Method for manufacturing optical fiber unsensitive to hydrogen

A manufacturing method and sensitive technology, applied in the field of optical fiber manufacturing, can solve the problems of complex production process, increased production process, long processing time, etc., to achieve the effect of improving processing effect, reducing subsequent processing steps, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

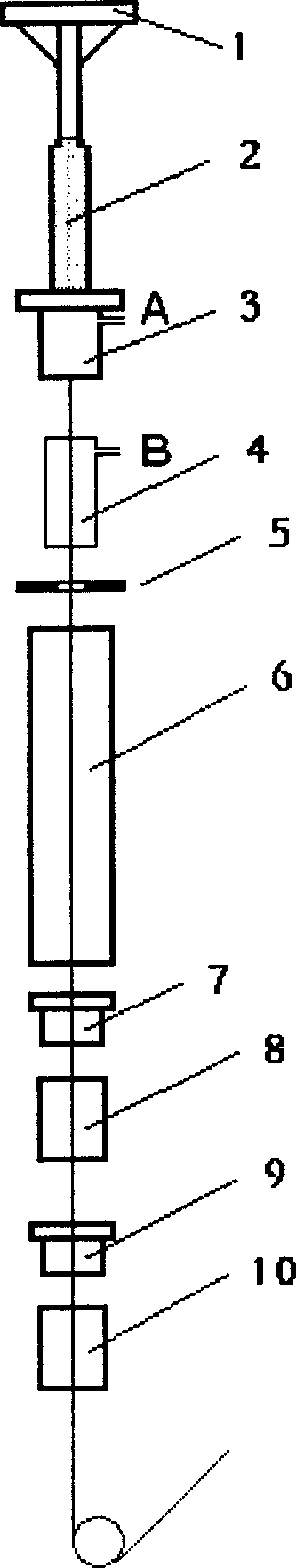

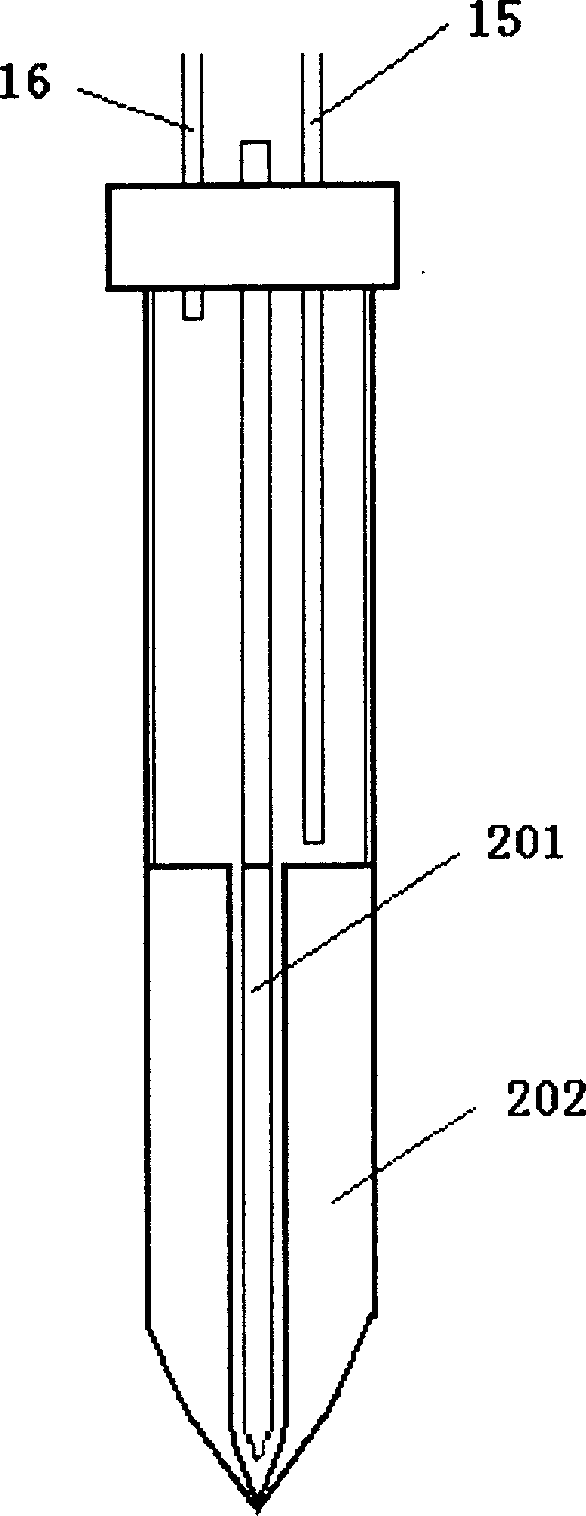

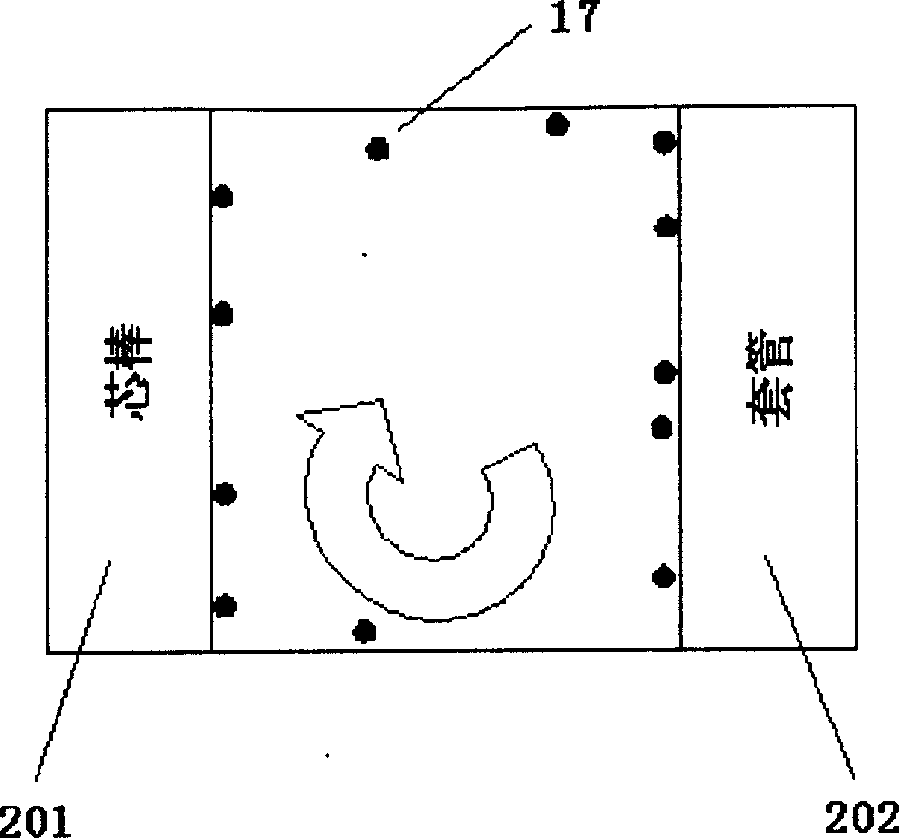

[0024] Manufacturing method and main device of the present invention such as figure 1 As shown, the drawing device includes a wire drawing furnace 3, and a preform rod 2 with a diameter of 80 mm is fed into the wire drawing furnace 3 at a certain rate under the action of the feeding mechanism 1, and the preform rod 2 is heated to 2000 °C in the wire drawing furnace 3. ℃, the bare optical fiber is drawn from the softened bottom of the preform, and its outer diameter is measured by the outer diameter measuring device 5 after passing through the holding furnace 4. The diameter of the bare optical fiber is generally 125 μm. The bare optical fiber enters the coater after passing through the cooling pipe 6, and resin is coated around the optical fiber to protect the optical fiber from damage. The resin coating is made of UV curable resin and cured by a UV curing furnace. After being cured by the inner coating applicator 7 and the curing furnace 8 and the outer coating applicator 9 a...

Embodiment 2

[0031] An optical fiber preform 2 with a diameter of 80 mm is sent into the drawing furnace 3 through the transmission mechanism 1, and in the drawing furnace 3, a mixed gas of deuterium, argon and helium is introduced into the furnace from position A, wherein the concentration of deuterium is is 2%, and the flow rate is 10L / min. At the same time, feed the mixed gas of the same concentration into the casing with a flow rate of 4L / min. The furnace temperature was raised to 1900°C and held there for one hour. Then keep the gas flow rate constant, raise the temperature to 2000° C., and draw wire at a speed of 1200 m / min according to the normal wire drawing process. The equipment used and other steps are the same as in Example 1.

[0032] The optical fiber obtained by this method was subjected to a hydrogen aging test, and the hydrogen loss was 0.003dB / km.

Embodiment 3

[0034] An optical fiber preform 2 with a diameter of 120 mm is sent into the drawing furnace 3 through the transmission mechanism 1, and a mixed gas of deuterium, argon and helium is introduced into the casing, wherein the concentration of deuterium is 4%, and the flow rate is 4L / min. After the wire drawing is started at a rate of 1200 m / min according to the normal process, the temperature of the holding furnace 4 is 1100 ° C, and the mixed gas of the same concentration is introduced into the furnace from the position B, and the flow rate is 10 L / min. The device used and other steps are the same as in the embodiment one.

[0035] The optical fiber obtained by this method was subjected to a hydrogen aging test, and the hydrogen loss was 0.005 dB / km.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com