Patents

Literature

35results about How to "Applicable production needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

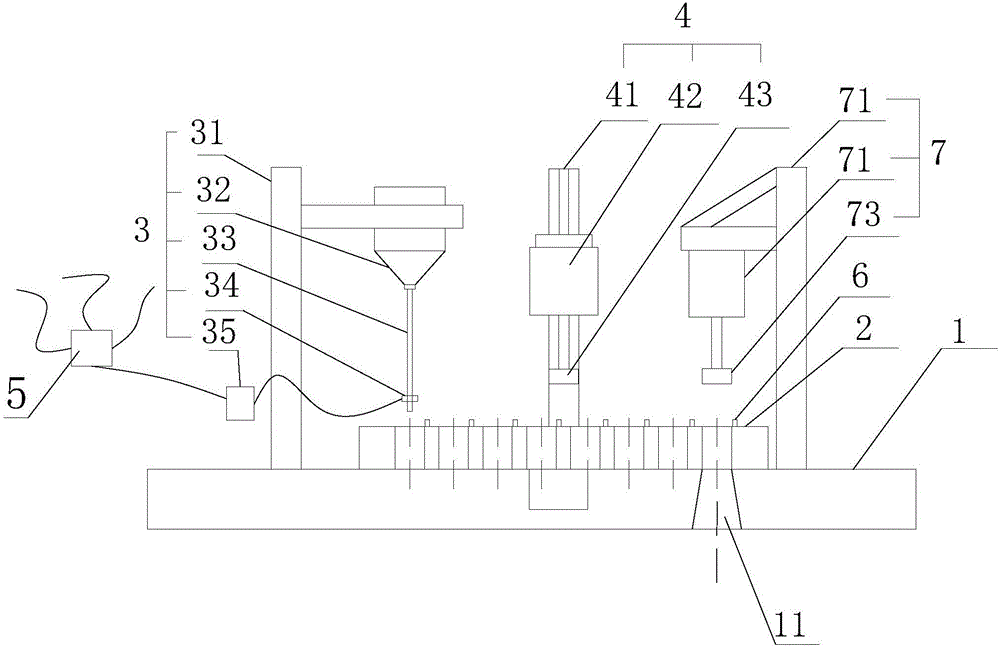

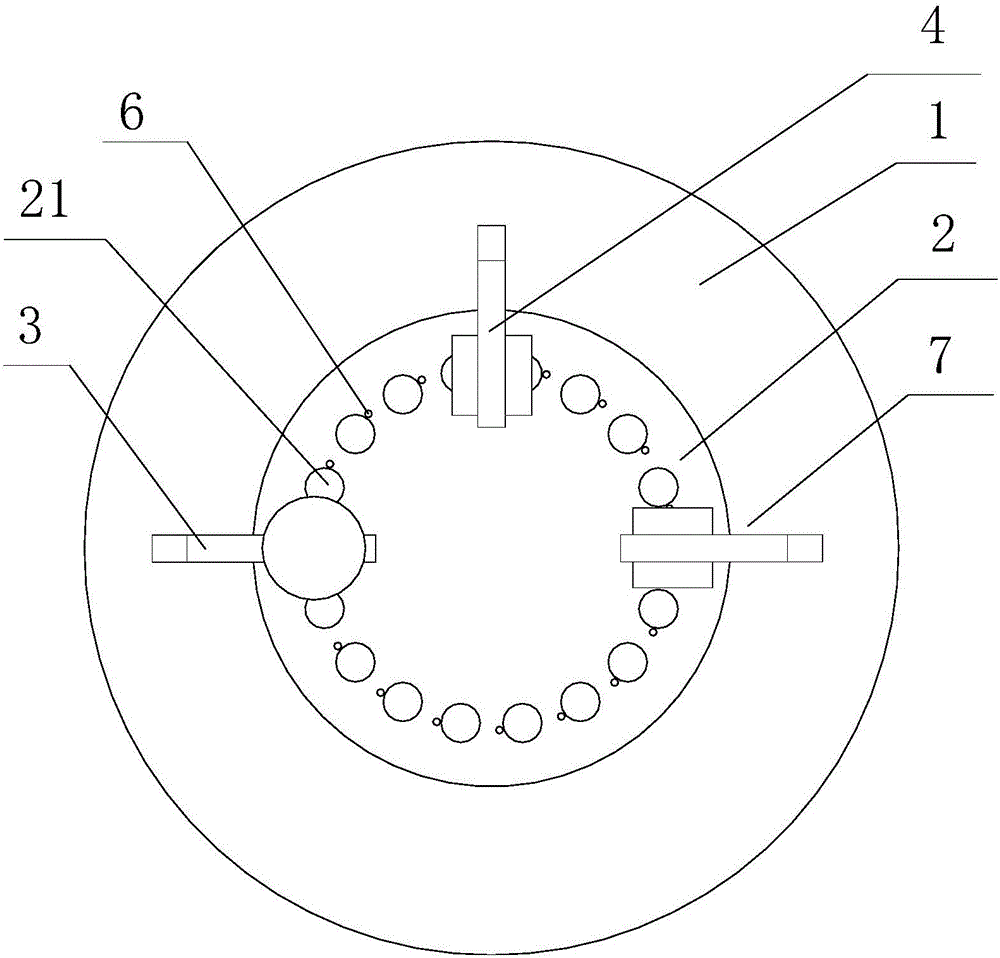

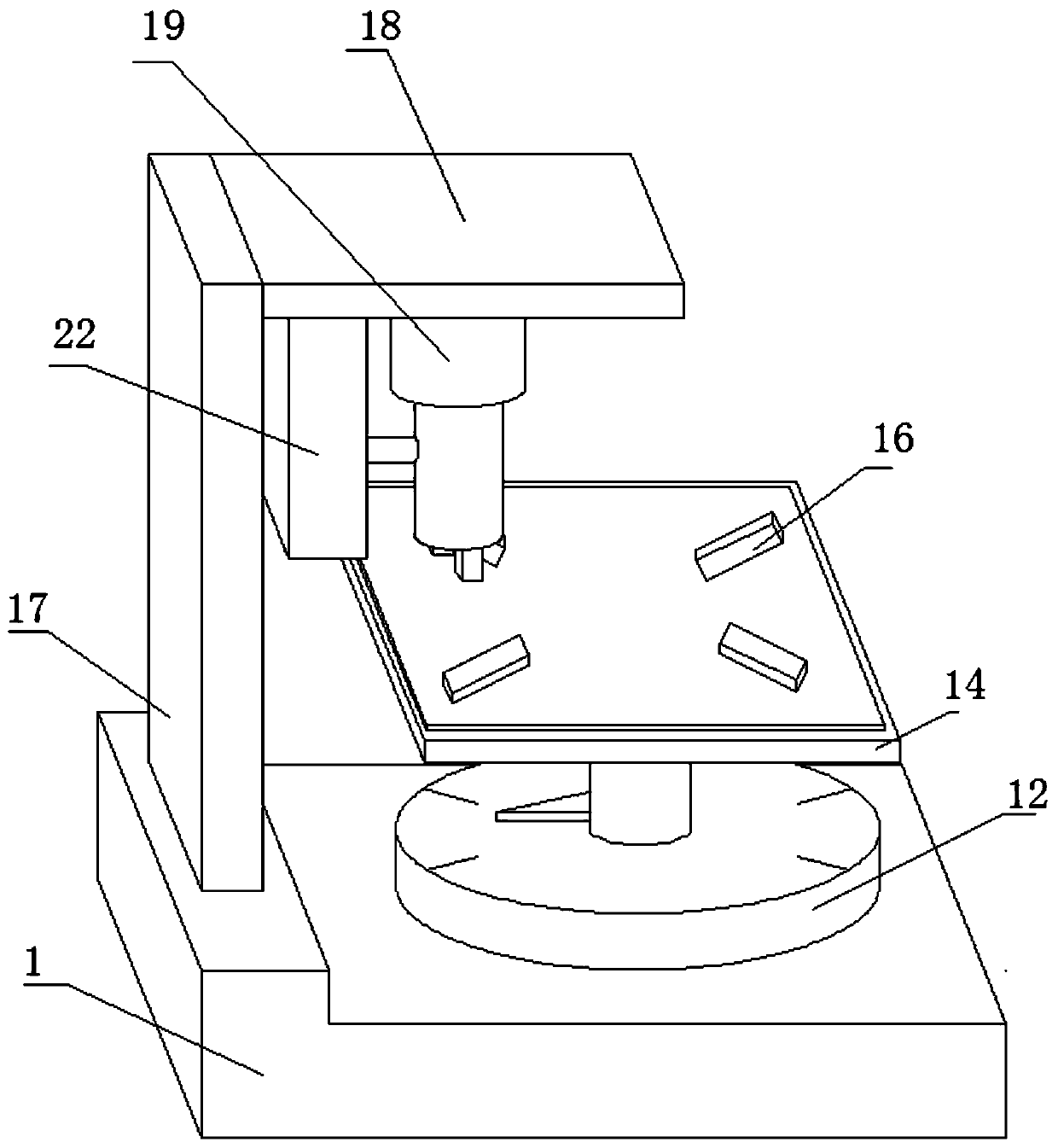

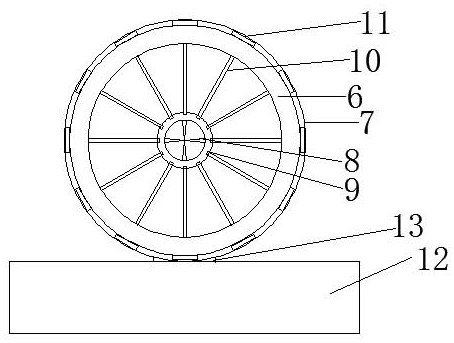

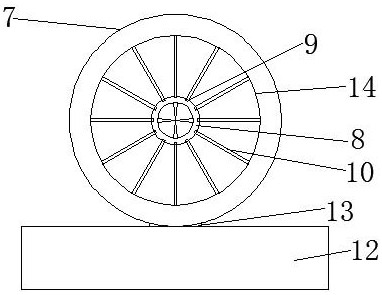

Automatic tablet compressing device

ActiveCN105015013AReduce work intensityGuaranteed uniformityShaping pressStart timeBiochemical engineering

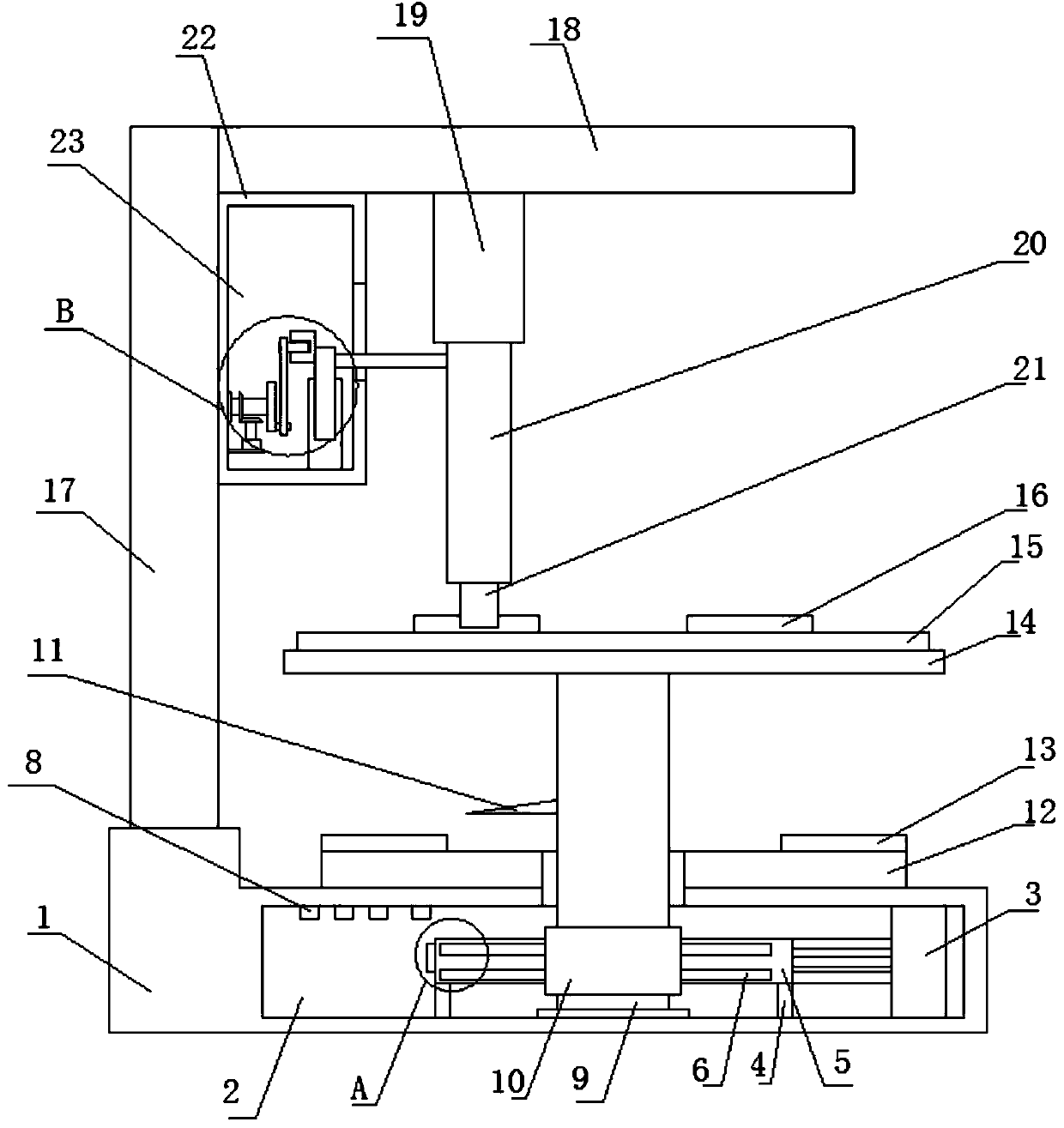

The invention discloses an automatic tablet compressing device. The tablet compressing device comprises a base, a turntable, a driving mechanism, a feeding mechanism, a compressing mechanism and a main control, wherein the turntable is arranged on the base and is driven to rotate by the driving mechanism; mold cavities are formed in the turntable; one side of each mold cavity is provided with a sensor which is connected with the main control; the main control controls the driving mechanism, the feeding mechanism and the compressing mechanism to work; a feeding station and a compressing station are arranged on the base; the feeding mechanism is arranged on the feeding station for injecting medicine powder into the mold cavities; and the compressing mechanism is arranged on the compressing station for compressing the medicine powder in the mold cavities into tablets. The automatic tablet compressing device is simple and reasonable in structure and high in automation degree, and the aim of automatic feeding and compressing is realized, so that the pharmacy efficiency is greatly improved; the work intensity of working personnel is lowered; and the device is applicable to the requirement of flow line production. Meanwhile, during a feeding process, the starting time of a solenoid valve is uniformly regulated, so that the adding uniformity of the medicine powder is ensured to a great extent.

Owner:刘宇

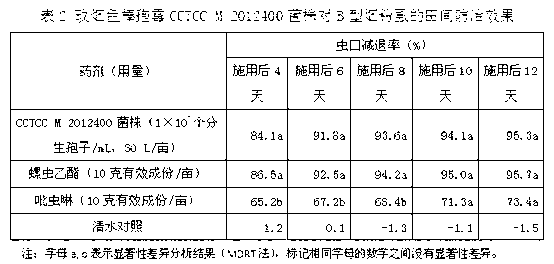

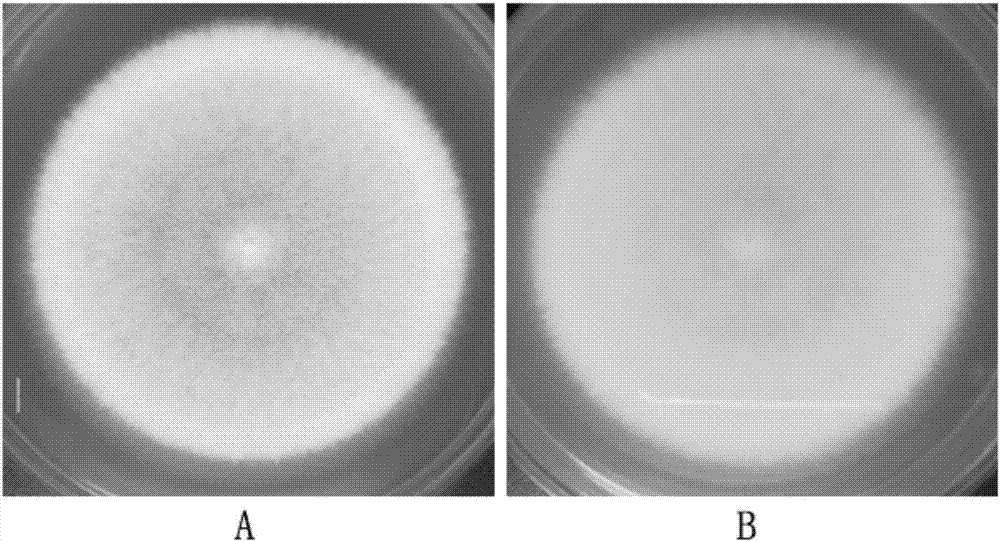

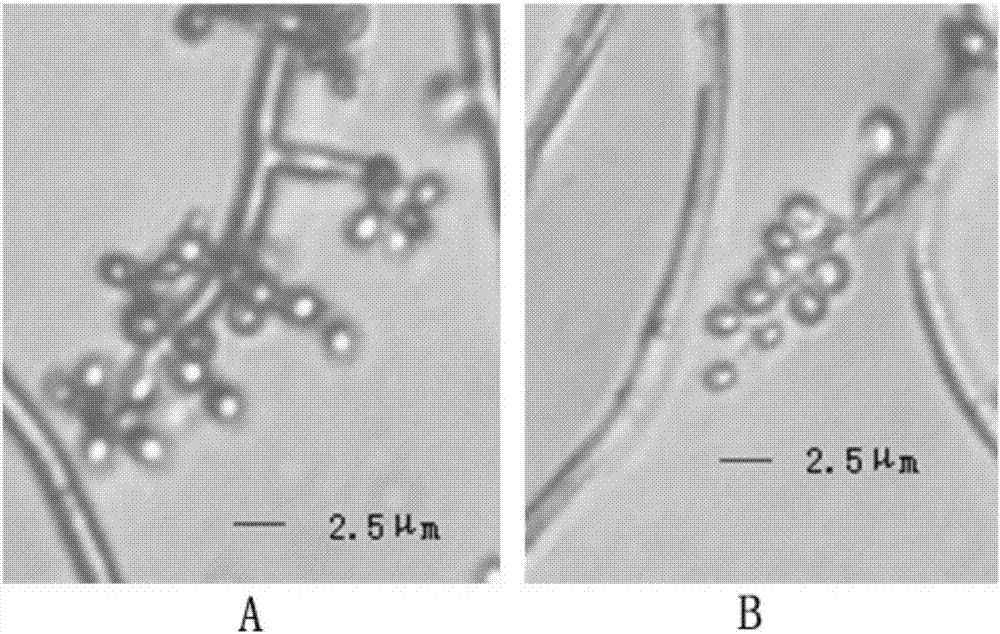

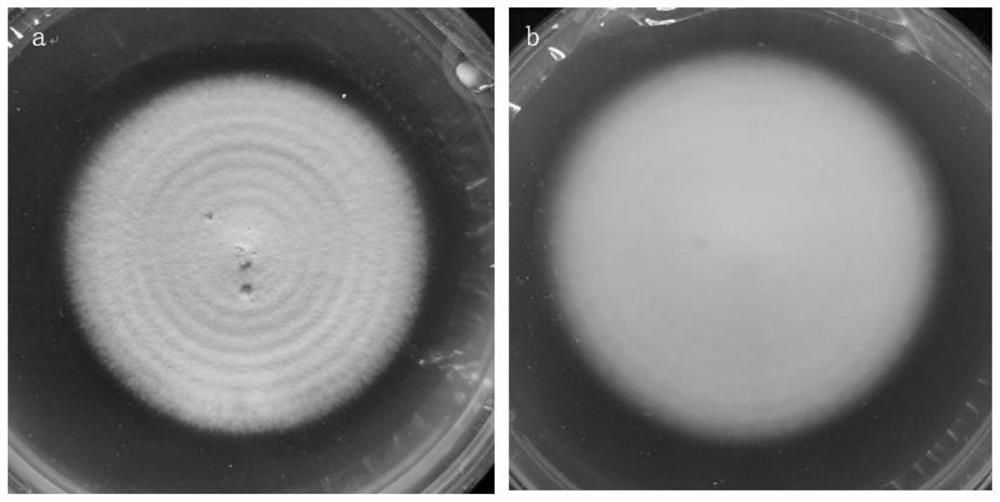

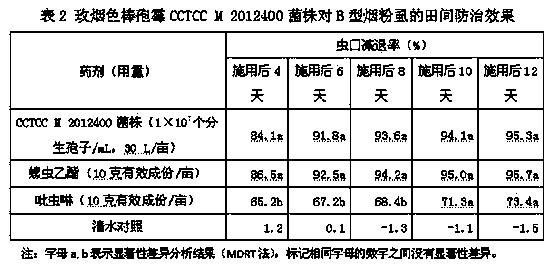

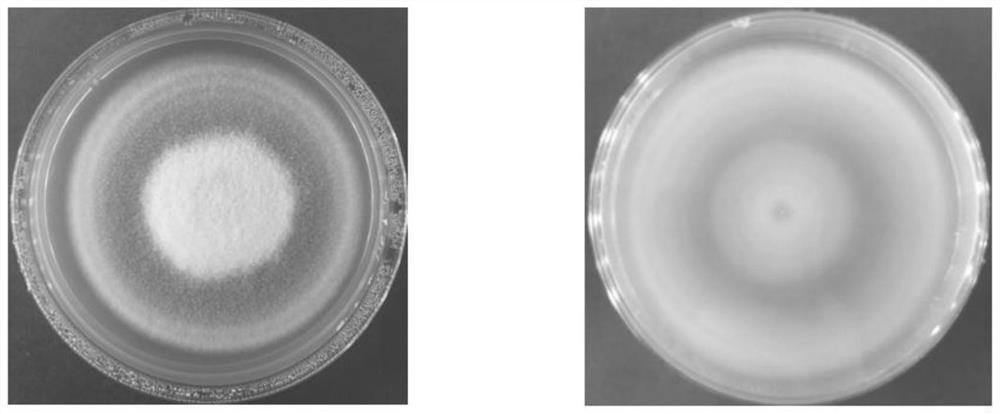

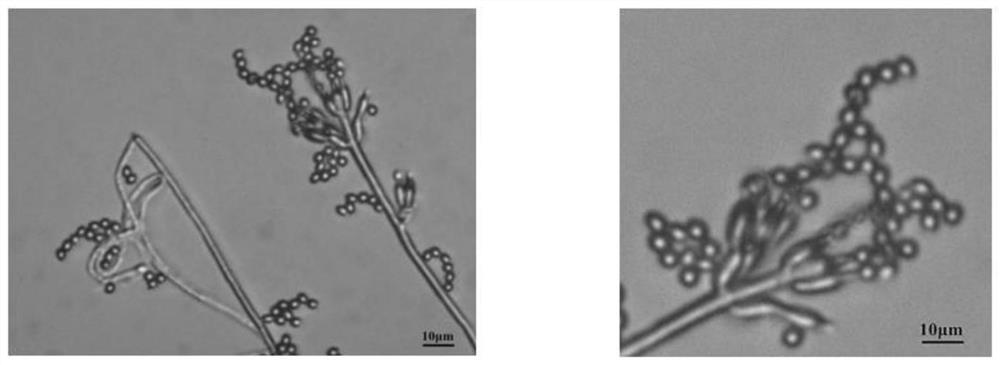

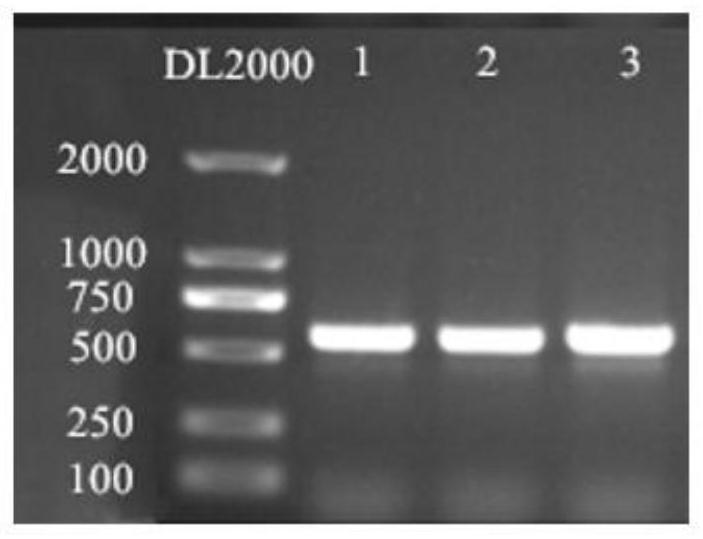

Isaria fumosoroseus and application thereof for preventing and treating bemisia tabaci

ActiveCN103122314AGood control effectImprove the effect of prevention and controlBiocideFungiBiotechnologyNymph

The invention relates to isaria fumosoroseus and application thereof for preventing and treating bemisia tabaci. The isaria fumosoroseus is preserved in China Center For Type Culture Collection, wherein the preserving data is 12th, October, 2012, and the preserving number is CCTCC M2012400. The taxonomic status belongs to Eumycota, Mitosporic fungi, Hyphomycetes, Hyphomycetales, Hyphomycetaceae and Isaria. The isaria fumosoroseus is highly pathogenic to B type bemisia tabaci, and the medial lethal concentration to two-year old nymph (LC50) is 7.5*10<5> conidia / mL (the fourth day after inoculation), and the field control efficiency to B type bemisia tabaci is over 90% which is equal to that of chemical insecticide spirotetramat. The isaria fumosoroseus serving as a living biological insecticide is free from environmental pollution and toxicity to human and livestock, and is suitable for production of organic agricultural products.

Owner:SOUTH CHINA AGRI UNIV

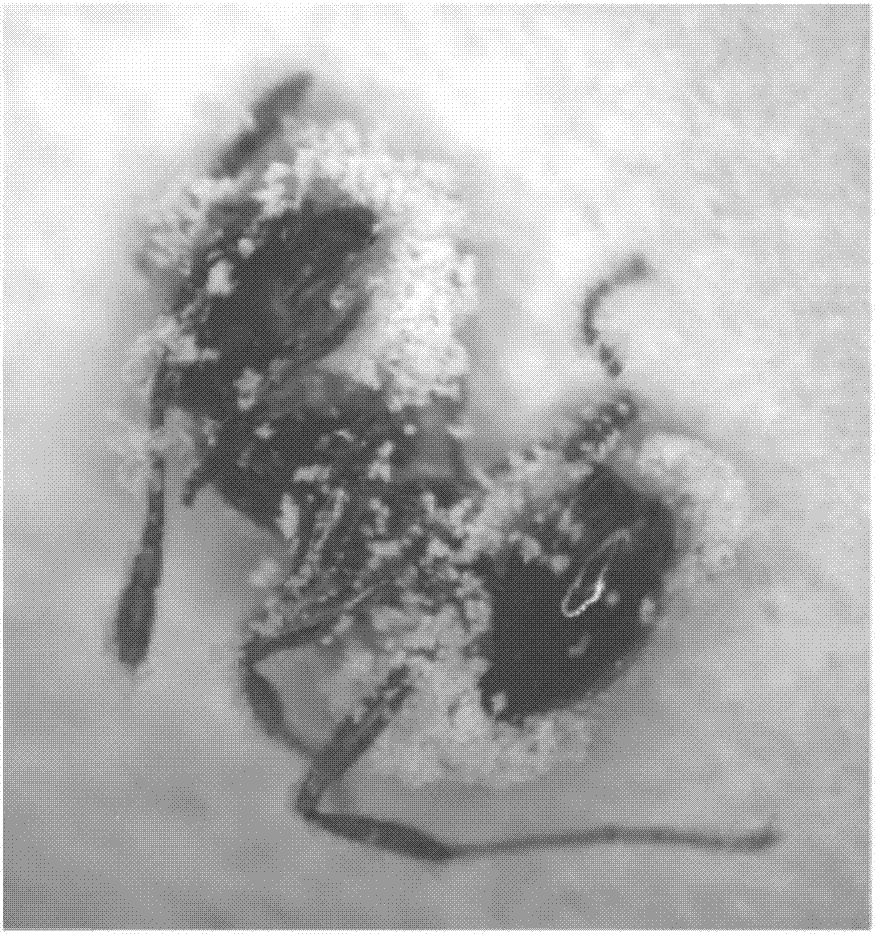

Beauveria bassiana BbL25 strain for preventing and treating solenopsis invicta and application thereof

ActiveCN107418899AGood field control effectNo pollution in the processBiocideFungiSporeHighly pathogenic

The invention discloses a Beauveria bassiana BbL25 strain for preventing and treating solenopsis invicta. The strain is preserved at China Center for Type Culture Collection on February 16, 2017 and the preservation number is CCTCC NO: M2017045. The Beauveria bassiana BbL25 strain is highly pathogenic to the solenopsis invicta, and half lethal concentration (LC50) to the solenopsis invicta is 8.15x10<5> conidium / mL on the 14th day after inoculation, and the strain has a good field controlling effect on the solenopsis invicta; the controlling effect of 1x10<7> / mL condinal suspension on the solenopsis invicta reaches 82.52% on the 14th day after drug delivering, and the effect is same as chemical insecticide 0.25% fluoxane. The Beauveria bassiana BbL25 strain can be used as a living biological insecticide and has no pollution to the environment and is non-toxic to human beings and animals and is suitable for the production of organic agricultural products, and great application prospects are achieved.

Owner:SOUTH CHINA AGRI UNIV

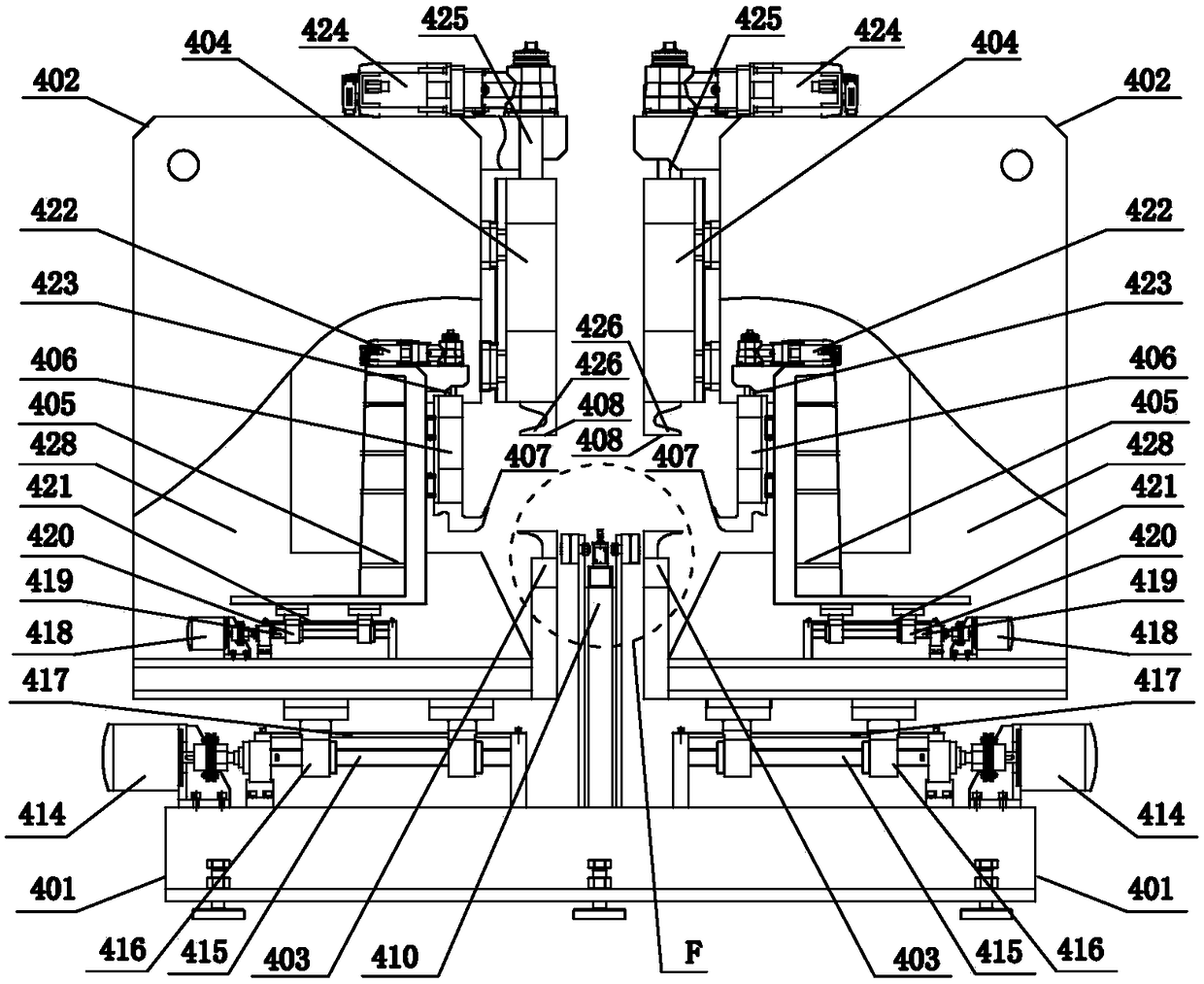

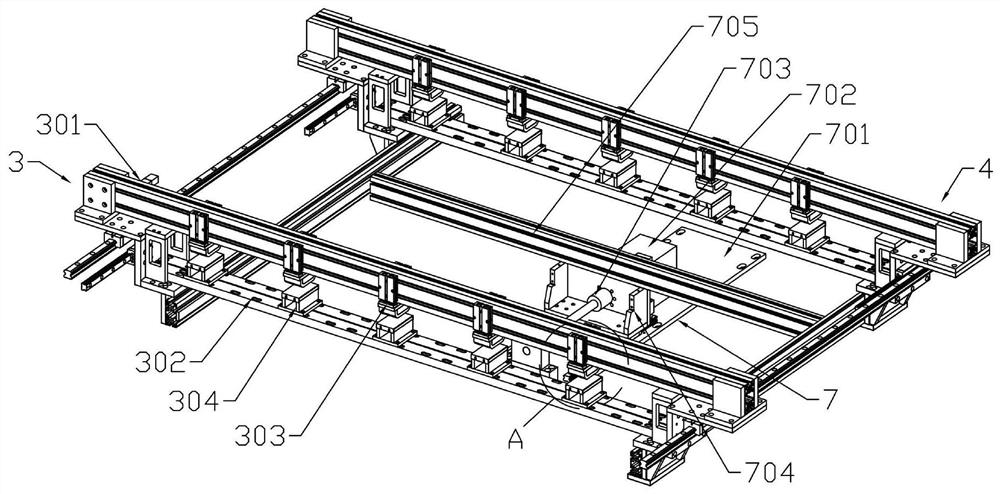

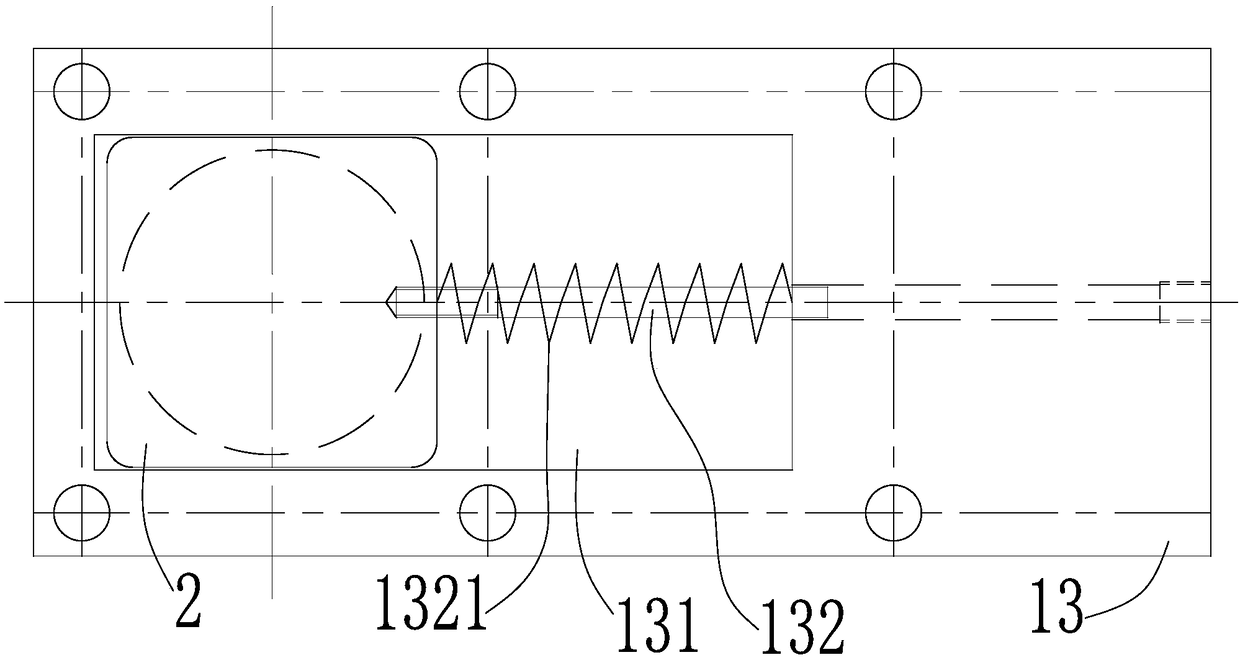

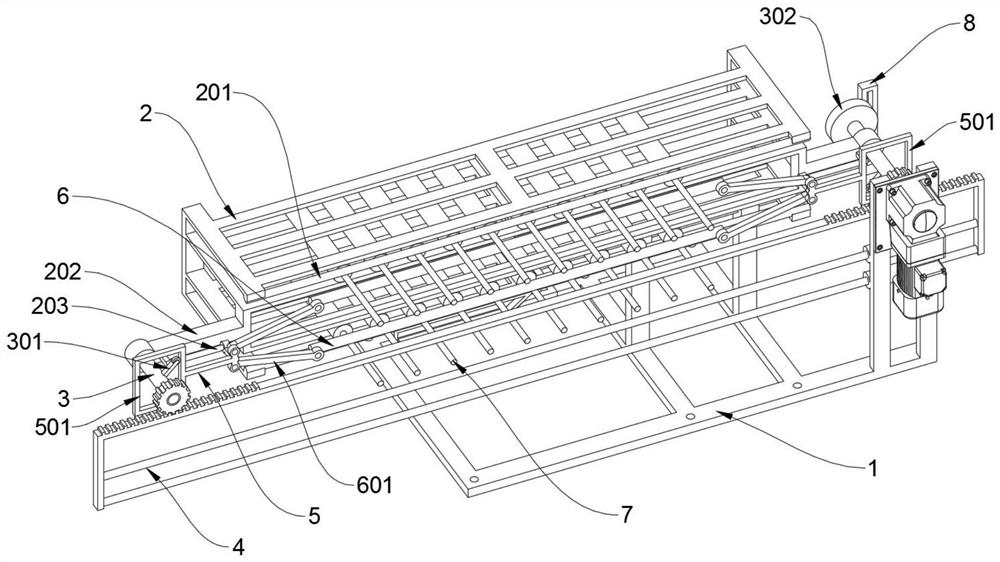

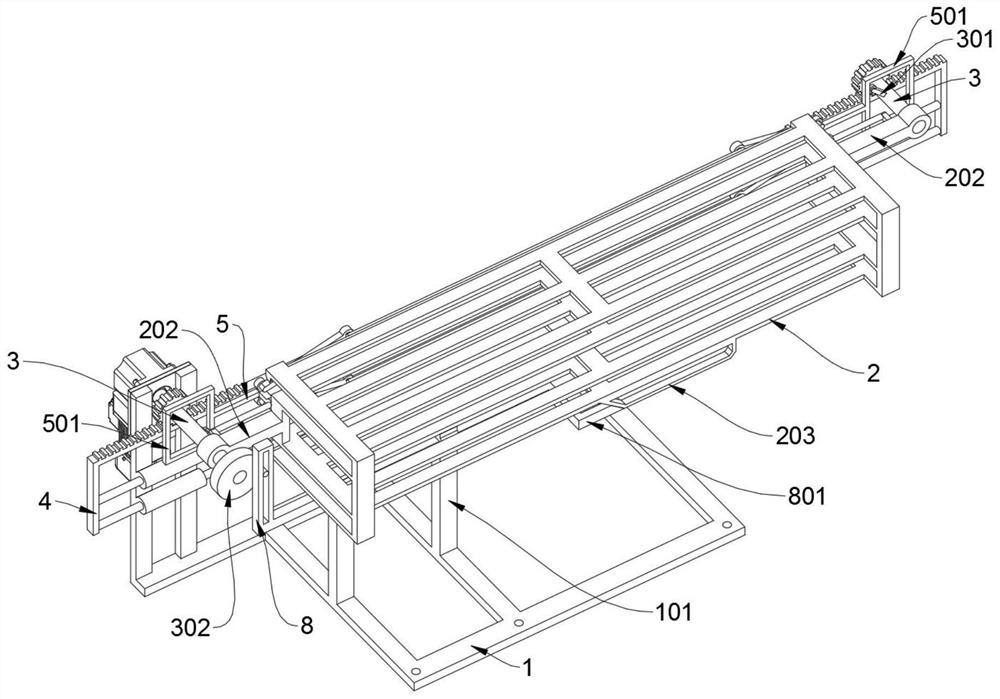

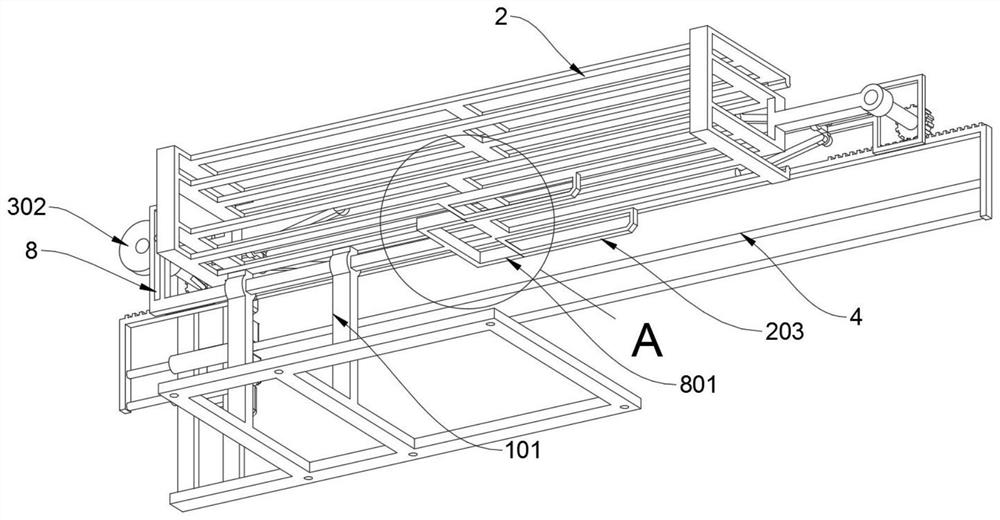

Flexible bending machine

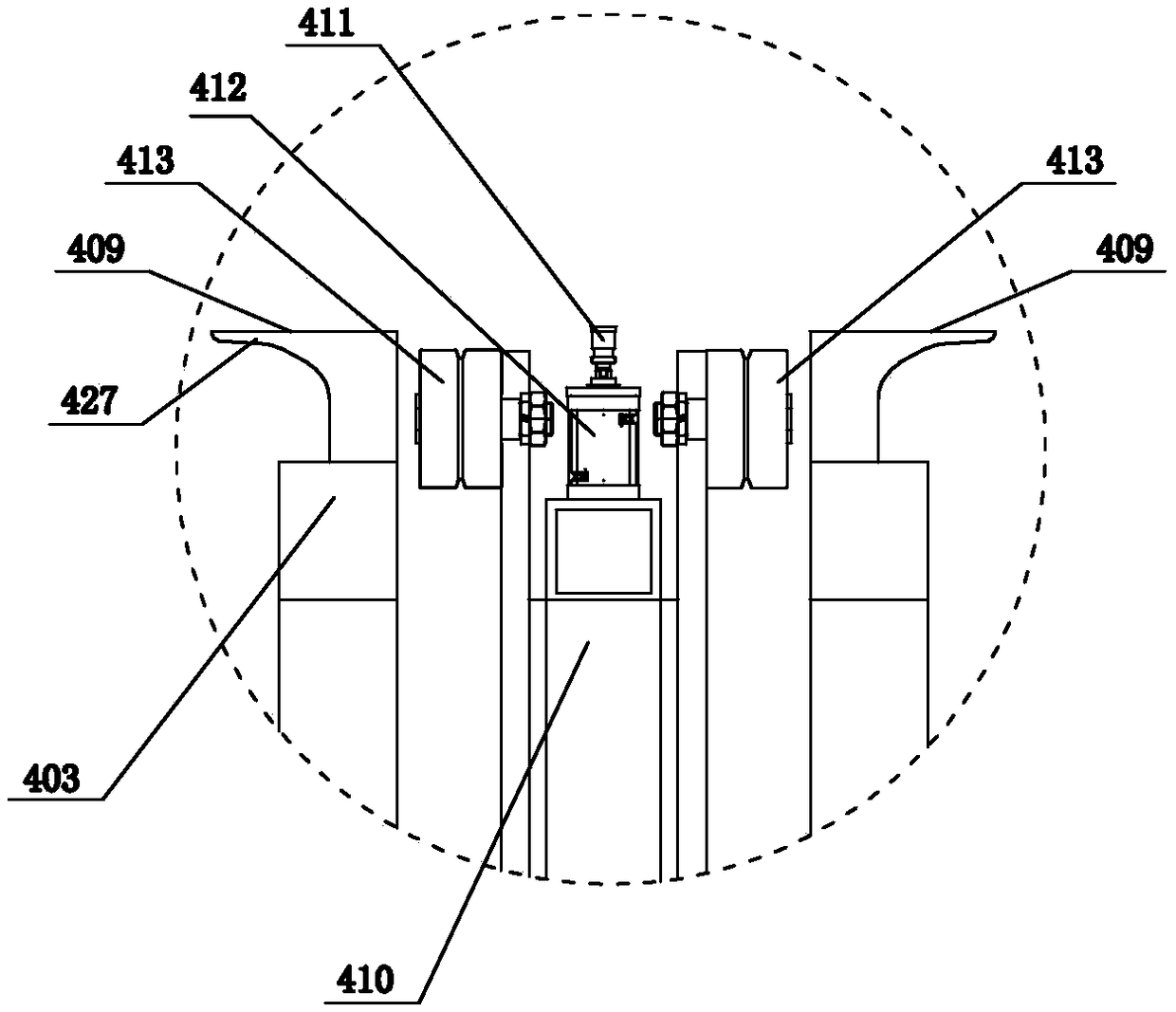

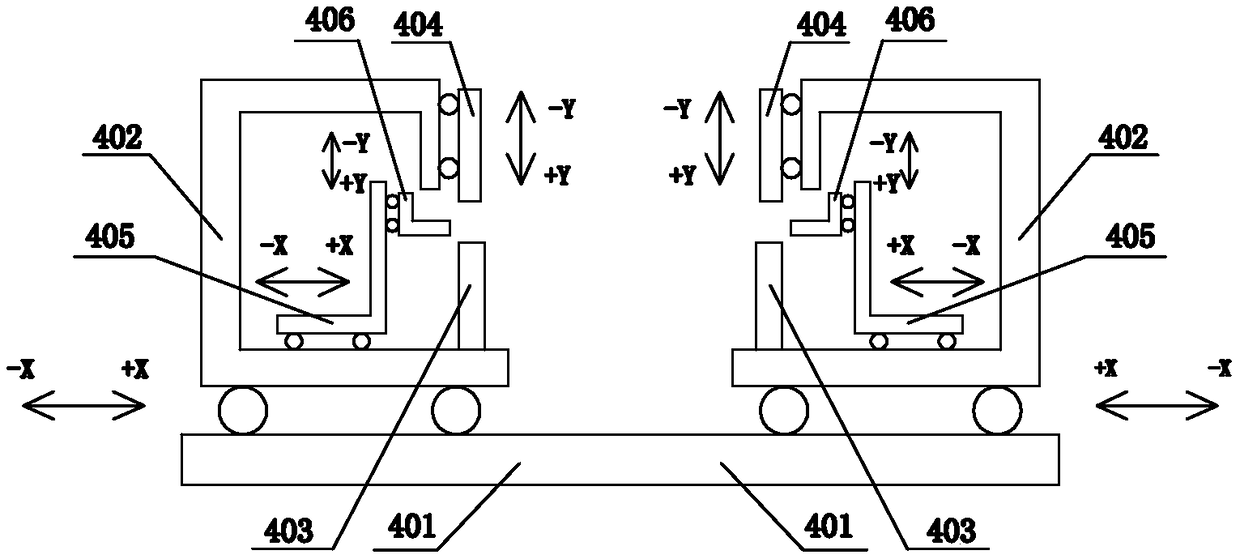

PendingCN109351816AApplicable production needsFlexible size changeMetal-working feeding devicesPositioning devicesEngineeringLower face

The invention discloses a flexible bending machine. The flexible bending machine comprises a base, a conveying table and two shoulder bases; the conveying table is arranged in the middle of the upperface of the base, the two shoulder bases are symmetrically arranged on the two sides of the conveying table, and can move in the width direction of the base, a supporting frame, a pressing frame and abending frame are arranged on each shoulder base, the supporting frames are fixed to the side faces of the shoulder bases, supporting planes are arranged on the supporting frames, the pressing framescan move up and down relative to the shoulder bases, a pressure application plane is arranged on the lower face of each pressing frame, the pressure application planes correspond to the supporting planes up and down, the bending frames are located on the side edges, back onto the conveying table, of the supporting frames, the bending frames can move up and down relative to the shoulder bases, andcan move in the width direction of the shoulder bases, and bending protruding sides facing the supporting planes are arranged on the bending frames. Plates of different thicknesses, different sizes and different materials can be bent, and the bending size and shape can be flexibly changed.

Owner:CHINA NAT ELECTRIC APP RES INST +1

Laser welding equipment

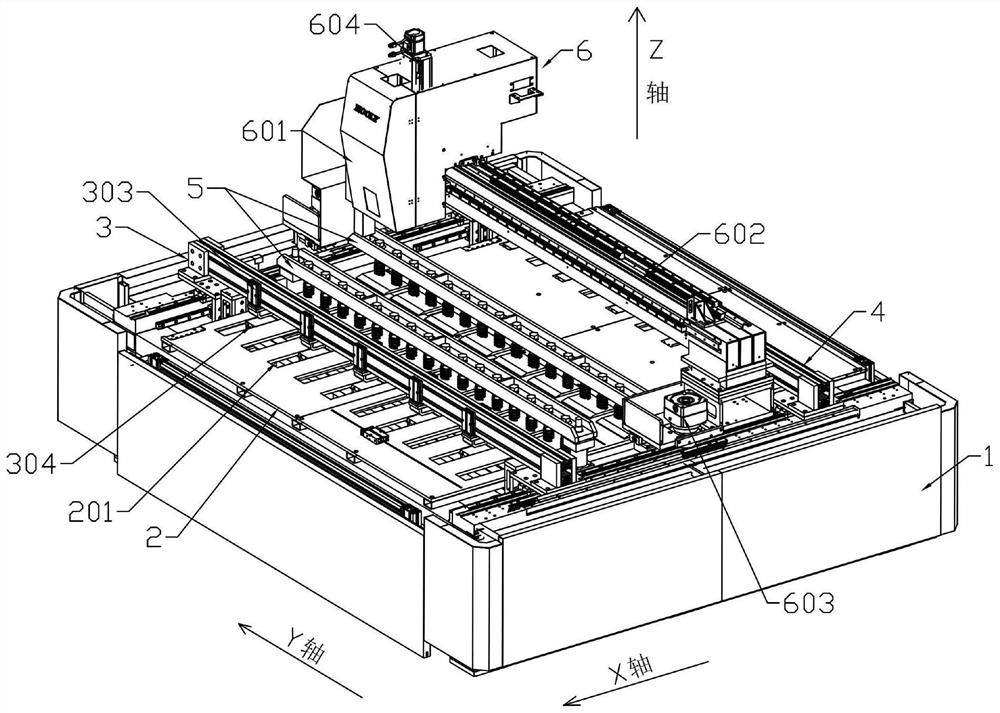

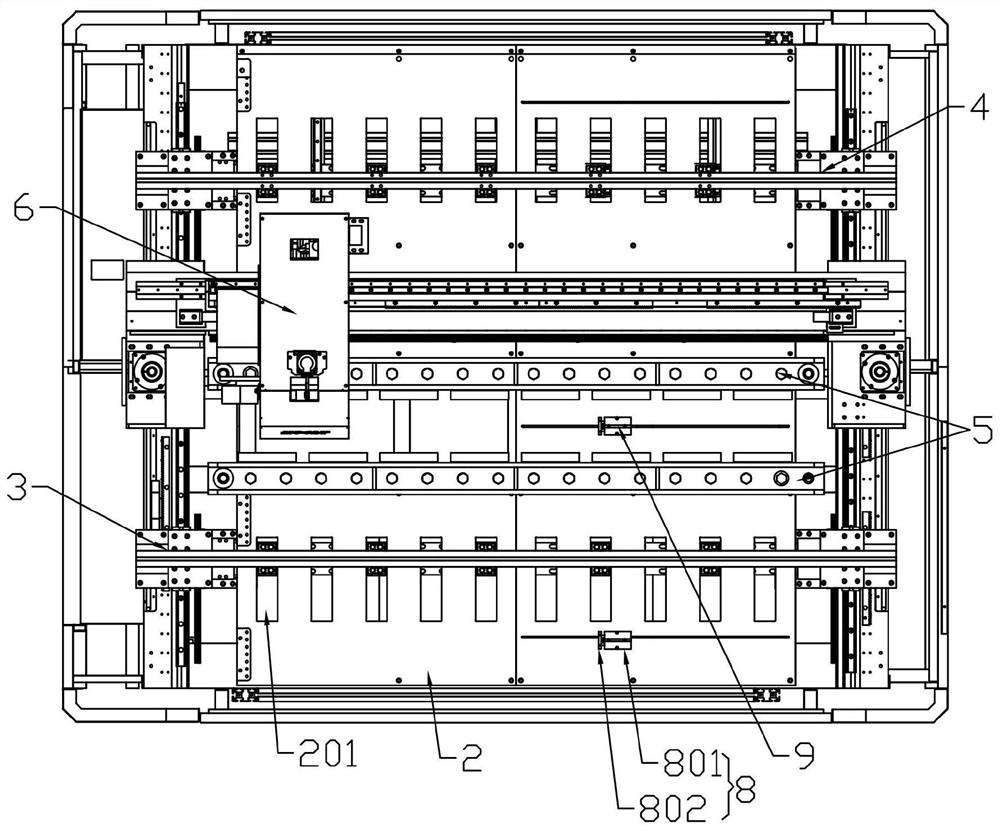

PendingCN112935550ACompact and reasonable structure designImprove flatnessWelding/cutting auxillary devicesAuxillary welding devicesMachiningWorkbench

The invention provides laser welding equipment. The equipment comprises a rack; a workbench is arranged above the rack; a first conveying device, a laser welding device and a second conveying device are sequentially arranged along the workbench from left to right; the laser welding device slides on the workbench; a main driving device is installed below the workbench; the first conveying device and the second conveying device are driven by the main driving device to synchronously slide on the workbench in the X-axis direction. Compared with the prior art, the laser welding equipment is compact and reasonable in structural design, laser welding machining is conducted through automatic feeding, metal plates are pressed and pulled to the laser welding position through synchronous movement of the first conveying device and the second conveying device to be subjected to laminated welding machining, manual material pulling and conveying are reduced, and the working efficiency of double-layer superposition welding of the metal plates is improved.

Owner:东莞市合力激光设备有限公司

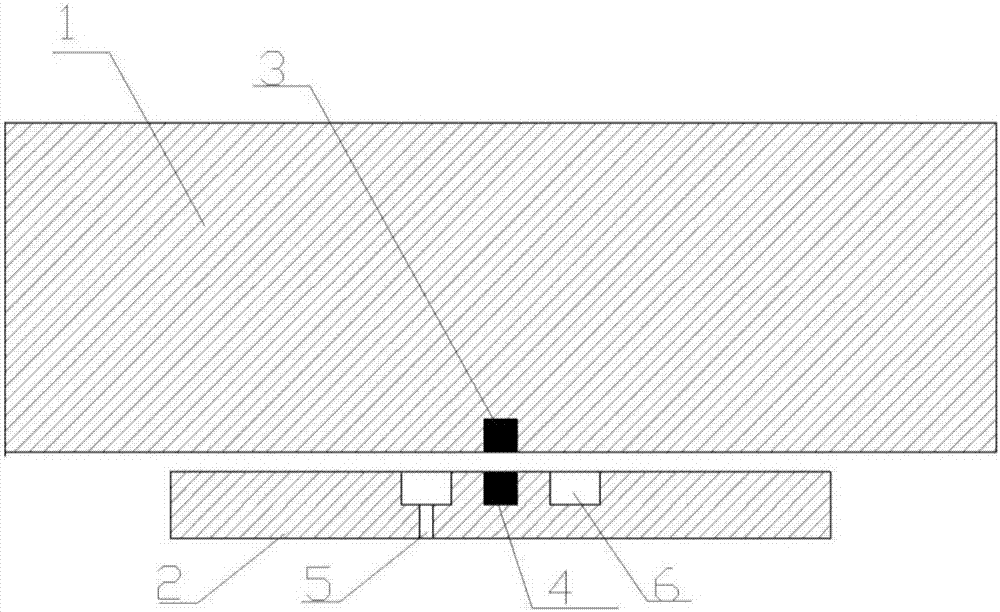

Small-size corn thresher device

A small-size corn thresher device comprises a machine body (1), wherein the whole structure of the machine body (1) comprises an end cover device (2) and a separation device (3), the end cover device (2) is internally provided with a fixing module (4), a miniature power thrust unit (5) and a handle (6), during use, corns are fixed at the lower part of the end cover, power supply is powered on to start the power thrust unit (5) to slowly extend the corns into the separation device (3), a blade assembly (7) quickly performs threshing, and corn kernels directly drop into a collecting device at the bottom; the separation device (3) comprises two frames, namely an inner frame and an outer frame, the edge of the inner frame is provided with small hole sites at intervals, and the outer frame is internally provided with absorption equipment (8) which is used for absorbing impurities generated during the separation process into the outer frame, so as to ensure the cleanness of the threshing; a prompt device (9) is arranged, and the prompting mode is a voice or LED (light-emitting diode) light display; the corn kernels can be quickly obtained, and reselecting is not needed.

Owner:江苏海迅铁路器材集团股份有限公司

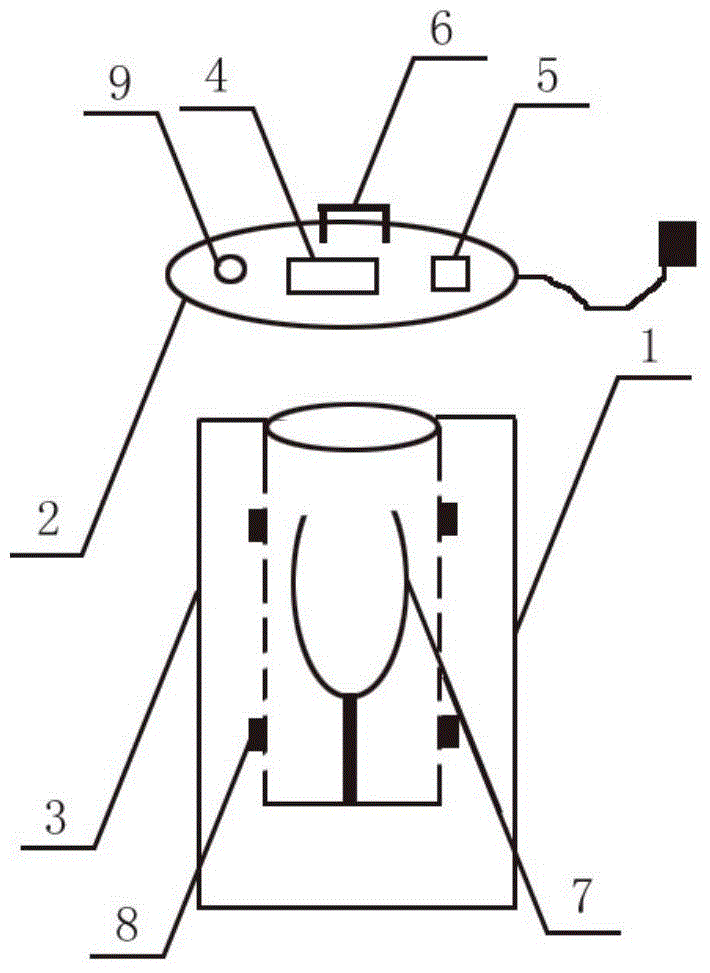

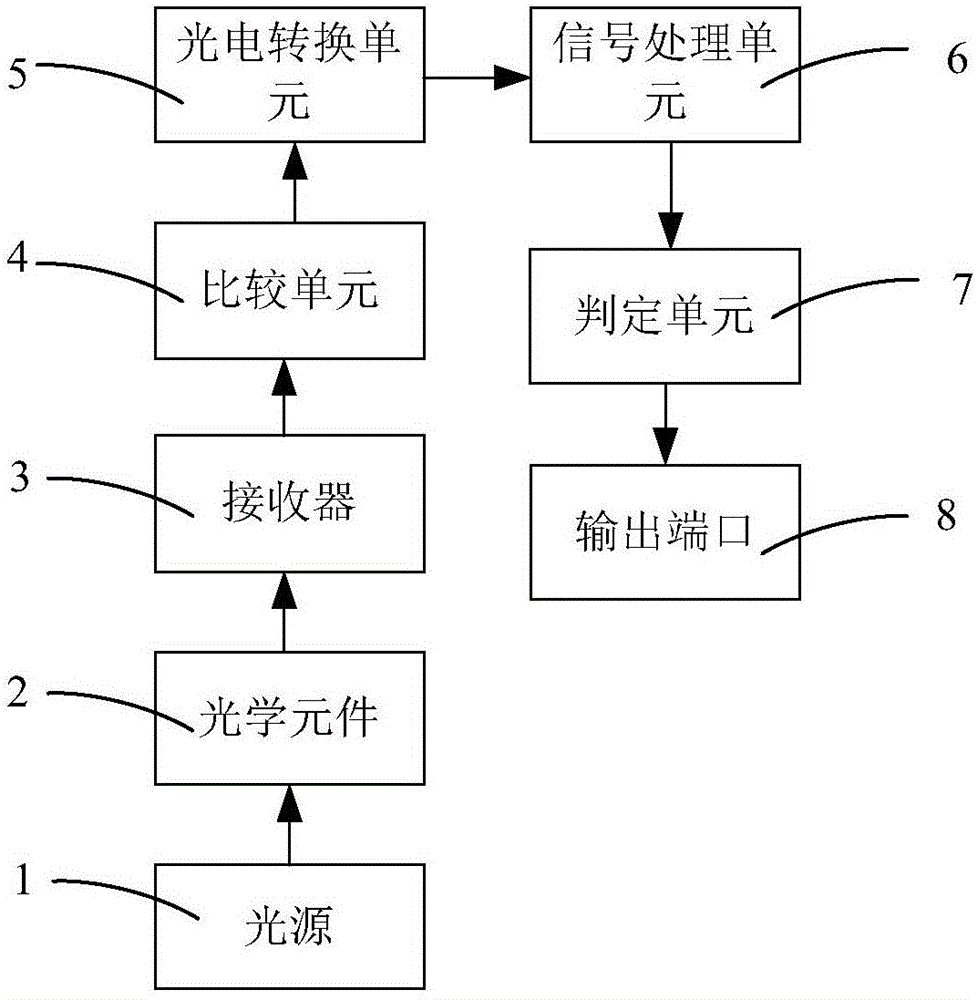

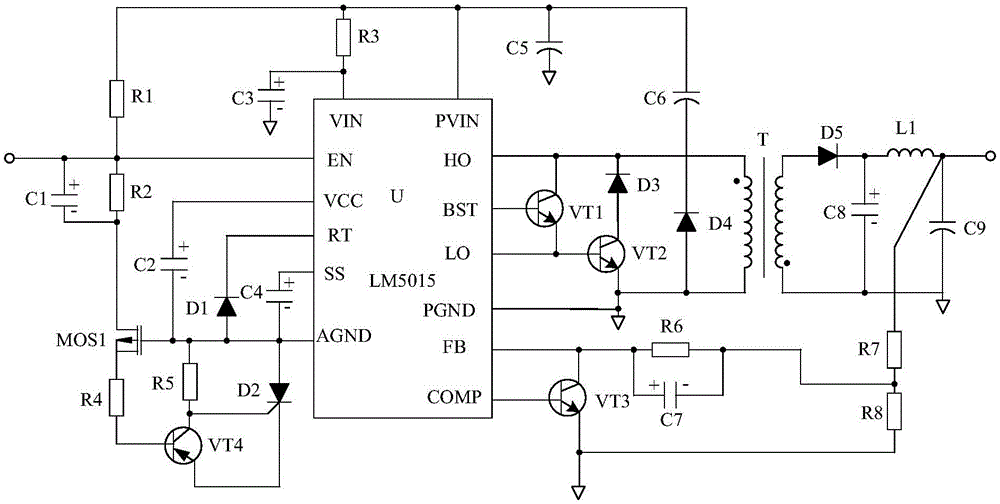

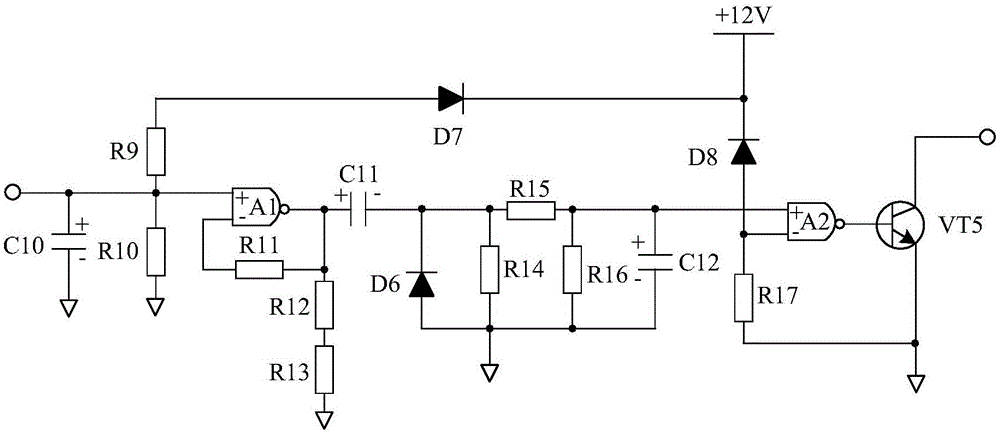

Hybrid high-sensitivity photoelectric sensor system

InactiveCN105115527AHigh sensitivityReduce volumeConverting sensor output opticallyFrequency bandOpto electronic

The invention discloses a hybrid high-sensitivity photoelectric sensor system which comprises a light source (1), an optical element (2) connected with the light source (1), a receiver (3) connected with the optical element (2), a comparison unit (4) connected with the receiver (3), a photoelectric conversion unit (5) connected with the comparison unit (4), a signal processing unit (6) connected with the photoelectric conversion unit (5), a determination unit (7) connected with the signal processing unit (6), and an output port (8) connected with the determination unit (7). The hybrid high-sensitivity photoelectric sensor system has excellent anti-electromagnetic interference capability, and prevents the detection precision from being affected by the interference of a magnetic field. The hybrid high-sensitivity photoelectric sensor system is wide in frequency band width, high in sensitivity, excellent in linearity and minimal in dynamic error, and is more suitable for current production requirements.

Owner:NINGBO MOMI INNOVATION WORKS ELECTRONICS TECH

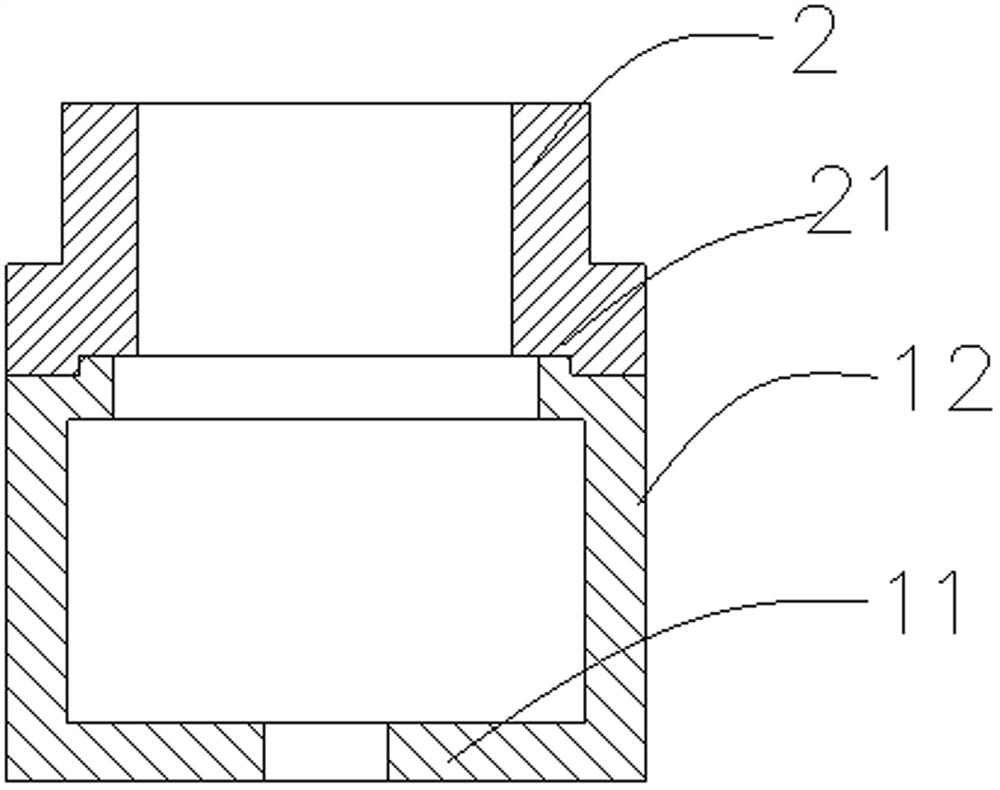

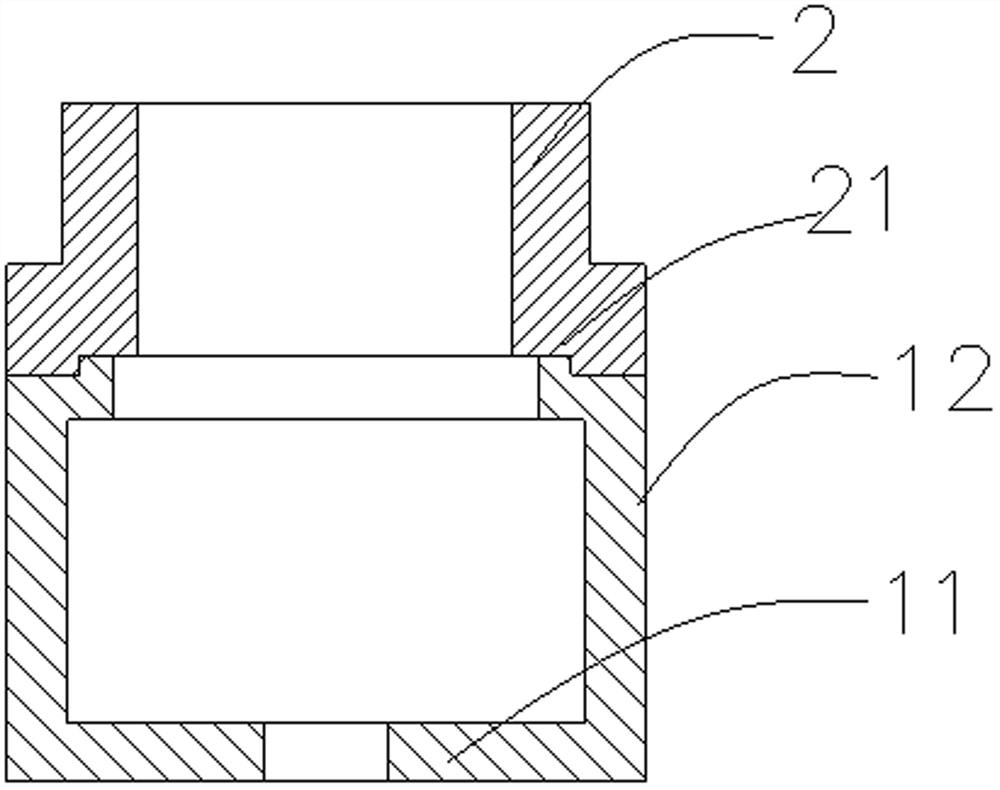

Inner hole clamp for workpiece for high-frequency induction heating

PendingCN112140033AMeet strength requirementsNo sparkingWork holdersEngineeringMechanical engineering

The invention discloses an inner hole clamp for a workpiece for high-frequency induction heating. The inner hole clamp comprises a support plate and arc-shaped quartz plates installed on the support plate, wherein the support plate comprises a base and a support beam; the base and the support beam form an angle of 90 degrees; a mounting table protruding out of a mounting surface is arranged at oneend, away from the base, of the support beam; mounting holes are formed in the mounting table; the arc-shaped quartz plates are fixedly connected with the mounting table of the support beam; and a plurality of arc-shaped quartz plates form a circular structure and are attached to an inner hole of a workpiece. Through the arrangement of the overall structure of the clamp, the requirement for the strength of the clamp is met, and the whole clamp cannot generate an electric spark to affect the product quality, and has great practical significance and economic value.

Owner:株洲市湘宁高中频设备有限责任公司

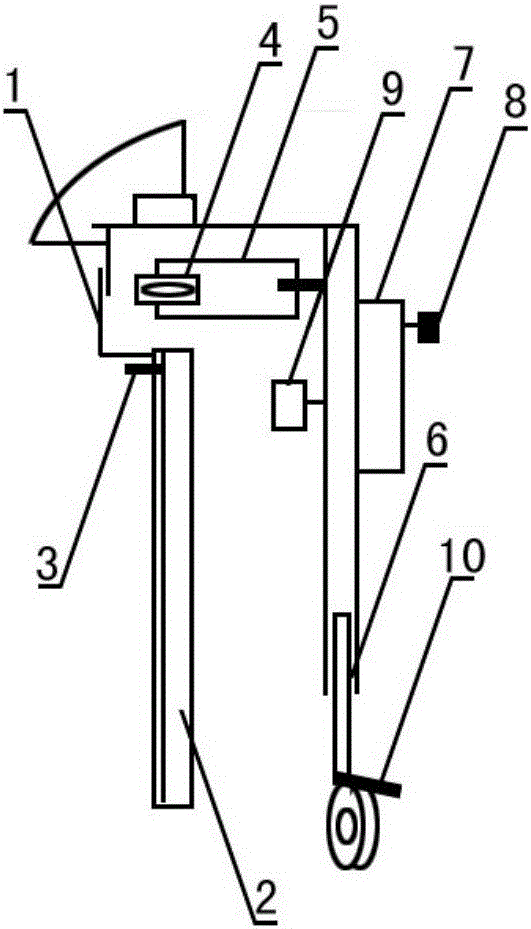

Large wire harness sleeving special-purpose device

InactiveCN106057367ANovel structural designImprove work efficiencyManufacturing wire harnessesComputer moduleEngineering

The invention discloses a large wire harness sleeving special-purpose device which includes a rack body (1) which is designed to be move unilaterally. The left side of the rack body (1) is provided with a sleeving positioning mechanism which includes an elongated hollow tube apparatus (2) and a smoothing out structure (3). The upper end of the rack body is provided with a pushing wheel (4) and a transverse cover casing apparatus (5). The right side of the rack body (1) is provided with an elevating support column (6). When the device is in usage, an electric apparatus (7) is started, the entire height of a corresponding part is regulated based on the length of the sleeving, after which the sleeving is positioned inside the hollow tube apparatus (2), and a long electric wire is sleeved within the groove of the pushing wheel (4) through an inlet end for performing sleeving work. The outside of the rack body (1) is provided with an alert apparatus (8). An output counting module (9) is arranged directed at real-time tracking integrated output. The bottom part of the rack body (1) is provided with a double-row roller apparatus (10). The device effectively increases working efficiency of the sleeving, at the same time guarantees clear output counting, provides convenience for operators, is suitable to mass production, and is economic and practical.

Owner:ANQING FENGBANG IND PROD DESIGN

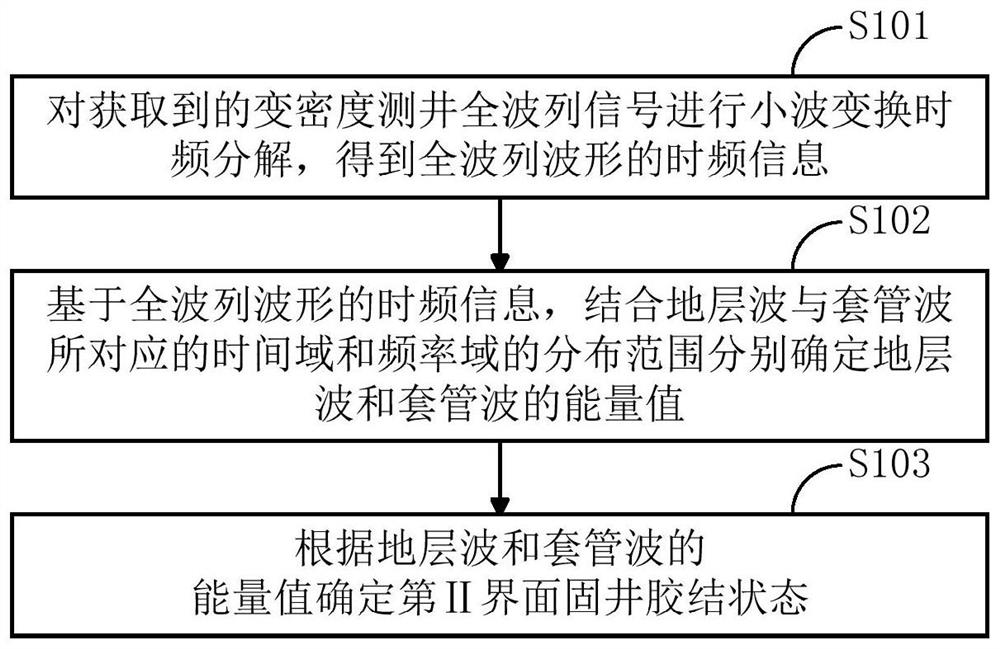

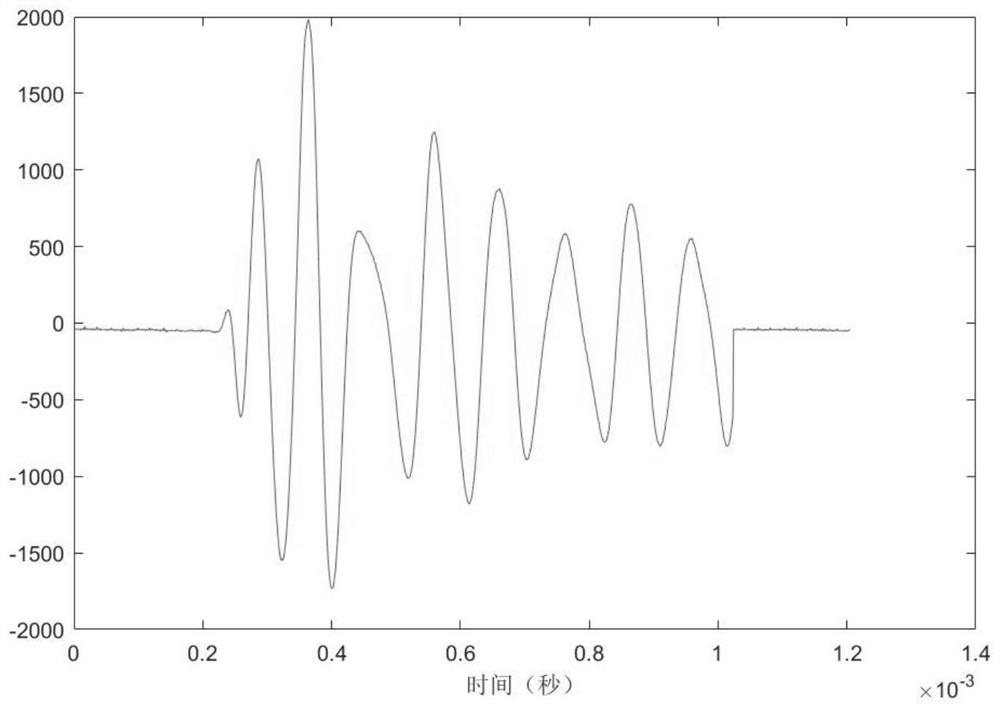

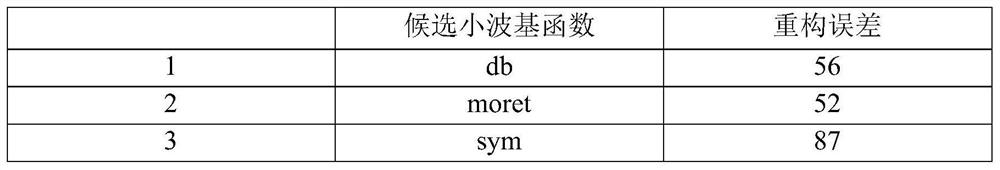

Interface II well cementing quality evaluation method

ActiveCN111827975ARealize quantitative evaluationThe result is accurateConstructionsDesign optimisation/simulationTime domainFull wave

The invention discloses an interface II well cementing quality evaluation method. The method comprises the following steps that 1, wavelet transform time-frequency decomposition is performed on an obtained variable-density logging full-wave-train signal by utilizing a preset wavelet basis function to obtain time-frequency information of a full-wave-train waveform; 2, energy values of a stratum wave and a casing wave are separately determined according to time-frequency information of the full-wave-train waveform and combing distribution ranges of a time domain and a frequency domain corresponding to the obtained stratum wave and the obtained casing wave; and 3, an interface II well cementing state is determined according to the energy values of the stratum wave and the casing wave. According to the method, quantitative evaluation on the quality of interface II well cementing can be realized, compared with the prior art, an implementation mode of the method is simpler and faster, the result obtained through the method is more accurate, and therefore the method is more suitable for production requirements.

Owner:CHINA PETROLEUM & CHEM CORP +1

Automobile inspection tool rotating device

PendingCN110936366AHigh implementabilityImprove processing efficiencyProgramme-controlled manipulatorWork benchesMechanical engineeringAutomotive engineering

The invention belongs to the field of automobile inspection tools, and particularly relates to an automobile inspection tool rotating device. The automobile inspection tool rotating device aims at solving the problems that an existing automobile inspection tool cannot carry out one-time machining operation on a plurality of machining stations of a workpiece, so that the machining efficiency of theinspection tool is low, and the production requirement cannot be met. According to the scheme, the automobile inspection tool rotating device comprises a base, a cavity is formed in the base, a vertical shaft is rotationally mounted on the inner wall of the bottom of the cavity, the top of the vertical shaft penetrates through the inner wall of the top of the cavity and extends to the upper portion of the base, the top of the vertical shaft is rotationally connected with the inner wall of the top of the cavity, a pointing block is fixedly mounted on the outer side of the vertical shaft, a rotating assembly is in transmission connection with the vertical shaft, and a placing disc is fixedly mounted at the top of the vertical shaft. Compared with a traditional automobile inspection tool, the automobile inspection tool rotating device has the advantages that machining work of all the machining stations on the workpiece can be completed at a time, the practicability is high, the machiningefficiency is high, the production requirement can be met, and the automobile inspection tool rotating device is worthy of being widely popularized and used.

Owner:长沙市奥思得精工模具有限公司

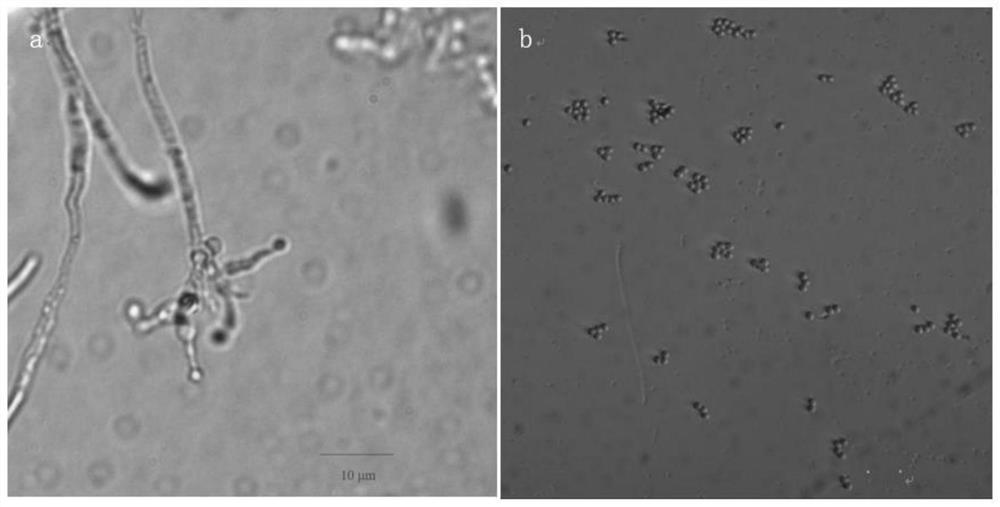

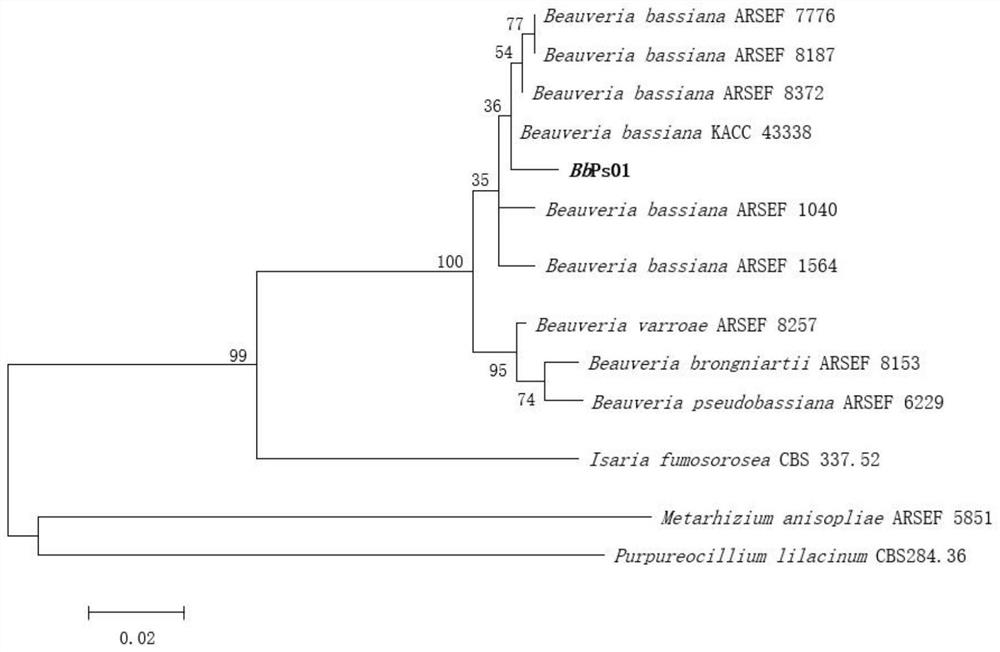

Beauveria bassiana strain with broad-spectrum insecticidal property and application thereof

The invention relates to a Beauveria bassiana BbPs01 strain with a broad-spectrum insecticidal property and an application of the Beauveria bassiana BbPs01 strain, and belongs to the technical field of biological pesticides. The strain BbPs01 has been deposited in Guangdong Microbial Culture Collection Center (GDMCC) at February 4, 2021 with a deposit number of GDMCC NO: 61494. The strain BbPs01 has high activity on pests such as phyllotreta striolata of coleoptera, rhopalosiphum padi, diaphorina citri and bemisia tabaci of hemiptera, solenopsis invicta of hymenoptera and the like; has a potential of serving as a fungal pesticide, has characteristics of no pollution to the environment and no toxicity to human and livestock as a biological living pesticide, and is suitable for the production requirements of organic agricultural products.

Owner:SOUTH CHINA AGRI UNIV

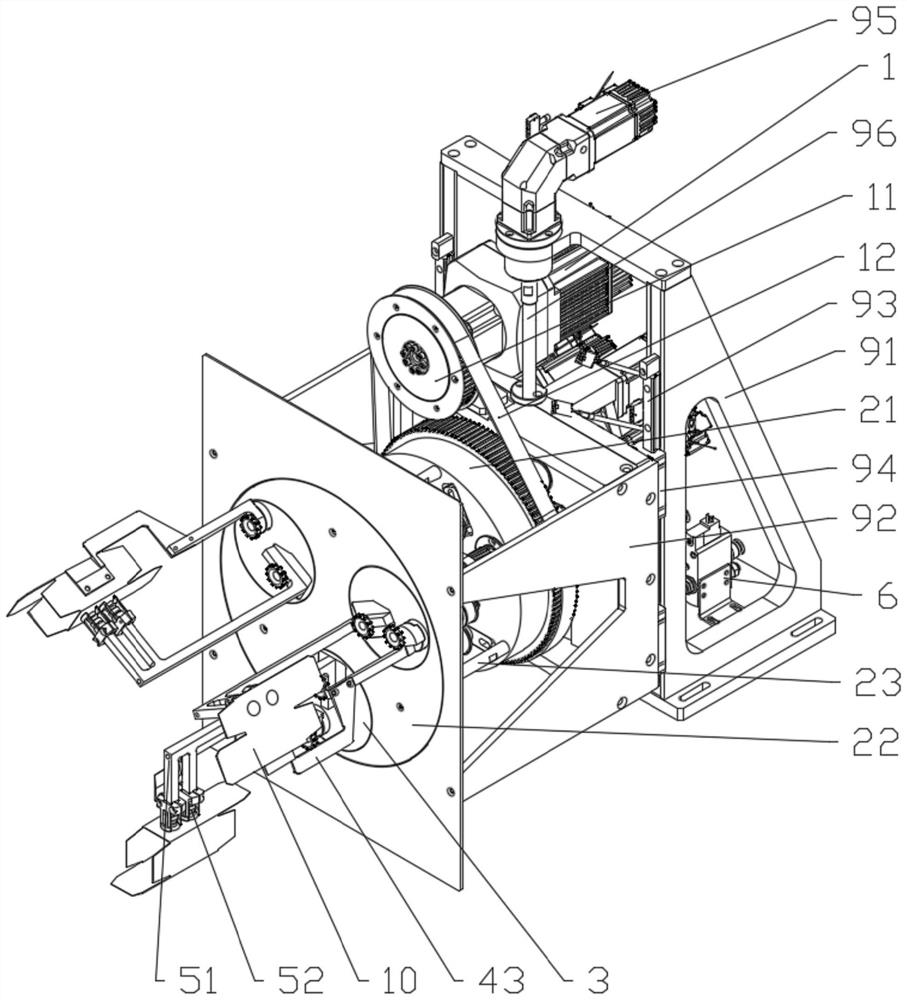

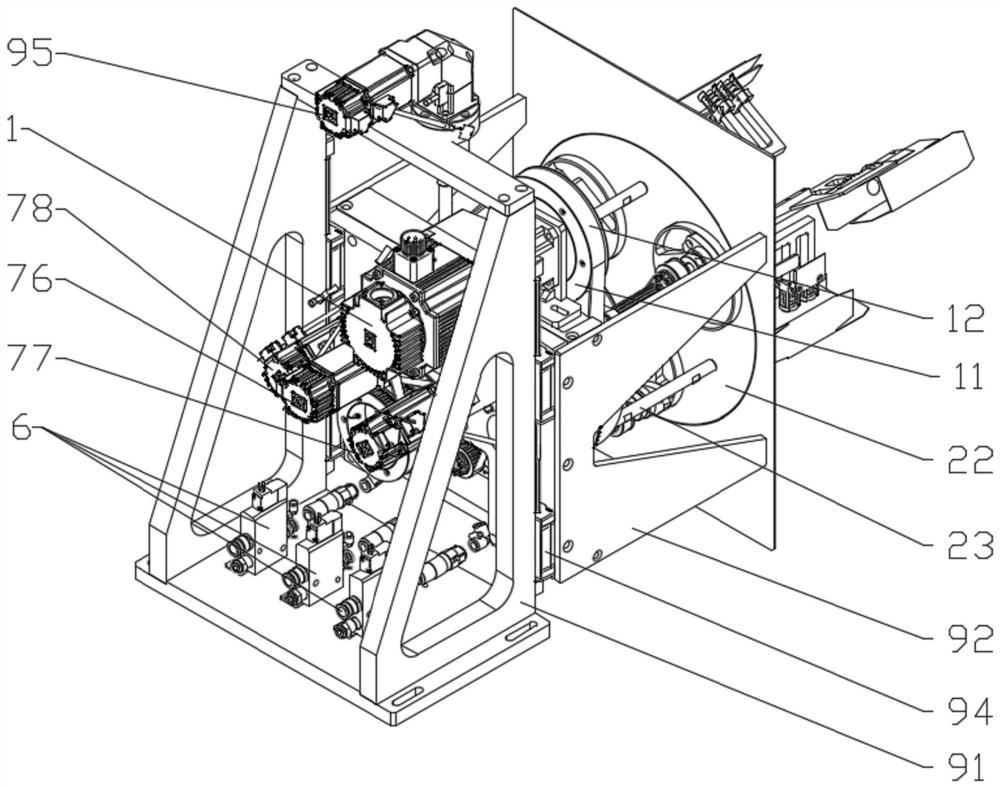

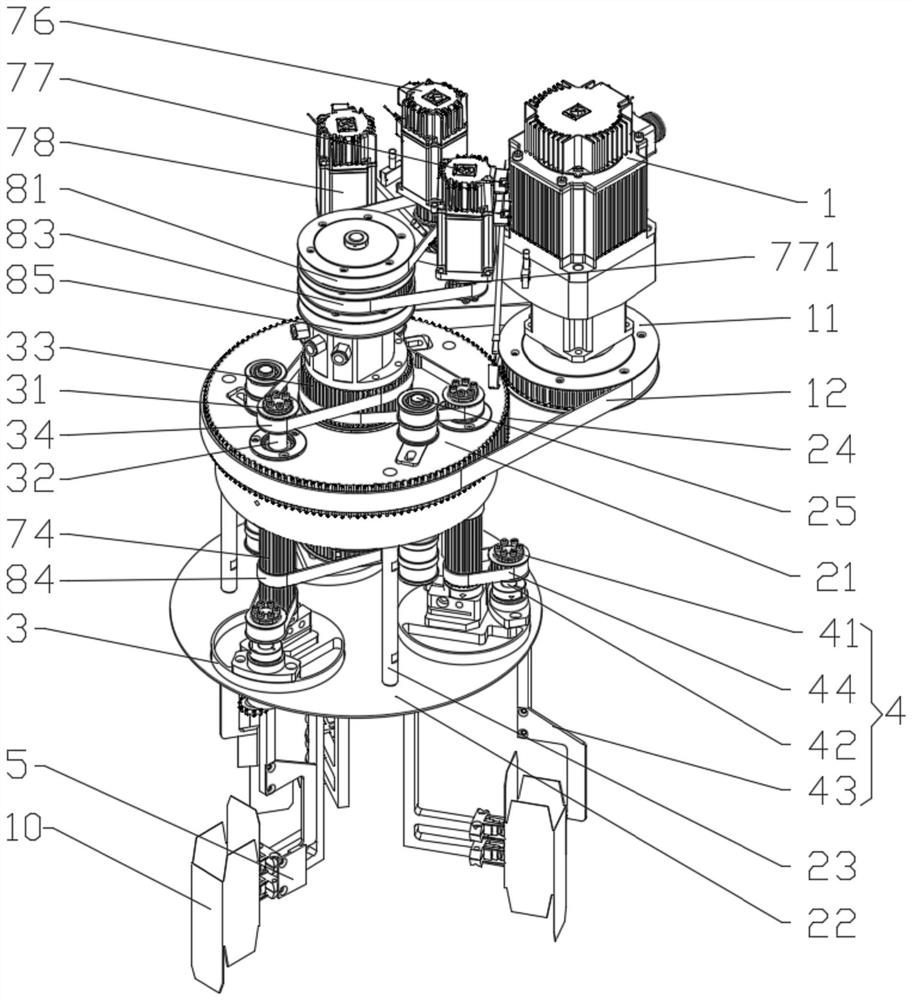

Paper box opening device for box packing machine

The invention discloses a paper box opening device for a box packing machine. The paper box opening device comprises a main driving servo assembly, a main driving disk, rotation disks, rotation disk driving assemblies, box preopening servo assemblies, box opening assemblies, box suction assemblies and vacuum assemblies. The main driving servo assembly is in transmission connection with the main driving disk. The main driving disk is provided with the three rotation disk driving assemblies distributed circumferentially and the three rotation disks distributed circumferentially. Each rotation disk driving assembly controls one rotation disk to rotate. The rotating direction of the main driving disk is opposite to that of the rotation disks. Each rotation disk is provided with one box openingassembly and one box suction assembly. Each box opening assembly is independently controlled by one box preopening servo assembly. Each box suction assembly is connected with one vacuum assembly. Thepaper box opening device for the box packing machine can improve the working efficiency and is convenient to control and stable and reliable in operation.

Owner:GUANGZHOU PHARMA INTELLIGENT EQUIP CO LTD

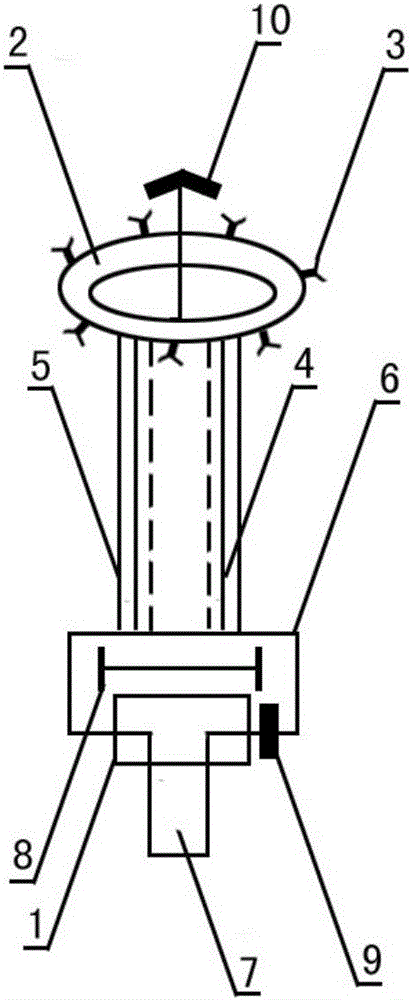

Internal diameter spraying treatment machine

InactiveCN105709977AApplicable production needsImprove stabilityPretreated surfacesLiquid spraying apparatusLacquerEngineering

The invention relates to an internal diameter spraying treatment machine. The internal diameter spraying treatment machine comprises a machine body (1) which is integrally designed by adopting a telescopic structure, wherein a circular hollow pipe device (2), and sprinkler heads (3) are arranged at the front end of the machine body (1); a pipe body is connected with a long hollow pipeline device (4), a hanging bracket (5) is positioned on two sides of the pipe body, and a housing device (6), a connecting clamping groove (7) and a handrail device (8) are arranged at the lower end. When the internal diameter spraying treatment machine is used, a pressure pump (9) is started, the pipeline is filled with anticorrosion paint, and the pipeline extends into a circular object, the handrail device (8) is pulled to perform movable spraying operation; a drying lamp assembly (10) is arranged, penetrates through the middle part of the circular hollow pipe device (2) and is in a telescopic hanging state; a connecting design mode is adopted, so that the stability is high, not only can the size of a ring position be adjusted flexibly, but also manual extending treatment can be performed, and the internal diameter spraying treatment machine meets the production requirements of small diameter objects, and has high practicality.

Owner:ANQING LINGKANG ELECTROMECHANICAL PROD DESIGN

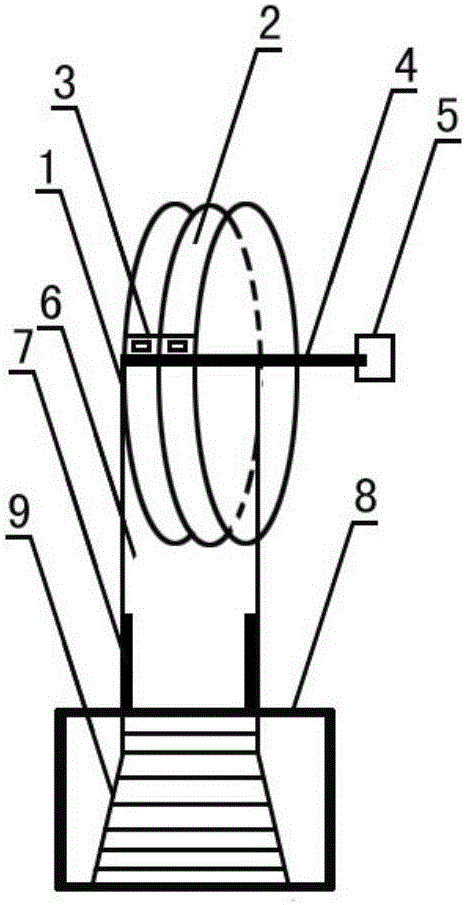

Energy saving assembly used in rattan weaving

InactiveCN105856353AEasy to stretchApplicable production needsCane mechanical workingCircular discEngineering

An energy saving assembly used in rattan weaving comprises a frame body (1), wherein the frame body (1) is overall upright; a disc structure is arranged on the upper portion of the frame body (1) and comprises two groove-shaped disc devices (2), a positioning module (3), a rotary shaft device (4) and a clamping position device (5); a vertical supporting rod device (6) is arranged in the middle of the frame body (1); a lifting device (7) is arranged on the inner side of a rod body; a base cover device (8) is arranged at the bottom of the frame body (1); in the use process, rattans are stretched, positioned and the like according to the weaving requirements, and time and labor are saved; a pedal device (9) is arranged at the bottom of the frame body (1), connected with the rotary shaft device (4) and used for adjusting the operation speed; and a thread structure is arranged inside the clamping position device (5) and the clamping position device (5) does not rotate along with the rotary shaft device (4). Convenience is provided for stretching of the rattans, intelligent adjustment can also be conducted, operation is easy, and the energy saving assembly is suitable for the production requirement of the weaving operation, accurate in positioning and high in practicability.

Owner:ANQING DADONG ELECTRONICS SCI & TECH CO LTD

Isaria fumosoroseus and application thereof for preventing and treating bemisia tabaci

The invention discloses a strain of Corynesium fumosoroseus (Isariafumosoroseus) and its application in preventing and treating Bemisia tabaci. The strain is preserved in the China Type Culture Collection Center, the preservation date is October 12, 2012, the preservation number CCTCC NO: M2012400, and the taxonomic status belongs to Eumycota, Mitosporic fungi, Hyphomycetes ), Hyphomycetales, Hyphomycetaceae, Isaria. Corynesporium fumigata rosea strain of the present invention is highly pathogenic to type B whitefly, and its semi-lethal concentration (LC50) to 2nd instar nymphs is 7.5 × 105 conidia / mL (the 4th day after inoculation) , the field control effect on Bemisia tabaci can reach more than 90%, which is equivalent to the chemical insecticide spirotetramat. As a live biopesticide, the bacterial strain has no pollution to the environment and no toxicity to humans and animals, and is suitable for the production of organic agricultural products.

Owner:SOUTH CHINA AGRI UNIV

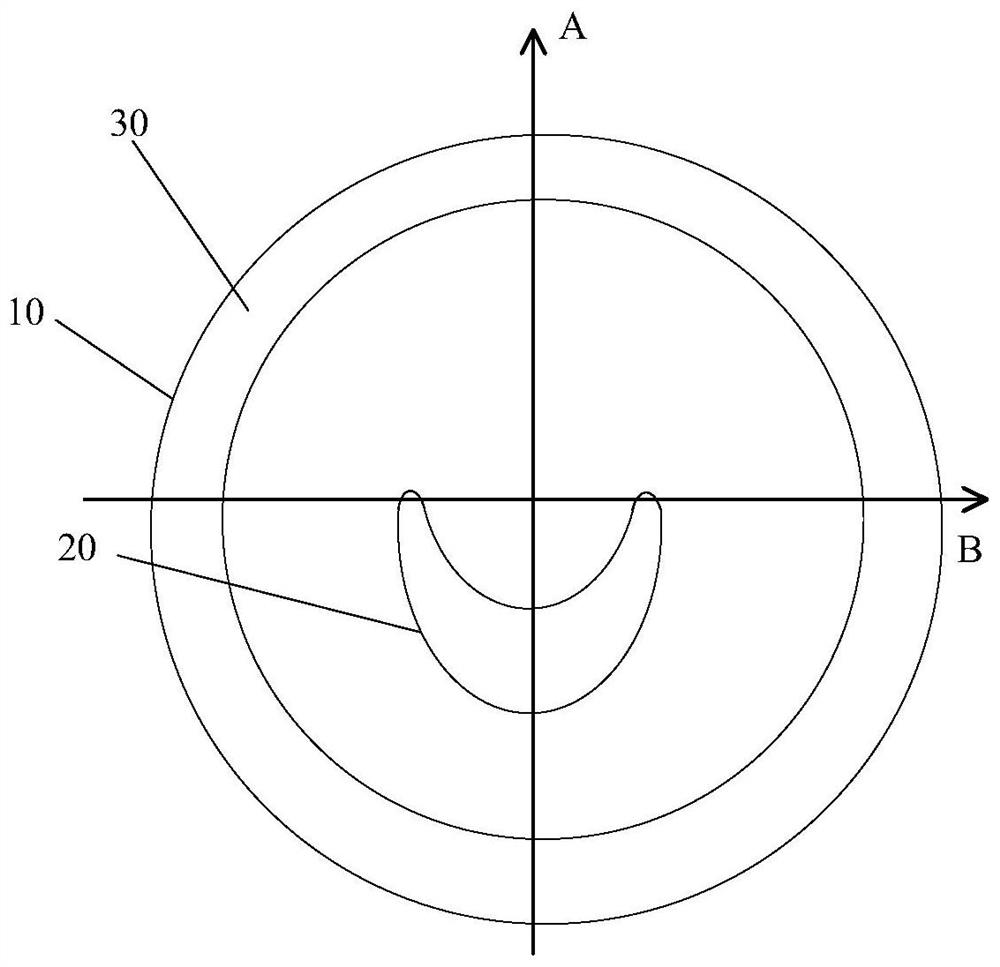

A magnetically positioned air-floating turntable

ActiveCN105810228BHigh rotation accuracyReduce vibrationUndesired vibrations/sounds insulation/absorptionRecord information storageFriction lossEngineering

The invention discloses a magnetic positioning air flotation turntable which comprises a rotary table (1) and a support plate (2).A rotary table magnet (3) is inlaid in the middle of the bottom face of the rotary table (1); the support plate (2) is located below the rotary table (1), a support plate magnet (4) is inlaid in the middle of the top face of the support plate (2), the rotary table magnet (3) and the support plate magnet (4) are mutually attracted, an annular buffer slot (6) is formed in the top face of the support plate (2), and an admission piece (5) is connected to the annular buffer slot (6).According to the air rotary table system, the revolution precision is high, vibration is small, no direct contact exists, and no friction loss exists.The magnetic positioning air flotation turntable can be applicable to the production demands of high-end long-playing players.

Owner:NANTONG JUJIU NEW MATERIAL SCI & TECH CO LTD

Rolling machine air valve manual adjusting device

PendingCN108953745AFlexible adjustment of openingControl openingOperating means/releasing devices for valvesAir volumeWind system

The invention relates to the field of rolling machines, in particular to a rolling machine air valve manual adjusting device. The rolling machine air valve manual adjusting device comprises a body, amoving plate arranged on the body in a sliding mode and a driving mechanism; and an air port is formed in the body, moreover, the air port is located in the sliding range of the moving plate, and themoving plate is connected to the driving mechanism. The rolling machine air valve manual adjusting device has the advantages that the driving mechanism drives the moving plate to slide in the body, the air port is located in the sliding range of the moving plate, then opening and closing of the air port are achieved, meanwhile, the air volume can be flexibly adjusted through the size of the area of the part, shielded by the moving plate, of the air port, for the rolling machine air valve manual adjusting device, the opening degree of the moving plate can be visually controlled, the adjusting process is reliable, moreover, the manual adjusting device can work in a high-temperature environment for a long time, and is more suitable for production requirements, the influence caused by wind system faults on production is greatly reduced, meanwhile, the leakage quantity of air can be well guaranteed, then the production requirements can be met, moreover, the structure is relatively simple, the installation is convenient, the cost is saved, and the production efficiency is improved.

Owner:BENGBU TRIUMPH ENG TECH CO LTD

Filtering method of aluminum drawing oil

InactiveCN107349676AReduce consumable costsEfficient removalFiltration circuitsLiquid mediumPower flow

The invention discloses a filtering method of aluminum drawing oil. The method includes the following steps that 1, the oil passes through a cartridge filter of a vacuum membrane pump; 2, an electric current passing through a filter is applied on the oil, wherein the electric current has specific frequency and dynamic changing voltage; 3, pollutant particles in the oil go into a potential separation chamber after charged; 4, the pollutant particles with opposite charges become larger after mutual attraction; 5, a liquid medium is separated by a centrifuge, and the particles becoming larger are adsorbed on a drum; 6, the drum is cleaned at regular time. The method has the advantages that the filtering precision can reach 0.01 micrometer, a filtering net is not needed, and a large amount of consumable expense is saved.

Owner:JIANGSU GANGTONG CABLE

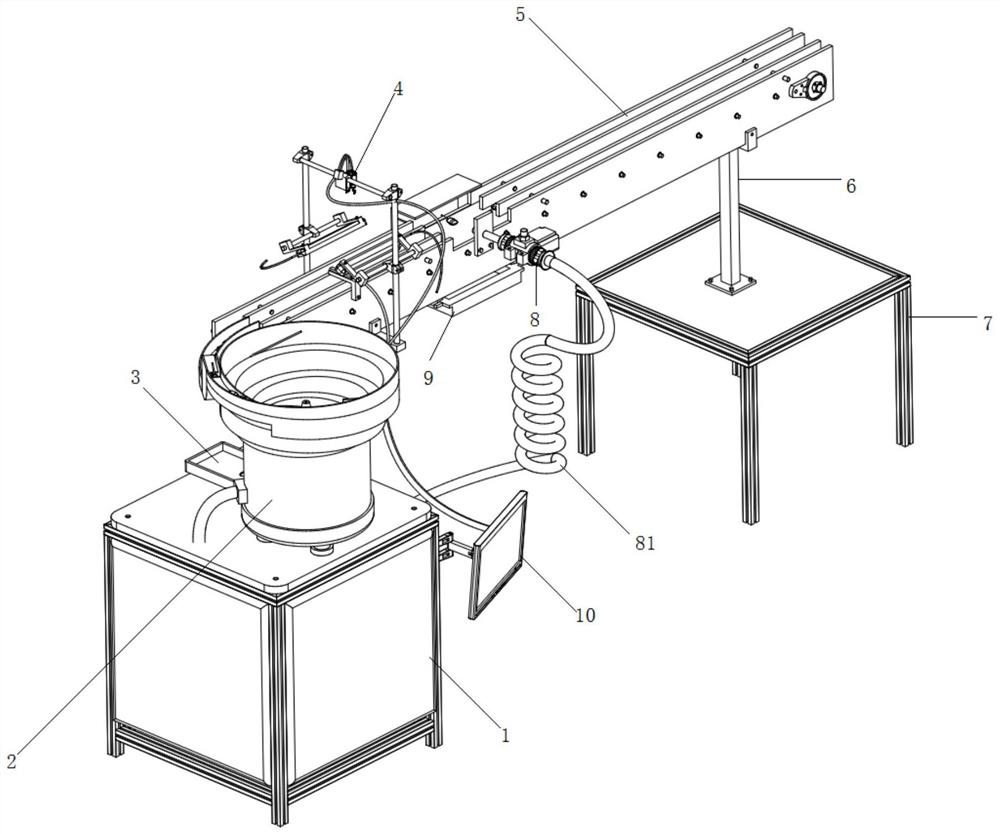

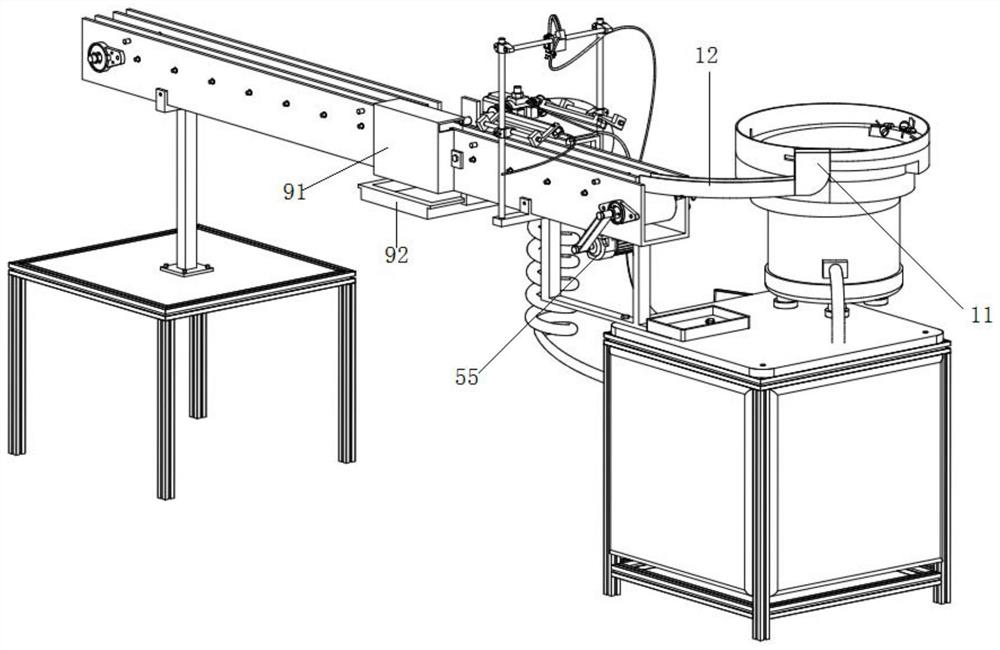

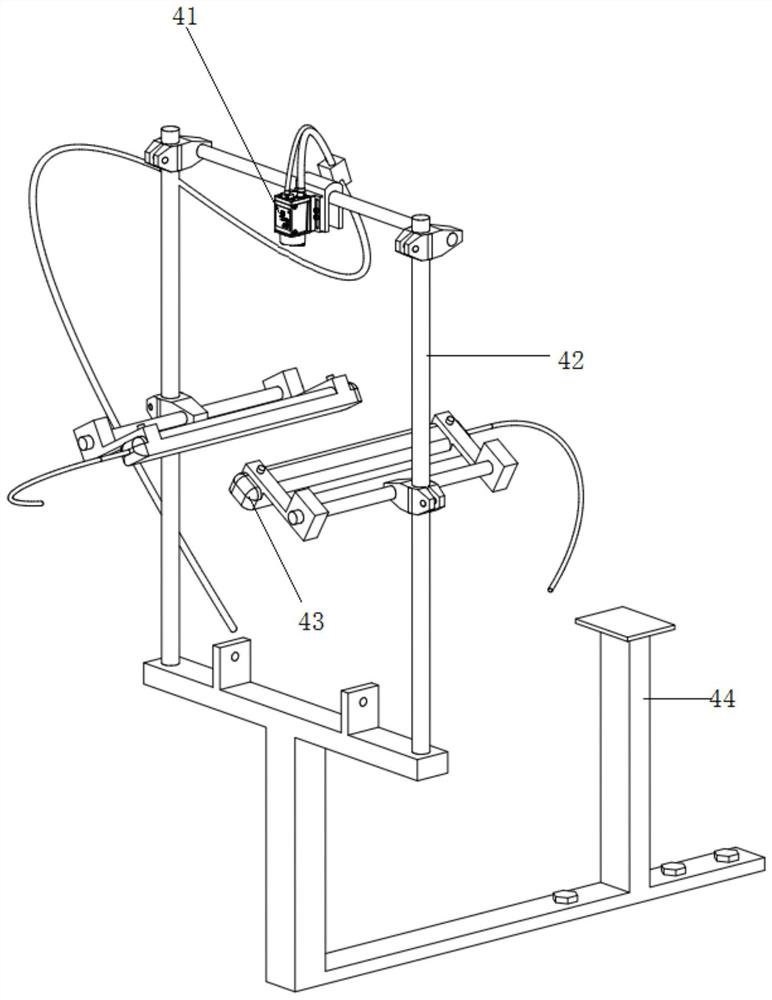

Candy quality detection method based on machine vision and feeding rejecting system

PendingCN114700273AReduce lossAccurate detectionImage enhancementImage analysisProcess engineeringDelivery system

The invention discloses a candy quality detection method based on machine vision and a feeding and rejecting system. The candy quality detection system is characterized by comprising an ordered discharging system, a visual detection and rejecting system and a feeding and conveying system, the feeding conveying system is connected to the rear end of the orderly discharging system, and the visual detecting and removing system is erected on the upper portion of the feeding conveying system and used for detecting the quality of candies and removing defective products. According to the device, orderly discharging of candy products and appearance quality detection and removal can be achieved, the problems of adhesion and different discharging directions in the candy production process are effectively solved, the quality inspection quality and efficiency of candies are improved, and the labor cost is saved.

Owner:广东猛犸象智能机器人制造有限公司

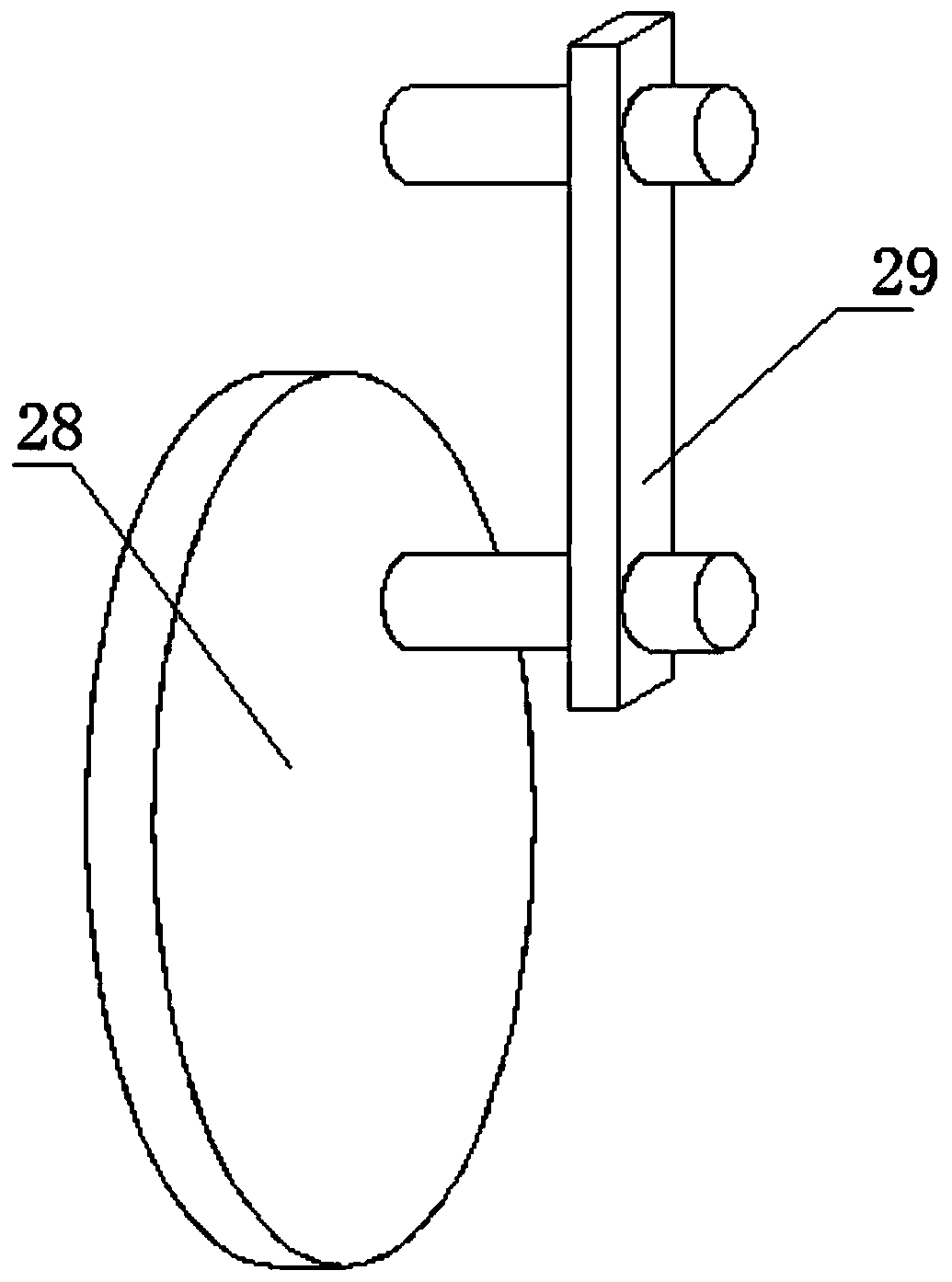

A strain of P. lilacinus and its application in the control of flea beetle

The invention relates to a P. lilacensis strain and its application in preventing and treating flea beetle, and belongs to the technical field of biological pesticides. The Purpureocillium lilacinum PlSC59A3 strain has been preserved in the Guangdong Microbial Culture Collection Center on October 16, 2020, and the preservation number is GDMCC No: 61232. The PlSC59A3 strain of P. lilacinus provided by the present invention is highly effective in preventing and treating flea beetle. The strain is an entomopathogenic fungus. As a biological pesticide, it has no pollution to the environment, is not easy for pests to develop drug resistance, and is harmless to humans and animals. It is suitable for the production needs of green and healthy agricultural products.

Owner:SOUTH CHINA AGRI UNIV

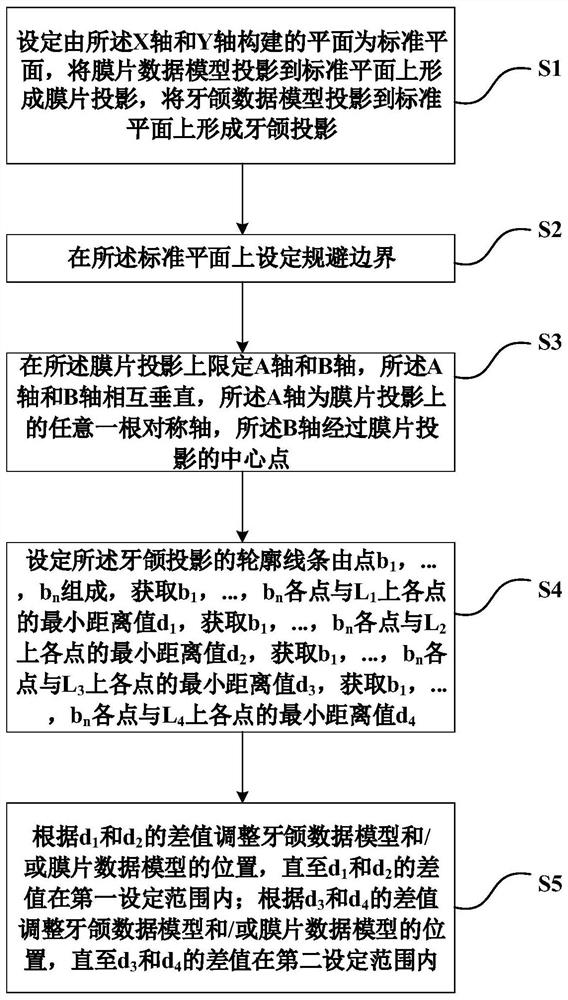

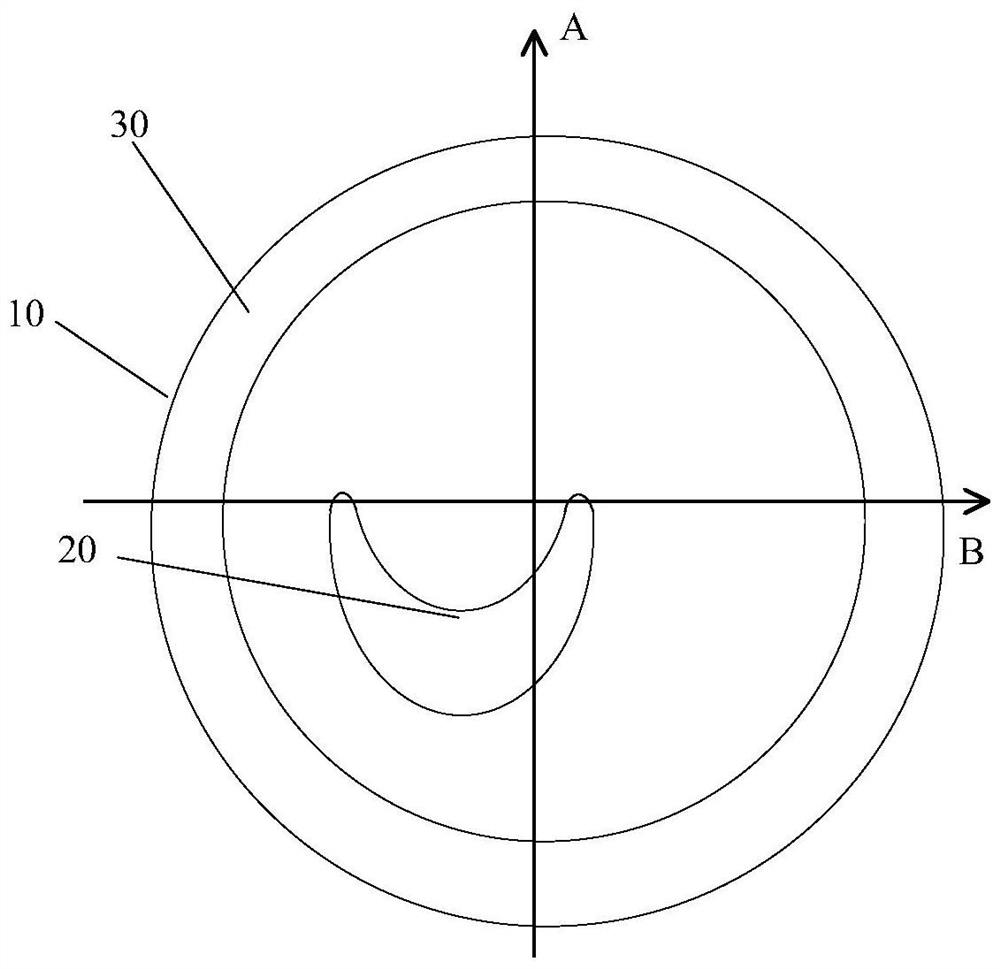

Method for determining positions of diaphragm and dental model, diaphragm and selection method and system

PendingCN114533312AEasy to operateImprove the efficiency of the production processOthrodonticsManufacturing computing systemsBiomedical engineeringDental Models

The invention provides a method for determining a spatial relative position relationship between a diaphragm data model and a dental data model. The method comprises the following steps of: establishing a coordinate system, setting an avoiding boundary on a standard plane, limiting a coordinate axis on a diaphragm projection, calculating minimum distance values from points on a contour line of a tooth jaw projection to the avoiding boundary, and adjusting each minimum distance value to be within a set range, so as to optimize a relative position relationship between a diaphragm and a tooth jaw model; the compatibility of the membranes is verified by using a large number of dental models, the membranes compatible with different dental models are effectively selected, the utilization rate of the membranes is improved, the waste of membrane materials is effectively avoided, and the production cost is reduced. The invention further provides a diaphragm data model selection method and system, the diaphragm, electronic equipment and the like, manual operation is not needed, the efficiency of the whole production technology is improved, and the phenomenon of waste of the diaphragm in the production process is avoided.

Owner:SHANGHAI SMARTEE DENTI TECH CO LTD

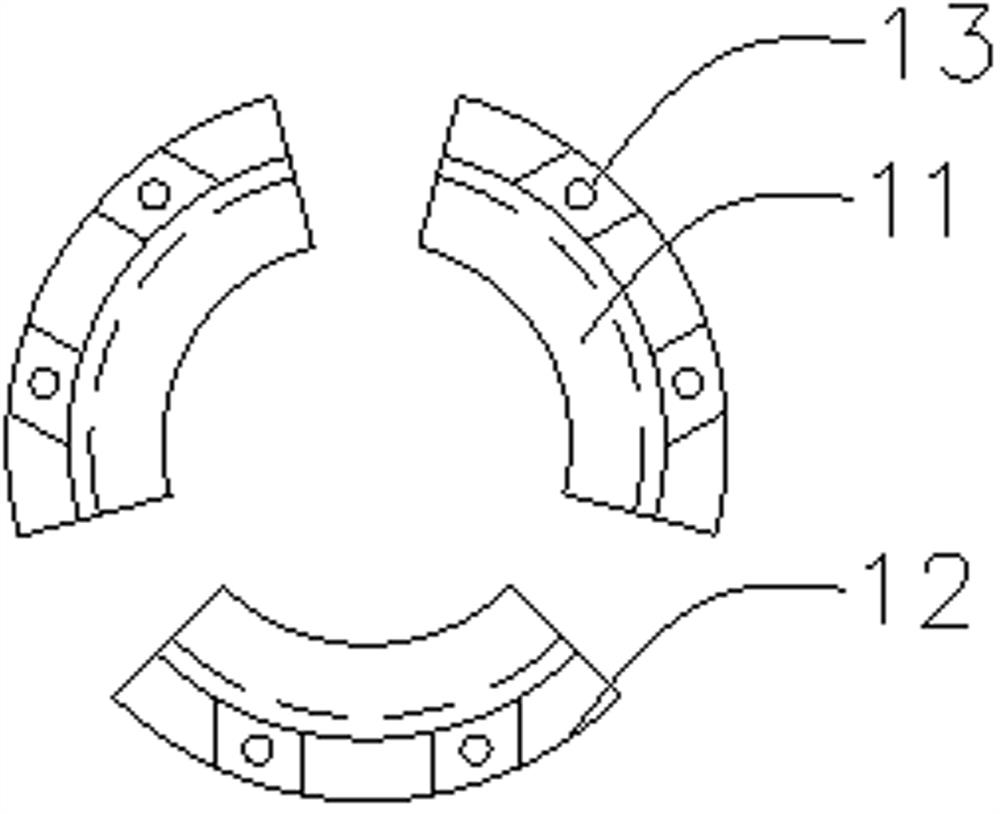

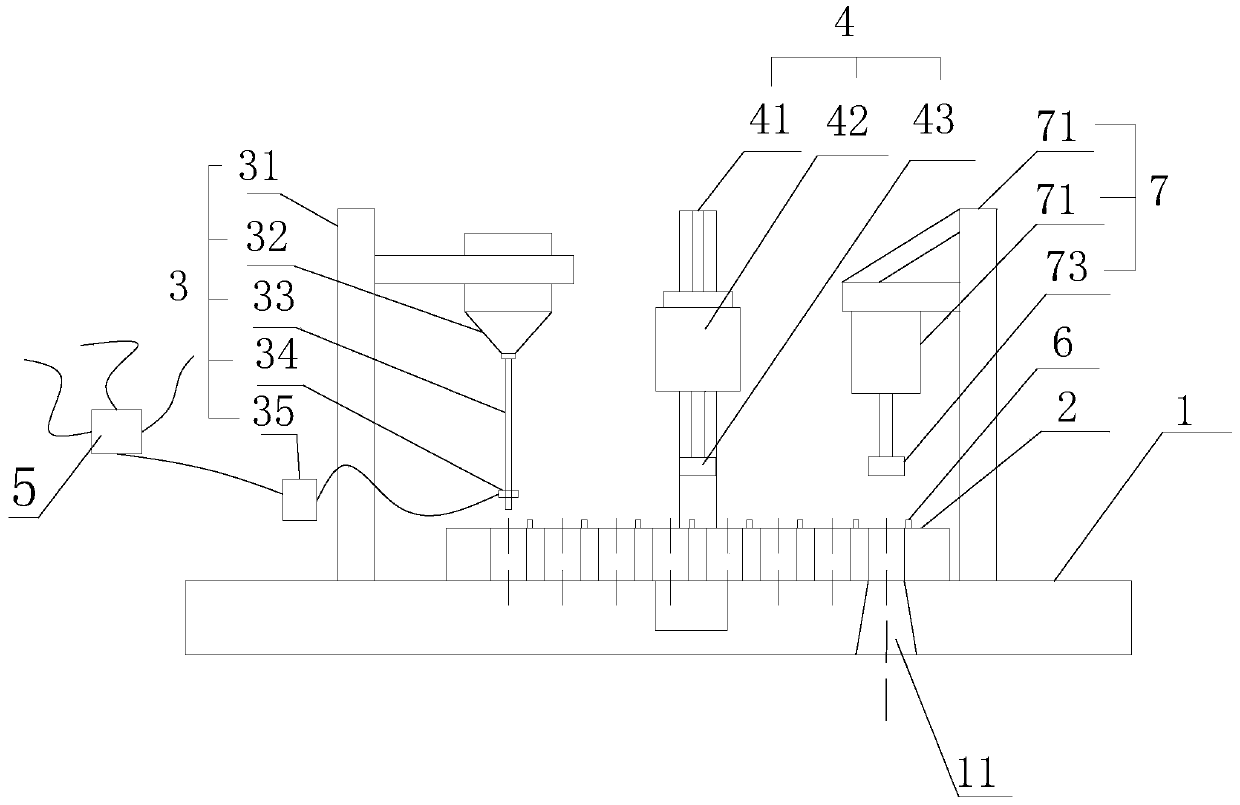

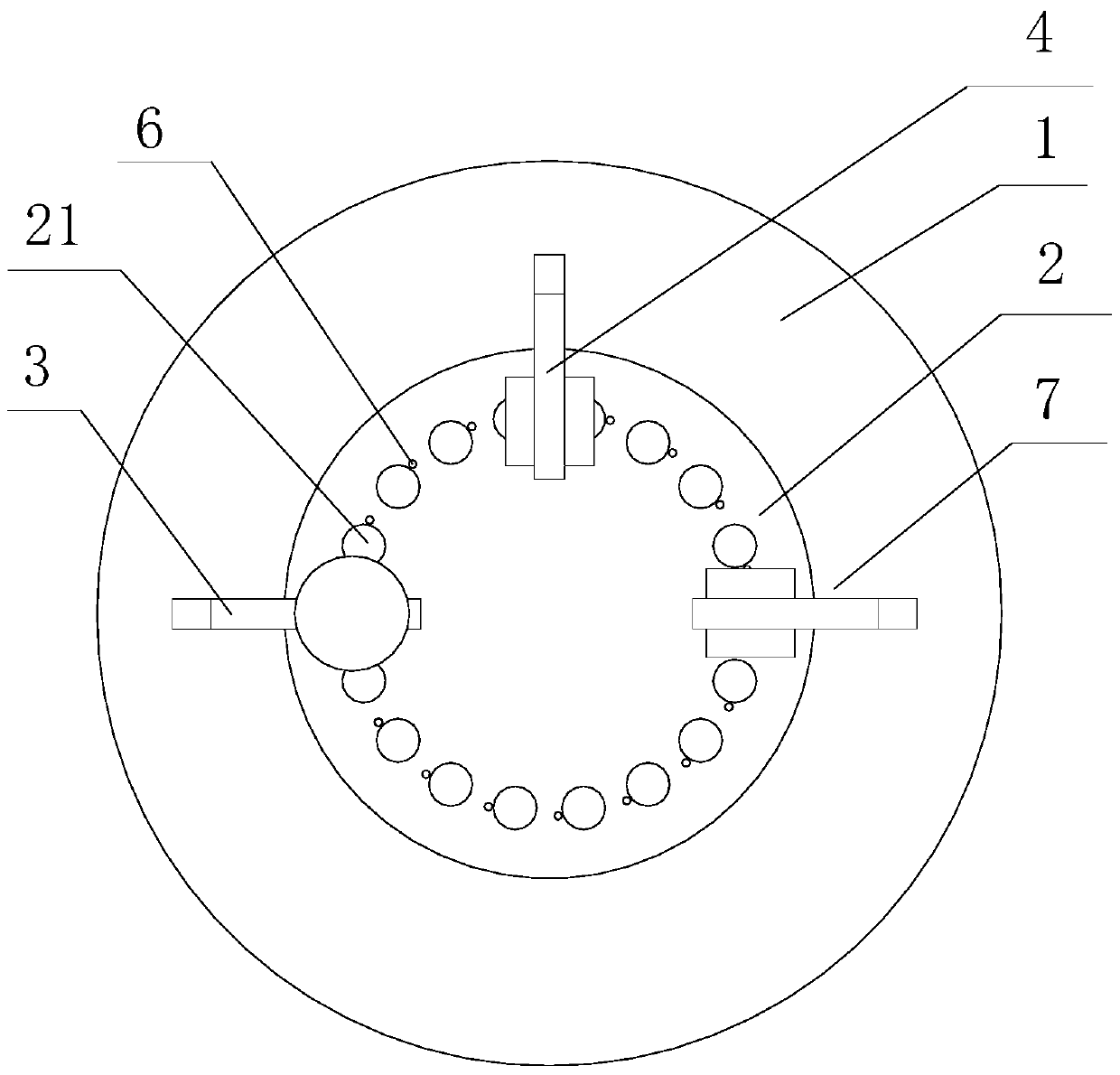

Pressure quenching production method for annular workpiece

PendingCN114457219AImprove stabilityImprove pass rateFurnace typesIncreasing energy efficiencyEngineeringInductor

According to the pressure quenching production method for the annular workpiece, the annular workpiece is conveyed to a tooth alignment machine tool through a feeding machine tool, a finger air cylinder of the tooth alignment machine tool fixes the annular workpiece to a positioning disc of a tooth alignment station, a second air cylinder with a positioning switch moves the positioning switch to the position of the tooth alignment workpiece, the workpiece rotates to the position of the positioning switch and stops, and then the annular workpiece is pressed and quenched. Tooth alignment is completed; the annular workpiece subjected to tooth alignment is transferred to a heating machine tool, the output end of a heater of the heating machine tool is connected with an inductor, and the inductor is aligned with the part, needing to be heated, of the part to conduct induction heating; and the manipulator moves the heated workpiece to the quenching temperature and sends the workpiece to a pressure quenching workbench for quenching. According to the pressure quenching production method for the annular workpiece, the whole heat treatment method for the annular workpiece is solidified through adjustment and design of all procedures before and after pressure quenching, and the stability of the workpiece and the qualified rate of batch products are improved.

Owner:株洲市湘宁高中频设备有限责任公司

Structural adhesive for automobile and preparation method of structural adhesive

PendingCN113025215AReduce viscosityEasy to stir and mixNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveAdhesive cementAdhesive glue

The invention provides a structural adhesive for an automobile and a preparation method of the structural adhesive, and relates to the field of glue preparation. The structural adhesive for the automobile is prepared from the following components (in parts by weight): 50-80 parts of an acrylate composition, 3-8 parts of a photoinitiator, 1-5 parts of a coupling agent, 10-20 parts of a filler and 1-2 parts of a dispersing agent. The preparation method of the structural adhesive for the automobile comprises the steps of primary stirring, secondary stirring, tertiary stirring, filling and packaging. By reasonably selecting the materials, the prepared product is stable and is suitable for the production requirements of automobiles, and meanwhile, the stirring efficiency can be improved by adopting a dilution mode in the production of the product.

Owner:东莞市博翔电子材料有限公司

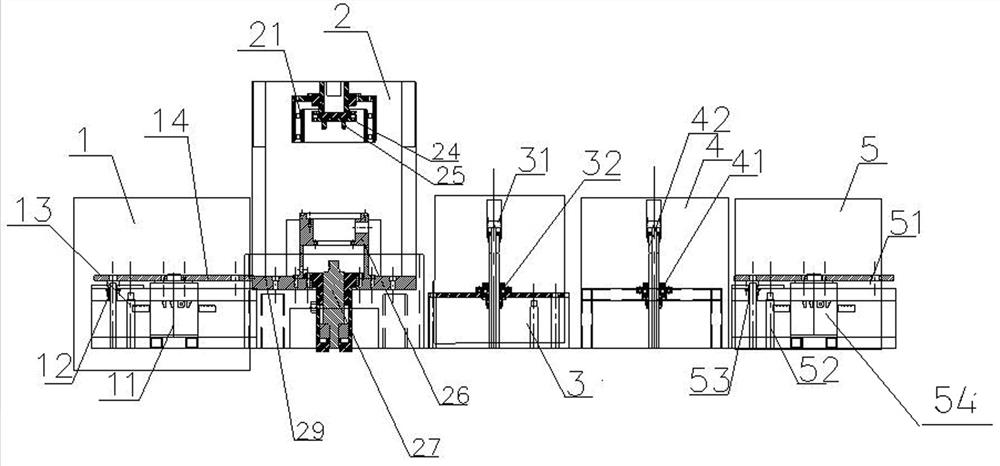

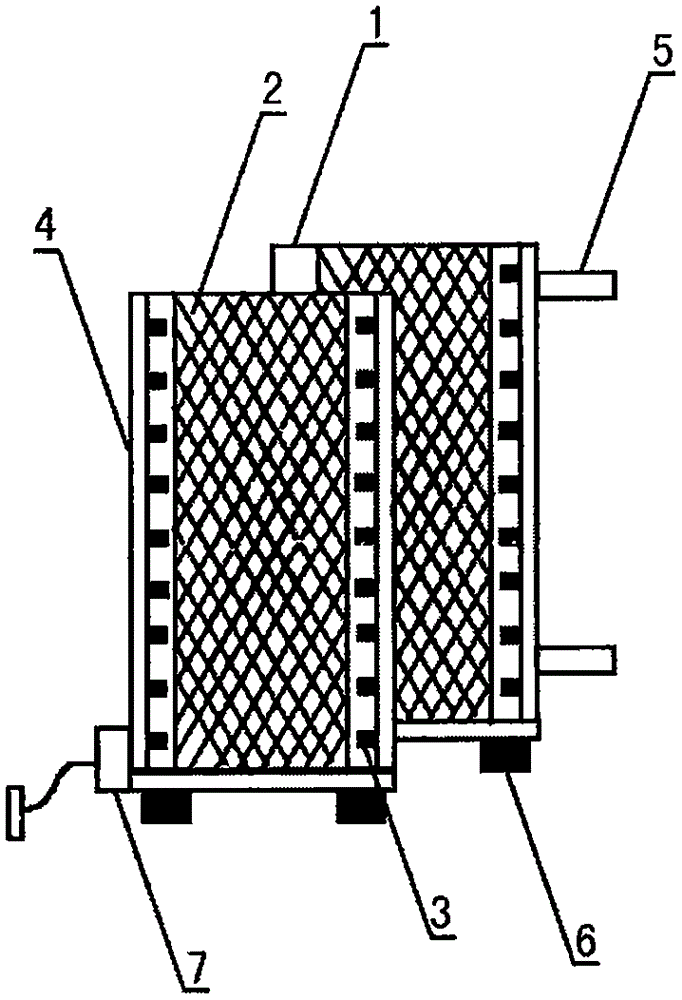

Automatic pressure quenching production system for steel rings

PendingCN114457213AApplicable production needsSimple structureFurnace typesIncreasing energy efficiencyBall screwElectric machinery

The invention discloses an automatic steel ring pressing and quenching production system which comprises an automatic feeding machine tool, a tooth aligning machine tool, synchronizer heating equipment, a pressing and quenching machine tool and an automatic discharging machine tool which are sequentially arranged, the automatic feeding machine tool comprises a material storage rotating disc on the machine tool, the material storage rotating disc is provided with a plurality of mounting positions, and the material storage rotating disc is driven by a motor and positioned by a divider; a ball screw I is arranged at the bottom of the storage turntable; the tooth aligning machine tool comprises a tooth aligning mounting position, a first air cylinder and a second air cylinder with a positioning switch. The synchronizer heating equipment comprises a heater and a heating mounting position, the output end of the heater is connected with an inductor, and the inductor is aligned to the part, needing to be heated, of the part; a discharging rotating disc is arranged on the automatic discharging machine tool, and a second ball screw is arranged at the bottom of the discharging rotating disc. The heating quenching system has the advantages of advanced structure, simplicity in operation, convenience in maintenance and the like. The control part of the steel ring automatic pressure quenching production system adopts PLC + touch screen control, and has the characteristics of convenience and simplicity in operation and stable performance.

Owner:株洲市湘宁高中频设备有限责任公司

Raw bamboo slitting machine capable of adjusting size of bamboo canes and used for processing bamboo mats

PendingCN112873455AReduce maintenance costsEasy to openCane mechanical workingProfiling/shaping machinesKnife bladesStructural engineering

The invention discloses a raw bamboo slitting machine capable of adjusting the size of bamboo canes and used for processing bamboo mats, and belongs to the technical field of bamboo processing devices. The raw bamboo slitting machine comprises a transmission device, a slitting device, a limiting device, a fixing device and a base, the slitting device and the limiting device are arranged on the base, and the fixing device is installed on the transmission device; the slitting device mainly comprises an inner ring, a fixed lantern ring, a section breaking blade, a cutting blade, a limiting block and a fixed bottom plate; the section breaking blade is conical, an inserting groove is formed in the outer side of the section breaking blade, the cutting blade penetrates through an inserting hole in the inner ring to be connected with the inserting groove in an embedded manner, the end, arranged at the outer side of the inner ring, of the cutting blade is fixedly connected with the limiting block, the fixed lantern ring is arranged at the outer side of the limiting block, and a limiting ring is arranged at one end of the fixed lantern ring; and the lower portion of the fixed lantern ring is connected with the fixed bottom plate in an embedded manner through a connecting clamping block. By means of the raw bamboo slitting machine, the cutting blade can be detached, the production requirements of the bamboo canes with different widths can be met, the equipment maintenance cost is reduced, and abrasion to the cutting blade is small.

Owner:ZHEJIANG UNIV OF TECH

A tablet automatic pressing device

The invention discloses an automatic tablet molding device, which comprises: a base, a turntable, a driving mechanism, a feeding mechanism, a molding mechanism and a main controller. The turntable is installed on the base and driven to rotate by the driving mechanism. There is a cavity, and one side of the cavity is equipped with a sensor connected to the main controller; the main controller controls the work of the driving mechanism, the feeding mechanism and the molding mechanism; the base is equipped with a feeding station and a molding station; The mechanism is installed at the feeding station for injecting powder into the cavity; the pressing mechanism is installed at the pressing station for tableting the powder in the cavity. The invention has simple and reasonable structure, high degree of automation, and realizes the purpose of automatic feeding and pressing, greatly improves the efficiency of pharmacy, reduces the work intensity of staff, and is suitable for the needs of assembly line production; at the same time, due to the In the process, the opening time of the solenoid valve is uniformly stipulated, which ensures the uniformity of powder addition to a large extent.

Owner:刘宇

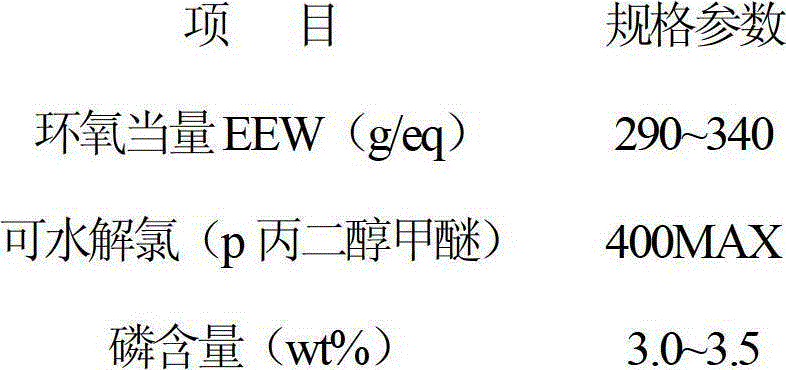

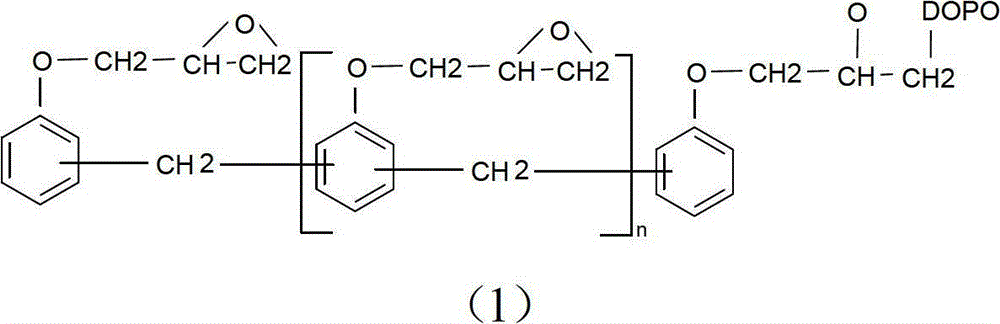

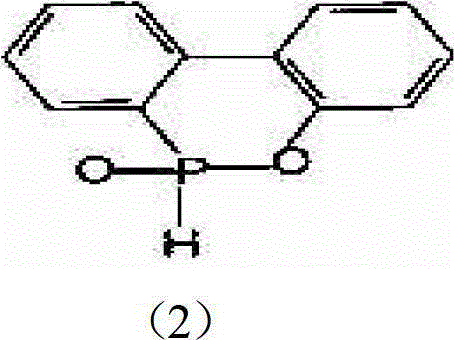

A flame-retardant copper-clad laminate coated with phosphorus-containing and halogen-free solids and its preparation method

ActiveCN102975430BImprove featuresImprove heat resistanceNon-macromolecular adhesive additivesLamination ancillary operationsFiberEpoxy

Owner:NANYA NEW MATERIAL TECH CO LTD

Adhesive sticker quick drying module of screen structure

InactiveCN106802073ANovel structural designApplicable production needsDrying gas arrangementsHeating arrangementTemperature controlMedium enterprises

The invention discloses an adhesive sticker quick drying module of a screen structure. The module comprises a frame body (1); the frame body (1) is divided into two corresponding screen formats with equal structures; a wide-screen electric heating silk screen device (2) is arranged at the middle part; ventilation hole devices (3) are inwards distributed on two sides at equal intervals; the gas transmission is performed through a hollow pipe (4); a guide device (5) is arranged on one side of the frame body (1); two frame bodies (1) are placed at the front part of a winding drum device in use; after a newly printed adhesive sticker penetrates through the middle part, the targeted drying operation is performed; a substrate device (6) is arranged at the bottom of the frame body (1), and adopts an antiskid rubber bottom material design to achieve high stability; and a temperature control device (7) is arranged on the side edge of the frame body (1) for manually setting corresponding temperatures and performing the timing reminding. The module is novel in appearance structural design, effectively uses two side screens for performing multi-surface drying, is convenient to adjust, meanwhile, performs intelligent temperature control, is low in manual participation degree, and is suitable for production demands of small and medium enterprises.

Owner:俞泓

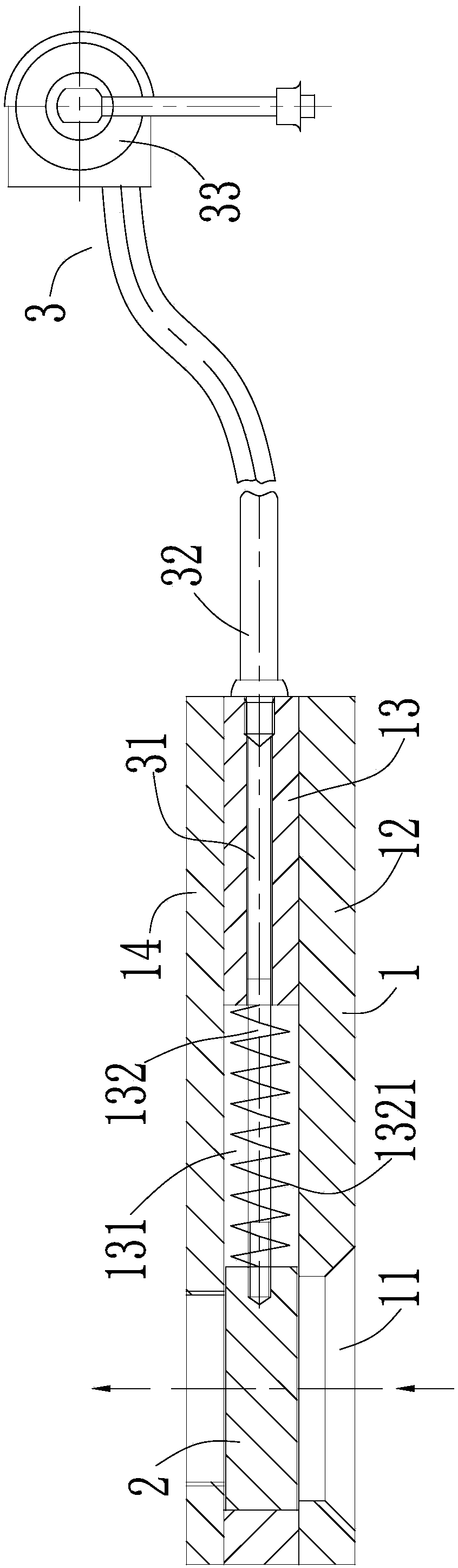

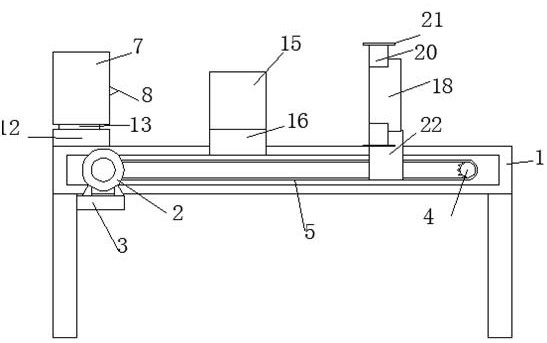

Inner core bending mechanism for wheel speed sensor

InactiveCN112845962AImprove bending efficiencyApplicable production needsDrive wheelWheel speed sensor

The invention discloses an inner core bending mechanism for a wheel speed sensor, relates to the technical field of bending mechanisms, and solves the problems that an existing inner core bending mechanism is required to manually and frequently unload bent inner cores, the relatively-high working intensity of workers is caused by high-frequency repeated operation, and the existing inner core bending mechanism is more troublesome, strenuous and inconvenient to use. The inner core bending mechanism for the wheel speed sensor comprises a base, the base comprises vertical supporting rods, the whole base is of a rectangular structure, the two vertical supporting rods are welded to the middle of the top end of the base at an interval, an L-shaped driving rod is inserted into the top end sections of the two vertical supporting rods in a penetrating mode, a motor is locked and vertically supported at the right end of the base, and a rotating shaft is mounted on a speed reducer of the motor in a coupling manner; and a positioning frame is rotationally mounted on the rotating shaft on the right side in a sleeving manner. The L-shaped driving rod is driven by a driving wheel and can share the same motor with two bending shafts, so that a driving motor additionally matched with the positioning frame is omitted, and the weight, the manufacturing cost and the power consumption of equipment are reduced.

Owner:赵瑞霞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com