Test system and test method for vehicle-mounted sliding vane type air compressors

An air compressor and testing system technology, applied in pump testing, liquid variable capacity machinery, mechanical equipment, etc., can solve the problems of inability to evaluate the performance status of the whole machine, high cost, low measurement efficiency, etc., to solve the integrated parameters The effect of testing problems, reducing testing costs, and improving testing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

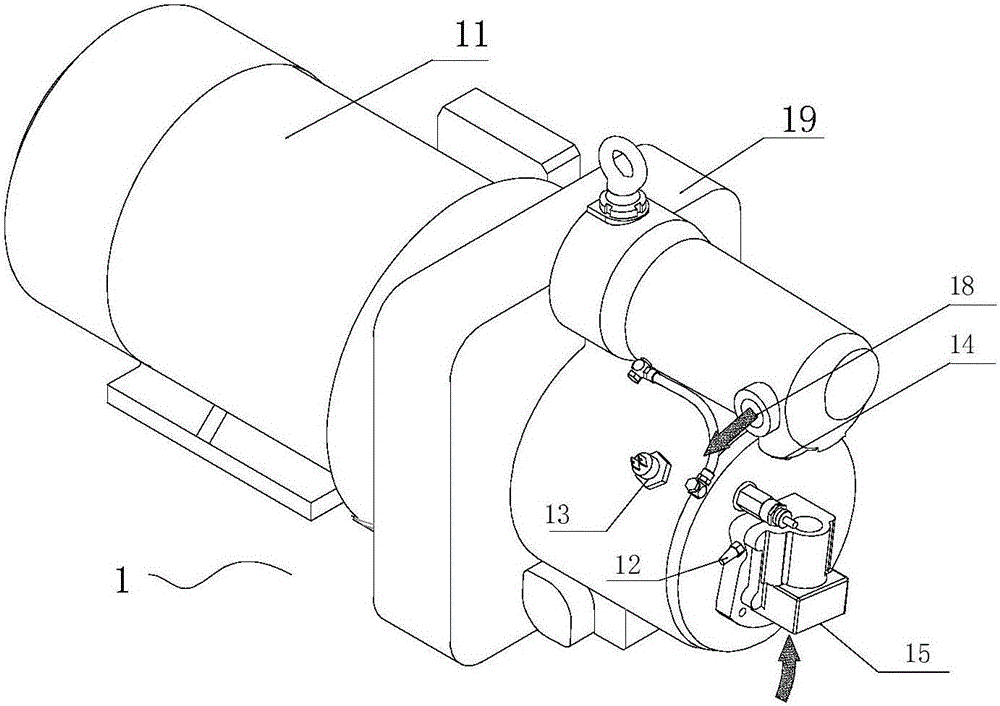

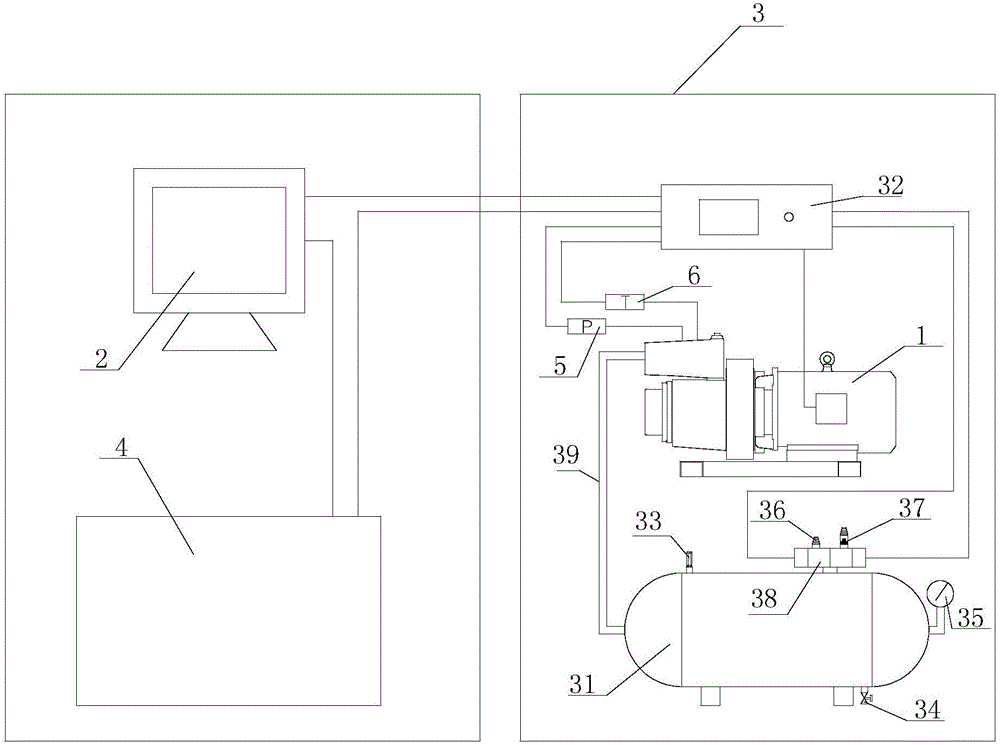

[0029] see figure 1 , figure 2, the present embodiment discloses a test system for a vehicle-mounted sliding vane air compressor 1, including a host computer 2 and a plurality of test units respectively connected to the host computer 2, a plurality of test units and a plurality of test stations 3 one by one Correspondingly, each test unit includes an air storage tank 31 , an operation console 32 and an air compressor 1 to be tested, and the upper computer 2 and the operation console 32 are powered through the power distribution cabinet 4 . One end of the operation console 32 is electrically connected to the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com