Automatic plastic tube cutting machine

A cutting machine and plastic pipe technology, applied in metal processing, etc., can solve the problems of high labor intensity, easy to cause waste products, and occupy a large space, and achieve the effect of reducing labor intensity, high accuracy, and large cutting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

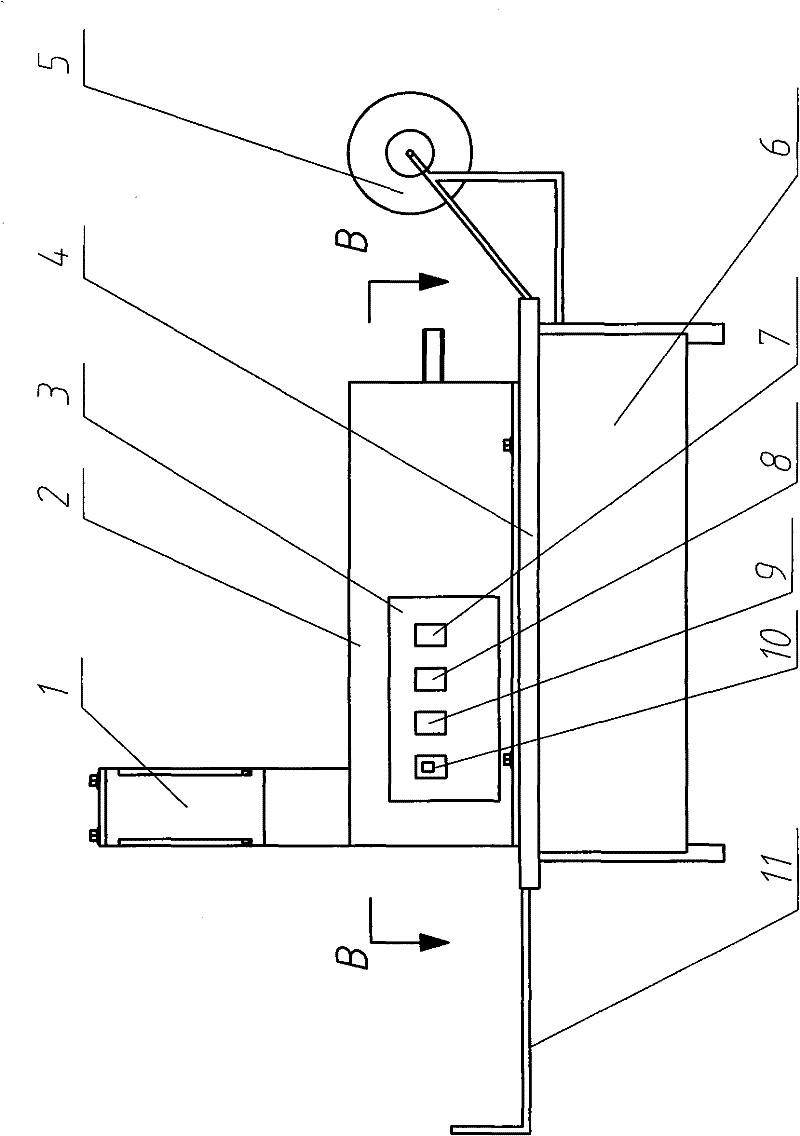

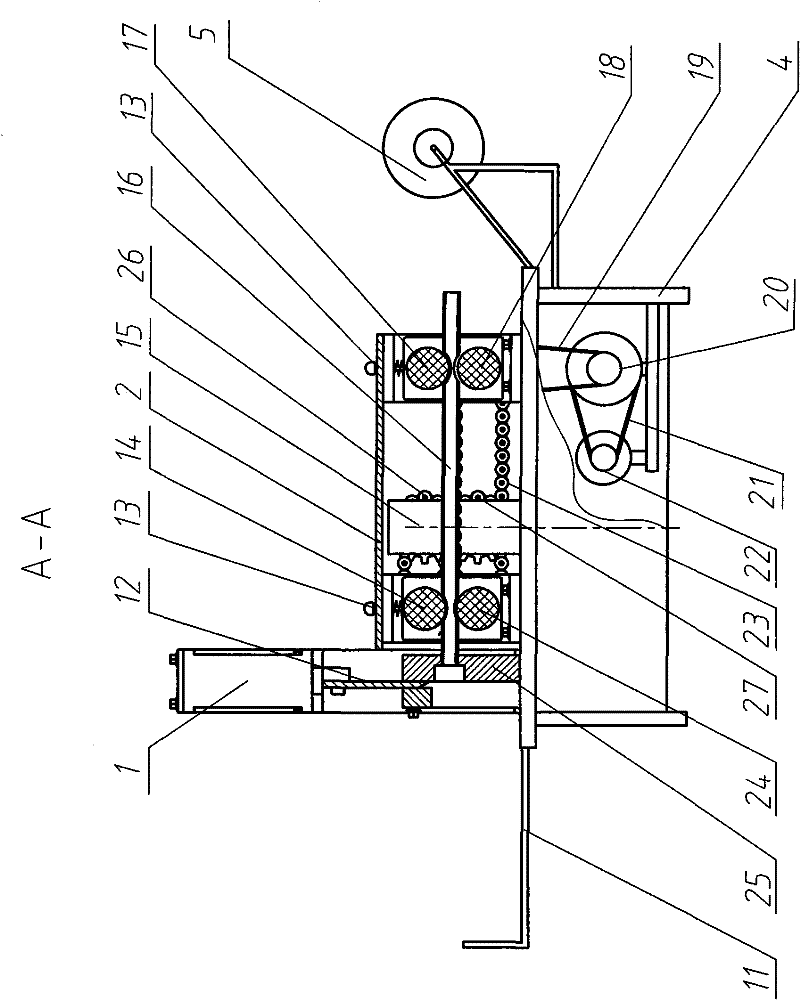

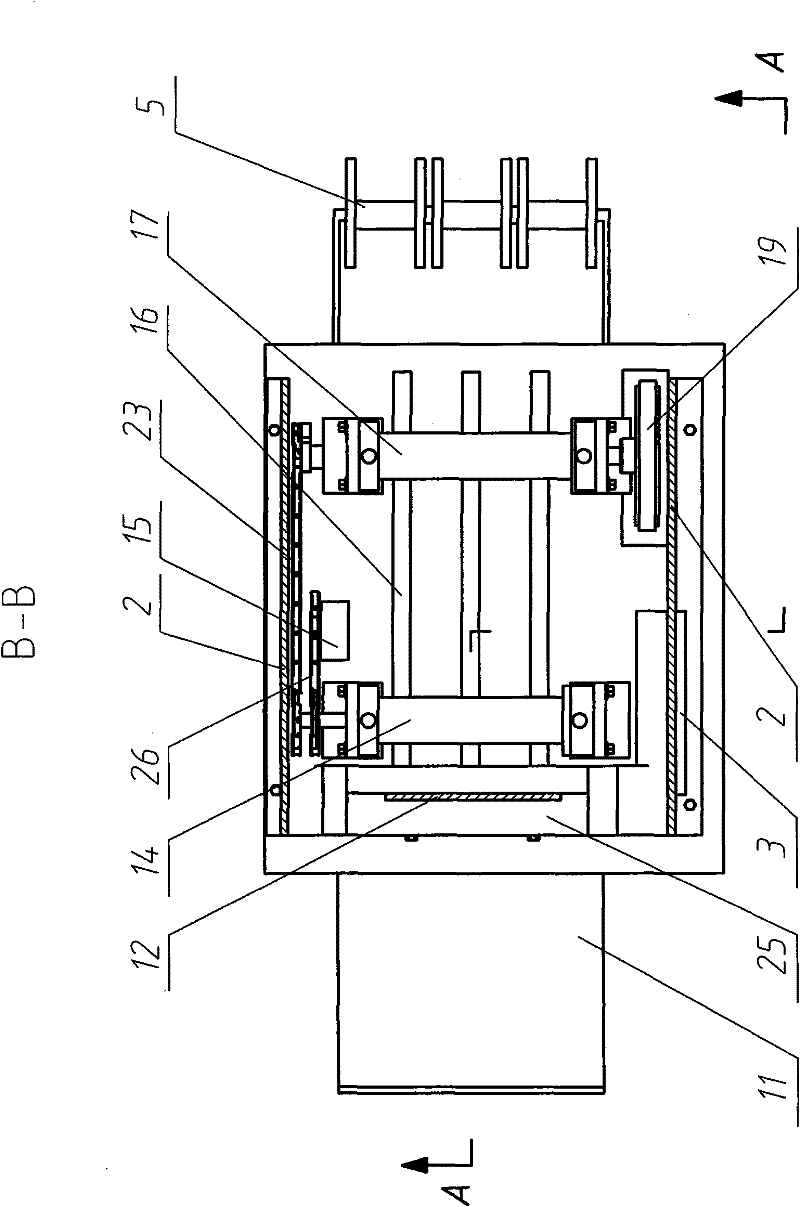

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown, the plastic pipe automatic cutting machine of the present invention is made of power transmission (motor 22, speed reducer 20, belt one 21, belt two 19), feeding device (supporting rack 5, upper roller 14, lower roller one) 18. Lower roller 2 24, guide pipe 16, auxiliary roller 17, lower chain 1 23, upper chain 26, lower chain 2 27, reverser 15, adjusting bolt 13), unloading device (cutter 12, cylinder 1, Cutter positioning block 25, feeding tray 11), safety protection device (workbench 4, protective cover 2, belt guard 6), control device (adjustable time delay device 9, relay 8, power switch 7, control panel 3), counter 10 is formed.

[0015] The power transmission device is located below the workbench 4, and the feeding device and the unloading device are located above the workbench 4. One end of reducer 20 is connected with motor 20 through belt one 21, and one end is connected with lower roller one 18 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com