Textured silicon carbide whisker toughened alumina-based ceramic, preparation method and application thereof

A technology for texturing silicon carbide and silicon carbide whiskers, which is applied in the field of composite gradient ceramic materials, can solve the problems of limiting high-speed cutting performance, inability to effectively increase thermal conductivity, and low thermal conductivity of alumina tools, and achieve high The effect of stability, high production efficiency, and less processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Preparation

[0036] (1) Alumina powder (purity 99.99%), silicon carbide whiskers, sintering aid Y with a volume ratio of 60:55:5 2 o 3 (purity 99.99%) for batching, using ethanol as a solvent, alumina balls as a ball milling medium, and a rotating speed of 200r / min, performing roller ball milling and mixing for 10 hours, and drying to obtain a mixed powder;

[0037] (2) Disperse the mixed powder in hot paraffin, and pour it into a mold (80mm in outer diameter, 75mm in height, and the ratio of outer diameter to inner diameter is 1.6) while it is hot, and cast it into a cylindrical casting;

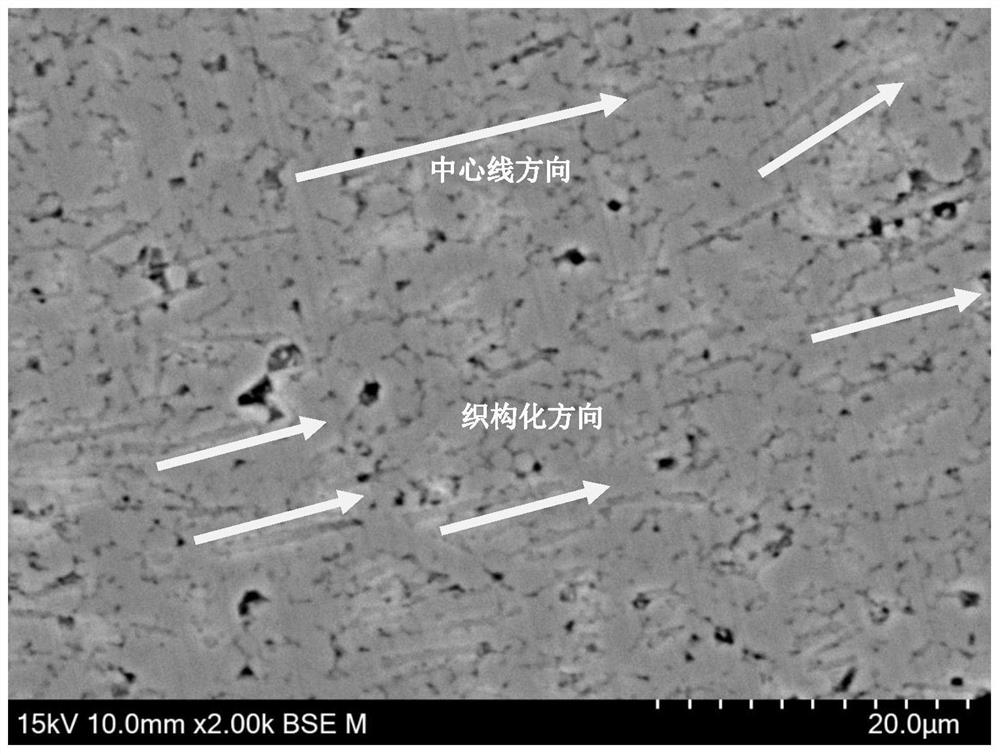

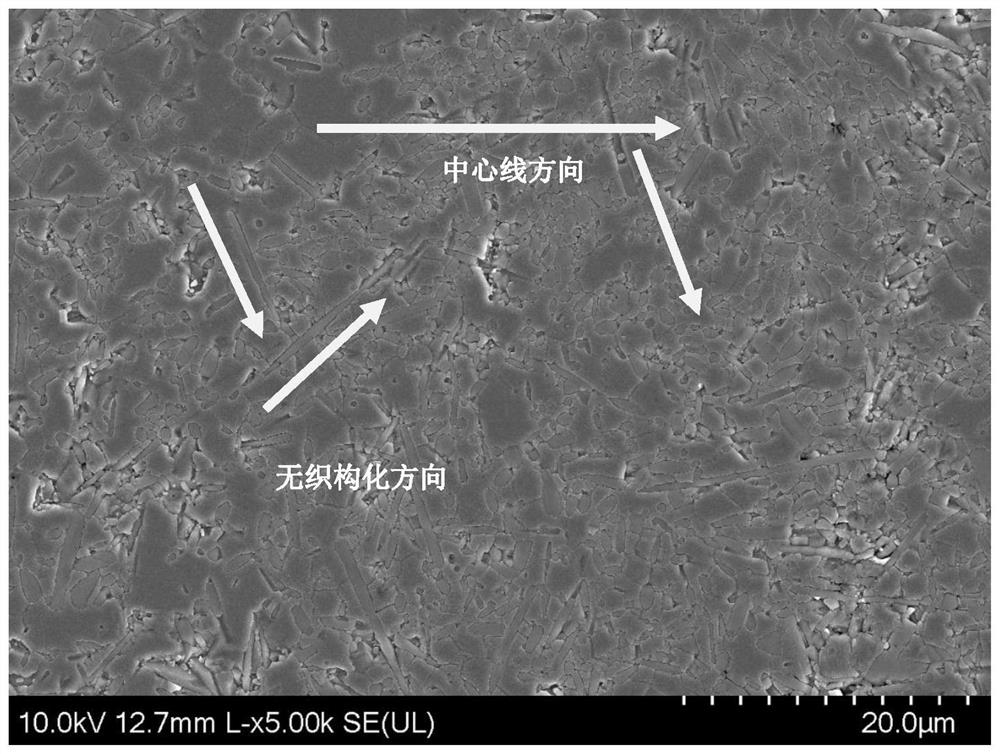

[0038] (3) Apply an axial pressure of 90 MPa to the casting at room temperature, and the casting deforms along the center under high pressure to form a textured extrusion with radially arranged whiskers.

[0039] (4) Debinding the textured extruded part at 250°C under normal pressure to completely volatilize the paraffin to obtain a green body;

[0040] (5) Put the green body ...

Embodiment 2

[0051] The difference from Example 1 is that the axial pressurization described in step (5) is 20MPa,

[0052] The micromorphology of the alumina ceramic obtained in this example shows that the whiskers on the surface perpendicular to the pressing direction are basically arranged radially, and the relative density is 98.5%. The Vickers hardness on the surface is 20GPa, and the Vickers hardness at the center of the chord section is 19GPa.

Embodiment 3

[0054] The difference from Example 1 is that: the axial pressure in step (5) is 50 MPa, the sintering temperature is 1500° C.; the holding time is 50 min.

[0055] The micromorphology of the alumina ceramics obtained in this embodiment shows that the whiskers on the surface perpendicular to the pressing direction are basically arranged radially, and the relative density is 98%. The Vickers hardness on the surface in the compressive direction is 21GPa, and the Vickers hardness on the center of the chord section is 20GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com