High-power LED packaging structure

A technology of light-emitting diodes and packaging structures, which is applied to electrical components, electric solid-state devices, circuits, etc., can solve problems affecting LED brightness and service life, and achieve the effects of saving materials, short heat conduction paths, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

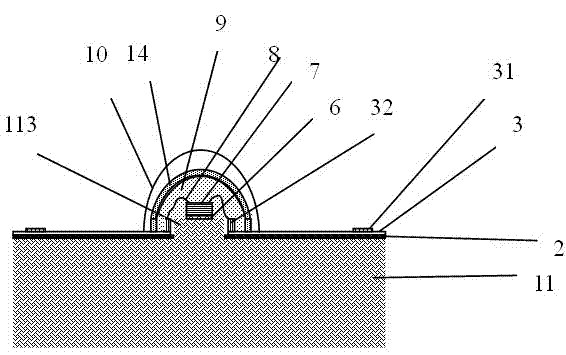

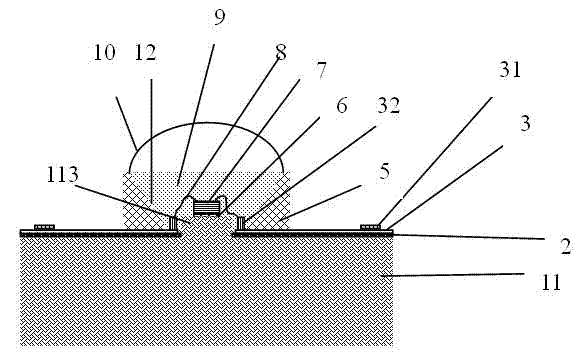

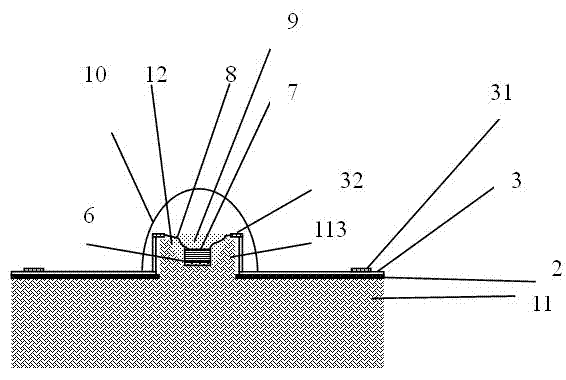

[0030] refer to Figure 1 to Figure 3 As shown, the present invention provides a preferred embodiment of the high-power LED packaging structure, but the embodiment of the present invention is not limited thereto.

[0031] Such as figure 1 As shown: the heat dissipation substrate 11 has a square-shaped protrusion 113 at the center, and the LED chip 7 is fixed on the protrusion 113 through the die-bonding glue 6 . There is an adhesive layer 2 and a circuit layer 3 on the heat dissipation substrate 11 . When the heat dissipation substrate 11 is an insulating material, such as co-fired ceramics, the adhesive layer 2 can be conductive, and when the heat dissipation substrate 11 is conductive, such as copper, the adhesive layer 2 is also an insulating layer. There is a hole in the center of the adhesive layer 2 and the circuit layer 3, and the size of the hole matches the size of the protrusion 113. The heat emitted by the LED chip 7 on the protrusion 113 does not pass through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com