Patents

Literature

633results about "Corner/edge joints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

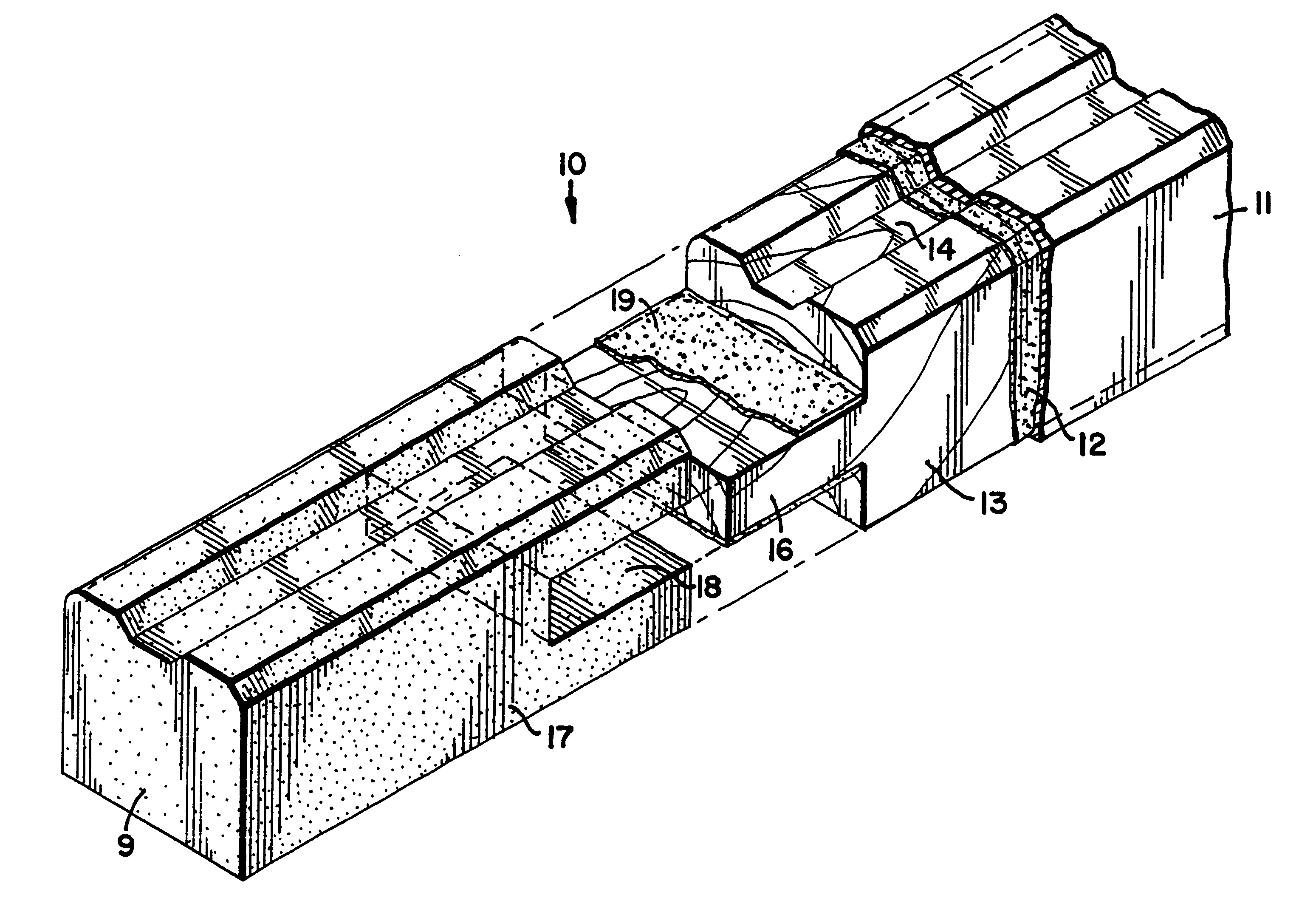

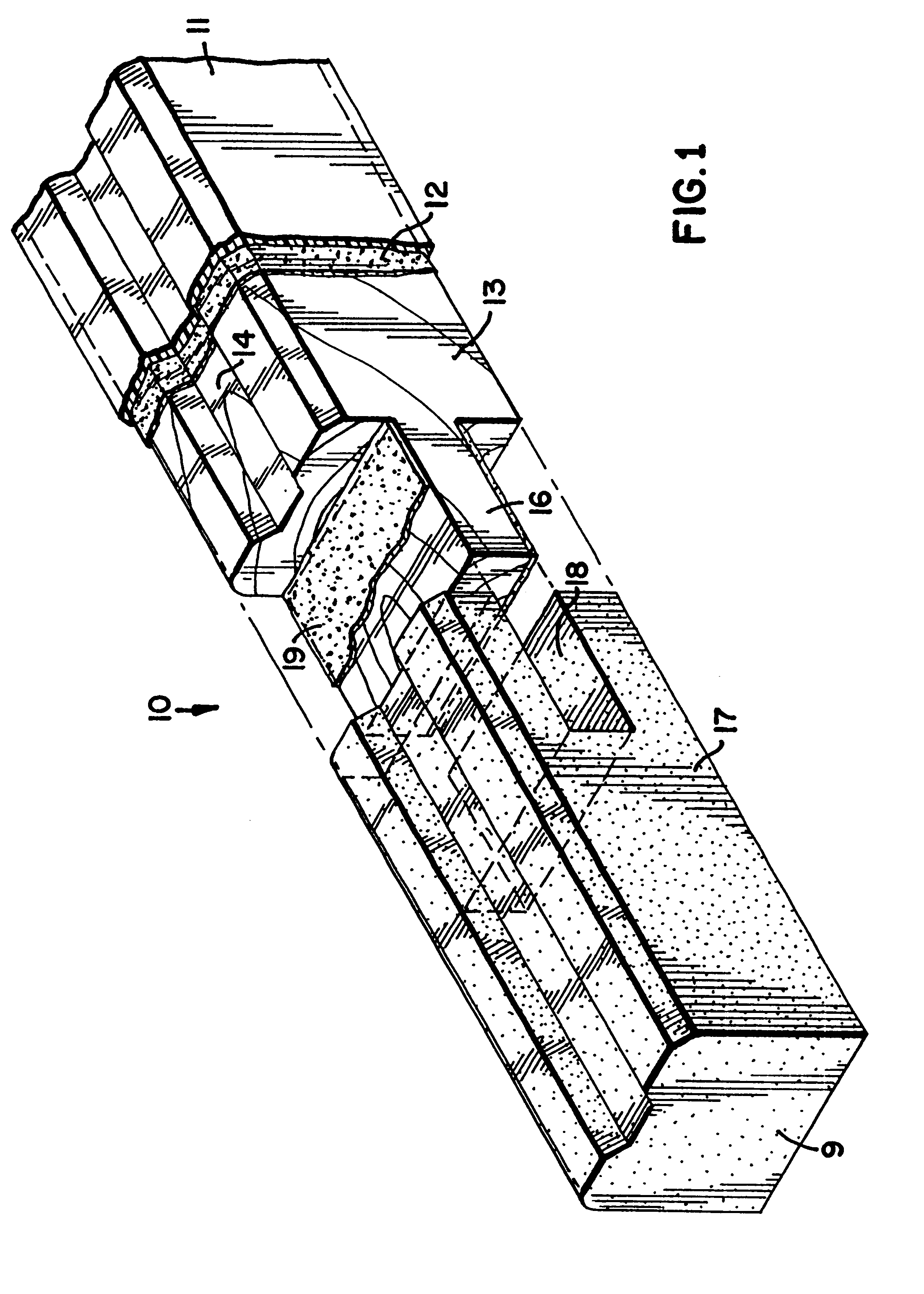

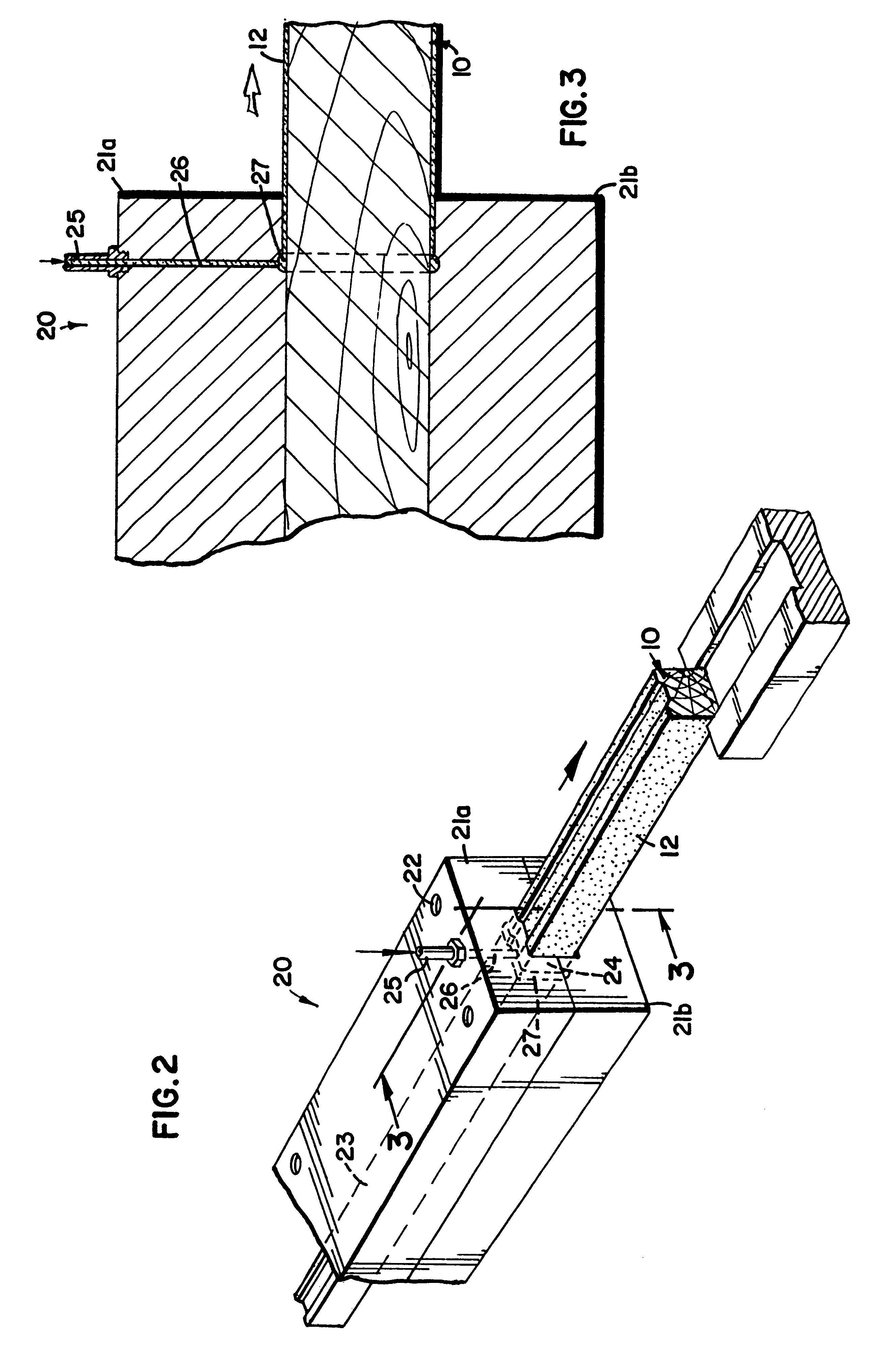

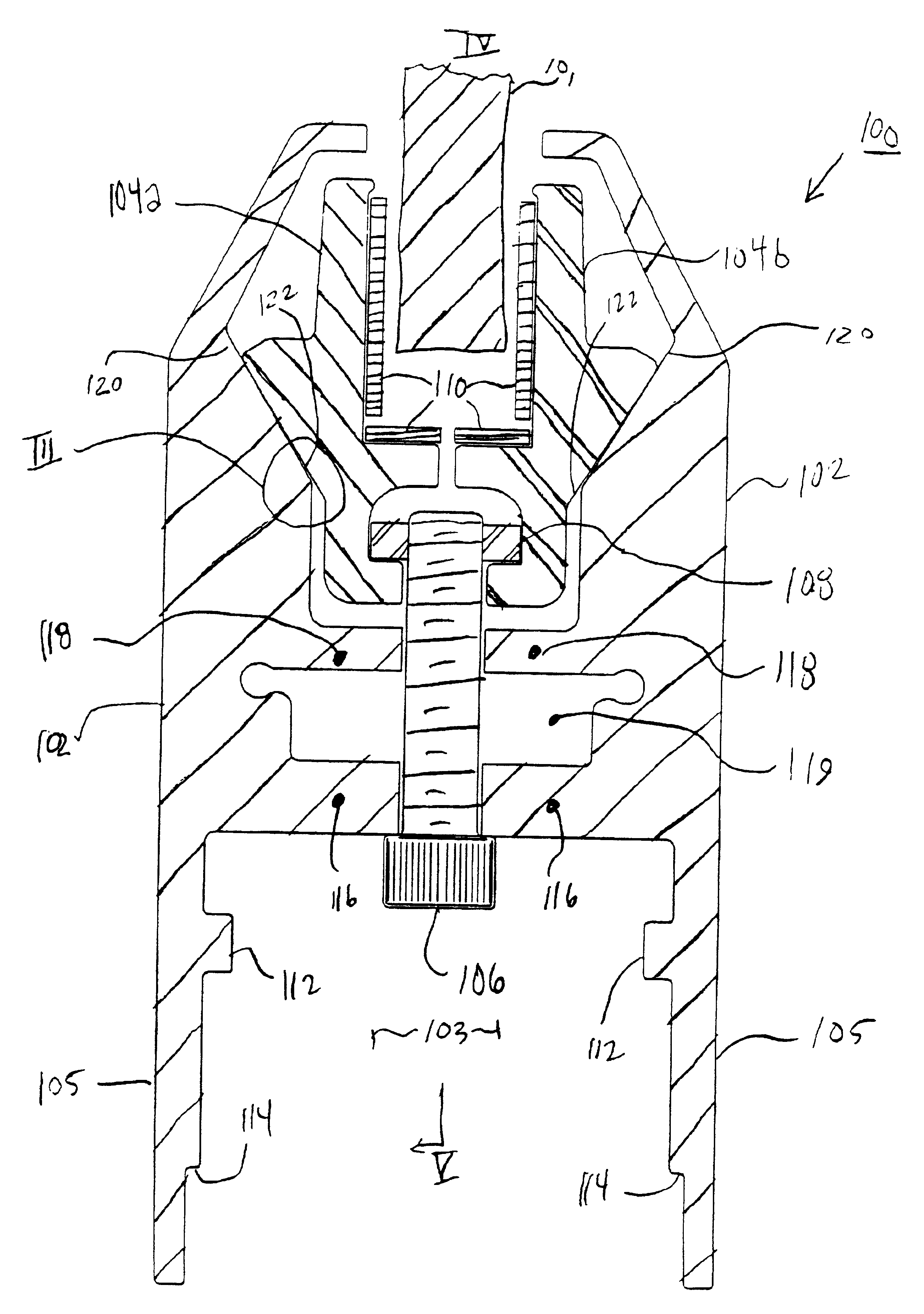

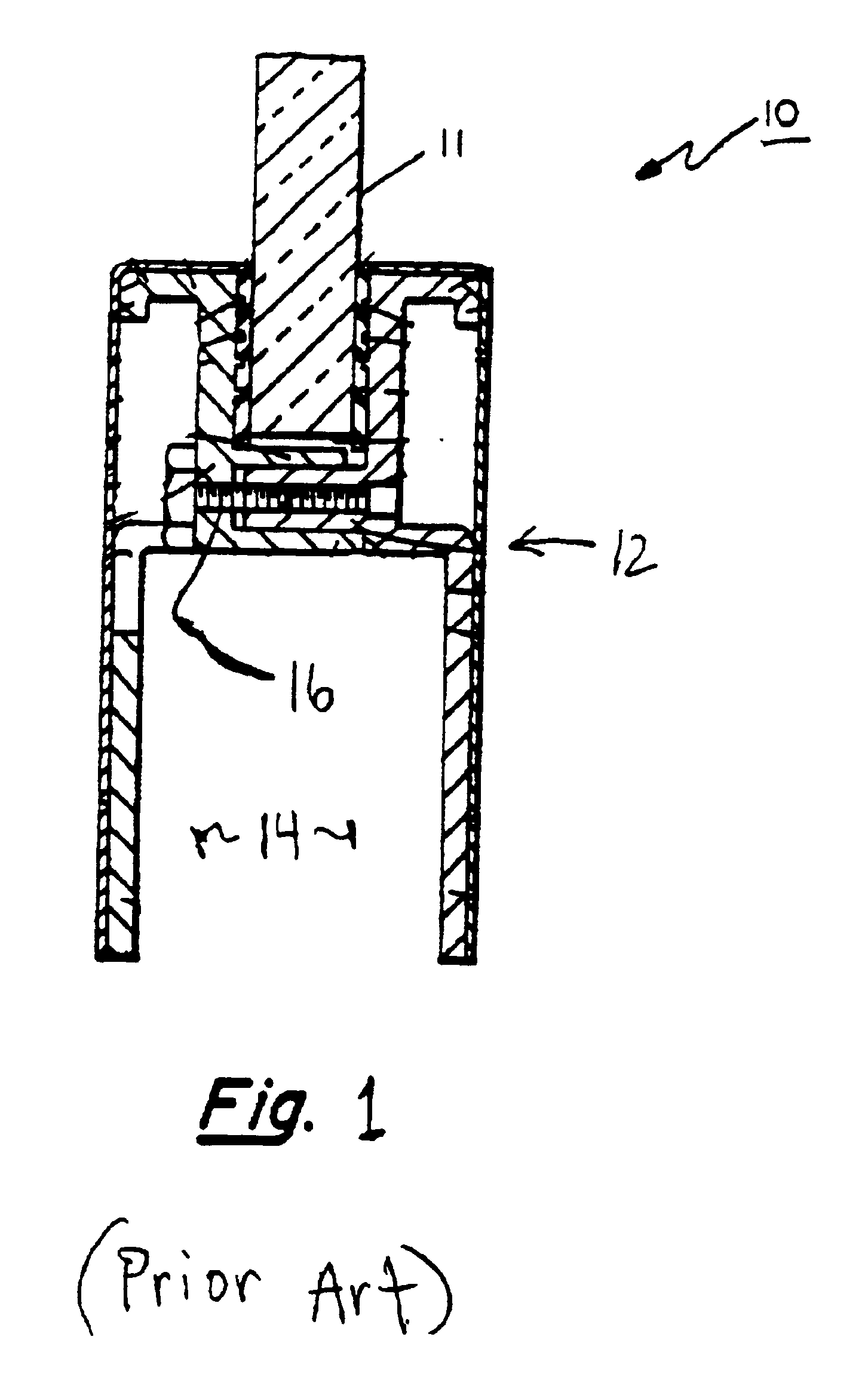

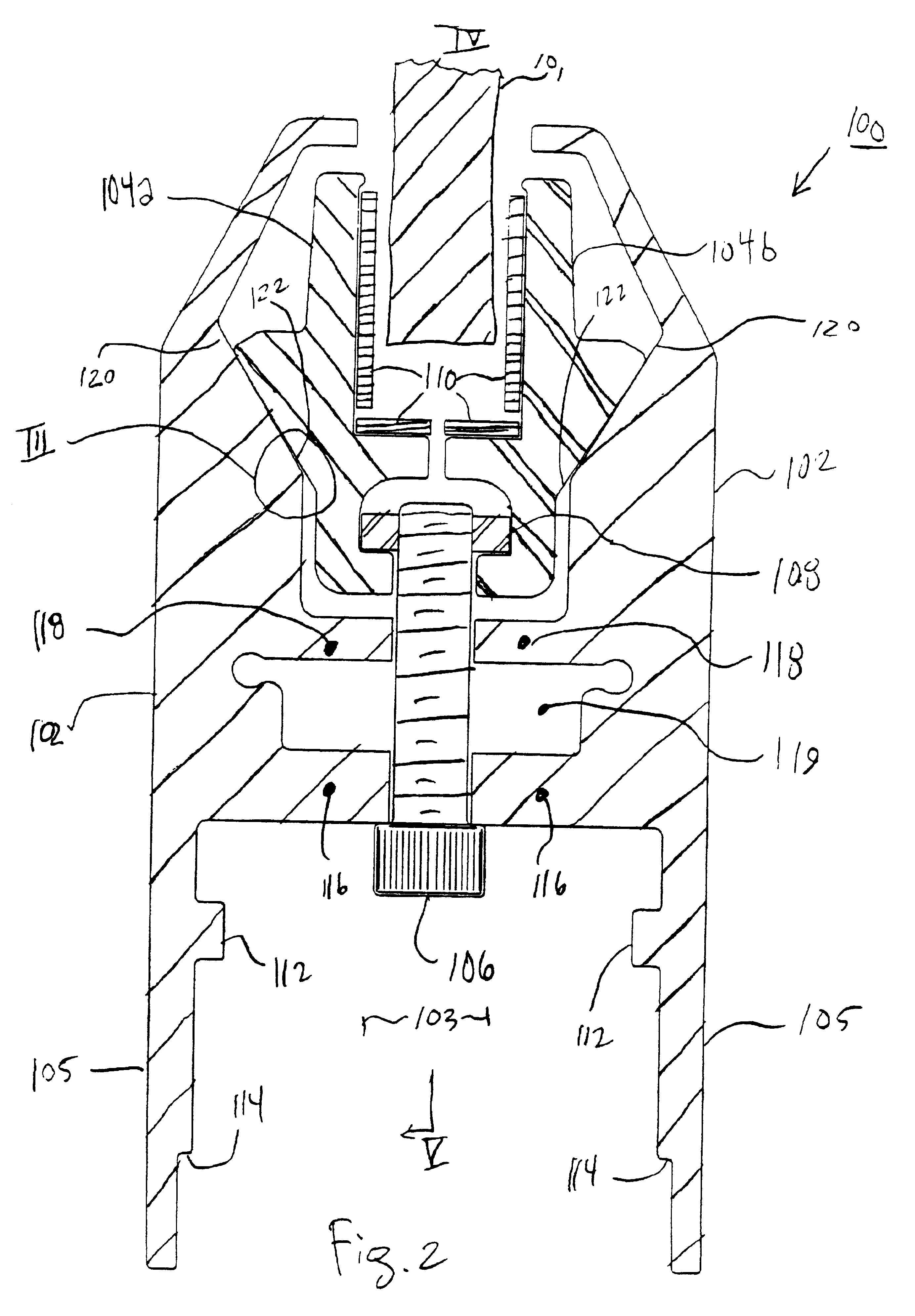

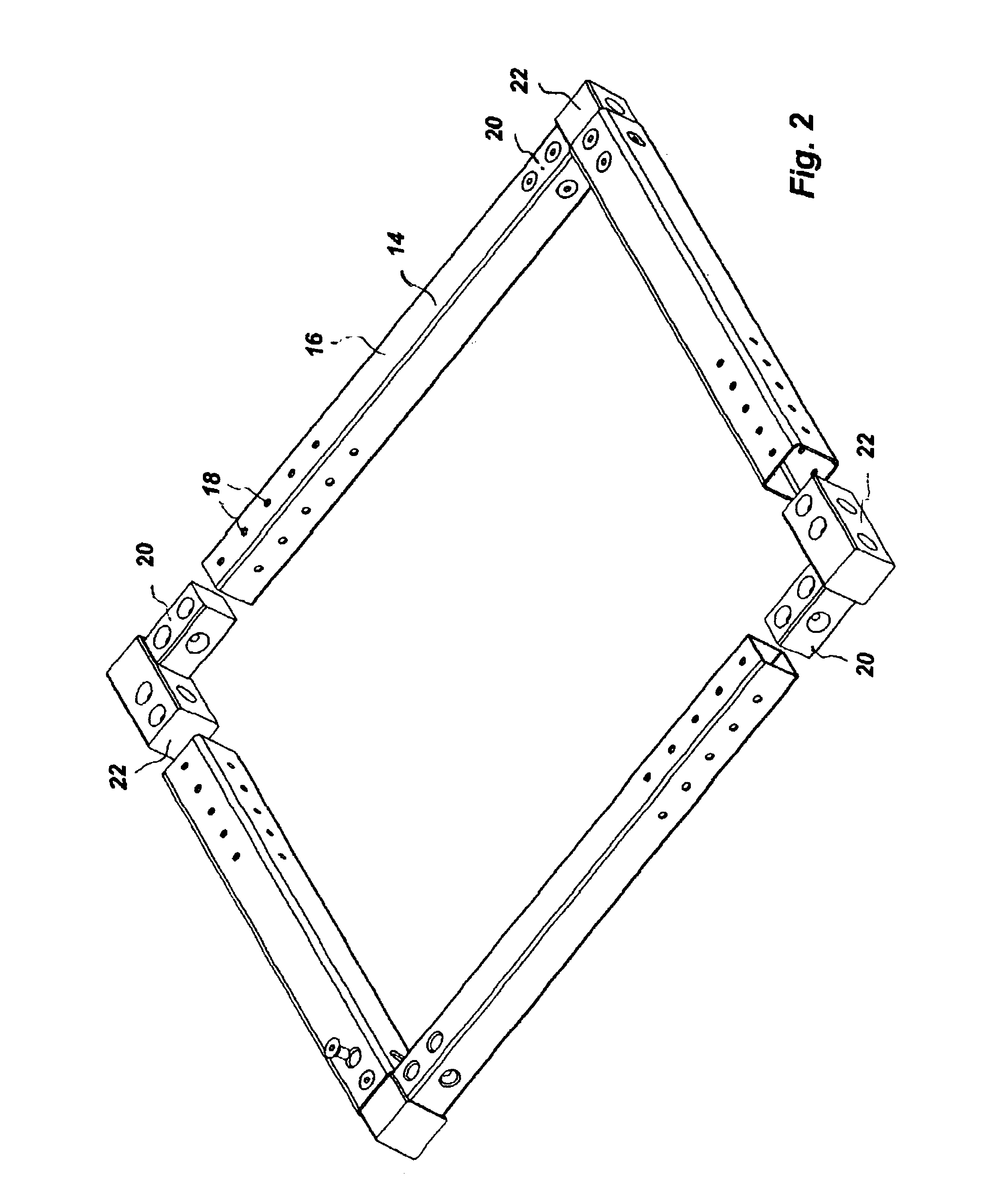

Polymer covered advanced polymer/wood composite structural member

InactiveUS6357197B1Corner/edge jointsMetal rolling stand detailsComposite constructionMoisture absorption

A composite structural member of the invention comprises a linear member having a first end and a second end attached to each end of the linear member as an end piece or end cap structure. Covering the composite member is a thermoplastic envelope preferably adherently bonded to the composite member. The end caps or end pieces are preferably thermoplastic materials typically thermoplastic composites comprising a thermoplastic resin and a fiber. Such a member is environmentally stable, resists moisture absorption, forms strong mitered joints and can be used in the assembly of fenestration products for commercial and residential real estate.

Owner:ANDERSEN CORPORATION

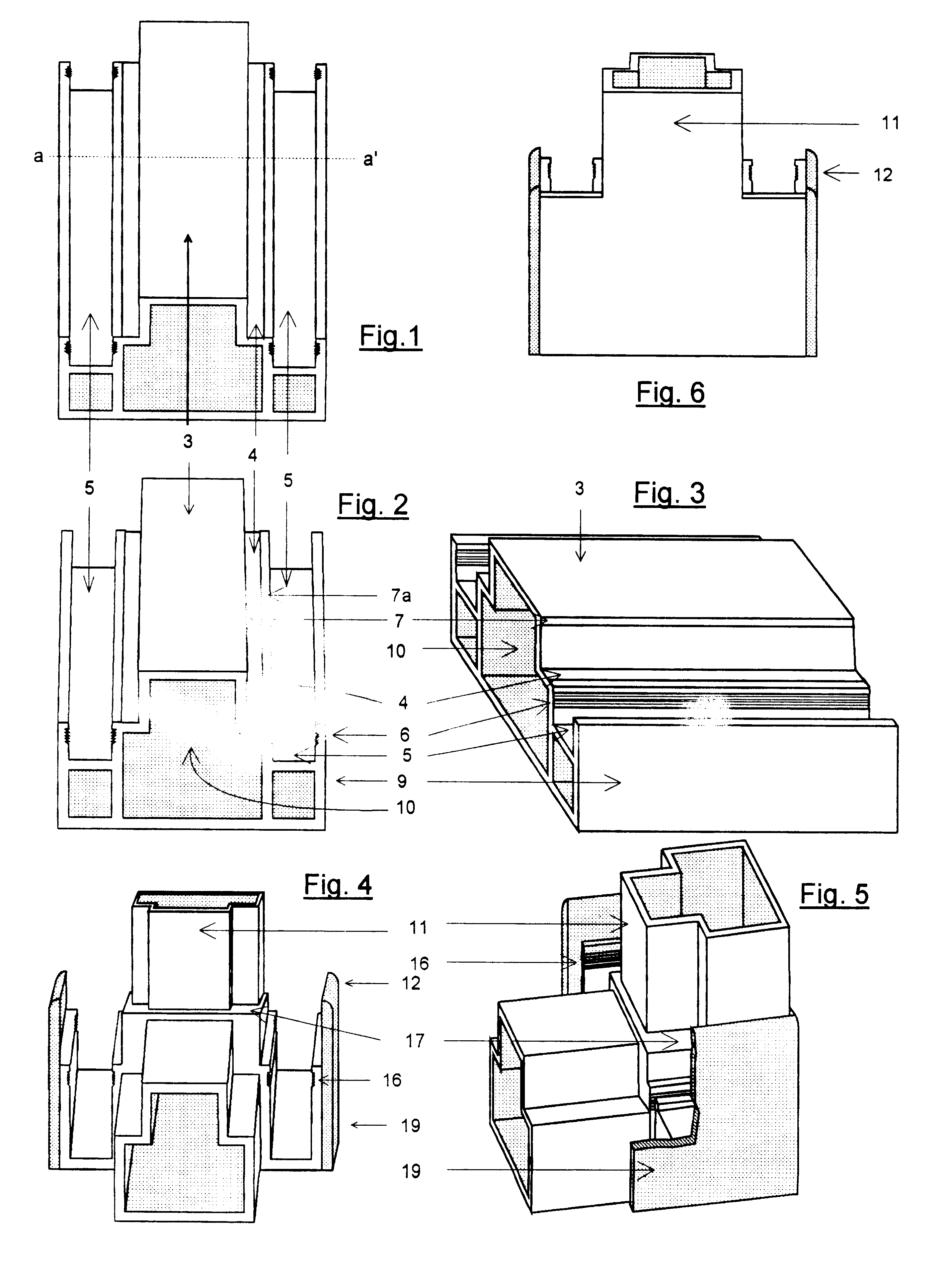

Assembly system for thermoacoustic windows

An assembly system used to build two pane thermoacoustic windows for houses and buildings is provided. The assembly system uses a set of profiles and joints and a permanently installed valve to assemble the window frame without a fusion welding machine. The system creates an airtight chamber directly on the frame. The valve allows the assembler to evacuate the air in the airtight chamber to make a vacuum, or to inflow a gas. The system improves the insulating thermal and acoustic capacity of the window, and allows a supplier to sell the components to build the window, which is then assembled by snapping together profiles and joints. The system can also be applied to assembly one pane window and for other purposes.

Owner:VALDERRAMA MARIO

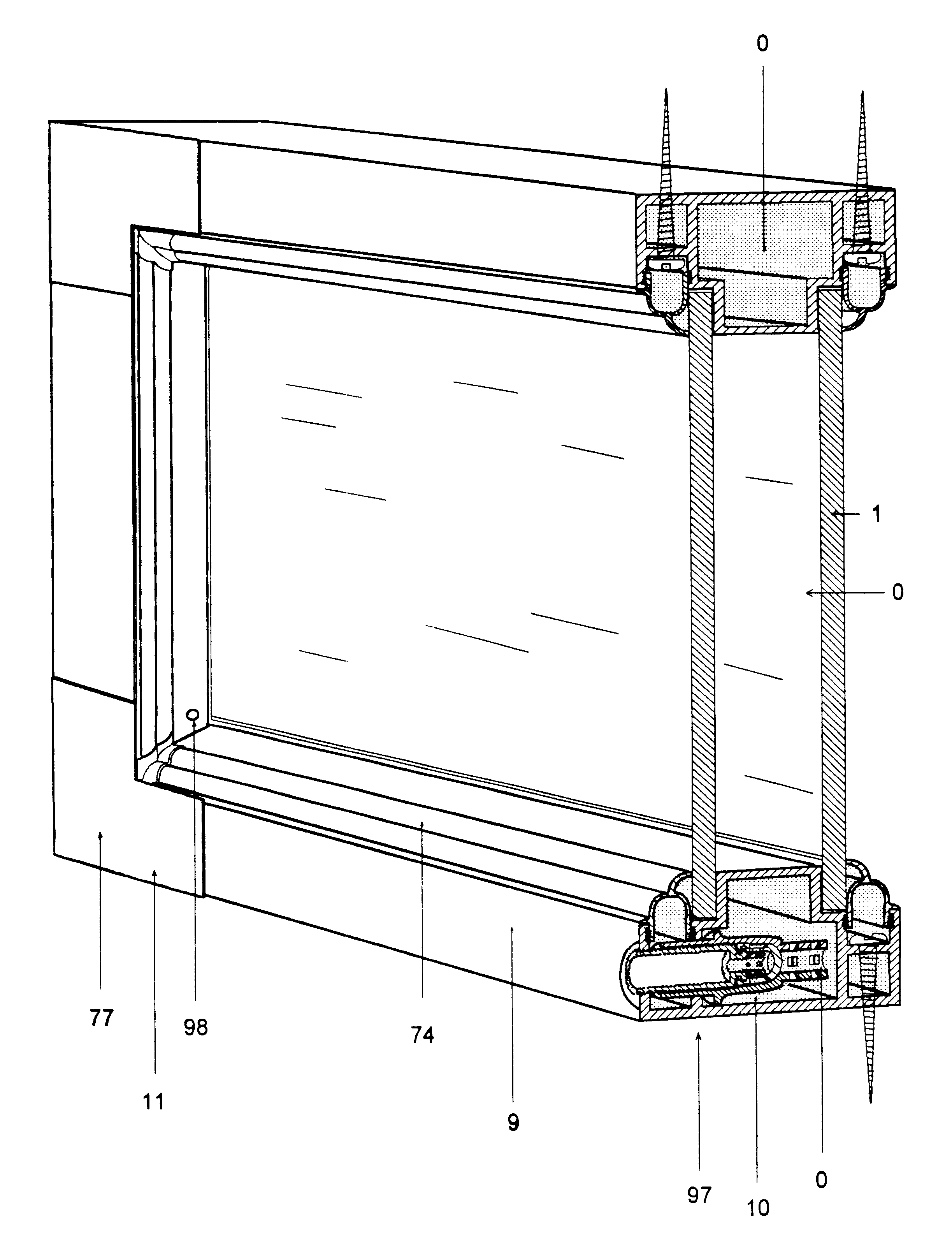

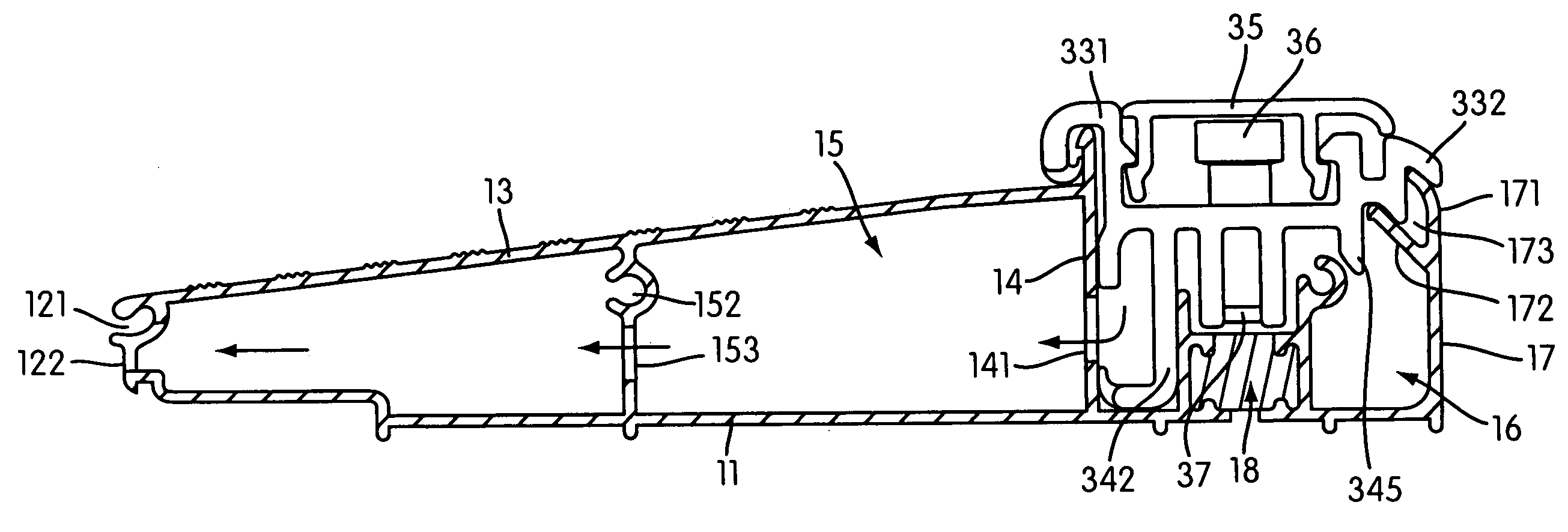

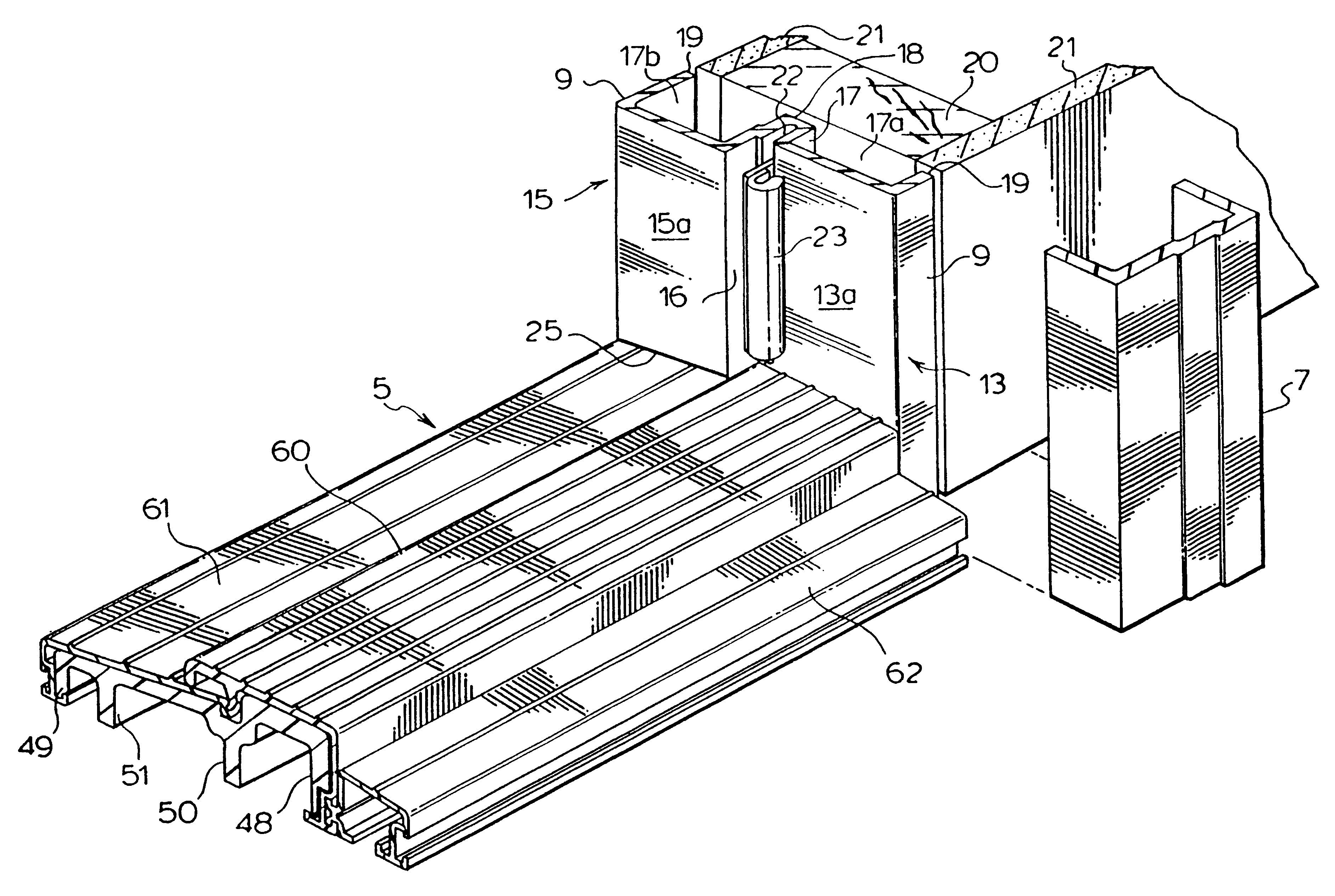

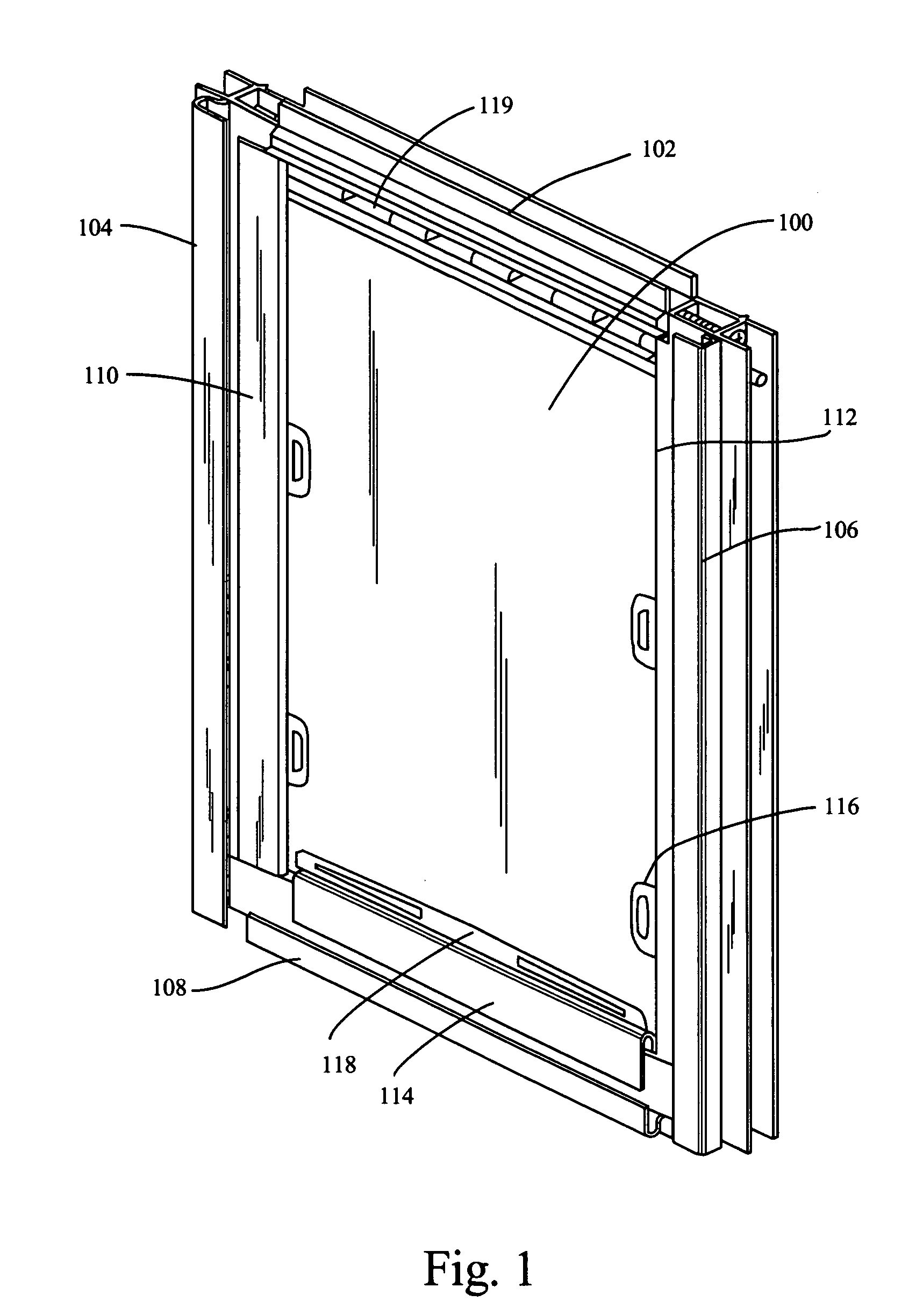

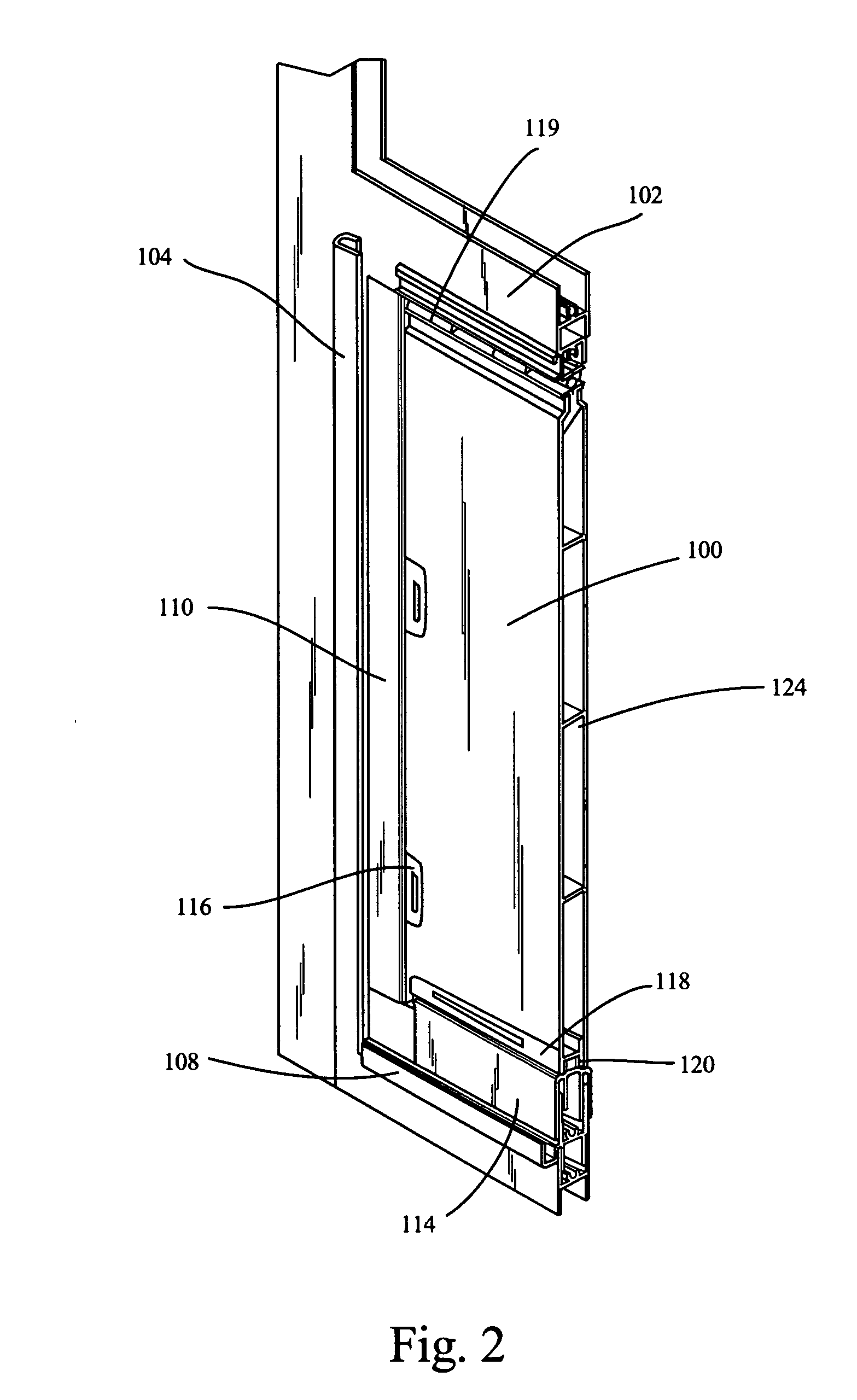

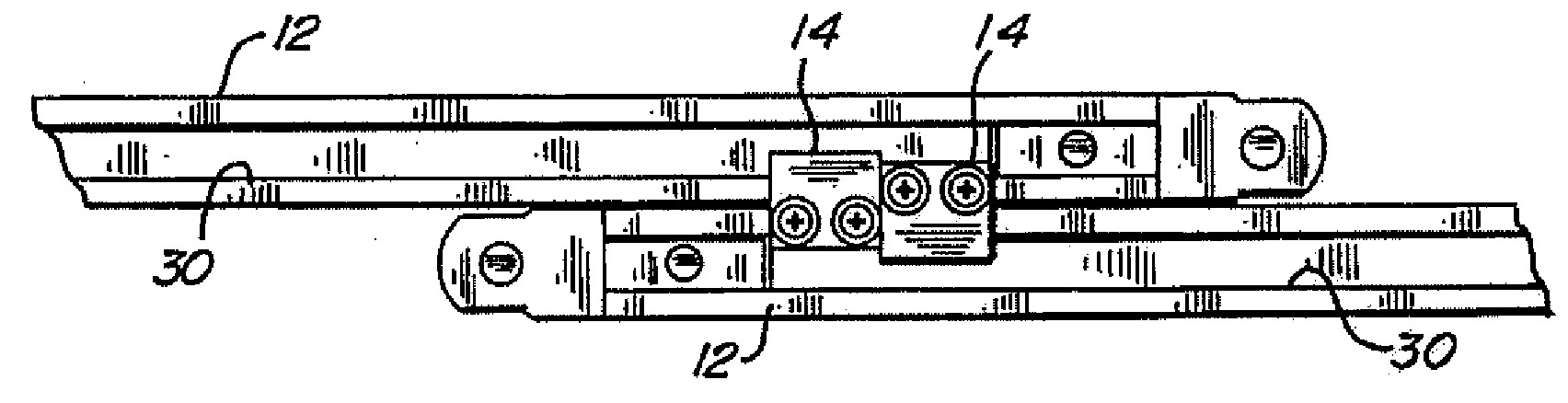

Adjustable rail assembly for exterior door still assembly and components for the same

InactiveUS7263808B2OptimizationShorten the timeCorner/edge jointsWindow/door framesEngineeringMechanical engineering

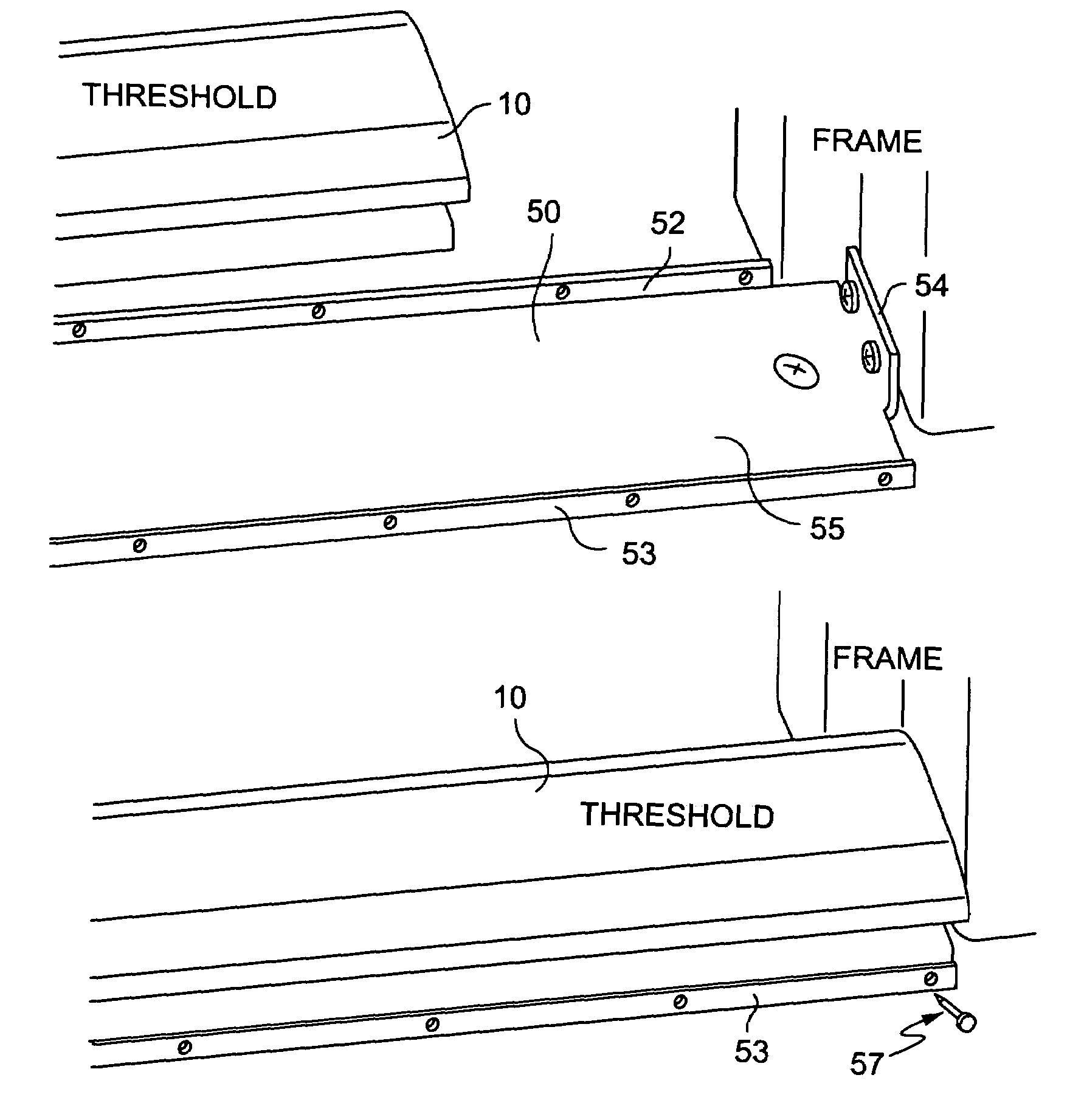

A modular exterior threshold and door sill assembly is provided for an entryway. The threshold and sill assembly includes an elongated sill assembly having at least one elongated channel. An elongated rail assembly is provided that extends at least a portion of the length of the elongated sill assembly. A portion of the elongated rail assembly is received within the elongated channel. The threshold and sill assembly includes at least one sill component connected to one of the elongated rail assembly and the elongated channel, wherein the at least one sill component includes at least one of a cover assembly, an astragal bolt receiver assembly, a mullion boot assembly, a side panel spacer assembly and an outswing rail assembly. The elongated rail assembly may be fixed or adjustable. The adjustable rail assembly may be adjusted using adjustors that are fixedly secured to the sill assembly.

Owner:PREMDOR INT +1

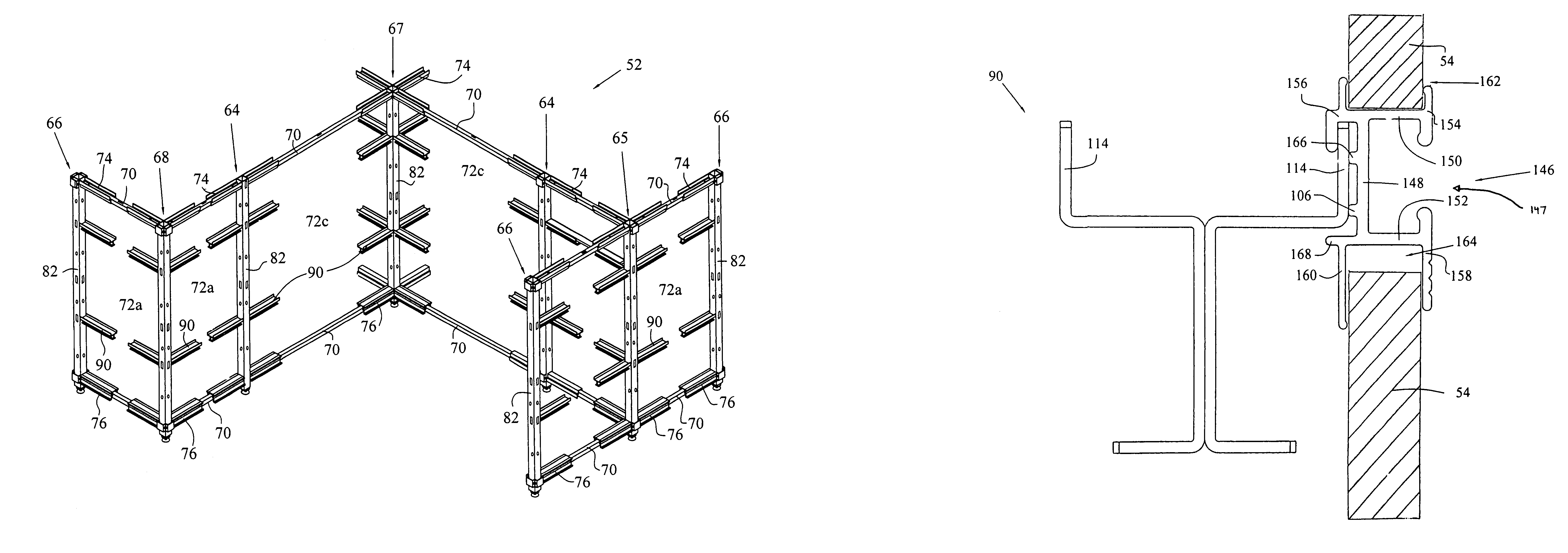

Partition system

InactiveUS7150127B2Easily attachable to the frameworkEasy to changeCorner/edge jointsLight protection screensBrickEngineering

Owner:KIMBALL INTERNATIONAL

Molded snap-together frame

InactiveUS7010888B2Quick assemblyLower cost of capitalCorner/edge jointsWindow/door framesEngineeringFlange

A frame assembly is formed of two molded sub-assemblies, each sub-assembly being identical to the other. Each sub-assembly has a perimeter wall having an inner surface facing an opening and an outer surface to face a edge of an aperture in a partition. A first edge of the wall confronts a surface of the window while a flange projects outward from the outer surface of the perimeter wall. A plurality of joining elements are fixed to and project normally from the flange. Each joining element includes an alignment element and a locking surface to engage a similar surface on an aligned joining element of a confronting sub-assembly. The joining elements are arranged in a pattern that permits any two sub-assemblies made in the same mold to be permanently snapped together without the use of any separate fasteners.

Owner:L L CULMAT

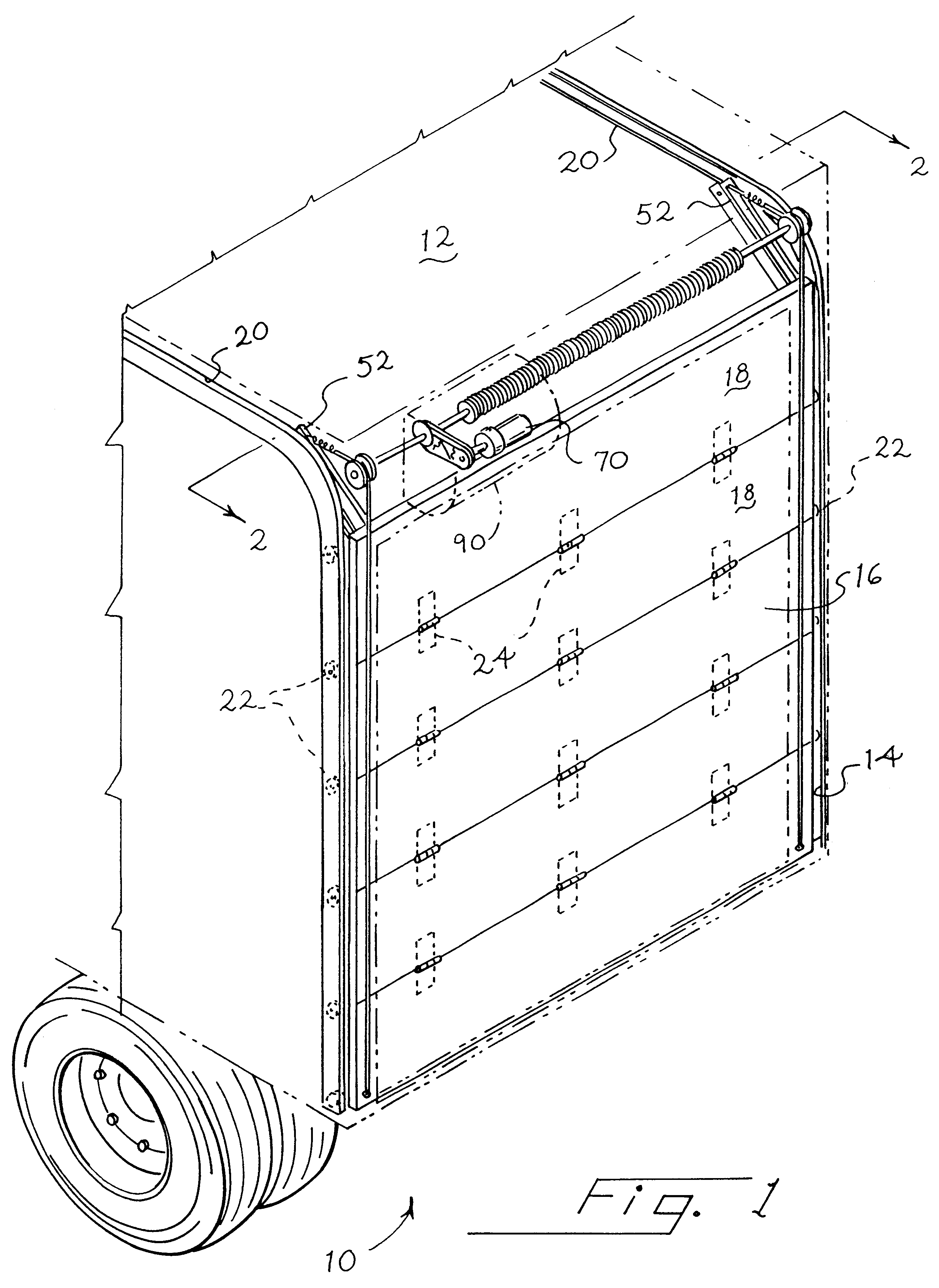

Roll-type door opener

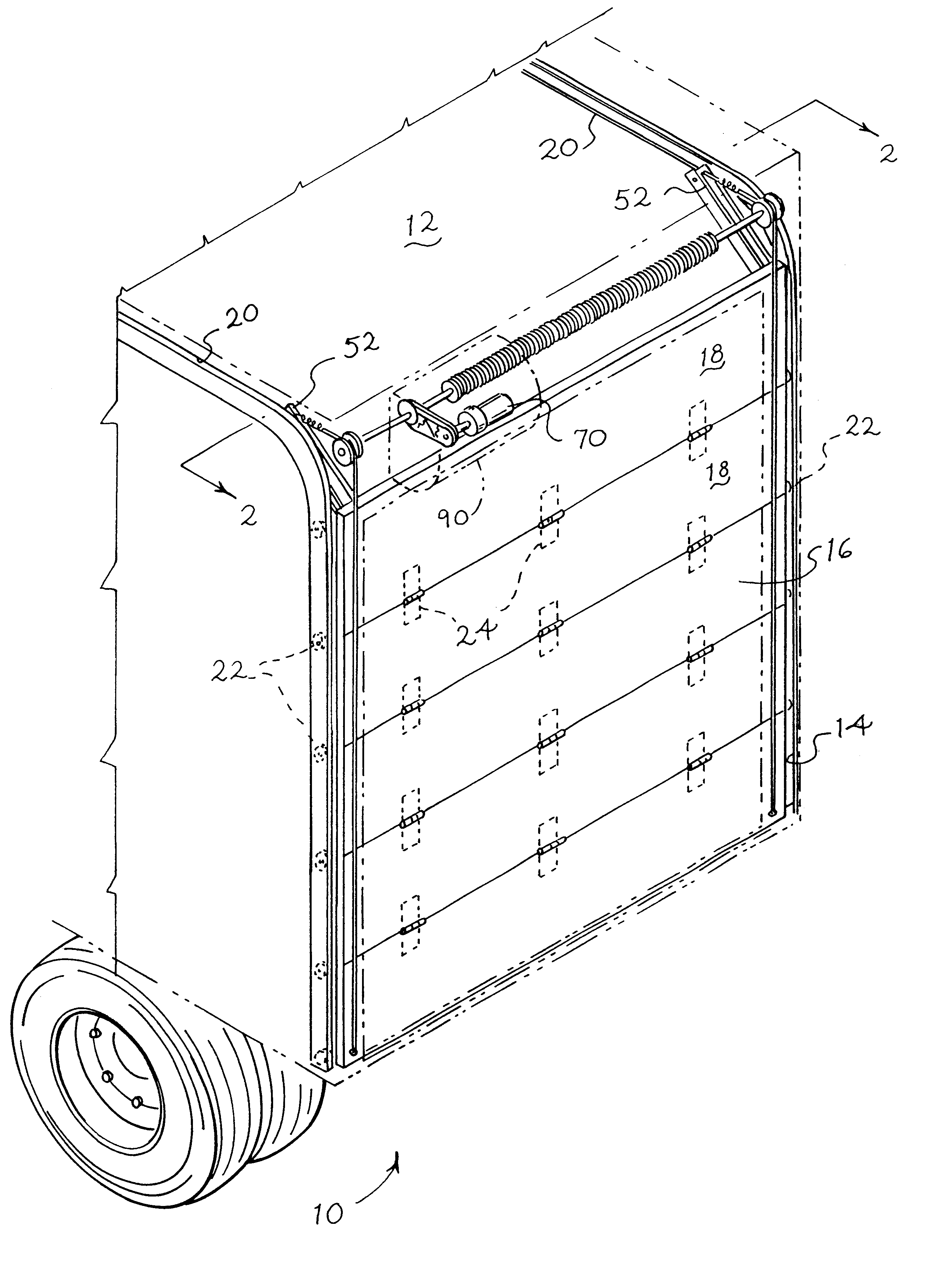

InactiveUS6276744B1Optimize space utilizationMinimizing compromiseCorner/edge jointsCurtain suspension devicesEngineeringTruck

A door opener for a roll-type door in a cargo van includes a shaft that is mounted for rotation within the cargo van body and is coupled with the door such that shaft rotation causes the door to move between opened and closed positions. The shaft is rotated by a motor that is mounted outside of the cargo van body and is coupled to the rotatable shaft by a drive system that extends through the cargo van body. This arrangement allows a relatively large conventional motor to be used without extending into the door opening or compromising the height of the door opening.

Owner:INTELLITEC PRODS

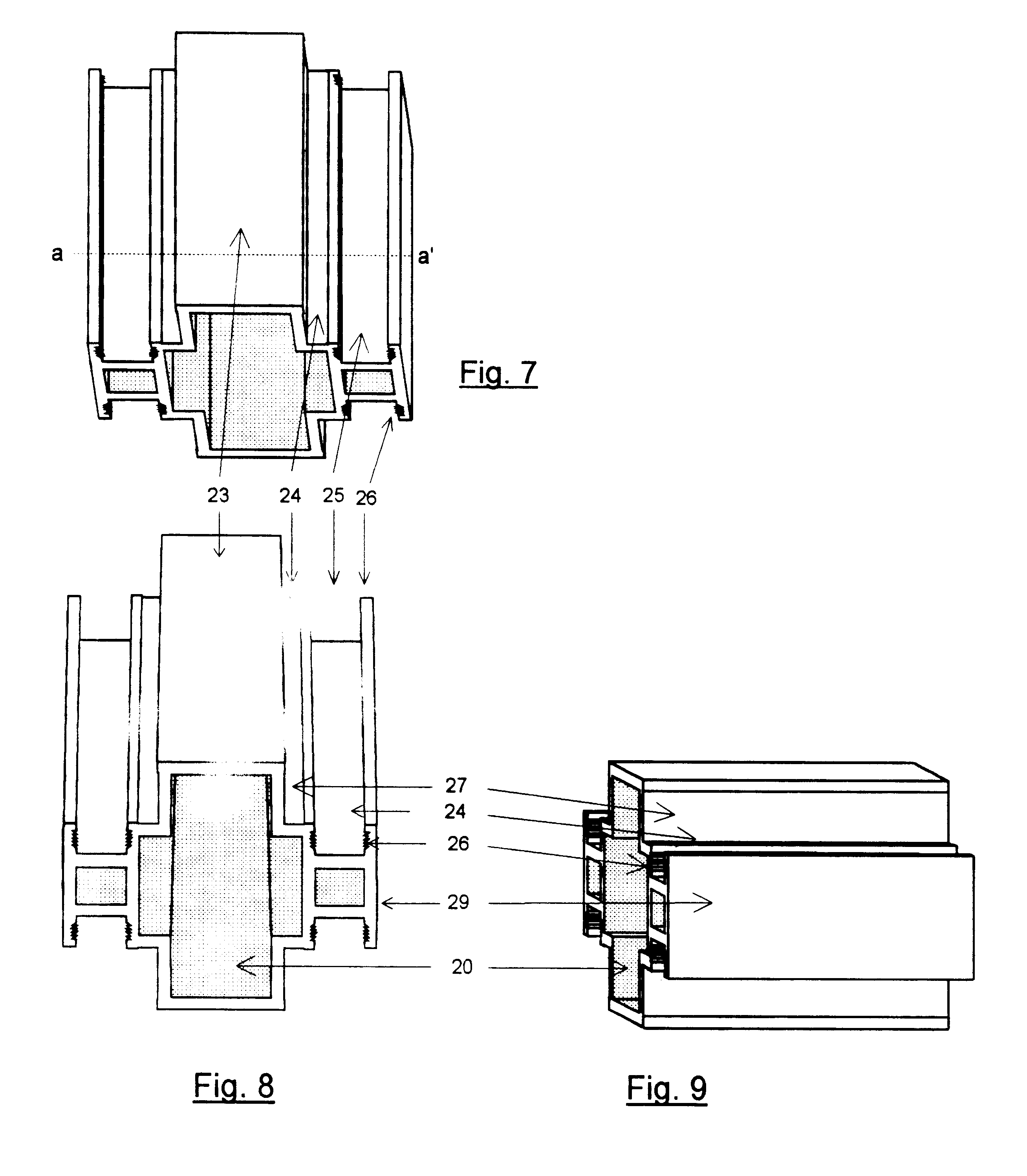

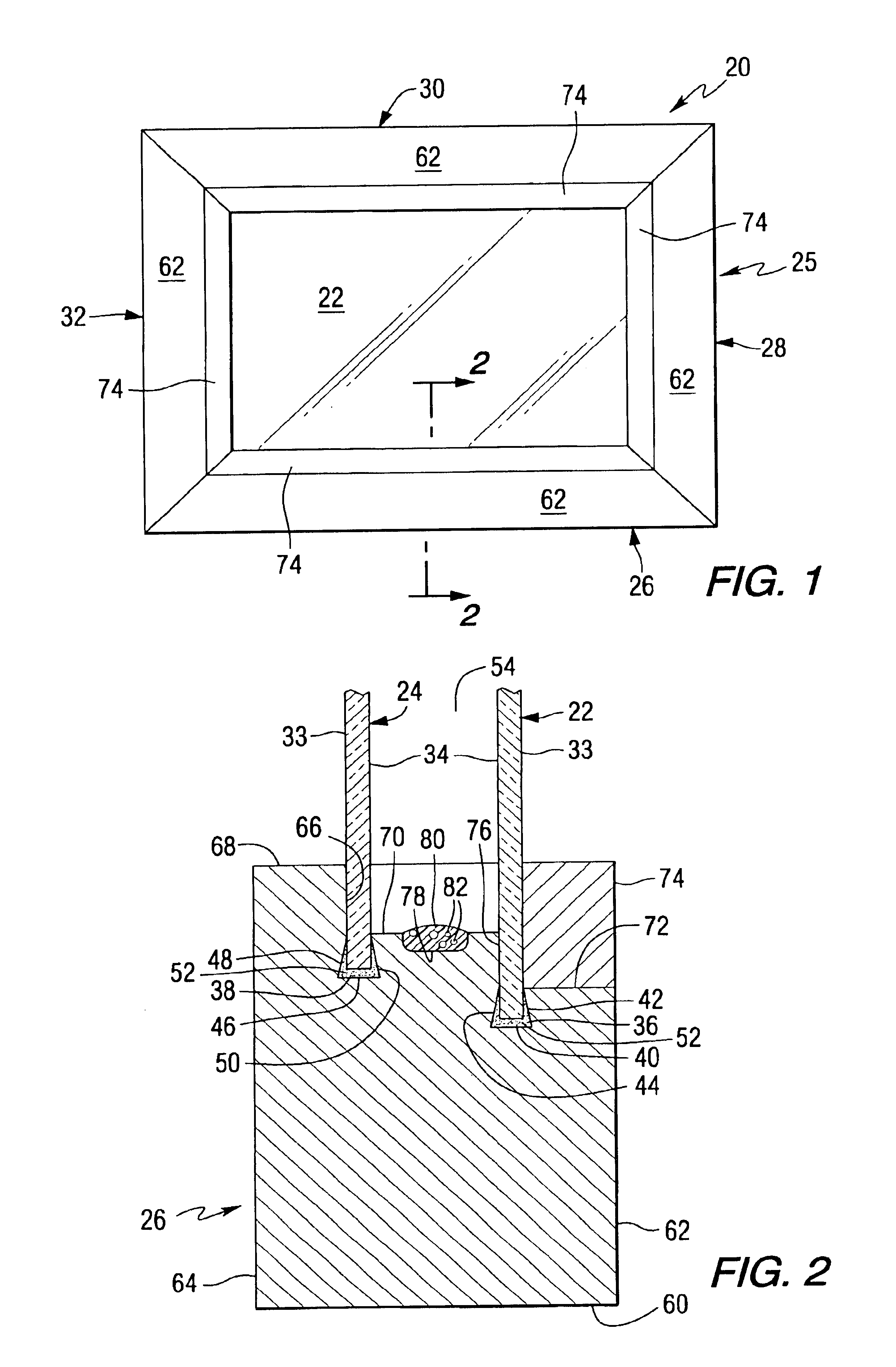

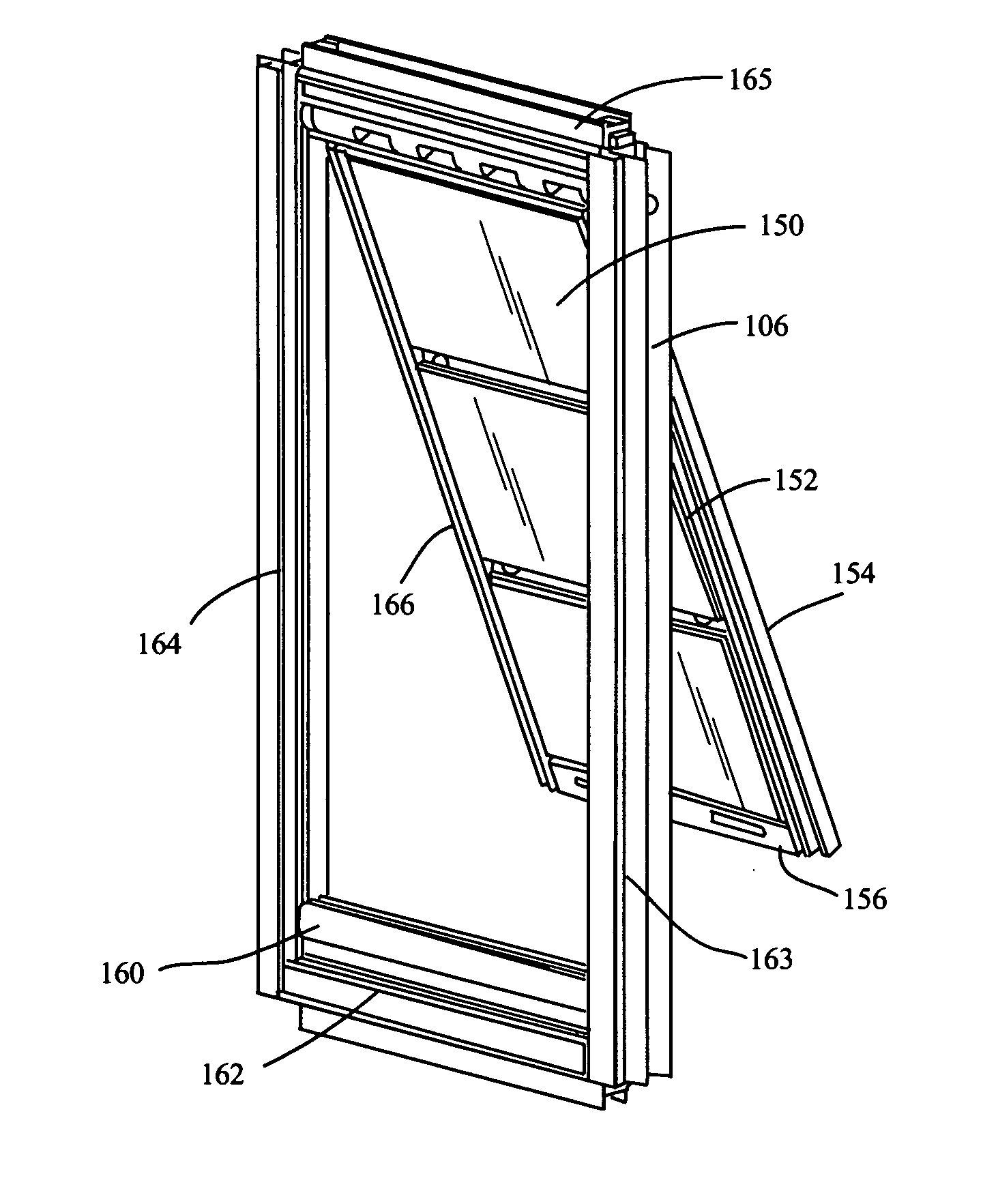

Insulating unitless window sash

InactiveUS6886297B1Avoid problemsImprove thermal efficiencyCorner/edge jointsCondensed water formation preventionEngineeringMechanical engineering

An insulating unitless window sash includes a sash frame made of four linear sash members having their mitered edges joined together. Each of the sash members in cross section includes a peripheral surface, a first and outer side walls and a first groove spaced from a second groove. Each of the grooves has a base and spaced walls. The base of the first groove is spaced a greater distance from the peripheral surface than the base of the second groove. Peripheral and marginal edges of a first sheet are in the first groove and peripheral and marginal edges of a second sheet are in the second groove. A shim is mounted on the sash frame adjacent the outer surface of the first sheet to give a balance configuration.

Owner:VITRO FLAT GLASS LLC

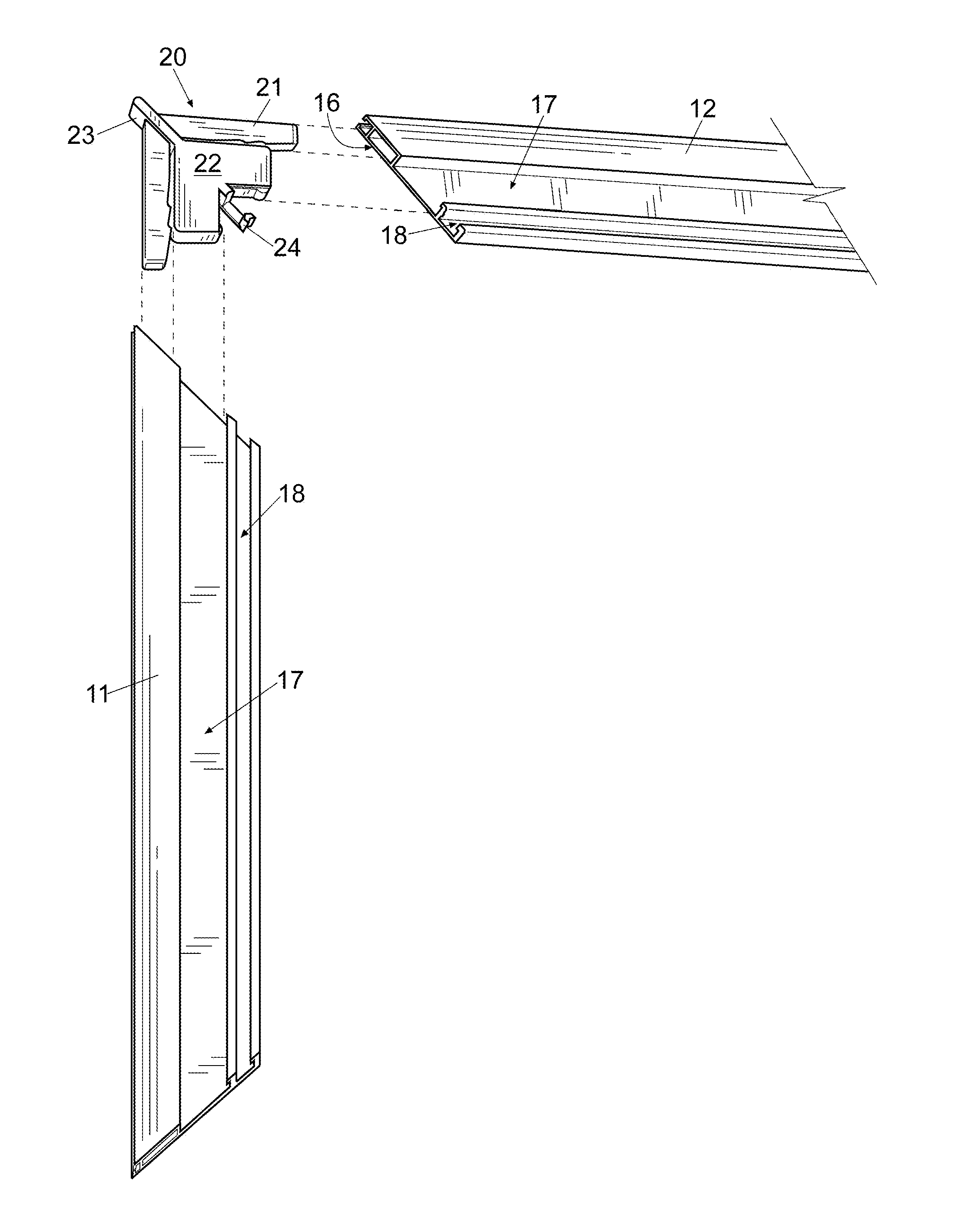

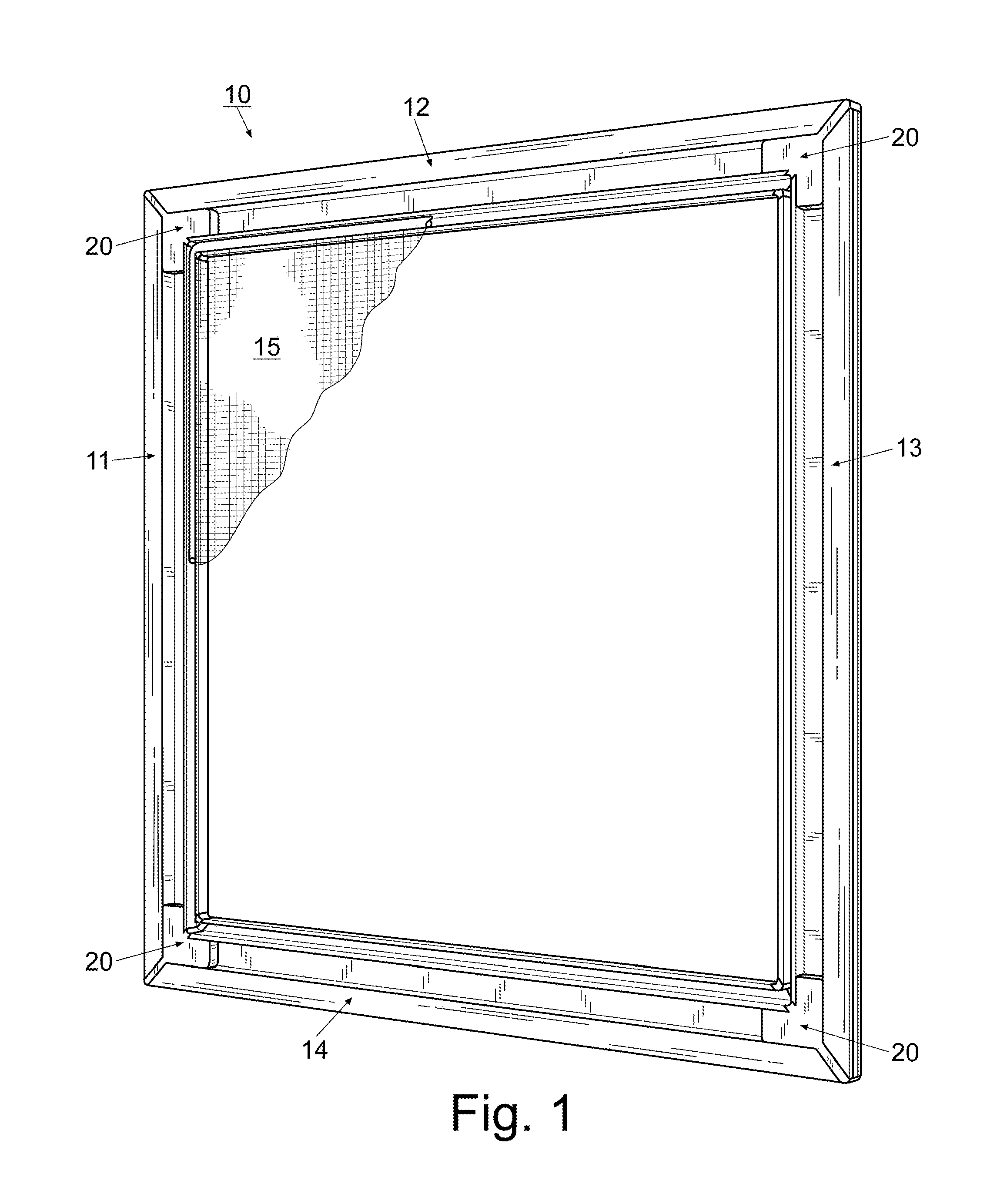

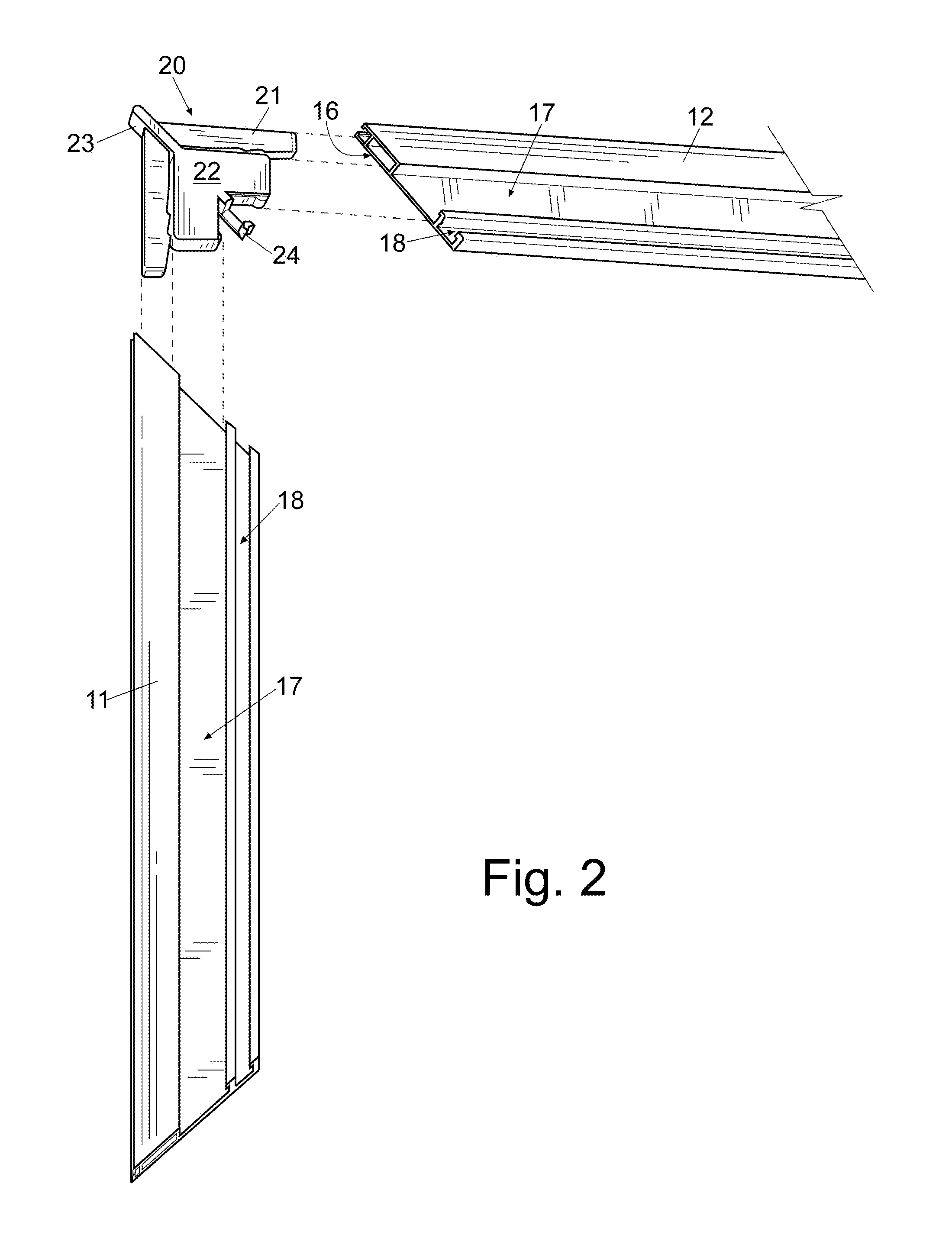

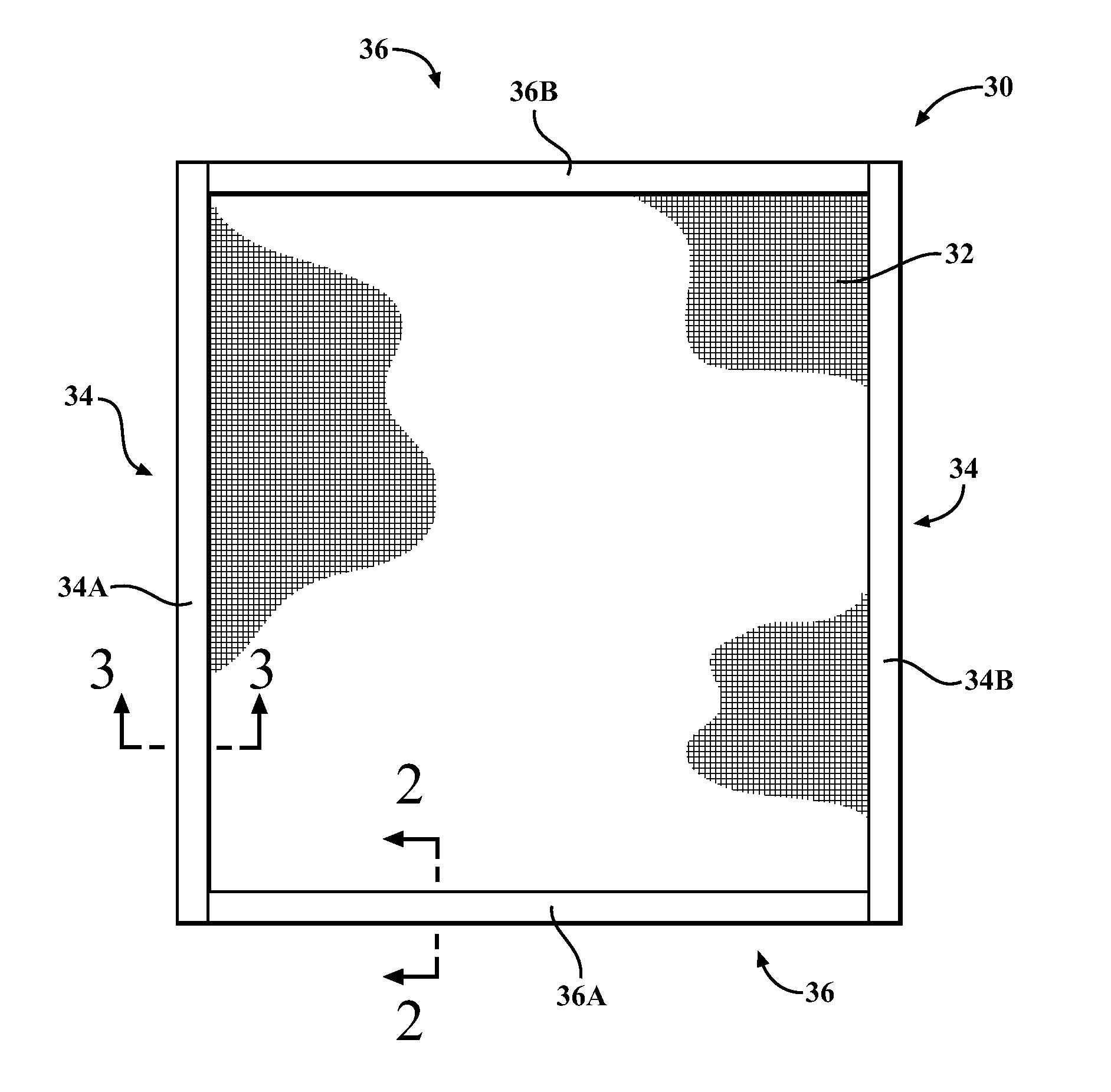

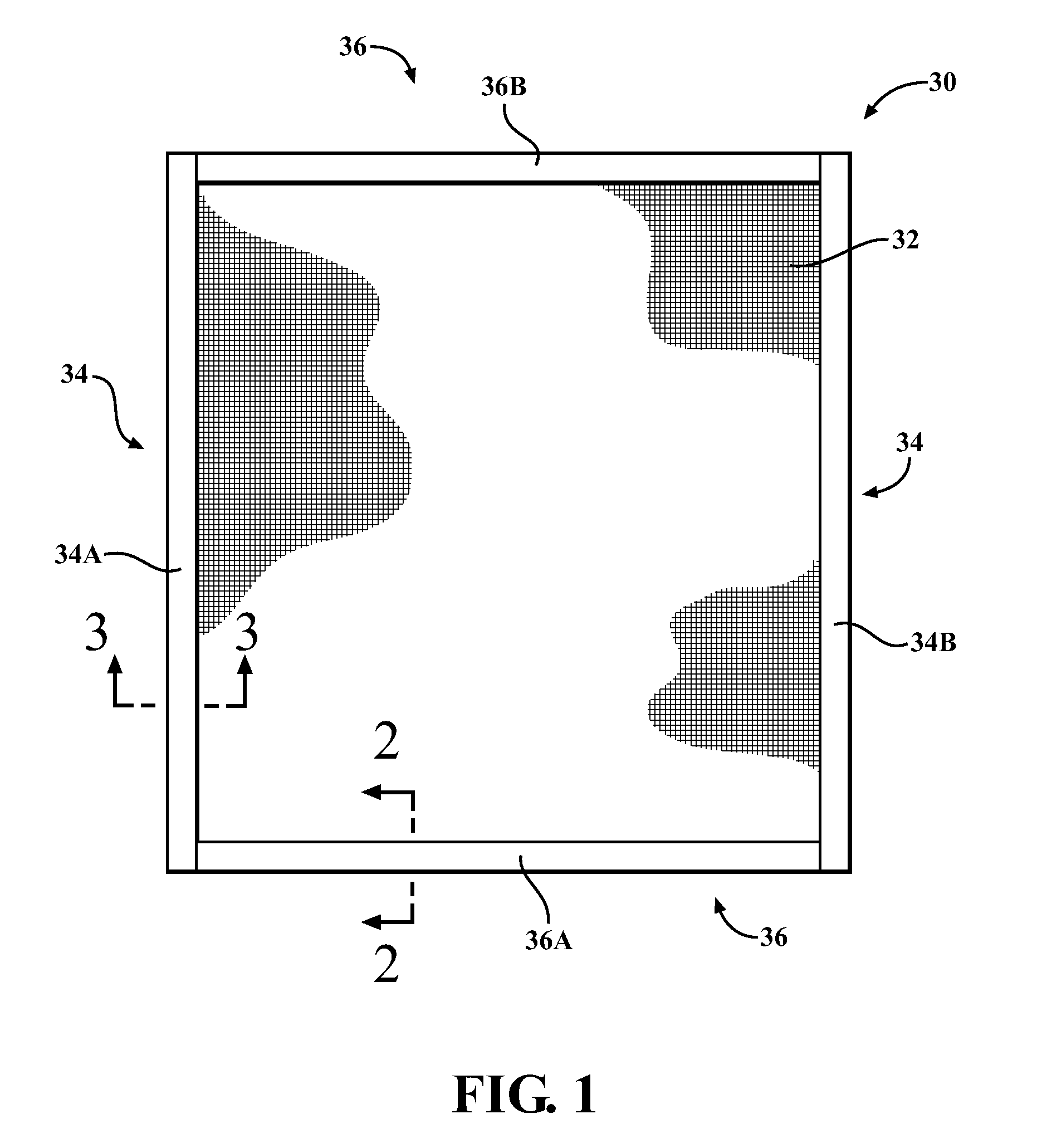

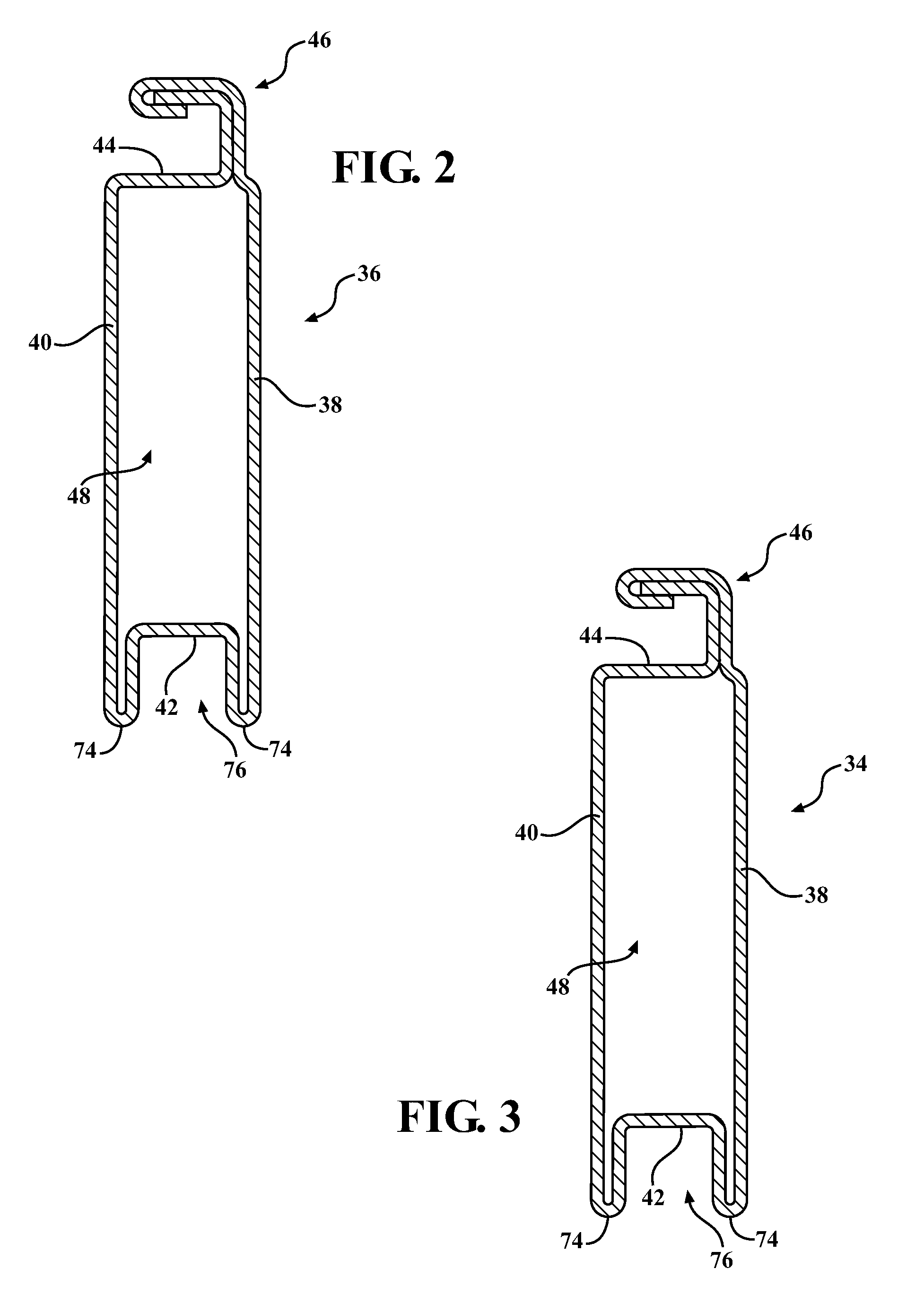

Framed window screen and connector

A framed window screen formed from four (4) rails which each include a channel, a wide groove and a narrow groove and are each cut at a forty-five degree (45°) angle at the terminal ends. A durable, sturdy corner connector joins each rail one to another, which may be molded from a durable polymeric material having an L-shaped member, a groove support and a stanchion. The groove support is V-shaped and joined to the L-shaped member by a rib. Each end of the L-shaped member of the connector is inserted into adjacent rail channels with the groove support positioned in the wide grooves of the adjacent rails. Once the screen frame is assembled using the connectors, a suitably cut screen wire can be placed over the frame with the edges proximate the narrow groove whereby a rubber seal is inserted to maintain the screen in the narrow groove by friction.

Owner:LAWRENCE BARRY G

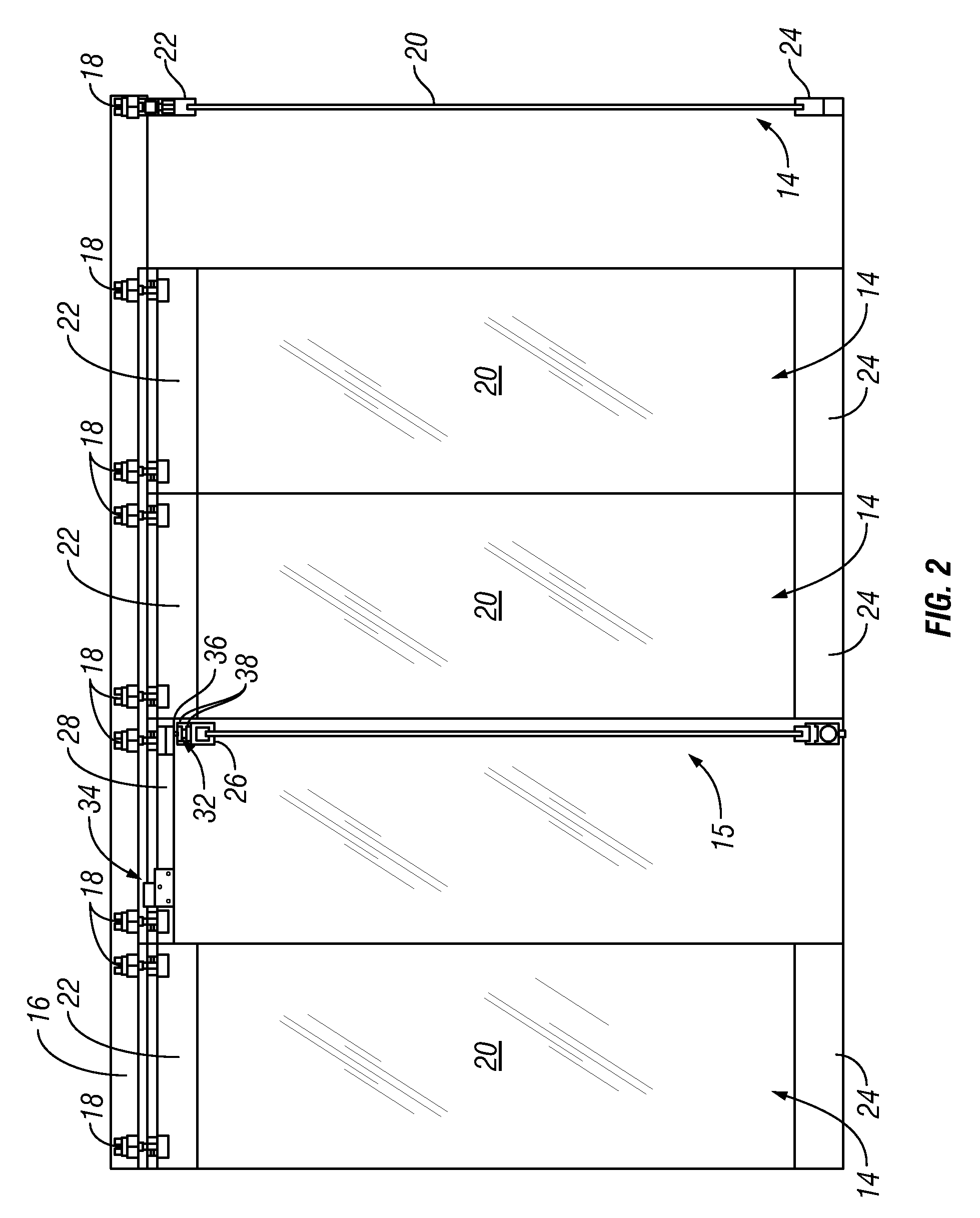

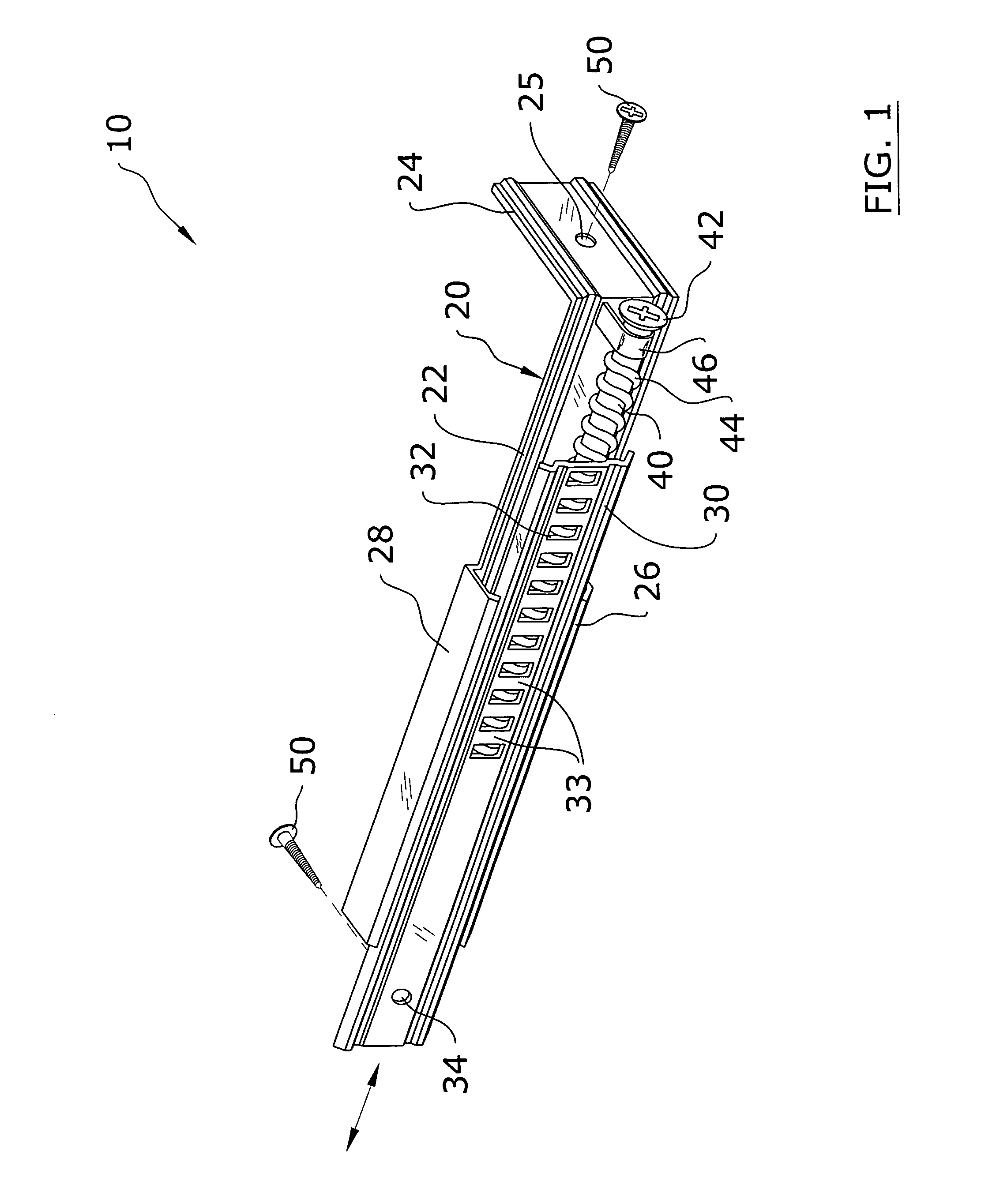

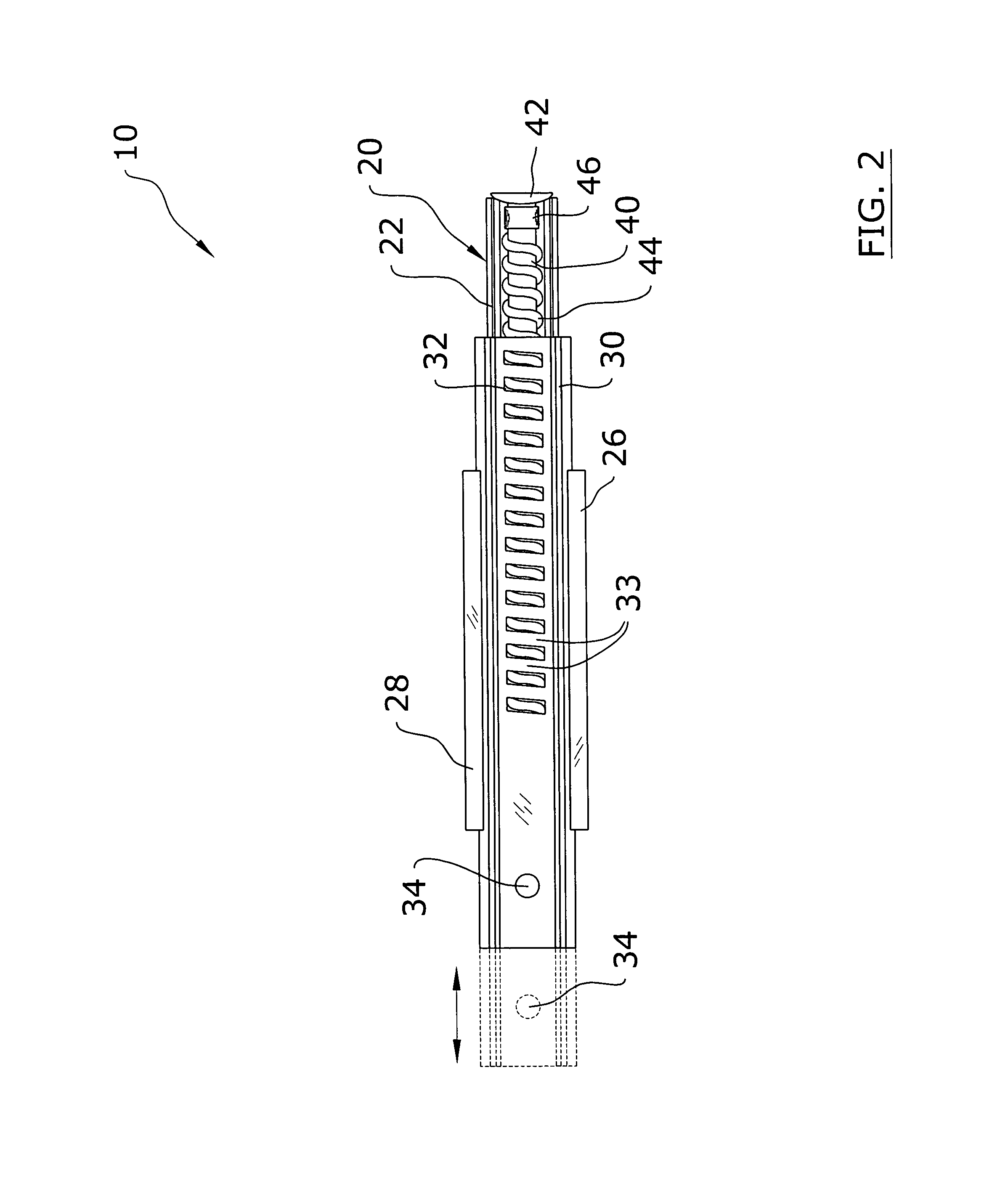

Door rail system

InactiveUS6912818B2Easy to disassembleConvenient to accommodateRailway roofsCorner/edge jointsFlat glassEngineering

A rail system for holding a panel, such as a plate glass pane, in a door and / or wall partition. The rail system includes a housing and a clamp member having a wedging geometry so that when the clamp member is actuated with respect to the housing in a first direction, at least a portion of the clamp member will move in a clamping direction, which is different than the first direction to clamp the panel.

Owner:C R LAURENCE

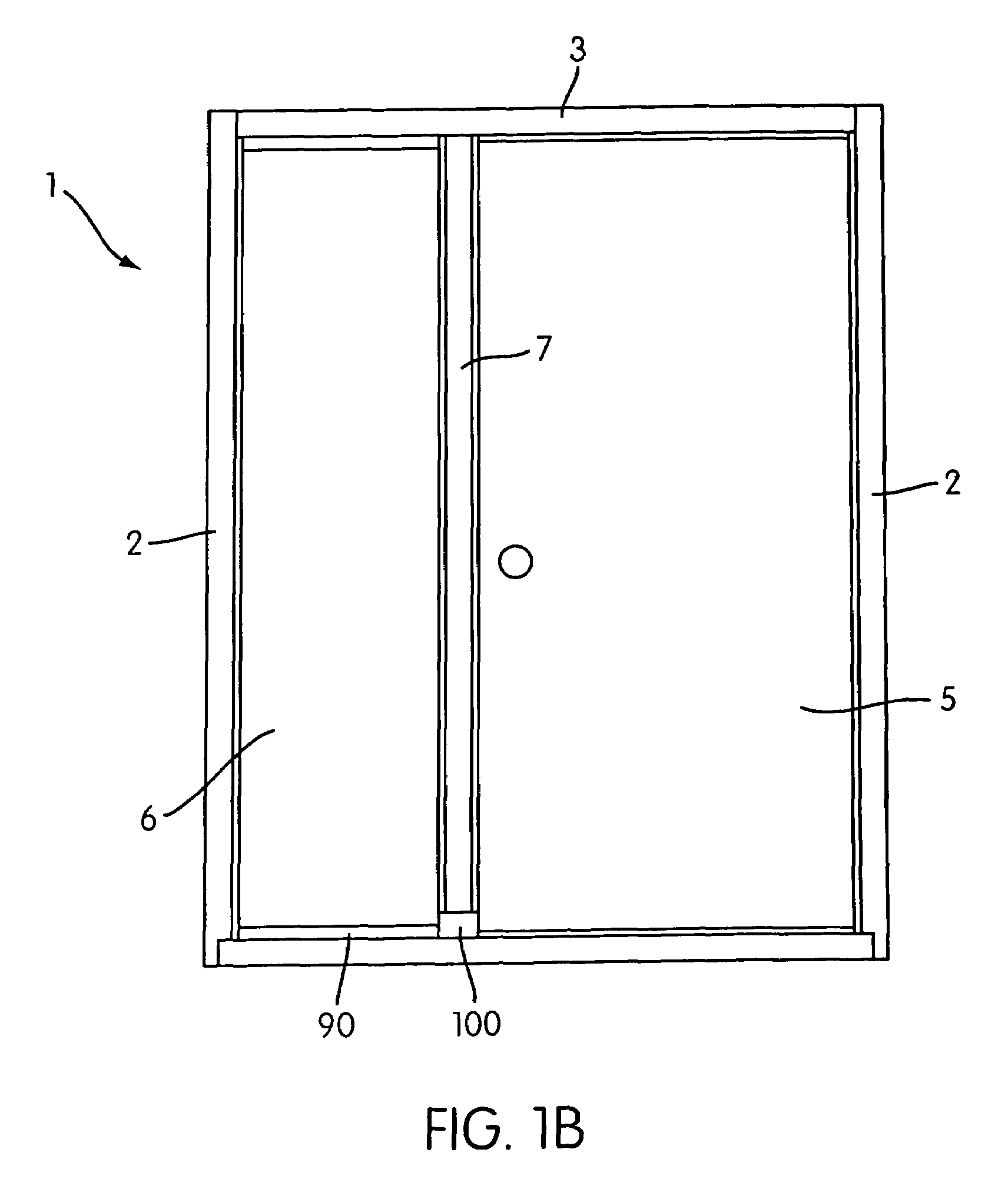

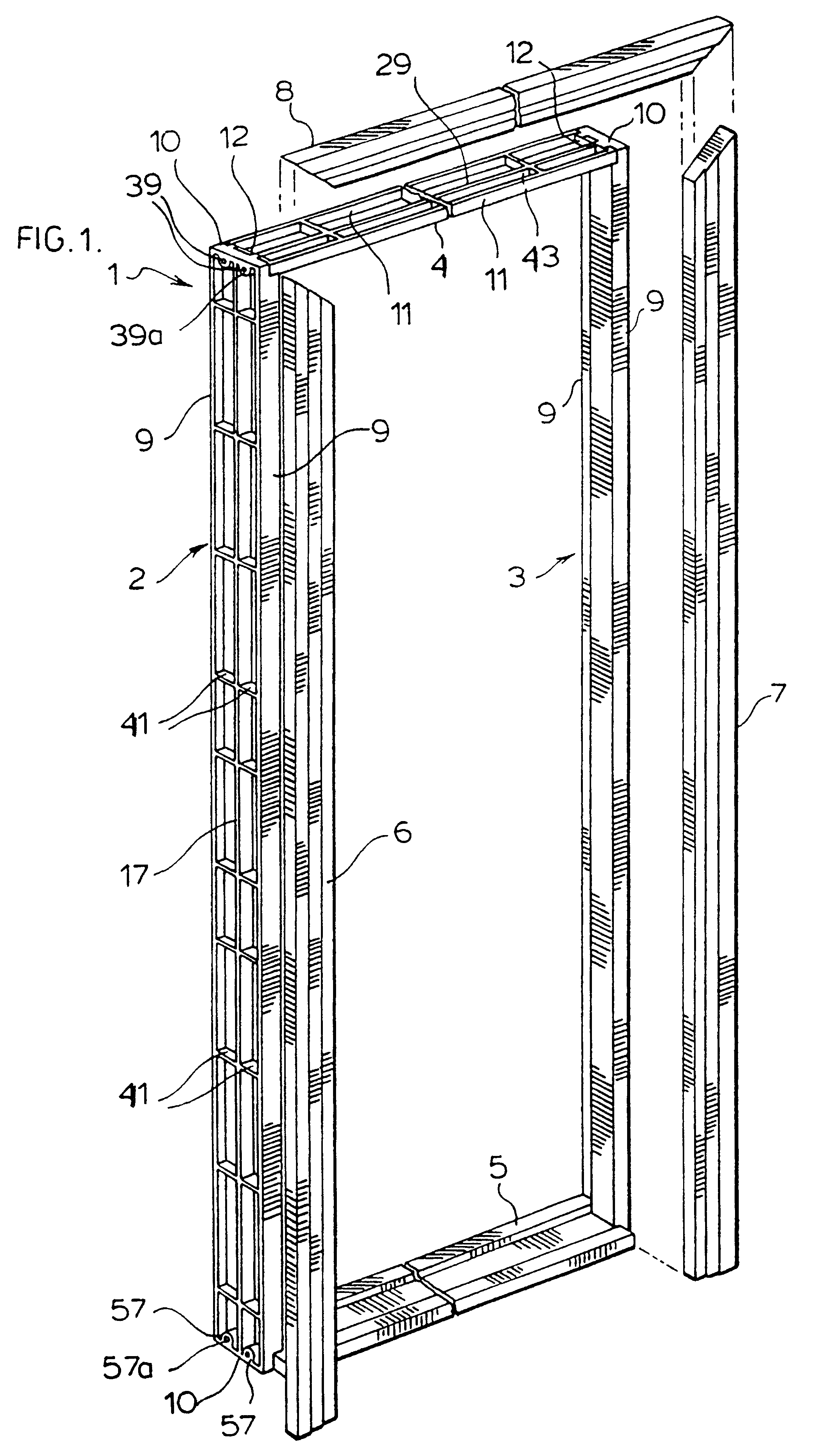

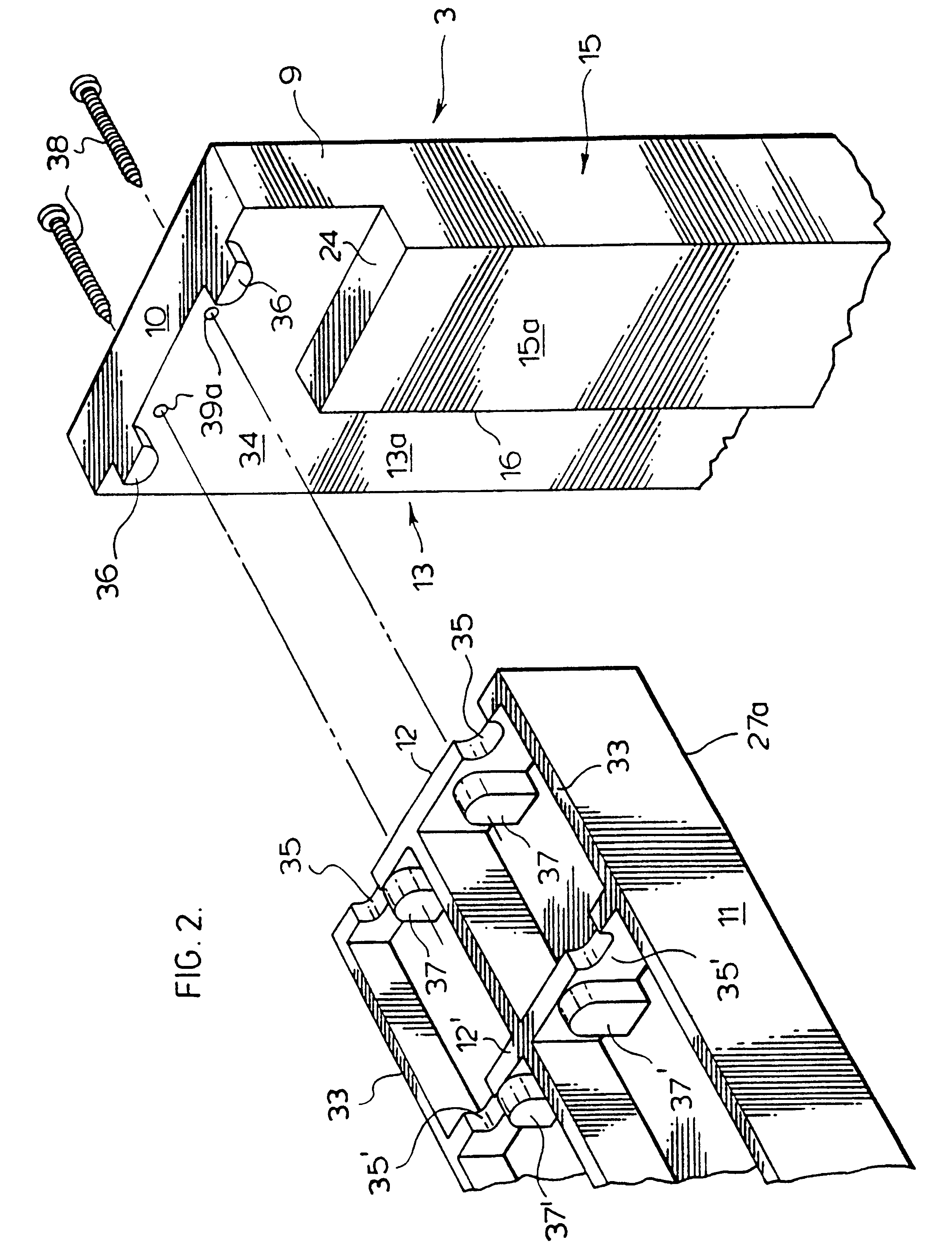

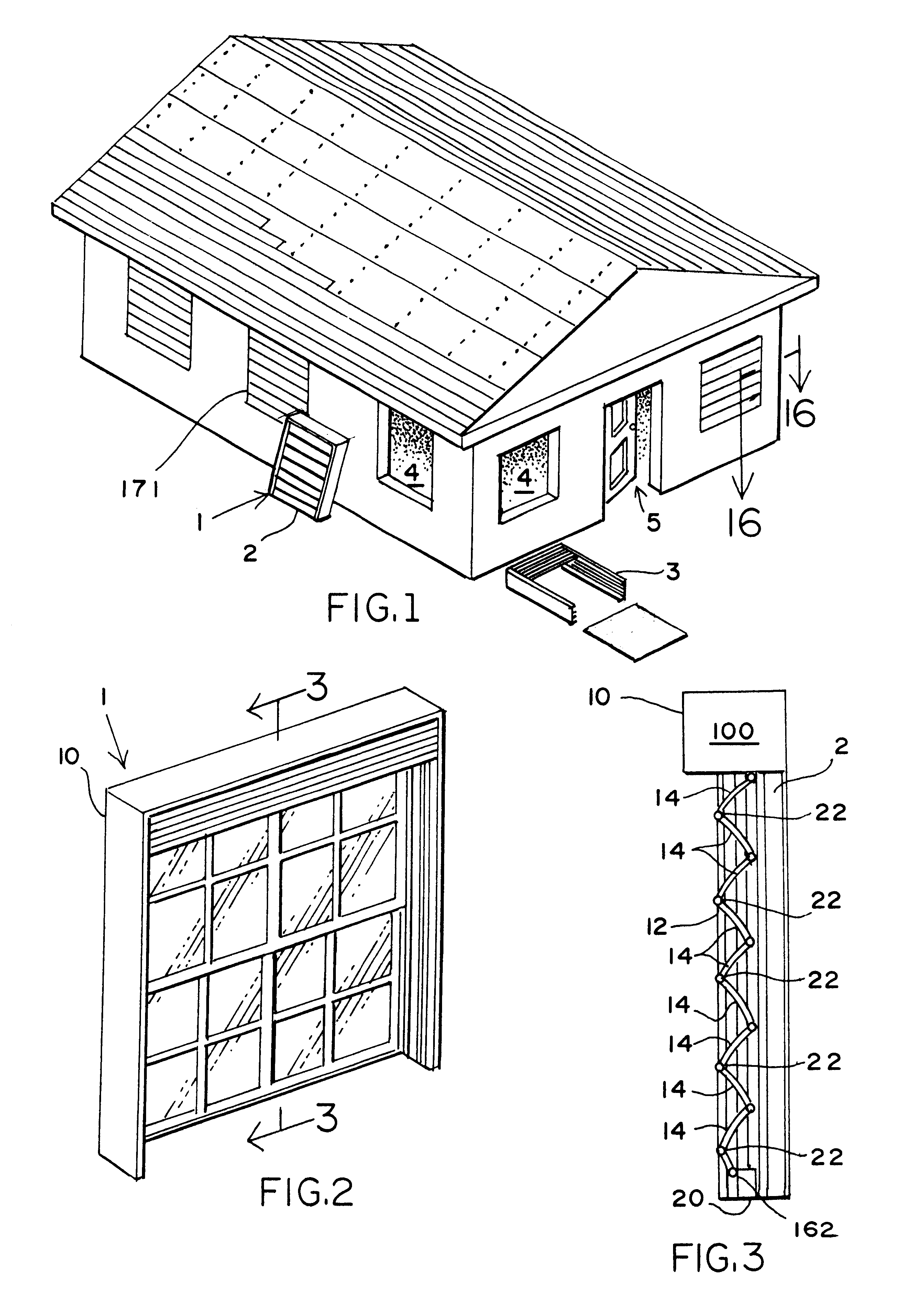

Composite door frames

InactiveUS6412227B1Quickly and easily and accurately assembledMinimal materialCorner/edge jointsWindow/door framesCompression moldingEngineering

A frame assembly (1) for mounting doors and the like comprising a pair of jambs (2, 3) and a header (4) for connecting said jambs, and, where required, a sill, each said jambs and header and sill (5) where required being a compression molding of filler, waste, or recycled particulate material bound together by a thermoplastic binder, each said jambs (2, 3) and header (4) presenting when assembled an inwardly facing planar surface of a width to receive a door to be mounted in said frame assembly and an inwardly projecting door stop shoulder formation projecting inwardly of said planar surface.

Owner:ROYAL GRP TECH LTD

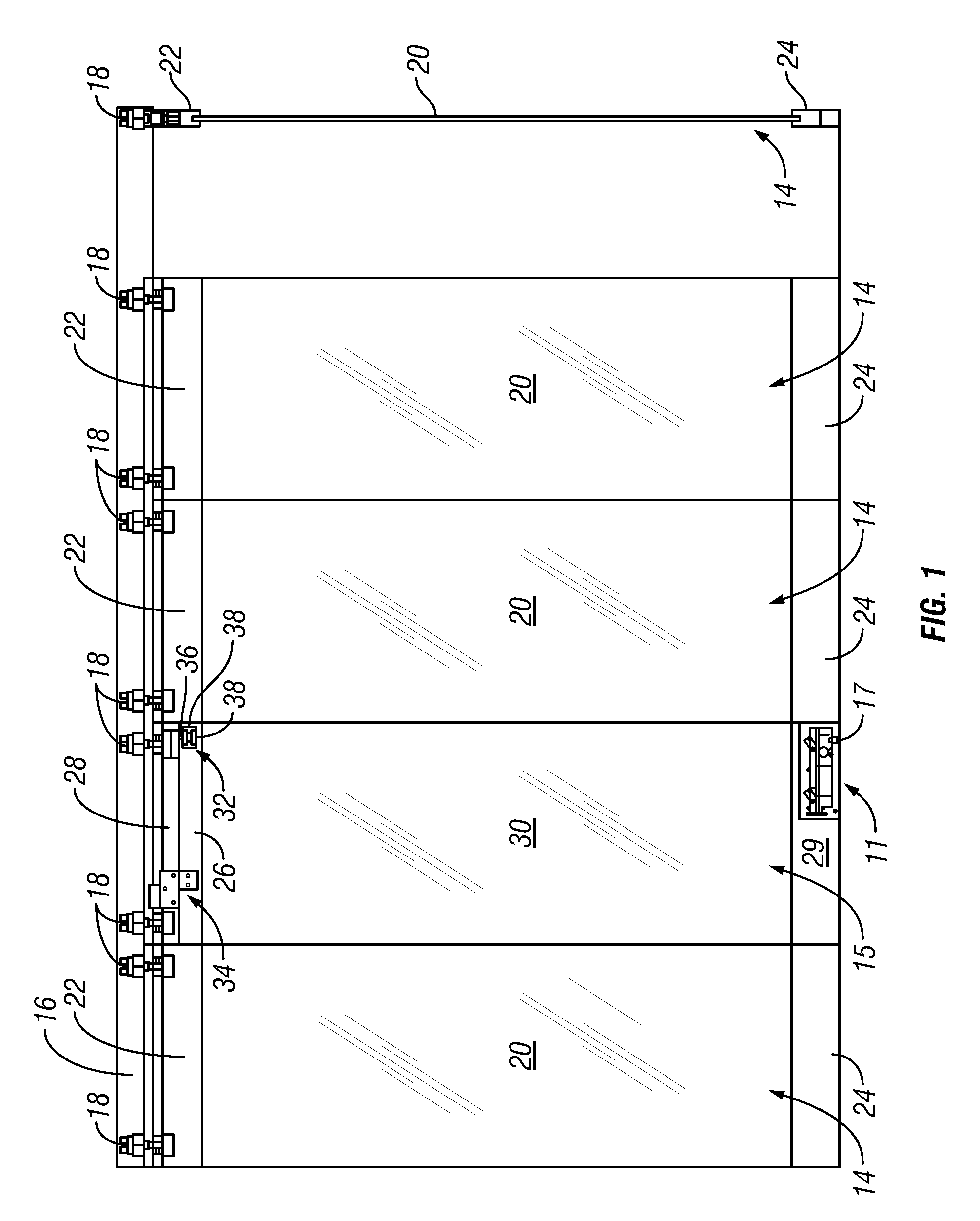

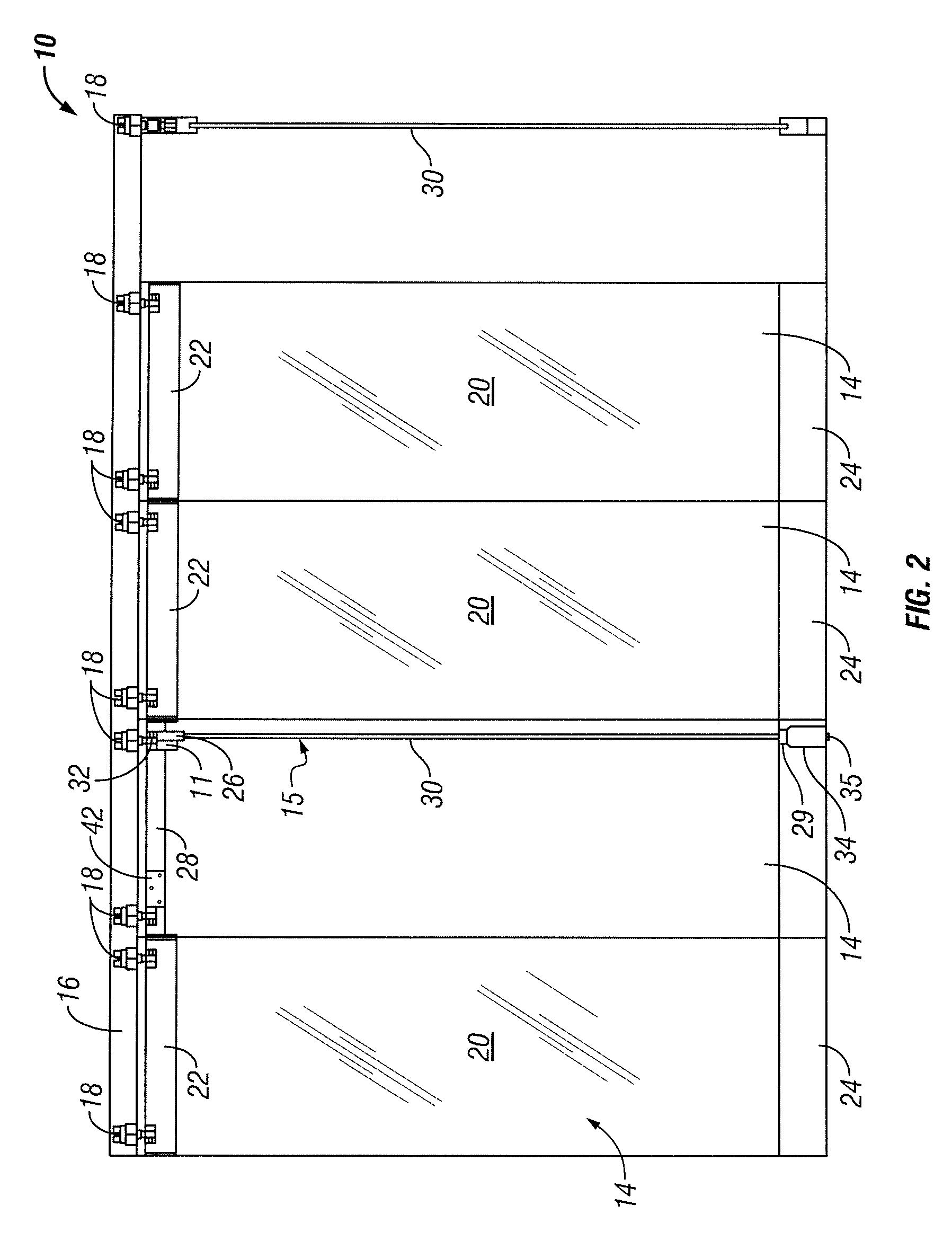

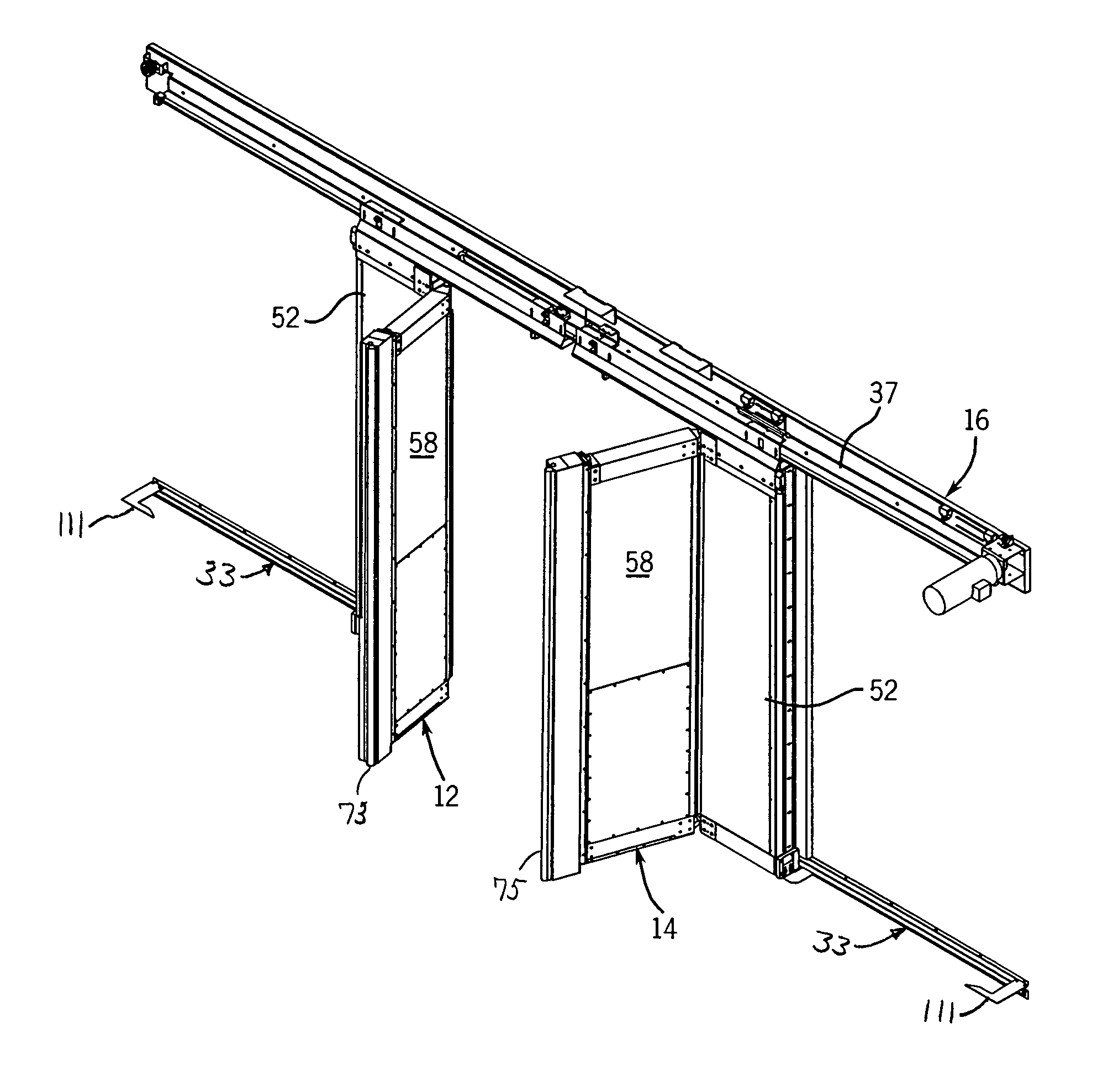

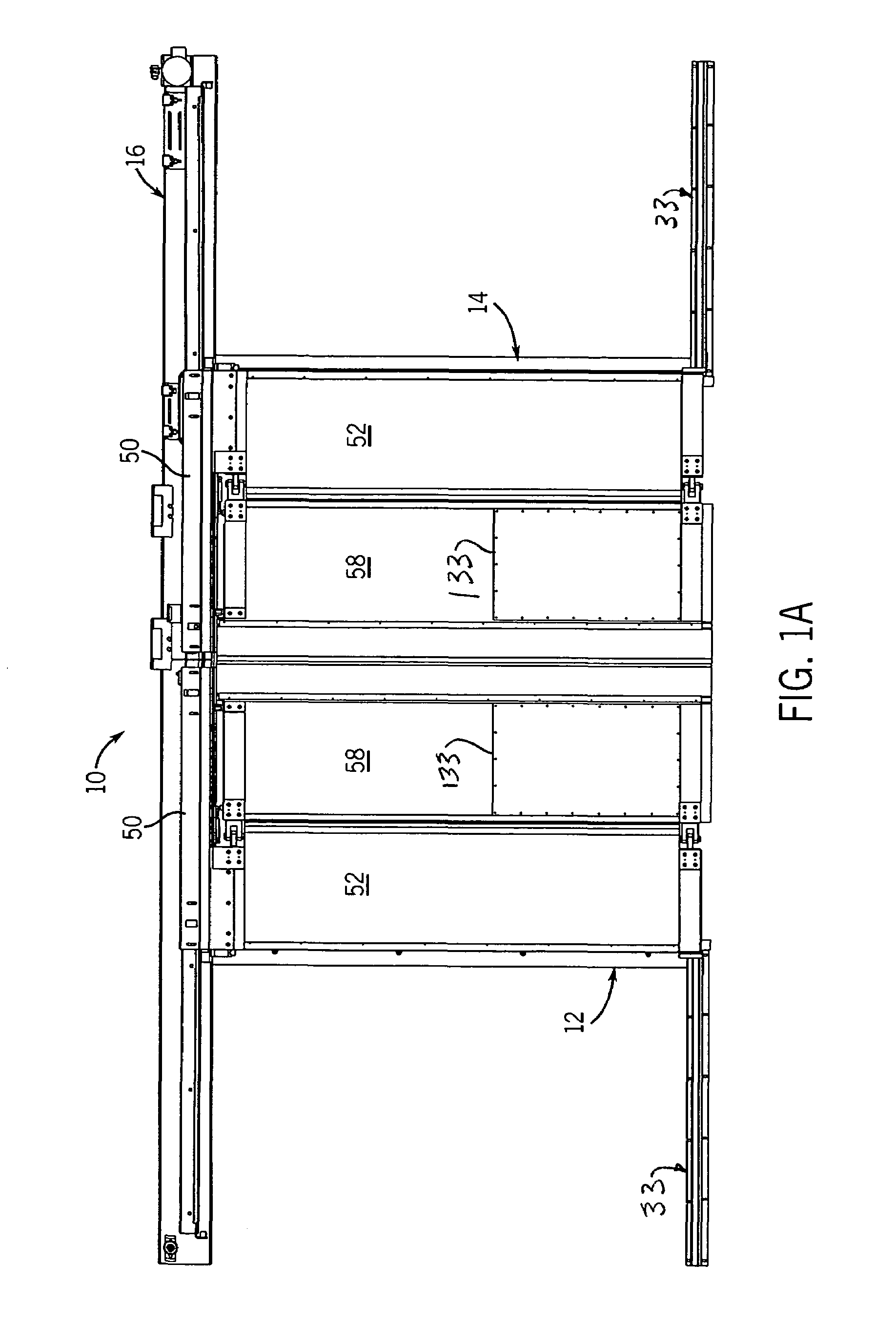

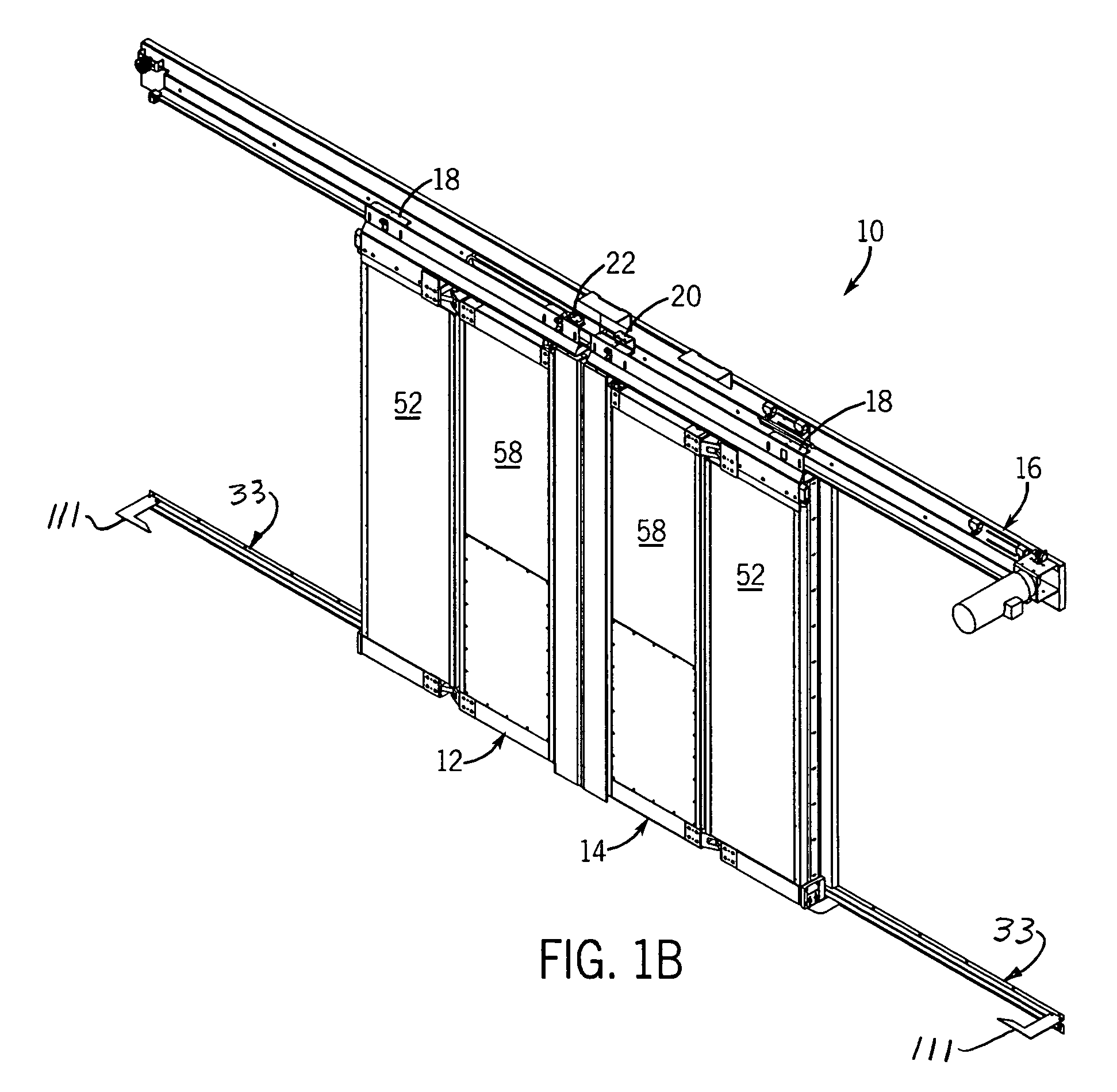

Wall panel system including a retractable floor anchor and method

A wall panel system including a retractable floor anchor for converting a wall panel assembly between a sliding configuration and a pivoting configuration. The wall panel system includes a sliding wall panel assembly and a pivoting wall panel assembly that may be configured to slide or pivot. A retractable floor anchor configured to be included in the pivoting wall panel assembly includes retractable spindle that is coupled to a base member by a linear actuator. The spindle is rotatably coupled to a door closer included in the retractable floor anchor.

Owner:C R LAURENCE

Pet door

An apparatus comprising a first door panel; a second door panel coupled to the first door panel such that the first door panel and the second door panel form a hollow portion of a door panel assembly; and an insulating material placed within the hollow portion of the door panel assembly. An apparatus comprising a door panel assembly including a front side, a back side, a top side, a bottom side, a left side and a right side; a door frame surrounding the door panel assembly at the bottom side, the left side and the right side of the door panel, the door frame including a bottom portion, a left portion and a right portion; means for magnetically coupling the left side of the door panel assembly to the left portion of the door frame; means for magnetically coupling the right side of the door panel assembly to the right portion of the door frame; means for magnetically coupling the bottom side of the door panel assembly to the bottom portion of the door frame.

Owner:PATIO PACIFIC

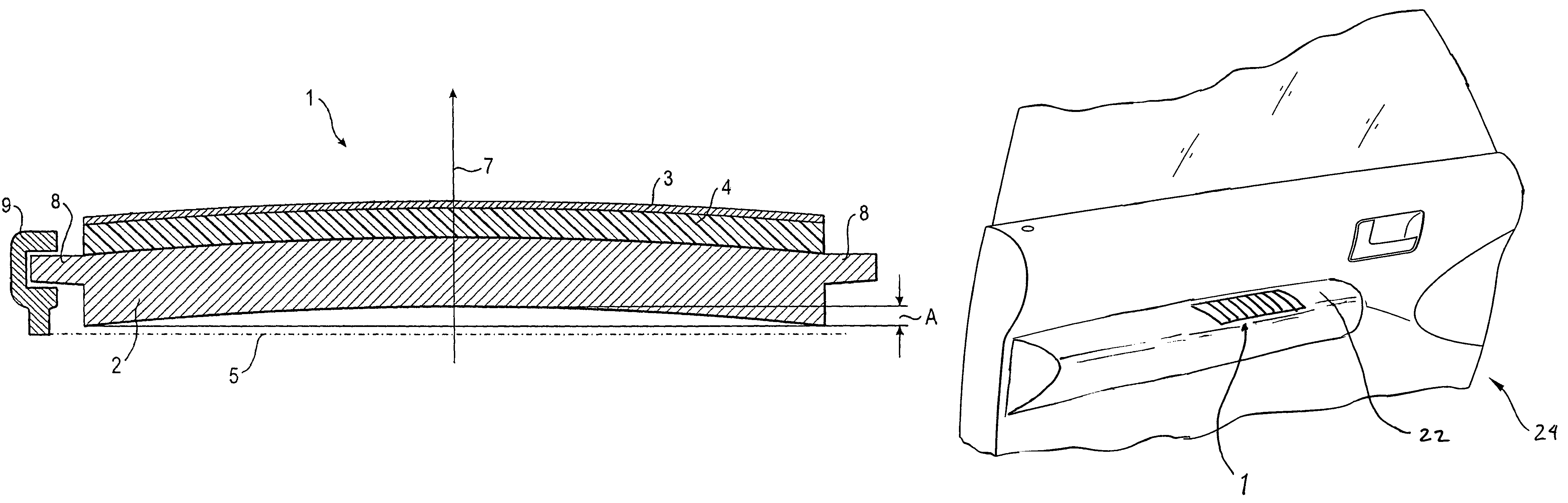

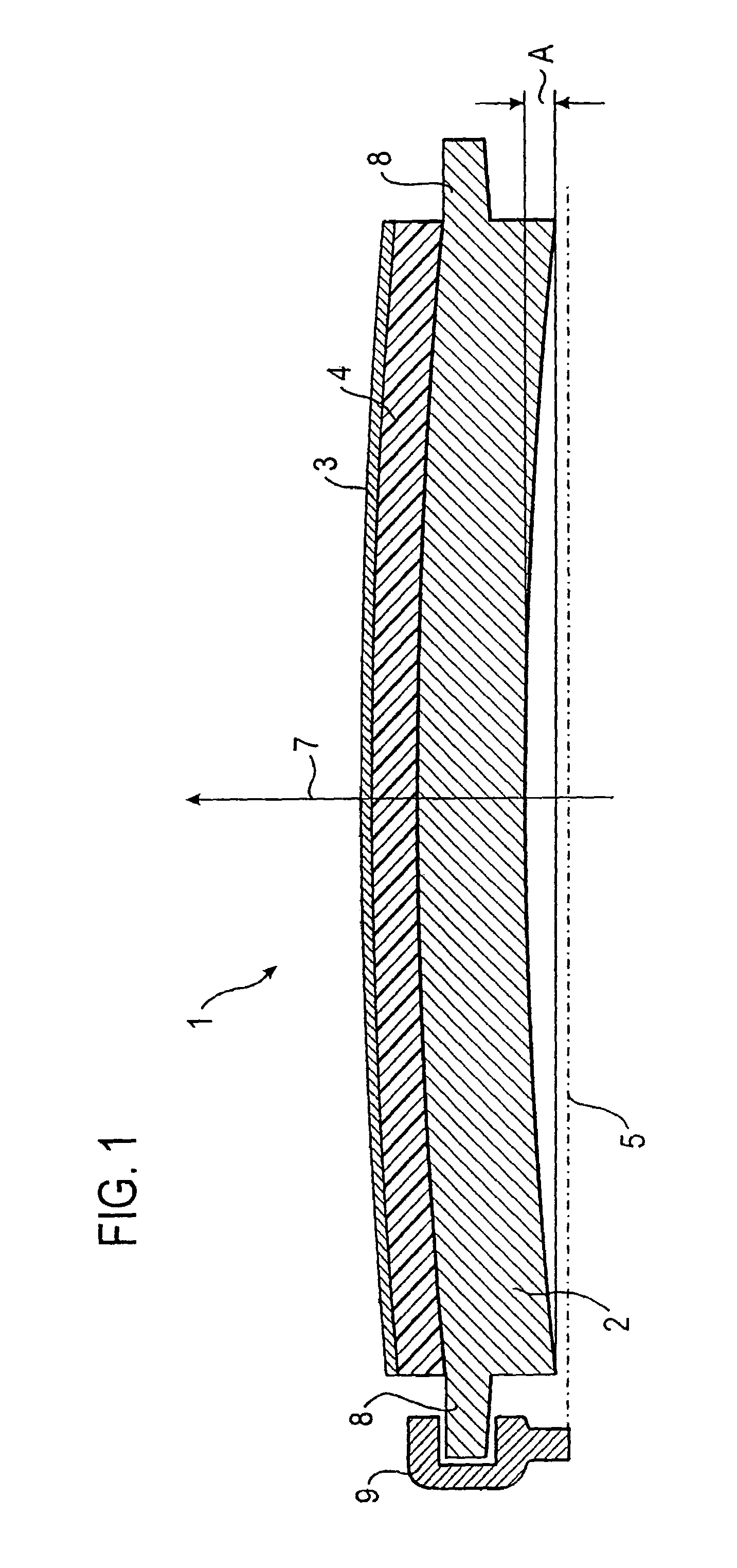

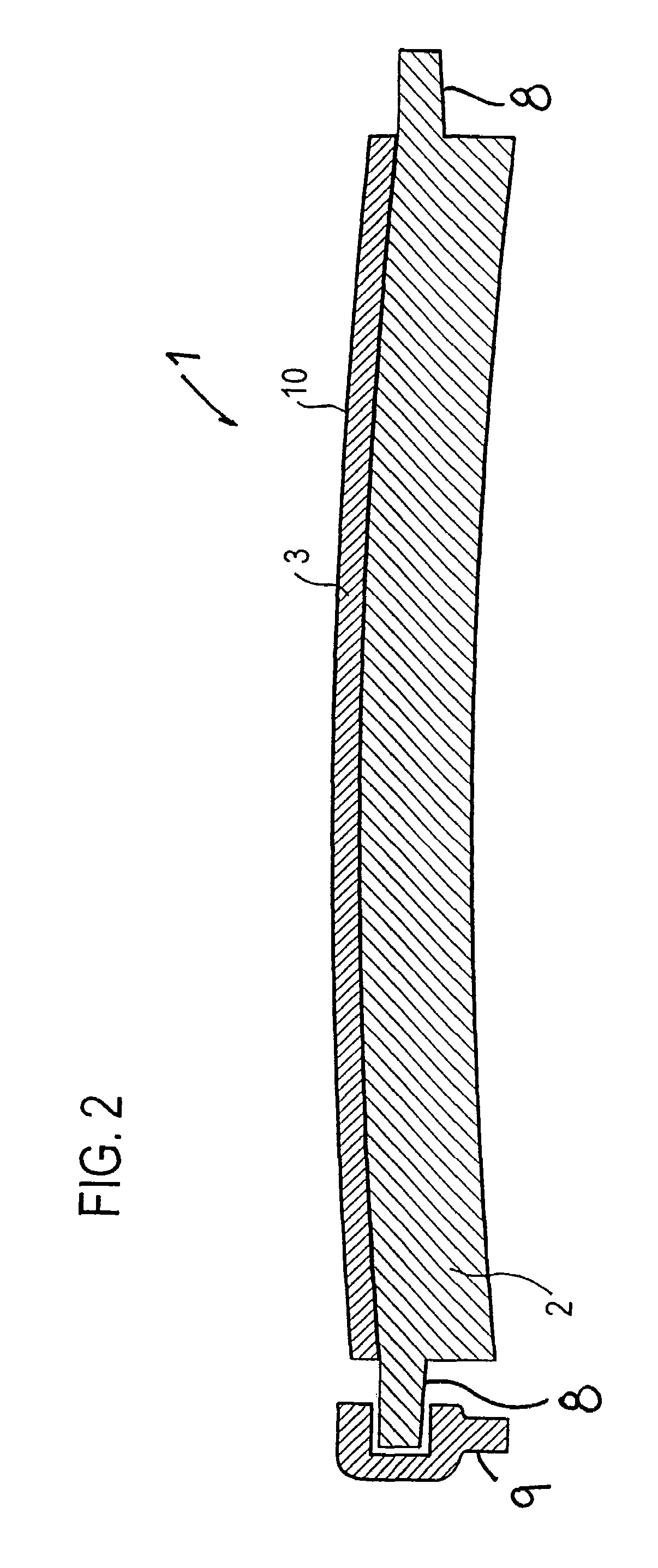

Roller blind with curved surface

A roller blind for opening and closing the opening of a compartment, a storage box, a control console or similar enclosure, in particular for use in motor vehicles, is disclosed. At least one support element and at least one elastic layer disposed on the support element are included. Each support element has a curvature in its longitudinal direction with a deflection in a direction perpendicular to the plane of the opening to be closed by the roller blind. A method for the production of a roller blind is also disclosed.

Owner:LISA DRAXLMAIER GMBH

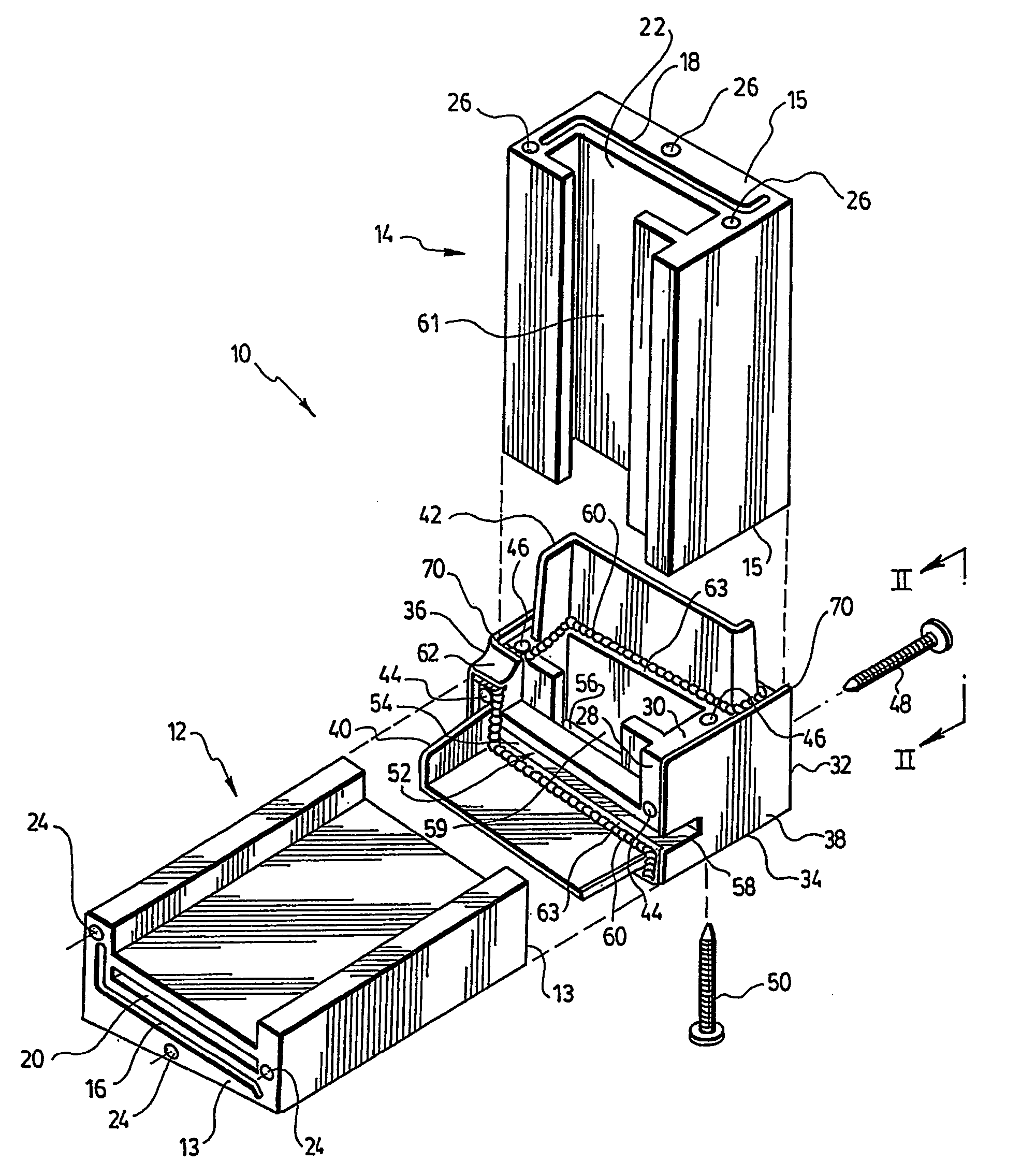

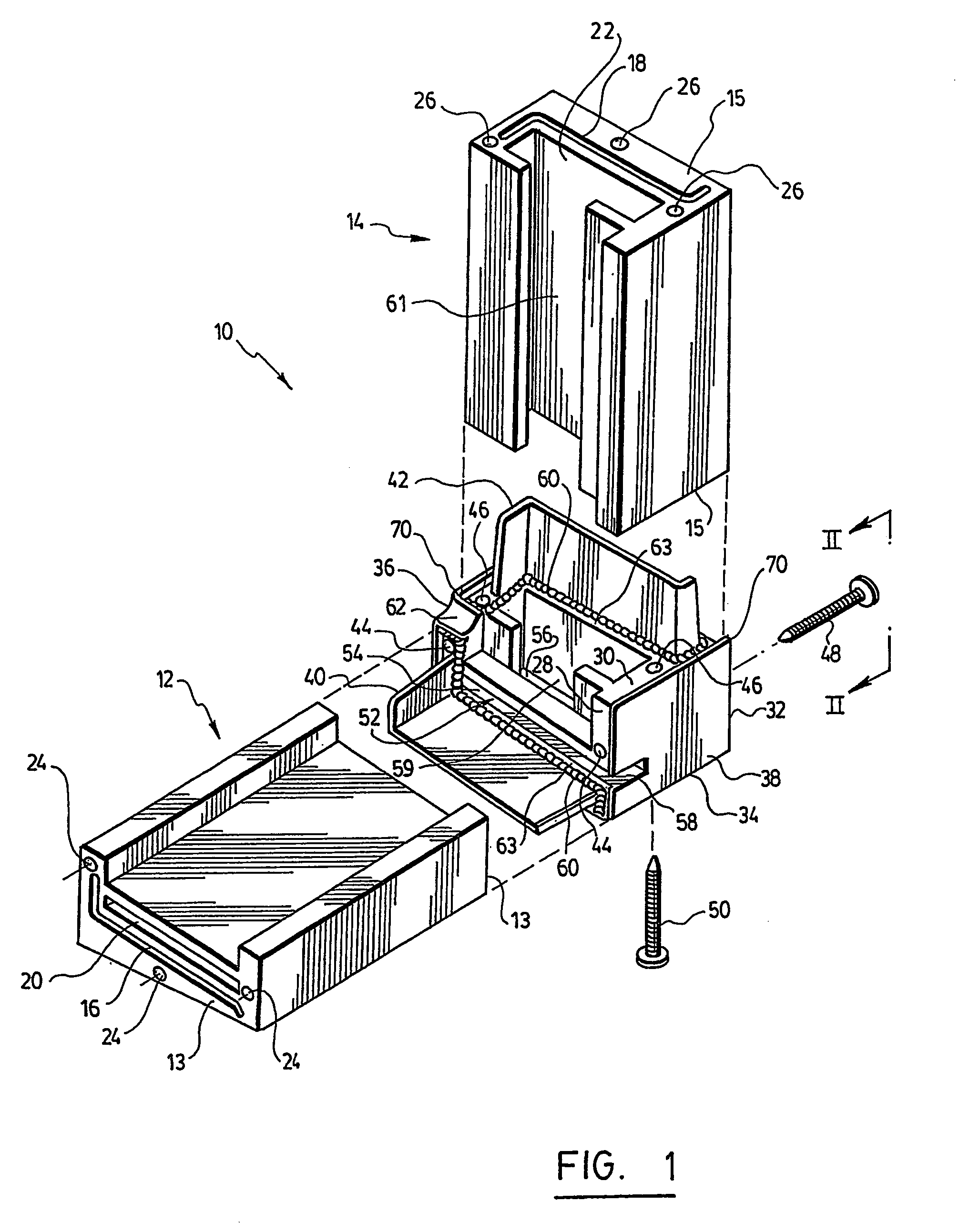

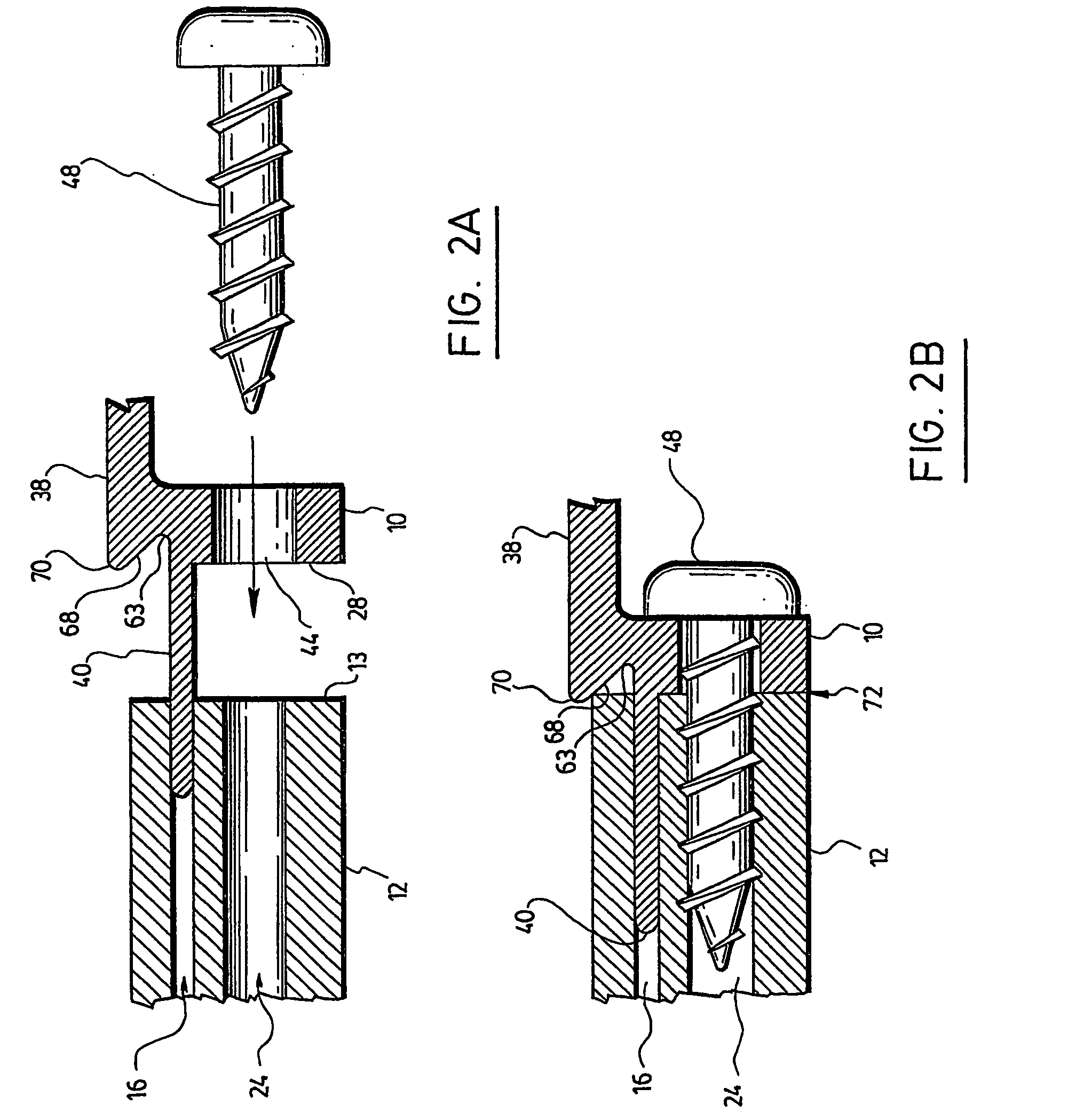

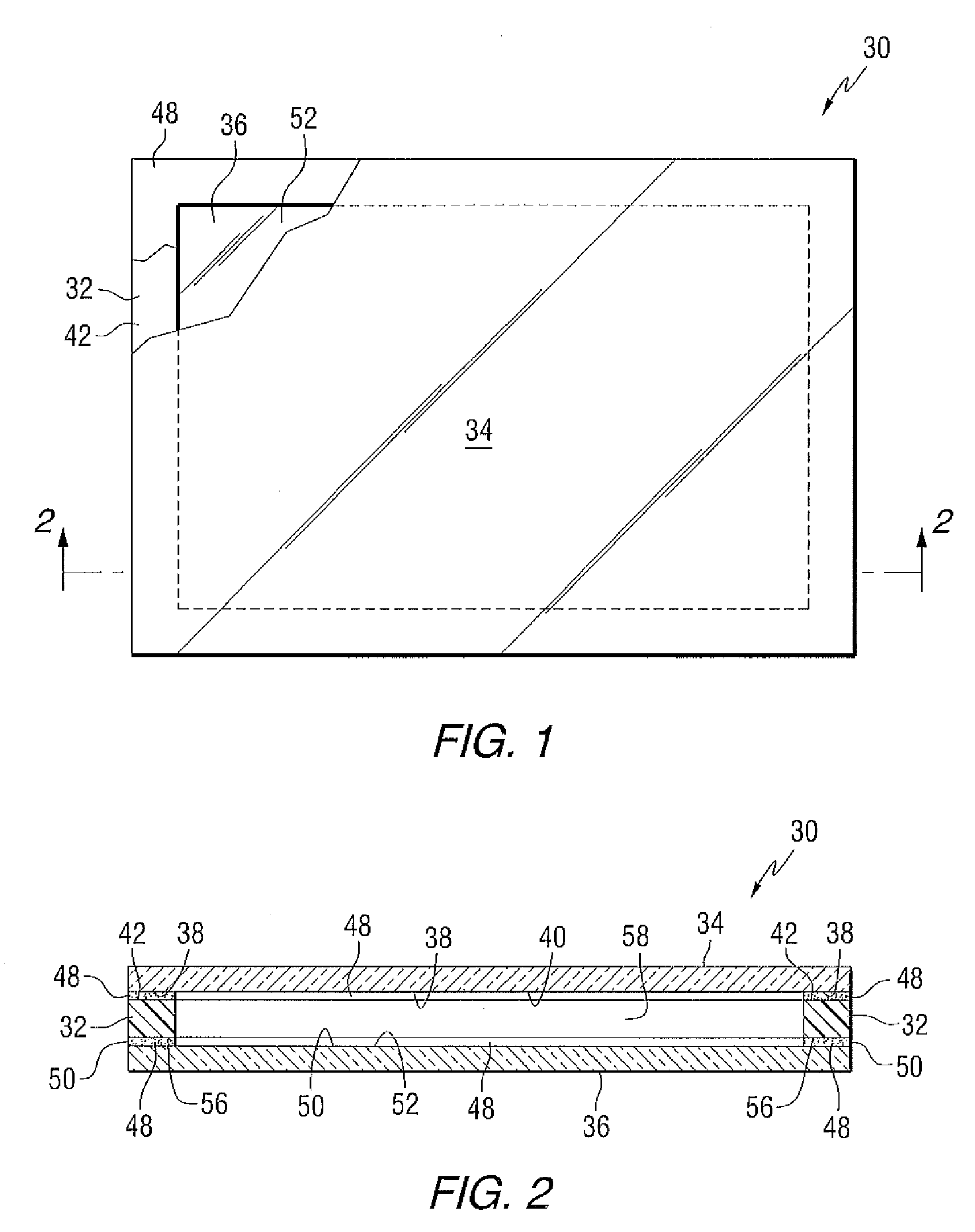

Corner key for connecting profiles together and frame work assembly

InactiveUS20050115178A1The method is simple and reliableMinimal effortBuilding roofsCorner/edge jointsCouplingFrame work

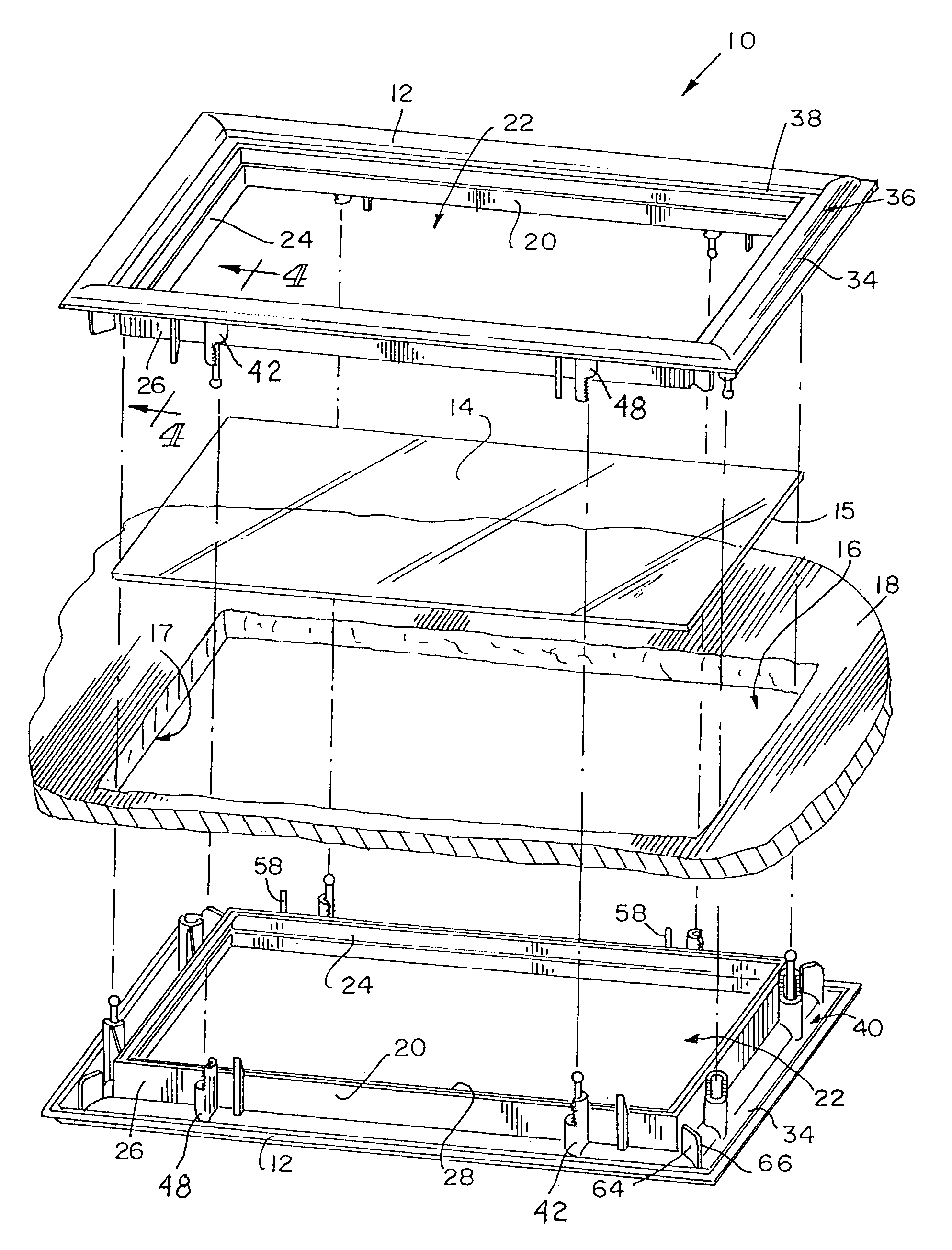

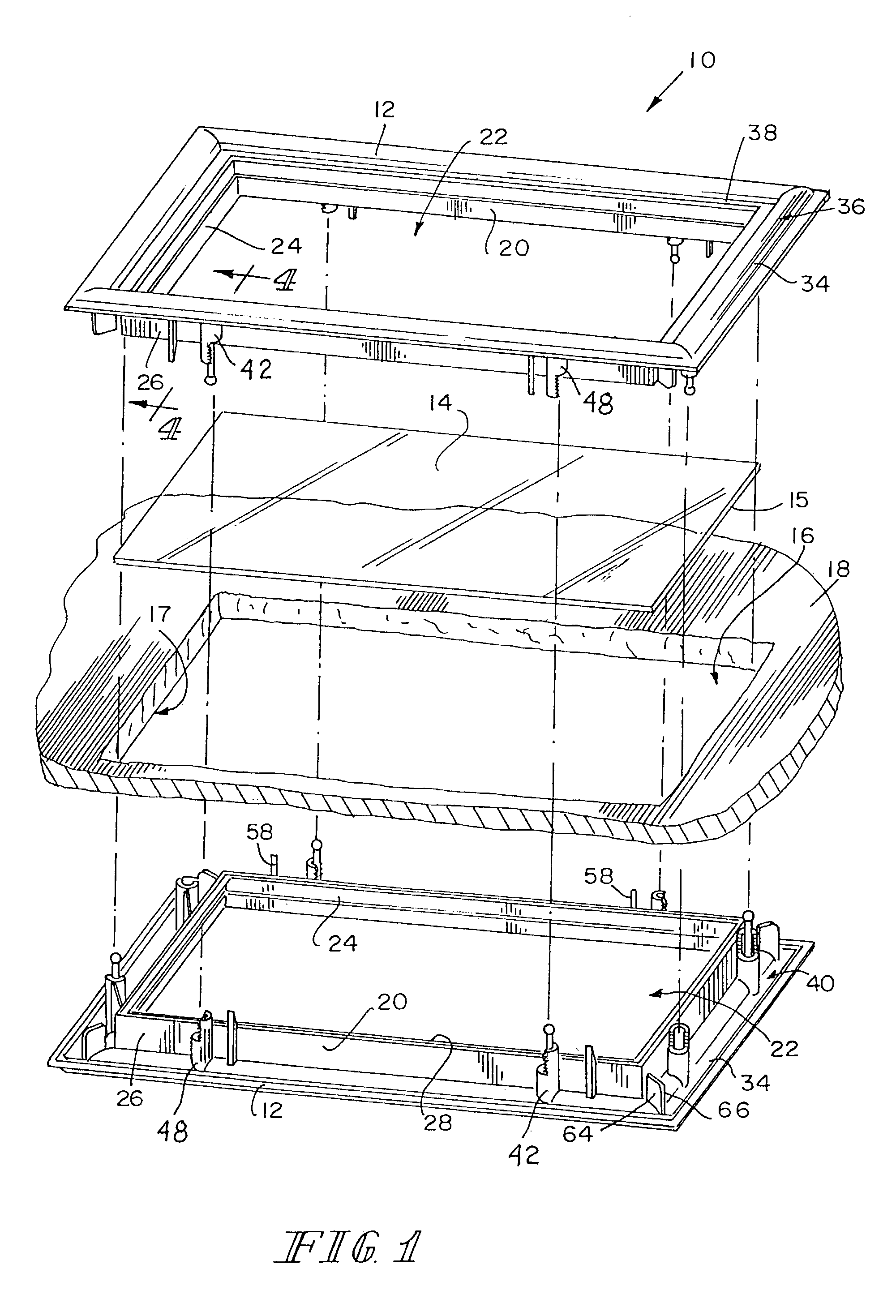

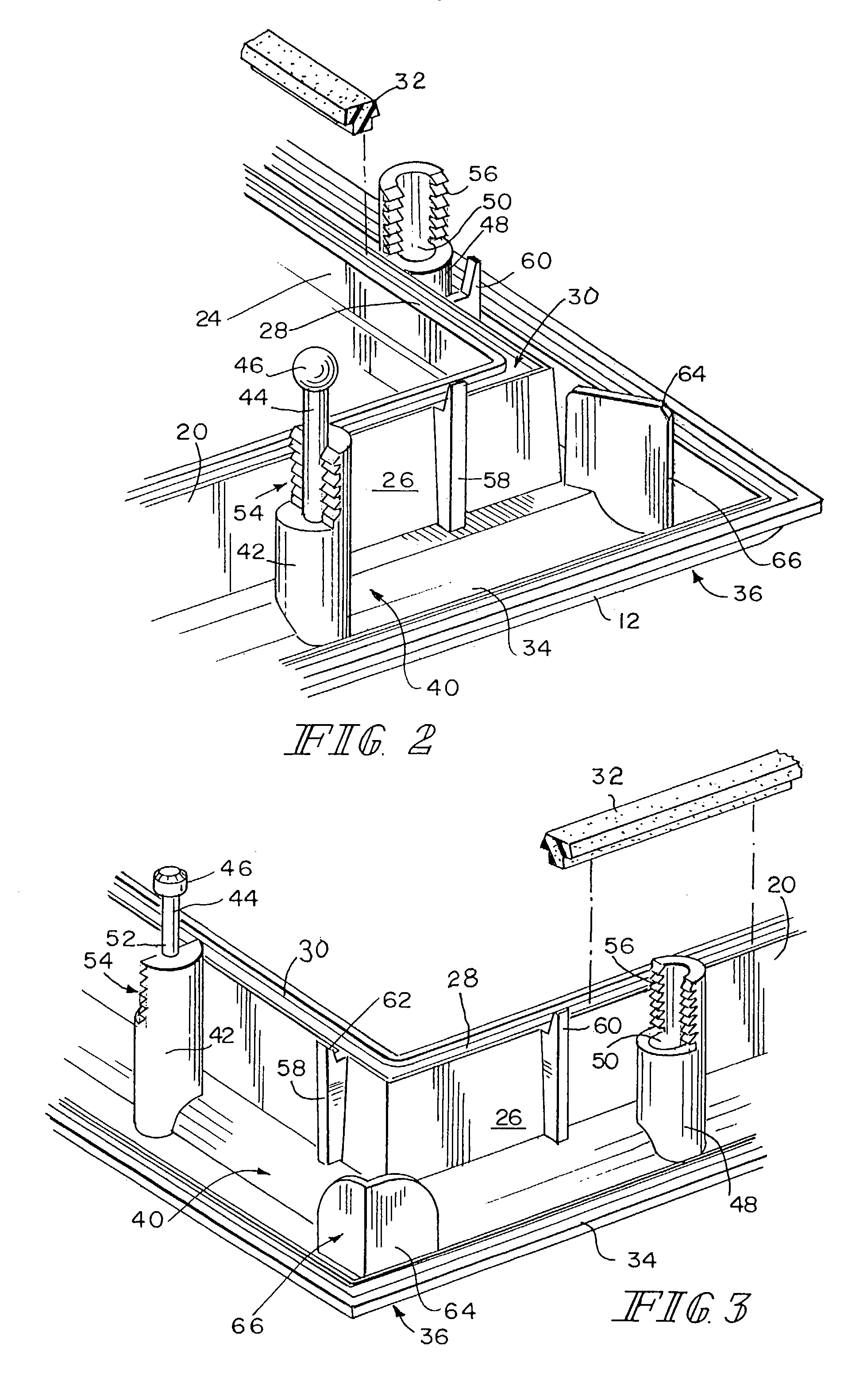

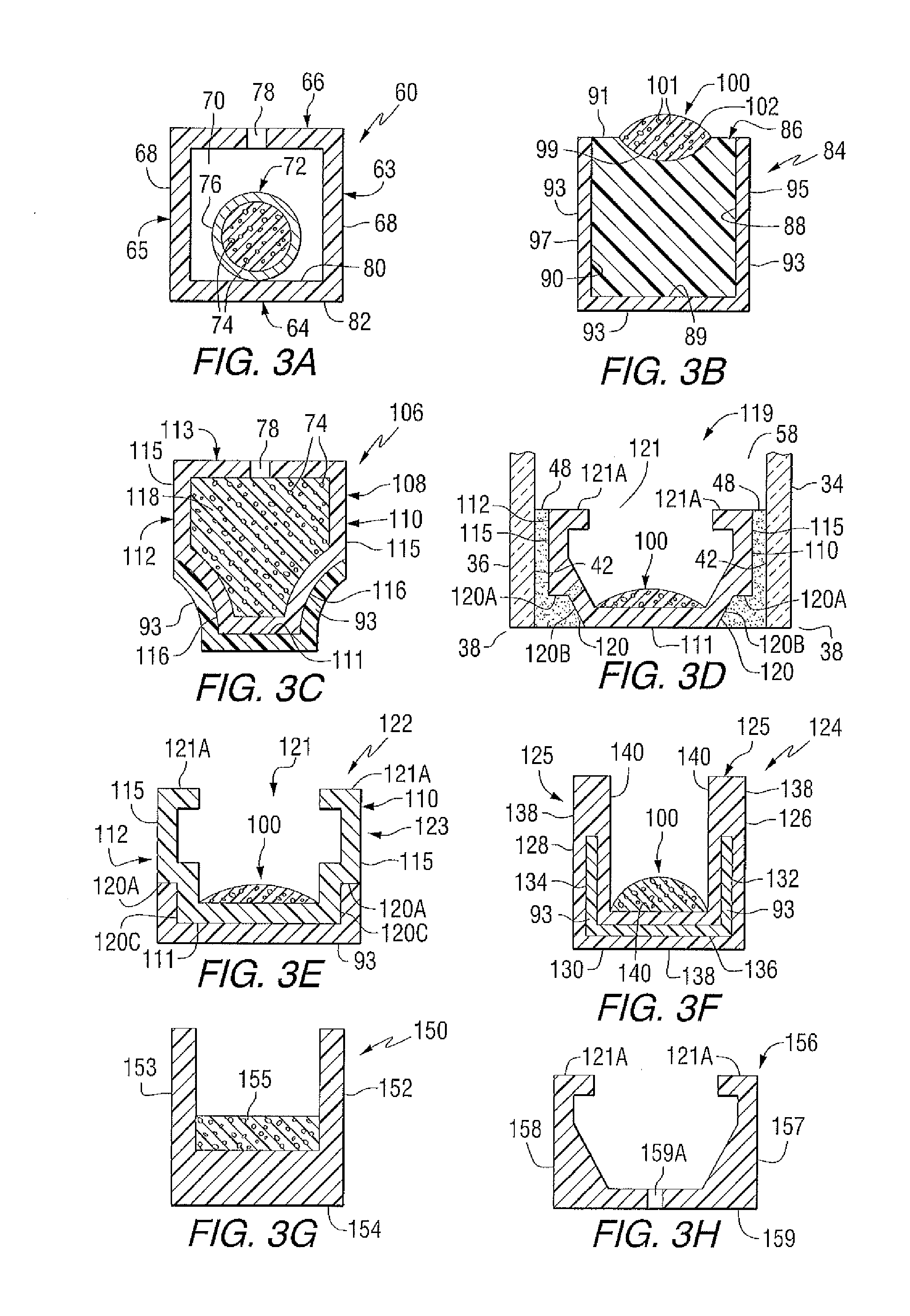

A corner key (10) for connecting profiles (12, 14) together and a frame work assembly formed of such corner keys (10) and (profiles (12, 14). Each profile (12, 14) has an anchoring channel (16, 18), a drainage and venting passage (20, 22) and a securing bore (24, 26). The corner key (10) has two adjacent inner corner faces (28, 30), two adjacent outer corner faces (32, 34), and opposite inner and outer side corner faces (36, 38). Tabs (40, 42) on the inner corner faces (28, 30) guide the coupling of the profiles (12, 14). Fasteners (48, 50) are inserted through the outer corner faces (32, 34) in corner key bores (44, 46) and in the bores (24, 26) of the profiles (12, 14). A drainage and venting passage (52) in the corner key (10) communicates with the drainage and venting passages (20, 22) of the profiles (12, 14).

Owner:FENEGLOBE SYST

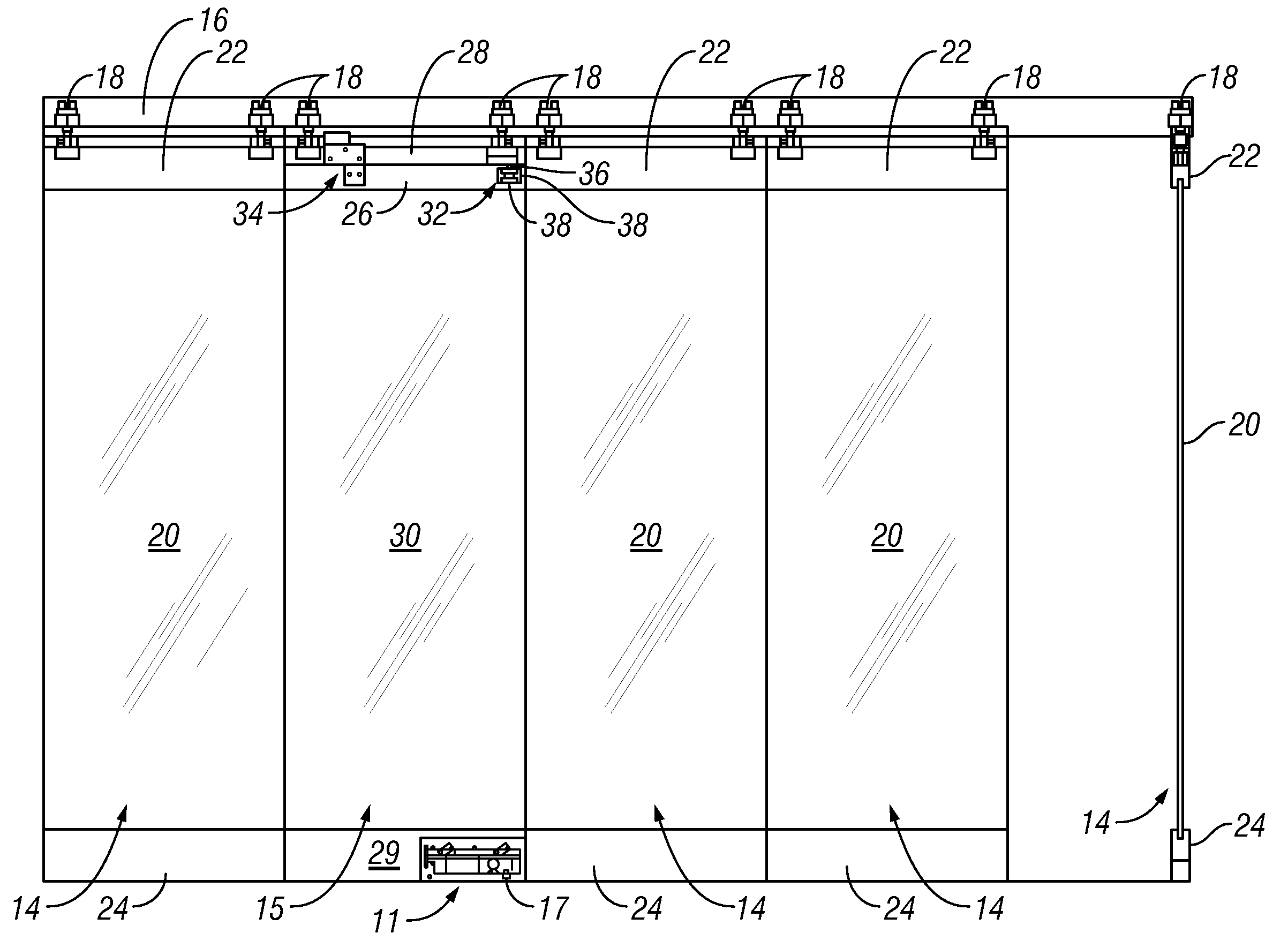

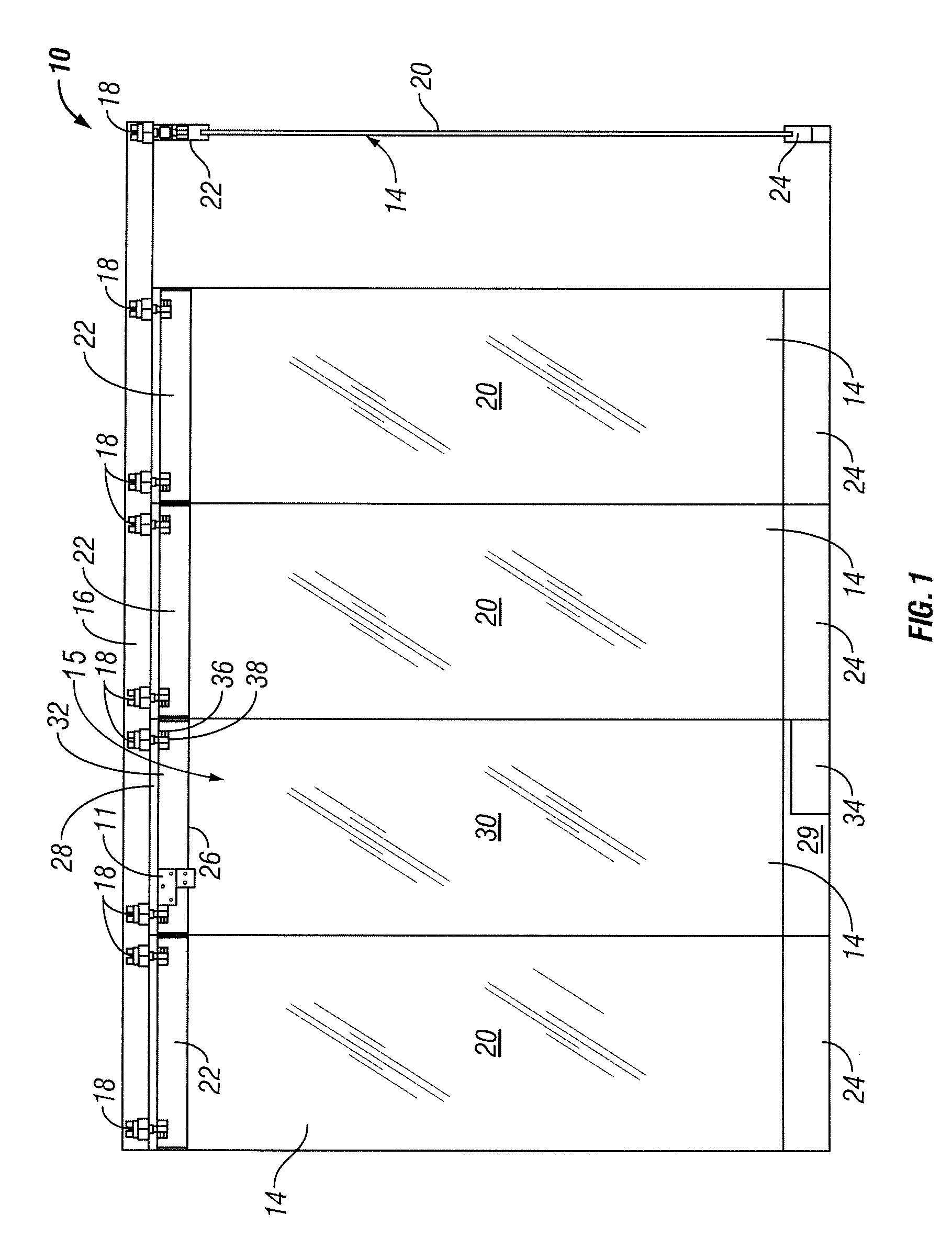

Wall panel system including a pivot lock

ActiveUS7861475B2Easy to operateReduce disadvantagesBuilding roofsDispersed particle filtrationEngineeringWing configuration

A wall panel system includes a sliding wall panel assembly that includes a pivot lock for converting the wall panel assembly between a sliding configuration and a pivoting configuration. The pivot lock includes a first lock member that is configured to selectively prevent translation of the wall panel assembly along a track and a second lock member that is configured to selectively prevent pivoting of at least a portion of the wall panel assembly relative to the track.

Owner:C R LAURENCE

Impactable door

An industrial sliding door has one or more panel assemblies, each panel assembly having a track panel secured to a header and a swinging panel hinged at the inner edge of the track panel to pivot in either direction about a vertical axis if the swinging panel is impacted by a vehicle such as a fork lift. Both panels can also pivot in at least one direction about a horizontal axis. A rail mounted stationary relative to the doorway at the lower edge of the door holds the lower edge of the door in proximity to the doorway and is disengagable if the door is hit from the opposite side, to permit the door panel assembly to swing about the horizontal axis away from the doorway. The swinging panel is held by a detent in the plane of the track panel in a normal position.

Owner:ASI TECH

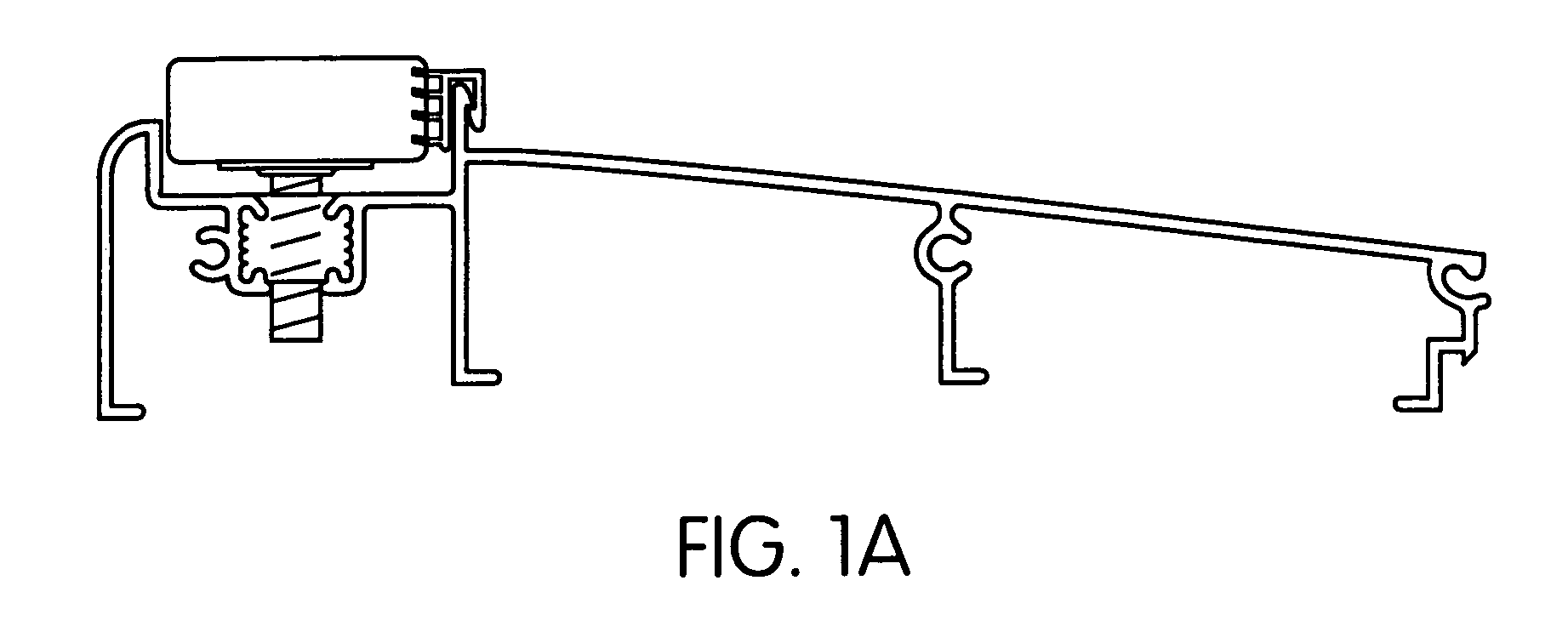

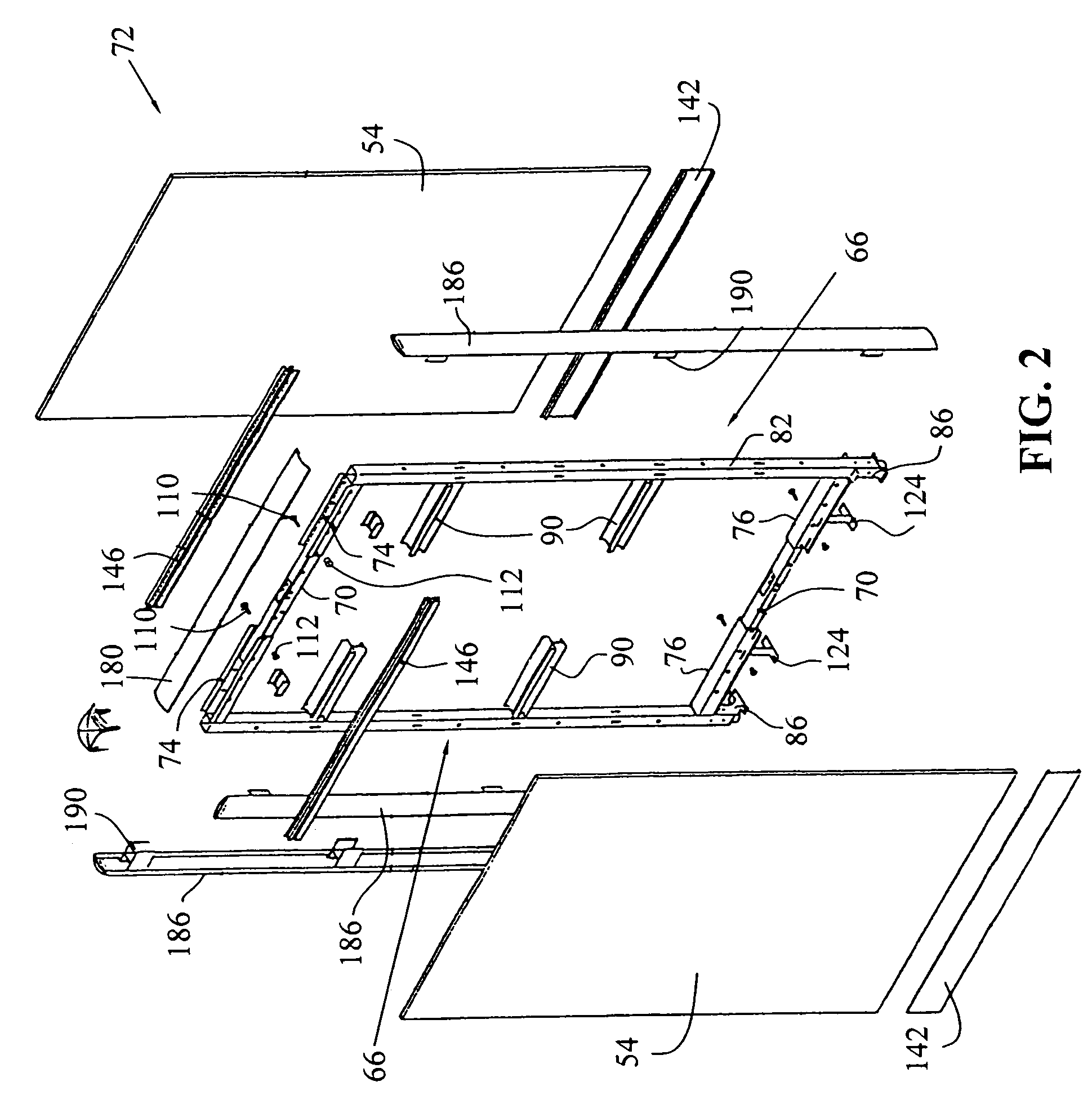

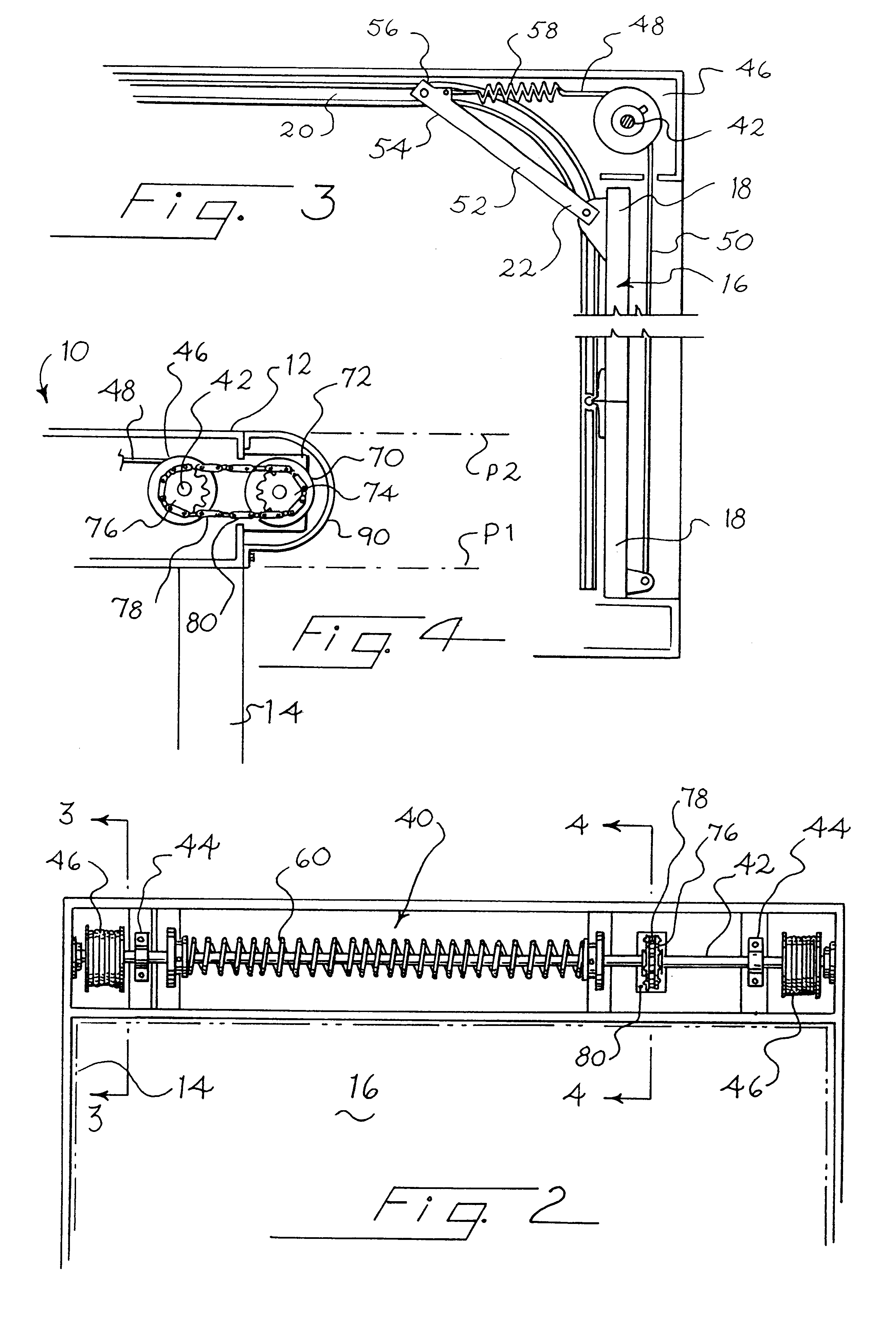

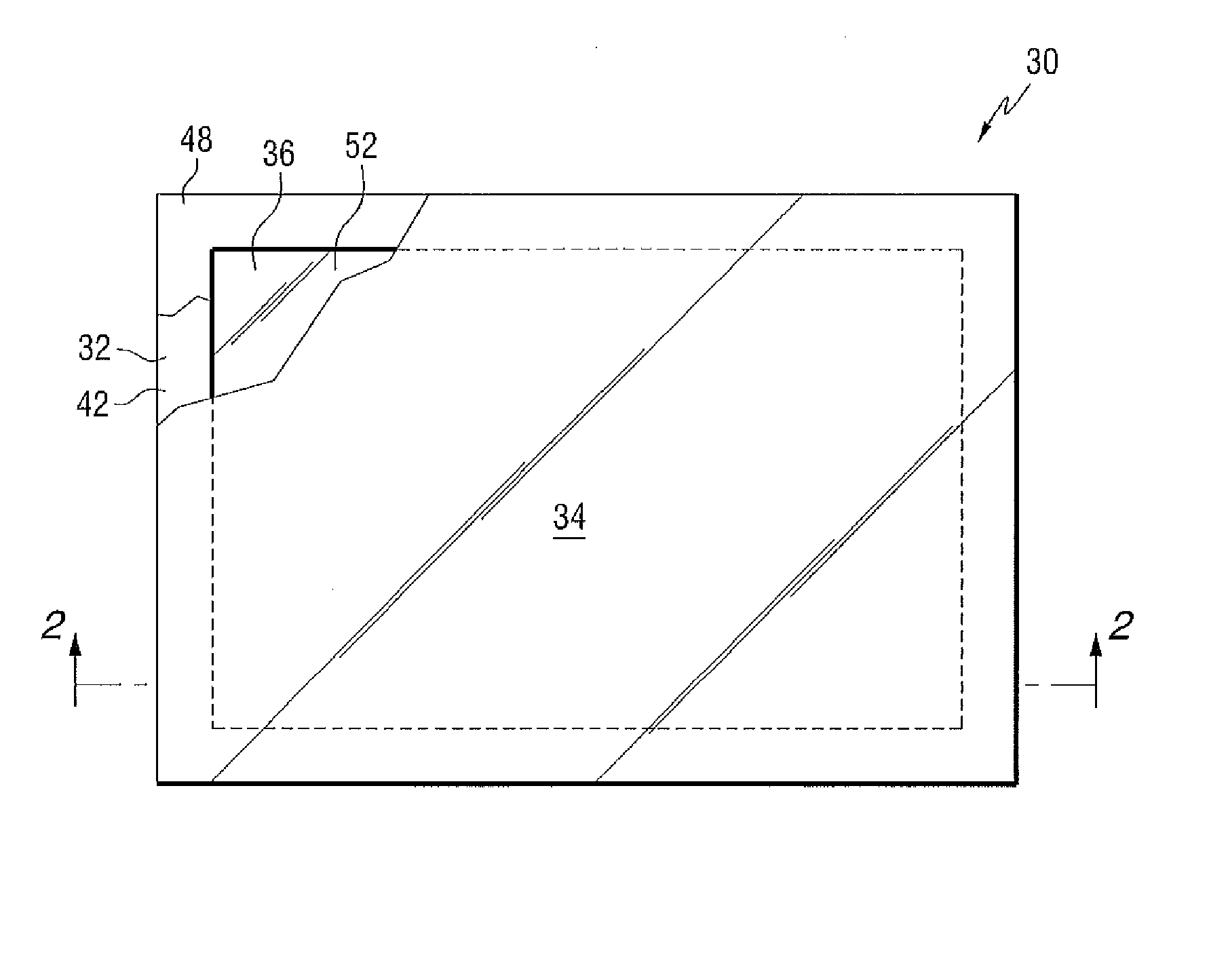

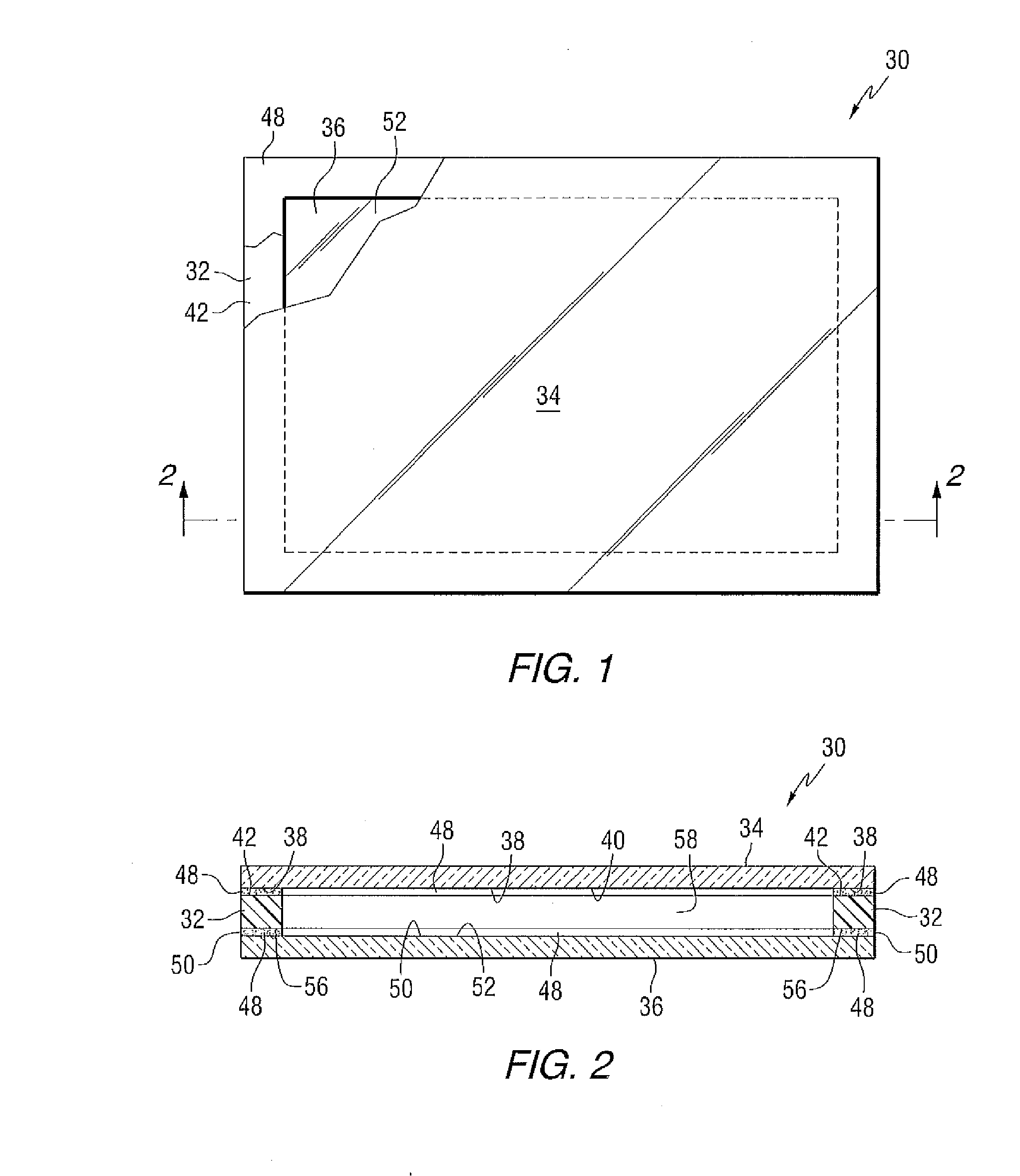

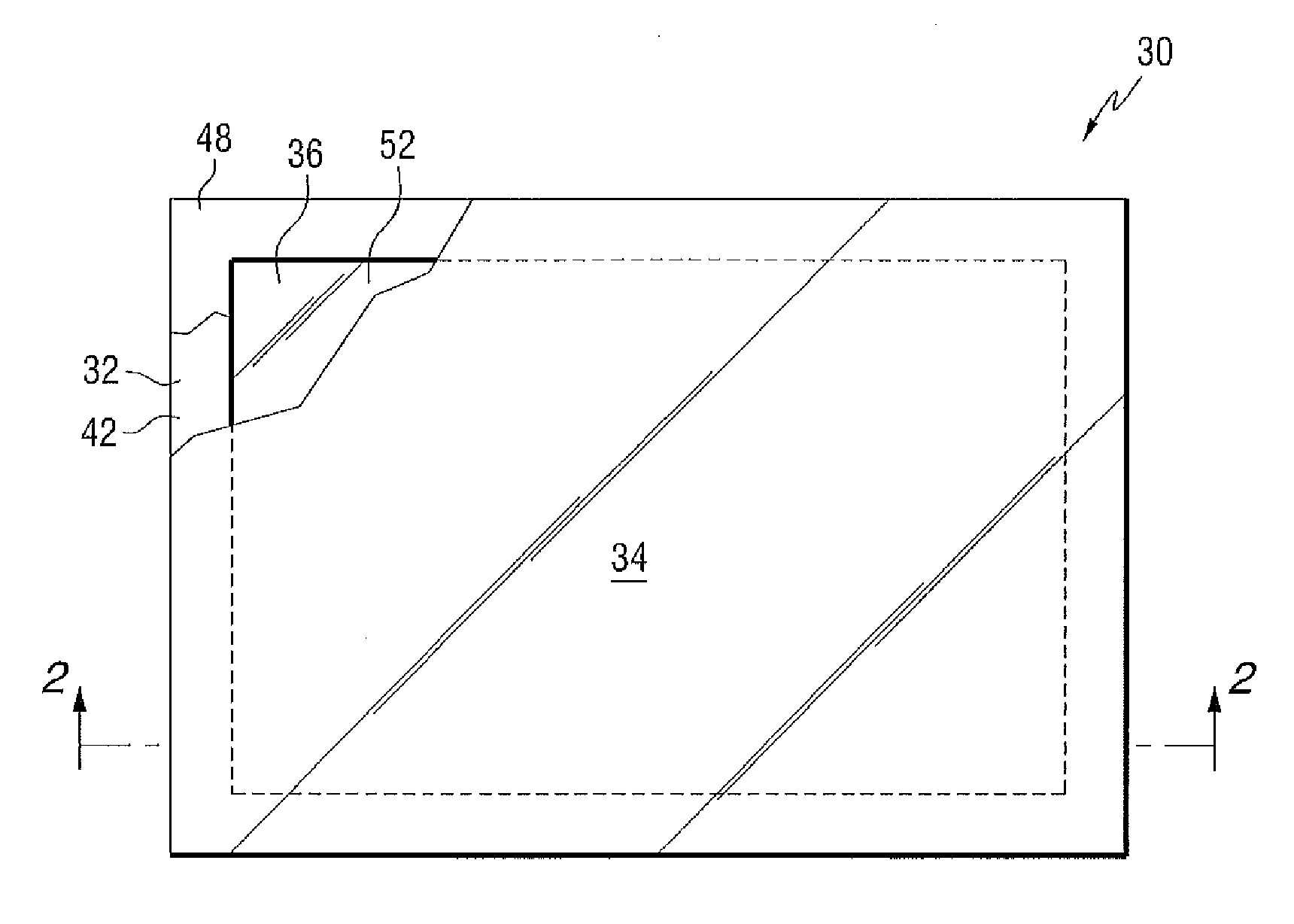

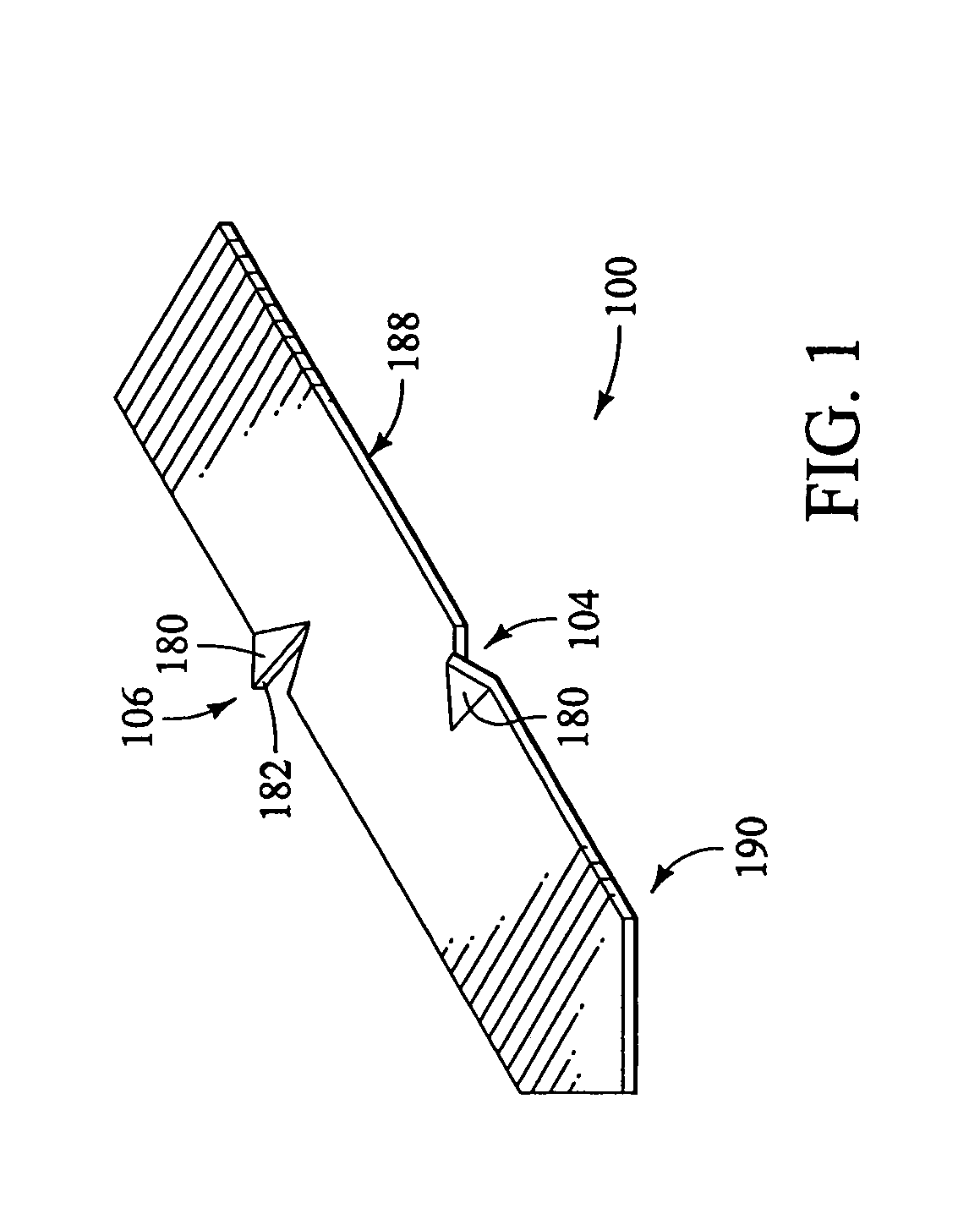

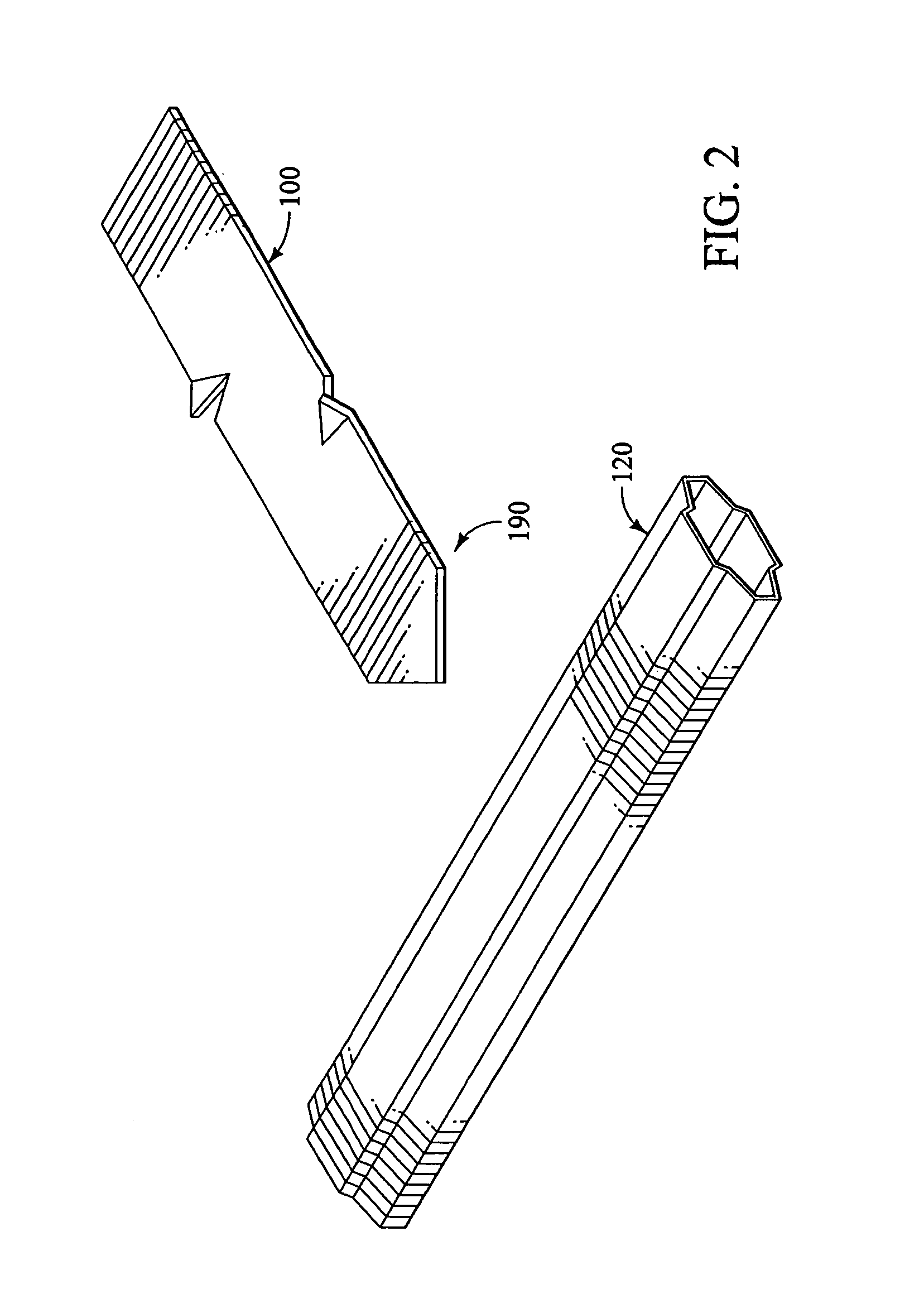

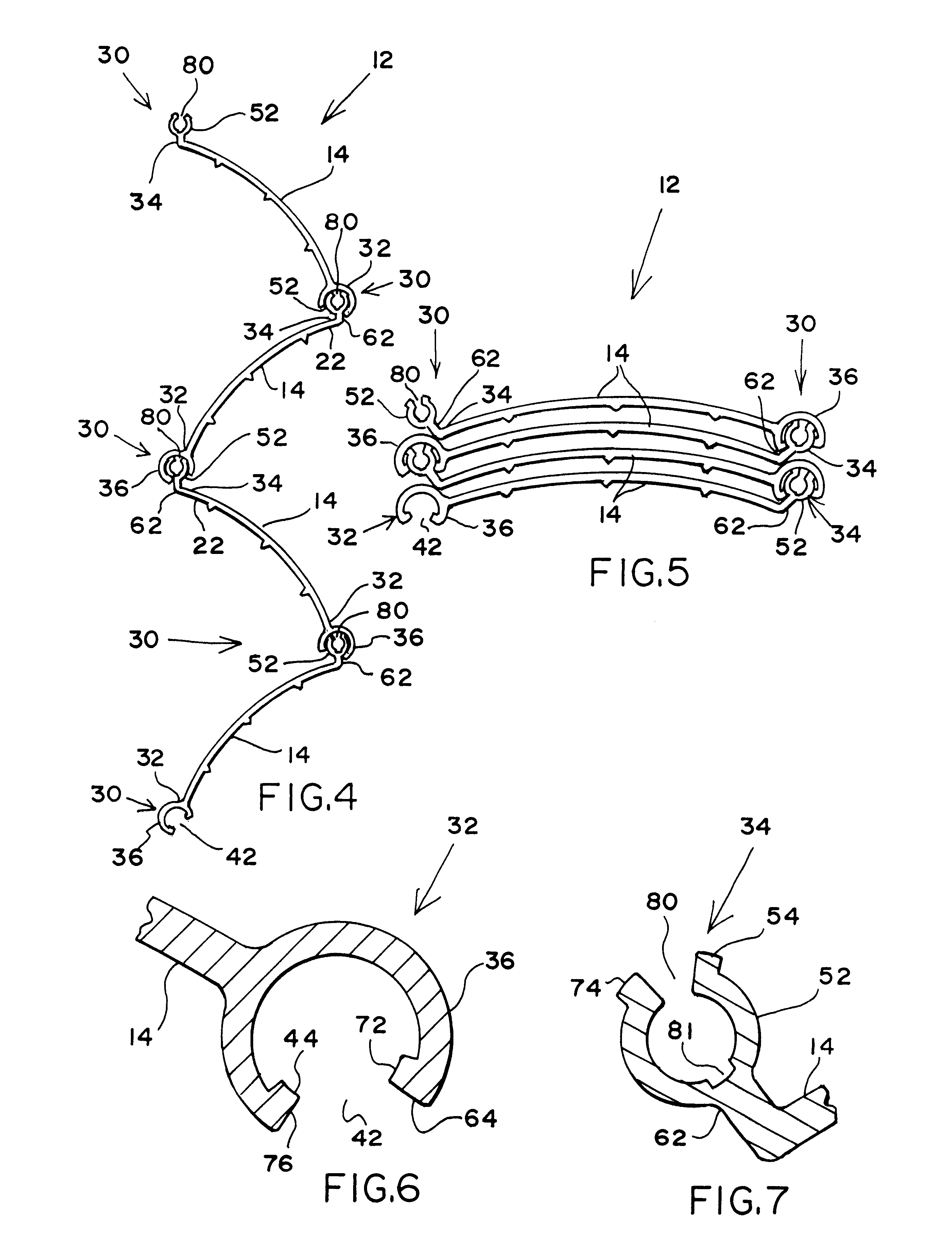

Plastic spacer stock, plastic spacer frame and multi-sheet unit, and method of making same

The present invention provides a multi-sheet unit with a spacer frame having at least three sides, at least three corners, a first sheet supporting surface and an opposite second sheet supporting surface. The spacer frame includes a spacer stock member having a first end, an opposite second end, the at least three sides and at least two corners of the at least three corners; a corner key comprising a bendable elongated body having a first end in the first end of the spacer stock member, an opposite second end in the second end of the spacer stock member to provide one of the corners of the at least three corners of the spacer frame, and a cut out between the ends of the corner key, the ends of the corner key bendable relative to one another to decrease the spacing of the cut out; a first sheet secured to the first sheet supporting surface by a first moisture and / or gas impervious layer, and a second sheet secured to the second sheet supporting surface by a second moisture and / or gas impervious layer.

Owner:PPG IND OHIO INC

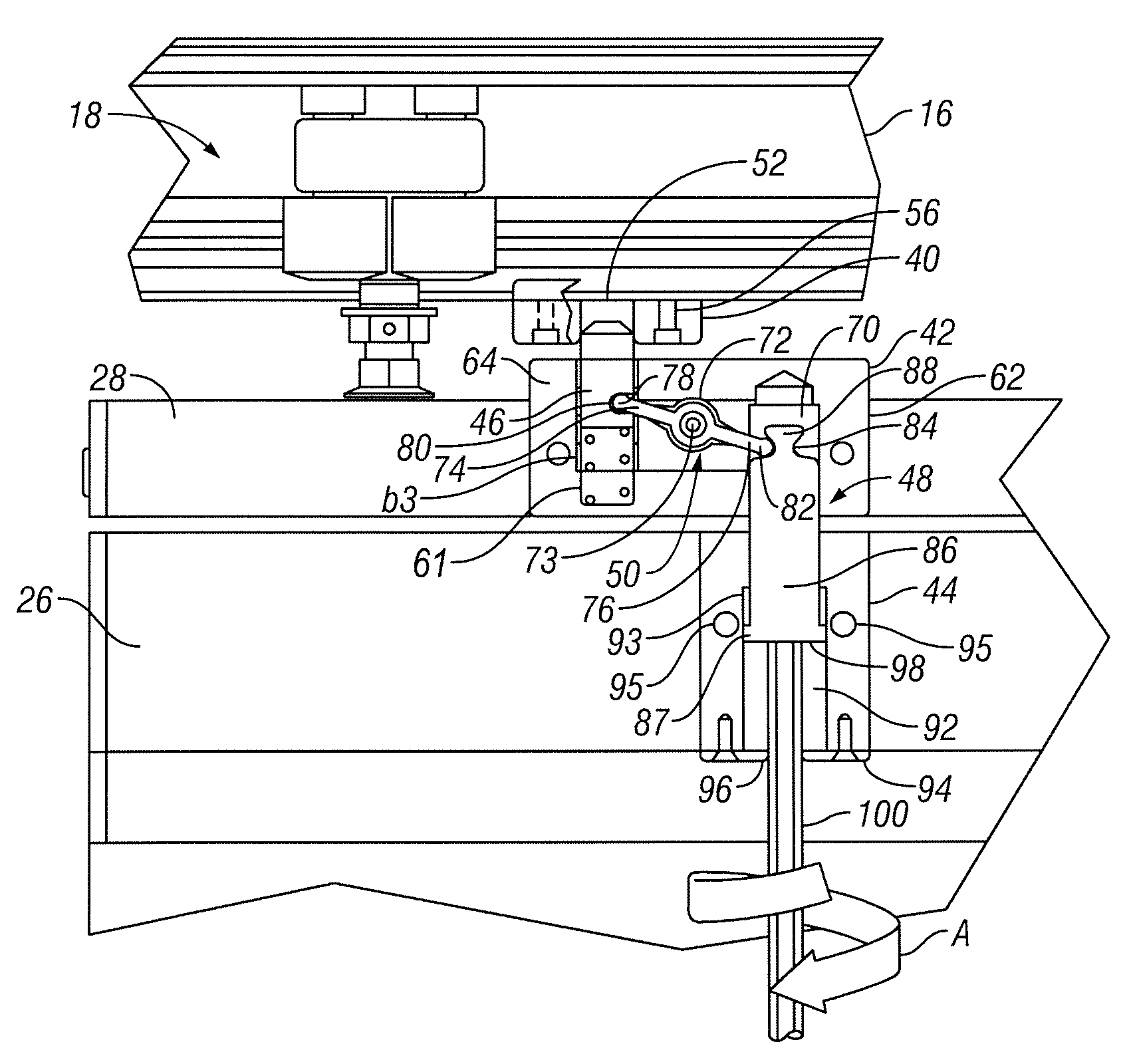

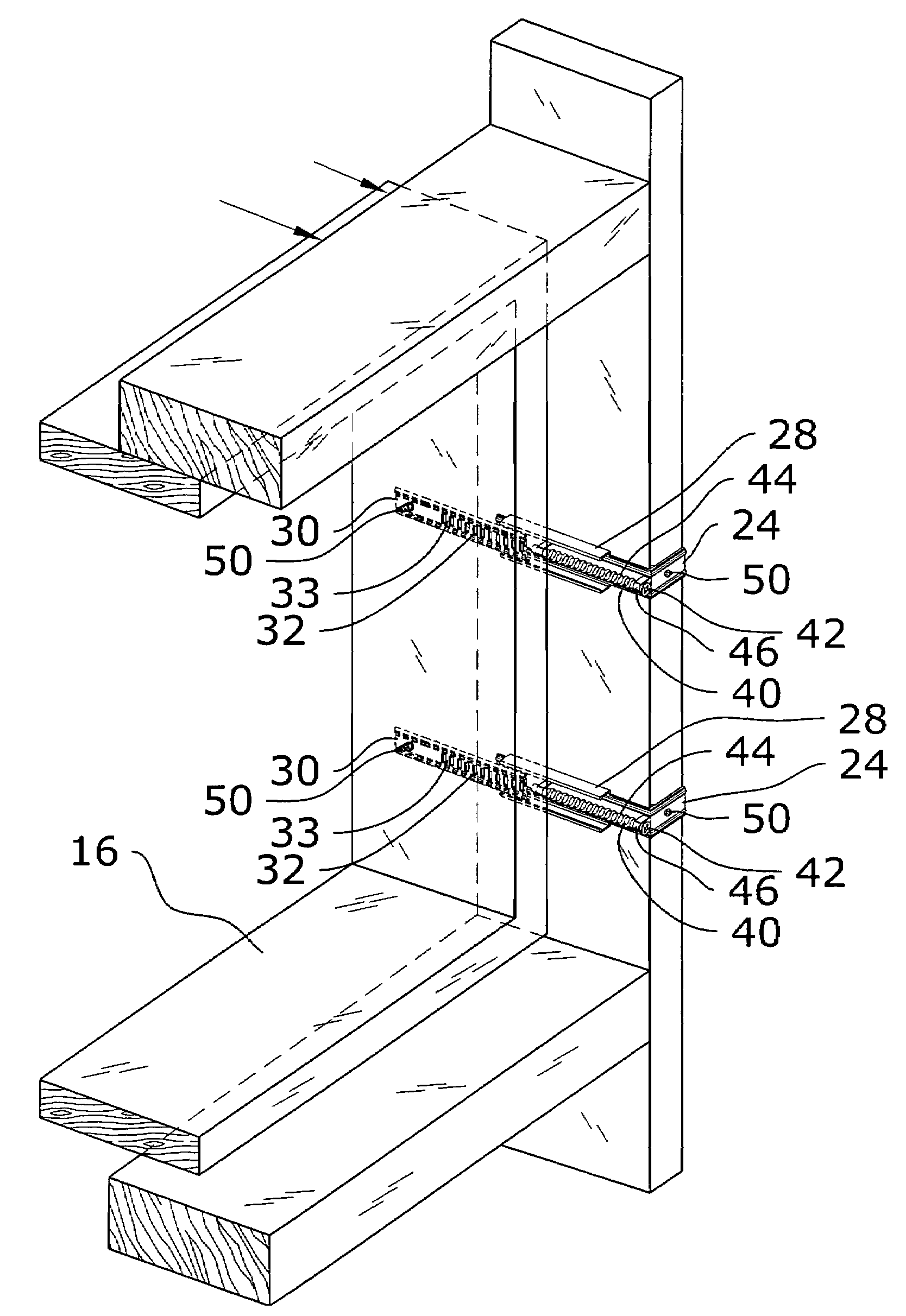

Window and door jamb adjustment system

A window and door jamb adjustment system for accurately installing windows and doors and providing for later adjustment of the same. The window and door jamb adjustment system includes a support member attachable to a building frame, an alignment member slidably attached to the support member and attachable to an extension jamb, a door or window, and a threaded shaft attached to the support member and threadably engaging the alignment member. As the threaded shaft is rotated, the rotational motion is converted to linear motion of the alignment member. As the alignment member is moved with respect to the support member, the extension jamb, a door or window, is correspondingly moved inwardly or outwardly for proper alignment with plasterboard.

Owner:B3 PRODS

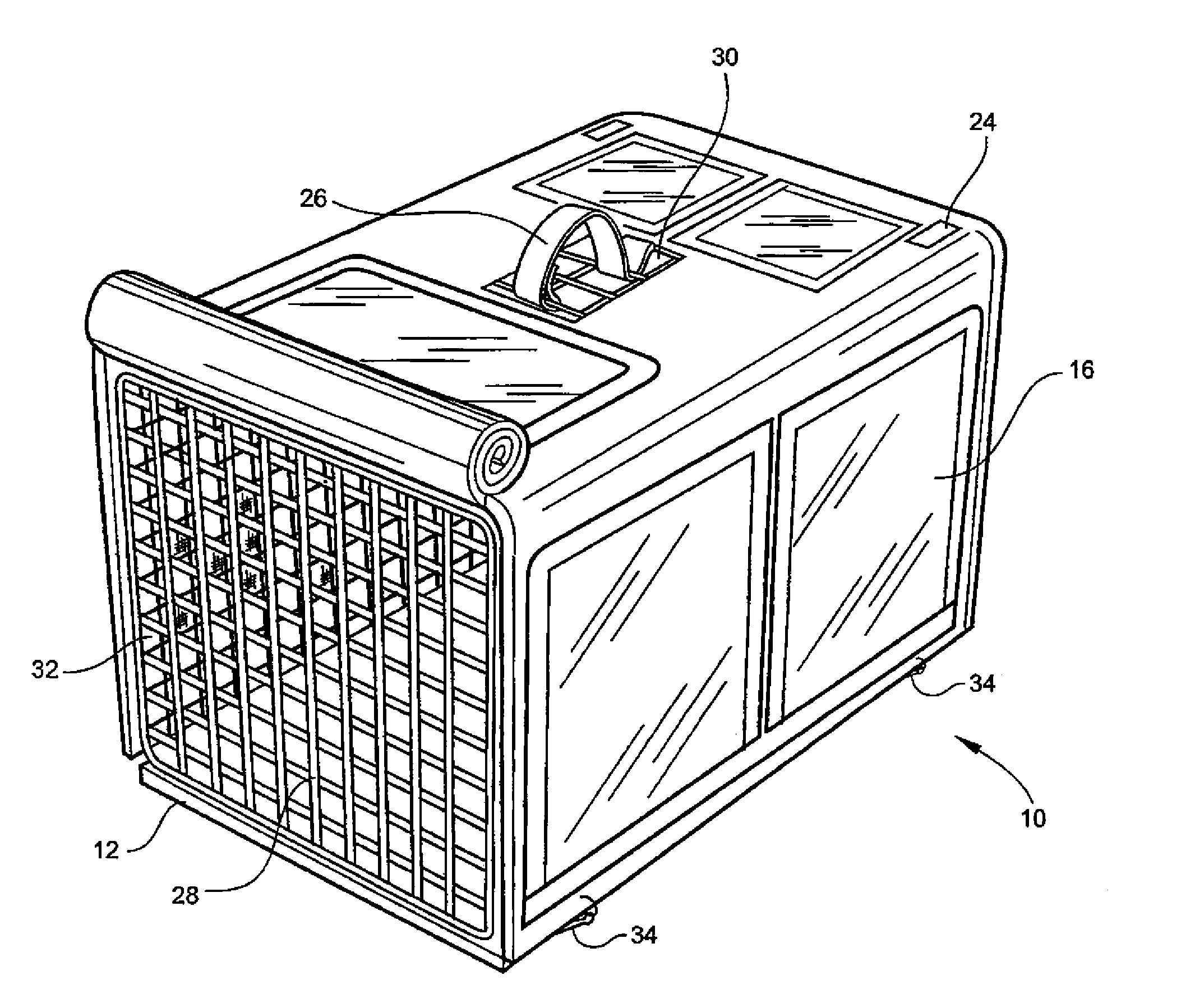

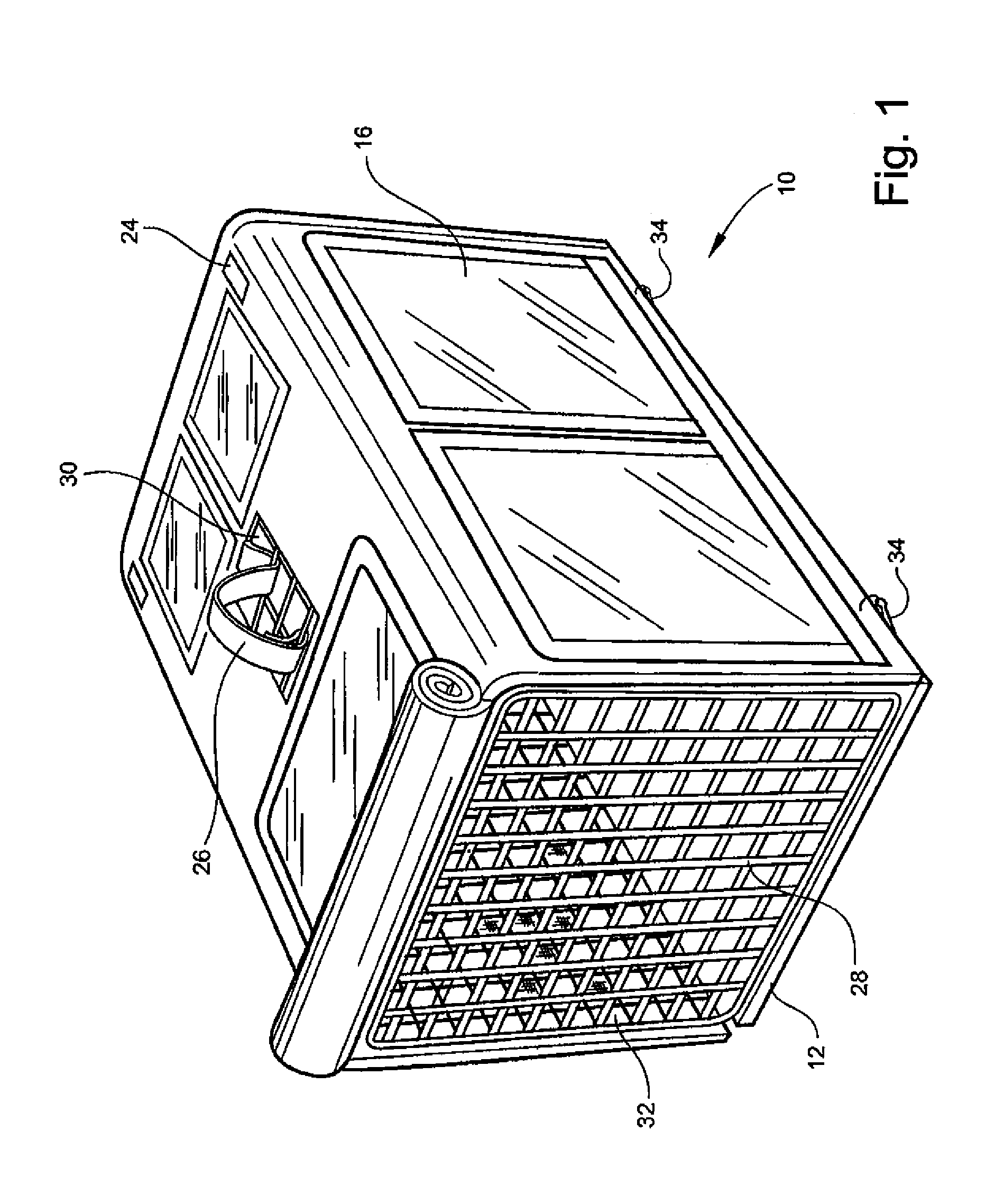

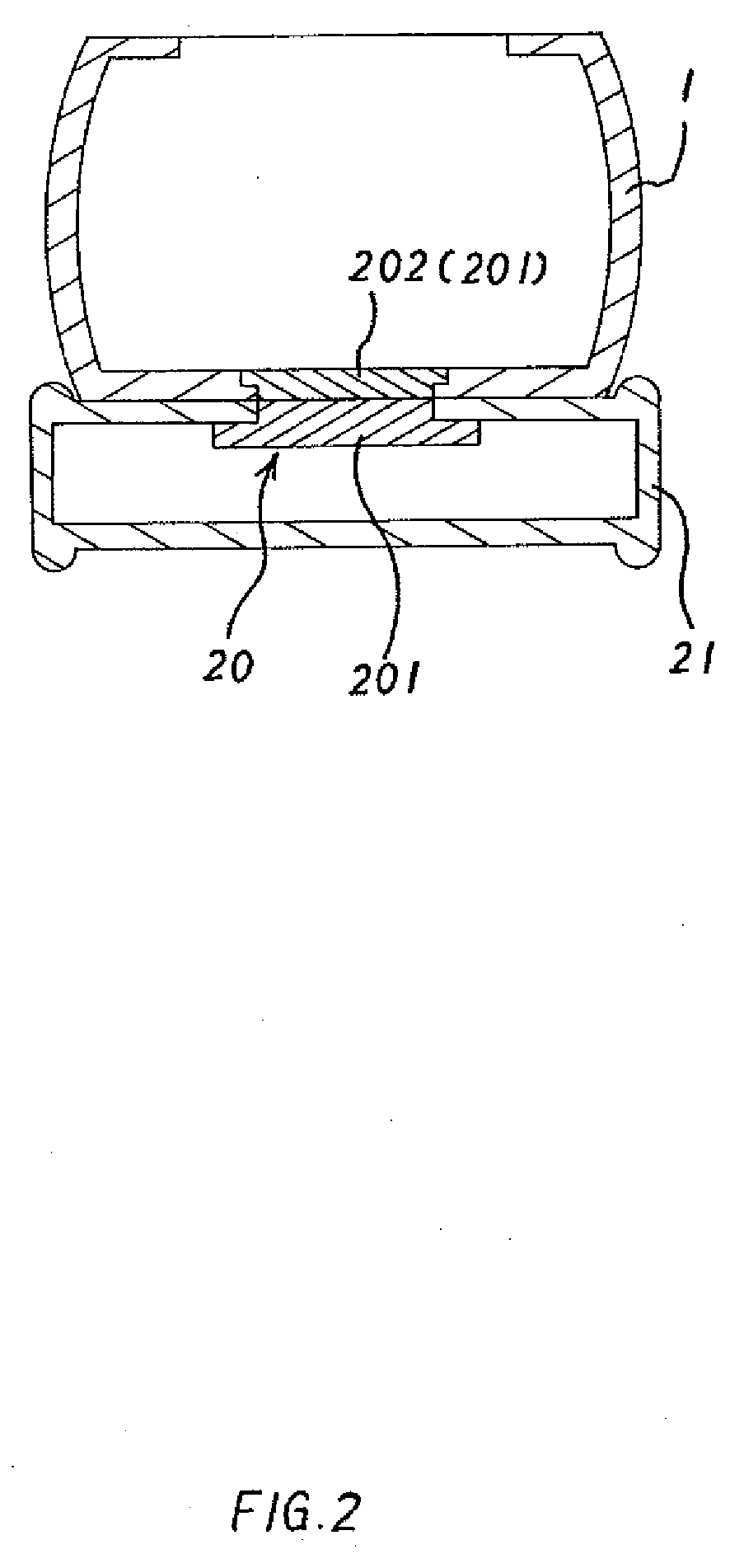

Cover for a pet carrier

InactiveUS20090101075A1Easy to fixImprove ventilationCorner/edge jointsAnimal housingEngineeringMechanical engineering

Owner:MATLACK CAROLYN BIRCKHEAD

Plastic spacer stock, plastic spacer frame and multi-sheet unit, and method of making same

The present invention provides a multi-sheet unit with a spacer frame having at least three sides, at least three corners, a first sheet supporting surface and an opposite second sheet supporting surface. The spacer frame includes a spacer stock member having a first end, an opposite second end, the at least three sides and at least two corners of the at least three corners; a corner key comprising a bendable elongated body having a first end in the first end of the spacer stock member, an opposite second end in the second end of the spacer stock member to provide one of the corners of the at least three corners of the spacer frame, and a cut out between the ends of the corner key, the ends of the corner key bendable relative to one another to decrease the spacing of the cut out; a first sheet secured to the first sheet supporting surface by a first moisture and / or gas impervious layer, and a second sheet secured to the second sheet supporting surface by a second moisture and / or gas impervious layer.

Owner:PPG IND OHIO INC

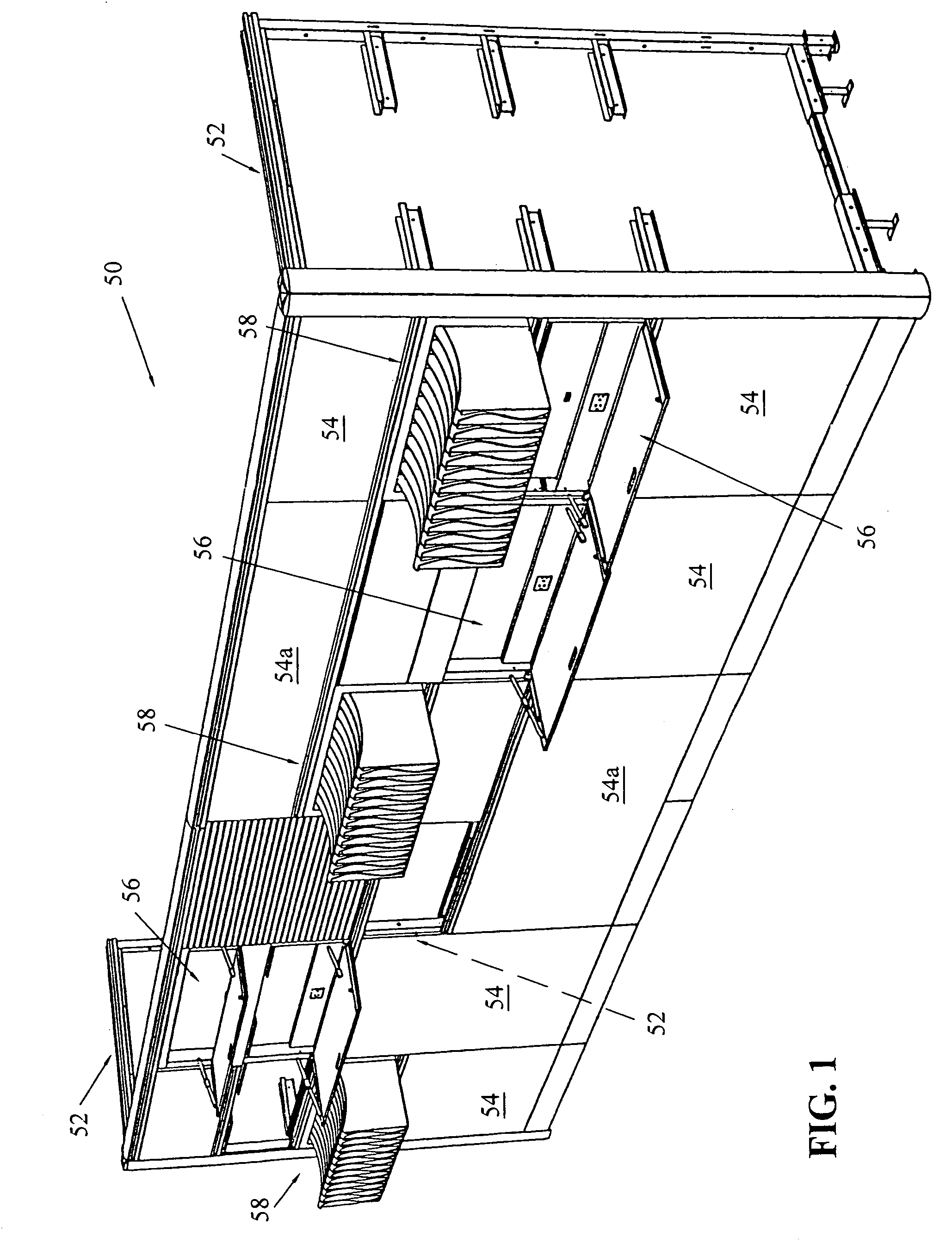

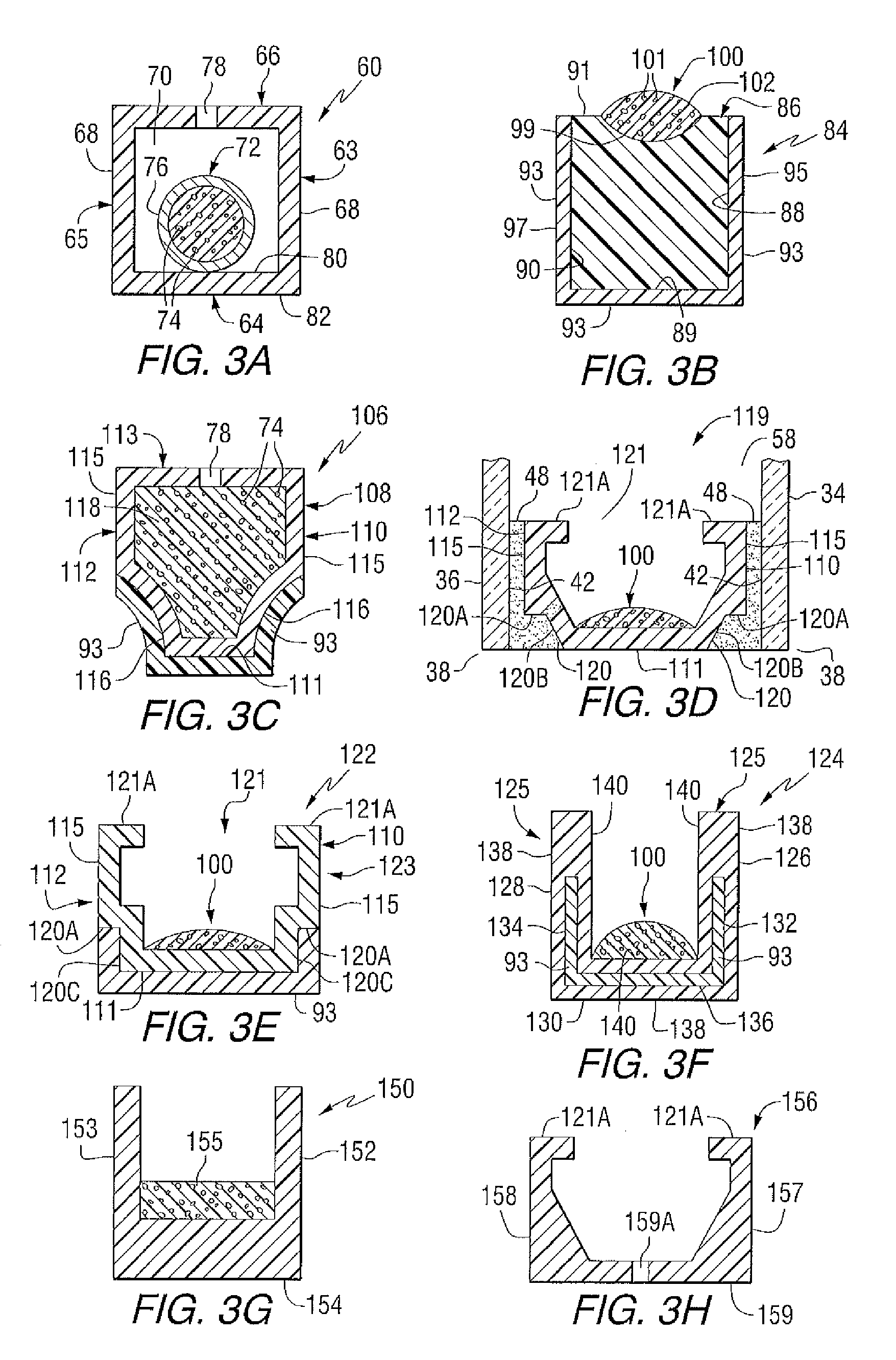

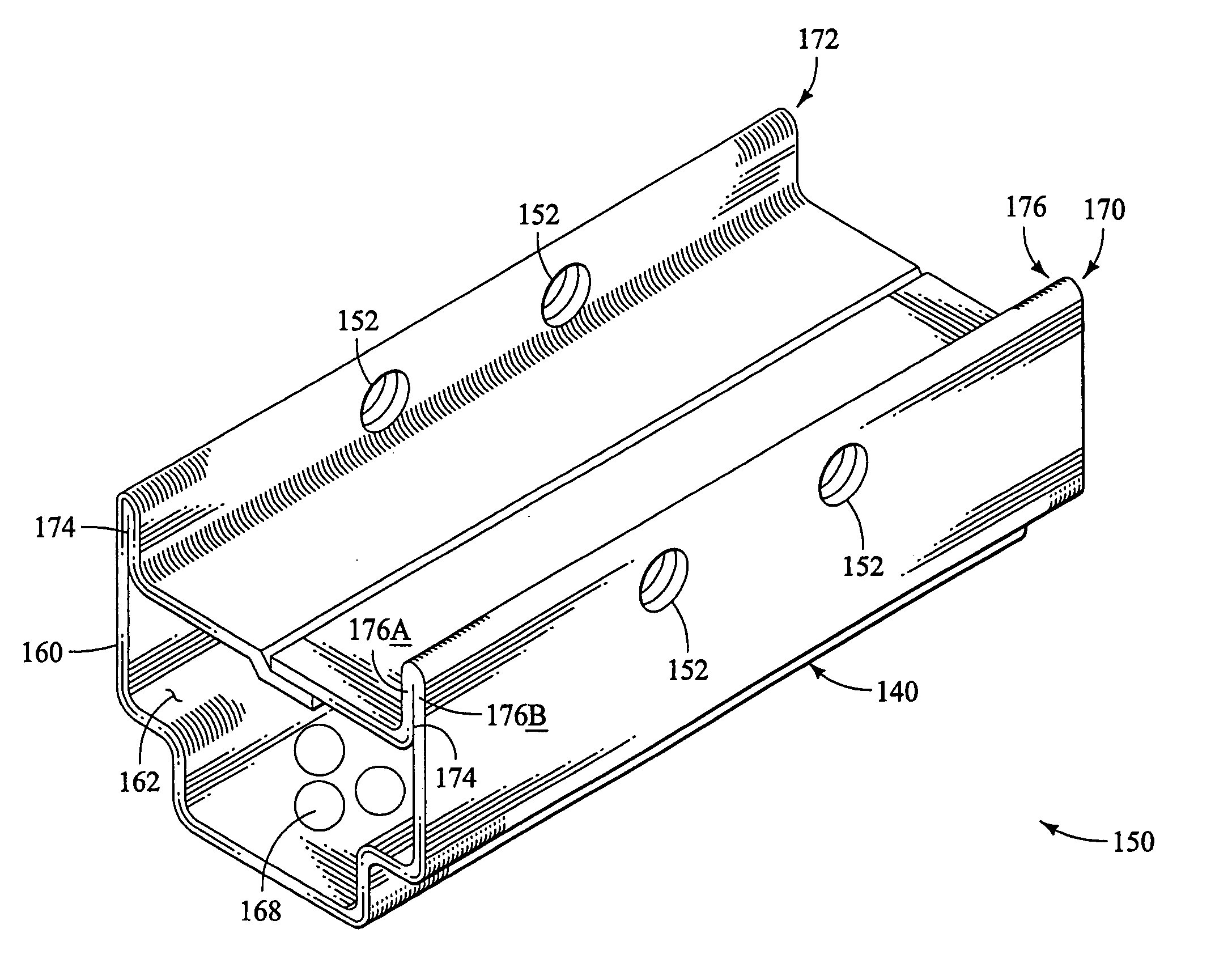

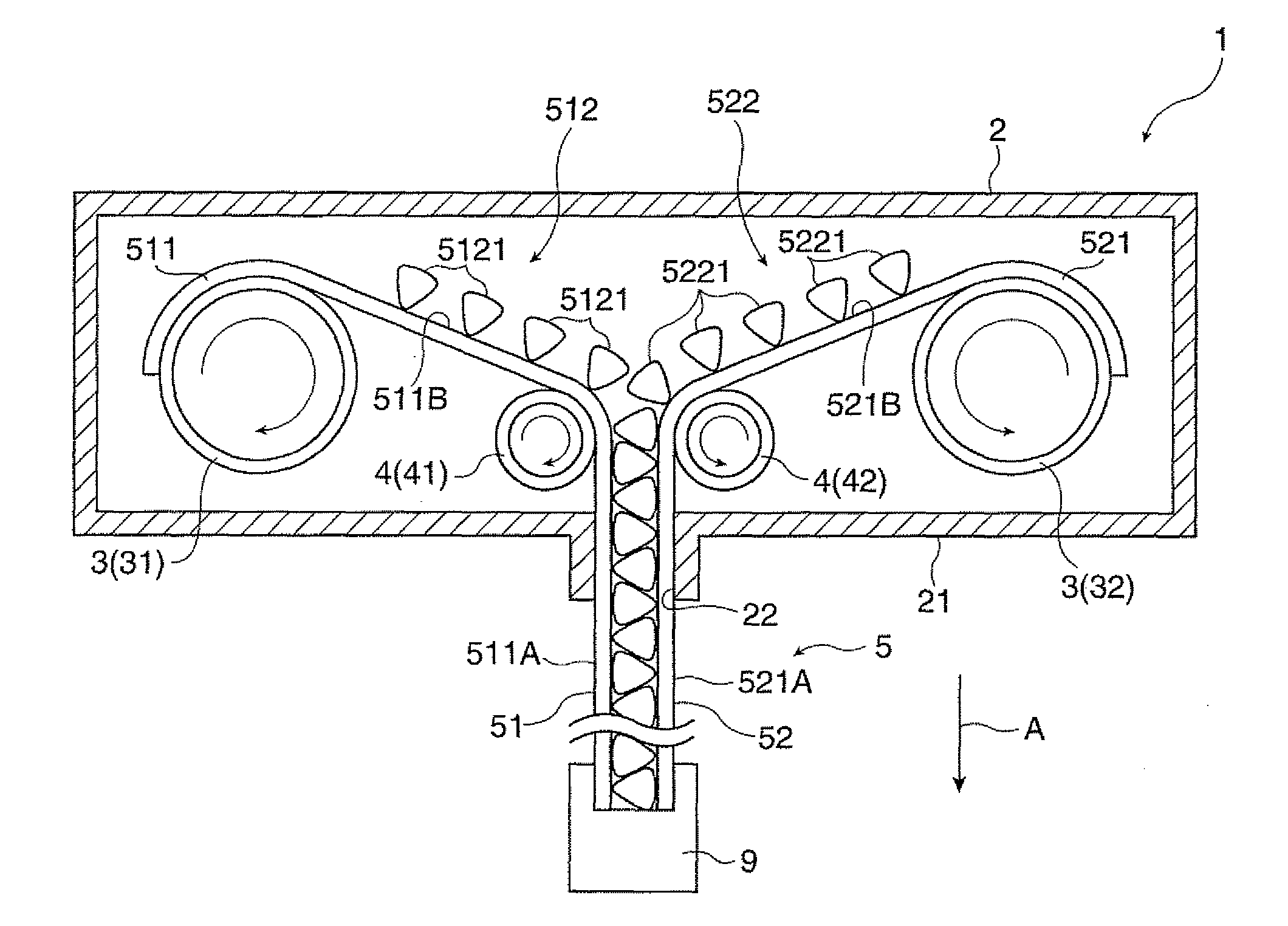

Apparatus for manufacturing muntin bar assemblies

InactiveUS7076927B2Avoid relative motionCorner/edge jointsCondensed water formation preventionFlangeMuntin

Methods and apparatus for assembling muntin bar lattices and spacer frames for use in insulating glass units are disclosed. One method of assembling a muntin bar lattice in accordance with the present invention comprises the steps of providing a muntin bar segment and a keeper dimensioned for piercing a wall of the muntin bar segment. A keeper in accordance with an exemplary embodiment of the present invention comprises an elongate body including a tip portion that is dimensioned for piercing a wall of the muntin bar segment to create an opening therein. A spacer for the separation of panes in an insulating glass unit in accordance with one exemplary embodiment of the present invention may include a tubular member comprising a wall defining a lumen and a mounting flange defining a plurality of mounting holes.

Owner:CARDINAL CG

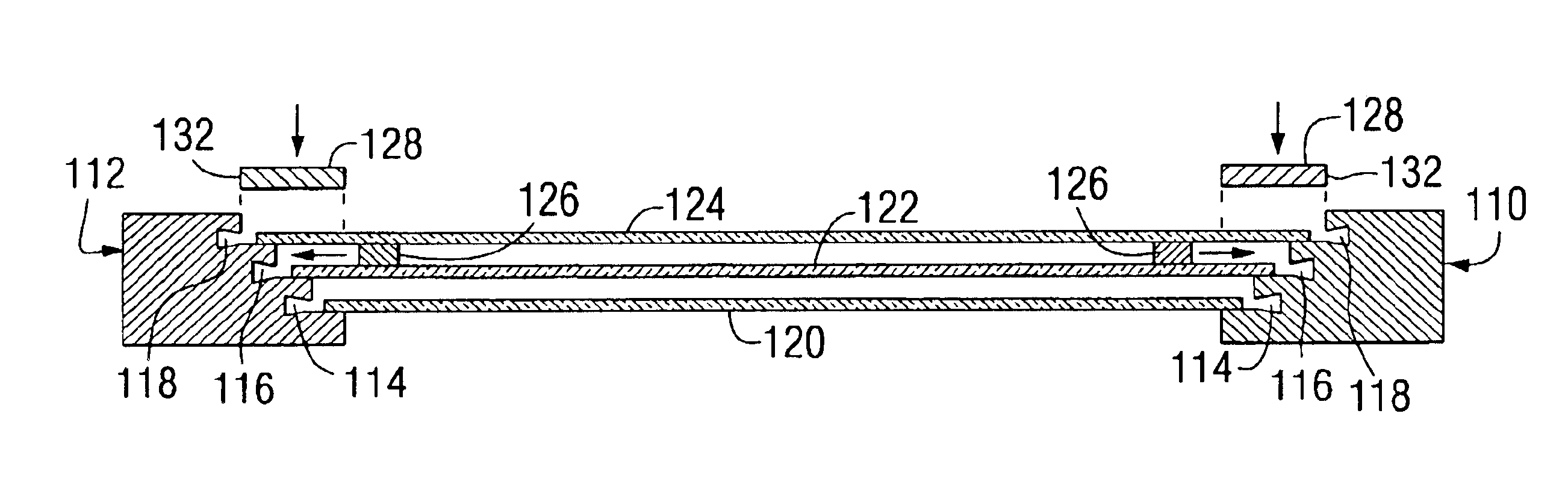

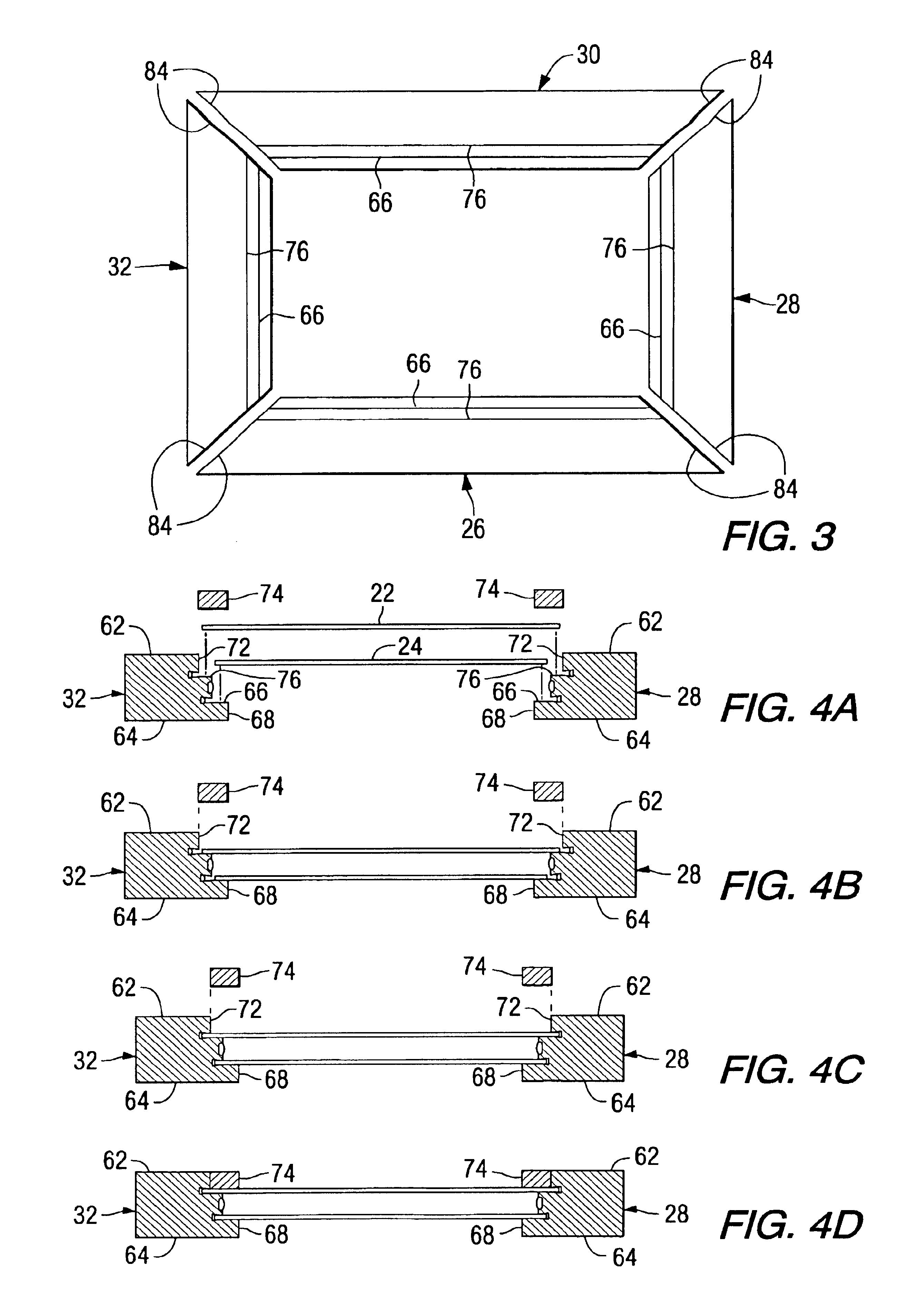

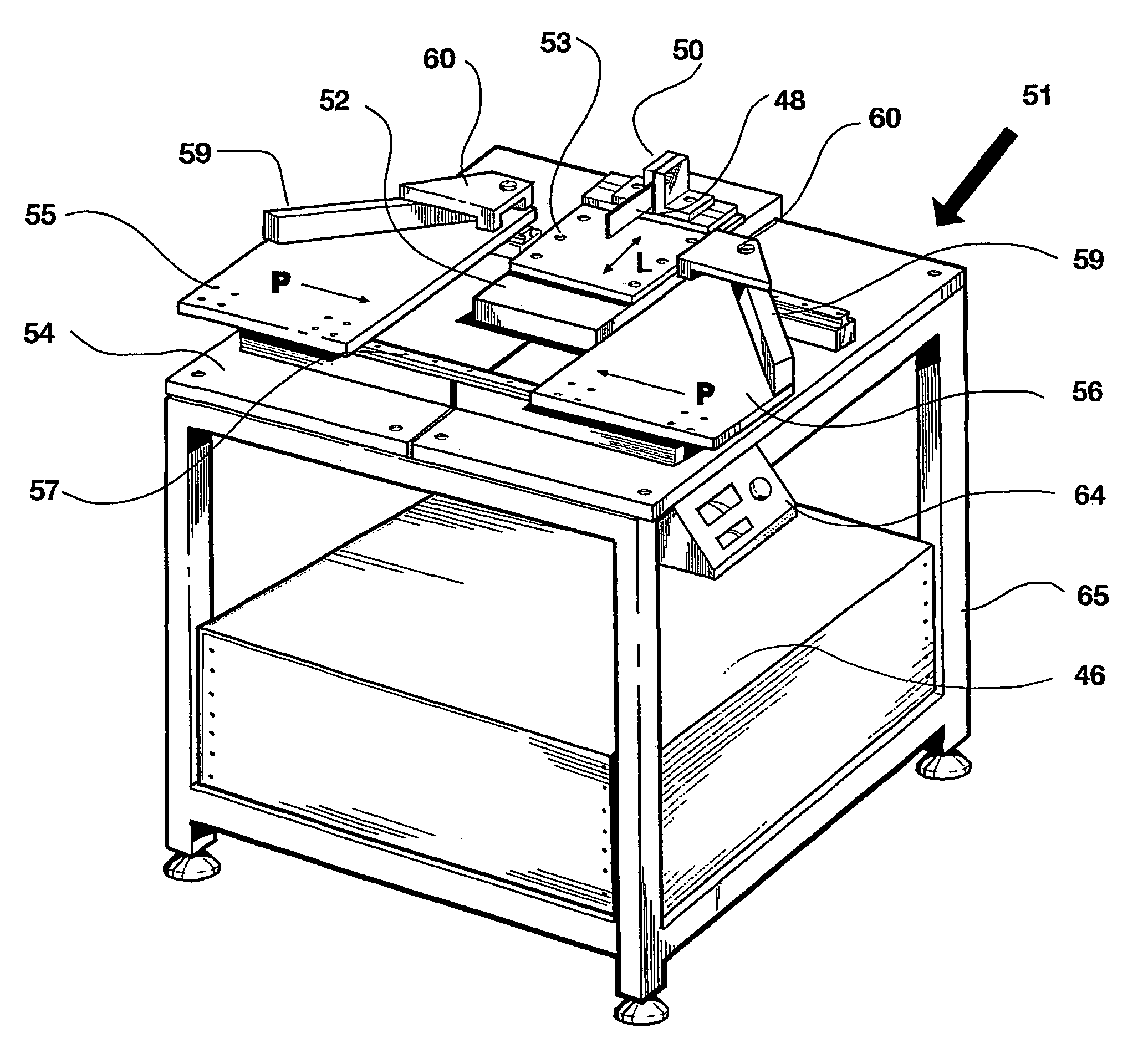

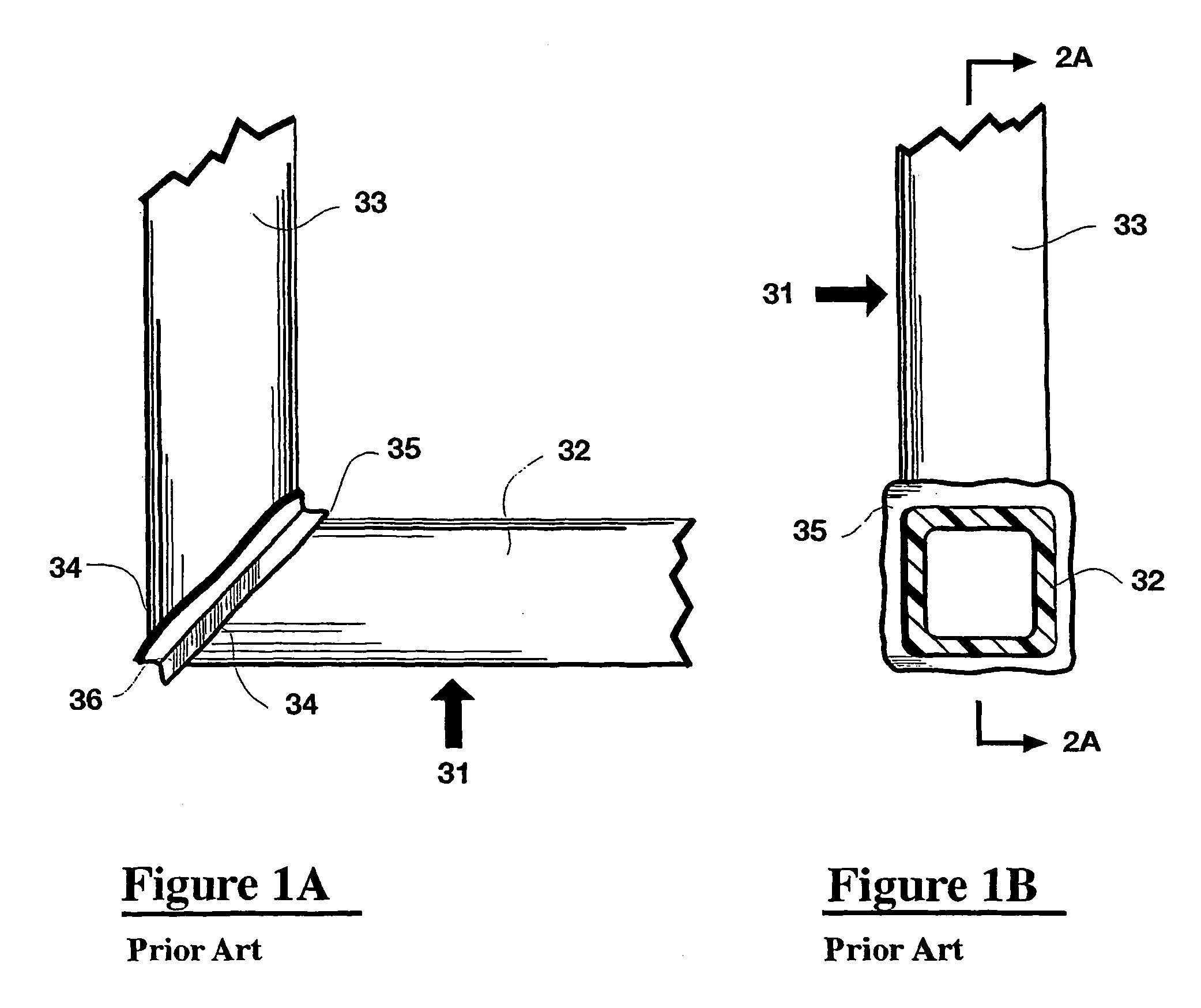

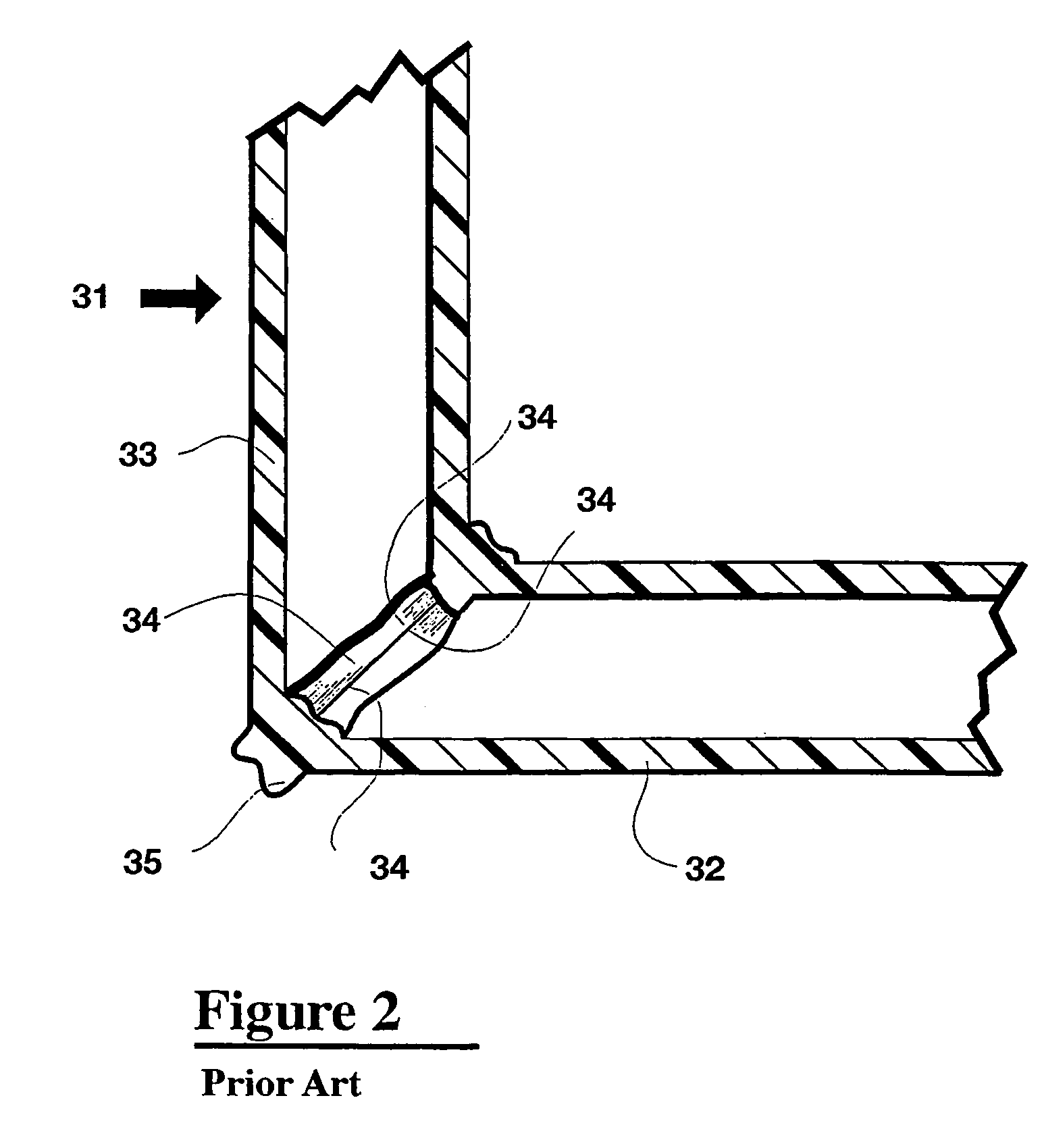

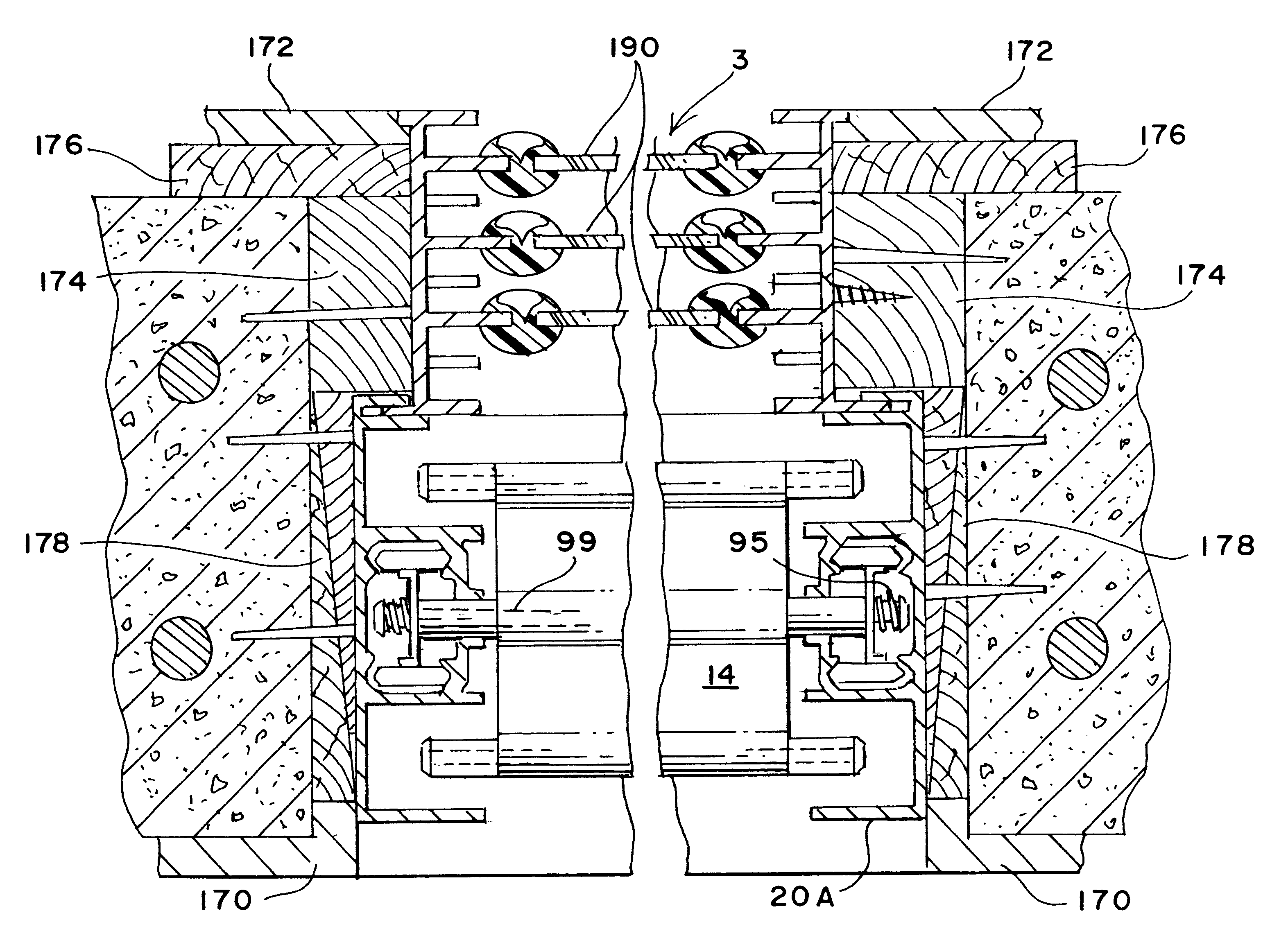

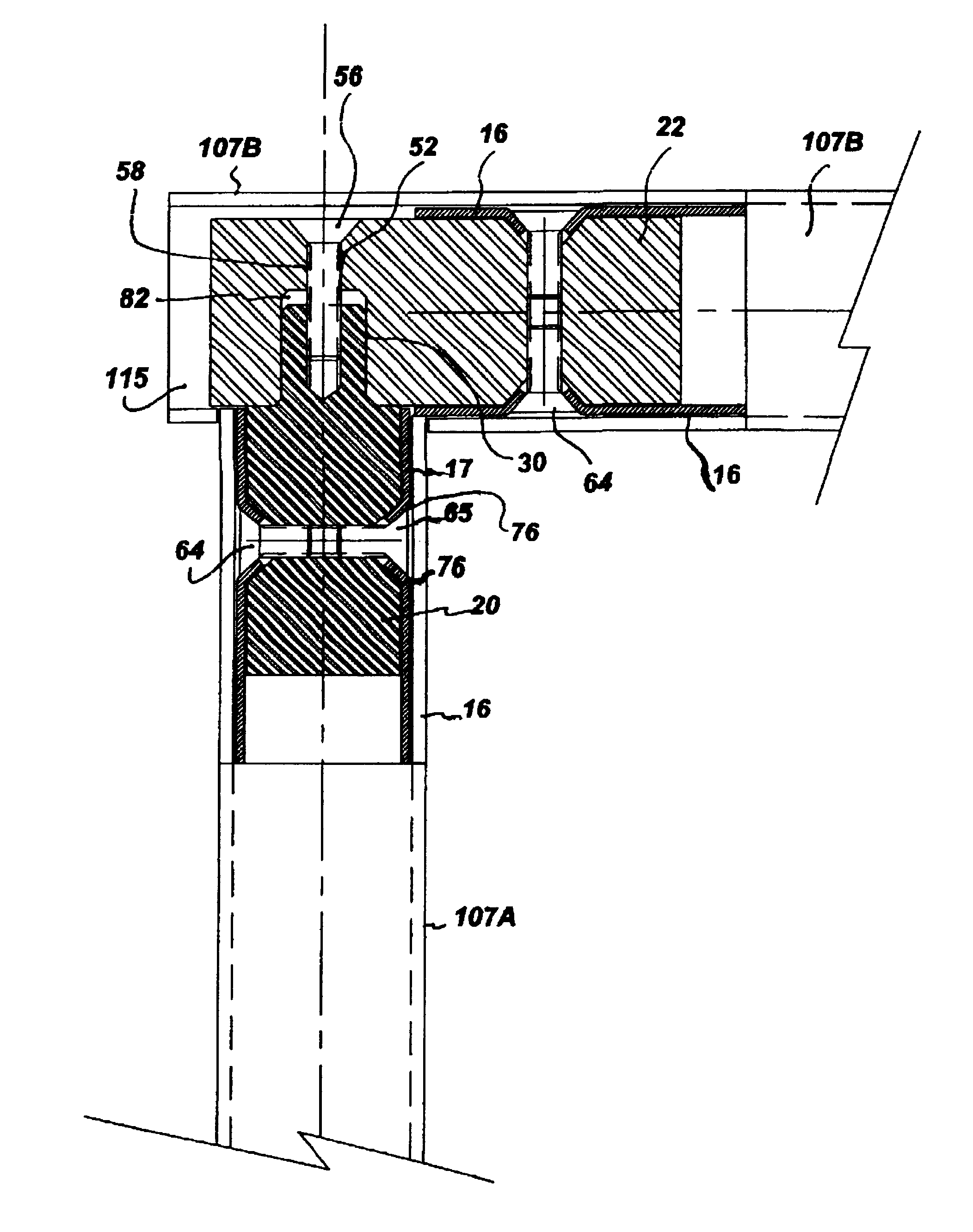

Method and apparatus for vibration welding of thermoplastic components

InactiveUS7122088B2Build-up may accumulateLamination ancillary operationsCorner/edge jointsControl mannerEngineering

Vibratory welded connections are formed between first and second members (32, 33) of thermoplastic material by interposing a junction piece (47) of similar material and vibrating the junction piece (47) at high speed while pressing the first second members (32,33) in a controlled manner against opposite sides of the junction piece (47). Friction created by the vibration generates heat which melts a small amount of material at the engaging surfaces which upon cooling provides a strong welded joint having minimal flash. Entire frame systems such as window-frames can be fabricated by an apparatus system (120) which forms a friction welded joint between adjacent ends of the frame members (134, 135, 136, 137). Furthermore the frame can be fabricated around a panel such as a glazing panel. The welded connections formed by the system do not mar the finish of the frame members and produce no unsightly flash bead requiring subsequent machining steps for its removal.

Owner:BYSTRONIC MASCH

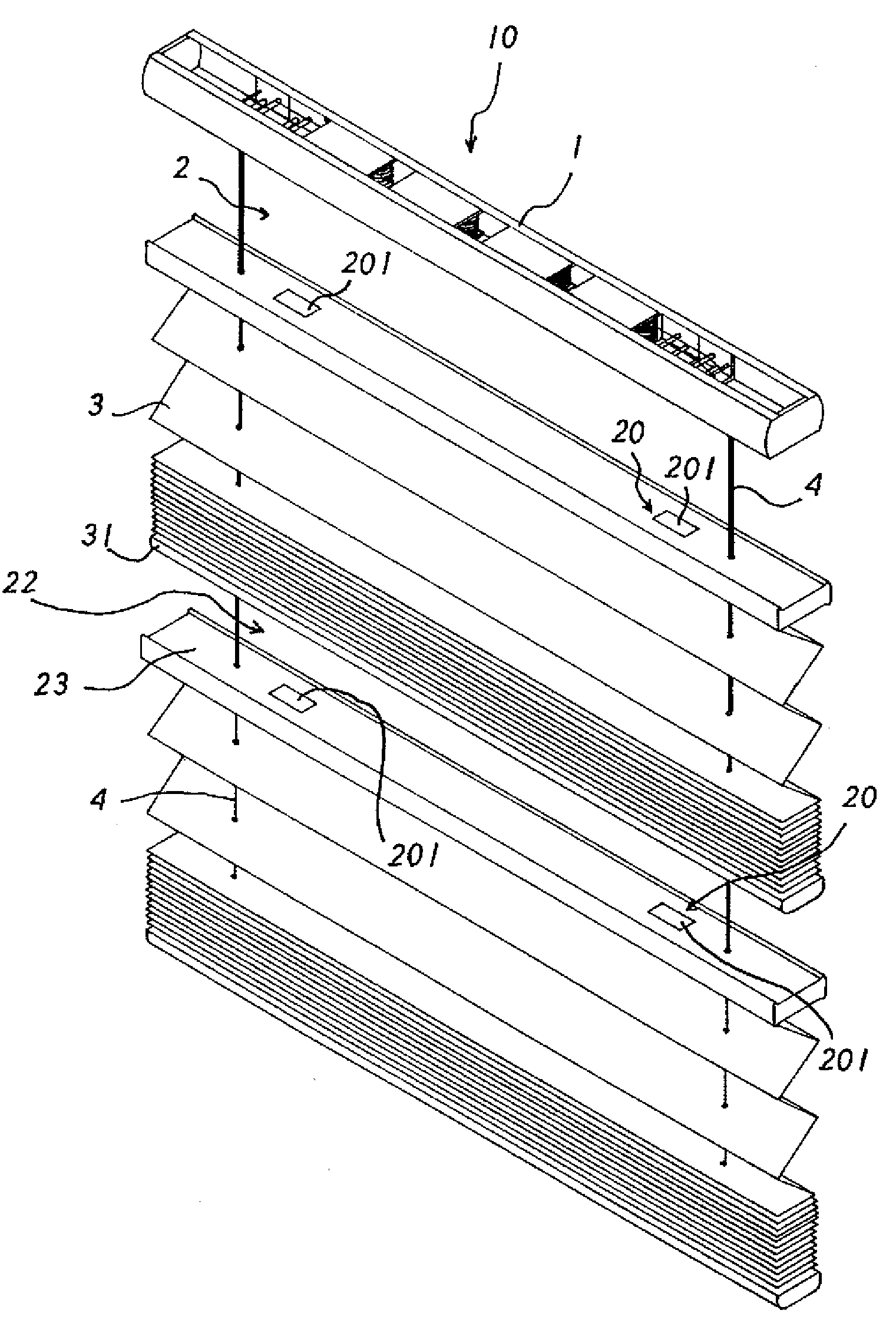

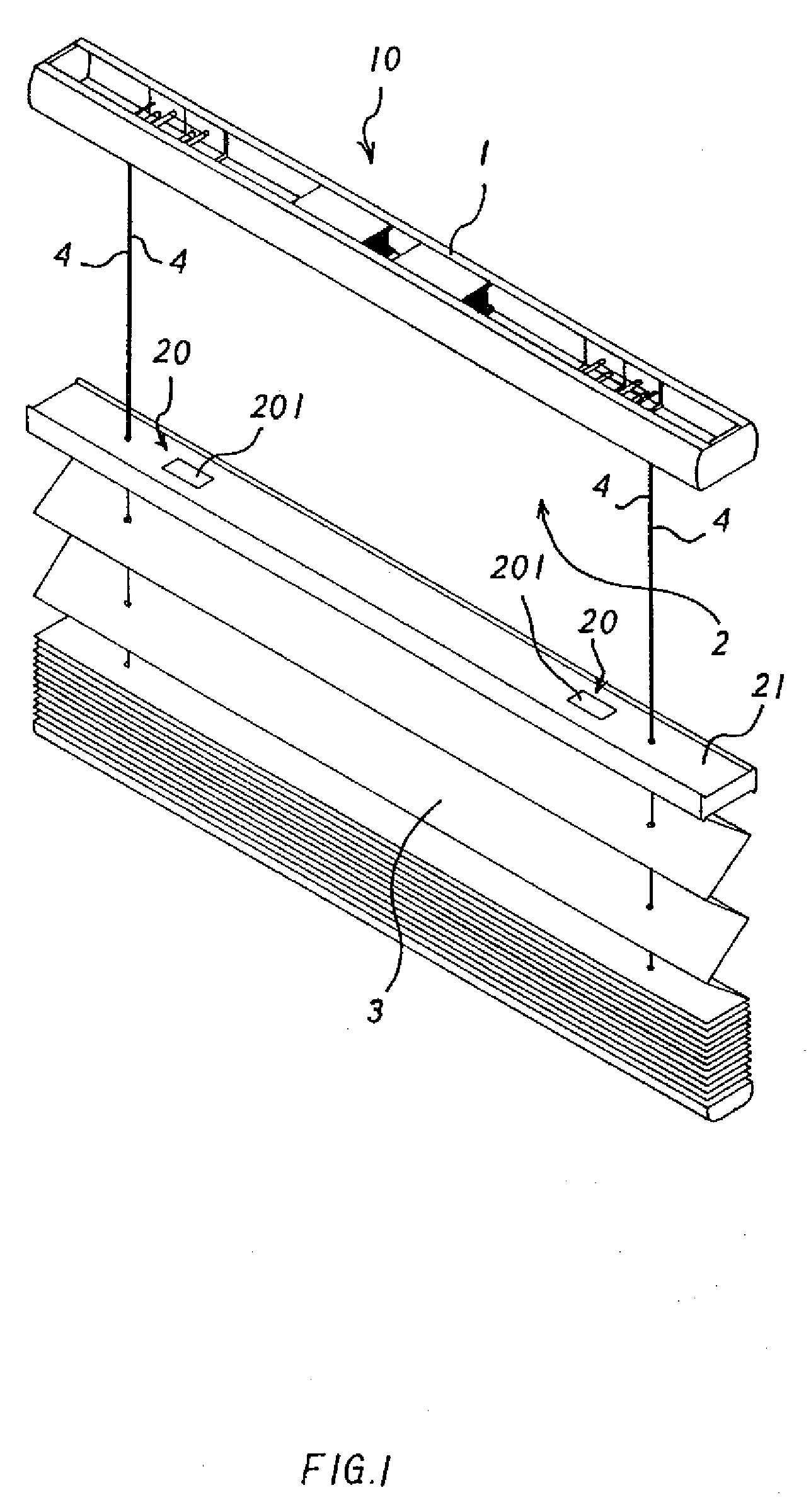

Multi-Section Curtain

InactiveUS20090014133A1Door/window protective devicesCorner/edge jointsEngineeringMechanical engineering

A multi-section curtain comprises an upper rail including a first curtain body provided therebeneath and fixed by a first offset rail, and including a second curtain body, top end of which is connected with the bottom of the first offset rail, wherein between the first offset rail and the upper rail is defined with a magnetic structure for magnetically engaging the first offset rail with the upper rail together, such that an interspace may be avoidable while reeling the curtain by a reeler.

Owner:LIN SHIH MING

Shower screen

InactiveUS7273084B2Solidly and smoothly anchoring structureAvoid volatilityCorner/edge jointsBathsEngineeringMechanical engineering

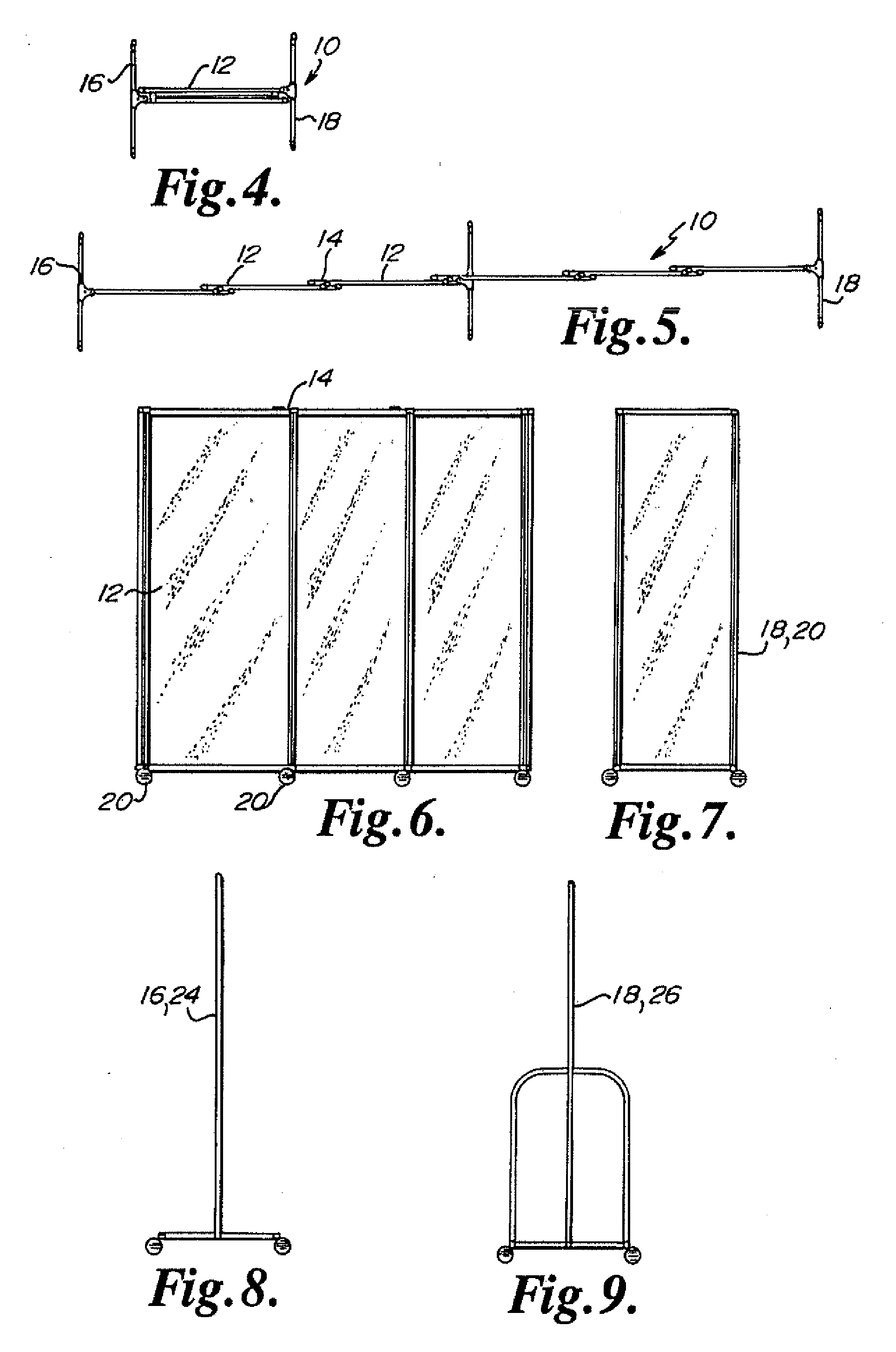

A shower screen includes an upper guide rod secured on top of two posts, a screen member having a number of panels foldably coupled together and having an upper portion slidably attached to the guide rod, and two beams secured to sides of the screen member. A lower guide bar is secured to lower portions of the posts, and includes a downwardly facing passage. The beams and the screen member each includes a hook member or hook device having a projection slidably engaged into the passage of the guide bar, to anchor the lower portions of the beams and the screen member to the guide bar, and to prevent the beams and the screen member from fluctuating or vibrating relative to the guide bar.

Owner:CHEN CHANG THAN

Frame assembly having stile and rail tabs for coupling stile and rail members together

A frame assembly supports a fenestration article. The frame assembly comprises a stile member and a rail member coupled substantially transverse to the stile member. A stile tab extends axially from the stile member and a rail tab extends axially from the rail member. The stile tab is bent around the rail member and the rail tab is bent around the stile member for coupling the stile member to the rail member.

Owner:QUANEX HOMESHIELD LLC

Shutter window/door and method

A single generally rectangular frame, with extruded guides on the lateral sides, which guides contain tracks for a retractable pleated shutter system, and similarly contain channels for the mounting of a window or a door. The shutter system utilizes extracted pleated plates of uniform cross-section. At the ends of the shutter panels, provision is made for a guide assembly which is secured internally of the tracks on the lateral sides of the frame. In one embodiment, means are provided for removing and replacing the shutter system and shutter panels, which does not require the removal of any cement, stucco, or any other permanent securing materials.

Owner:CHILL PILL

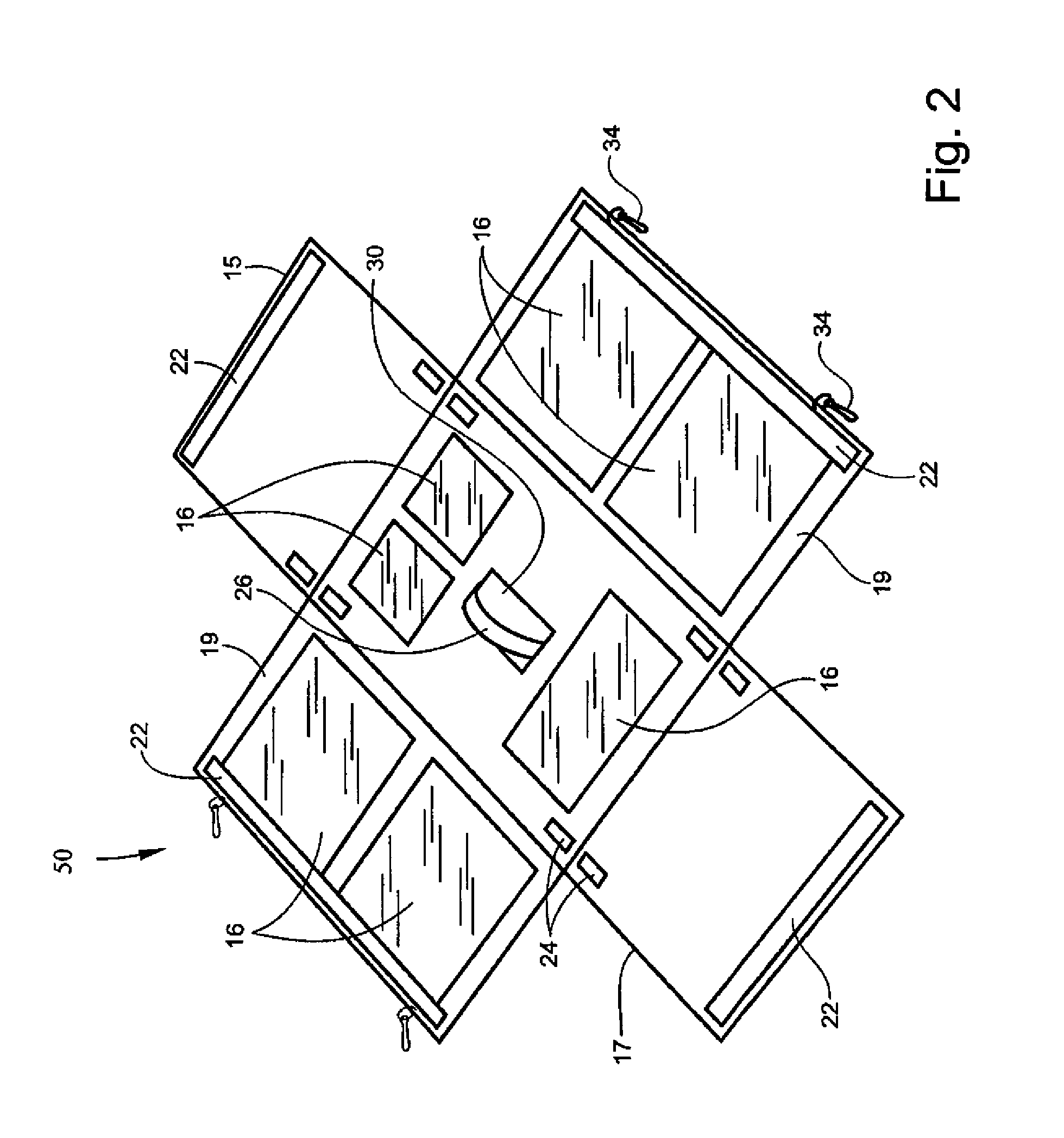

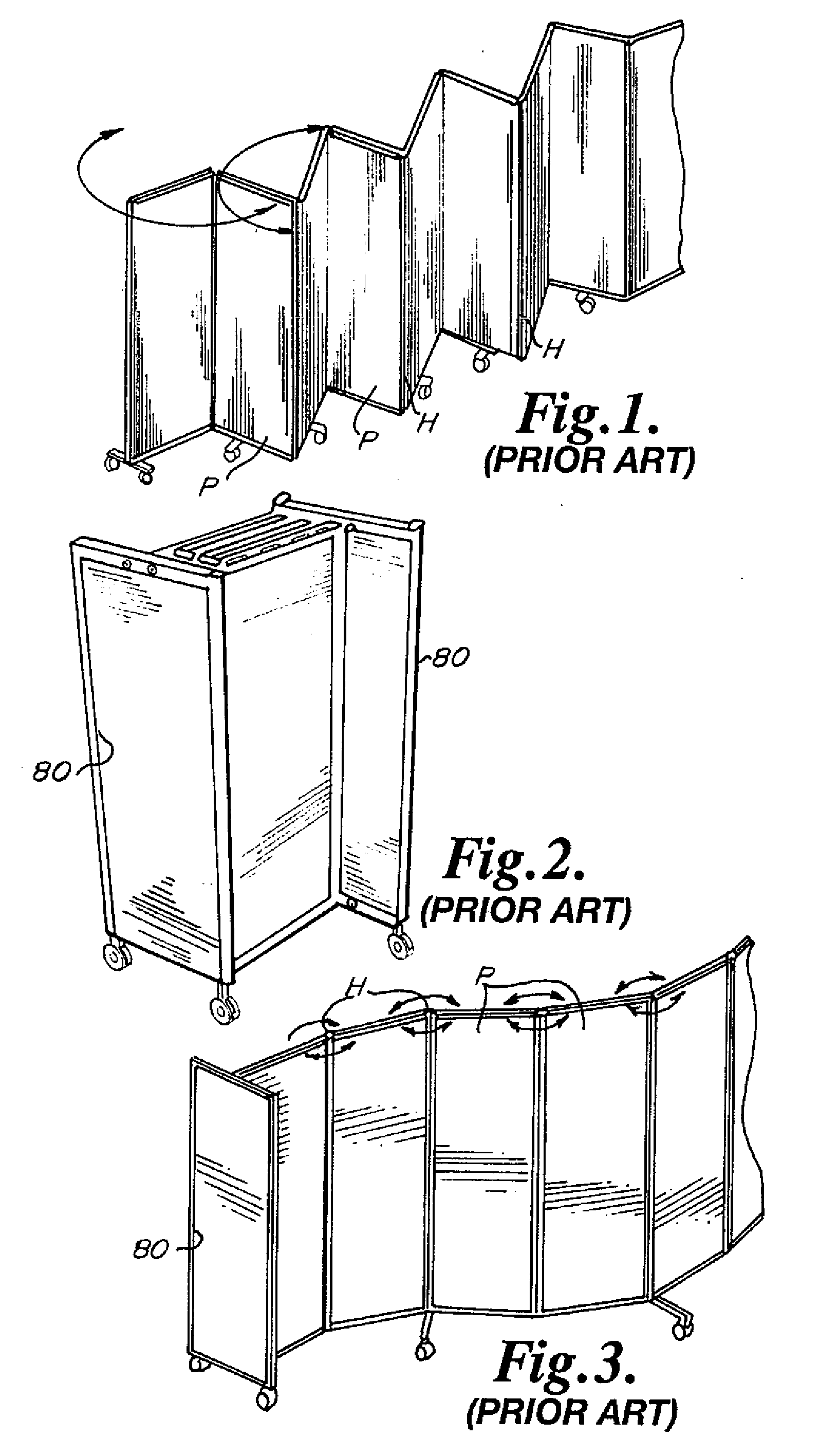

Expandable portable wall partition

Owner:VERSARE SOLUTIONS

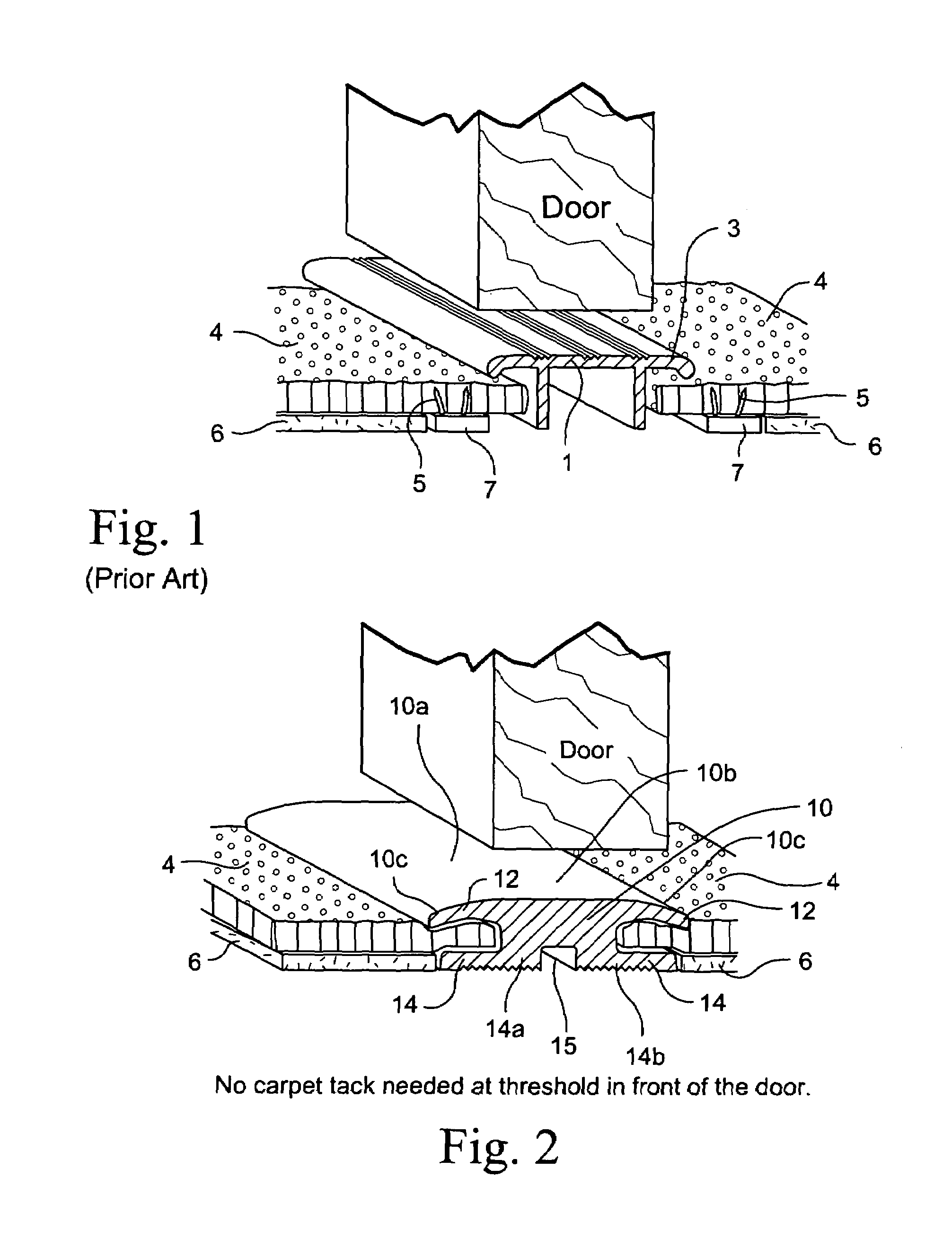

Door threshold

ActiveUS7062881B2Threshold can be reduced and/or eliminatedTreadsCorner/edge jointsEngineeringLower threshold

Owner:RISSONE ROBERT

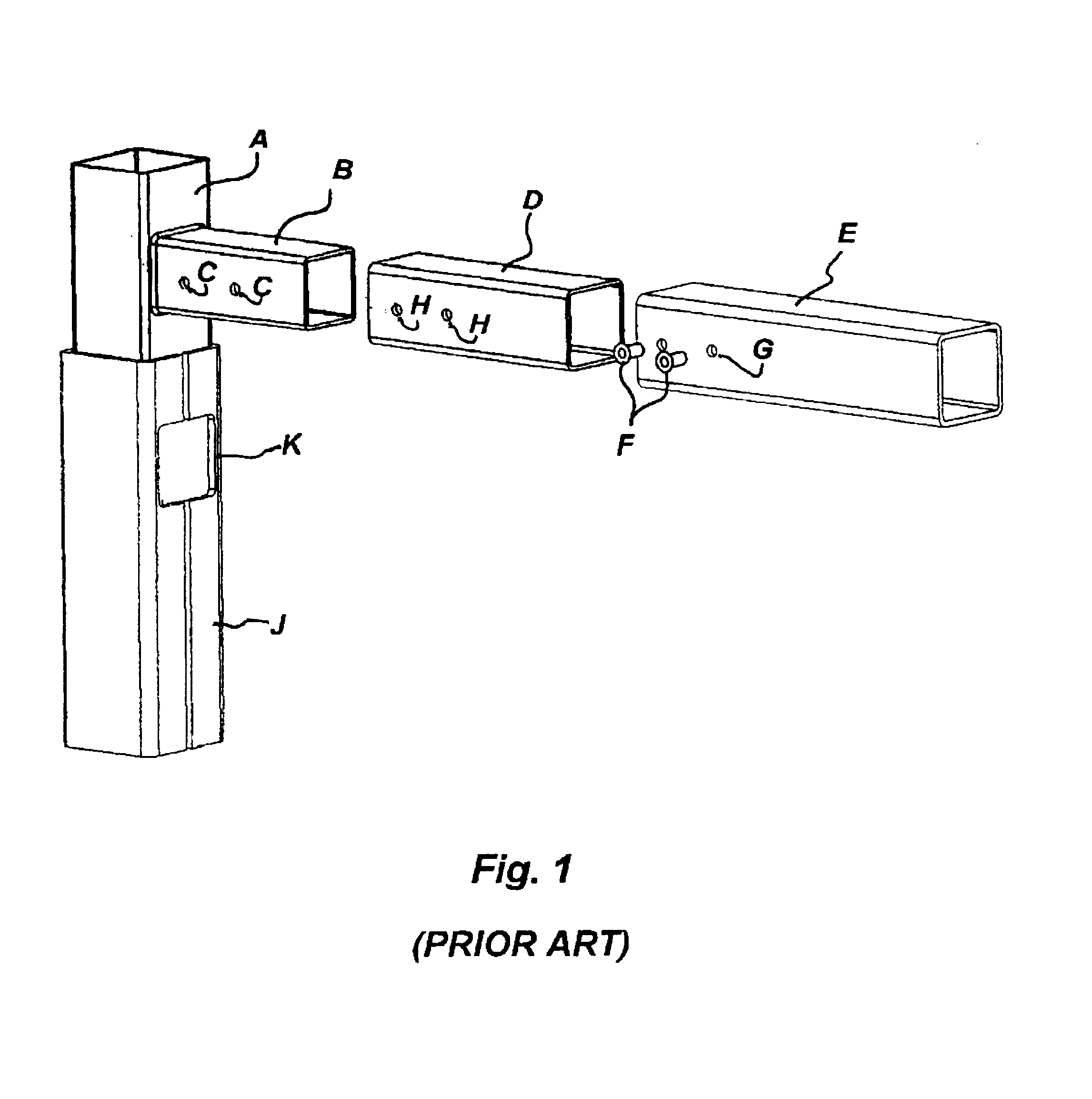

Frame connection mechanism

InactiveUS6881005B2Same strengthEasily substitutedScaffold connectionsGates/doorsEngineeringElectrical and Electronics engineering

A frame connection structure for use in connecting tubular or open channel elements one to another includes two or more inserts configured for respective insertion within the elements to be interconnected. Each of the inserts defines one or more channels therein, each channel being configured to be aligned with a respective aperture defined within the tubular / open channel element in which it is to be retained. A connection member is positioned within each aperture and its aligned respective insert channel. A portion of the tubular / open channel member proximate the aperture is displaced into the channel of the insert member whereby the that portion of the tubular / open channel member is disposed intermediate the sidewall of the channel and the connection member. The two inserts are configured to be connectable one to another. Each insert is therefore securely associated with a respective tubular / open channel member and the inserts are connectable one to another to facilitate the construction of a frame assembly.

Owner:SOSA SAUL SINEY

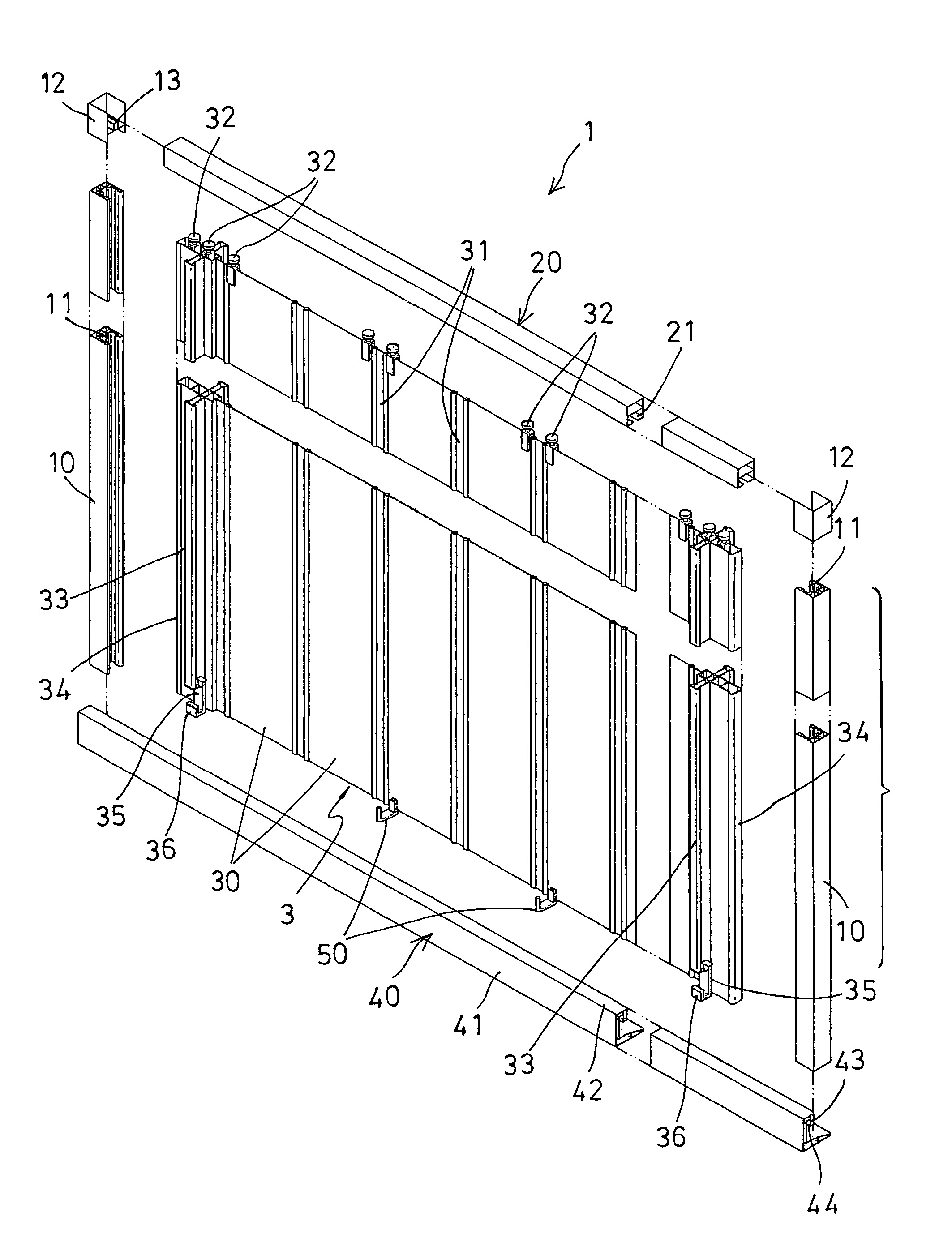

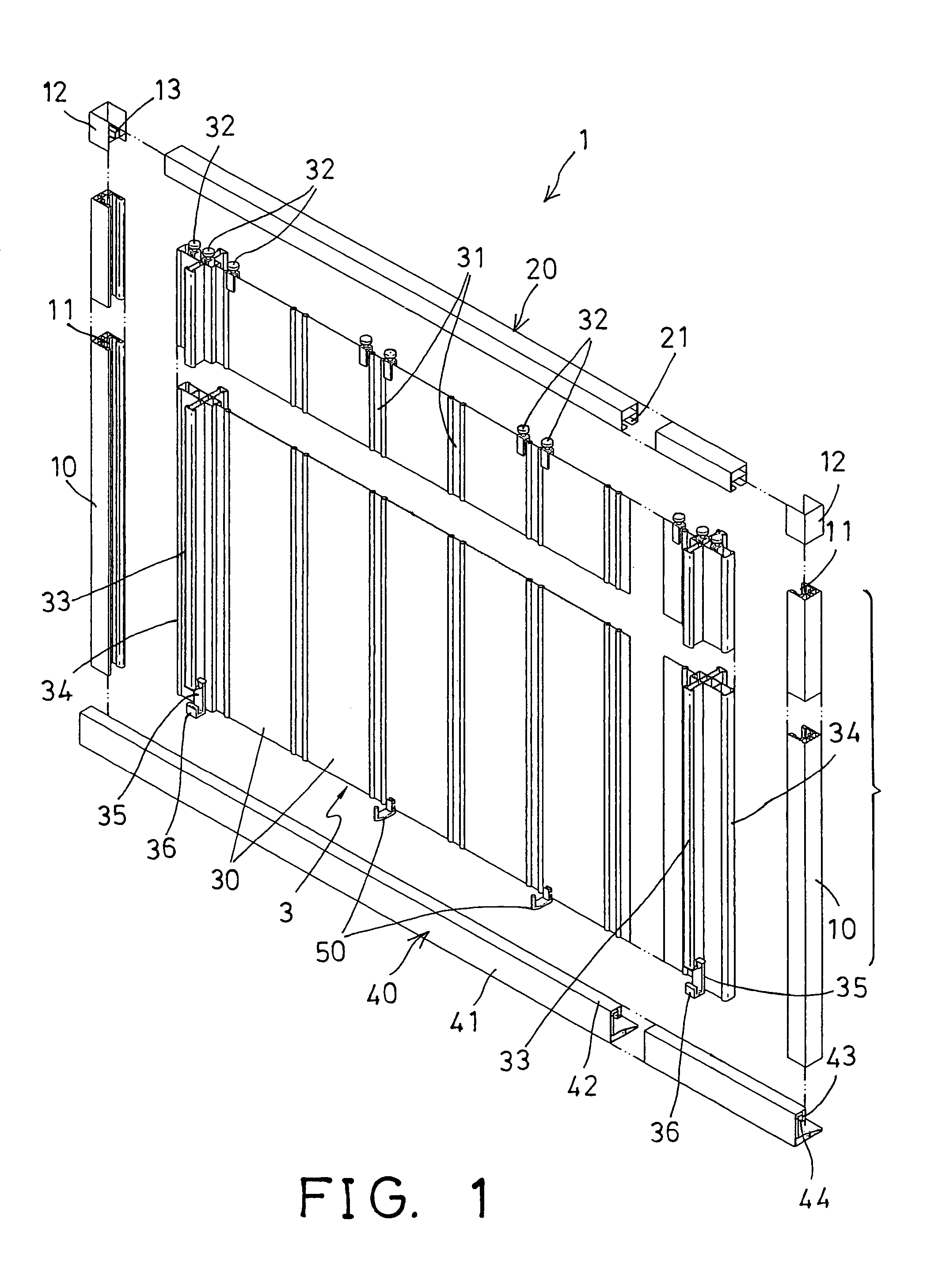

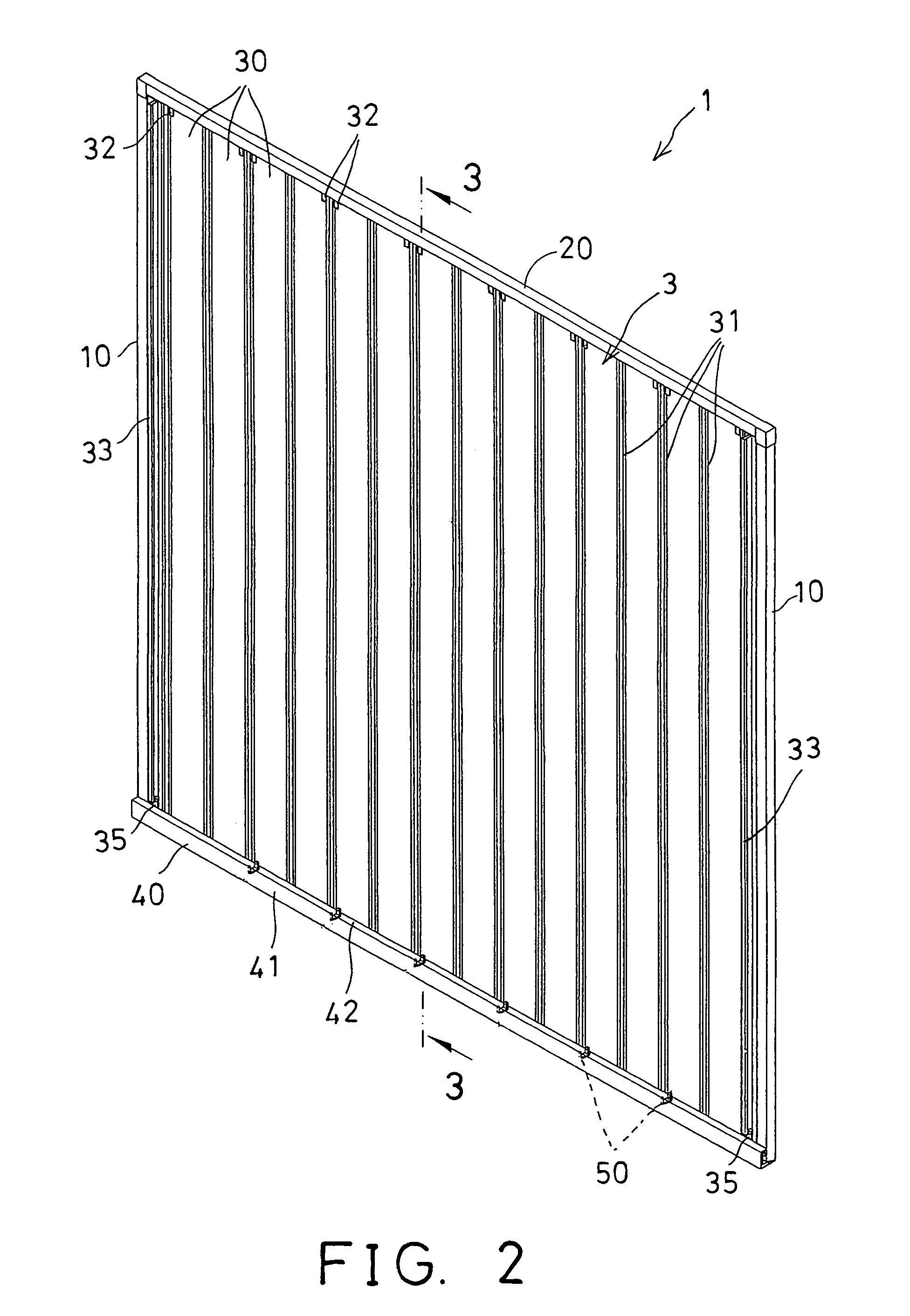

Screen

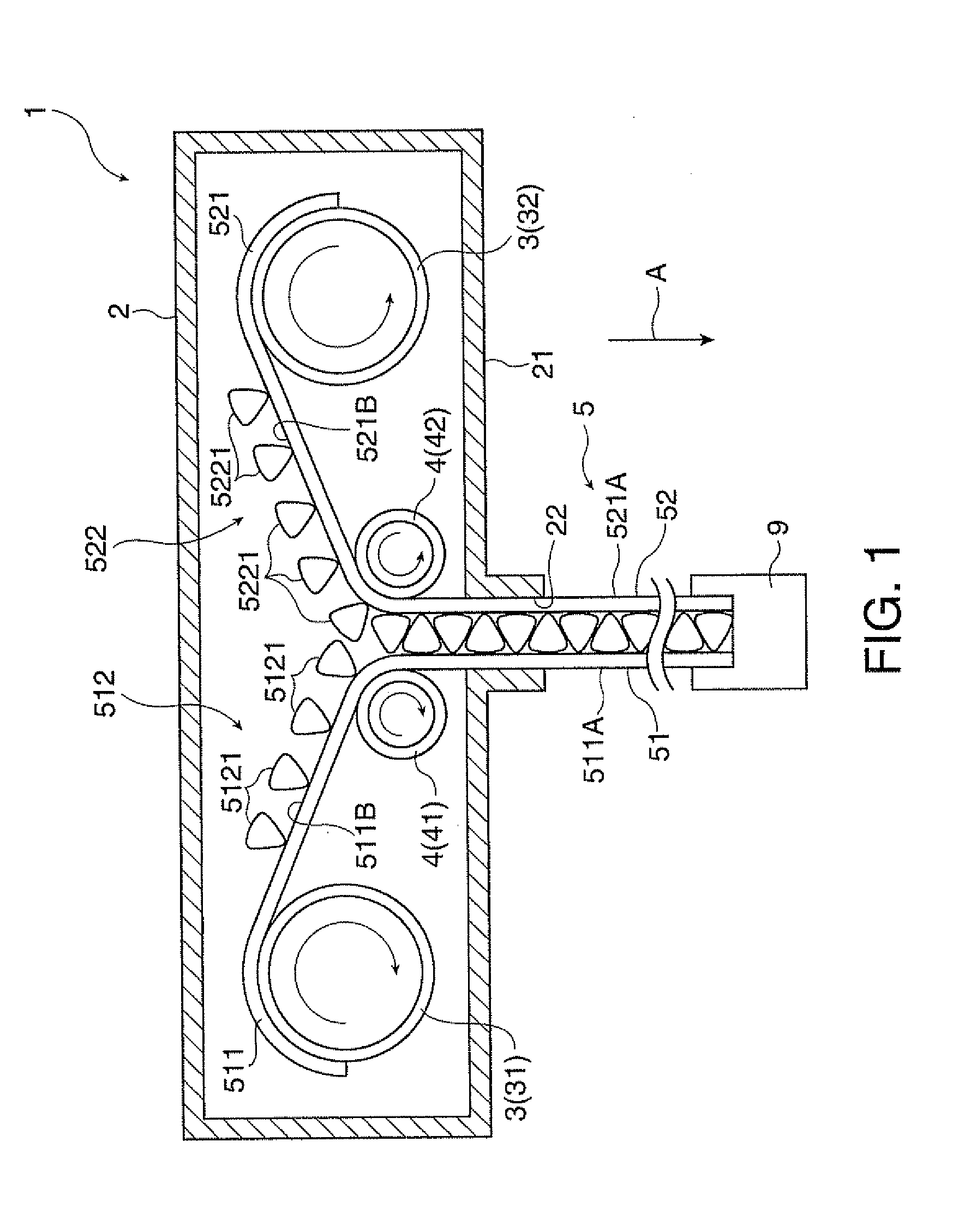

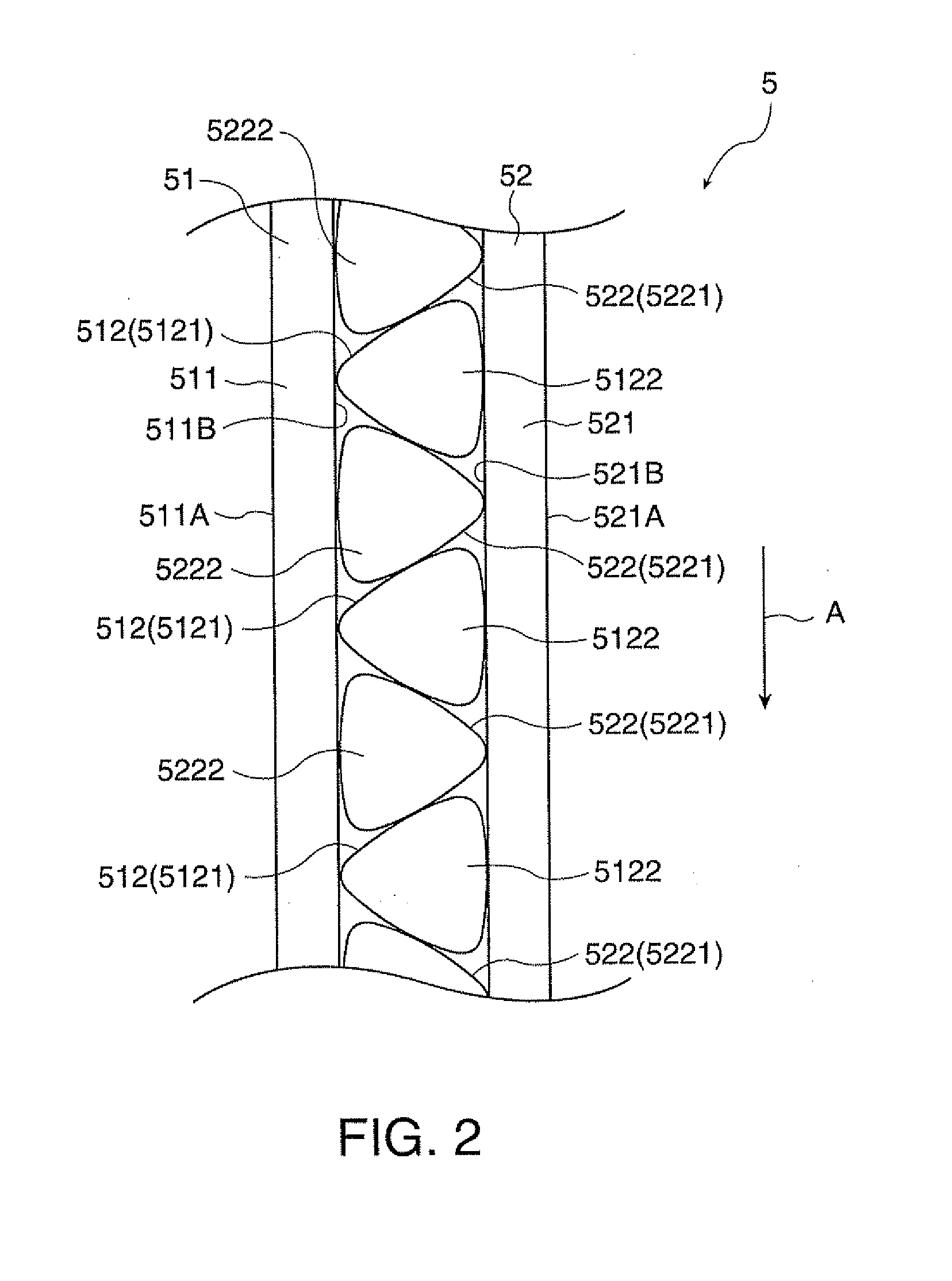

ActiveUS20110011542A1Well formedCombine accuratelyScreensShutters/ movable grillesEngineeringMechanical engineering

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com