Automatic tablet compressing device

A tablet and automatic technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems of low degree of automation, reduced pharmaceutical efficiency, and inaccurate dosage of medicines, etc., to achieve simple and reasonable structure and high degree of automation , Reduce the effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below, the technical solution of the present invention will be described in detail through specific examples.

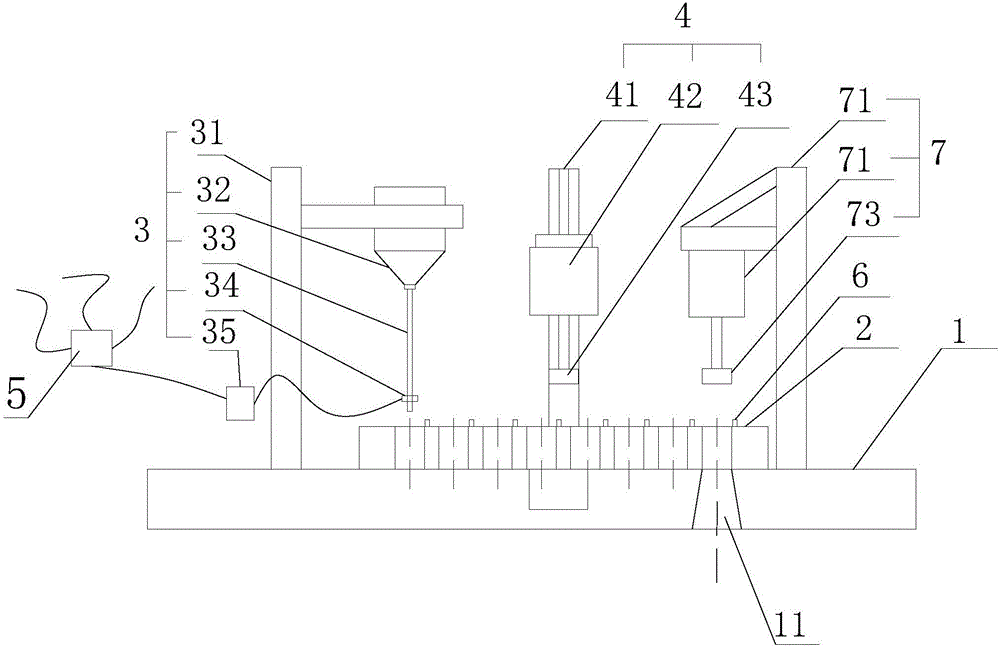

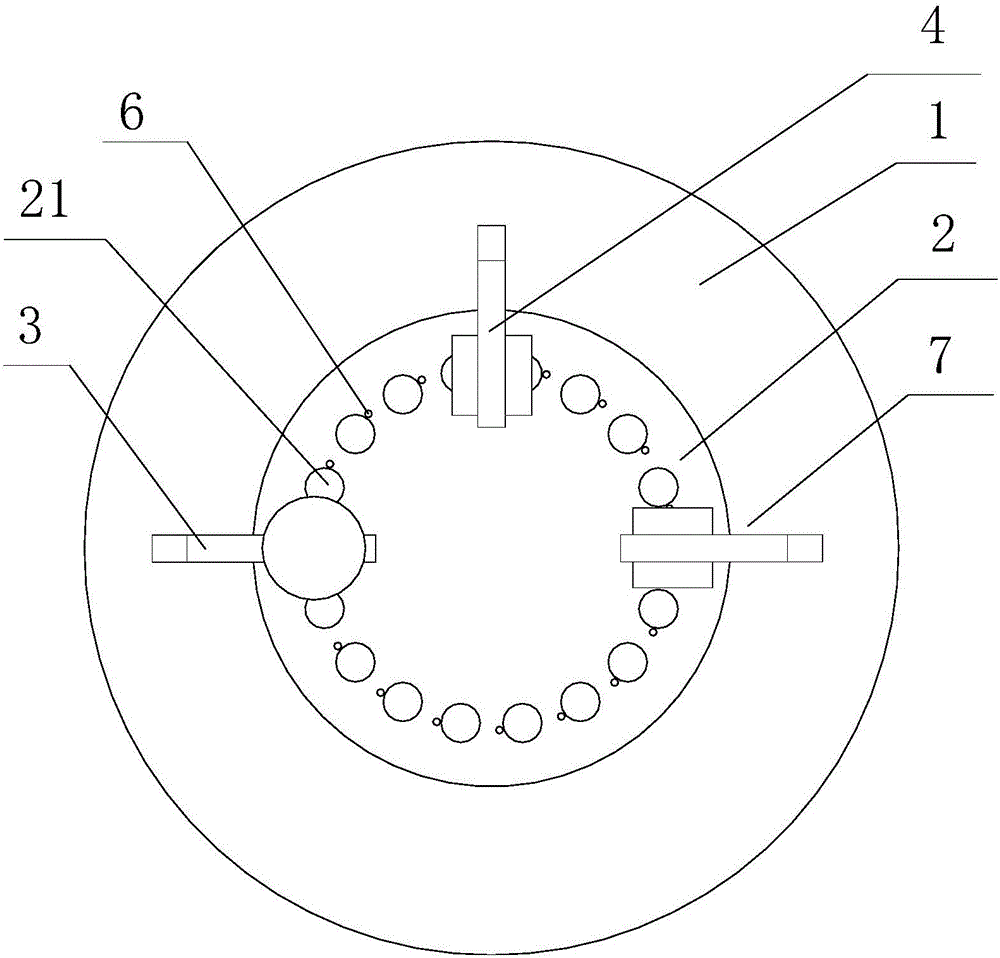

[0025] Such as Figure 1-2 as shown, figure 1 It is a structural schematic diagram of an automatic tablet molding device proposed by the present invention; figure 2 It is a top view of an automatic tablet pressing device proposed by the present invention.

[0026] refer to Figure 1-2 , an automatic tablet molding device proposed in the embodiment of the present invention, comprising: a base 1, a turntable 2, a driving mechanism, a feeding mechanism 3, a molding mechanism 4, a feeding mechanism 7 and a main controller 5, wherein:

[0027] The turntable 2 is installed on the base 1, and the turntable 2 is provided with a plurality of cavities 21 annularly distributed around the outer circumference of the axis line. The cavities 21 run through the turntable 2. The turntable 2 is rotated on the base 1 to seal, and the bottom of the cavity 21 or the side wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com