Mobile construction waste crushing station

A construction waste, mobile technology, applied in construction waste recycling, recycling technology, solid waste removal and other directions, can solve the problems of large consumption of land requisition costs, construction costs for garbage removal costs, flying environment, occupation of cultivated land, etc. To achieve the effect of simple structure, reduce pollution and reduce floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention can be explained in more detail by the following examples, the present invention is not limited to the following examples, the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention;

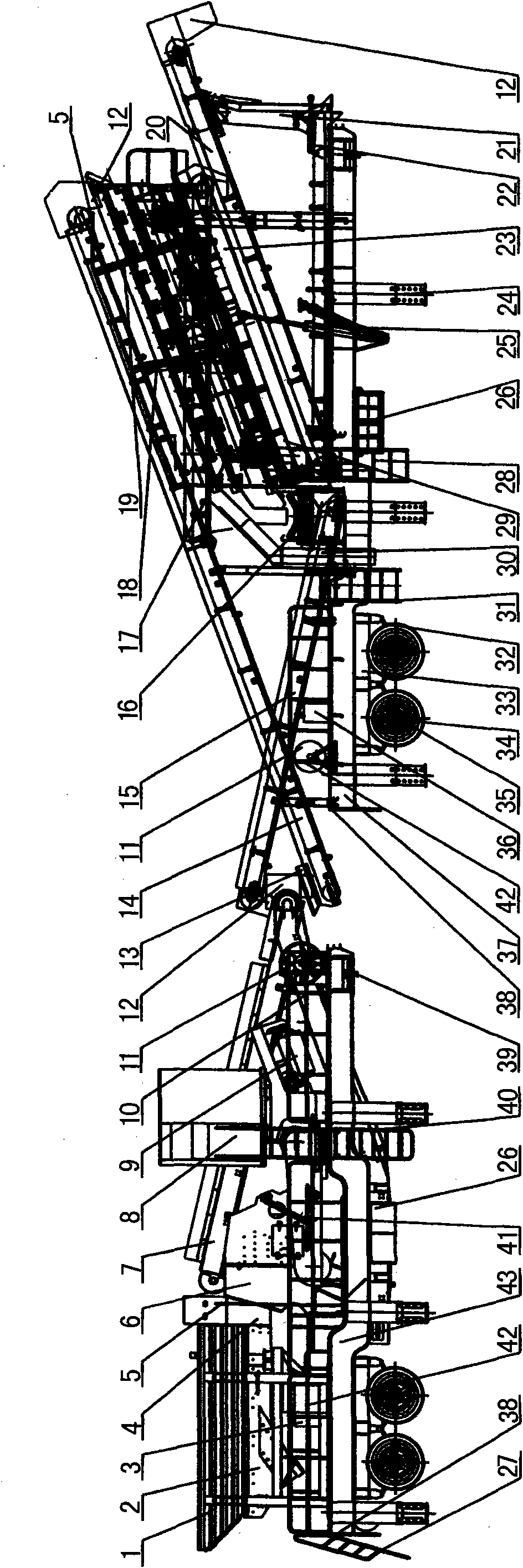

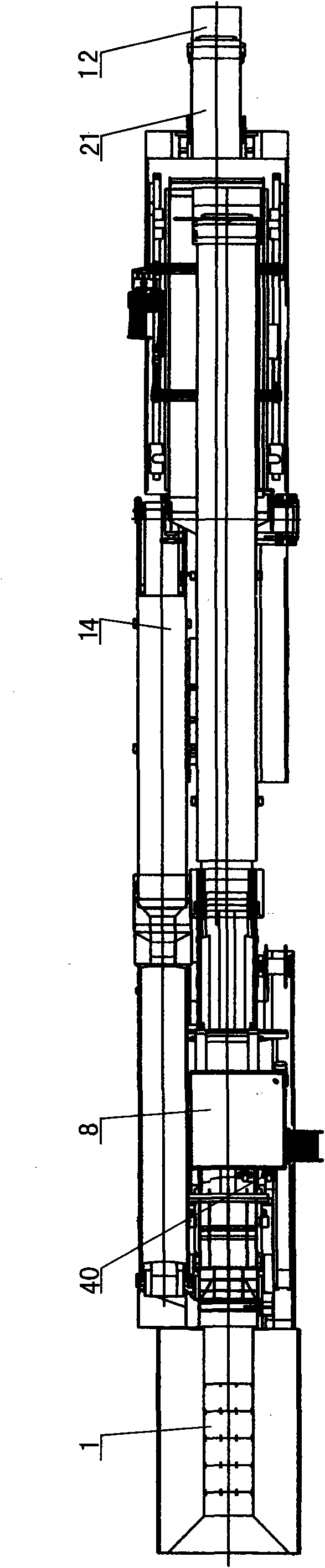

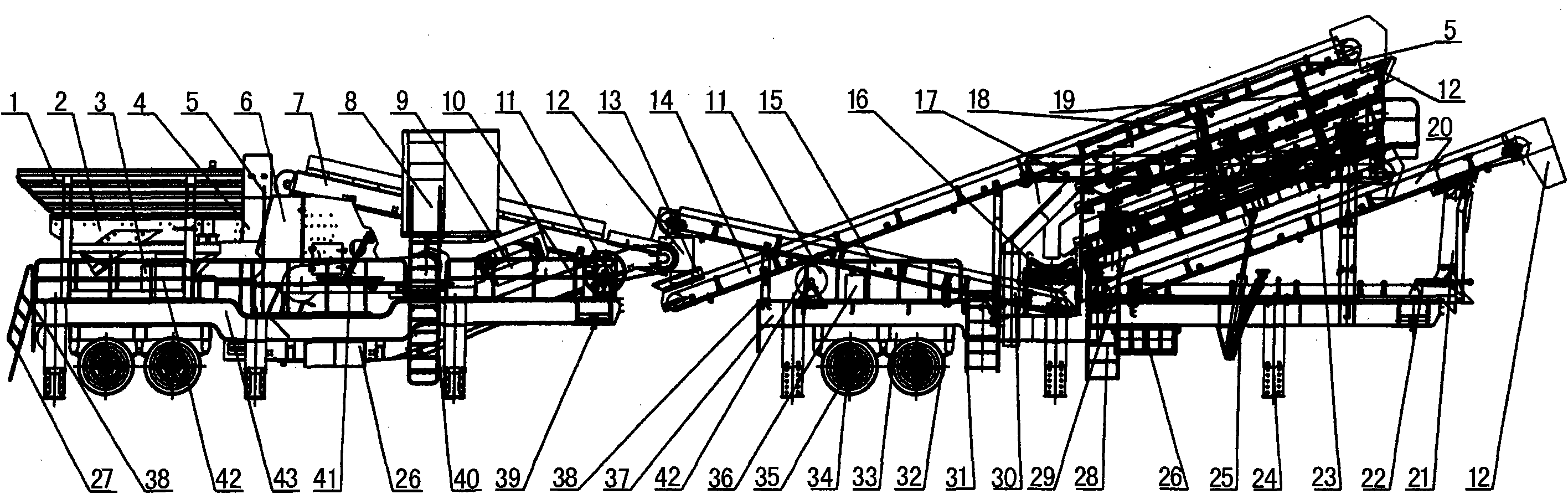

[0022] combined with figure 1 Or the mobile construction waste crushing station described in 2 includes a mobile construction waste vibrating crushing feeding mechanism and a mobile construction waste screening system, and the mobile construction waste vibrating crushing feeding mechanism mainly includes another vehicle frame main body Beam 43, hydraulic outrigger 24, wheels, operating room 8, raw material bin 1, vibrating feeder 2, construction waste crusher feed hopper 4, construction waste crusher A6, waste crusher hydraulic cylinder 41, return belt conveyor A7, iron remover 9, feeding belt conveyor A10 and belt conveyor discharge hopper 12, the two sides and the front of the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com