Natural fiber-reinforced thermoplastic composite material and preparation method and application thereof

A composite material and thermoplastic technology, applied in transportation and packaging, textiles and papermaking, vehicle parts, etc., can solve the problems of difficult degradation of waste, limited material resources, natural environment pollution, etc., to achieve green, simple process, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

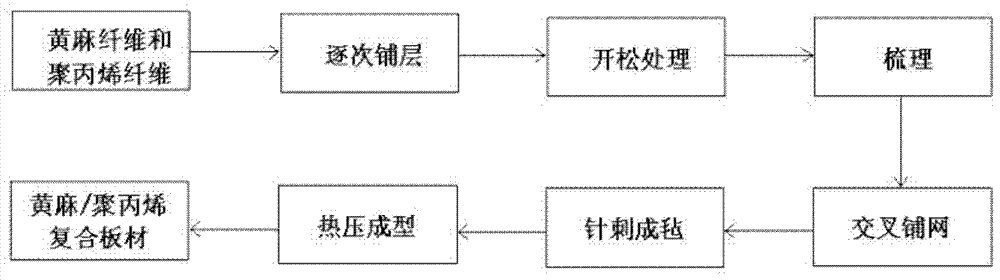

[0038] (1) The jute / polypropylene composite material is composed of jute fiber and polypropylene fiber, wherein the mass percentage of the two fibers is: jute fiber 50%, polypropylene fiber 50%, jute fiber and polypropylene fiber are cut by a cutting machine into 60mm chopped fiber; the preparation process of jute / polypropylene composite material is as follows figure 1 As shown, earlier the cut jute fiber and polypropylene fiber are layered successively according to the above-mentioned ratio, and the jute fiber and polypropylene fiber are respectively laid in 20 layers, and the feed is carried out continuously.

[0039] (2) Then send it to the opening machine for one opening, and then send it to the next opening machine through the automatic feeding device for the second opening;

[0040] (3) carding through a carding machine to obtain fluffy and uniformly mixed fibers, each fiber is distributed in a monofilament shape;

[0041] (4) Send the mixed fibers into the web-laying m...

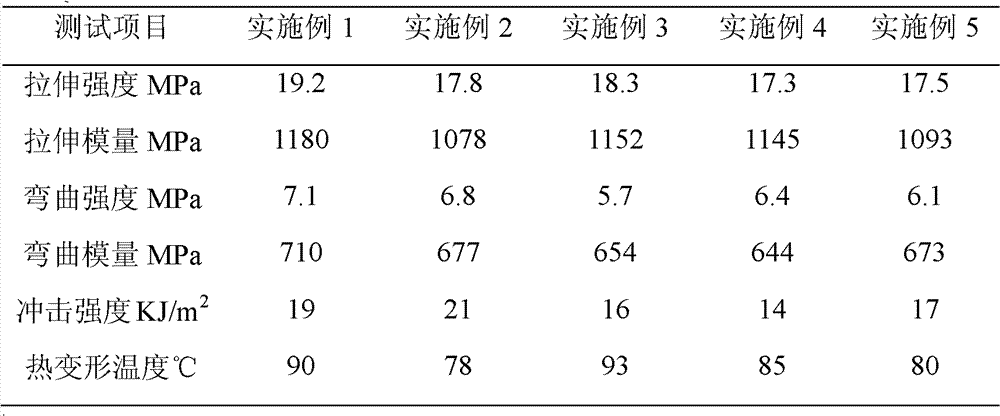

Embodiment 2

[0045] The difference between the present embodiment and Example 1 is: the mass percent of two kinds of fibers is: jute fiber 40%; Polypropylene fiber 60%, jute fiber layer number is 16 layers, and polypropylene fiber is 24 layers, one deck or Multiple layers of jute fibers alternate with one or more layers of polypropylene fibers.

Embodiment 3

[0047] The difference between the present embodiment and Example 1 is: the mass percent of two kinds of fibers is: jute fiber 60%; Polypropylene fiber 40%, jute fiber layer number is 24 layers, and polypropylene fiber is 16 layers, one deck or Multiple layers of jute fibers alternate with one or more layers of polypropylene fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com