Linear rotation mechanism of automatic buzzer assembly line

An automatic assembly and buzzer technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of dependence on manual work, high production cost, uneven product quality, etc., and achieve reciprocal use and reasonable and compact structure design , Stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

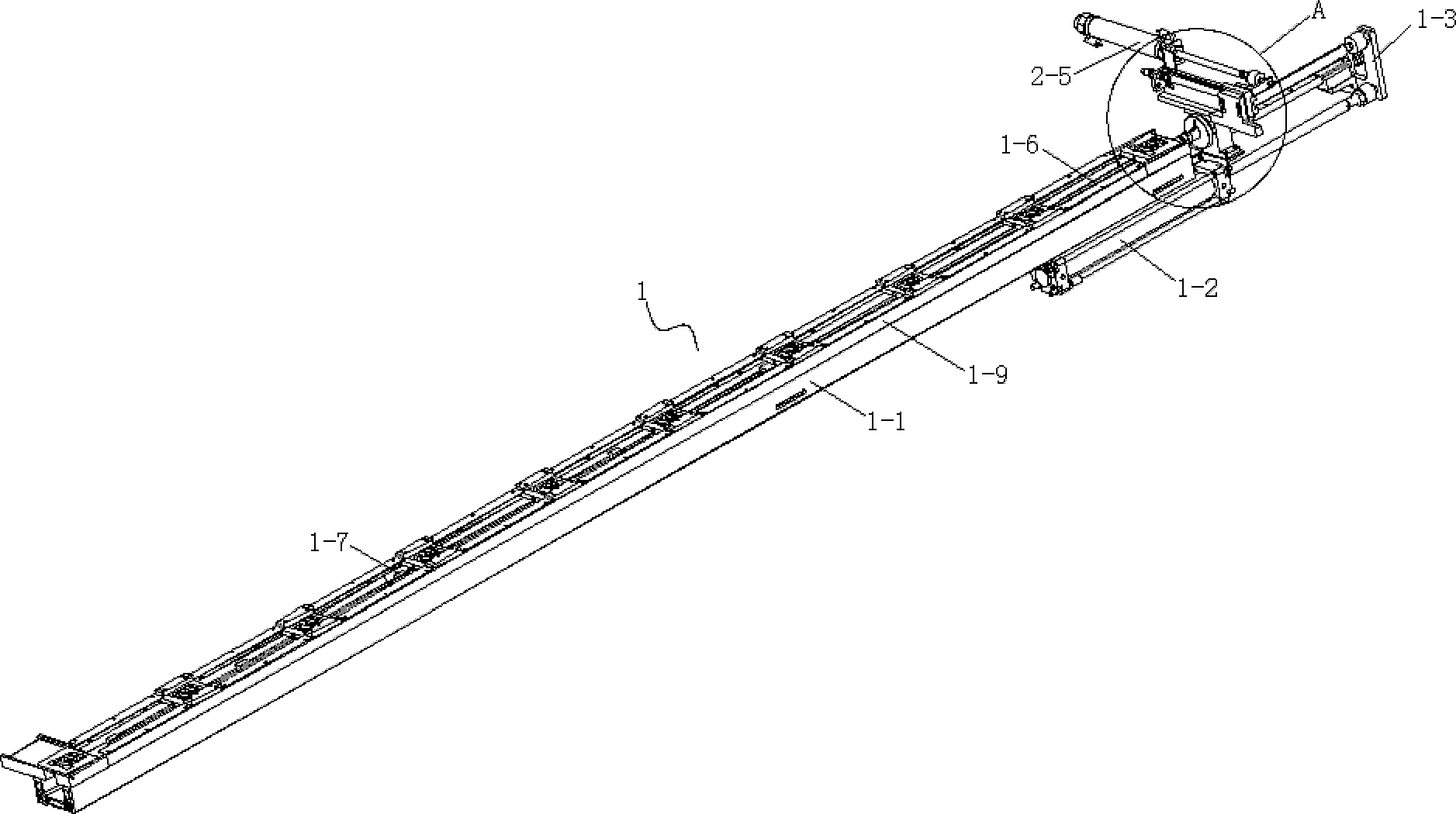

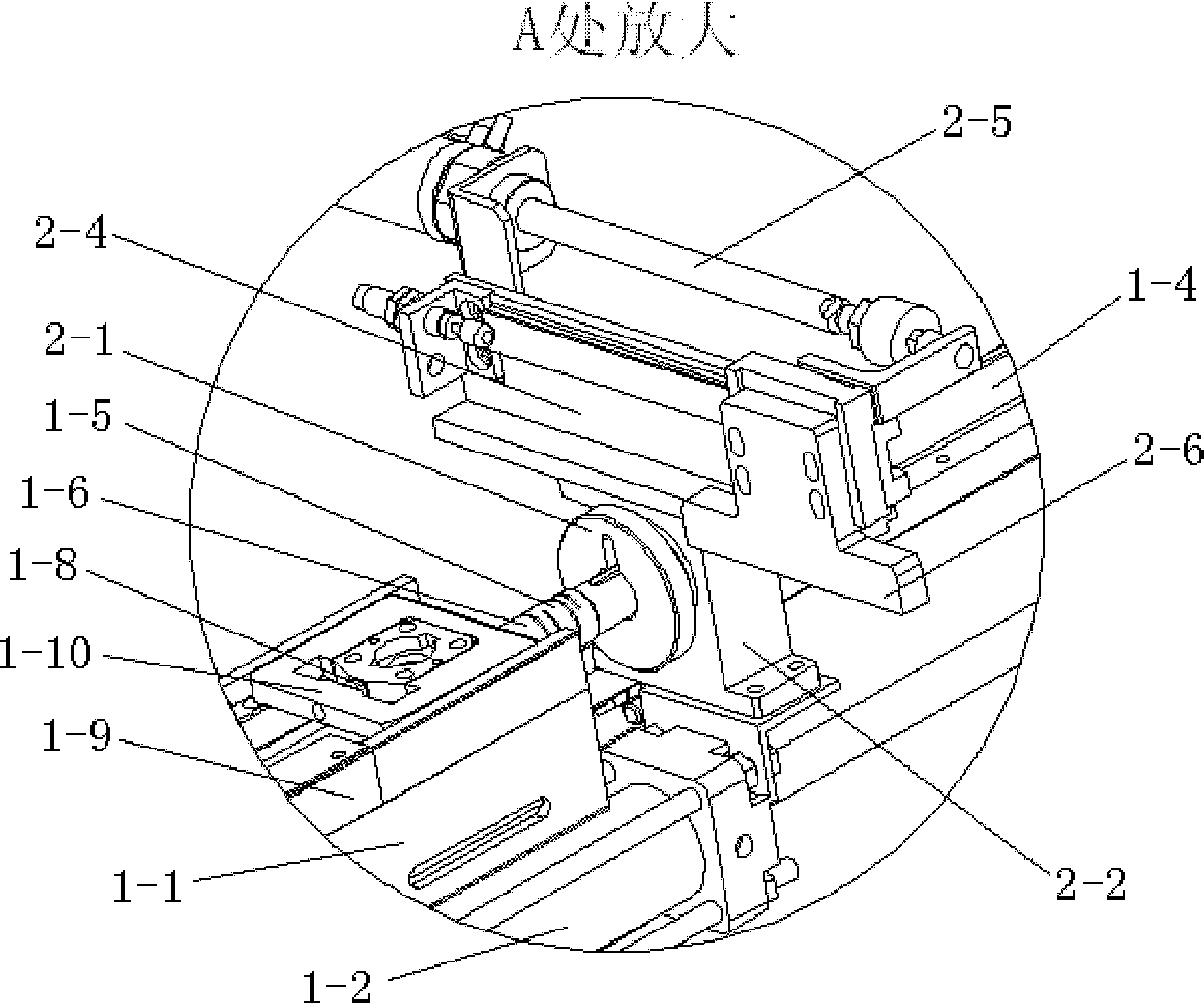

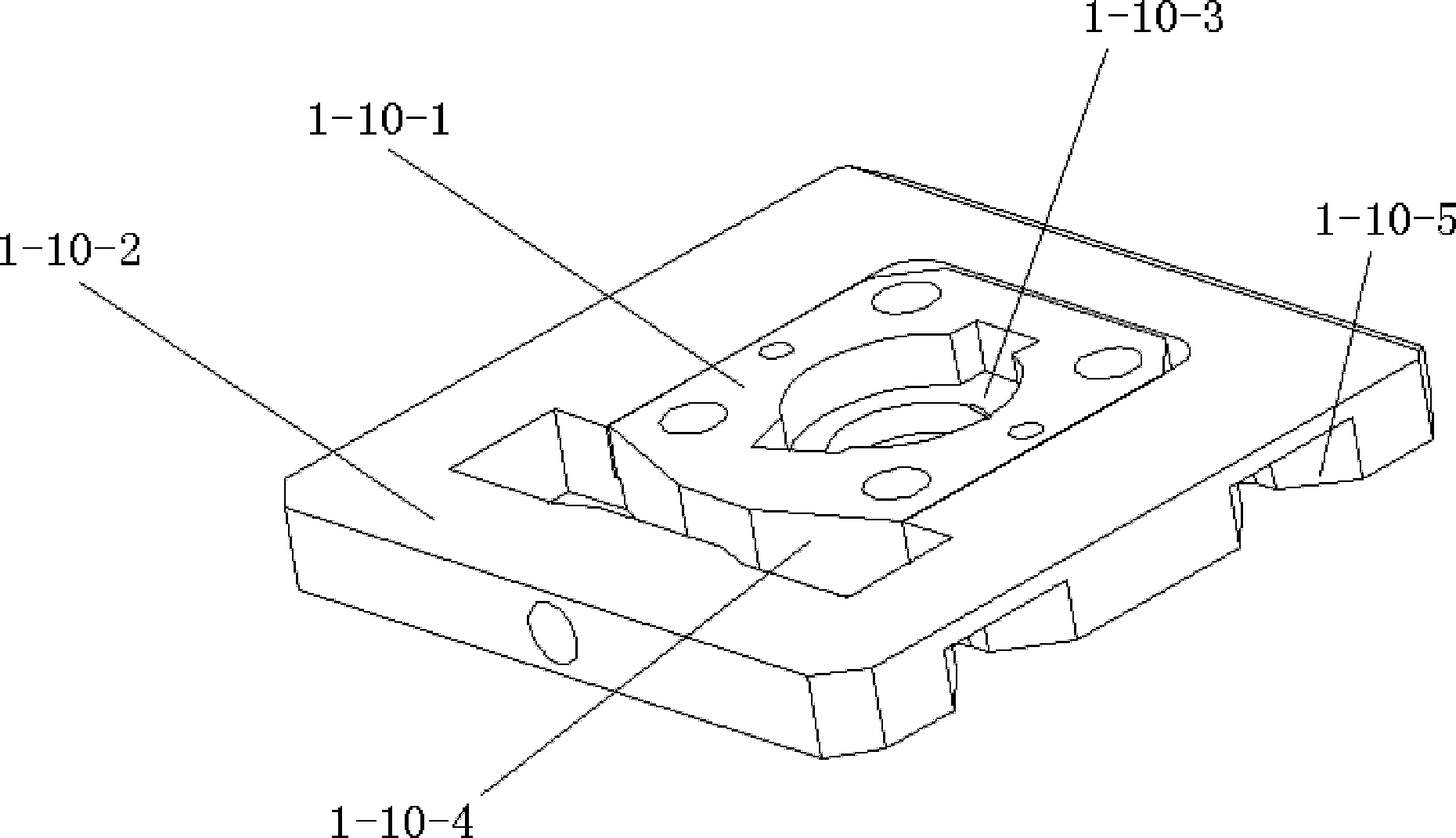

[0029] This embodiment includes a workbench, a cylinder shift module 1 , a rack rotation module 2 , a belt conveyor 3 , a cylinder positioning module 4 , a first electromagnetic transfer module 5 and a second electromagnetic transfer module 6 .

[0030] The cylinder displacement module 1, the rack rotation module 2, the belt conveyor 3, the cylinder positioning module 4, the first electromagnetic transfer module 5 and the second electromagnetic transfer module 6 are fixed on the workbench. The rack rotation module 2 is coupled with the cylinder displacement module 1 . The cylinder shifting module 1 and the belt conveyor 3 are installed in parallel. The cylinder positioning module 4 is installed near the front end of the cylinder displacement module 1 . The first electromagnetic conveying module 5 and the second electromagnetic conveying module 6 are respectively arranged near the front and rear ends of the cylinder shifting module 1 .

[0031] See figure 1 and figure 2 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com