Method for manufacturing wooden sash section bar and method for assembling wooden window and door by using the same

A manufacturing method and technology for wooden doors and windows, which are used in manufacturing tools, window/door frames, wood processing appliances, etc., can solve the problems of easy damage to the overall wooden doors and windows, easily damaged material surface, low connection strength, etc., and achieve low cost and transportation. Convenience and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] The manufacturing method of the wooden door and window frame profile of the present embodiment comprises the following steps:

[0041] a. sawing the wood made of the finger-jointed integrated material according to the predetermined size and shape, the cross-sectional size of the wood after sawing in this embodiment is 50mm×80mm;

[0042] The finger-jointed glulam used in this embodiment is a single-layer glulam, which can meet the strength requirements and is not easy to deform, and can save about 40% of wood;

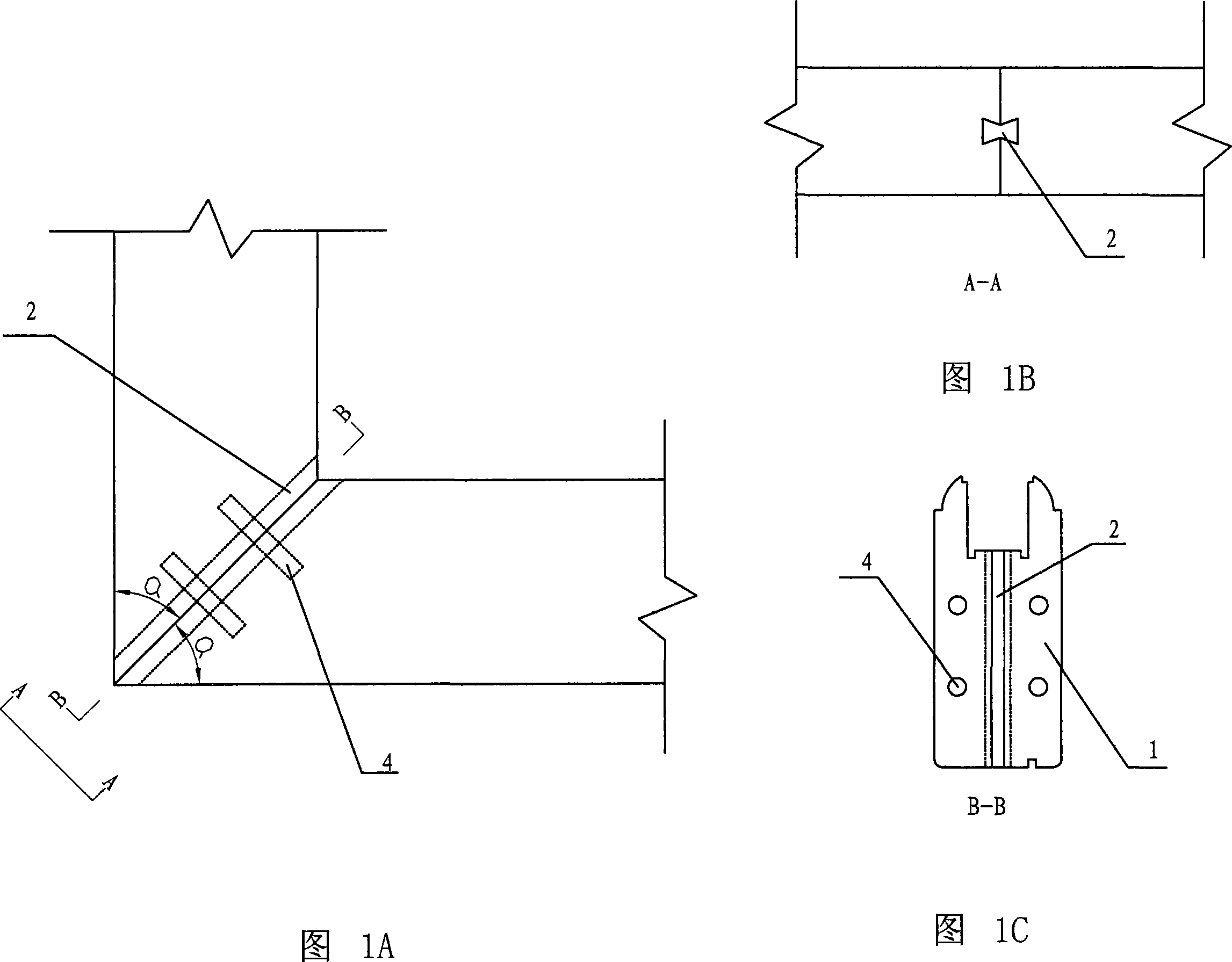

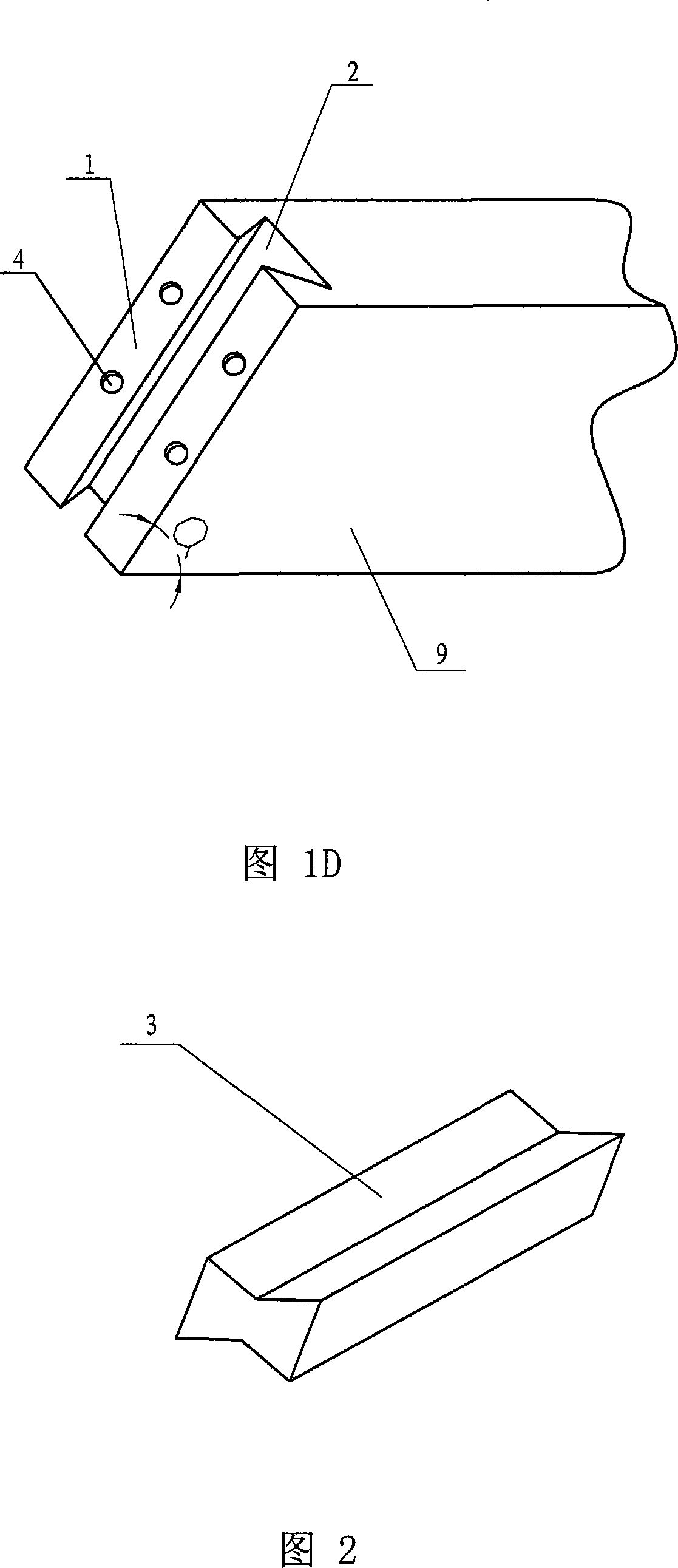

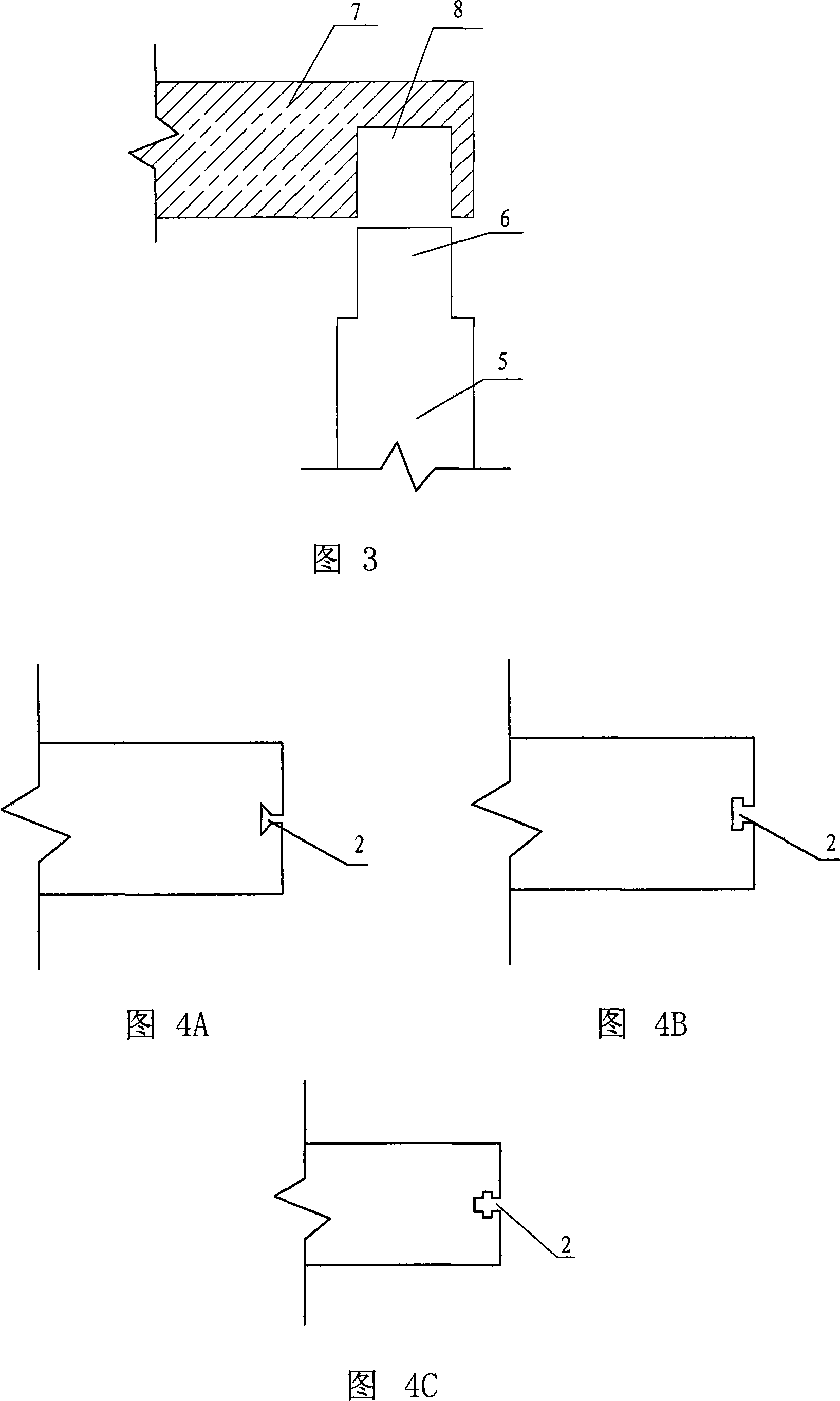

[0043] b. As shown in Fig. 1A, Fig. 1B, Fig. 1C, Fig. 1D and Fig. 2, a joint surface 1 is formed at the two ends of the wood after sawing, and the clamping surface 1 and the longitudinal direction of the wood are formed. Angle a is an acute angle, specifically 45 degrees in this embodiment, which facilitates the processing and assembly of the adjacent wooden door and window frame profiles; the joint surface 1 is perpendicular to the frame where the wooden door a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com