Inner hole clamp for workpiece for high-frequency induction heating

A high-frequency induction heating and workpiece technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems affecting the heating production quality of workpieces, easy to conduct electricity, etc., achieve great practical significance and economic value, and meet the needs of fixture strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

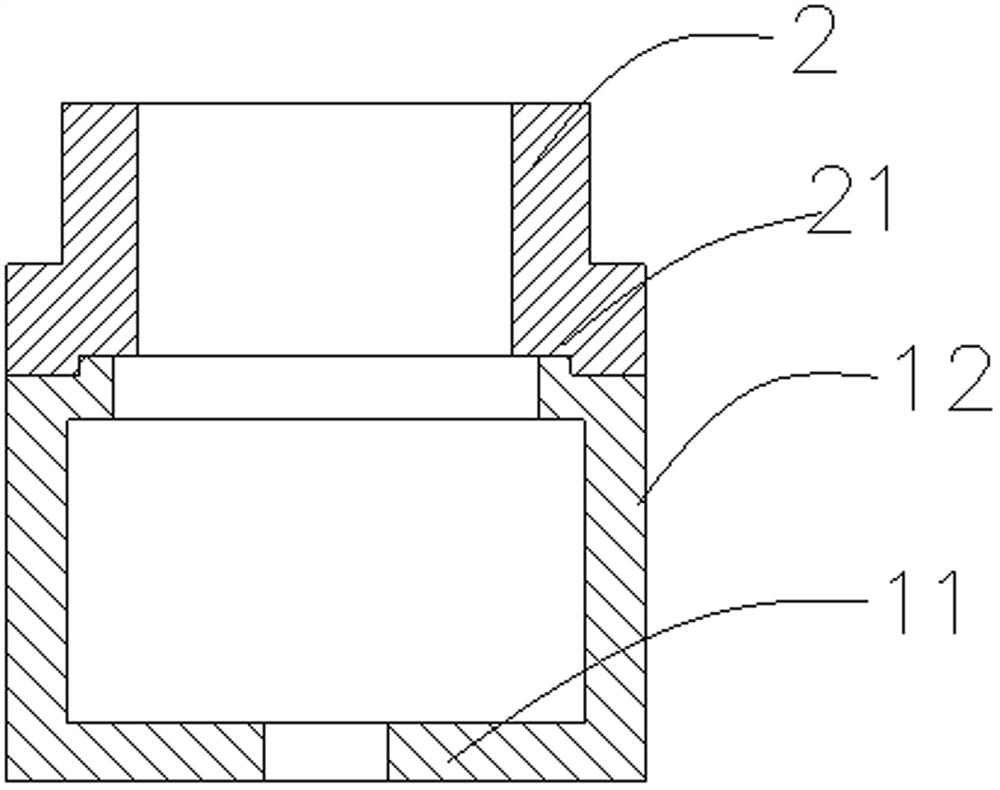

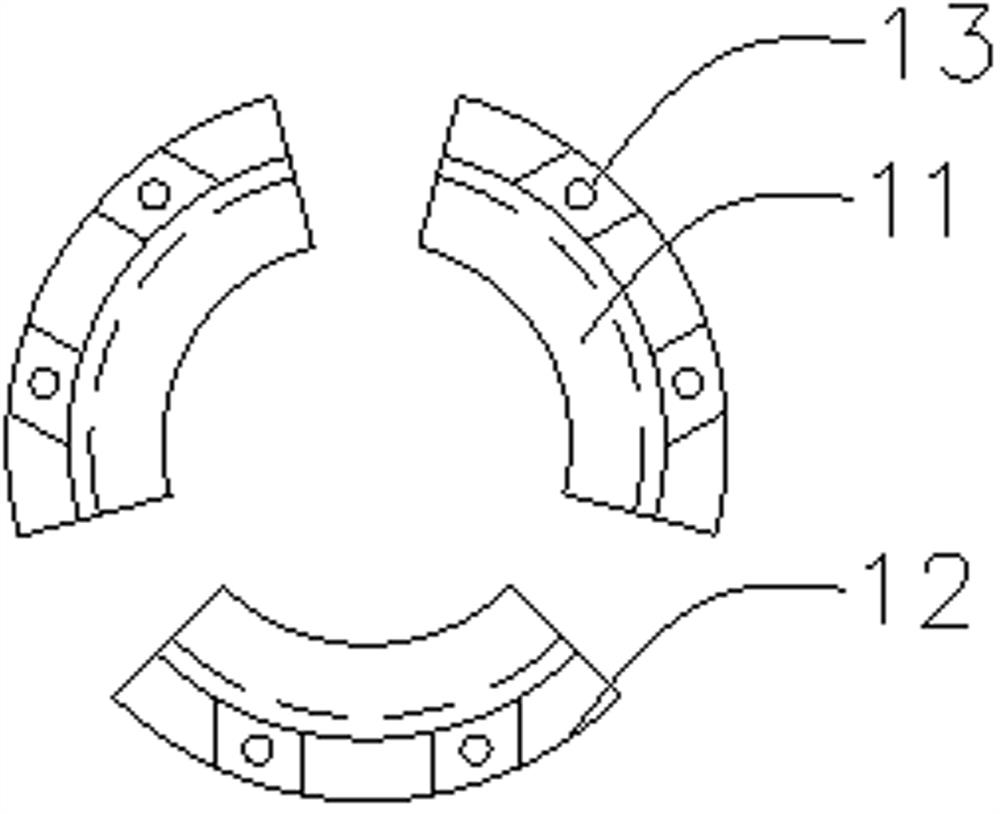

[0020] like figure 1 and figure 2 As shown, the workpiece inner hole fixture for high-frequency induction heating disclosed in this embodiment includes a support plate and an arc-shaped quartz plate 2 installed on the support plate. The support plate includes a base 12 and a support beam 11. The base 12 and The support beam 11 is 90 degrees, and the end of the support beam 11 away from the base 12 is provided with a mounting platform protruding from the installation surface and has a mounting hole 13; the installation platform of the arc-shaped quartz plate 2 and the support beam 11 is fixed by bolts Connection; there are multiple arc-shaped quartz plates 2, three in this embodiment, forming a circular structure that fits the inner hole of the workpiece.

[0021] In this embodiment, the support plate is integrally formed with a stainless steel body, and the support beam is an arc-shaped structure. The support plate in this embodiment maintains the existing stainless steel m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com