Cutting device for glass table board of integrated cooker and cutting method by adopting cutting device

A technology of cutting device and integrated cooker, which is applied in the field of integrated cooker, can solve the problems of large processing size error, increased economic cost, high defective rate, etc., achieve the goals of reducing mechanical vibration and noise pollution, ingenious and reasonable design, and improving operation safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

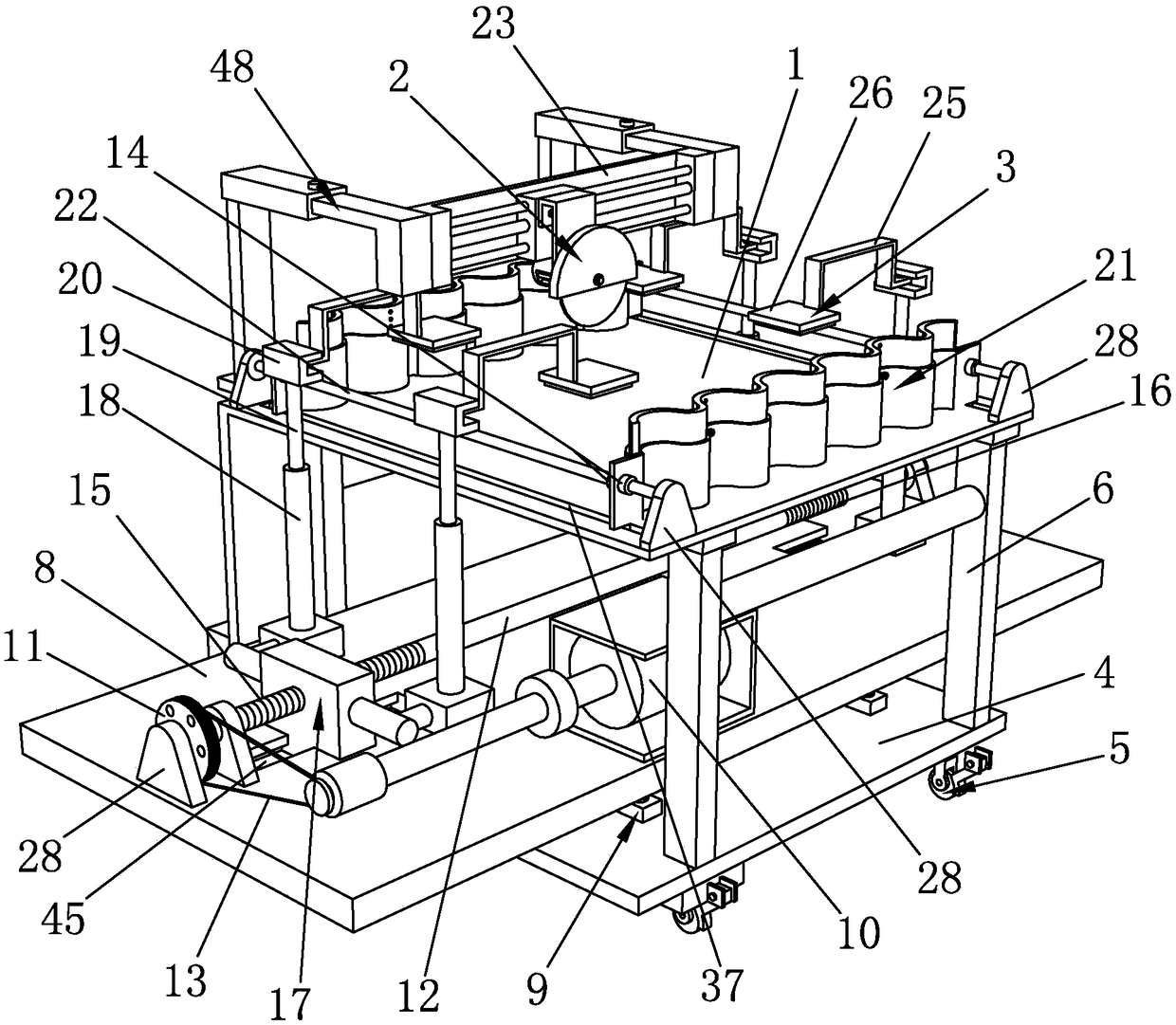

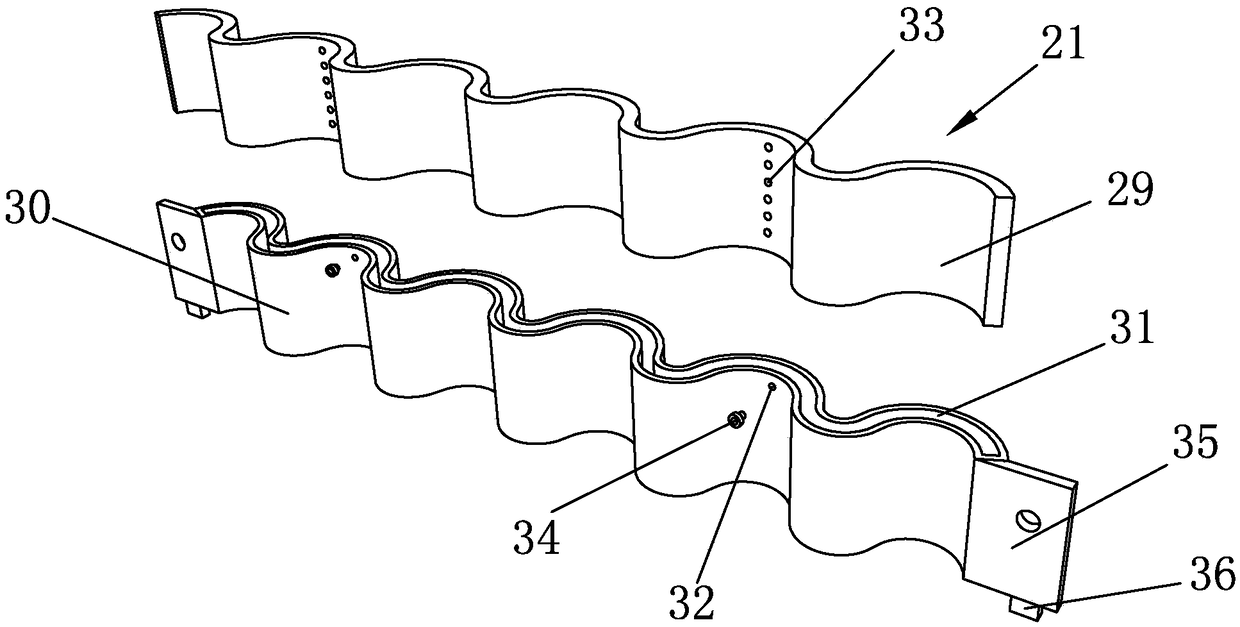

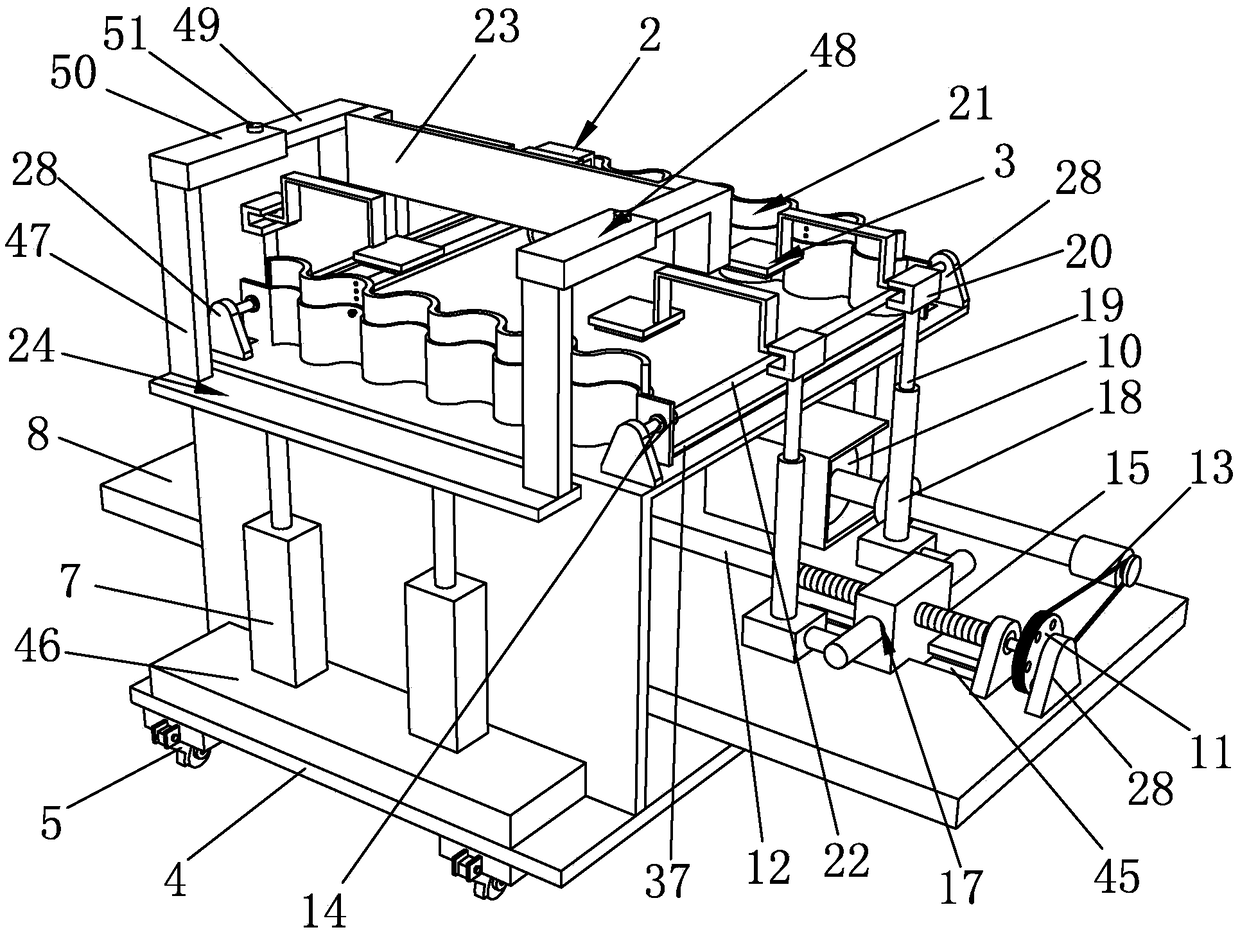

[0041] Such as Figure 1 to Figure 5 As shown, it is a cutting device for an integrated stove glass tabletop according to the present invention, which includes a workbench 1, a cutting mechanism 2 and a clamping device 3. A moving seat 4 is arranged under the workbench 1, and a moving wheel is arranged at the bottom of the moving seat 4. Group 5, the mobile wheel group 5 can facilitate the handling and movement of the cutting device, making the use of the cutting device more convenient. The workbench 1 is fixedly connected to the mobile seat 4 through the support column 6, and the mobile seat 4 is provided with at least 2 lifts. Column 7, the bottom of lifting column 7 is provided with shock-absorbing block 46, and lifting column 7 is fixed on the shock-absorbing block 46, and shock-absorbing block 46 is fixedly connected with mobile seat 4, and the design of shock-absorbing block 46 can reduce the time when lifting column 7 works. The mechanical noise and the amplitude of vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com