Automatic assembly production line of buzzers

An automatic assembly and production line technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low degree of automation, uneven product quality, and dependence on manual work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

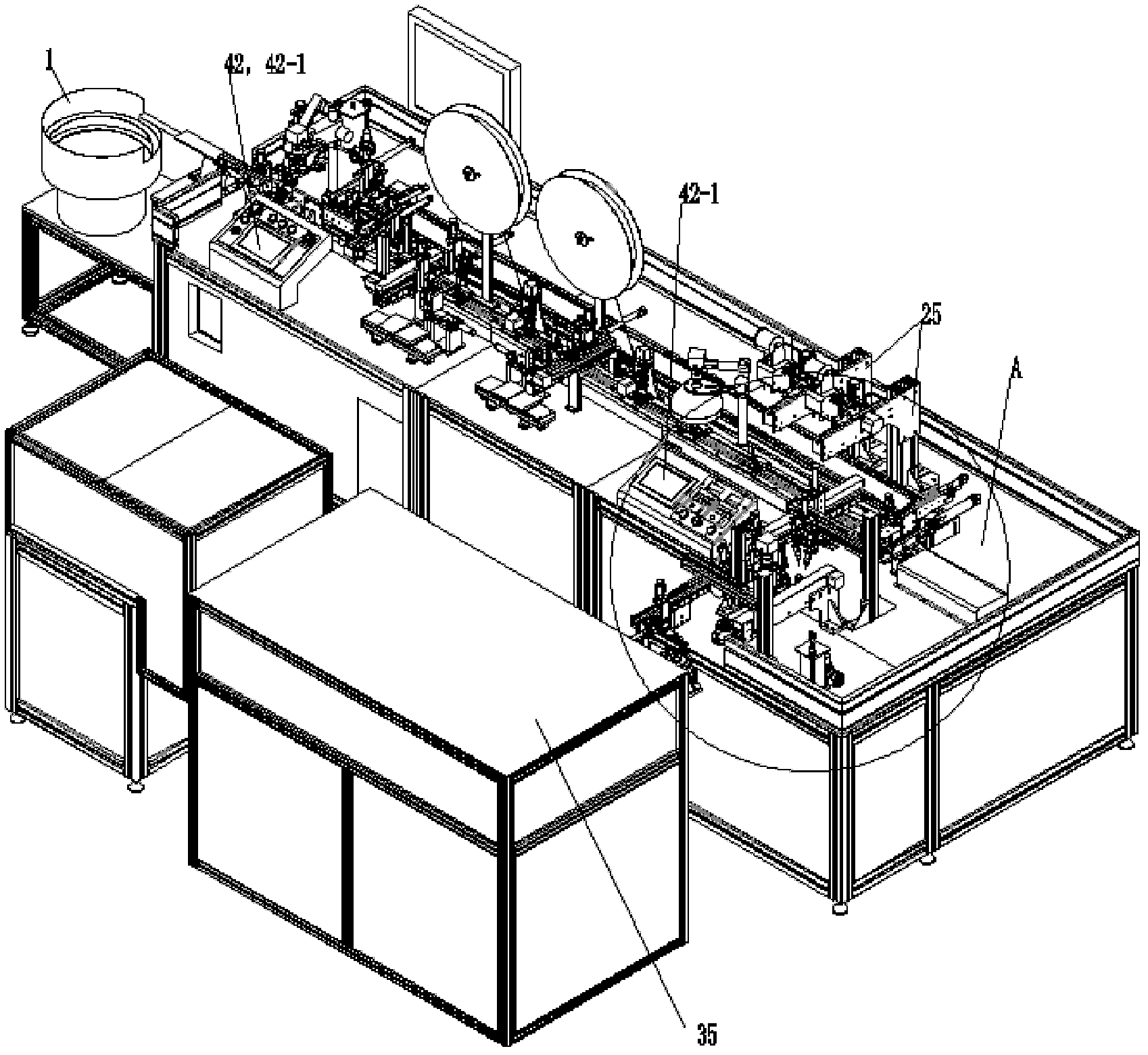

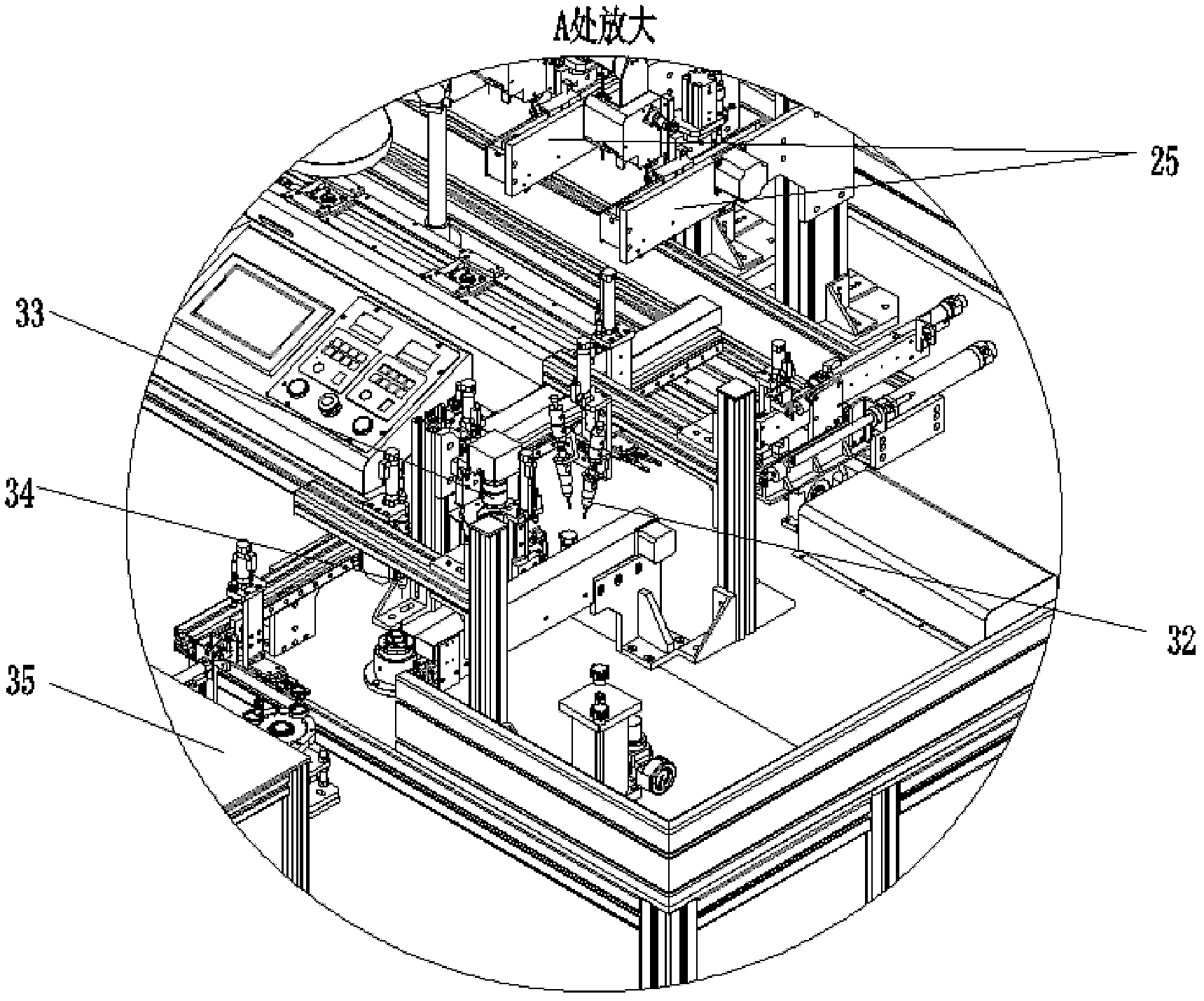

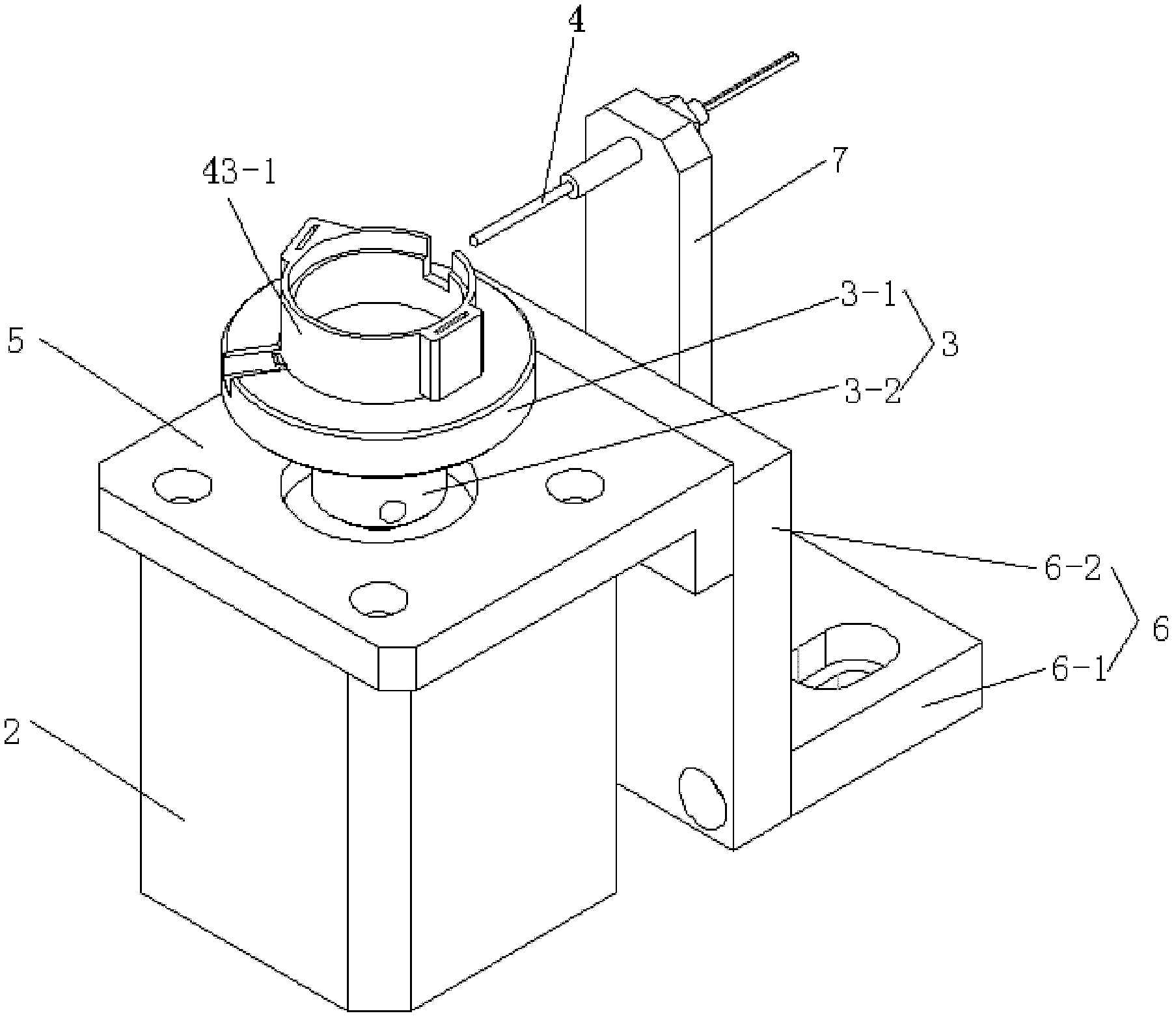

[0065] See figure 1 , the buzzer automatic assembly production line of the present embodiment includes an operation instrument 42 and a feeding mechanism 1, a glue coating mechanism, a buzzer chip placement mechanism, a straight pin placement mechanism, a first thermoplastic Tube placement mechanism, oblique pin placement mechanism, second thermoplastic tube placement mechanism, thermoplastic tube heat sealing mechanism, pin welding mechanism 25, glue dispensing mechanism 32, visual inspection mechanism 33, painting mechanism 34, curing mechanism 35 And detection and sorting mechanism, as well as the buzzer chip placement mechanism, straight pin insertion mechanism, first thermoplastic tube placement mechanism, oblique pin insertion mechanism, second thermoplastic tube placement mechanism, thermoplastic tube heat sealing mechanism A linear rotary mechanism connected with the pin welding mechanism 25; the operating instrument 42 includes a main operating instrument 42-1 and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com