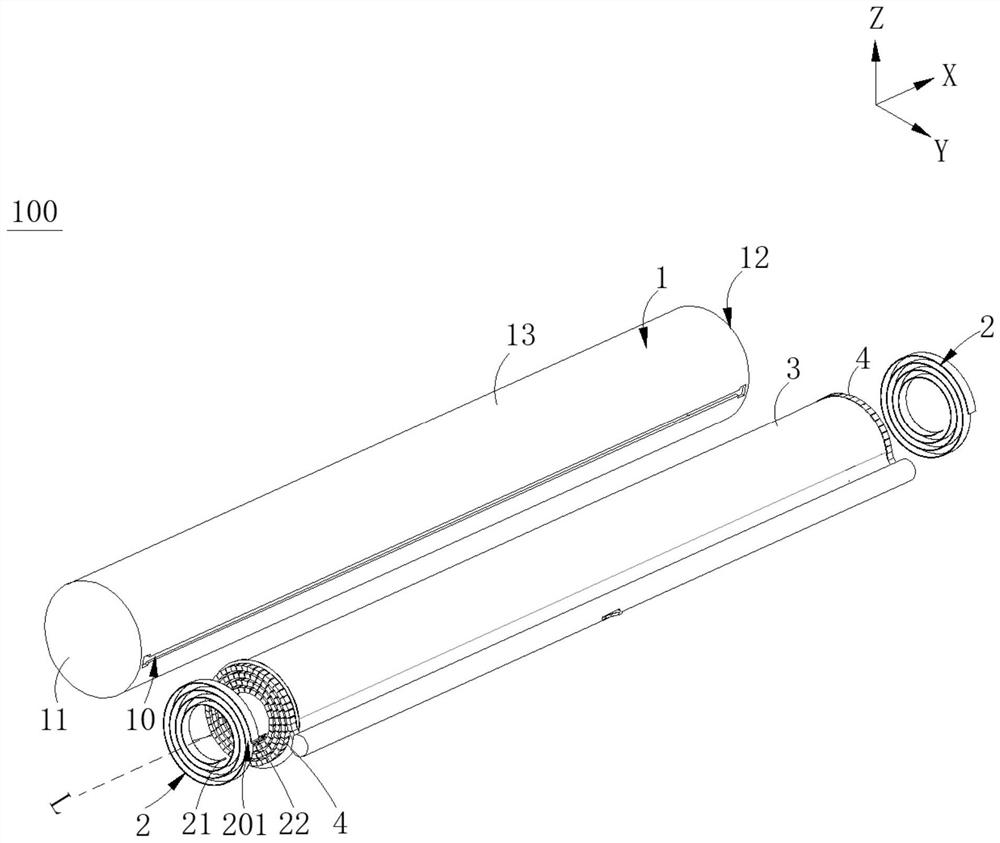

Scroll screen and electronic equipment

PendingCN114464091AThe size of the screen area can be changed flexiblyImprove user experienceIdentification meansPhysicsEngineering

The invention relates to the technical field of scroll screens, in particular to a scroll screen and electronic equipment. The scroll screen comprises a first shell and a second shell, wherein the first shell is provided with a containing cavity; the spiral guide piece is arranged on the first shell and located in the containing cavity, the spiral guide piece is provided with a starting end and a terminating end, and the spiral radius of the spiral guide piece is gradually increased in the direction from the starting end to the terminating end, so that a spiral cavity channel is formed by the spiral guide piece; the spiral cavity channel comprises a cavity channel opening close to the terminating end, and an opening communicated with the cavity channel opening is formed in the first shell; and the flexible screen is arranged in the spiral cavity channel in a reciprocating sliding mode in the spiral direction of the spiral guide piece. According to the scroll screen provided by the invention, the size change of the screen area of the scroll screen is gradually changed, and the size change of the screen area is very flexible.

Owner:WINGTECH COMM

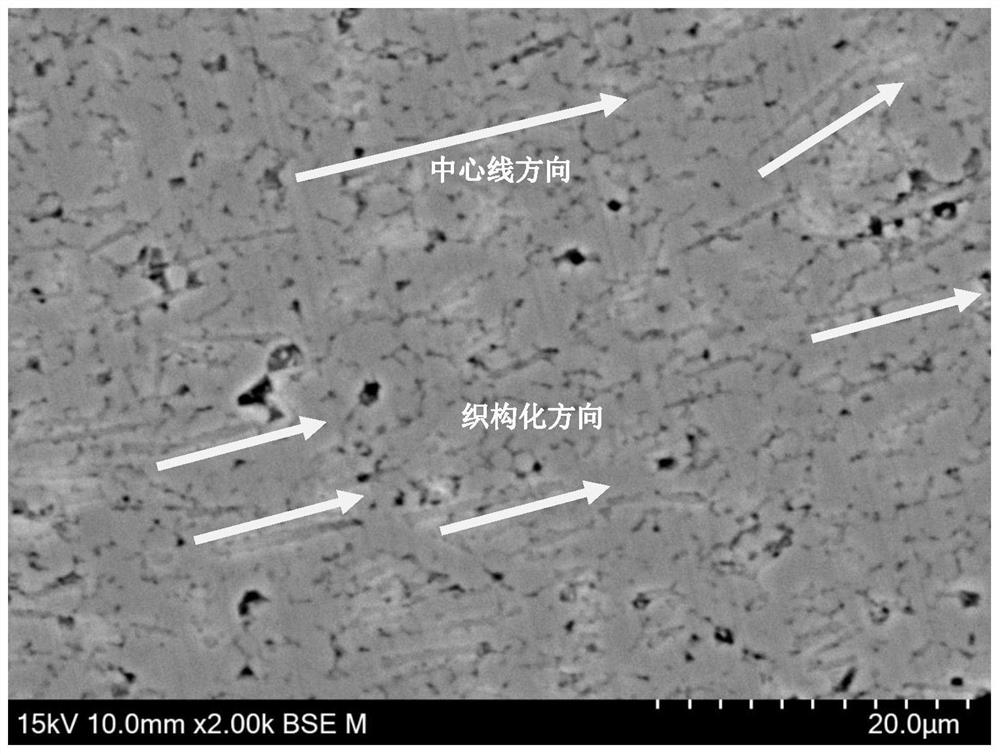

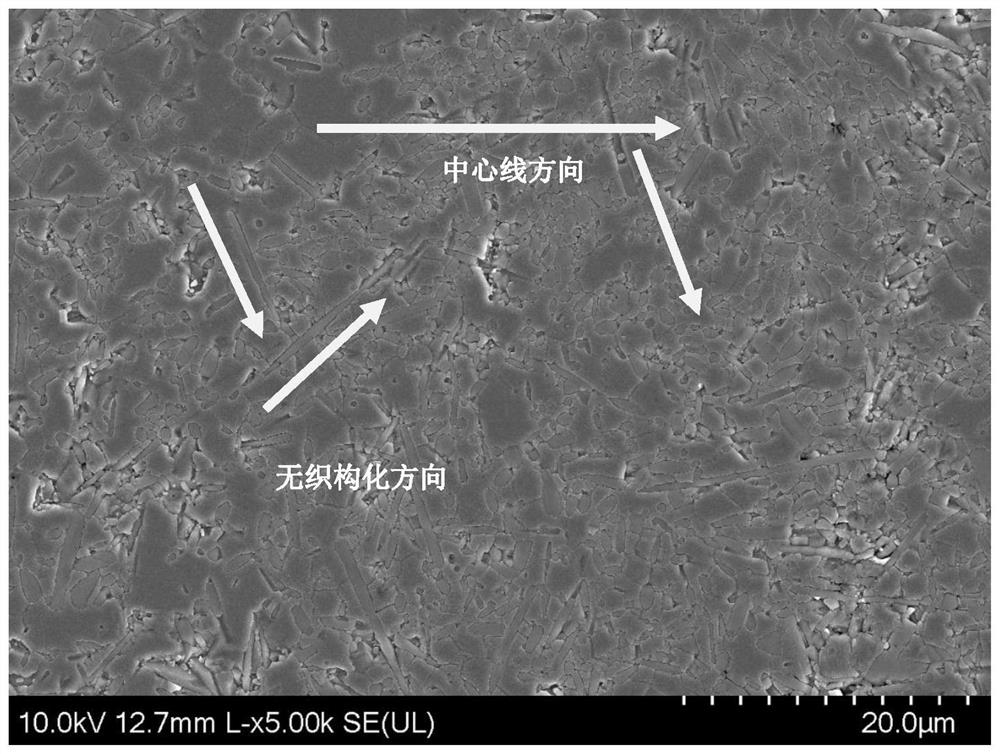

Textured silicon carbide whisker toughened alumina-based ceramic, preparation method and application thereof

ActiveCN112079645AImprove wear resistanceHigh thermal conductivityCeramic shaping apparatusParaffin waxCarbide silicon

The invention belongs to the field of composite gradient ceramics, and discloses textured silicon carbide whisker toughened alumina-based ceramic, a preparation method and application thereof. The alumina-based ceramic is prepared by the following steps of: taking alumina, silicon carbide whiskers and a sintering aid MgO or Y2O3 as the raw materials, and adopting paraffin as a structural aid, mixing the raw materials to obtain mixed powder, dispersing the mixed powder into liquid hot paraffin, performing casting and cooling to obtain a casting, extruding the casting at normal temperature to realize texturing, and removing paraffin at high temperature to obtain a green body, and axially pressurizing the green body to 20-50MPa, performing heating to 1500-1800DEG C, and conducting sintering.According to the method, preparation of the textured alumina-based ceramic with the silicon carbide whiskers arranged in the radial direction is achieved, the textured alumina-based ceramic has high abrasion resistance and heat conductivity on a friction surface, the cutting temperature can be reduced when heat-resisting alloy and high-hardness metal materials are machined at a high speed, and thetextured alumina-based ceramic has higher stability, compared with common ceramic cutters in the market, the ceramic cutter made of the textured silicon carbide whisker toughened alumina-based ceramic has obvious application advantages.

Owner:GUANGDONG UNIV OF TECH

Paging message transmission method, base station and user equipment

ActiveCN111918390AReduce detection power consumptionFlexible size changeWireless communicationPagingUser equipment

Provided are a paging message transmission method, a base station and a user equipment, the paging message transmission method comprising: determining indication information contained in a first paging message, with the indication information being used for indicating a user equipment (UE) to receive the first paging message and / or receive a second paging message; sending a first paging message containing the indication information, wherein the first paging message is contained in a first transmission block; wherein the indication information indicates that the user equipment receives the second paging message and sends the second paging message, the second paging message is contained in a second transmission block, and the second transmission block and the first transmission block are different transmission blocks which are independently transmitted.

Owner:HUAWEI TECH CO LTD

Modular saw chain type cutting box and using method thereof

The invention discloses a modular saw chain type cutting box and a using method thereof. The cutting box comprises a body module box, a front end module box, a rear end module box and a saw chain set;the front end module box is detachably installed at the front end of the body module box; the rear end module box is detachably installed at the rear end of the body module box; a front slide rail isarranged on the outer side of the front end module box in the height direction; a rear slide rail is arranged on the outer side of the rear end module box in the height direction; the saw chain set comprises a chain and cutters installed on the chain at certain intervals; and the chain is encircled on the front slide rail and the rear slide rail to form closed loop chain transmission. The modularsaw chain type cutting box and the using method thereof can achieve modular assembling of the cutting box, can be suitable for continuous wall construction of mud protecting walls, and can be also besuitable for continuous wall construction of synchronous cutting pouring concrete.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

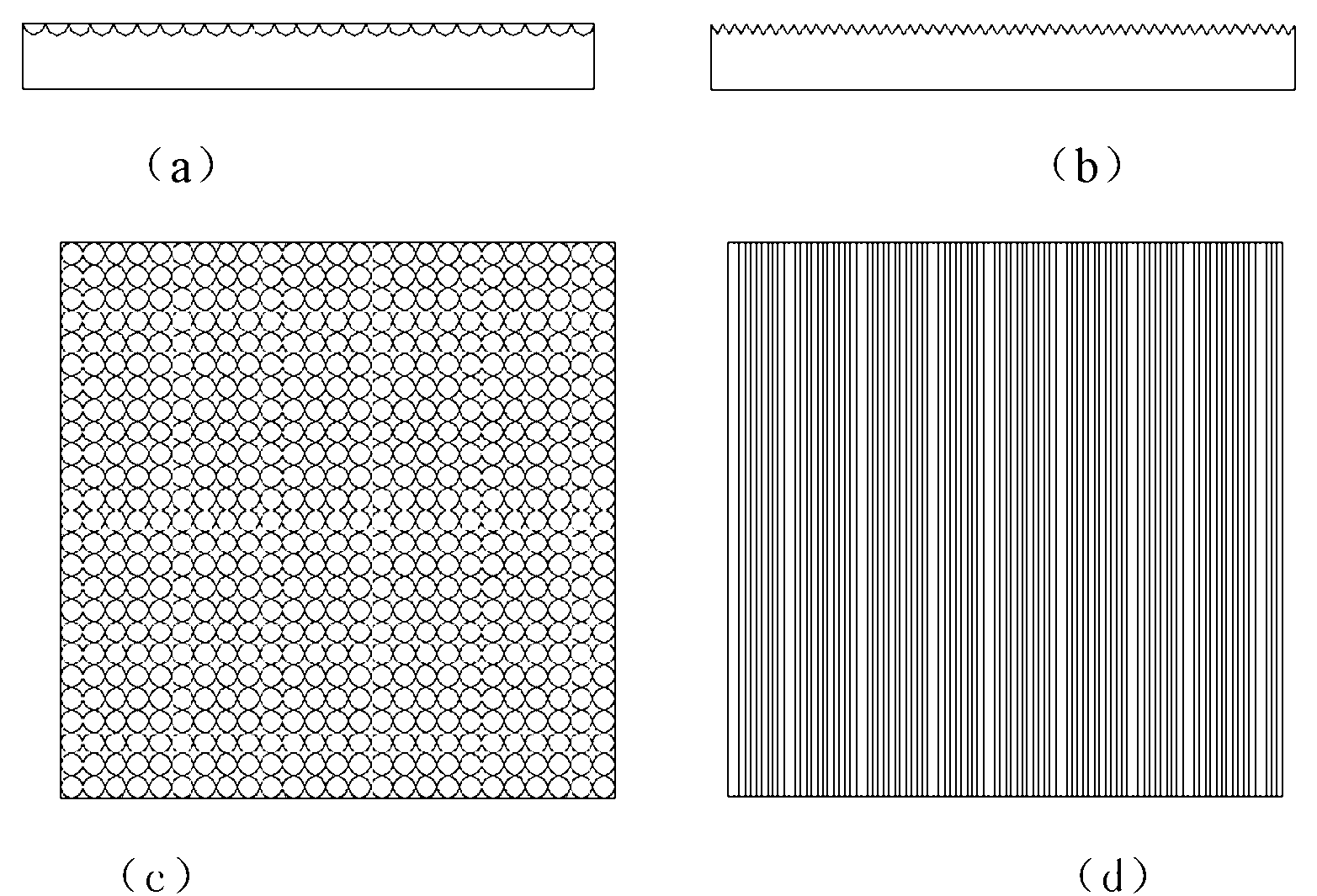

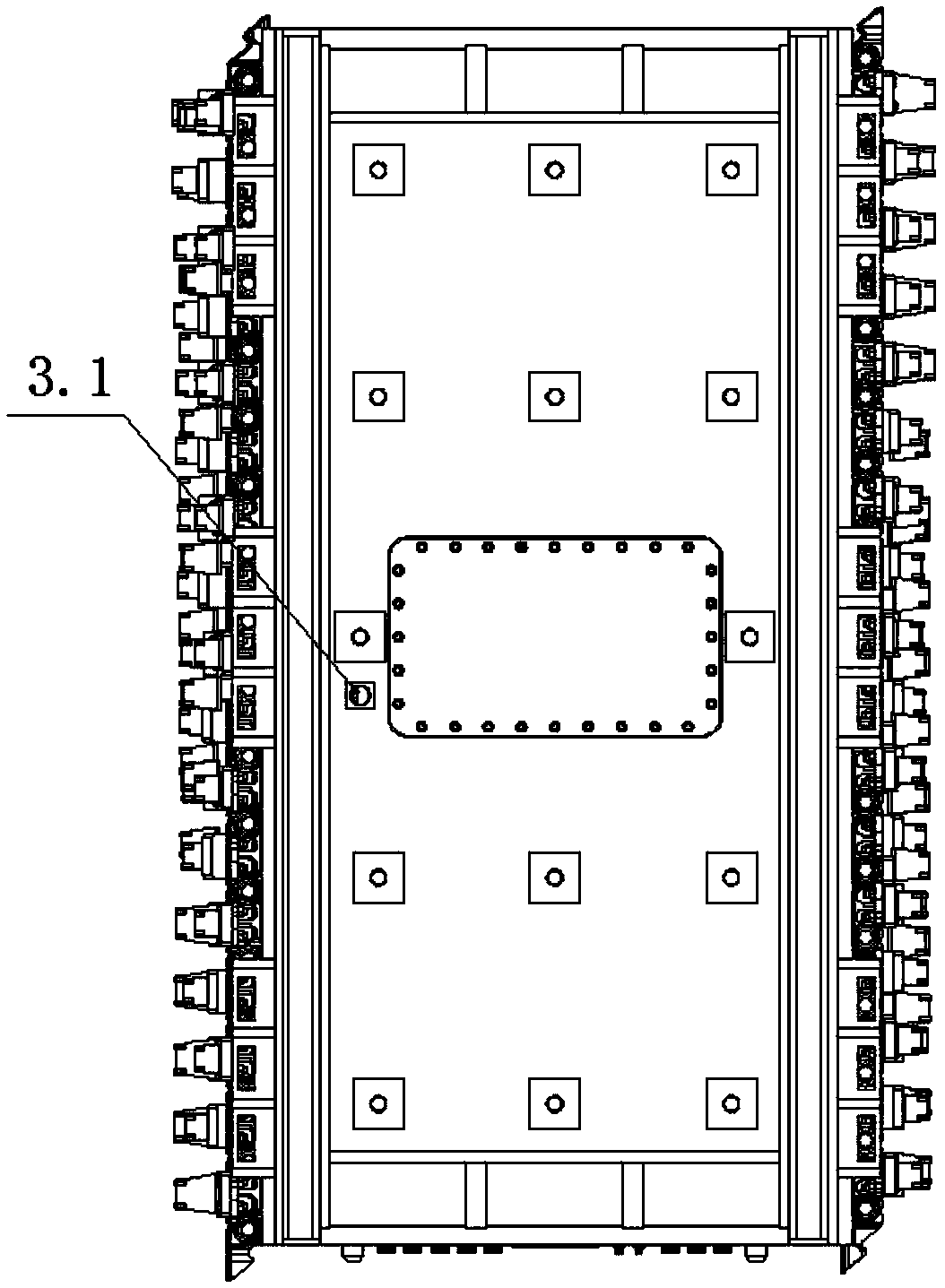

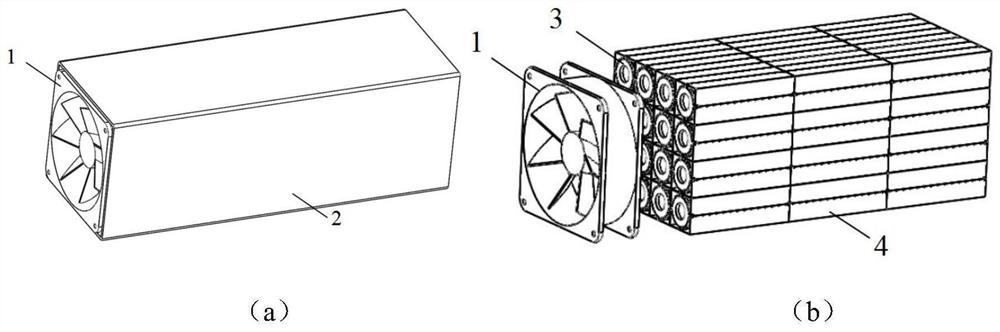

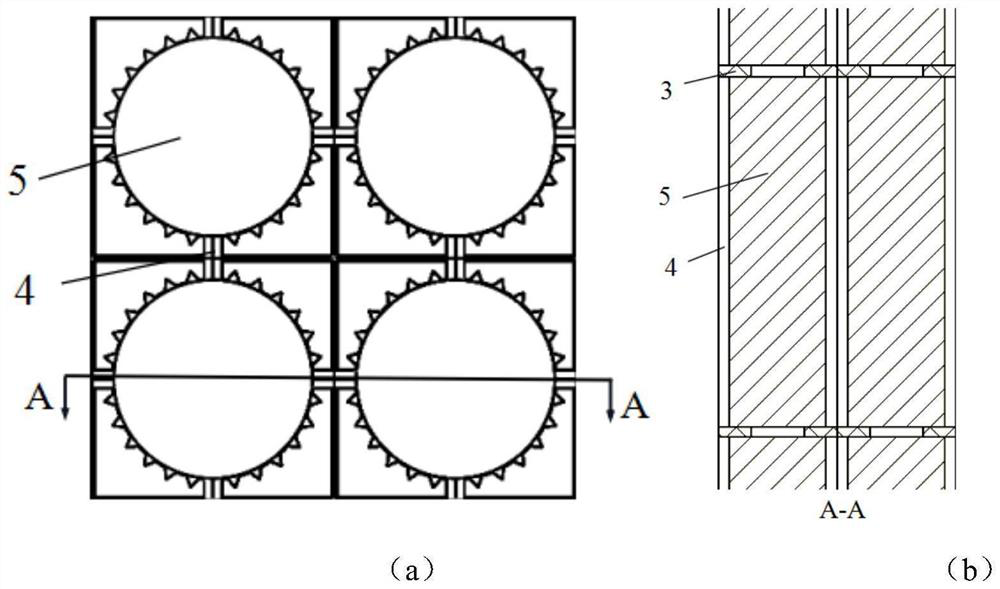

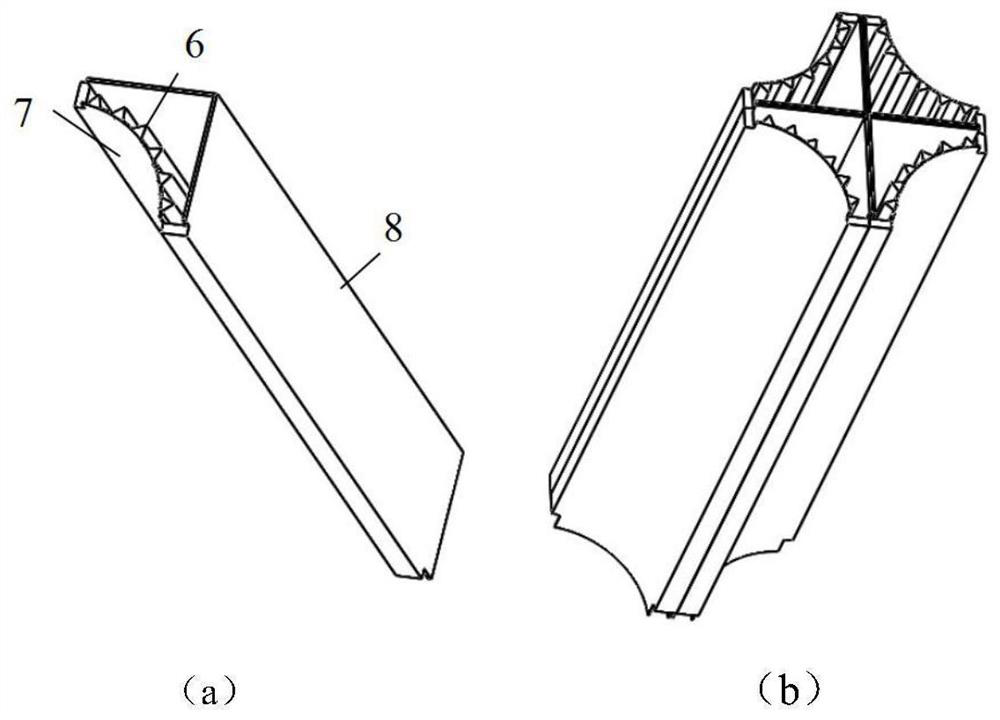

Air-cooled cylindrical power battery pack containing bionic surface microstructure heat dissipation piece

ActiveCN112038727AFlexible size changeEnhance heat transfer efficiencySecondary cellsPower batteryEngineering

The invention discloses an air-cooled cylindrical power battery pack containing a bionic surface microstructureheat dissipation piece, and belongs to the technical field of power battery thermal management. The battery pack mainly comprises a fan, a shell, an insulating fixing frame, the bionic surface microstructure heat dissipation piece and a cylindrical power battery, wherein the outer side ofthe curved surface of the bionic surface microstructure heat dissipation piece is in contact with the surface of the battery, and the inner side of the curved surface is provided with a bionic surface microstructure. The cylindrical power battery is axially arranged, and when the fan drives the cooling air flow to enter the battery pack, the bionic surface microstructure heat dissipation piece can improve the heat exchange efficiency between the cooling air flow and the battery. The insulating fixing frame is arranged between each row of batteries and plays a role in supporting and insulating. On the basis of traditional axial air cooling, the bionic surface microstructure heat dissipation piece is added, the size and the structure of the battery pack are not changed, and the battery packhas the advantages of being convenient to install, simple in structure, enhanced in heat dissipation effect and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com