Method for compositing alkyl phosphonic acid dialkyl ester

The technology of a dialkyl alkylphosphonate and a synthesis method, which is applied in the chemical industry, can solve problems such as high requirements for industrial equipment, unsuitability for industrial production, and impact on industrial production safety, so as to achieve cost saving of raw materials, easy acquisition, and high production efficiency. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

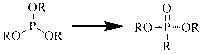

Method used

Image

Examples

example 1

[0024] Under the protection of nitrogen, 5 mmol of trimethyl phosphite, 10 mg of potassium carbonate, and 20 mg of benzonitrile were successively added to a 25 mL round bottom flask, heated to reflux for reaction, and the pressure was maintained at 1.2-1.4 MPa. Distilled under high pressure to collect fractions, namely the product, the yield was 88.9%.

example 2

[0026] Under the protection of inert nitrogen gas, add 5mmol of triethyl phosphite, 10 mg of sodium carbonate, and 15 mg of o-chlorobenzonitrile in a 25mL round-bottomed flask, and heat to reflux for reaction. After the reaction was over, vacuum distillation was performed to collect fractions, namely the product of 92.6% in yield.

example 3

[0028] Under the protection of inert nitrogen gas, add 5 mmol of tripropyl phosphite, 10 mg of sodium hydroxide, and 15 mg of o-chlorobenzonitrile to a 25 mL round-bottomed flask successively, heat to reflux for reaction, and maintain the pressure at 1.2-1.4 MPa, GC After the end of the follow-up reaction, distillation under reduced pressure was carried out to collect fractions, namely the product of 91.5% in yield.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com