Iron casting drilling device and drilling method thereof under inner cooling and low temperature trace lubricating condition

A technology of micro-lubrication and drilling equipment, which is applied in the direction of drilling/drilling equipment, drill repairing, drilling tool accessories, etc., which can solve the problems of poor cooling effect, difficulty for cutting oil to reach the cutting part, poor lubrication effect, etc. Achieve the effect of high cooling uniformity, good cooling effect and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

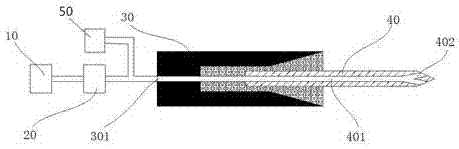

[0036] Such as figure 1 As shown, this embodiment provides a cast iron drilling method under the condition of internal cooling, low temperature and minimal lubrication, including: oil mist generating assembly: including a gas supply part and an atomizing device 20, and the atomizing device 20 includes an air inlet and an air outlet , the gas supply part is connected to the atomization device 20 through the air inlet; the low-temperature compressed gas supply part 50 refers to the gas cooling device or directly accesses the low-temperature gas; the machine tool spindle 30: the machine tool spindle 30 is provided with a main shaft inner cooling device The hole 301, the main shaft internal cooling hole 301 communicates with the air outlet; the tool 40: the tool 40 is fixedly connected with the machine tool spindle 30, and the tool 40 is provided with a tool internal cooling hole 401 along the axial direction; the tool internal cooling hole 401 is connected to the main shaft intern...

Embodiment 2

[0041] The present embodiment provides a drilling method of the cast iron drilling device under the internal cooling low-temperature minimal quantity lubrication condition as in Embodiment 1, comprising the following steps:

[0042] S1. After connecting the gas supply part and the atomization device 20 in sequence, they are connected to the low-temperature gas supply part, and then connected to the machine tool spindle 30 and the cutter 40, and the gas supply part is opened to supply gas to the atomization device 20, so that the gas in the atomization device 20 The lubricating oil is atomized, and the low-temperature compressed gas supply part 50 is opened;

[0043] S2. Open the gas supply part to provide gas to the atomizing device 20 to atomize the lubricating oil in the atomizing device 20; the gas pressure at the gas outlet of the atomizing device 20 is 0.35MPa, and the lubricating oil The oil output is 0.5 L / h. After the atomized lubricating oil is connected with the low...

Embodiment 3

[0048] This embodiment provides a drilling method for a cast iron drilling device under the condition of internal cooling, low temperature and minimal lubrication, including the following steps:

[0049] S1. After connecting the gas supply part and the atomization device 20 in sequence, they are connected to the low-temperature gas supply part, and then connected to the machine tool spindle 30 and the cutter 40, and the gas supply part is opened to supply gas to the atomization device 20, so that the gas in the atomization device 20 The lubricating oil is atomized, and the low-temperature compressed gas supply part 50 is opened;

[0050] S2. Open the gas supply part to provide gas to the atomizing device 20 to atomize the lubricating oil in the atomizing device 20; the gas pressure at the gas outlet of the atomizing device 20 is 0.9MPa, and the lubricating oil The oil output is 0.01 L / h, and the atomized oil mist is mixed with low-temperature gas and cooled to -45°C. The tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com