Corner key for connecting profiles together and frame work assembly

a technology for connecting profiles and frame work, which is applied in the direction of corners/edge joints, doors/windows, and building roofs, etc., can solve the problems of assembly requirements, large working area, and high cost of cutting equipment, and achieves high production efficiency and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

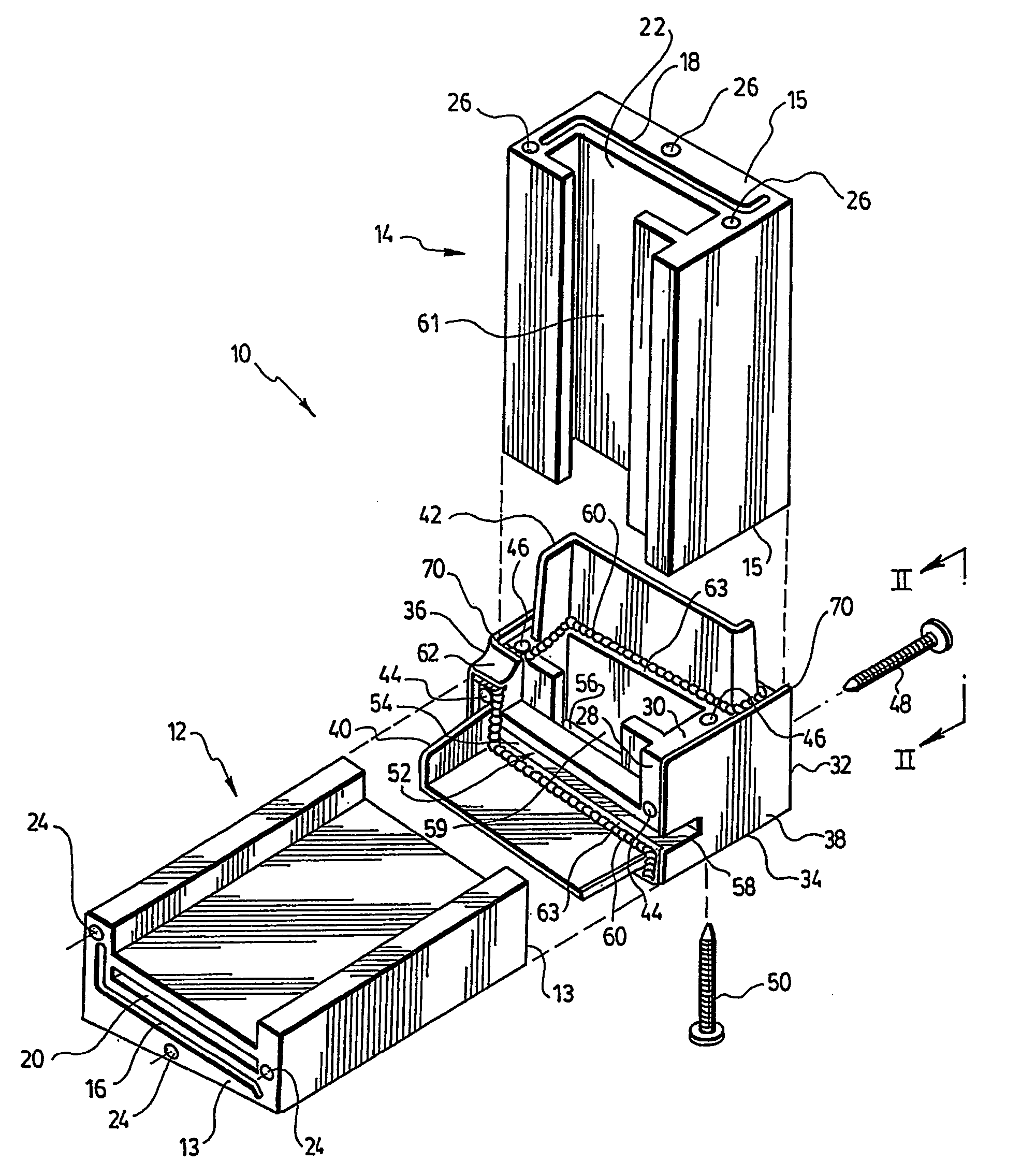

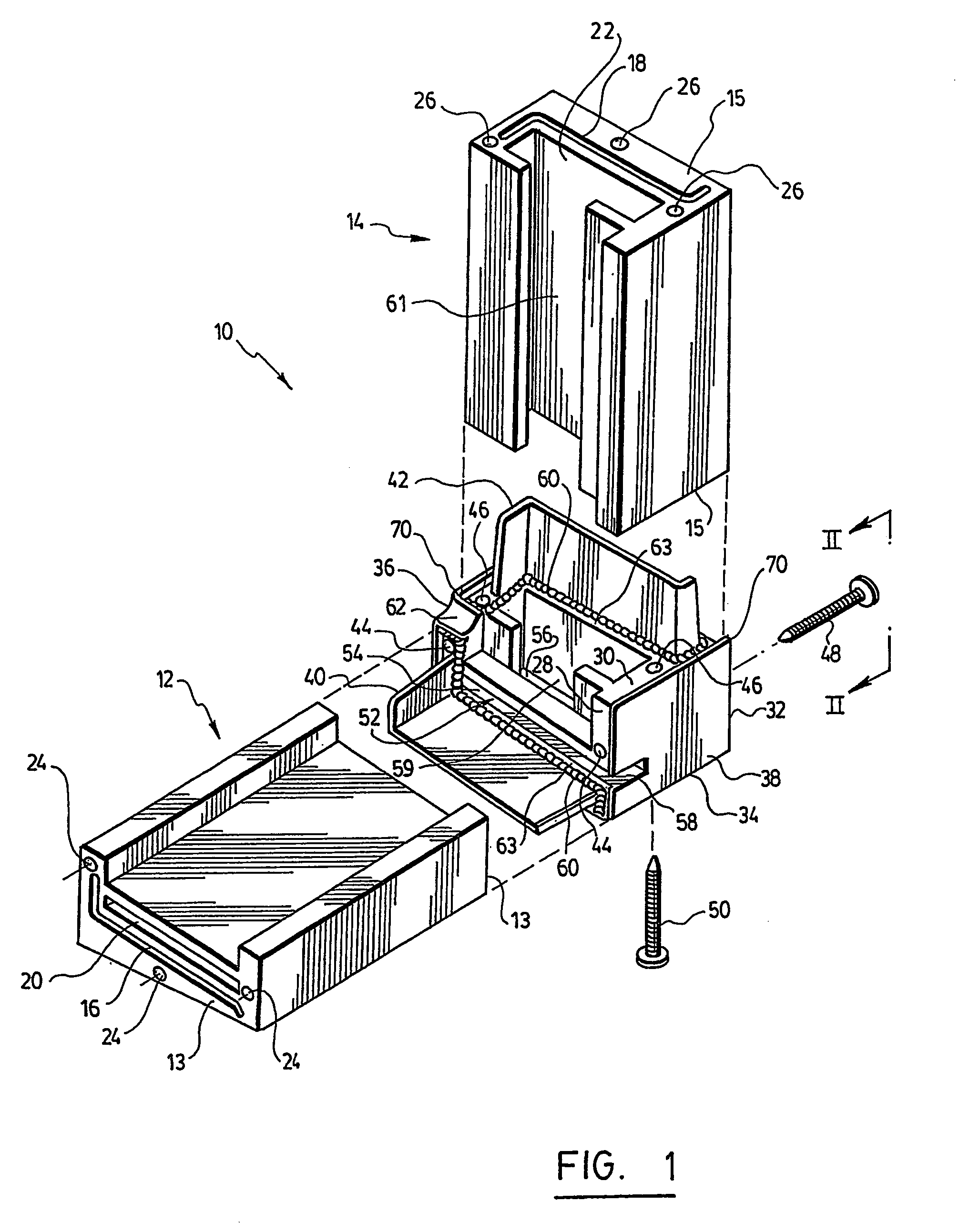

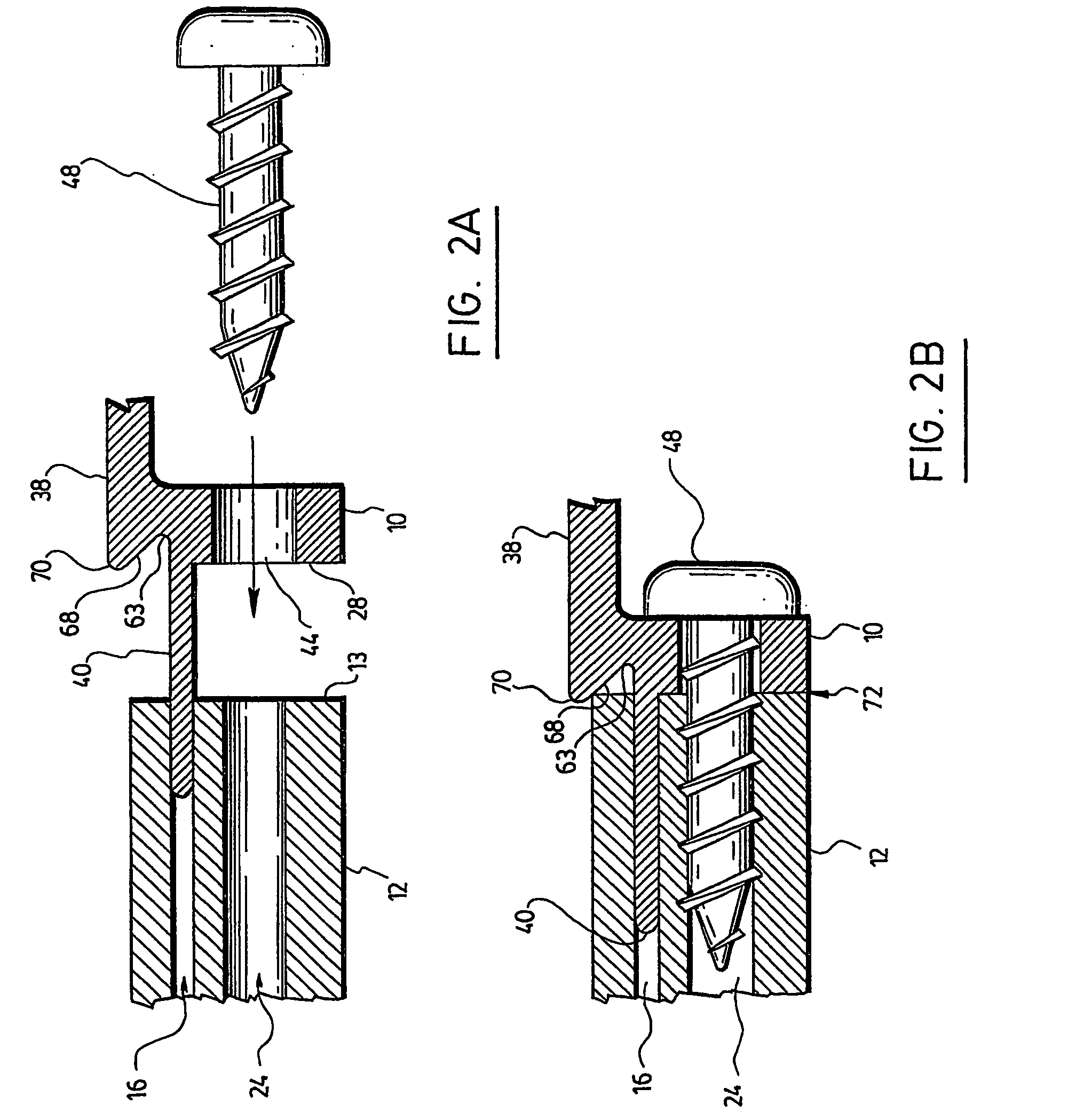

[0050] Referring to FIG. 1, there is shown a corner key 10 according to a preferred embodiment of the present invention. Also shown are portions of two profiles, one corresponding to a sill 12 and the other to a jamb 14 that are to be connected together by means of the corner key 10 to form part of a window frame assembly.

[0051] Those skilled in the art will understand that although only two window frame profiles 12, 14 are illustrated, the teachings according to the present invention are also applicable to any number of profiles or to any other general purpose profiles that are to be jointed with a corner key. In particular, it will be understood that the present teachings apply not only to window frames, but also to door frames, and to other similar structural assemblies as well.

[0052] The corner key 10 that is illustrated is preferably used as a right side lower corner key, but those skilled in the art will also understand that this corner key 10 can be modified so that it can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com