A flame-retardant copper-clad laminate coated with phosphorus-containing and halogen-free solids and its preparation method

A copper-clad laminate, solid technology, applied in chemical instruments and methods, aldehyde/ketone condensation polymer adhesives, epoxy resin adhesives, etc. Oxygen resin hardening adverse effects and other problems, to achieve good toughness and peel strength, good heat resistance and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

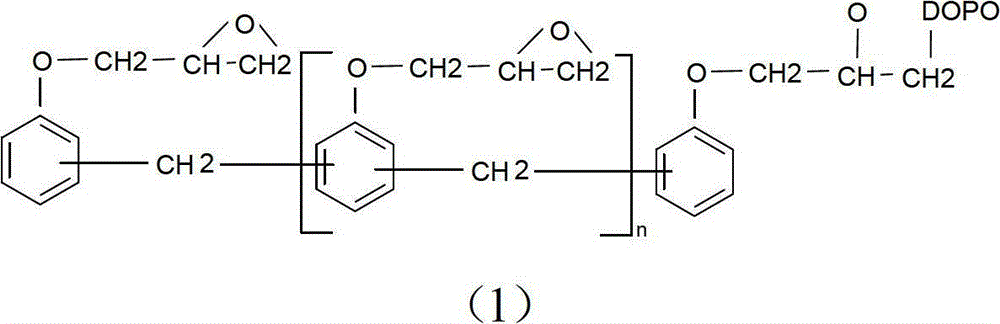

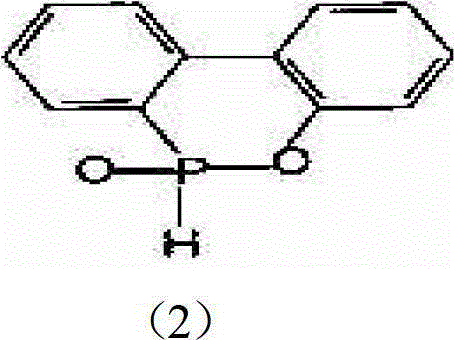

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] (1) prepare adhesive

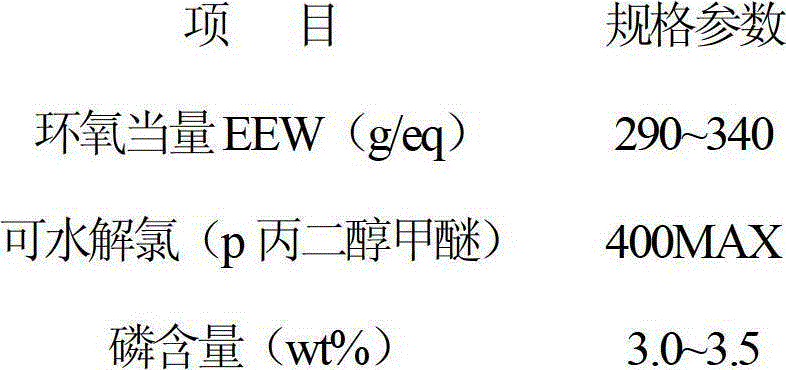

[0077] The mass percentage of solids in the binder used is 65.2%, and the rest is organic solvents (such as propylene glycol methyl ether). Wherein, the formula of solids is shown in Table 4 (by weight)

[0078] Table 4

[0079]

[0080] 1) Add 106Kg of organic solvent into the stirring tank according to the above weight, turn on the stirrer at a speed of 600 rpm, keep stirring continuously and control the temperature of the tank at 40°C, then add aluminum hydroxide and silicon dioxide, and continue to Stir for 20 minutes;

[0081] 2) Add phosphorus-containing epoxy resin, isocyanic acid-modified epoxy resin, phosphorus-containing curing agent, and phenolic resin in sequence according to the formula amount in the stirring tank, and keep stirring at 1000 rpm during the feeding process. Then turn on high-efficiency shearing and emulsification for 3 hours, and at the same time carry out cooling water circulation to keep the temperature of the co...

Embodiment 2

[0099] (1) Preparation of adhesive

[0100] The mass percentage of solids in the adhesive used is 66%, and the rest is organic solvents (such as propylene glycol methyl ether). Wherein, the formula of solids is shown in Table 6 (by weight)

[0101] Table 6

[0102]

[0103] 1) Add 98Kg of organic solvent propylene glycol methyl ether into the stirring tank according to the above weight, turn on the stirrer at a speed of 600 rpm, keep stirring continuously and control the temperature of the tank at 40°C, then add aluminum hydroxide and silicon dioxide, add Continue stirring for 20 minutes after completion;

[0104] 2) Add phosphorus-containing epoxy resin, isocyanic acid-modified epoxy resin, phosphorus-containing curing agent, and phenolic resin in sequence according to the formula amount in the stirring tank, and keep stirring at 1000 rpm during the feeding process. Then turn on high-efficiency shearing and emulsification for 3 hours, and at the same time carry out cooli...

Embodiment 3

[0122] (1) Preparation of adhesive

[0123] The mass percentage of solids in the adhesive used is 66%, and the rest is organic solvents (such as propylene glycol methyl ether), wherein the formula of solids is shown in Table 8 (by weight)

[0124] Table 8

[0125]

[0126] 1) Add 99Kg of organic solvent propylene glycol methyl ether into the stirring tank according to the above weight, turn on the stirrer at a speed of 600 rpm, keep stirring continuously and control the temperature of the tank at 40°C, then add aluminum hydroxide and silicon dioxide, add Continue stirring for 20 minutes after completion;

[0127] 2) Add phosphorus-containing epoxy resin, isocyanic acid-modified epoxy resin, phosphorus-containing curing agent, and phenolic resin in sequence according to the formula amount in the stirring tank, and keep stirring at 1000 rpm during the feeding process. Then turn on high-efficiency shearing and emulsification for 3 hours, and at the same time carry out coolin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com