Purification method for split influenza virus vaccine

A purification method and influenza virus technology, applied in the field of purification of influenza virus split vaccine, can solve the problems of large workload, cumbersome operation, poor homogeneity of samples in the same batch, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The cultivation of embodiment 1 influenza virus

[0030] Include the following steps:

[0031] 1. Take 9-11 day-old chicken embryos, and remove unqualified chicken embryos such as damaged, dirty, dead, weak, and spermless embryos.

[0032] 2. Dilute the influenza virus working seeds to 2LgEID50, inoculate the allantoic cavity of chicken embryos, 0.2mL / embryo, and culture at 32°C for 48 hours.

[0033] 3. After the end of culture, select live embryos and chill them at 2°C for 12 hours.

[0034] 4. Harvest the allantoic fluid after the cold embryo is finished.

[0035] 5. Add formaldehyde solution with a final concentration of 1 / 4000 to inactivate for 96 hours.

[0036] 6. Obtain the influenza virus inactivation solution after inactivation.

Embodiment 2

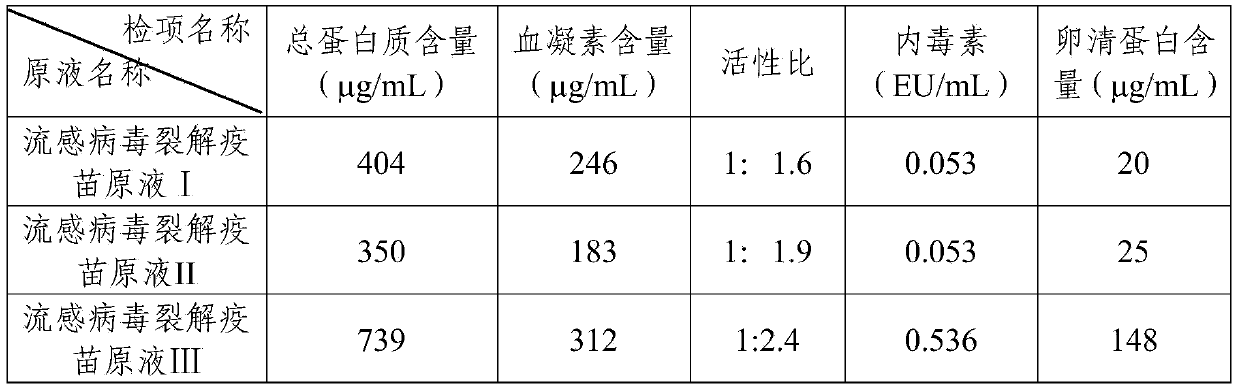

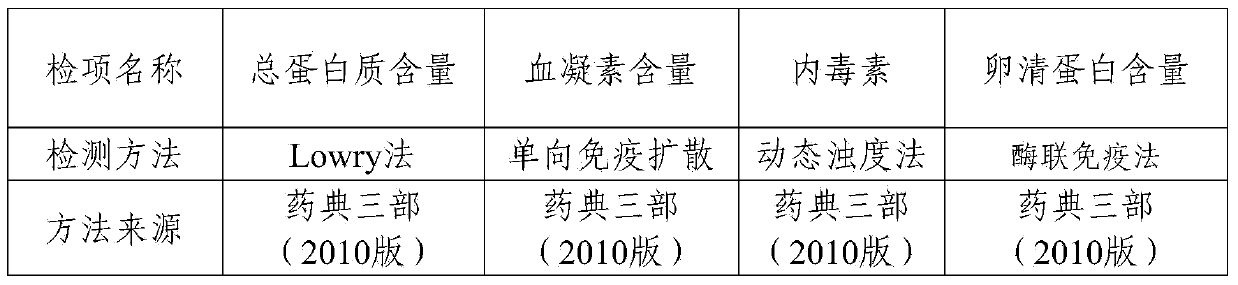

[0037] The purification of embodiment 2 influenza virus split vaccines

[0038] Purify the influenza virus inactivated liquid harvested in Example 1, the purification process is as follows:

[0039] 1. The inactivation solution is concentrated 20 times by 300KD membrane bag ultrafiltration to obtain the ultrafiltrate.

[0040] 2. The ultrafiltrate was subjected to sucrose density gradient centrifugation in a KII continuous flow centrifuge with a sucrose concentration of 45% and a centrifugation time of 1 hour. The target sample was collected by a detector to obtain a superchaotrope.

[0041] 3. The ultra-chaotropic solution was filtered through a 100KD membrane bag using 0.01mol / L PBS buffer solution to remove sucrose and obtain a desugar solution.

[0042] 4. The desugar solution was subjected to molecular sieve chromatography with a loading volume of 2% of the column volume, and the gel used was Sehparose4Fast Flow. The eluent is 0.01mol / L PBS buffer, and the elution speed...

Embodiment 3

[0047] The purification of embodiment 3 influenza virus split vaccines

[0048] The influenza virus liquid harvested in Example 1 is purified, and the purification process is as follows:

[0049] 1. The virus harvest liquid obtained by chicken embryo culture in Example 1 was inactivated by formaldehyde, the final concentration of formaldehyde was 1 / 2000, and the inactivation time was 120 hours to obtain the influenza virus inactivation liquid.

[0050] 2. The inactivation solution is concentrated 40 times by 700KD membrane bag ultrafiltration to obtain ultrafiltrate.

[0051] 3. The ultrafiltrate was subjected to sucrose density gradient centrifugation in a KII continuous flow centrifuge with a sucrose concentration of 60% and a centrifugation time of 3 hours. The target sample was collected by a detector to obtain a superchaosate.

[0052] 4. The ultra-chaotropic solution was filtered through a 100KD membrane bag using 0.01mol / L PBS buffer solution to remove sucrose and obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com