Construction method for internally penetrating steel pipes for top pipe of water diversion project

A water diversion engineering and construction method technology, applied in the direction of pipes/pipe joints/fittings, pipe laying and maintenance, mechanical equipment, etc., can solve the problems of reducing the anti-deformation capacity of pipelines, pipe jacking deformation, steel pipe damage, etc., and it is not easy to achieve freedom Sliding, reducing construction strength, and reliable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

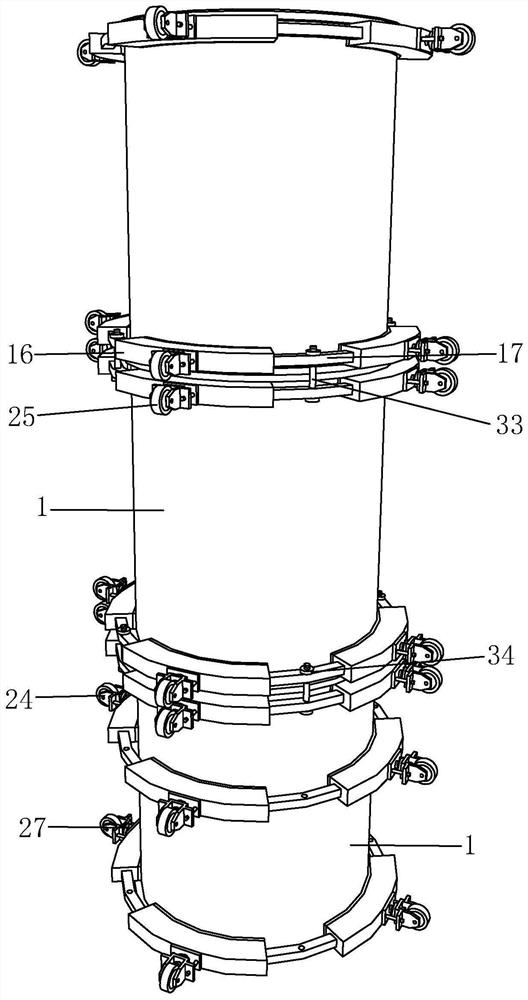

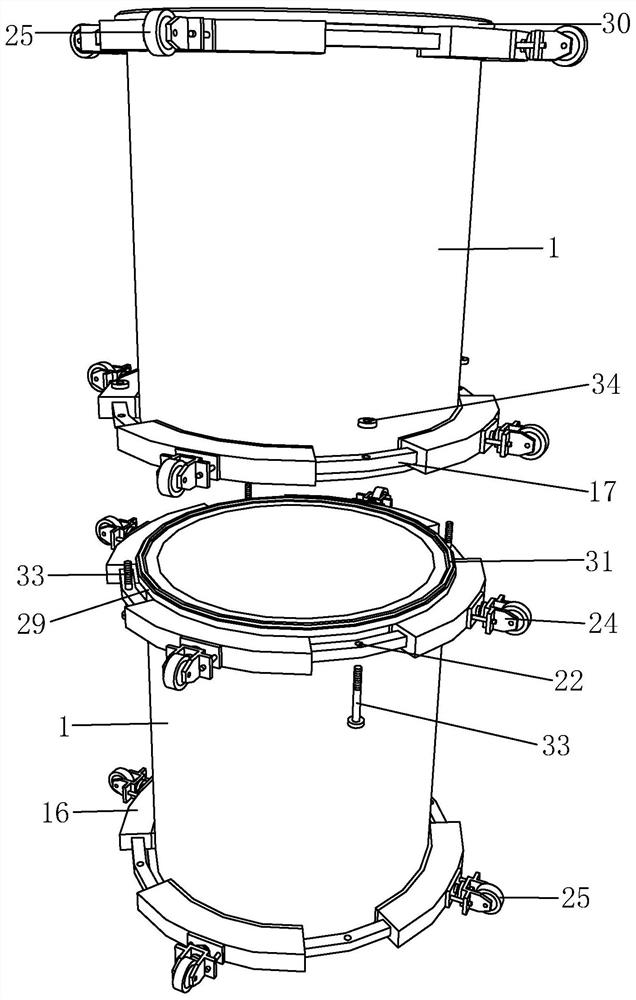

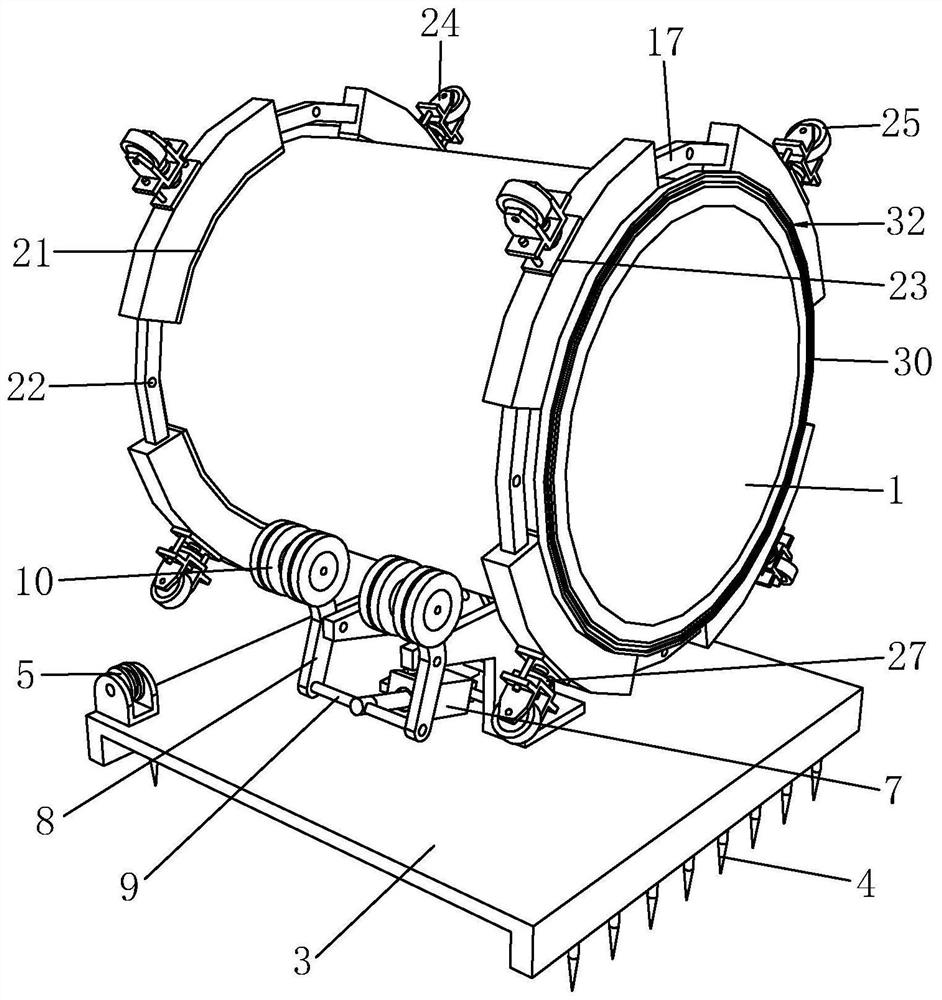

[0056] Such as Figure 1 to Figure 6 Shown, be the construction method of a kind of water diversion engineering pipe jacking of the present invention and wear steel pipe inside, comprise the steps:

[0057] (a) Preparation for construction:

[0058] ⑴Clean up the inner bottom surface of the working well, and compact and level it;

[0059] (2) Install a baffle at the end of the pipe jacking to seal the outlet of the pipe jacking;

[0060] (b) The first steel pipe 1 is in place: the stinger 2 includes a U-shaped base 3, and spikes 4 are evenly distributed on the bottom surface of the U-shaped support, which improves the soil-breaking ability of the U-shaped base 3, and is firm in gripping the ground, which is not easy Dumping, shifting, simple and practical. Fixed pulleys 5 and fixed brackets 6 are symmetrically distributed on the U-shaped base 3, hydraulic cylinders 7 are rotatably connected between the fixed brackets 6, V-shaped swing rods 8 are rotatably connected to both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com