Lightweight fireproof building brick and preparation method thereof

A construction and fire-resistant technology, applied in the field of construction bricks, can solve the problems of consuming a lot of arable land, unfavorable environmental management and development of the construction industry, etc., and achieve the effects of reducing waste discharge, labor intensity and energy consumption, and high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

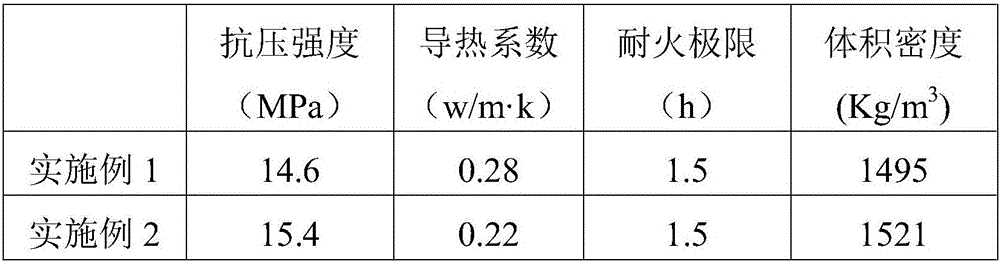

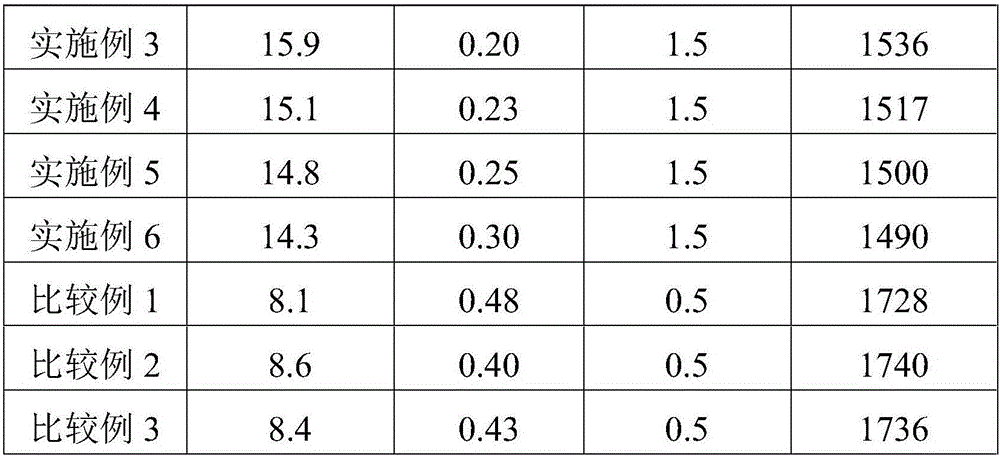

Examples

Embodiment 1

[0028] Embodiment 1: A light-weight refractory building brick, the raw materials of the light-weight refractory building brick are 67 parts of industrial waste, 50 parts of construction waste, 117 parts of waste water, 40 parts of sludge, and 15 parts of fly ash , 40 parts of river sand, 20 parts of cement, 20 parts of clay and 5 parts of sintering aid.

[0029] The industrial waste slag is at least two kinds of blast furnace slag, coal slag, carbide slag, nonferrous metal slag and steel slag;

[0030] The construction waste is at least two of waste tiles, waste plastics, waste bamboo and wood, waste mortar and waste gypsum;

[0031] The wastewater is at least two of petroleum wastewater, electroplating wastewater, printing wastewater, papermaking wastewater and mining wastewater.

[0032] The sintering aids are alumina and lithium oxide, the cement is ordinary Portland cement, the clay is refractory clay, the refractoriness of the refractory clay is >1580°C, and the moisture...

Embodiment 2

[0033] Embodiment 2: A light-weight refractory building brick, the rest are the same as in Example 1, the difference is that the raw materials of the light-weight refractory building brick are 50 parts of industrial waste, 70 parts of construction waste, and 113 parts of waste water. parts, 27 parts of sludge, 20 parts of fly ash, 30 parts of river sand, 15 parts of cement, 15 parts of clay and 8 parts of sintering aids, the sintering aids are alumina, lithium oxide and zinc oxide, the cement It is low-alkali Portland cement.

Embodiment 3

[0034] Embodiment 3: A kind of light-weight refractory building brick, the rest is the same as Example 1, the difference is that the raw materials of the light-weight refractory building brick are 60 parts of industrial waste, 53 parts of construction waste, and 100 parts of waste water. parts, 20 parts of sludge, 26 parts of fly ash, 34 parts of river sand, 17 parts of cement, 17 parts of clay and 7 parts of sintering aids, the sintering aids are lithium oxide, zinc oxide and silicon dioxide, the The cement is ordinary Portland cement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com