Patents

Literature

157results about How to "Suitable for mass production needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

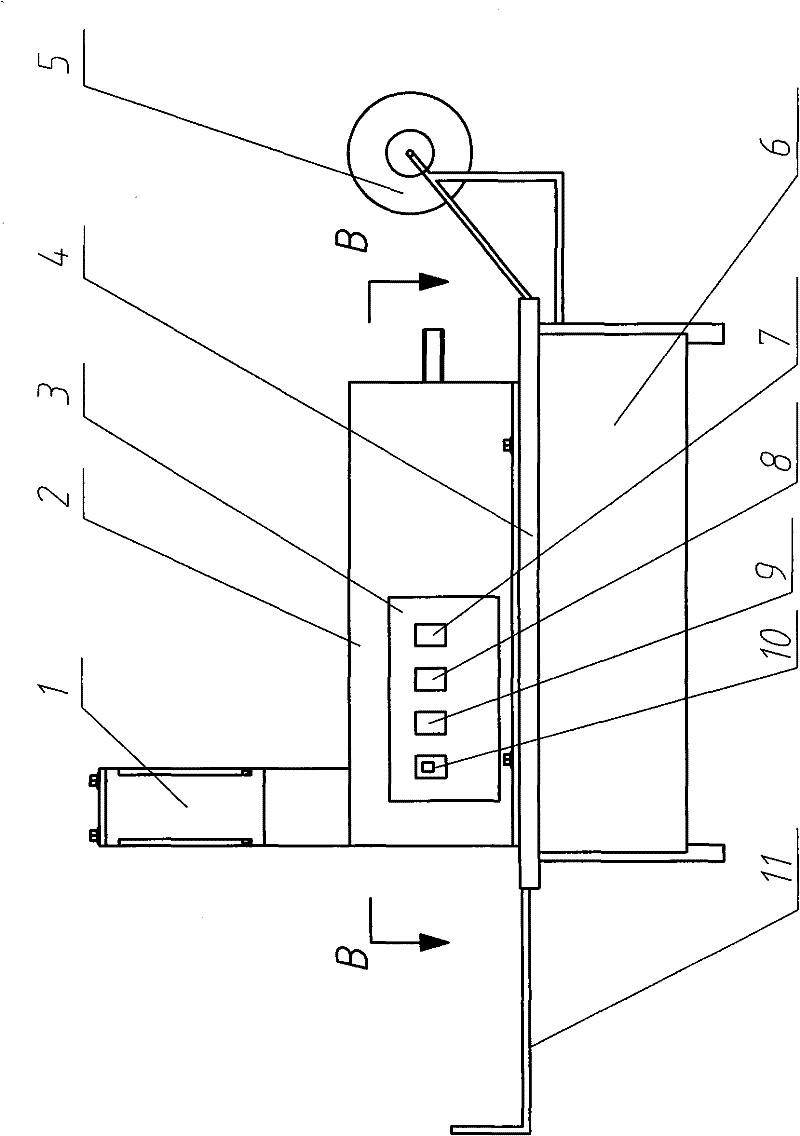

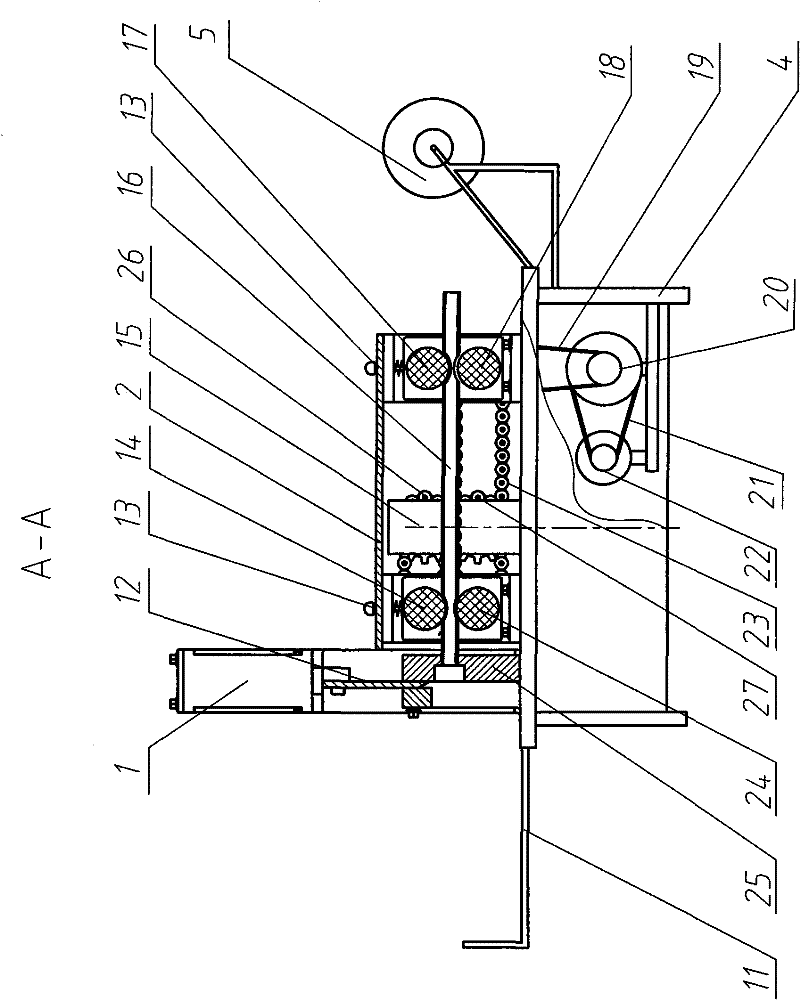

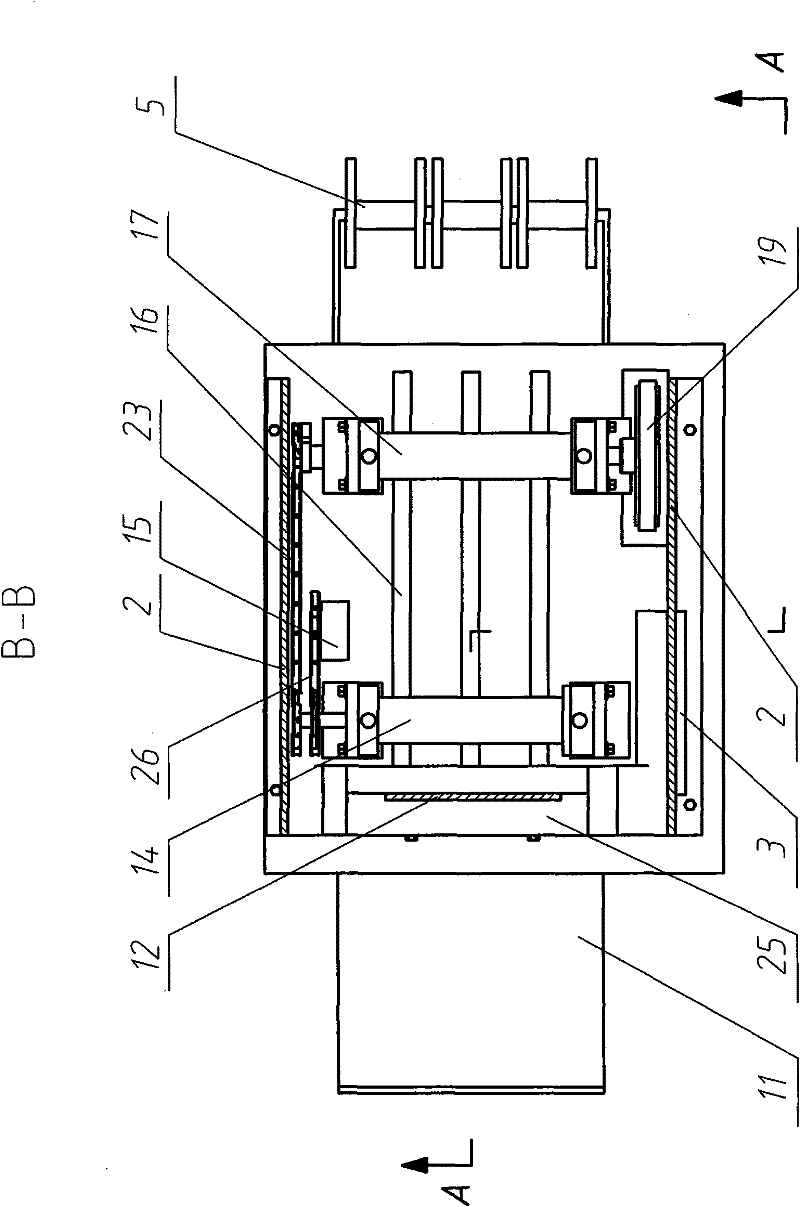

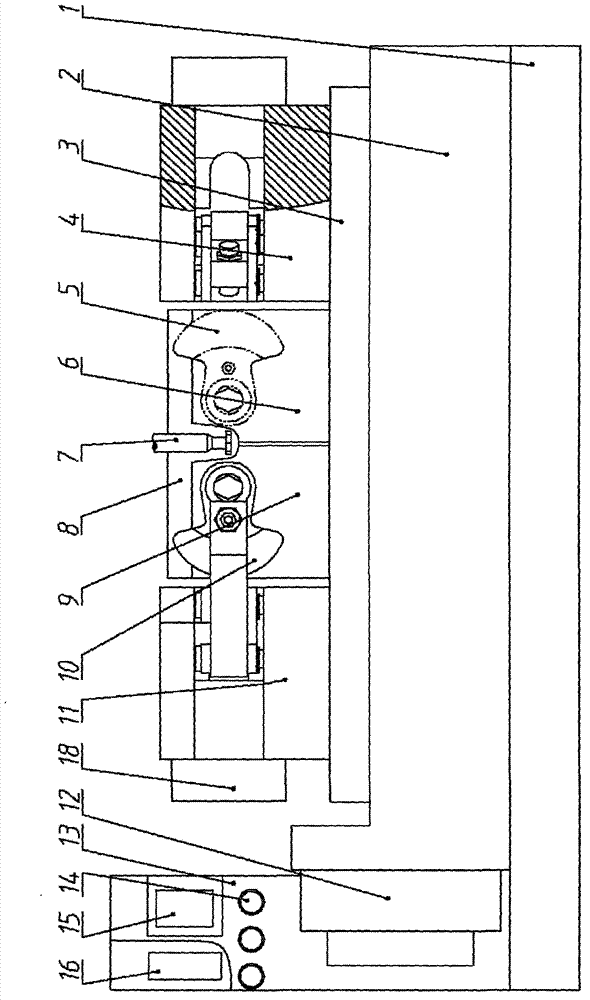

Automatic plastic tube cutting machine

The invention discloses an automatic plastic tube cutting machine, comprising a power transmission device, a feeding device, a blanking device, a safe protection device, a control device and a counter. The power transmission device transmits power to the feeding device, a plastic tube enters the blanking device through a guide tube under the driving of two pairs of rollers with opposite rotary directions, a relay controls a cylinder to drive a cutter to cut and a time adjustable delay timer adjusts the motion speed of the cutter, thus the control for blanking length is implemented. An inclination angle, which is 5 to 6 degrees, is formed by the lower plane of the cutter with respect to a horizontal direction; the width of a cutter guide concave slot of a cutter positioning block can be adjusted according to the cutter; the spacing between every pair of the rollers is adjustable; the counter can record the times of tube blanking automatically; and the safe protection device puts motion components under protection. By adopting such a structure, the automatic plastic tube cutting machine not only can cut the plastic tubes of different specifications, but also prominently reduces the labor intensity of operating staff and accordingly, remarkably enhances the working efficiency.

Owner:SHANDONG HUASHENG PESTICIDE APPL MACHINERY CO LTD

Process for manufacturing high-strength bolt

The invention provides a process for manufacturing a high-strength (above) bolt. The process comprises the following steps: selecting a proper steel material, and cutting out a cylindrical blank with proper size; molding the head part and the rod part of the bolt by adopting cold extrusion technology; heating; manufacturing the rod part, including coarse grinding and fine grinding; detecting injury by magnetic powder; manufacturing screw; and performing surface mechanical reinforcement and corrosion resistance treatment. The process solves the technical problems of insufficient strength and fatigue fracture which are easily generated on the bolt existing in the prior art for manufacturing the high-strength bolt, and is a high-strength bolt manufacturing process capable of improving tensile and fatigue strength resistance of the bolt.

Owner:浙江裕泰汽车配件有限公司

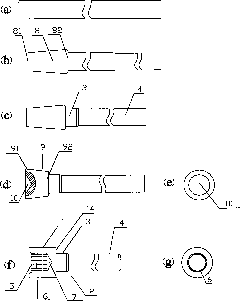

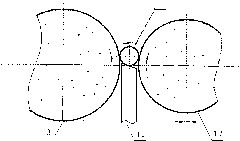

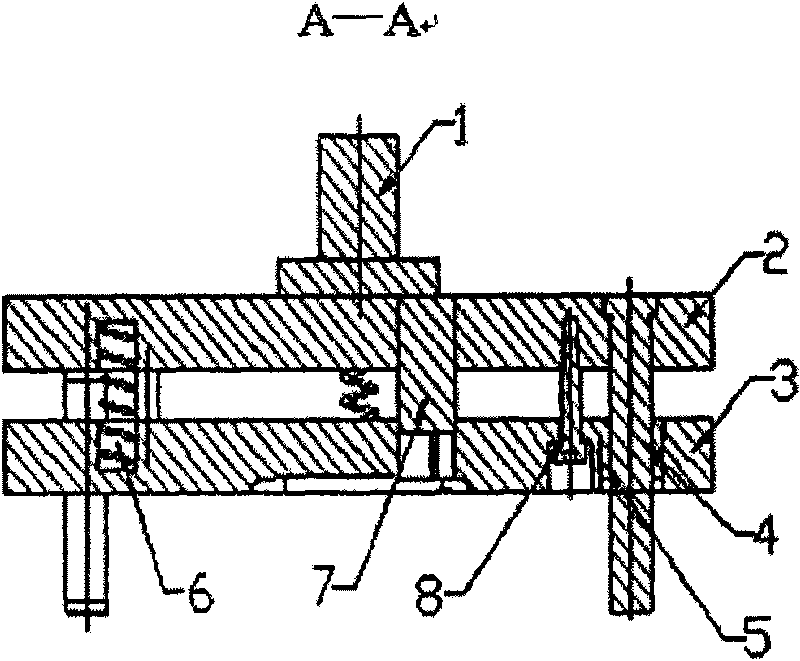

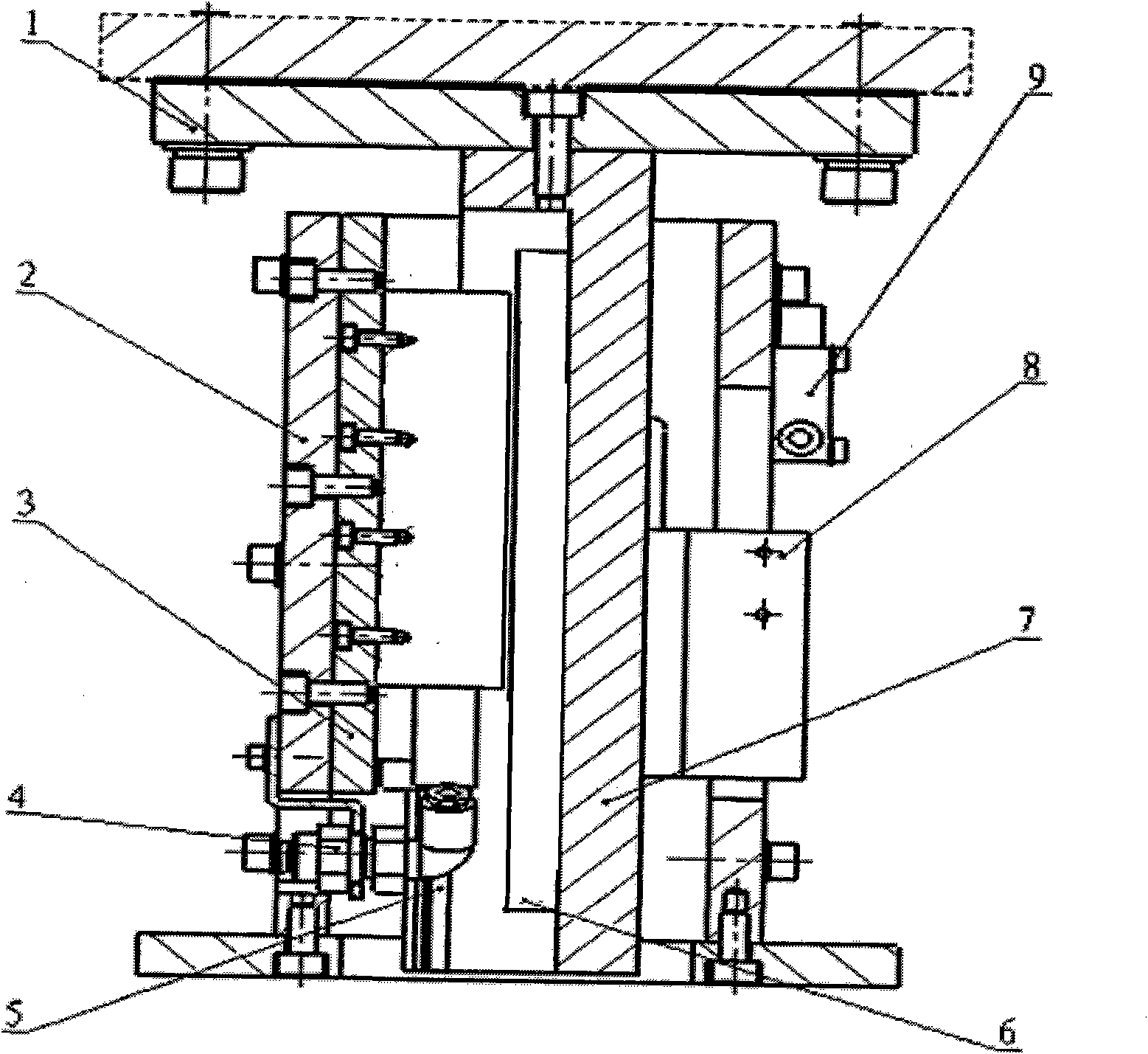

Multi-direction step-by-step tridimensional punching method of IML products and punching mould thereof

InactiveCN101698215AQuality assuranceGuaranteed stabilityShaping toolsPerforating toolsPunchingEngineering

The invention relates to a multi-direction step-by-step tridimensional punching method of IML products and a punching mould thereof, which is characterized in that a punching mould combing a direct punching mould and a lateral punching mould is adopted to dimensionally punch the cavern shapes and edge contours of IML product located on different surfaces step by step; the punching mould comprises an upper mould which comprises a punch (straight punching head) and a lower mould which comprises a die and air cylinder side cut assemblies; the punch of the upper mould and the die of the lower mould form a straight punching mode; the side wall of the die and four groups of air cylinder side cut assemblies of the lower mould form a side punching mode; a multidirectional step-by-step dimensional method is adopted to decompose the punching of the IML product with complex structure and shape into one-step punching with simpler shape, the power of one-step punching of side faces is provided by a straight air cylinder, thereby ensuring the quality and stability of quenching; in addition, the punching method has simple operation and accurate production orientation, the qualification rate can be above 90%, therefore, the method is applicable to large-scale batch production.

Owner:TIANJIN ZHONGHUAN HI TECH

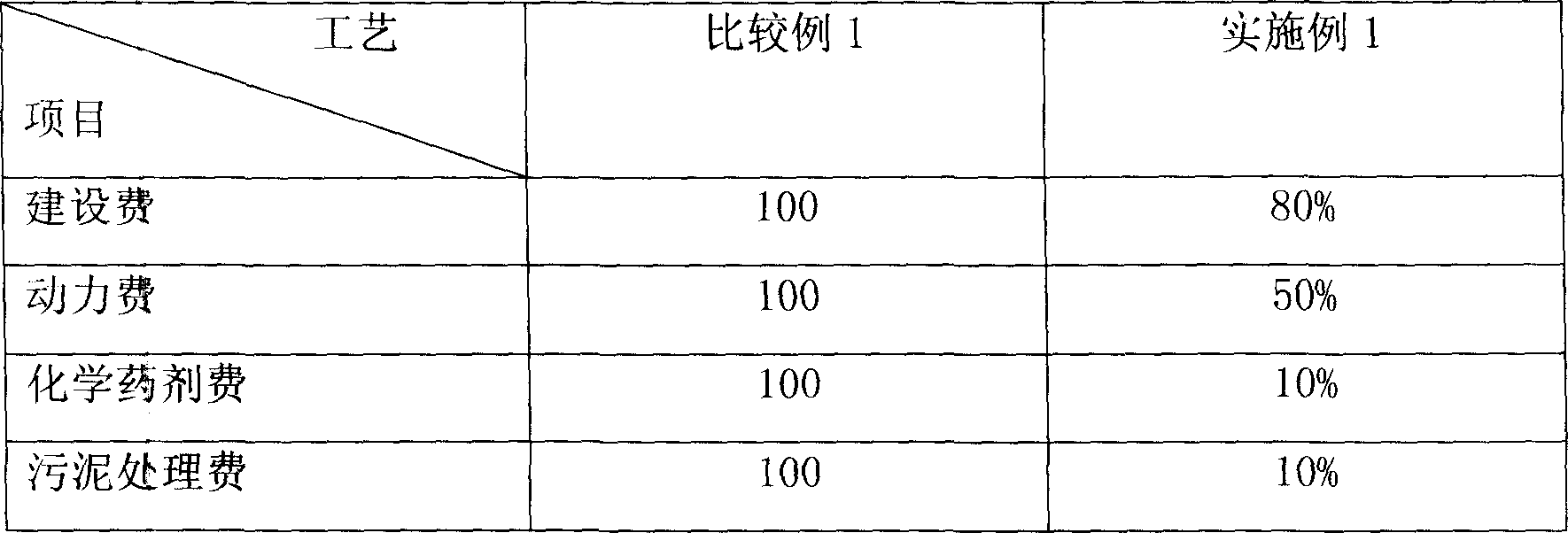

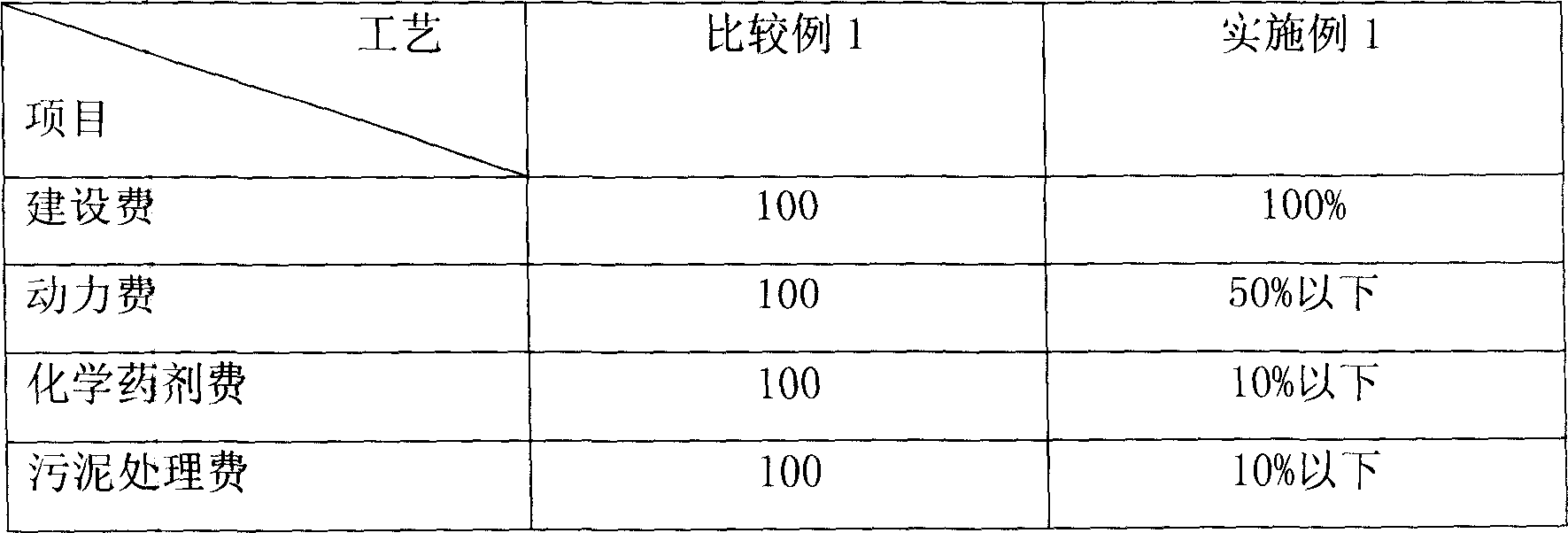

Method of producing composite and highly effective microorganism preparation for waste water treatment

InactiveCN101033450ANo toxicityNon-pathogenicMicroorganismsTreatment with aerobic and anaerobic processesEffective microorganismSludge

This invention relates to a preparation method for a compound high efficient microbe preparation used in processing waste water including: A, selecting and cultivating, B, fermenting and cultivating the preparation of oxygen and anaerobic compound microbes, C, fermenting and cultivating the preparation of aerobic microbes, D, mixing them. 1, the preparation prepared in this invention is avirulent and will not cause second time pollution, 2, microbes in this preparation can degradate organics and ammonia nitrogen pollutant factors thoroughly due to multikind of microbes and quick speed to degradate pollutants in waste water, 3, output of mud is less, the life time is long and its settlement is good, 4, the preparation method is simple.

Owner:赵志龙 +1

Preparation method for efficiently extracting separating high-purity flavone components from ginkgo leaf

InactiveCN103110670AIncrease contentThe ingredients and content are clearNervous disorderGinkgophyta medical ingredientsChemistryKaempferol-3-O-rutinoside

Owner:北京华润高科天然药物有限公司

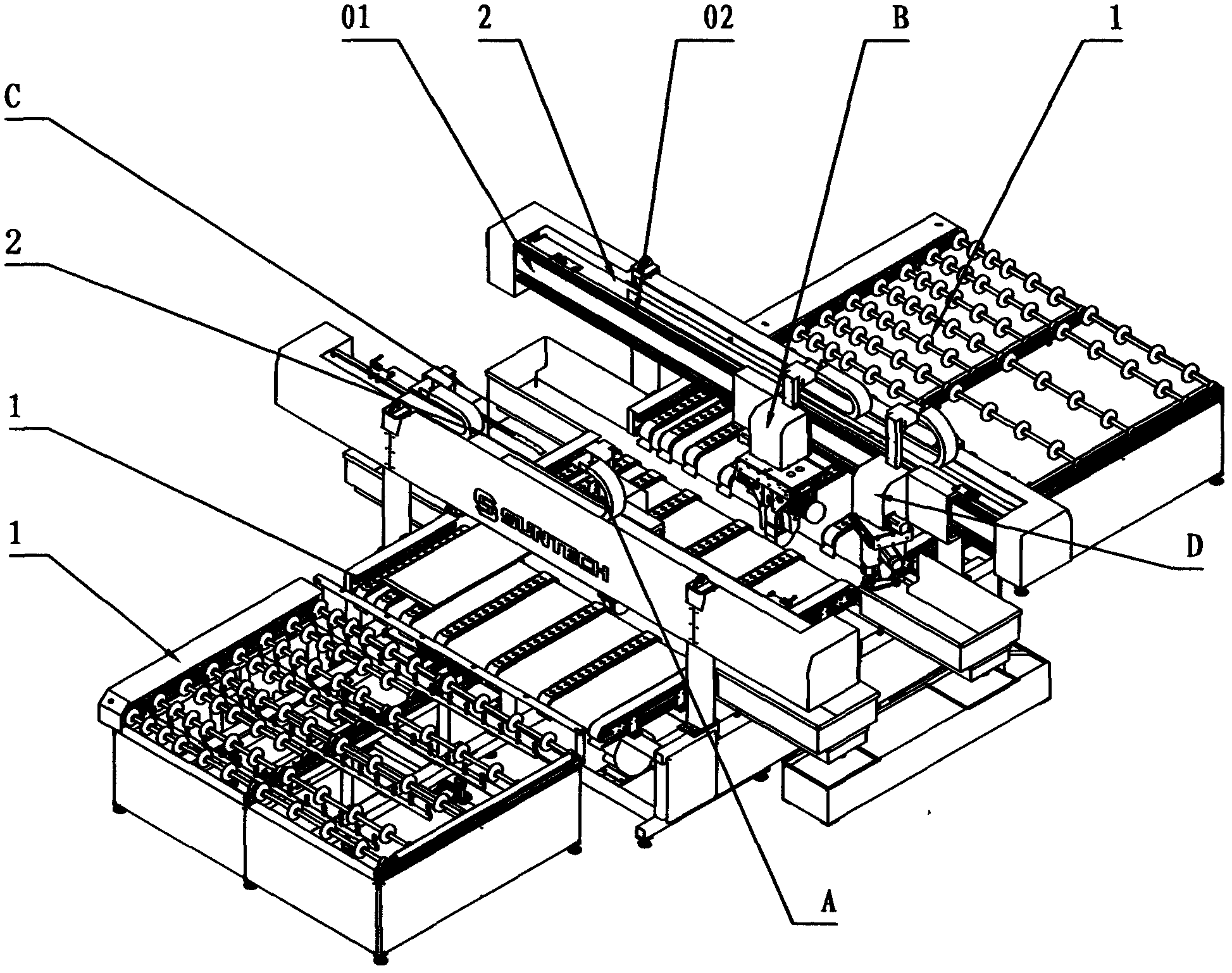

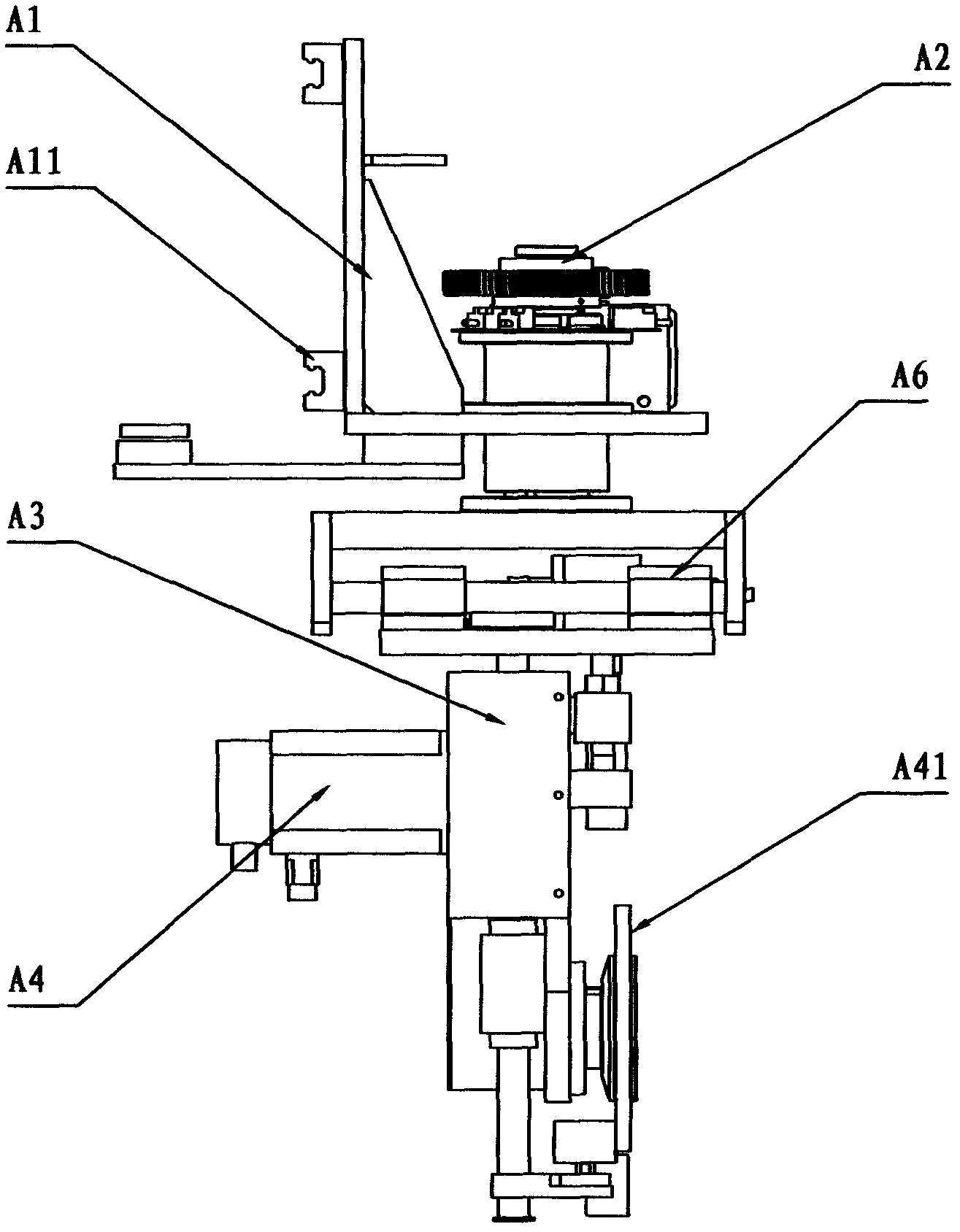

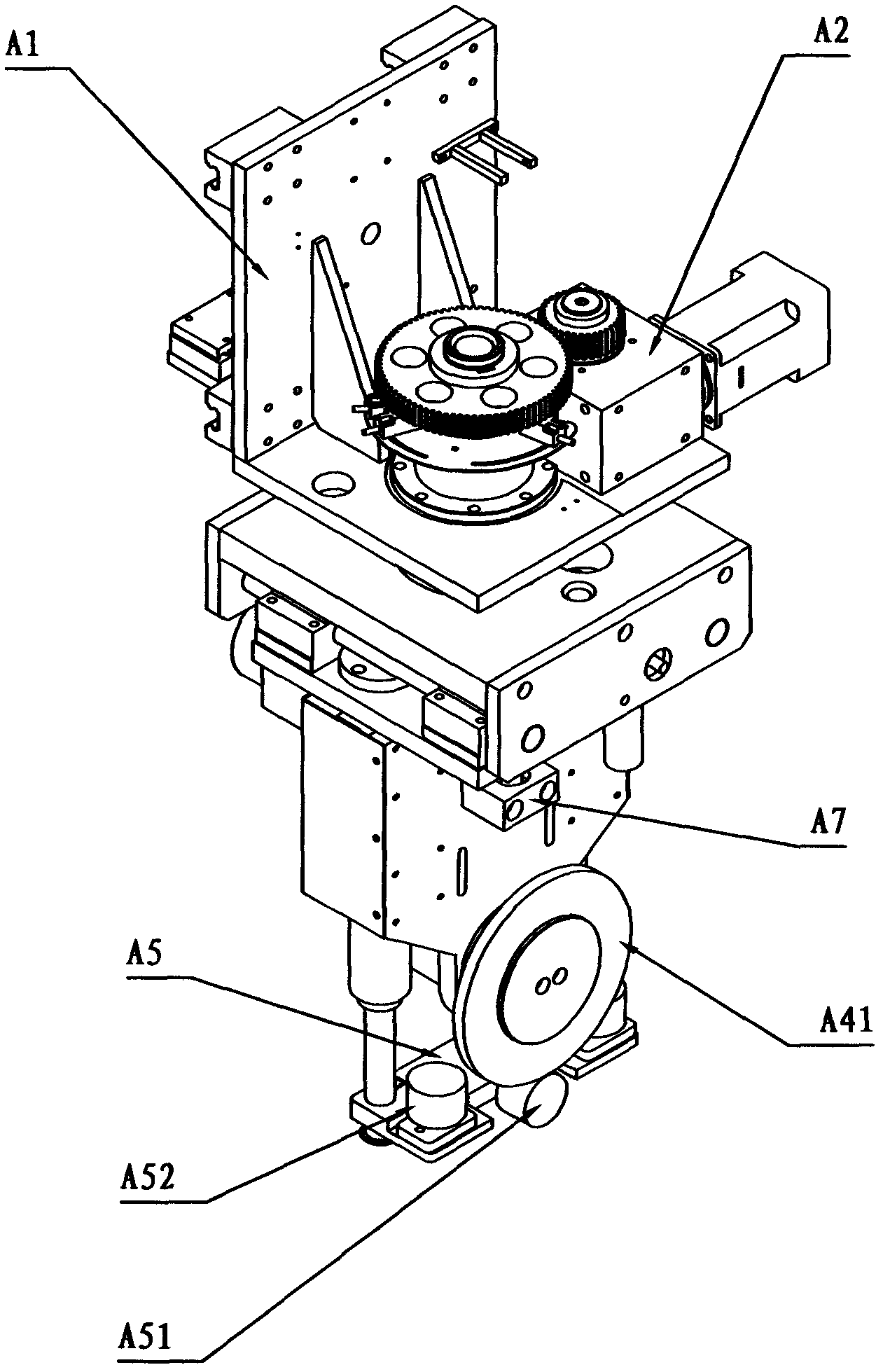

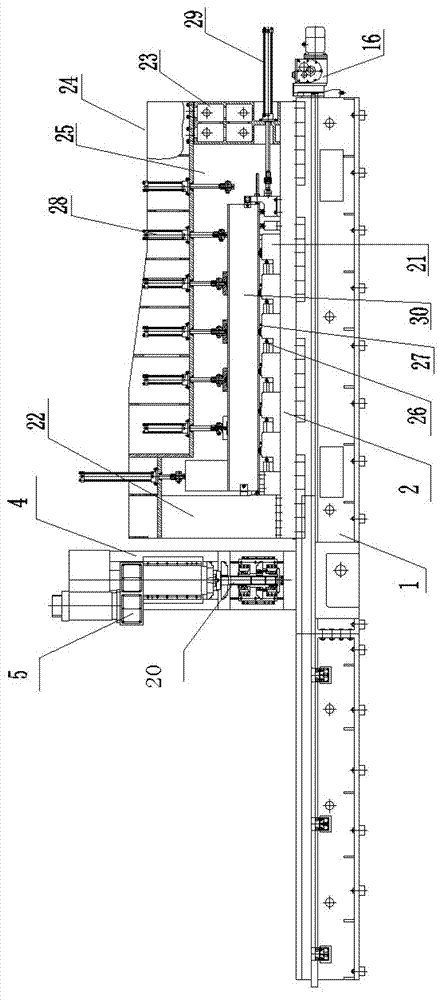

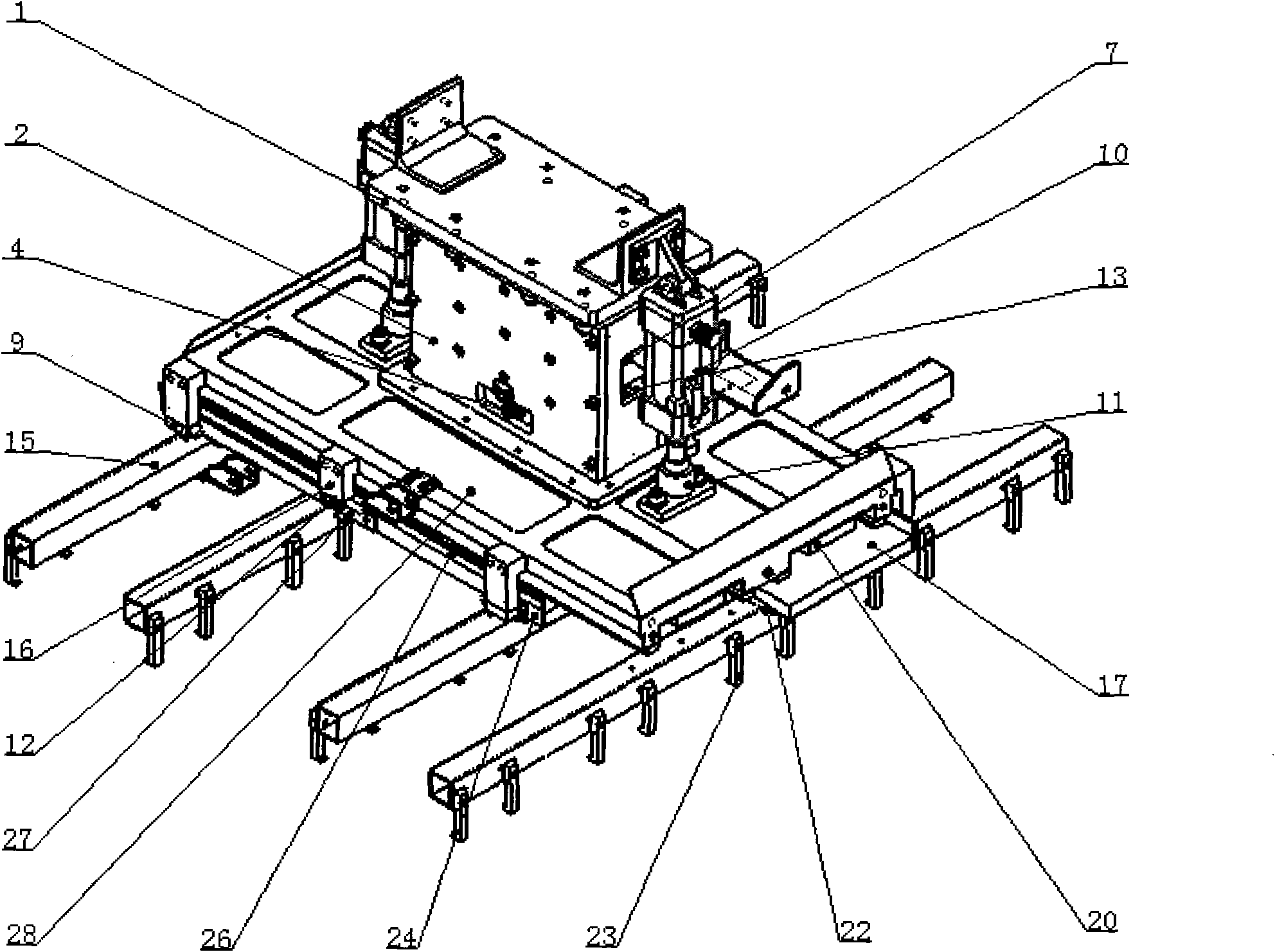

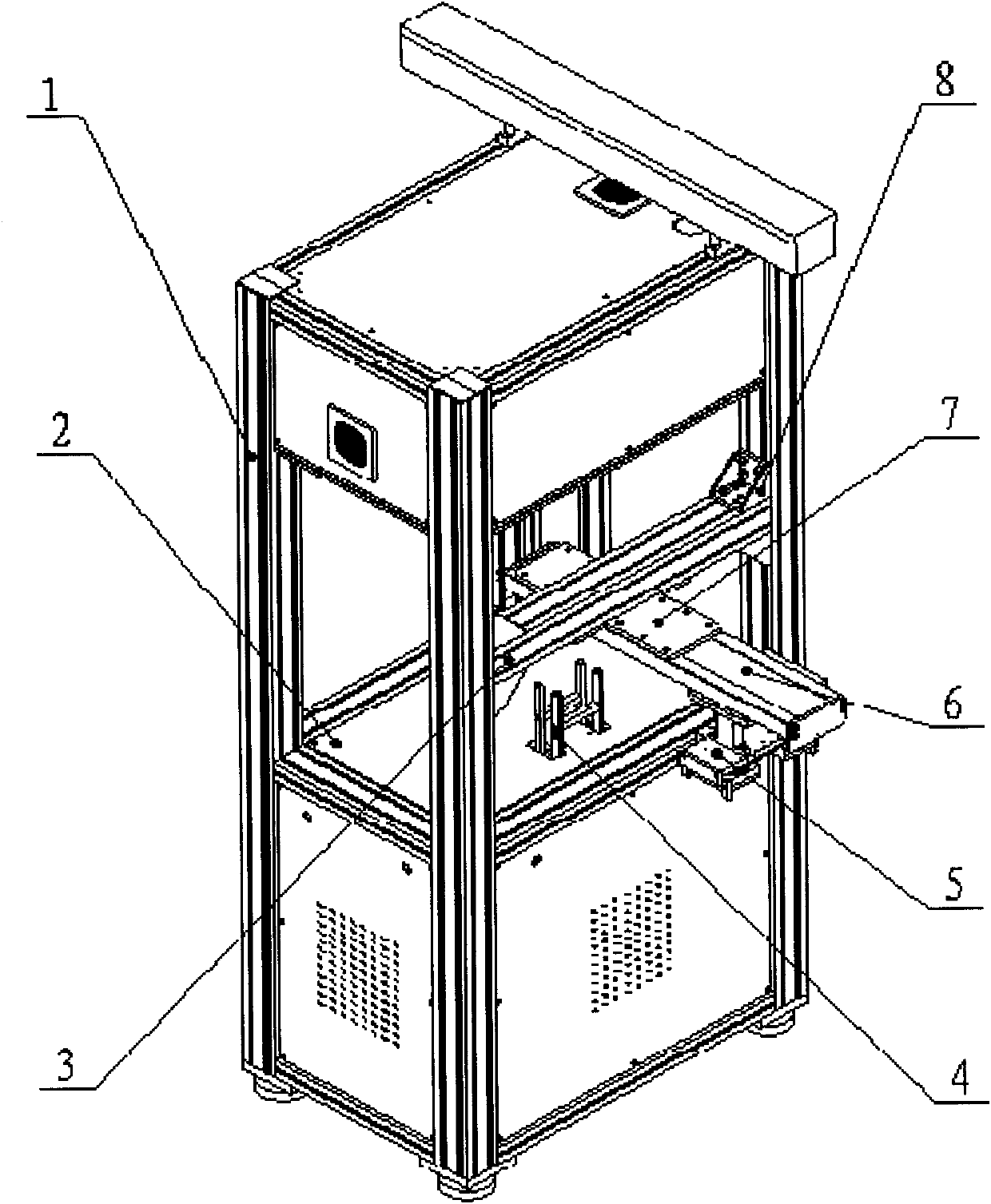

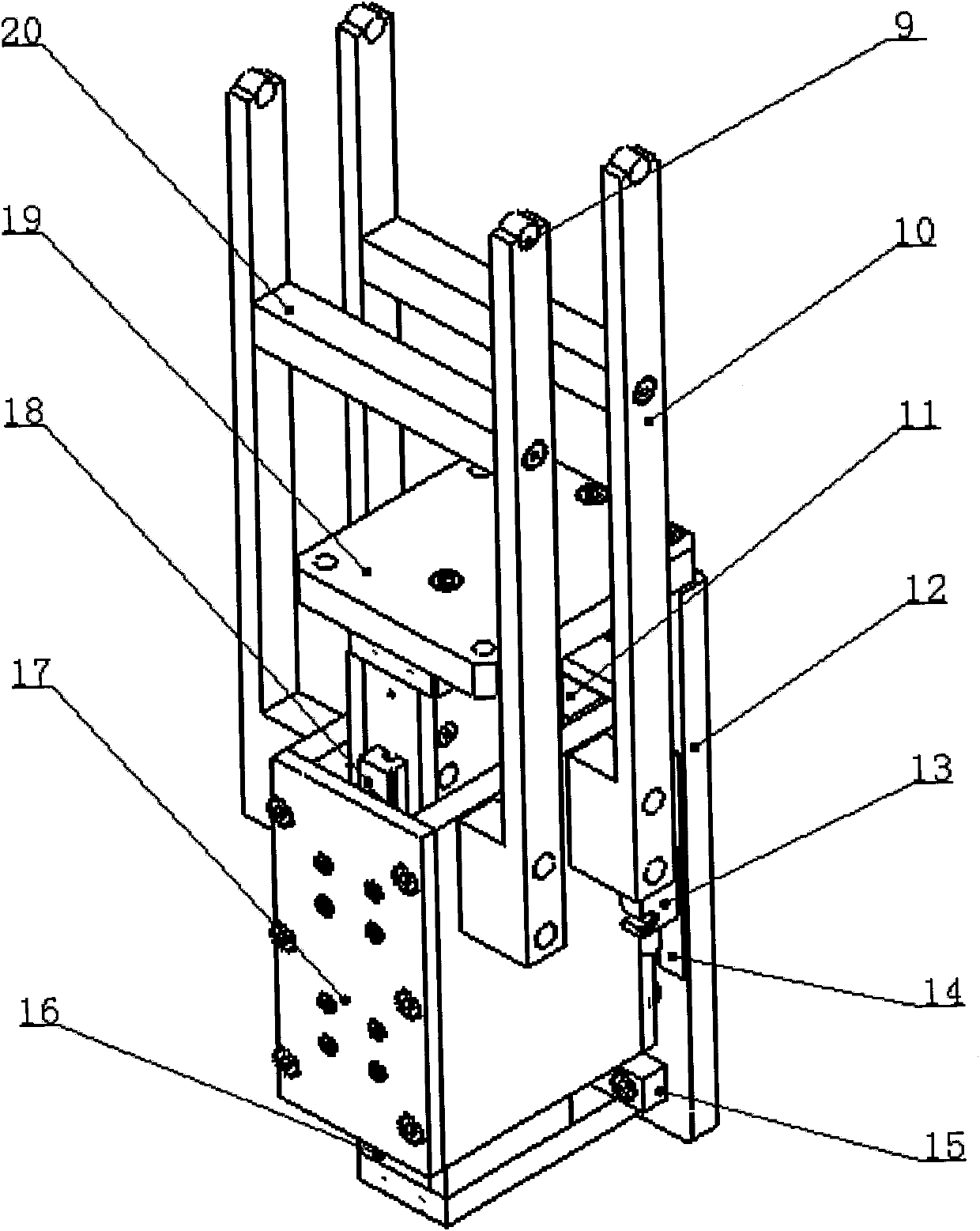

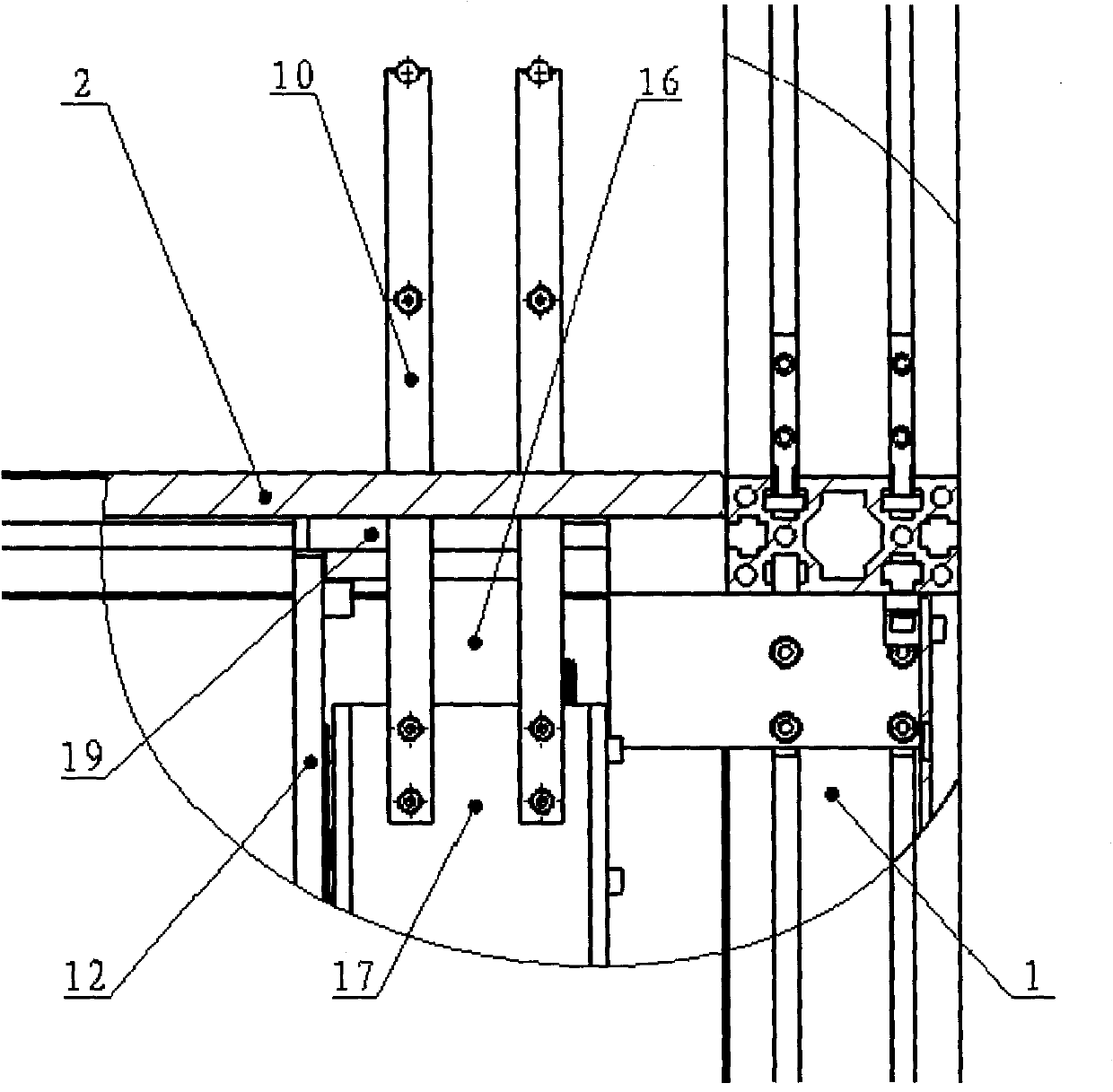

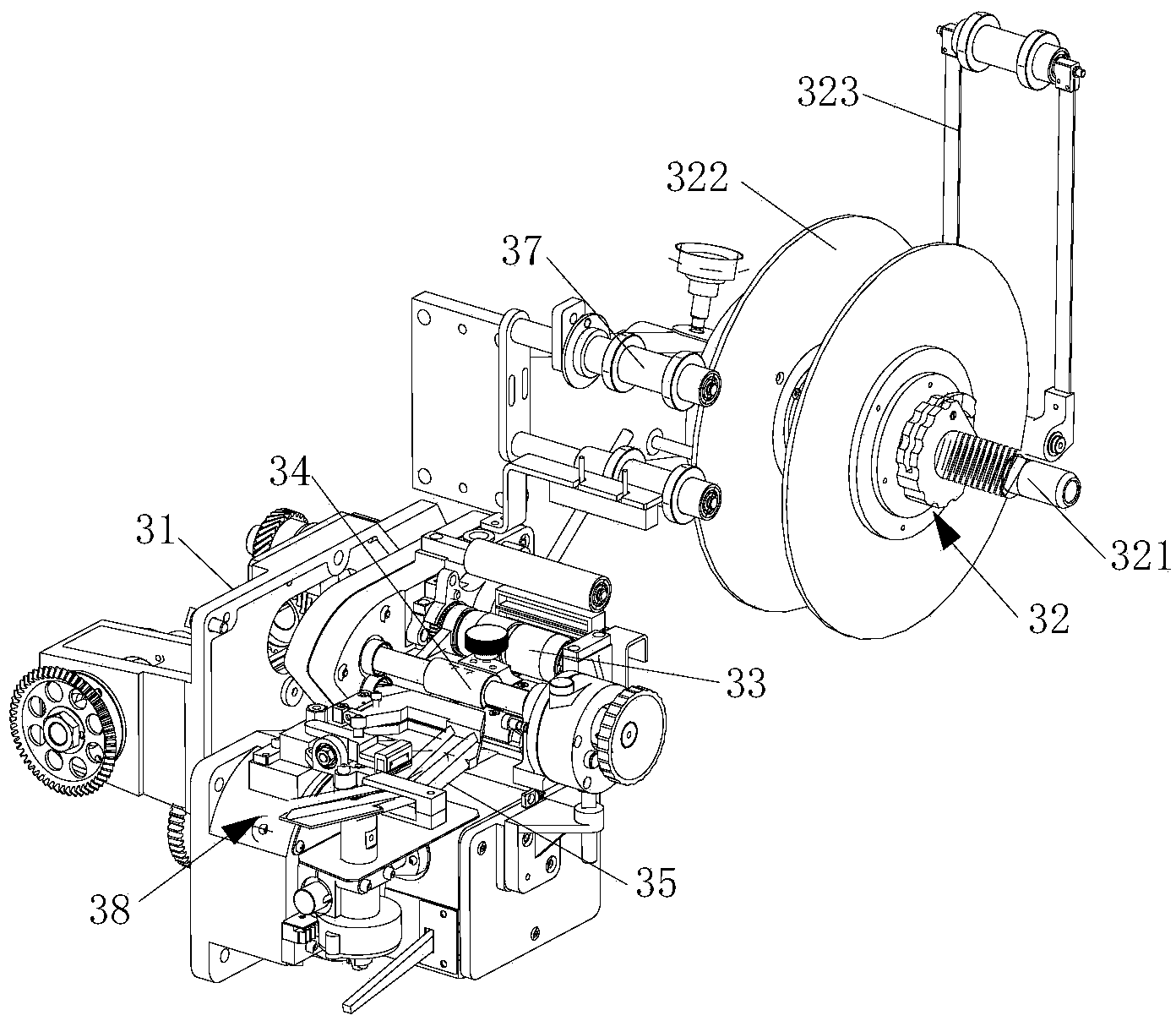

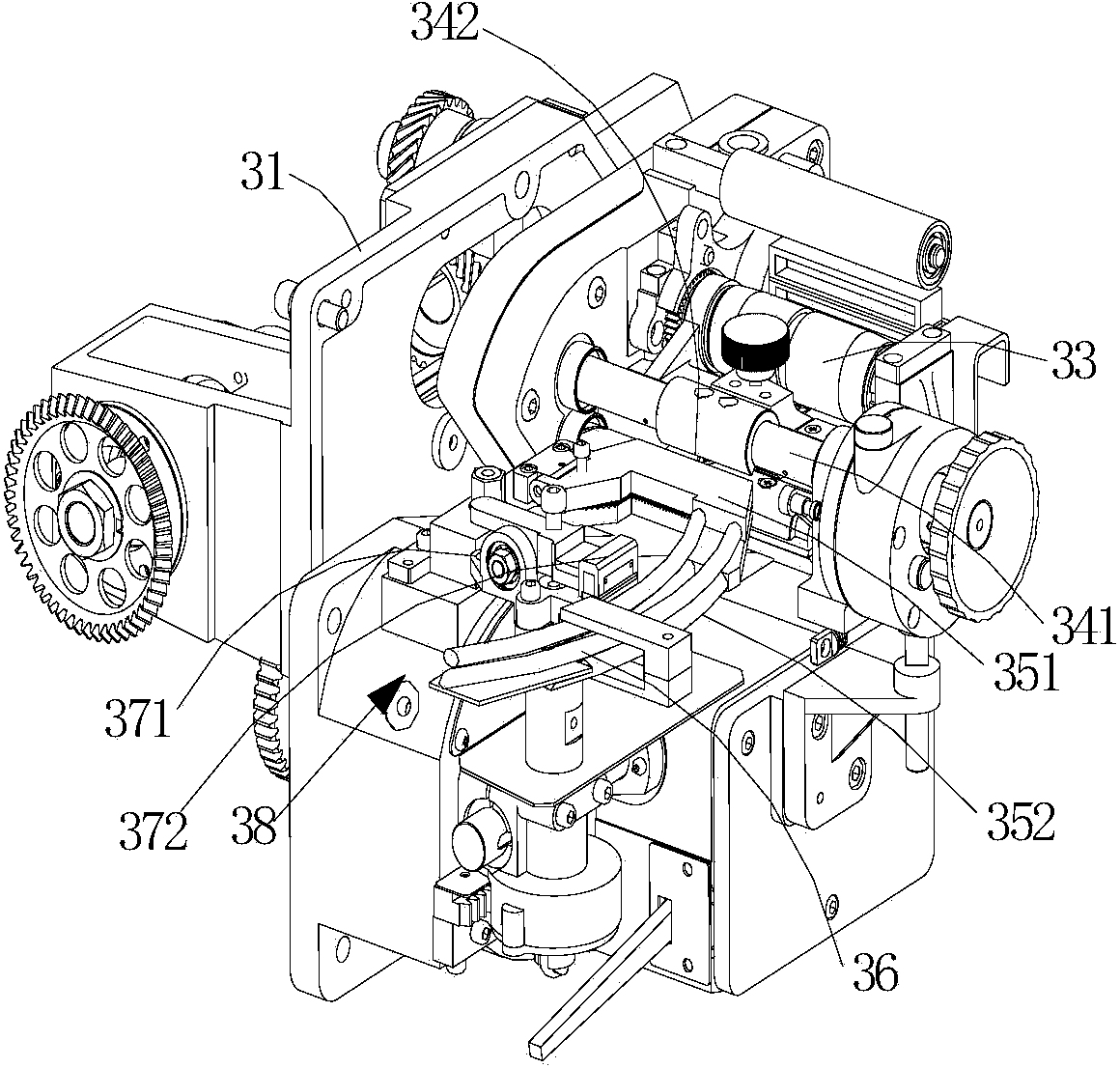

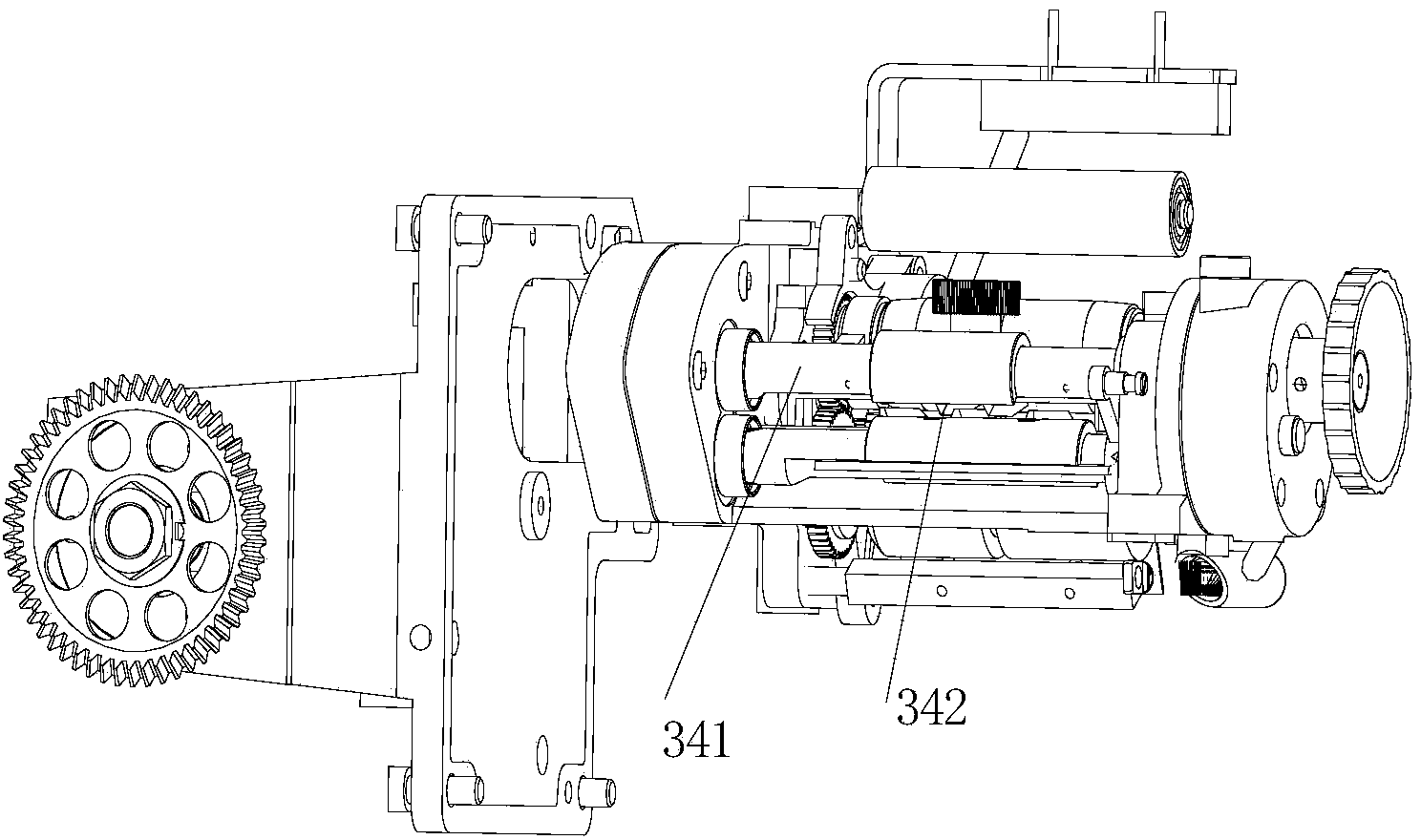

Full-automatic horizontal type glass edge polishing membrane removing machine

InactiveCN102554734ASuitable for mass production needsSave spaceEdge grinding machinesNumerical controlEngineering

The invention relates to an electromechanical integrated machine for glass machining, belonging to the technical field of glass machining machines, and particularly relates to a full-automatic horizontal type machine device with functions of glass edge polishing and membrane removing in the fields of numerical control electromechanical integration and automation. The machine comprises a conveying system assembly and an edge polishing mechanism assembly, wherein the edge polishing mechanism assembly is arranged on the conveying system assembly; the glass edge polishing machine further comprises a glass membrane removing mechanism; the glass membrane removing mechanism is hung under a linear guide track of a frame beam in the edge polishing mechanism assembly and is arranged in parallel to the edge polishing mechanism; the glass membrane removing mechanism can be driven by power to move along the linear guide track horizontally. According to the machine, membrane removing and polishing can be carried out synchronously; the machine is very applicable for large-scale production; the production efficiency is times that of a traditional technology; the guide track, a glass conveying system and a glass detection system of the edge polishing mechanism are shared; a great deal of space and resources are saved; and a membrane removing module can be closed when the membrane removing function is not needed.

Owner:广东新海岸机械有限公司

Method for preparing kaempferol-3-O-2'',6''-dirhamnosylglucoside

ActiveCN103113435AHigh purityHigh degree of automationSugar derivativesSugar derivatives preparationSpectroscopyEvaporation

The invention provides a method for preparing kaempferol-3-O-2'',6''-dirhamnosylglucoside, which comprises the following steps: by using a two-dimensional liquid phase chromatography-mass spectroscopy combination technology and taking methanol-water or acetonitrile-water as a mobile phase and a reversed phase C18 chromatographic column as a one-dimensional preparative chromatographic column, performing component cutting on a ginkgo leaf extract, and collecting a target component which is a kaempferol-3-O-2'',6''-dirhamnosylglucoside crude product; and by taking a reversed phase C18 chromatographic column as a two-dimensional preparative chromatographic column, under the guidance of selective ion peaks of mass spectroscopy, performing component cutting on the kaempferol-3-O-2'',6''-dirhamnosylglucoside crude product, collecting, and concentrating through rotary evaporation to obtain the high-purity kaempferol-3-O-2'',6''-dirhamnosylglucoside, wherein the purity can be up to 70% or above. According to the invention, the preparation process is high in repetitiveness and favorable in operability; and meanwhile, ginkgo leaves are abundant in resources and easy to acquire. Thus, the invention meets the requirements for large-scale production and can be used for the preparation of raw materials for a Shuxuening injection.

Owner:北京华润高科天然药物有限公司

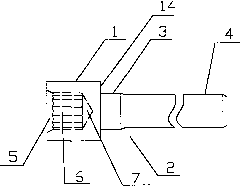

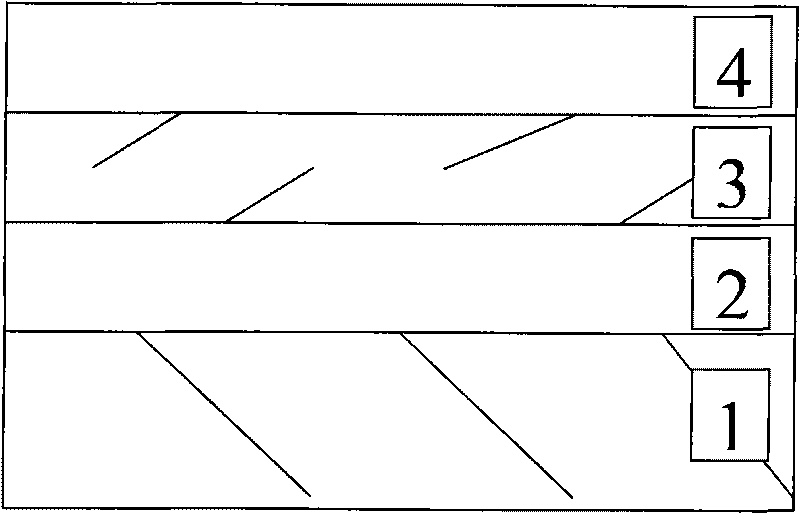

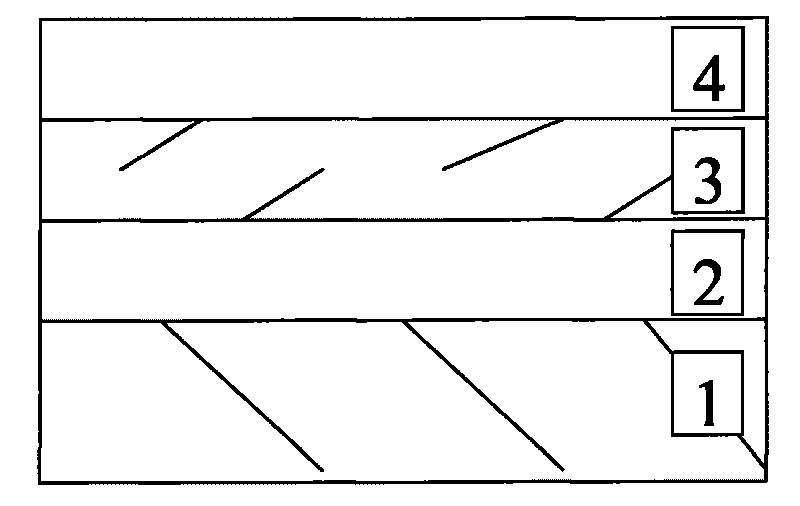

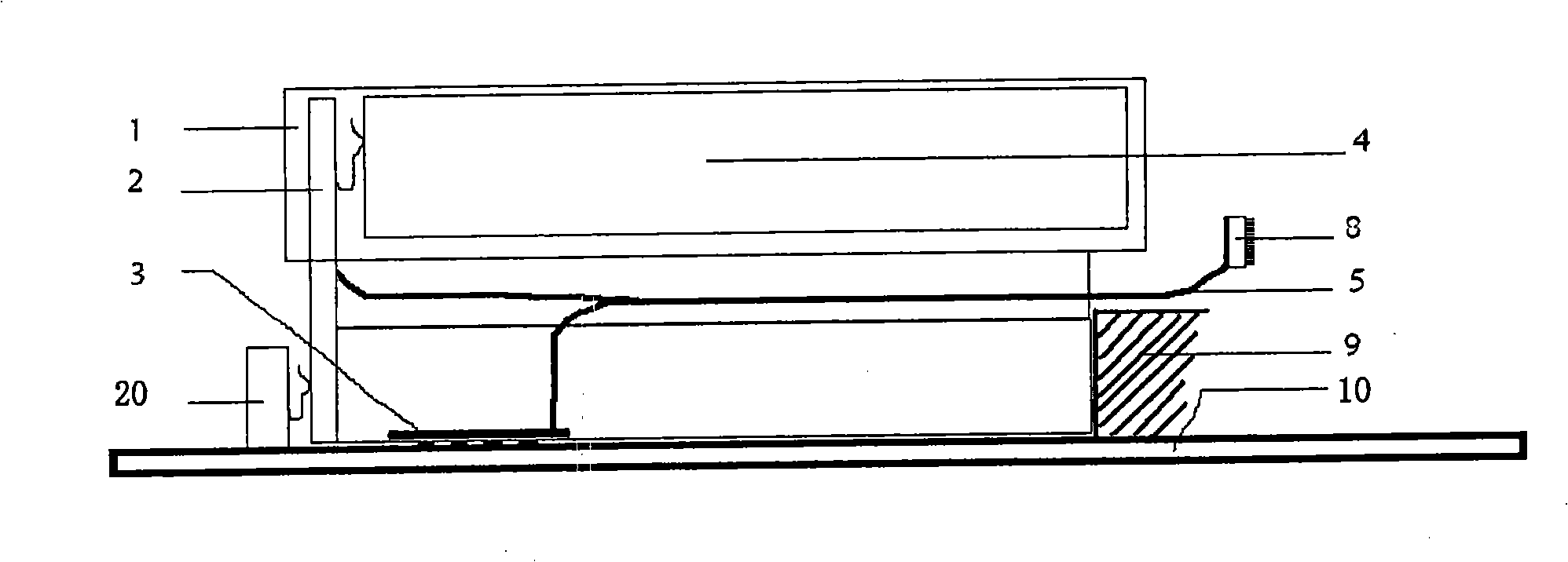

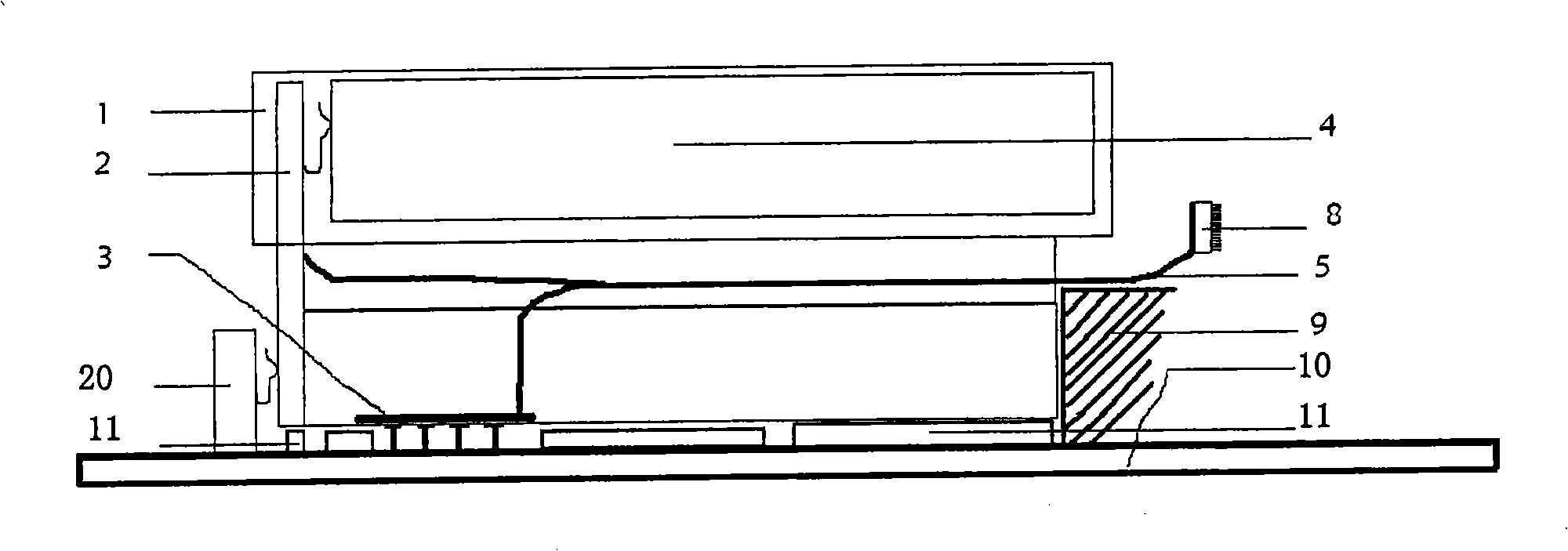

Permanent magnet with corrosion resistant coating and powder nanometer spraying method thereof

ActiveCN101728043AOperational securityEasy to operateLiquid surface applicatorsLiquid/solution decomposition chemical coatingAlloyMaterials science

The invention provides a permanent magnet with a corrosion resistant coating. The permanent magnet comprises a permanent magnetic material base body 1, an organic matter bottom layer 2, an organic matter transition layer 3 and a nanometer silver layer 4, and also comprises a powder nanometer spraying method for the permanent magnet with the corrosion resistant coating. As the metal base body is isolated from the contacted outside corrosion media through the inner and outer alloy layers, the metal base body is difficult to corrode and has good humidity and heat resistance property, and then the service life of the permanent magnet is prolonged. As the coating is thin, the influence on the magnet is small, and the magnet shielding does not exist. The product investment cost is reduced, and the safety production is ensured.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

Deburring method based on heat energy

InactiveCN102430833AImprove accessibilityGood quality de-stabbingGas flame welding apparatusHydrogenHigh volume manufacturing

The invention provides a deburring method based on heat energy, and the method is characterized by comprising the following steps of: placing a part to be processed on a fixture; then placing the fixture on which the part to be processed is well placed into a closed container; introducing the mixed gas of hydrogen and oxygen or the mixed gas of methane and oxygen into the closed container; igniting by use of an ignition device so as to quickly burn the mixed gas introduced into the closed container; and after the burning, taking out the fixture to finish the deburring. In the whole deburring process, as gas goes everywhere and has good accessibility, the method provided by the invention has a unique effect in removing burr or flash of the part. The method can be used for realizing the processing of multiple parts in a relatively short time due to the fixture and meeting the need for large-scale production, has a wide application range, and can be applied to the parts made from iron, cast iron, brass, aluminum, zinc, copper and the like. The method has the advantages of high efficiency, good deburring quality and the like, and is simple and convenient to operate.

Owner:龙工(上海)精工液压有限公司

Method for preparing kaempferol-3-O-rutinoside from ginkgo leaf extract

ActiveCN103113436AHigh purityHigh degree of automationSugar derivativesSugar derivatives preparationKaempferol-3-O-rutinosideEvaporation

The invention provides a method for preparing kaempferol-3-O-rutinoside from a ginkgo leaf extract, which comprises the following steps: by using a two-dimensional liquid phase chromatography-mass spectroscopy combination technology and taking methanol-water or acetonitrile-water as a mobile phase and a reversed phase C18 chromatographic column as a one-dimensional preparative chromatographic column, performing component cutting on a ginkgo leaf extract, and collecting a target component which is a kaempferol-3-O-rutinoside crude product; and by taking a hydrophilic TECys as a two-dimensional preparative chromatographic column, performing component cutting on the kaempferol-3-O-rutinoside crude product, collecting, and concentrating through rotary evaporation to obtain the high-purity kaempferol-3-O-rutinoside, wherein the purity can be up to 80% or above. According to the invention, the preparation process is high in repetitiveness and favorable in operability; and meanwhile, ginkgo leaves are abundant in resources and easy to acquire. Thus, the invention meets the requirements for large-scale production and can be used for the preparation of raw materials for a Shuxuening injection.

Owner:北京华润高科天然药物有限公司

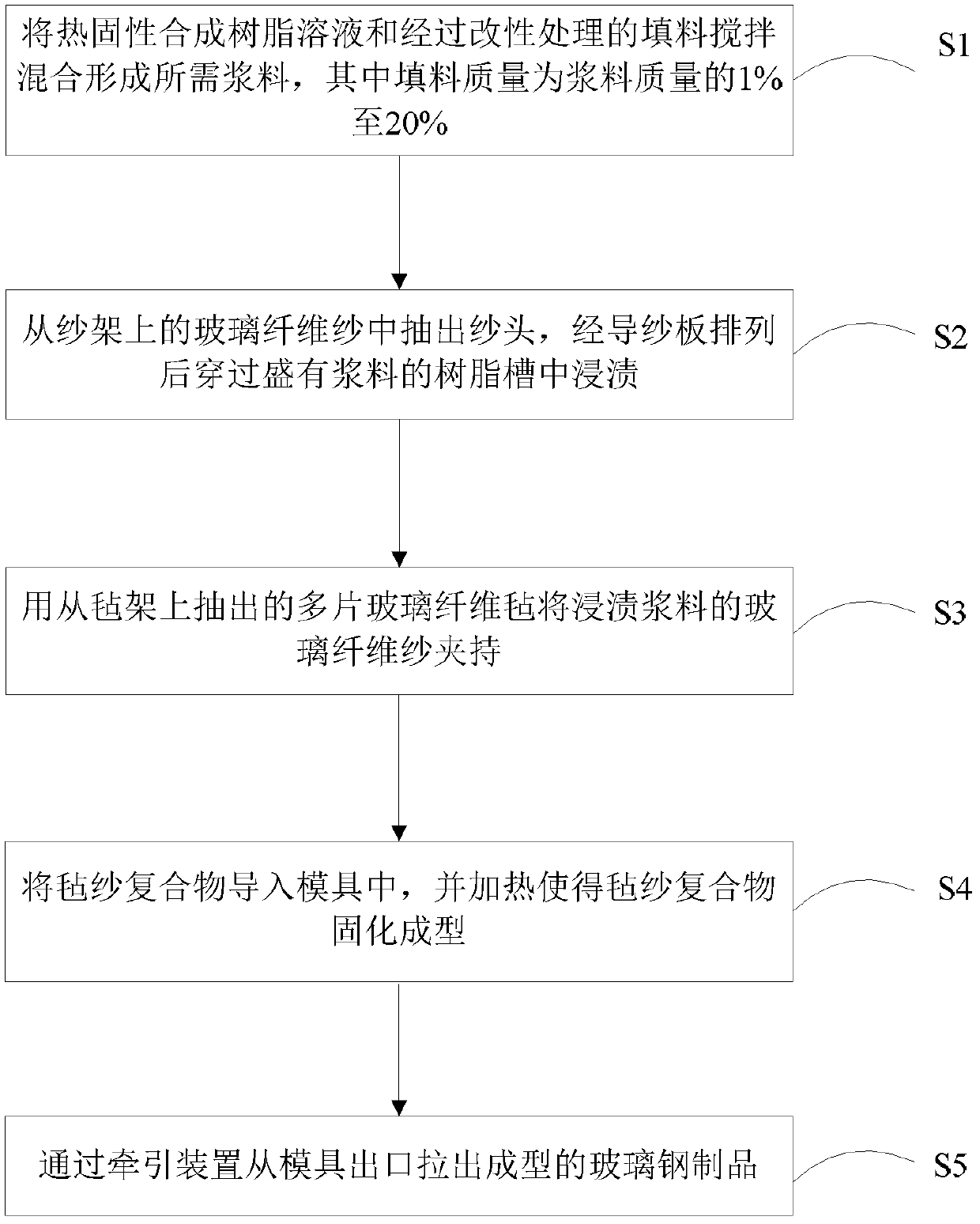

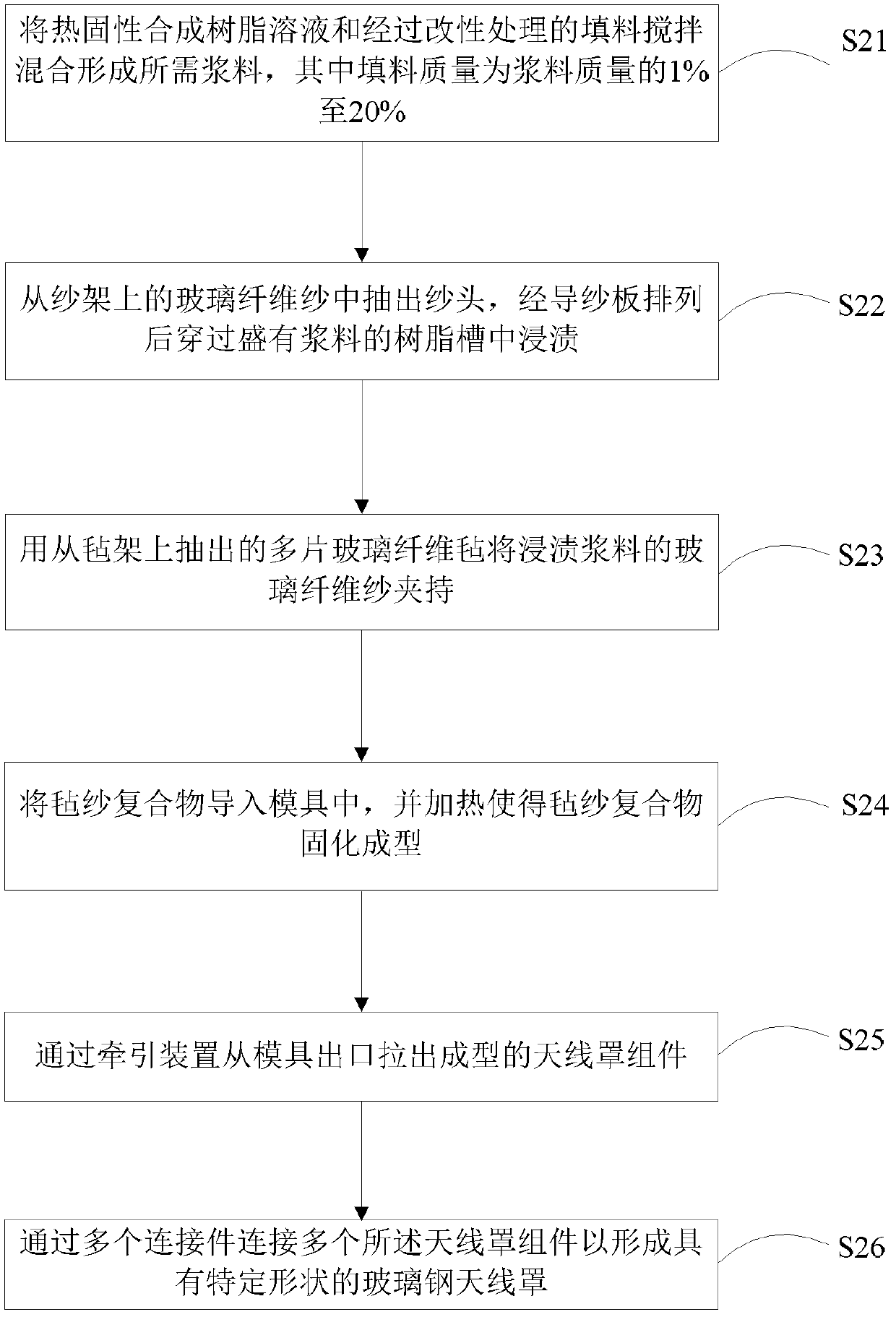

Preparation method of glass-reinforced plastic, and glass-reinforced plastic antenna housing and preparation method thereof

InactiveCN103286963AImprove bindingImprove the interface binding forceRadiating element housingsFiberYarn

The invention discloses a preparation method of glass-reinforced plastic, and a glass-reinforced plastic antenna housing and a preparation method thereof. The preparation method comprises the following steps: mixing a thermosetting synthetic resin solution and a modified filler to form a required slurry, and putting the slurry in a resin tank, wherein the filler accounts for 1-20 wt% of the slurry; drawing out a thrum from glass fiber yarn on a creel, arranging by a thread board, and passing through a slurry-containing resin tank for impregnation; clamping the slurry-impregnated glass fiber yarn with a plurality of glass fiber mats drawn from a mat frame; leading the mat yarn composite into a mold, and heating to cure and mold the mat yarn composite, thereby forming a glass-reinforced plastic product with the same shape as the mold core; and drawing the molded glass-reinforced plastic product out of the mold with a pulling device. The filler is added into the resin to improve the mechanical strength and lower the dielectric loss and cost. Surface modification is performed on the fiber fabric and filler to enhance the binding force between the resin and fiber fabric and between the resin and filler.

Owner:KUANG CHI INNOVATIVE TECH

Method for preparing high-purity rutin via two-dimensional liquid chromatography-mass spectrometry combined technology

ActiveCN103120706AHigh purityHigh degree of automationComponent separationMetabolism disorderHydrolysateOperability

The invention relates to the technical field of medicines, and discloses a method for preparing high-purity rutin via a two-dimensional liquid chromatography-mass spectrometry combined technology. The method comprises the following steps of: adopting the two-dimensional liquid chromatography-mass spectrometry combined technology, taking methanol-water or acetonitrile-water as a mobile phase, using a reversed chromatographic column as the first dimension for preparing a chromatographic column, performing component cutting on a ginkgo leaf extract, and collecting a target component, namely, a rutin crude product; and using the reversed chromatographic column as the second dimension for preparing a chromatographic column, performing component cutting on the rutin crude product under the guide of a mass spectrometry selected ion peak, collecting, rotationally evaporating and concentrating, and then obtaining the high-purity rutin having a purity which can achieve more than 80%. In the method disclosed by the invention, heating is not needed, so that the doping of a hydrolysate is avoided; the preparation is simple in process, high in repeatability, and good in operability; simultaneously, ginkgo leaves are abundant in resource and easy to obtain, thus reducing the cost; and the method is suitable for large-scale production.

Owner:北京华润高科天然药物有限公司

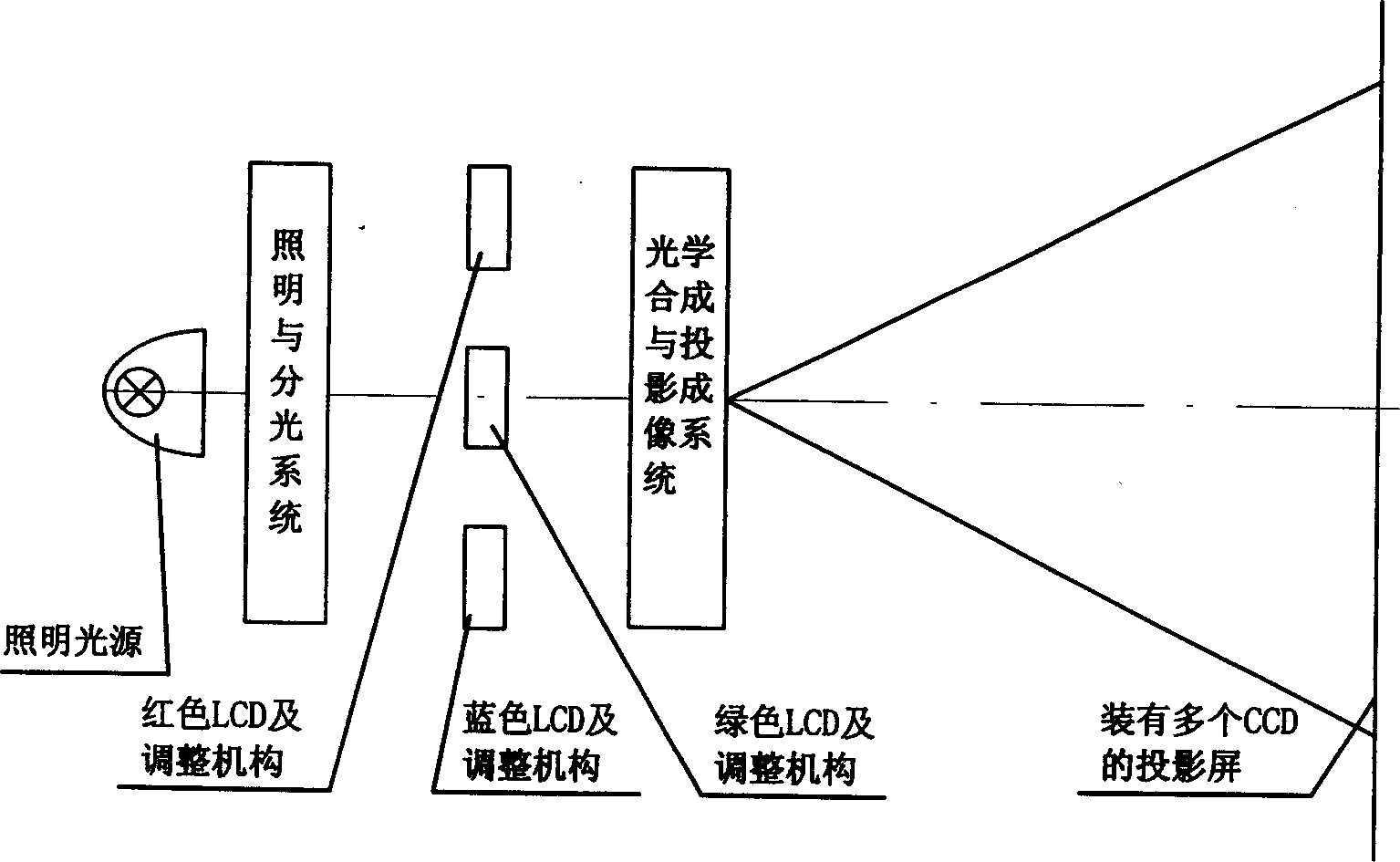

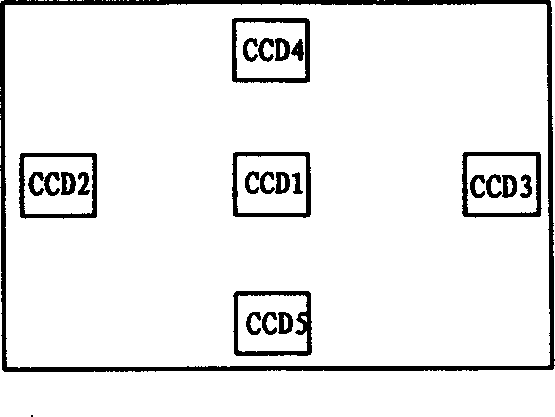

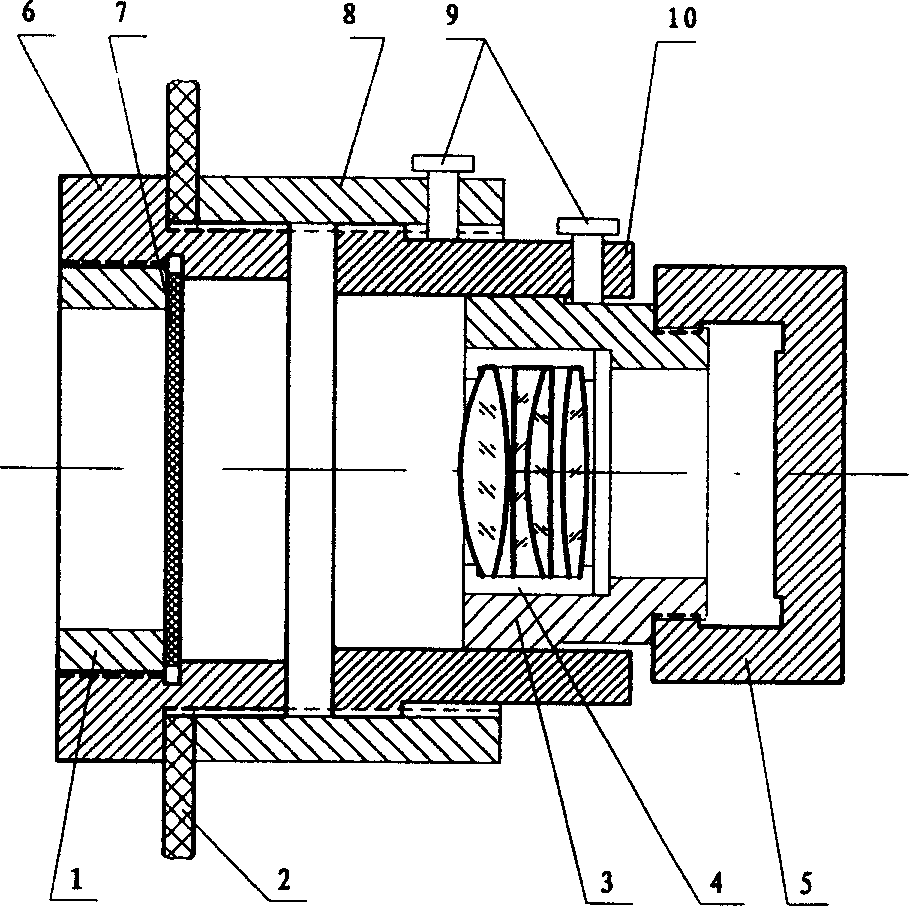

Object plane adjustment method of optical projection system based on defocus depth analysis and its device

InactiveCN1431556ANot affected by subjective factorsImprove adjustment accuracyProjectorsImage data processing detailsDepth from defocusControl system

The invented defocus depth analysis is as follows. The multiple CCD image collection assemblies are installed on the projection screen of the projection optical system in order to obtain the images. The quantity of the defocus depth, the amount of inclination in horizontal direction and in vertical direction, the quantity of rotation of the LCD in the object plane of the optical projection systemas well as the relative position deviations of the three pieces of LCD are obtained. Then, the adjusting parameters are given out. The advantages of the invention are (1) High accuracy of the adjustment: the precision is assured by the system, not affected by the operators. (2) Fast adjustment speed; the settings with 18 degree of freedom are given at same time and suitable to the need of large scale of production. (3) Simple operation.

Owner:ZHEJIANG UNIV

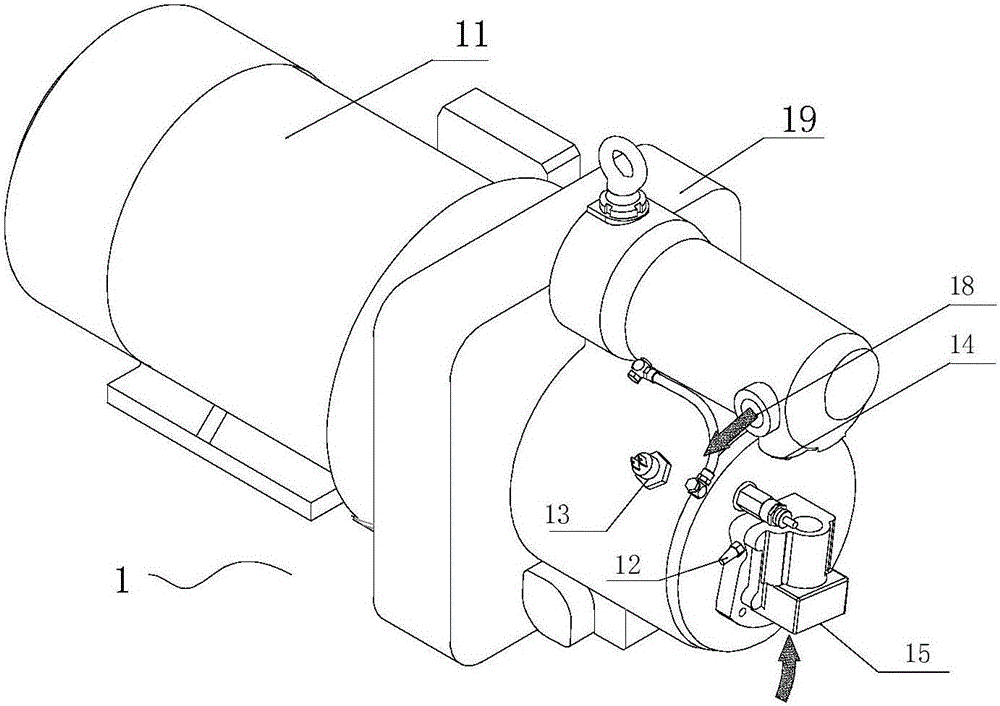

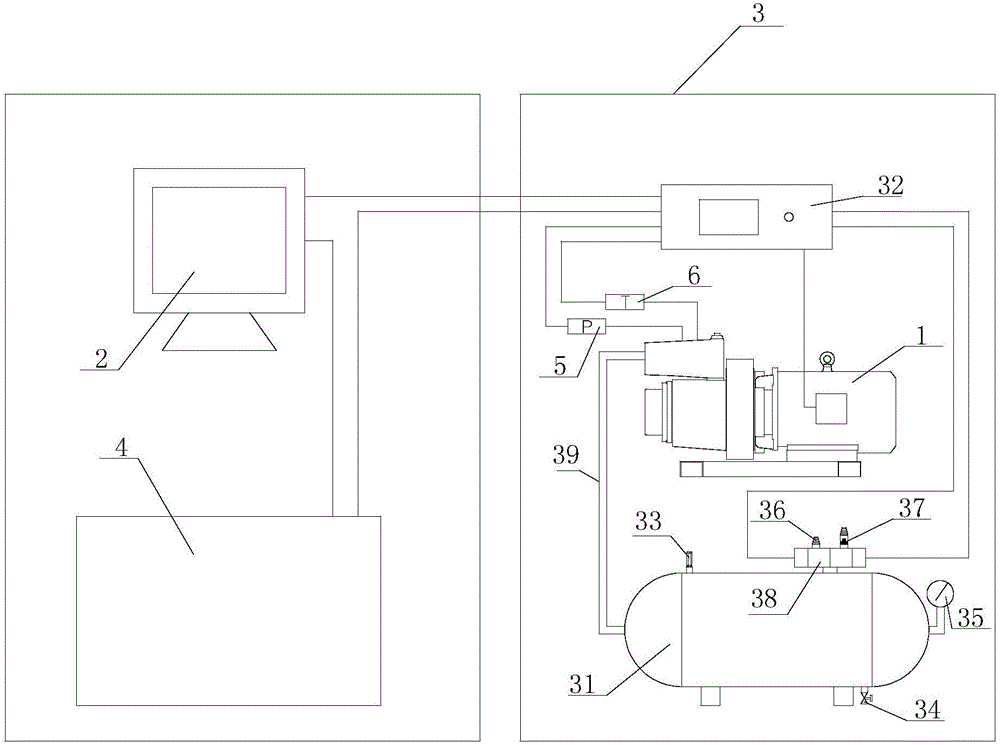

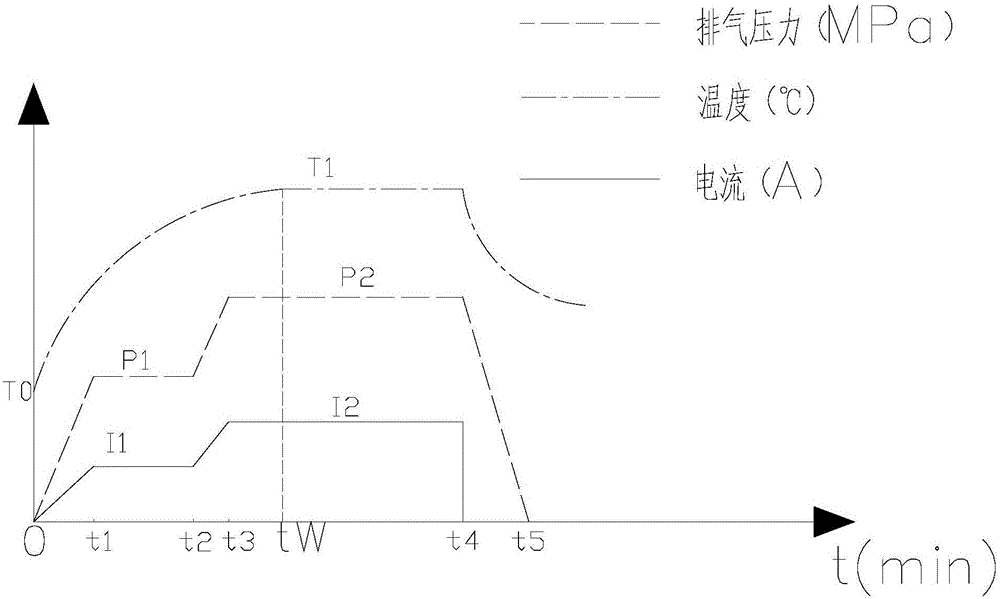

Test system and test method for vehicle-mounted sliding vane type air compressors

ActiveCN106014957ASolving All-in-One Parametric Testing ProblemsImprove test efficiencyPump testingPump controlTest efficiencySpray nozzle

The invention discloses a test system and a test method for vehicle-mounted sliding vane type air compressors. The test system comprises an upper computer and a plurality of testing units connected with the upper computer; each testing unit comprises a gas storage tank, an operation console and a to-be-tested air compressor; a temperature sensor and a pressure sensor are installed on a host of each air compressor; an air outlet of each air compressor is connected with the corresponding gas storage tank through an air outlet pipe; each gas storage tank is provided with a pressure meter and a small-hole flow measuring device; each small-hole flow measuring device comprises a silencer, a small-hole spray nozzle and an electromagnetic switching valve; each electromagnetic switching valve is electrically connected with the corresponding operation console; one end of each silencer and one end of the corresponding small-hole spray nozzle communicate with the corresponding gas storage tank through the corresponding electromagnetic switching valve; the other end of each silencer and the other end of the corresponding small-hole spray nozzle communicate with the outside world; and mutual switching between the silencers and the small-hole spray nozzles is achieved by switching the electromagnetic switching valves. The test system and the test method for the vehicle-mounted sliding vane air compressors have the beneficial effects that the function of measuring a plurality of performance parameters at multiple stations at the same time is really achieved, the testing efficiency is greatly improved, and the testing cost is reduced.

Owner:吴泰 +1

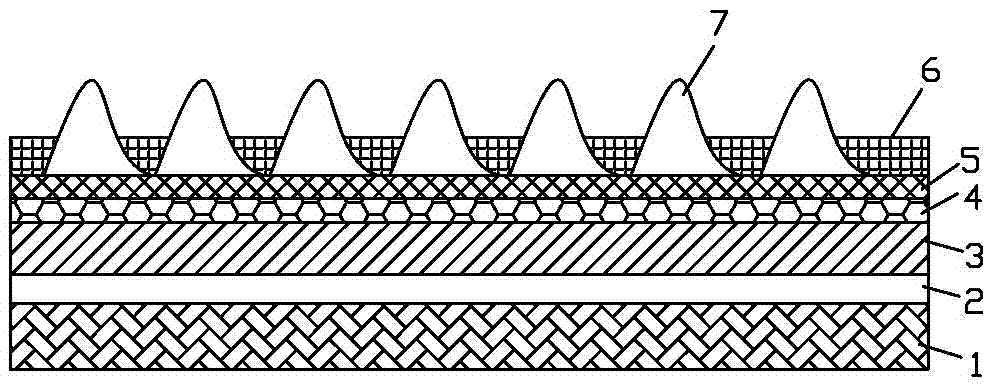

Composite base material polishing grinding apparatus and preparing method thereof

ActiveCN107344336AHigh mechanical strengthImprove wear resistanceSynthetic resin layered productsAbrasion apparatusAdhesive cementComposite substrate

The invention relates to the technical field of grinding polishing machining, in particular to a composite base material polishing grinding apparatus and a preparing method thereof. The composite base material polishing grinding apparatus comprises a composite base material and an abrasive material attached to the composite base material, the composite base material is formed by compounding a TPU thin film and a PET thin film through a modified adhesive, and the modified adhesive is prepared from, by weight, 100 parts of modified polyurethane resin, 10-20 parts of a curing agent, 5-30 parts of a filler and 10-40 parts of an organic solvent. Compared with the prior art, the self-made modified adhesive is adopted, a transfer binding method is adopted, the high-elasticity TPU thin film and the high-strength PET thin film are firmly bonded together, and therefore the composite base material has the high mechanical strength and heat-resisting and wear-resisting property, and has the excellent elasticity and softness; and the made polishing grinding apparatus meets premise polishing requirements of paint face repairing, irregular surfaces and curve faces and the like.

Owner:DONGGUAN GOLDEN SUN ABRASIVES

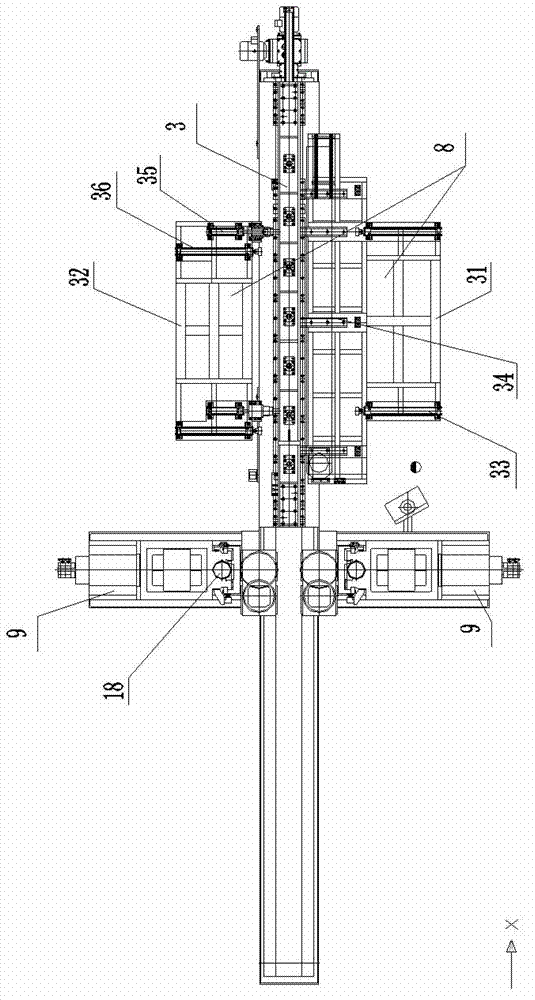

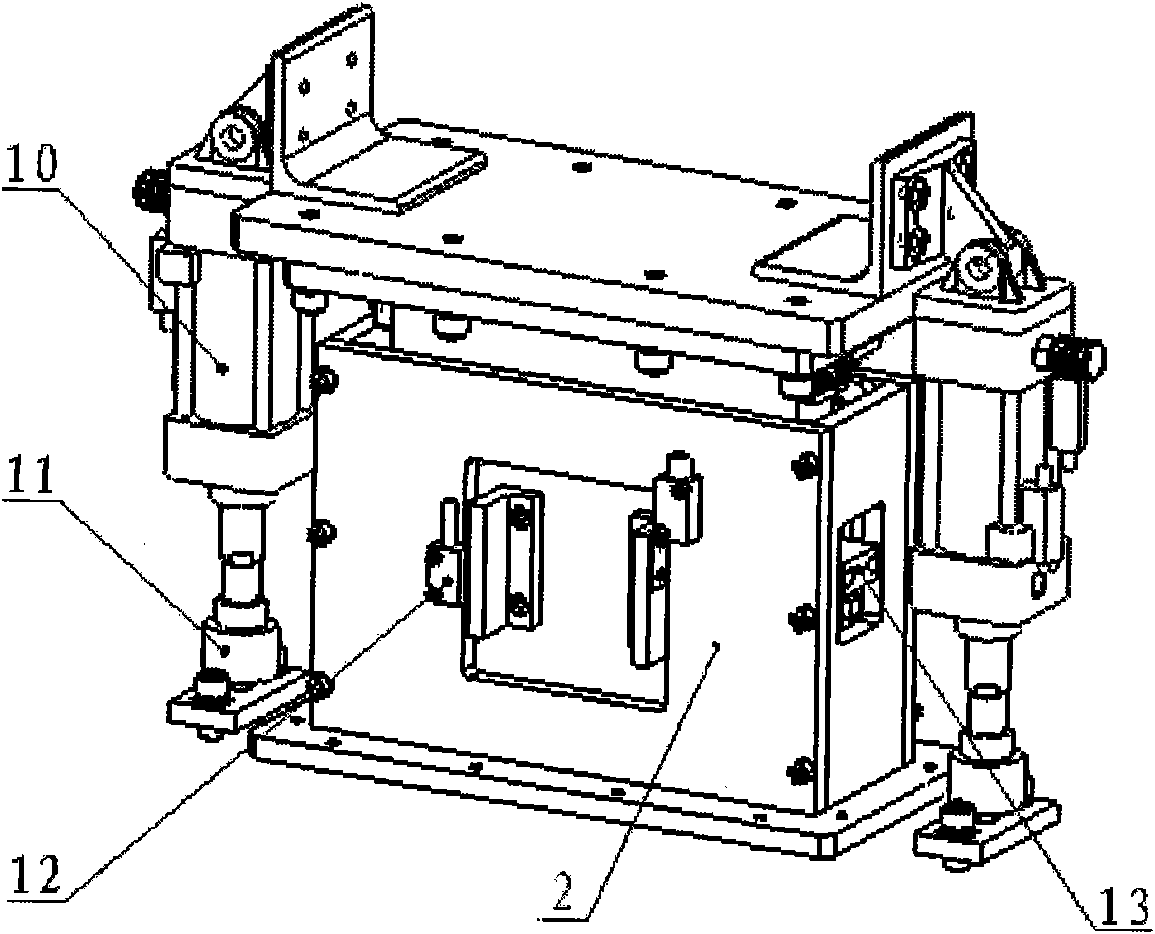

Vertical double-sided milling machine

ActiveCN102825310ASolve multiple clampingSolve the adjustmentLarge fixed membersMilling equipment detailsEngineeringMachining process

The invention discloses a vertical double-sided milling machine which comprises a middle base and two lateral bases which are symmetrically arranged at the two sides of the middle base. A middle slide table is arranged on the middle base; a clamping device is arranged on the middle slide table; a lateral slide table is arranged on each of the lateral bases; an upright post is fixed on each lateral slide table; an upright post slide table is arranged at the upper part of each front end of the upright post; a spline shaft sleeve is vertically arranged below the front end of each upright post; a cutter head I is fixed on the spline shaft sleeve; a power head is arranged on each upright post slide table; a cutter head II is arranged on a power output shaft at the lower end of the power head; a spline shaft extends below the cutter head II on the power output shaft, and the spline shaft is inserted into the spline shaft sleeve to drive the cutter head I to rotate when the power output shaft drives the cutter head II. According to the invention, four edges of a work-piece can be milled and chamfered at the same time by clamping once; the problems of fussy clamping and adjusting for a plurality of times in a work-piece processing process are solved; the processing precision and processing efficiency of the work-piece are greatly improved, and the vertical double-sided milling machine is especially suitable for mass production requirements.

Owner:BAOJI SAIWEI HEAVY DUTY MACHINE TOOL MFG CO LTD

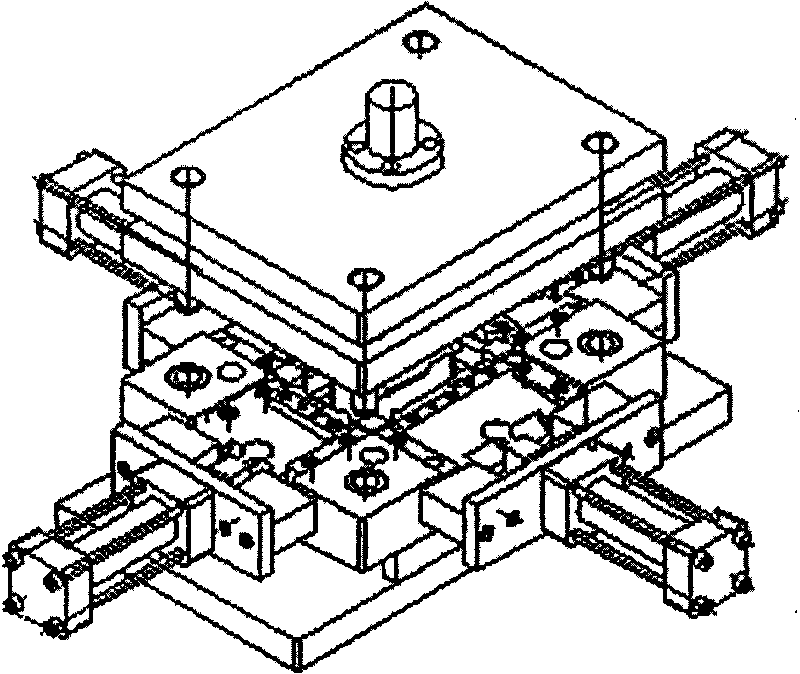

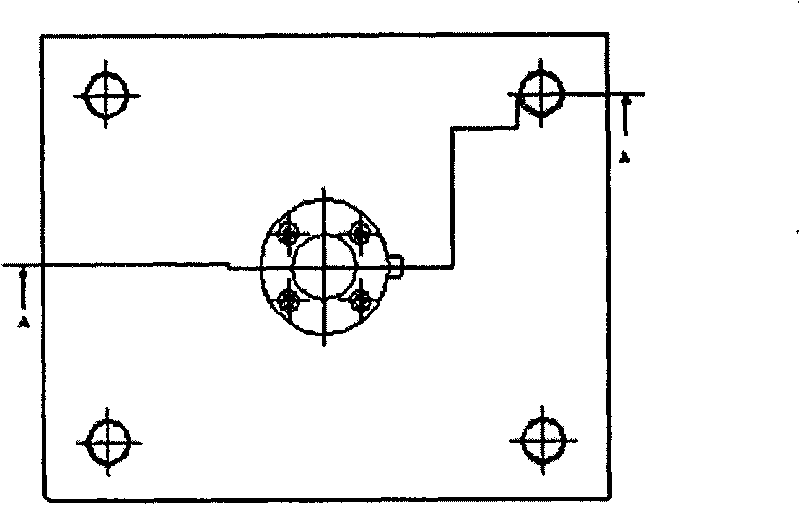

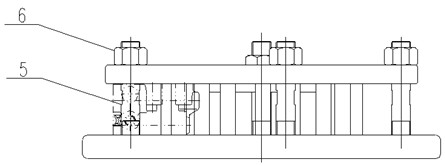

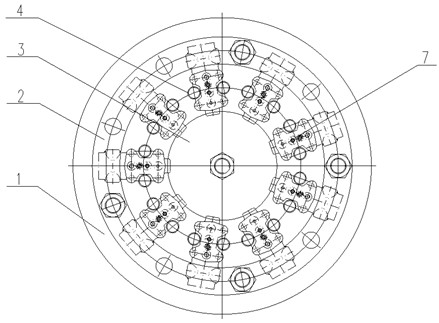

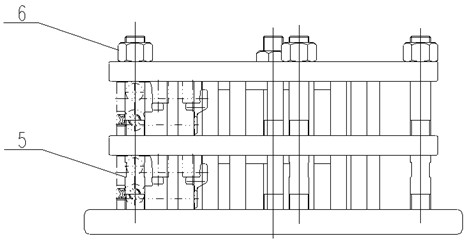

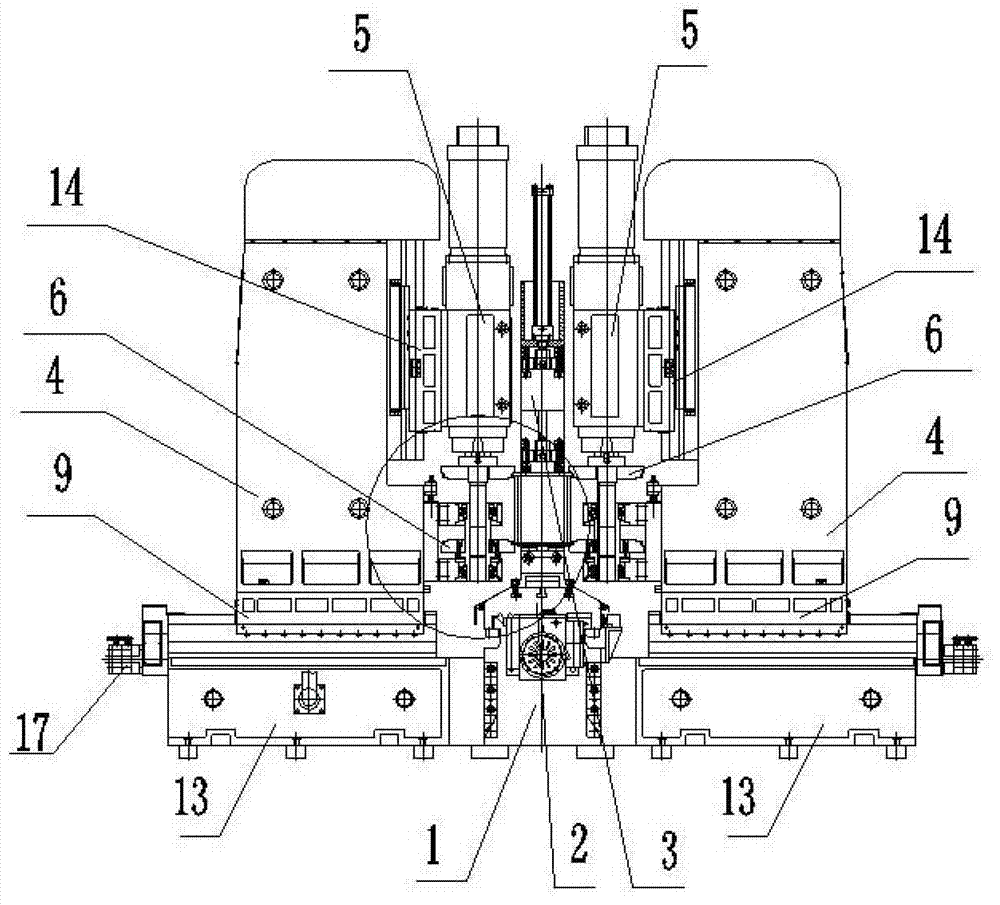

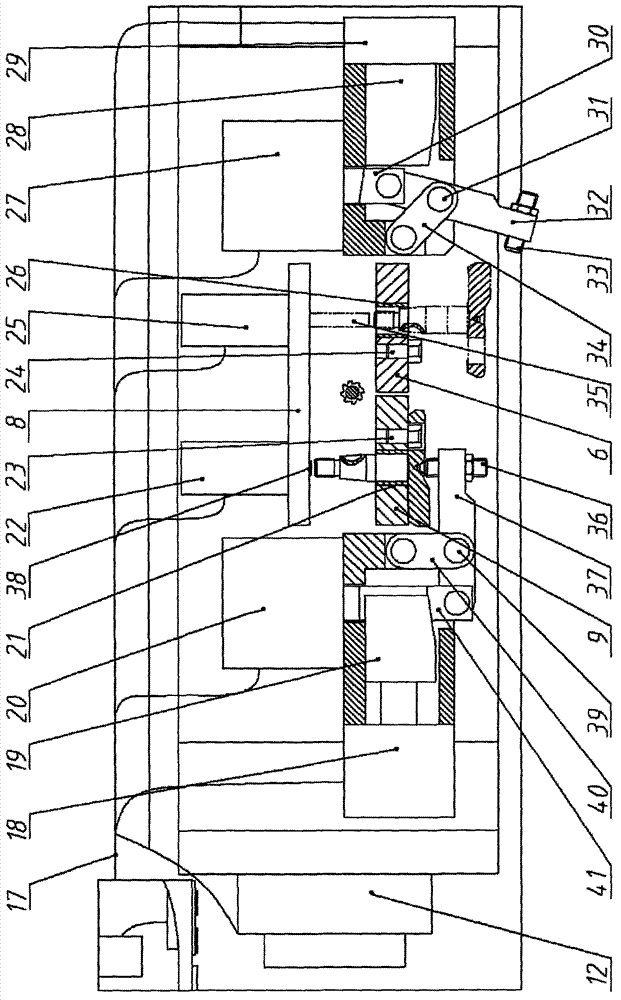

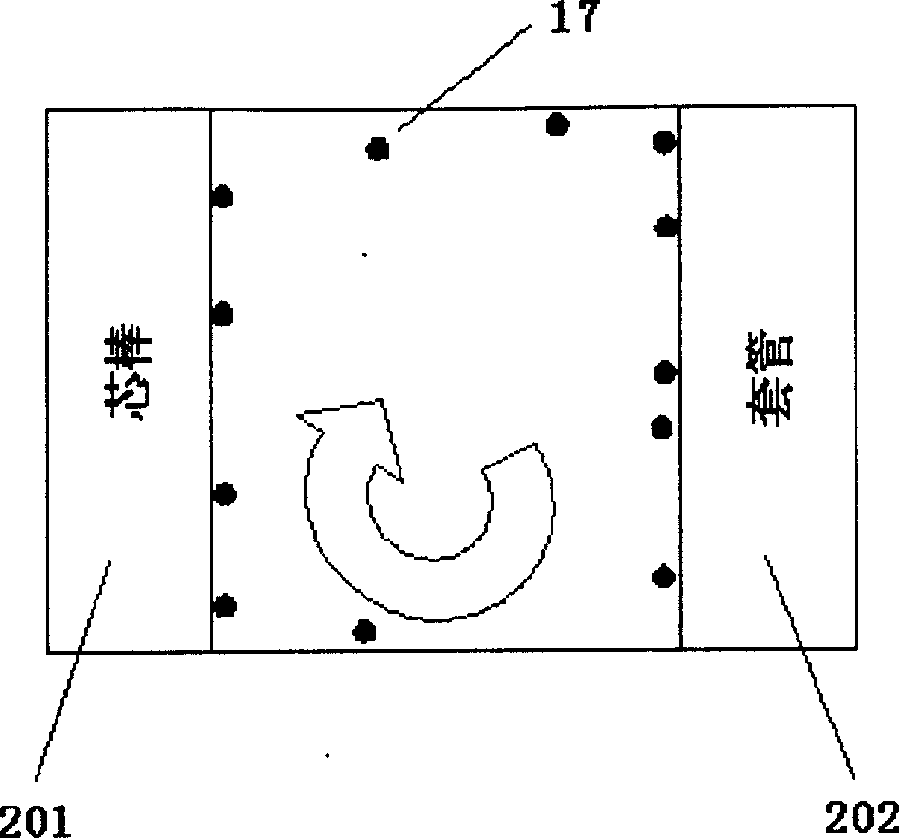

Apparatus for double-position automatically circular milling of crank shaft semi-circle keyway

InactiveCN102814541AImprove process reliability and process efficiencyReduce labor intensityMilling equipment detailsMetal working apparatusElectrical controlEngineering

The invention discloses an apparatus for double-position automatically circular milling of a crank shaft semi-circle keyway. The apparatus comprises a servo sliding stable, workpiece positioning mechanisms, pneumatic pressing mechanisms, pneumatic locking mechanisms, pneumatic ejection mechanisms and an electrical control system; the apparatus is characterized in that a left processing position and a right processing position are symmetrically arranged at the servo table; and a semi-circle keyway milling cutter is arranged between the two processing positions, and workpiece positioning plates, pneumatic clamping mechanisms, pneumatic clamping mechanisms, the pneumatic locking mechanisms and the pneumatic ejection mechanisms are respectively arranged at the two positioning positions. Except that the workpieces are manually mounted and clamping buttons are clicked, the other parts sequentially clamp, process and detach the workpieces under the control of the electrical control system, and the process is circularly operated until the workpieces are not clamped. In the working process, the labor intensity of the workers is obviously reduced, the working efficiency is improved, and the requirement of mass production is applicable.

Owner:SHANDONG HUASHENG PESTICIDE APPL MACHINERY CO LTD

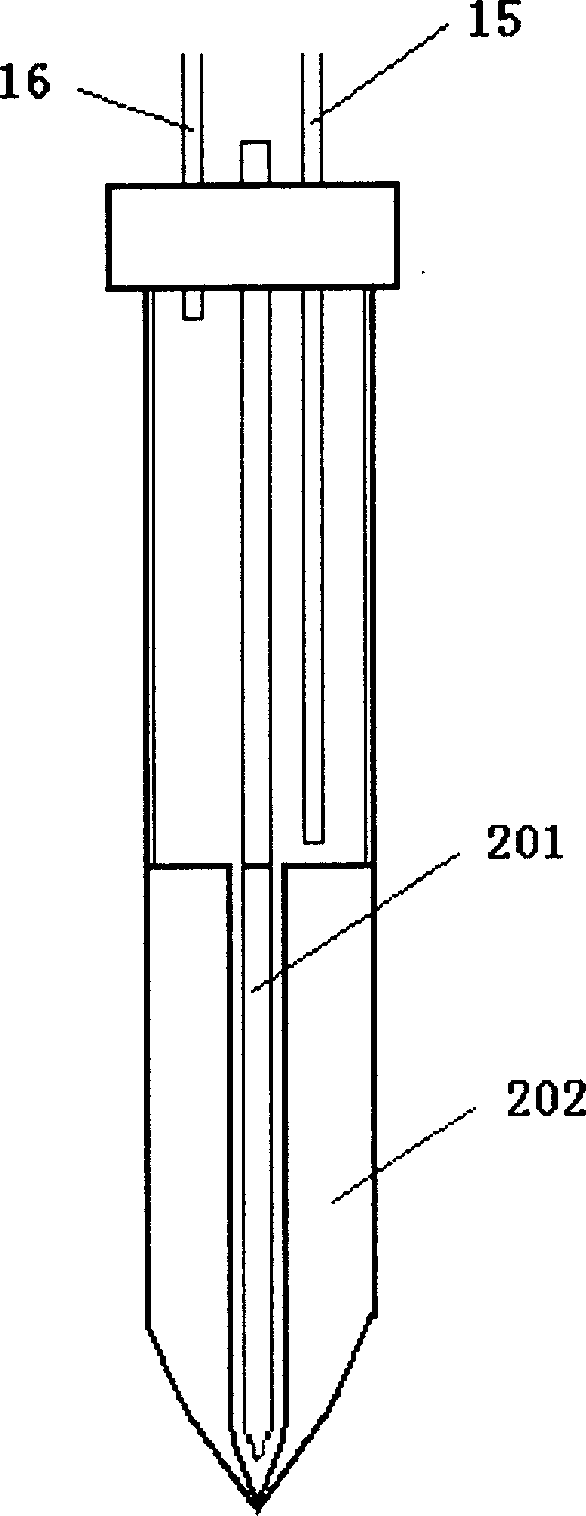

Method for manufacturing optical fiber unsensitive to hydrogen

ActiveCN1631825AFacilitated DiffusionEasy to handleGlass making apparatusGlass productionFiberHydrogen

The invention relates to a method for making optical fiber, concretely for a fiber without sensitivity to hydrogen, its characteristic is: blow into mixed air containing deuterium to process with optical fiber and optical fiber stick in the technical course of drawing the optical fiber and optical fiber stick, blowing into mixed air containing deuterium, there fore help deuterium diffusion by using the high temperature in the furnace and of optical fiber, which makes deuterium atom react with diadvantage and increase the processing effect of deuterium; it blows the mixed air directly into the jacket pipe of optical fiber stick through pipe, so that deuterium can penetrate into the core layer of optical fiber to react more completely, increasing the processing effect of deuterium compared with the present technology, the production efficiency, suitable for large-scale production.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Method for compositing alkyl phosphonic acid dialkyl ester

ActiveCN103073581ARaw materials are cheap and easy to getHigh yieldGroup 5/15 element organic compoundsPhosphorous acidDistillation

A method for compositing alkyl phosphonic acid dialkyl ester is characterized in that phosphorous acid trialkyl ester is taken as a raw material and alkyl phosphonic acid dialkyl ester is composited under alkali conditions through catalyst. The specific compositing steps are as follows: phosphorous acid trialkyl ester, alkali, catalyst are added in a container in sequence, a reflux reaction is performed, and the pressure is controlled to be within 1.2 to 1.4 MPa; and when the reaction is over, underpressure distillation is performed, distillate is collected, and then alkyl phosphonic acid dialkyl ester is obtained. Phosphorous acid trialkyl ester used in the method, which is taken as the raw material, is low in cost and easy to get; and the method has the advantages of high productivity and simplicity in operation and is more suitable for mass production.

Owner:HUBEI XINGFA CHEM GRP CO LTD

Sheet-grasping mechanical arm of full-automatic battery plate printing machine

InactiveCN101774173AAvoid squeezingAvoid vibrationProgramme-controlled manipulatorGripping headsHigh volume manufacturingElectric machinery

The invention relates to a sheet-grasping mechanical arm of a full-automatic battery plate printing machine, which comprises a vertical movement mechanism and a horizontal movement mechanism, wherein a front arm mechanism and a rear arm mechanism are arranged in the horizontal movement mechanism; the front arm mechanism and the rear arm mechanism have the same structure; the front arm mechanism comprises a pair of paw sheet mounting beams, a paw base, paw sheets, a sensor mounting plate, a magnetic grid and a sensor chip; the lower surface of the paw base is provided with a pair of parallel paw sheet mounting beams; 2 to 5 pairs of the paw sheets are uniformly distributed on one lateral surface of each paw sheet mounting beam; the front arm mechanism and the rear arm mechanism are fixedly connected with a mover of a corresponding X-direction linear motor respectively; and the lower ends of the paw sheets are provided with supporting sheets. The sheet-grasping mechanical arm of the full-automatic battery plate printing machine has the advantages of compact structure, high accuracy and quick motion, and can realize the synchronous conveying of two groups of materials and avoid extrusion and vibration to the materials in grasping movements; and the sheet-grasping mechanical arm of the full-automatic battery plate printing machine is safe and reliable to use, has a high working efficiency and meets requirements on mass production.

Owner:THE 45TH RES INST OF CETC

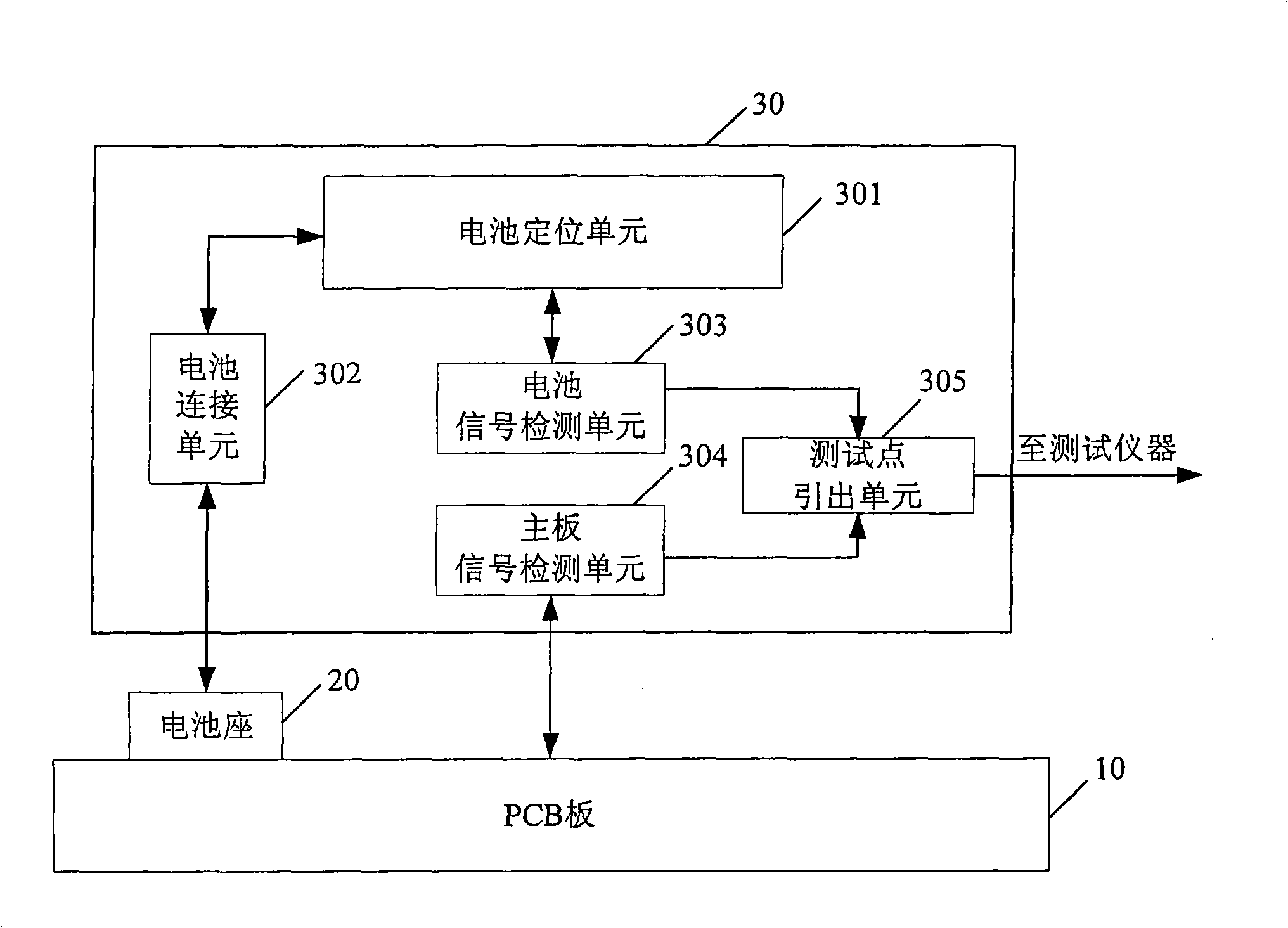

Device and method for testing electronic apparatus

ActiveCN101349733AEliminate test distractionsPrecise positioningElectronic circuit testingElectricityEngineering

The invention provides a test device for electronic equipments and a test method. The device comprises a cell positioning unit for positioning the cell of an electronic equipment above the main board of the electronic equipment, a cell connecting unit connecting a cell holder on the main board and the cell in the cell positioning unit for supplying the electricity of the cell to the electronic equipment, a main board signal detection unit connected with a plurality of test points on the main board for obtaining main board test signals, and a test point extraction unit connected with the main board signal detection unit and a test equipment for extracting the main board test signals to the test equipment. The device adopts a cell for power supply, can test the cell property as well as test a PCB board, eliminates special interfaces on the PCB board for loading and testing software, and improves the utilization of PCB board.

Owner:HUAWEI DEVICE CO LTD

Full-automatic battery slice transporting and baiting device

InactiveCN101792066ARealize the function of transmission and blankingAvoid squeezingCharge manipulationConveyor partsHigh volume manufacturingElectrical battery

The invention relates to a full-automatic battery slice transporting and baiting device, in particular to a device for realizing transportation and baiting to a solar energy battery silicon slice. The full-automatic battery slice transporting and baiting device comprises a frame, an operation panel, a top flat mechanism, a pulldown mechanism and a transportation mechanism, wherein the top flat mechanism comprises a top flat liner motor, a mandril, a transferring frame provided with the mandril, a mounting plate and an elevating guide rail; the transportation mechanism comprises a transmission seat, a transmission mounting plate, a cross-shaped mounting plate, a transmission liner motor and two groups of transmission guide rails; the pulldown mechanism comprises a fitting seat, a pulldown liner motor, two groups of translational guide rails and two paw seats. The device of the invention has compact structure, high precision, high speed, low fragment rate and adjustable transmission height and can avoid extrusion and shaking of material when fetching material. The invention has safe and reliable operation and high operation efficiency and is suitable for the requirements of large-scale production.

Owner:THE 45TH RES INST OF CETC

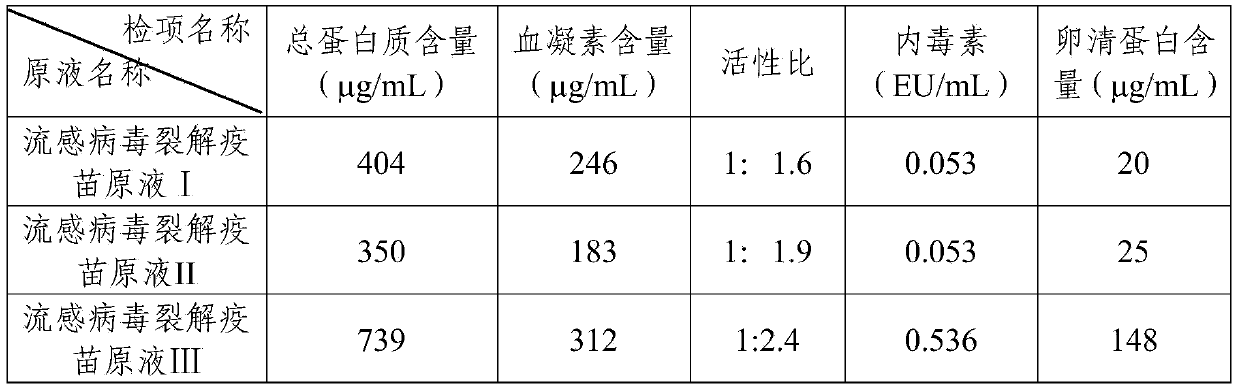

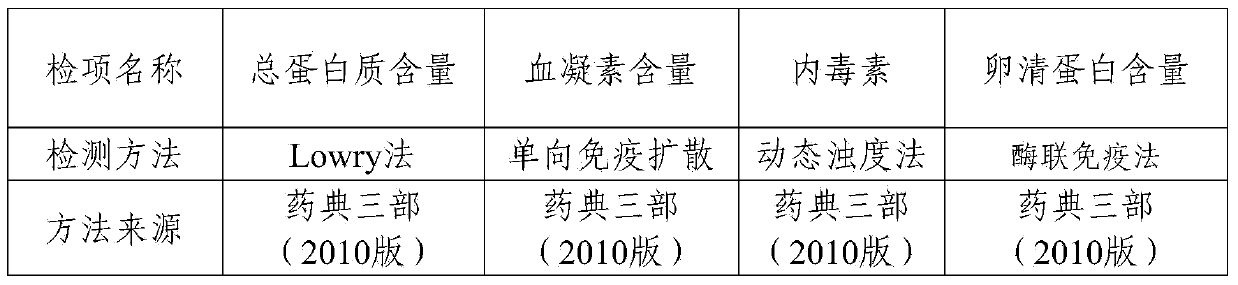

Purification method for split influenza virus vaccine

ActiveCN103721251AGuaranteed uniformityHigh removal rateAntiviralsAntibody medical ingredientsHemagglutininPurification methods

The invention provides a purification method for split influenza virus vaccine. An influenza virus strain is inoculated onto a chick embryo and cultured to obtain a virus solution; the virus solution is sequentially subjected to inactivation and ultrafiltration concentration to obtain an ultrafiltrate; the obtained ultrafiltrate is subjected to cane sugar density gradient centrifugation by using a KII continuous flow centrifuge to obtain an ultra centrifugal solution; the ultra centrifugal solution is subjected to ultrafiltration dialysis for cane sugar removal and molecular sieve gel chromatography to obtain a virus purification solution; the obtained virus purification solution is subjected to virus split by using a split agent TritonX-100 and sodium deoxycholate; after the split is over, the split agent is removed via ultrafiltration dialysis; impure protein is centrifugally removed from the obtained split solution; supernatant is collected, filtered and sterilized so as to obtain the purified influenza virus vaccine primary solution. The purification method is simple and convenient to operate, high in centrifugation capacity and suitable for large-scale production; by adopting a dual-split agent and a centrifugal process, the finished product is greatly improved in activity (hemagglutinin content / protein total content), and approaches the activity ratio of subunit vaccine, as a result, the high-grade split influenza virus vaccine product is obtained.

Owner:SINOVAC BIOTECH

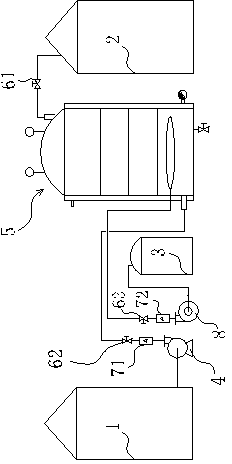

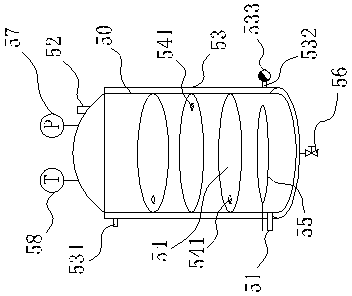

Quick aging apparatus for grape wine

The invention provides a quick aging apparatus for a grape wine, belonging to the technical field of the wine making equipment and aiming at solving the technical problems of long grape wine aging time, high cost, unachievable batch production and the like in the prior art. The quick aging apparatus comprises a first storage tank and an oxygen storage tank, wherein the first storage tank is connected with a first delivery pump, the first delivery pump is connected with a mixer, the oxygen storage tank is connected with the mixer, the mixer is connected with a second delivery pump, the second delivery pump is connected with a feeding hole of an aging tank, and the discharge hole of the aging tank is connected with the second storage tank through a first valve. The quick aging apparatus for the grape wine is capable of realizing the aging of the grape wine in short time and capable of meeting the requirements on large-scale production, and therefore, the production cost can be effectively reduced.

Owner:金丽秋

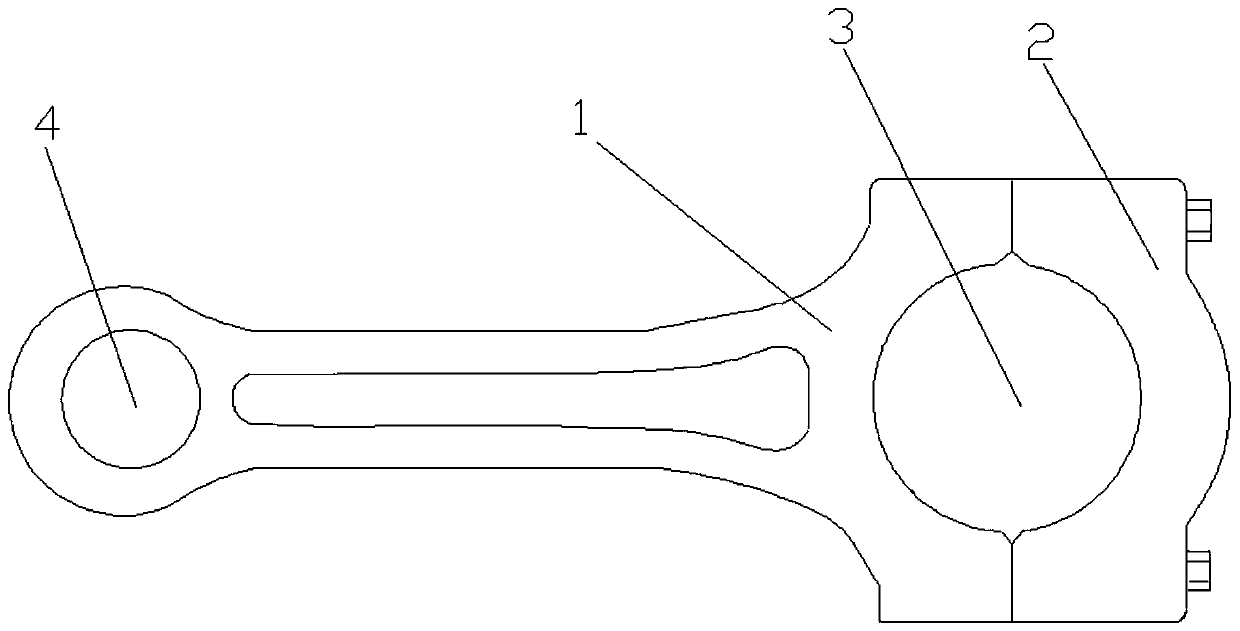

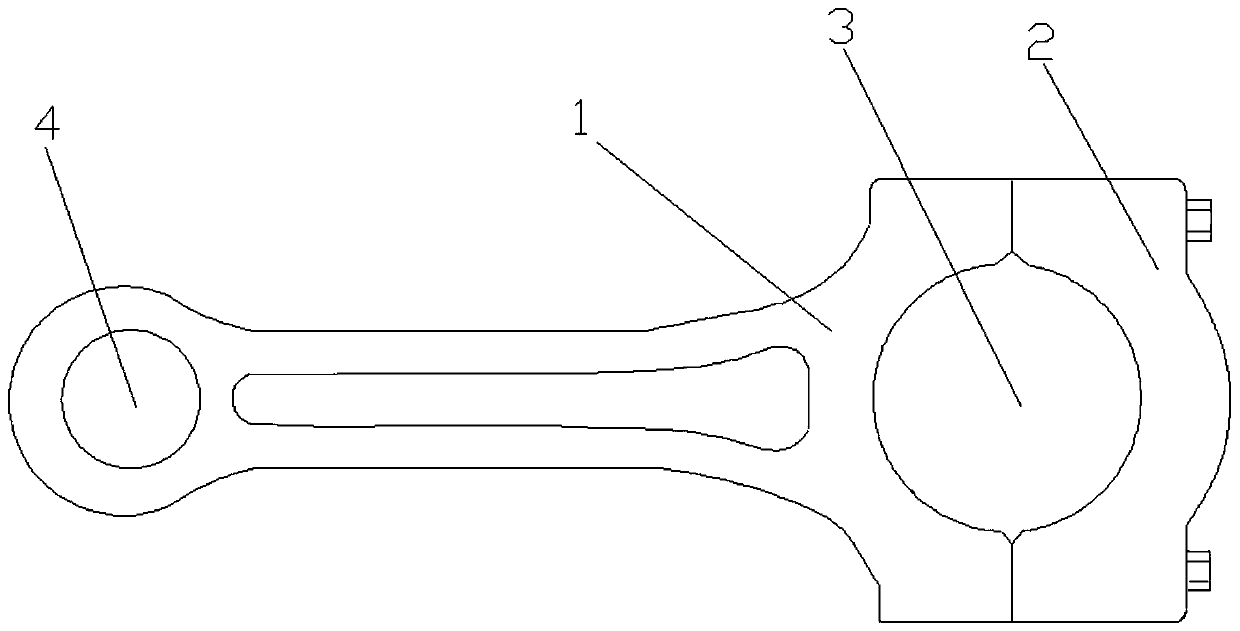

Novel connecting rod small end processing technique

InactiveCN111151984AGuaranteed lubrication effectReasonable design of processing technologyEngineeringMachining process

The invention relates to the technical field of engine connecting rod processing, in particular to a novel connecting rod small end processing technique. The novel connecting rod small end processingtechnique is characterized by comprising the following steps: (1) enabling a big end hole processed in a connecting rod blank to be a circular hole, and separating the connecting rod blank processed with the big head hole into a connecting rod body and a connecting rod cap in a cracking manner; (2) performing semi-finish boring of a small end hole; (3) performing finish milling of the small end bored hole; (4) grinding and trimming the small end bored hole; (5) performing inspection. The novel connecting rod small end processing technique completely achieves the development purpose, and is reasonable in design and accurate in position-fixing. The qualified rate of the processed small end holes of connecting rods is increased from 15% of existing traditional processing to more than 97%, andis increased by more than five times. The novel connecting rod small end processing technique has the advantages of reducing the production cost, improving the anti-fatigue lives of the connecting rods, ensuring the lubrication performance of elliptical holes of the connecting rods, fulfilling the requirement of mass production, solving a difficult technical problem in the industry, and satisfying the processing demand of the small end holes of the connecting rods.

Owner:YULIN CHENGXIN MACHINERY CO LTD

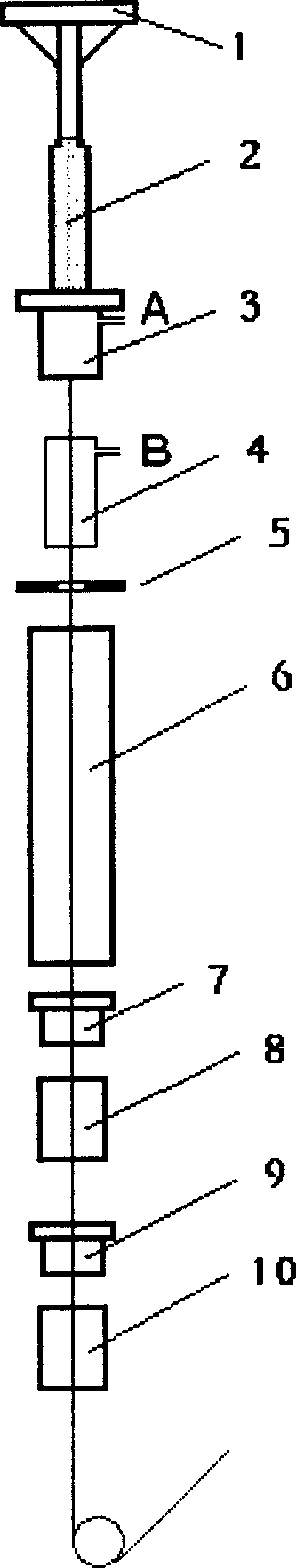

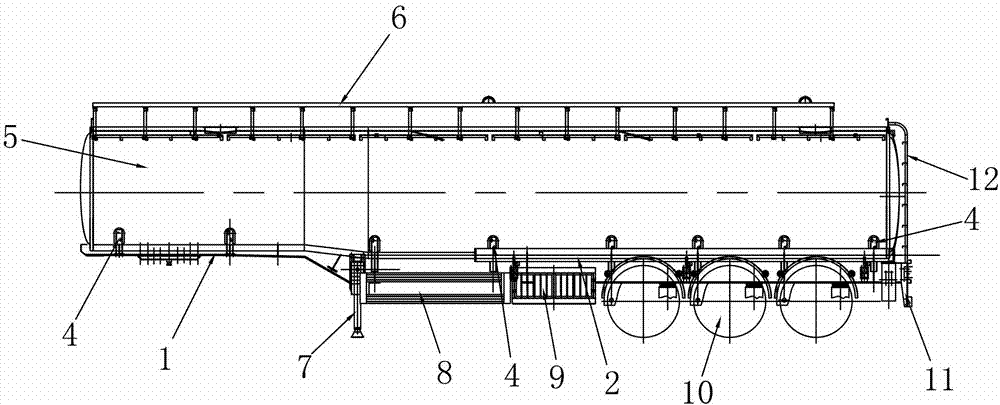

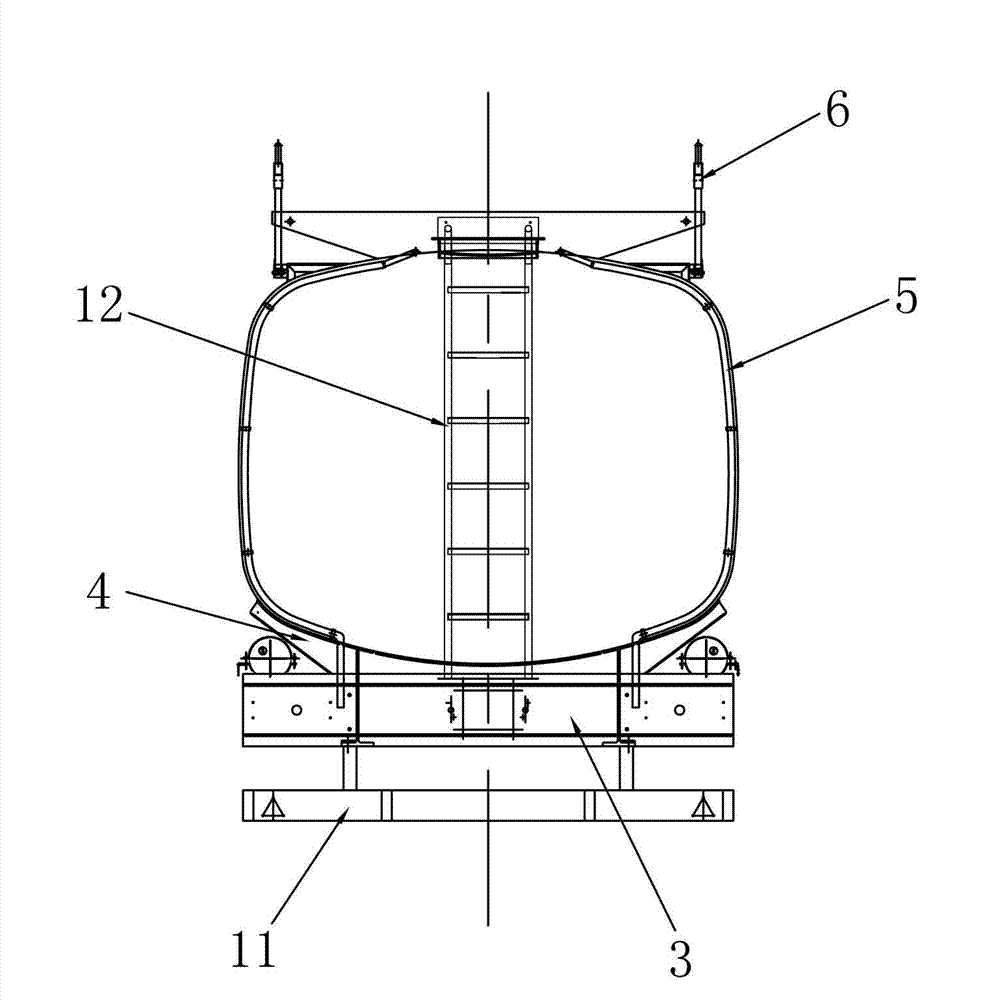

All aluminum alloy tank trailer

InactiveCN102951217AReduce processing difficultyReduce secondary processing workloadTank vehiclesTractor-trailer combinationsMachining processAluminium alloy

The invention discloses an all aluminum alloy tank trailer which relates to a trailer, and in particular to a box stake grid semitrailer made of an aluminum alloy material. The invention aims to provide an all aluminum alloy tank trailer which is suitable for large-scale production, energy-saving and environment-friendly and simple in machining process. The all aluminum alloy tank trailer provided by the invention comprises a frame consisting of a gooseneck (1), a vertical beam (2) and a cross beam (3). A plurality of tank body supporting brackets (4) are arranged sequentially from front side to back side on the frame. A Tank tank bodies body (5) are is arranged in front and back directions of the tank body supporting brackets. A guide frame (6) is arranged at the top of the tank body (5). A sSupporting legs (7), a side protector (8), a tool box (9), three groups of wheels (10) and a fender-guard (11) are sequentially arranged below the frame from front side to back side. A climbing bracket (12) is arranged at the rear end of the tank body. The gooseneck, the vertical beam, the cross beam, the tank body supporting frames, the guide frame, the supporting legs, the side protector, the tool box, the fender guard and the climbing bracket are made of the aluminum alloy material. The gooseneck, the vertical beam, the cross beam and the tank supporting brackets are mutually spliced.

Owner:CONGLIN GROUP

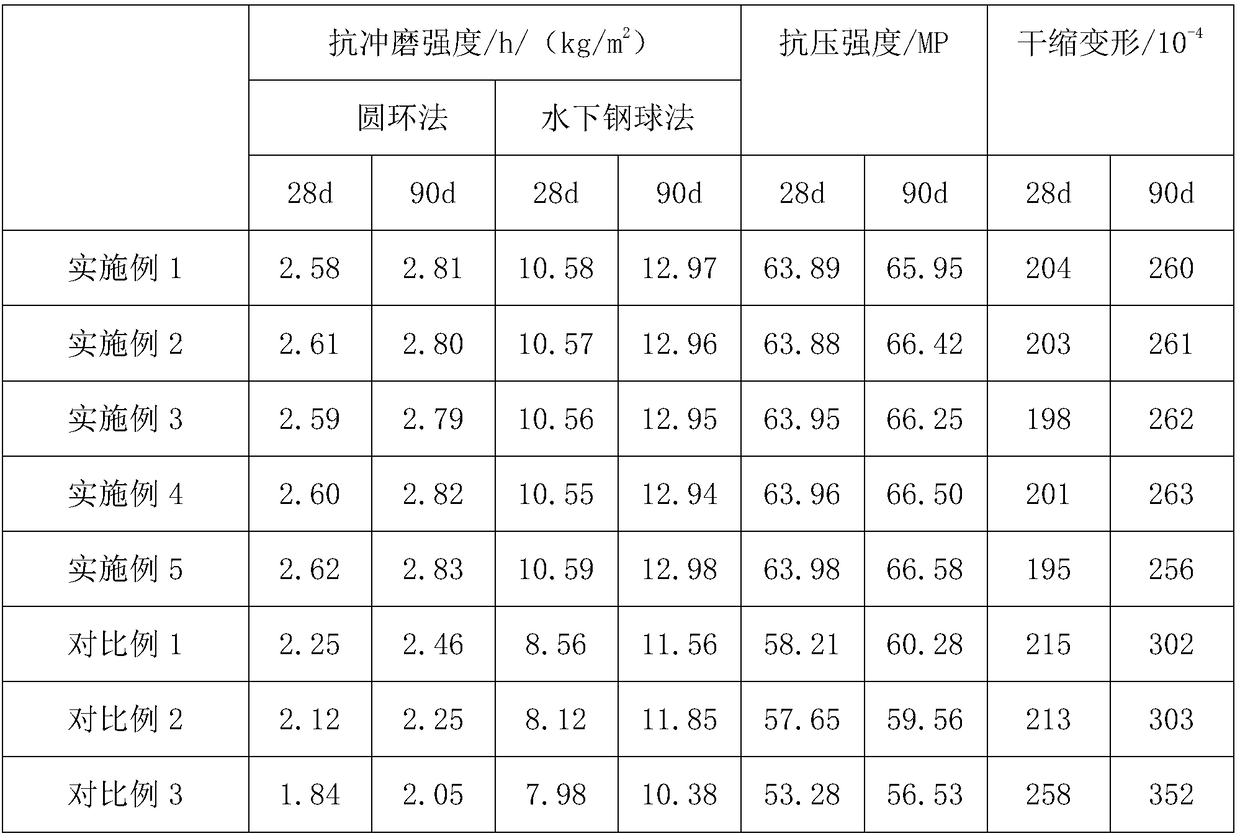

Impact-resistant abrasion-resistance concrete for hydraulic engineering and preparation method of impact-resistant abrasion-resistance concrete for hydraulic engineering

InactiveCN108529973AMeet construction needsImprove impact and wear resistanceGlass fiberActivated carbon

The invention discloses impact-resistant abrasion-resistance concrete for hydraulic engineering. The concrete is prepared from, by weight, 20-30 parts of modified glass fibers, 15-25 parts of modifiedbamboo activated carbon powder, 70-80 parts of ordinary Portland cement, 30-40 parts of aggregates, 50-60 parts of deionized water and 5-10 parts of a water reducing agent. The invention further discloses a preparation method of the impact-resistant abrasion-resistance concrete for hydraulic engineering. The preparation method includes steps: (1) modified glass fiber preparation; (2) modified bamboo activated carbon powder preparation; (3) mixing. On the basis that ordinary Portland cement is used as a concrete raw material currently, modified glass fibers and modified bamboo activated carbonpowder are added, and accordingly impact resistance and abrasion resistance of concrete are greatly improved; in addition, glass fibers and the bamboo activated carbon powder are extensive in source,energy saving, environmental friendliness, suitableness for large-scale production and high reliability are realized, and construction requirements of hydraulic engineering are met.

Owner:河南正海实业有限公司 +18

Paper feeding device of candy packaging machine

ActiveCN104176320AGood repeatabilityUnified size and shapeWrapping material feeding apparatusArticle deliveryPulp and paper industryPaper sheet

The invention relates to the technical field of packaging machinery and discloses a paper feeding device of a candy packaging machine. The paper feeding device comprises an inner paper rack, an unreeling component, a paper pulling component and a paper cutting component, wherein the unreeling component, the paper pulling component and the paper cutting component are sequentially installed on the inner paper rack, the paper pulling component consists of two matched rotation shafts which are in opposite movement, and surfaces of the rotation shaft are coated by anti-skidding materials. The paper feeding device is simple in structure, convenient to use, continuous and reliable in paper feeding process, good in repeatability, and high in production efficiency.

Owner:成都三可实业有限公司

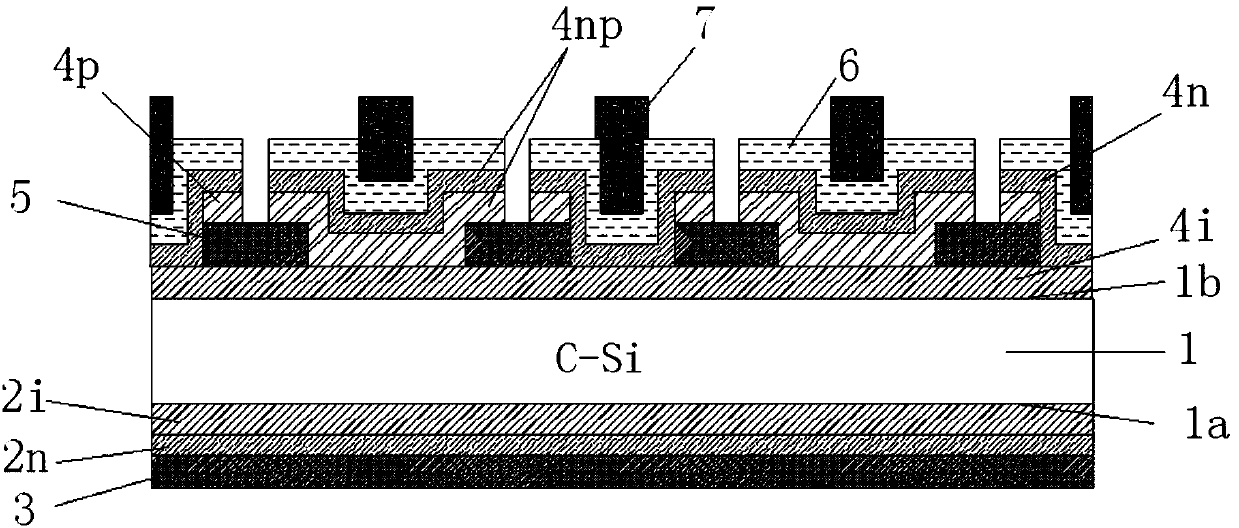

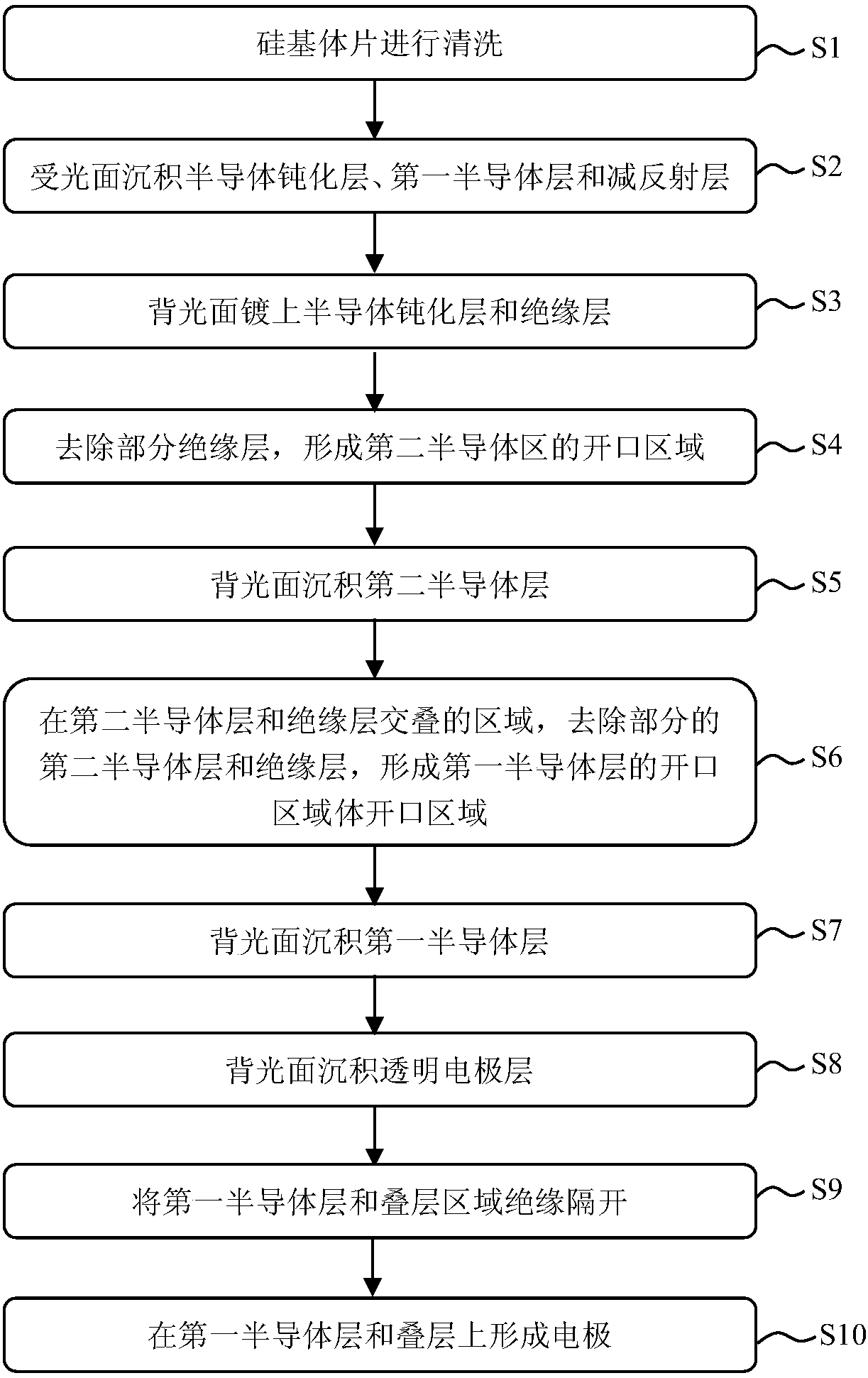

Novel back contact heterojunction battery and manufacturing method thereof

InactiveCN110047965AEasy to operateReduce production processFinal product manufacturePhotovoltaic energy generationHeterojunctionElectrical conductor

The invention discloses a novel back contact heterojunction battery and a manufacturing method thereof. The novel back contact heterojunction battery comprises a silicon substrate piece, wherein a semiconductor passivation layer, a first semiconductor layer and an antireflection layer are sequentially arranged on the light receiving surface of the silicon substrate piece, and the semiconductor passivation layer is arranged on the backlight surface; the first semiconductor layer and the laminated layer of a second semiconductor and a first semiconductor are arranged on the semiconductor passivation layer in a staggered mode; a transparent conductive thin film layer is arranged on the first semiconductor layer and the laminated layer separately; an electrode is arranged on the transparent conductive thin film layer; an insulating isolation layer is arranged between the first semiconductor layer and the laminated layer; and inter-band tunneling contact is formed between the second semiconductor layer and the first semiconductor layer. The manufacturing method is simple in operation steps, the first semiconductor layer directly covers the second semiconductor layer, and secondary masketching is not needed, so that the performance damage and complexity of alignment caused by multiple times of masking and etching in the manufacturing process is reduced, and the method is suitable for large-scale production requirements in the future.

Owner:GOLD STONE (FUJIAN) ENERGY CO LTD

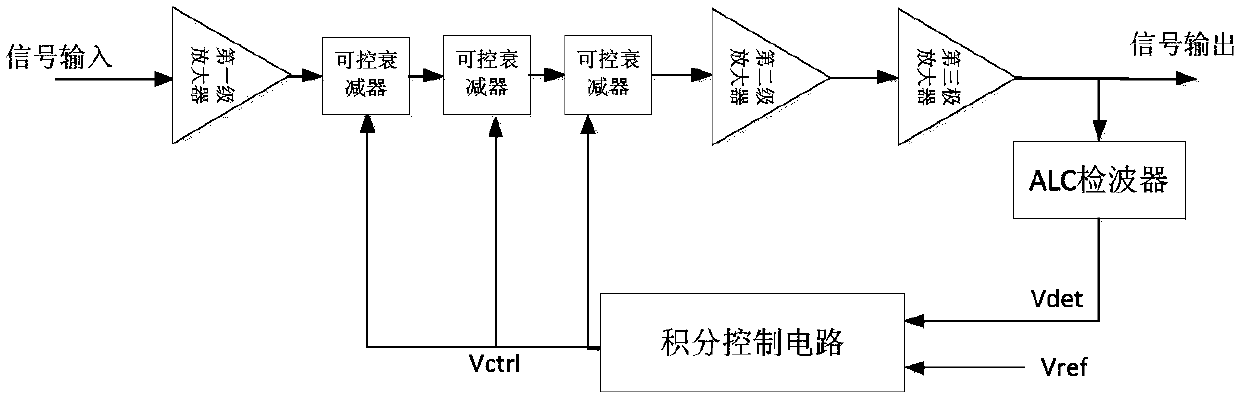

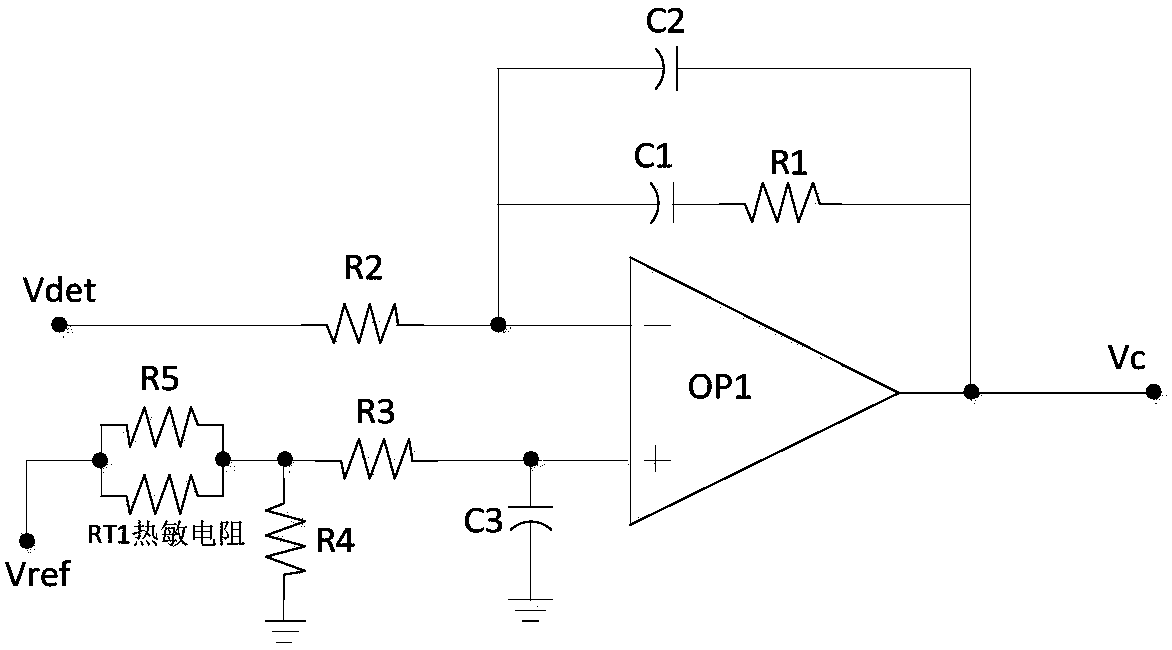

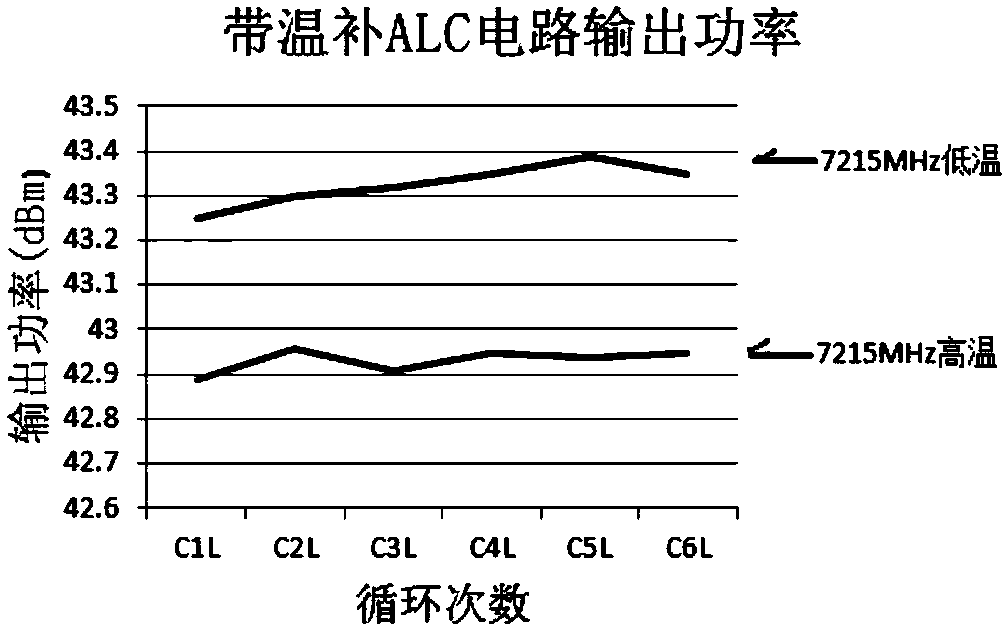

Large dynamic range ALC protection circuit with temperature compensation function

ActiveCN107863940ASimple circuit formEasy to implementHigh frequency amplifiersAmplifier modifications to reduce temperature/voltage variationRadio frequencyBatch production

The invention provides a large dynamic range ALC protection circuit with the temperature compensation function. The large dynamic range ALC protection circuit with the temperature compensation function comprises a variable gain amplifier, an ALC detector and an integral control circuit. The dynamic range of the input radio-frequency power is larger than 100dB; the output power gain fluctuation ofthe product is less than 0.5dB at a high and a low temperature; a circuit theory design method is completely provided, and the simulation and actual measurement verification is performed; and the whole circuit is designed and produced by multi-chip modules (MCM); therefore, the circuit meets the requirements of miniaturization, lightweight and batch production, and has broad application prospects.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com