Four-roller super-large drafting fancy yarn production device

A technology of super-large drafting and production equipment, which is applied to drafting equipment, yarns, spinning machines, etc., can solve the problems of increased cost and long process flow, and achieve the effects of high cost performance, shortened process flow, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

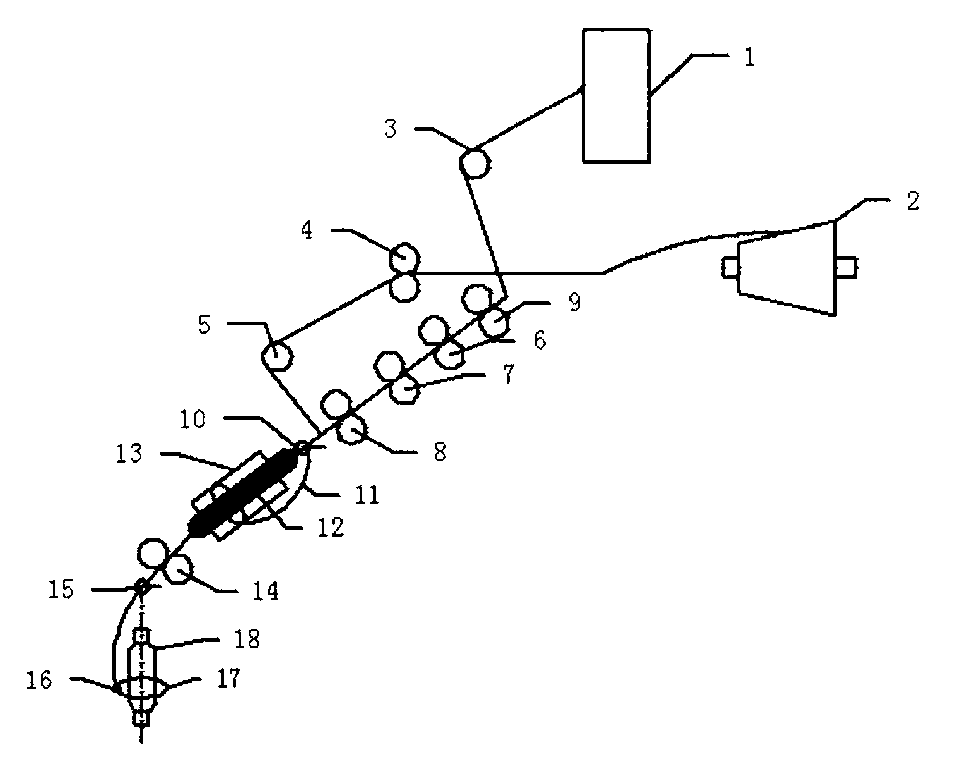

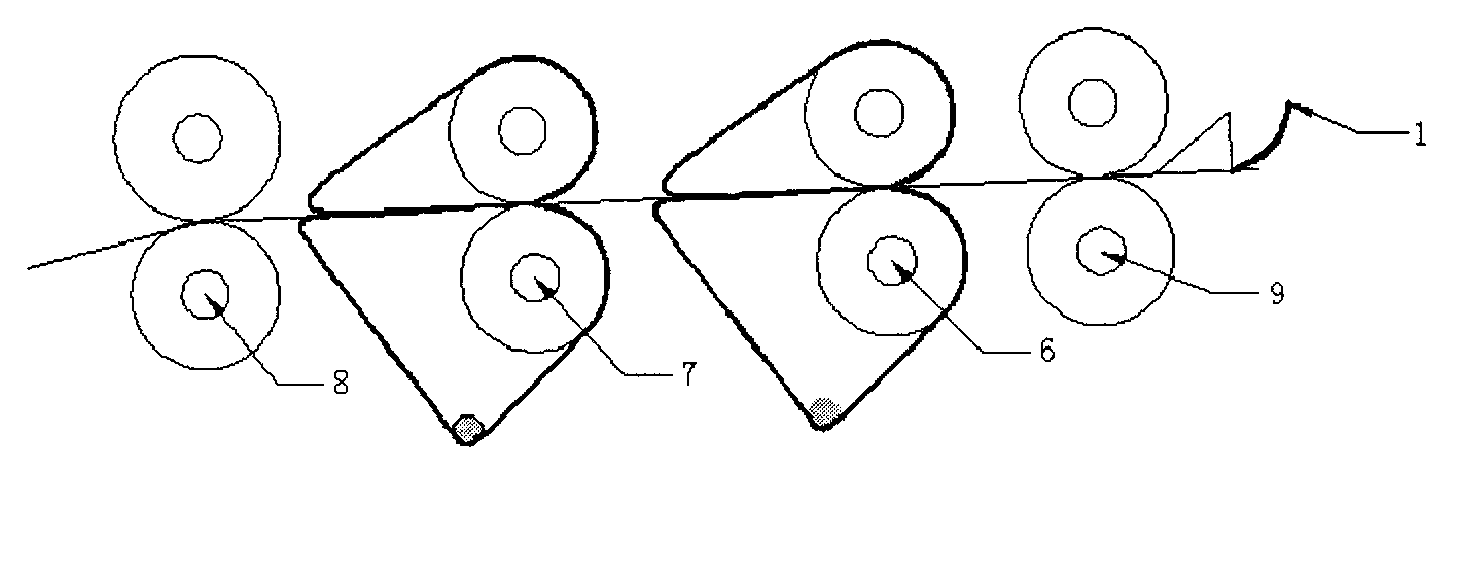

[0011] In the four-roller double-short apron trim yarn drafting device of the present invention, a set of apron rollers (6) is arranged. The apron drafting roller (6) is installed on the original rear roller position of the fancy twister, and the original rear roller (9) moves back along the original drafting horizontal line and the distance from the center of the apron roller (6) is 61 ~65mm, forming the front, middle and rear draft zones.

[0012] Extra large drafting device such as figure 2 As shown, including the rear draft zone formed between the rear roller (9) and the apron roller (6), the middle draft zone formed by the apron roller (6) and the middle roller (7), the middle roller (7) and the The front drafting zone formed by the front roller (8). Decorative yarn slivers or rovings (2) are twisted into spun yarns through the drafting action of the back, middle and front drafting zones respectively.

[0013] The present invention can be fed with roving or sliver, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com