Full-automatic battery slice transporting and baiting device

A battery chip, fully automatic technology, applied in the direction of transportation and packaging, charge manipulation, conveyor objects, etc., can solve the problems of increasing the fragment rate of material transmission, not suitable for mass production, squeezing or vibrating materials, etc., to achieve structural Compact, avoid extrusion, high work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

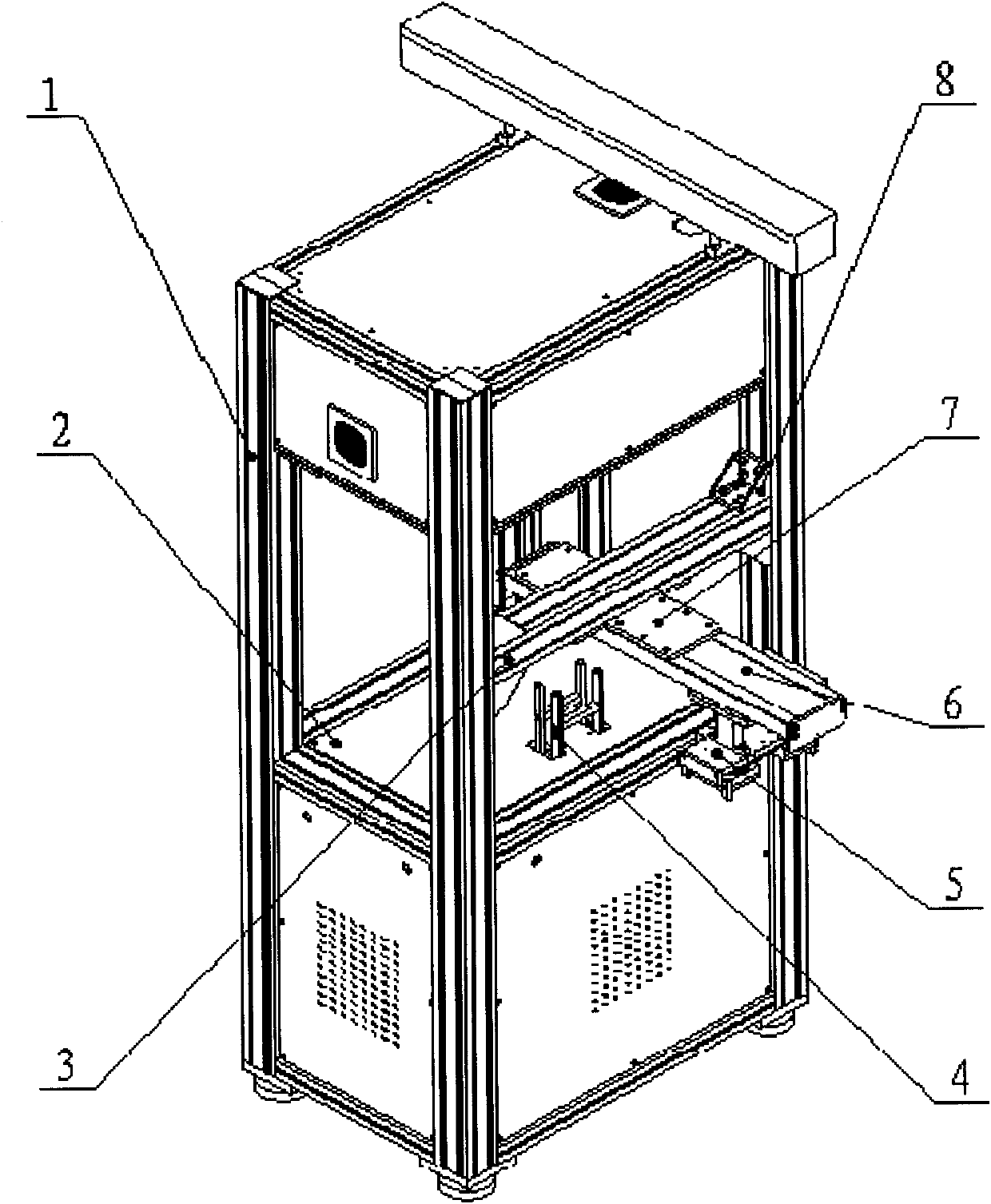

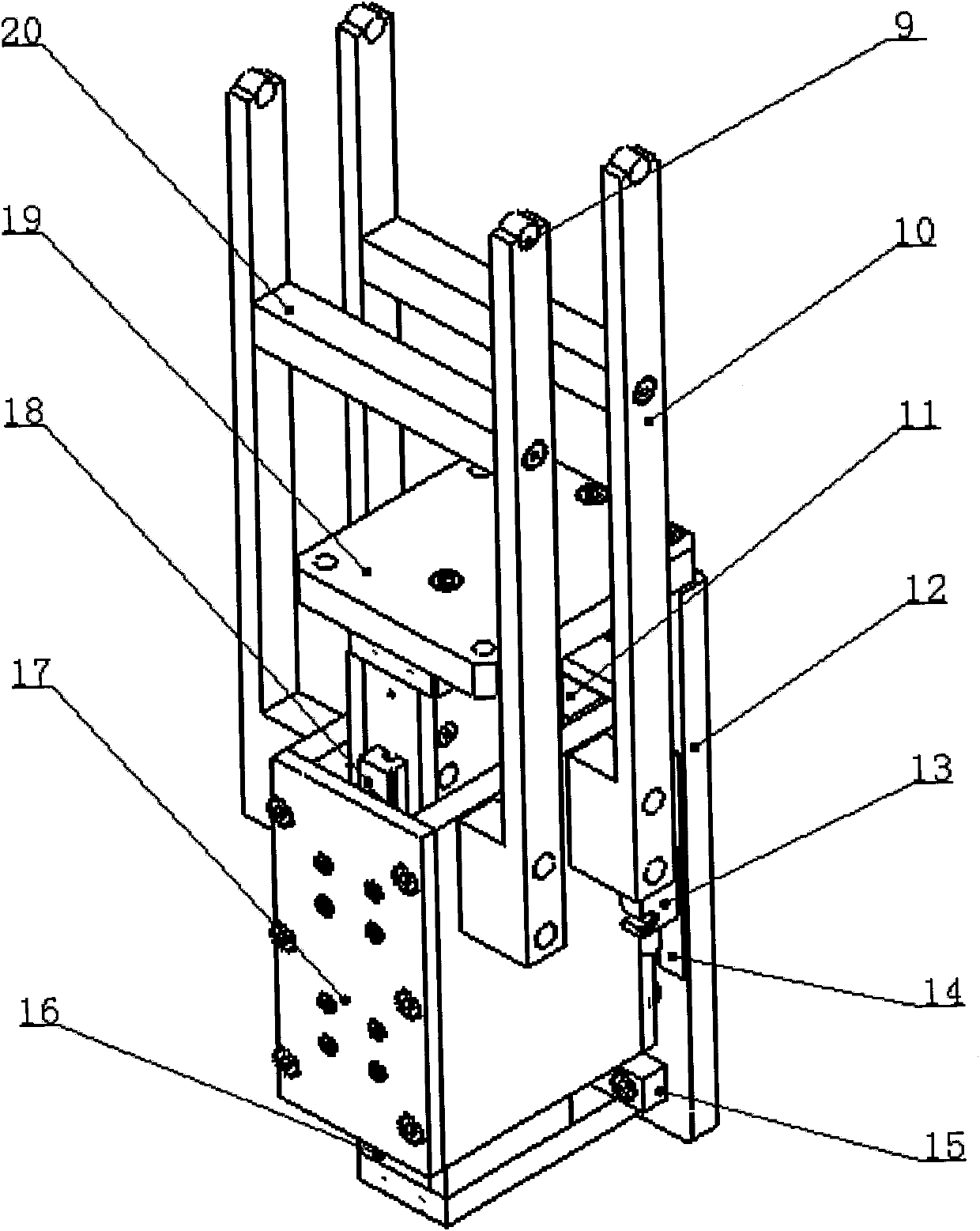

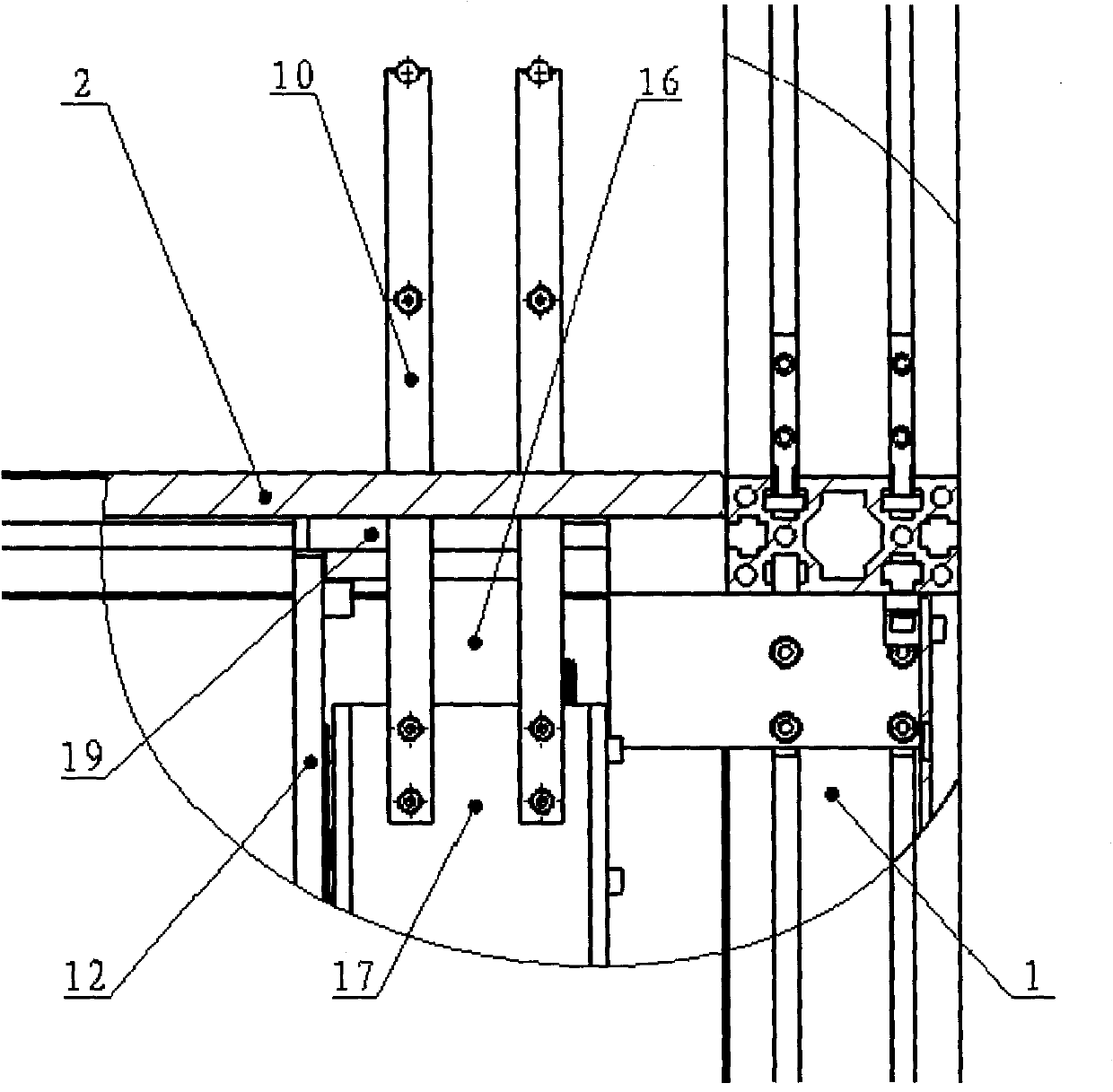

[0020] as attached figure 1 Shown, the present invention comprises frame 1, work flat plate 2, top film mechanism 4, grab piece mechanism 5 and transport mechanism 6; Wherein, as attached diagram 2-1 , 2-2 , shown in 2-3, the formation of top sheet mechanism 4 comprises top sheet linear motor, ejector pin 10, the transfer frame 17 that installs ejector pin 10, mounting plate 19 and lifting guide rail 18, top sheet linear motor stator 16 is fixed on the installation The lower part of the plate 19, the lifting guide rail 18 is installed on the end of the top piece linear motor stator 16, the top piece linear motor mover 11 is fixed inside the transmission frame 17, and the lifting slide block 21 matched with the lifting guide rail 18 is fixed on the transmission frame 17 Inside, the mounting plate 19 is fixed on the bottom of the working plate 2, and the side plate 12 is fixed on the lower part of one end of the mounting plate 19, and the top piece position stopper 15 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com