Adhesive sticker quick drying module of screen structure

A screen and glue speed technology, applied in drying, drying machine, drying gas arrangement, etc., can solve problems such as color sample adhesion, affecting the overall quality of the product, blurring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

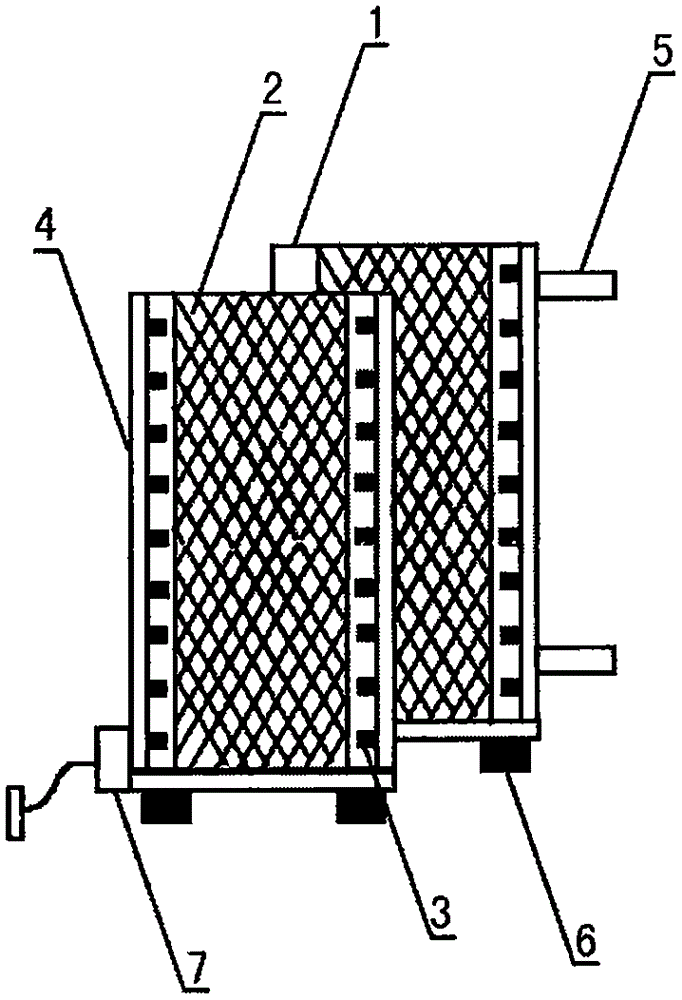

[0012] Embodiment: as shown in the accompanying drawing. A self-adhesive quick-drying component with a screen structure, comprising a frame body (1), the frame body (1) is divided into two equal structures and corresponding screen styles, and a wide-screen electric heating wire mesh device (2) is arranged in the middle, Ventilation hole devices (3) are equally spaced inward on both sides, and the air is transported through the hollow pipe (4). A guide device (5) is provided on one side of the frame body (1). When in use, place the two frame bodies (1) At the front of the roll device, after the newly printed self-adhesive passes through the middle, a targeted drying operation is carried out.

[0013] A self-adhesive quick-drying component with a screen structure, in which a base device (6) is arranged at the bottom of a frame body (1), and is designed with a non-slip rubber base material, and has high stability.

[0014] A self-adhesive quick-drying component with a screen str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com