High-intensity environment-protection type textilene reeled silk

An environmentally friendly, Teslin technology, applied in filament/thread forming, textile and paper making, fiber processing, etc., can solve the problems of poor environmental protection performance, achieve long service life, smooth and cool surface, and bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

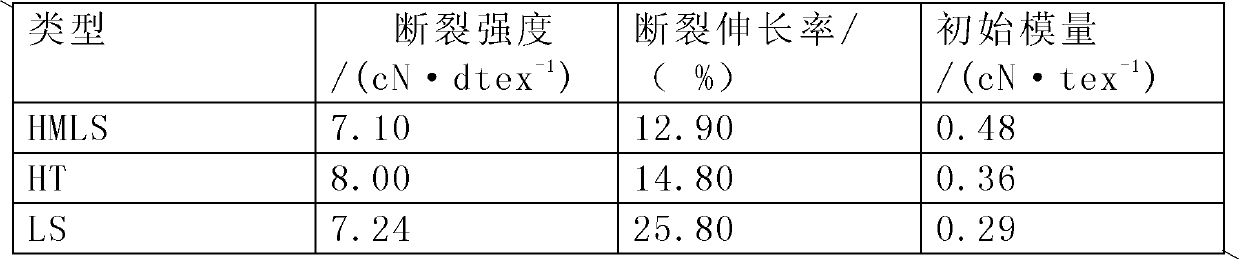

[0021] The Teslin skeins are twisted together by two different colors of Teslin long wires, one of which is a composite wire with a covering structure, the core is HT type polyester industrial filament, and the cortex is environmentally friendly PE / PP Copolymer material, the outer layer of pigment is made of brown color masterbatch; another kind of Teslin long thread is a composite thread with a cladding structure, the core is HT type polyester industrial filament, and the cortex is environmentally friendly PE / PP copolymer material, in black The masterbatch is used to make the outer layer of pigment.

[0022] The specific production process is: put the same color of environmentally friendly plastic masterbatch into the feed port of the plastic extruder, the environmentally friendly plastic masterbatch is plasticized into a uniform melt through the extrusion system of the plastic extruder, and passed through the The pressure built by the plastic extruder in this process is cont...

Embodiment 2

[0026] The Teslin skeins are twisted together by two different colors of Teslin long wires, one of which is a composite wire with a covering structure, the core is HMLS type polyester industrial filament, and the cortex is environmentally friendly PE / PP Copolymer material, the outer layer of pigment is made of red masterbatch; another kind of Teslin long thread is a composite thread with a cladding structure, the core is HMLS type polyester industrial filament, and the cortex is environmentally friendly PE / PP copolymer material, in black The masterbatch is used to make the outer layer of pigment.

[0027] The specific manufacturing process is the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0031] The Teslin skeins are twisted together by two different colors of Teslin long wires, one of which is a composite wire with a covering structure, the core is LS-type polyester industrial filament, and the cortex is environmentally friendly PE / PP Copolymer material, the outer layer of pigment is made of green color masterbatch; another kind of Teslin long thread is a composite thread with cladding structure, the core is LS type polyester industrial filament, and the cortex is environmentally friendly PE / PP copolymer material, in black The masterbatch is used to make the outer layer of pigment.

[0032] The specific manufacturing process is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com