Hybrid high-sensitivity photoelectric sensor system

A photoelectric sensor, high-sensitivity technology, applied in the field of photoelectric sensors, can solve problems such as poor linearity and large dynamic error, and achieve the effect of small dynamic error, wide frequency bandwidth, and improved application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

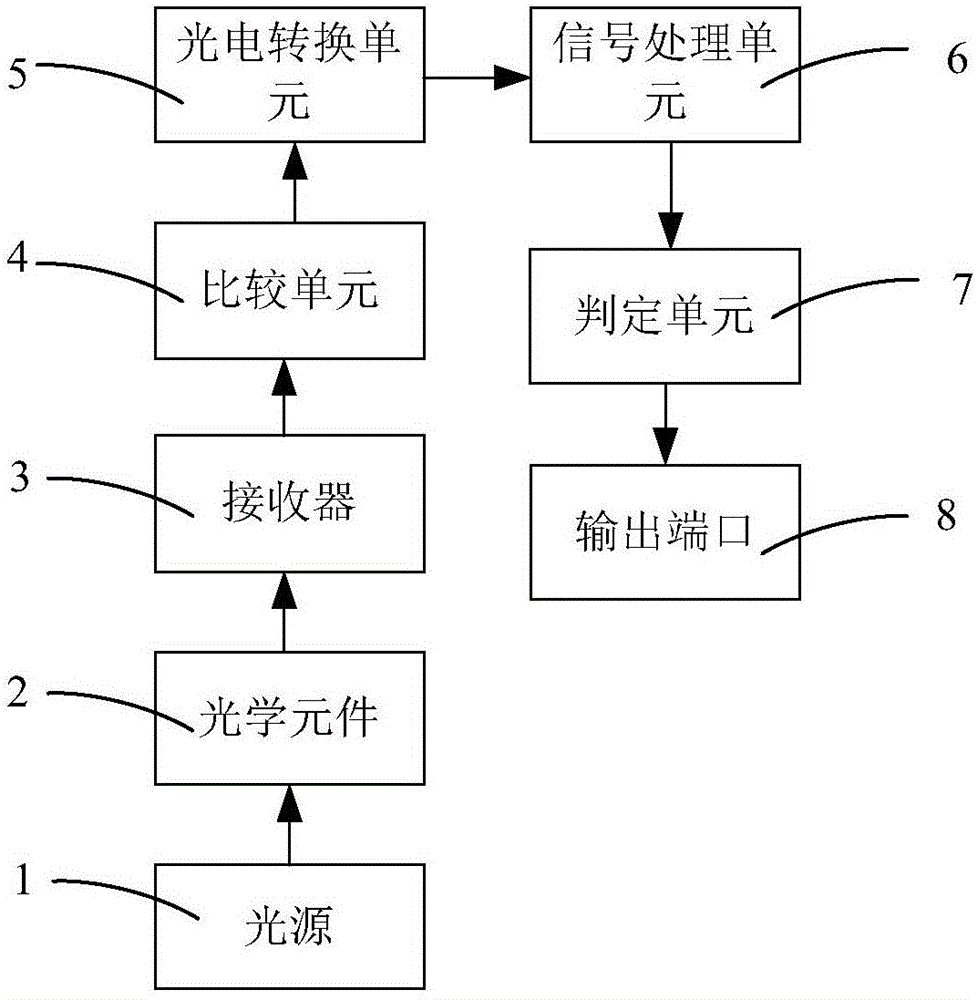

[0023] Such as figure 1 As shown, the present invention consists of a light source 1, an optical element 2 connected to the light source 1, a receiver 3 connected to the optical element 2, a comparison unit 4 connected to the receiver 3, and a photoelectric conversion unit connected to the comparison unit 4 Unit 5, a signal processing unit 6 connected to the photoelectric conversion unit 5, a determination unit 7 connected to the signal processing unit 6, and an output port 8 connected to the determination unit 7.

[0024] Wherein, the light source 1 is used to continuously emit light beams to the detection target, which can be realized by using light emitting diodes or laser diodes. The receiver 3 is used to receive the light beam reflected by the detected target, and analyze the light beam to confirm whether the reflected light beam is the light beam emitted by the light source 1, which can be realized by using a photodiode or a phototransistor. The optical element 2 can en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com