A switch reluctance motor position detection system and detection method

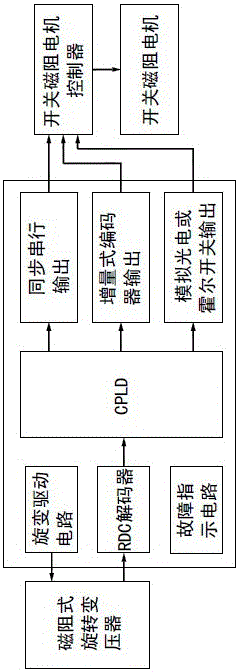

A switched reluctance motor and detection system technology, applied in control systems, electromechanical devices, AC motor control, etc., can solve the problems of being susceptible to interference, single mode, and the lead-out line length of sine and cosine analog position signals, etc., to achieve reliability High, easy to install, reduce interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Figure 1~6 It is the best embodiment of the present invention, below in conjunction with the attached Figure 1~6 The present invention will be further described.

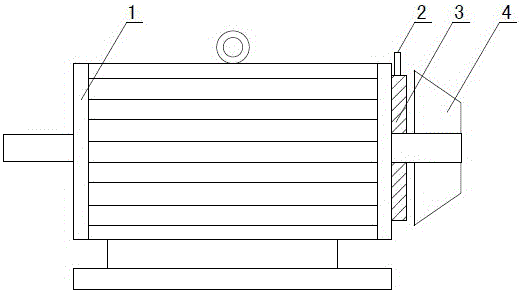

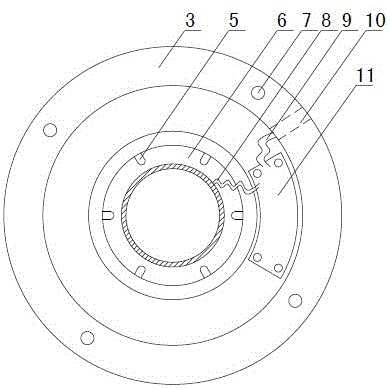

[0040] like figure 1 As shown, a switched reluctance motor position detection system includes a motor stator base 1, a sensor cover 3 is installed at the tail of the motor stator base 1, an extension line 2 is drawn from the side of the sensor cover 3, and the reluctance resolver Located inside the sensor housing 3, the rotor of the reluctance resolver is fixed on the shaft inside the motor. The rotor of the reluctance resolver is installed inside the motor, which has higher reliability when used in harsh environments such as vibration and dust, and can make the motor more beautiful as a whole. The fan 4 is fixed outside the sensor cover 3 .

[0041] In the existing position detection system using a reluctance rotary transformer and a switched reluctance motor, the reluctance rotary transformer is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com