Laser welding equipment

A technology of laser welding and equipment, which is applied in the direction of laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of inapplicable mass production operations and low processing efficiency, so as to reduce unqualified products, improve work efficiency, and improve The effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

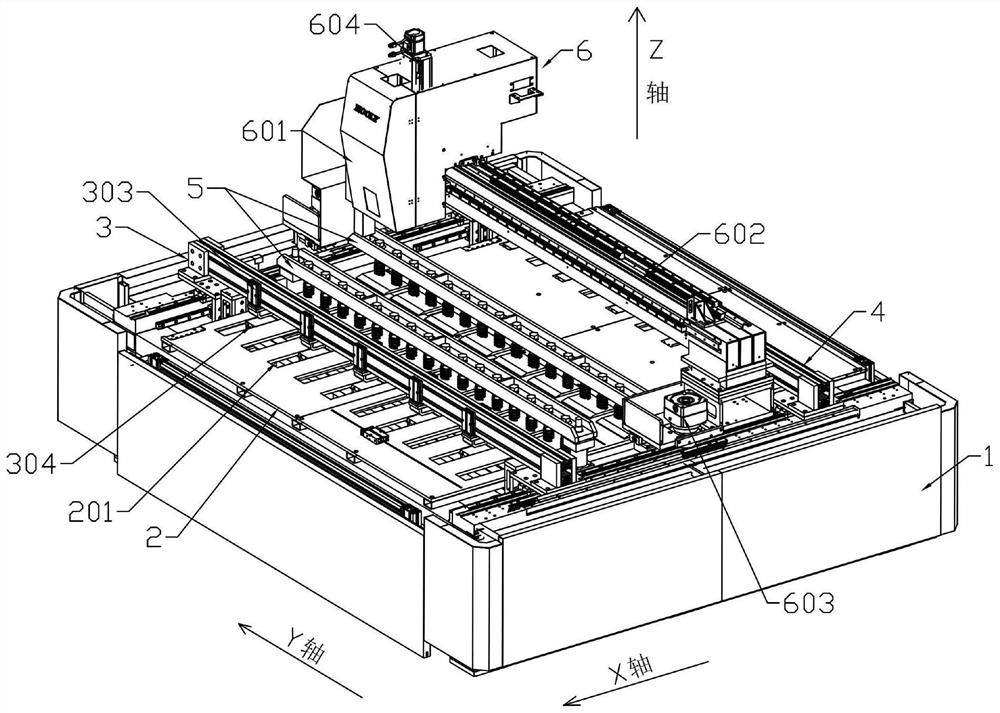

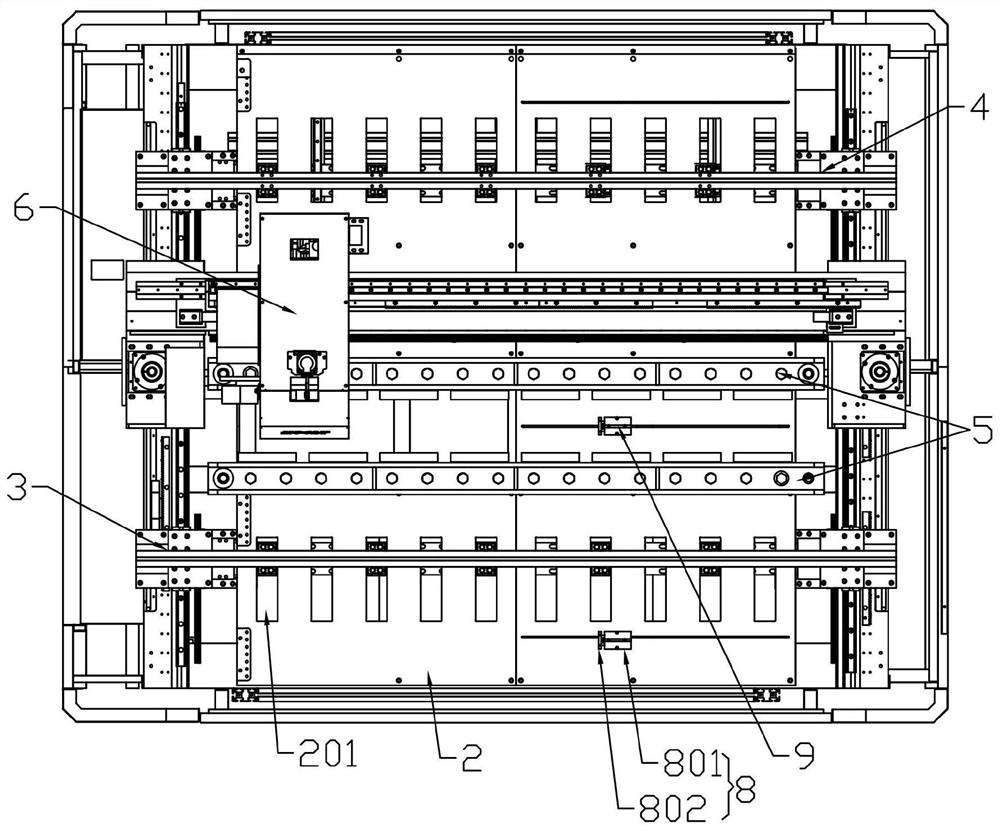

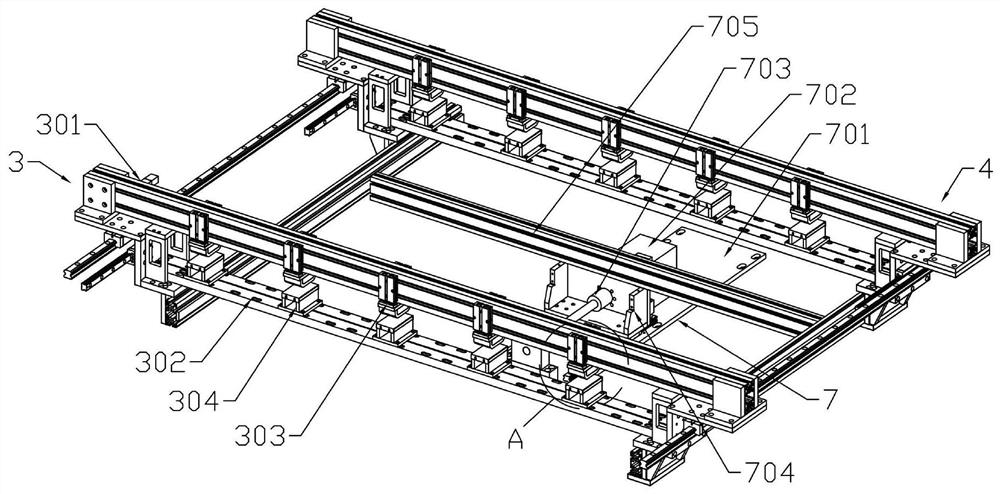

[0025] Specific Example 1: See Figure 1 to Figure 6 , in an embodiment of the present invention, a laser welding device includes a frame 1, a workbench 2 is arranged above the frame 1, and a first conveying device 3, Two sets of pressing device 5, laser welding device 6 and second conveying device 4 with the same structure, the metal plate to be processed is placed on the workbench 2, and the pressing device 5 is movably connected up and down on the workbench 2 to process the metal plate. Pressing and fixing, the laser welding device 6 slides along the X-axis direction on the workbench 2, the laser welding device 6 is above the pressing device 5, and the main driving device 7 is installed below the workbench 2. The first conveying device 3 and the second conveying device 4 are driven by the main driving device 7 to slide synchronously on the worktable 2 along the X-axis direction, and the first conveying device 3 and the second conveying device 4 press the metal plate delive...

specific Embodiment 2

[0036] Specific embodiment 2: refer to Figure 7 and Figure 8 , on the basis of Embodiment 1, the second conveying device 4 includes a third support rod 401 and a suction assembly 402 arranged on the third support rod 401, and the third support rod 401 is slidably connected with the frame 1 , the third support rod 401 is fixedly connected to the connecting frame 705 on the main driving device 7, the suction assembly 402 is above the workbench 2, and the suction assembly 402 includes a vacuum suction cup 402-2 and a suction cylinder 402 -1, the material suction cylinder 402-1 is fixed on the third support rod 401, the material suction cylinder 402-1 is provided with two symmetrically installed on the left and right sides of the third support rod 401, the material suction cylinder The drive shaft of 402-1 is driven and connected with the vacuum chuck 402-2. The vacuum chuck 402-2 is provided with several suction nozzles 402-2-1 connected to the vacuum pump. After the welding i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com