Full-automatic horizontal type glass edge polishing membrane removing machine

A glass edging and fully automatic technology, which is applied in the direction of machine tools, grinding machines, grinding/polishing equipment, etc. suitable for grinding the edge of workpieces, can solve the problems of long scattered fronts, high costs, space and resources in the processing process, etc. , to achieve the effect of saving space and resources, high degree of automation and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

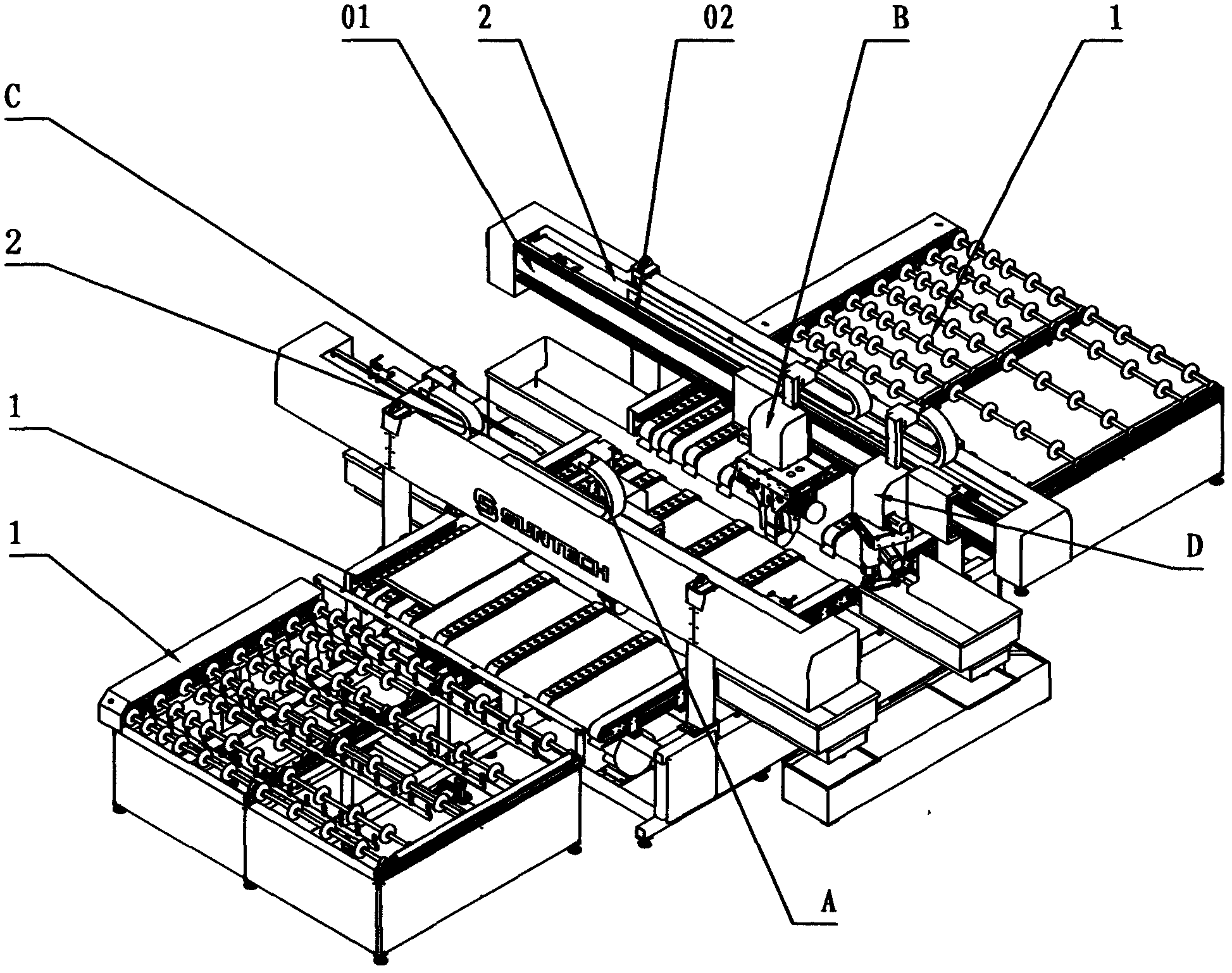

[0035] A fully automatic horizontal glass edging and film removing machine of the present invention is a patent of the name "a fully automatic horizontal glass four-sided linear edging machine" applied for by the applicant on March 30, 2011 (patent number: CN201110079394 .0), for a better understanding of this patent application, please refer to this patent application, patent application publication (announcement) date: 2011.09.21, publication (announcement) number: CN102189461A), the invention announced a full The automatic horizontal glass four-sided linear edging machine includes a feeding system, an edging system assembly, and a discharging system in sequence. The edging system assembly includes a conveying system assembly and an edging mechanism assembly, and the edging mechanism assembly It is arranged on the conveying system assembly, and it is characterized in that: the said edging mechanism is composed of 2 edging mechanisms, and the 2 edging mechanisms are arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com