Miniaturized bifunctional line electrode grinding device

A wire electrode grinding, dual-function technology, applied in the direction of grinding machine parts, grinding/polishing equipment, grinding machines, etc., can solve the problems of increasing the overall size of the machine tool, reducing the operating space of the machine tool, and large use space, etc. Achieve the effect of expanding comprehensive processing capacity, simple and compact structure and layout, and realizing space size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

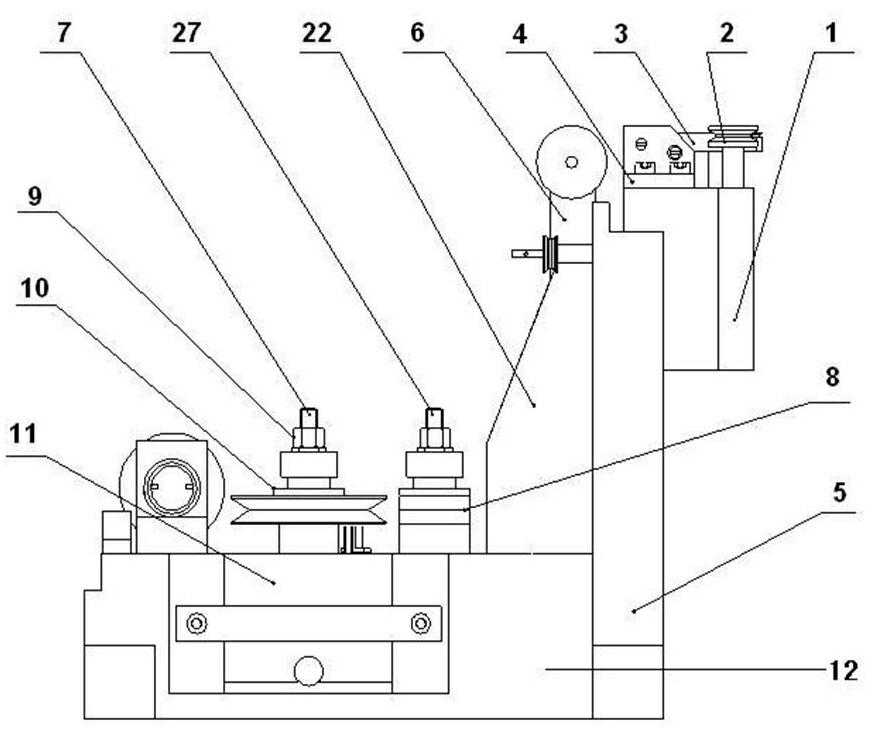

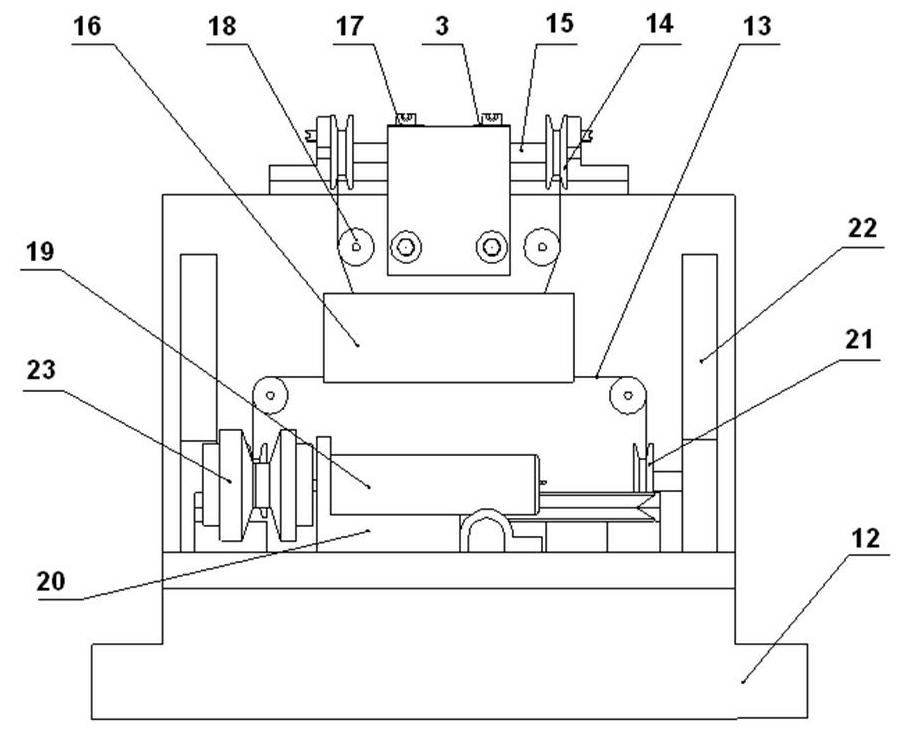

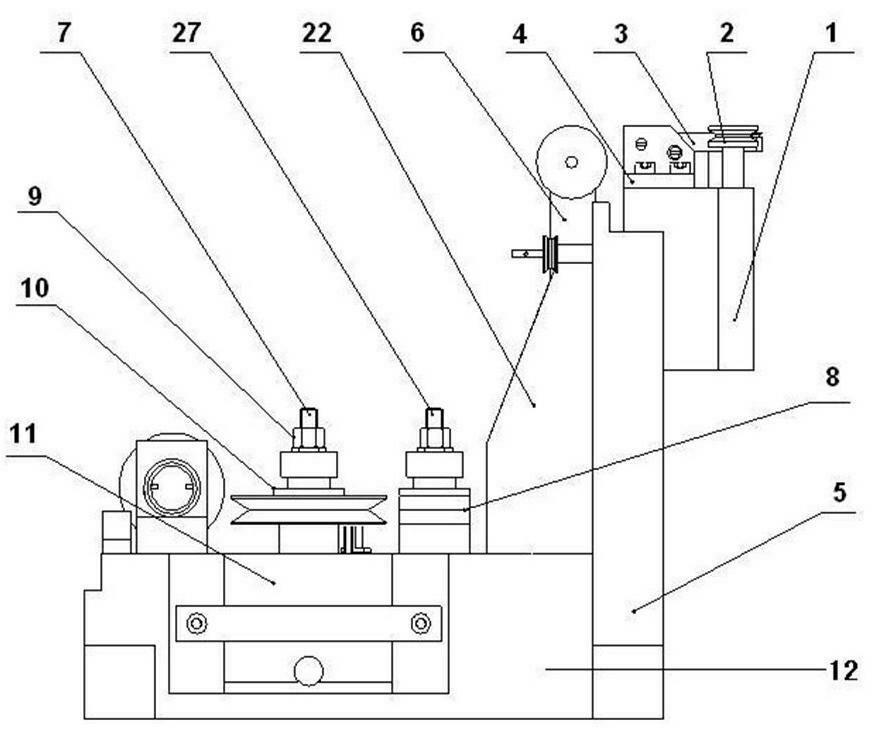

[0021] figure 1 It is a front view of a miniaturized dual-function wire electrode grinding device of the present invention, figure 2 It is a side view of a miniaturized dual-function wire electrode grinding device of the present invention. exist figure 1 , figure 2 Among them, the miniaturized dual-function wire electrode grinding device of the present invention includes a grinding head base 1, a fixed wheel 2, a right grinding head 3, a screw support 4, a supporting vertical plate 5, an upper transition wheel hanging plate 6, Support nail Ⅰ7, support nail Ⅱ 27, damping plate 8, set nut 9, wire outlet wheel 10, damper 11, support base plate 12, upper transition wheel 14, adjusting screw 15, shock absorber 16, left grinding head 17, Guide wheel 18, motor assembly 19, motor seat 20, lower transition wheel 21, reinforcing plate 22, wire receiving wheel 23; Its connection relation is, described adjusting screw rod 15 is assembled on the screw rod support 4 and can rotate free...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com