Goods Stacking device

A lifting device and fork technology, which is applied in the field of storage equipment, can solve the problems of inability to move the stacker, increase storage costs, and low utilization of equipment resources, and achieve the effect of improving the efficiency of stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

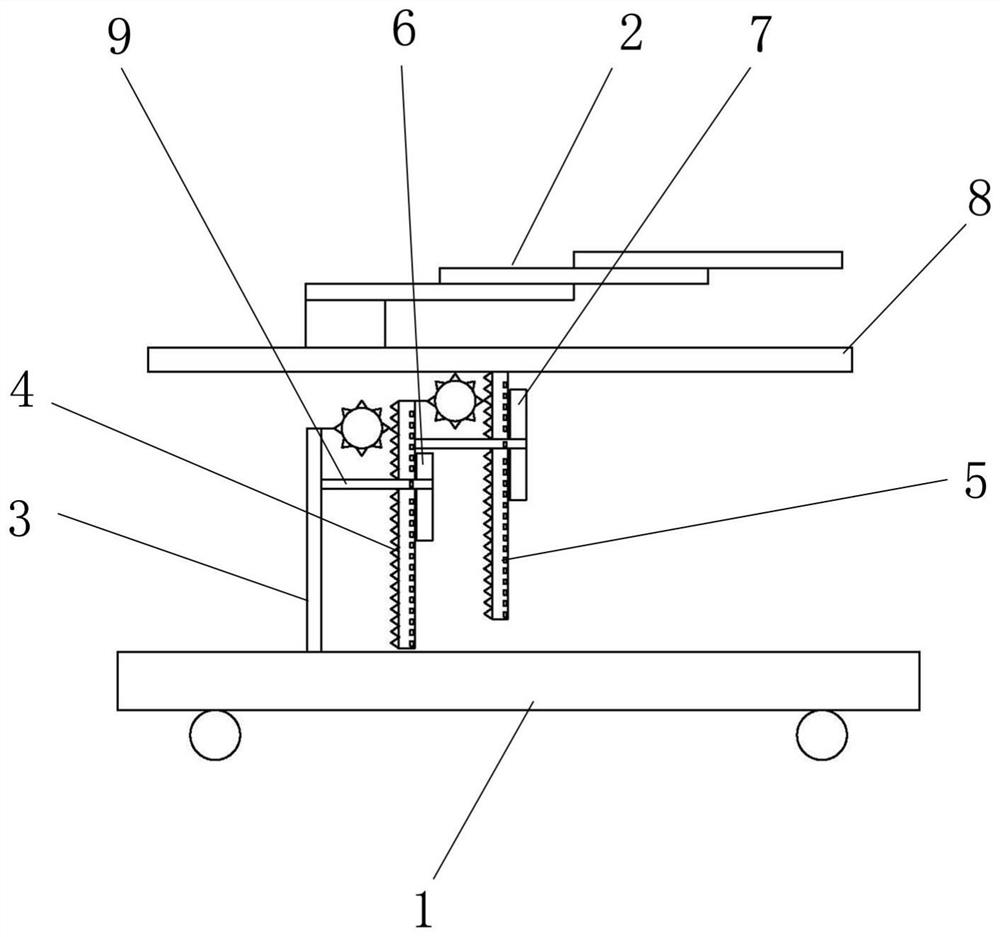

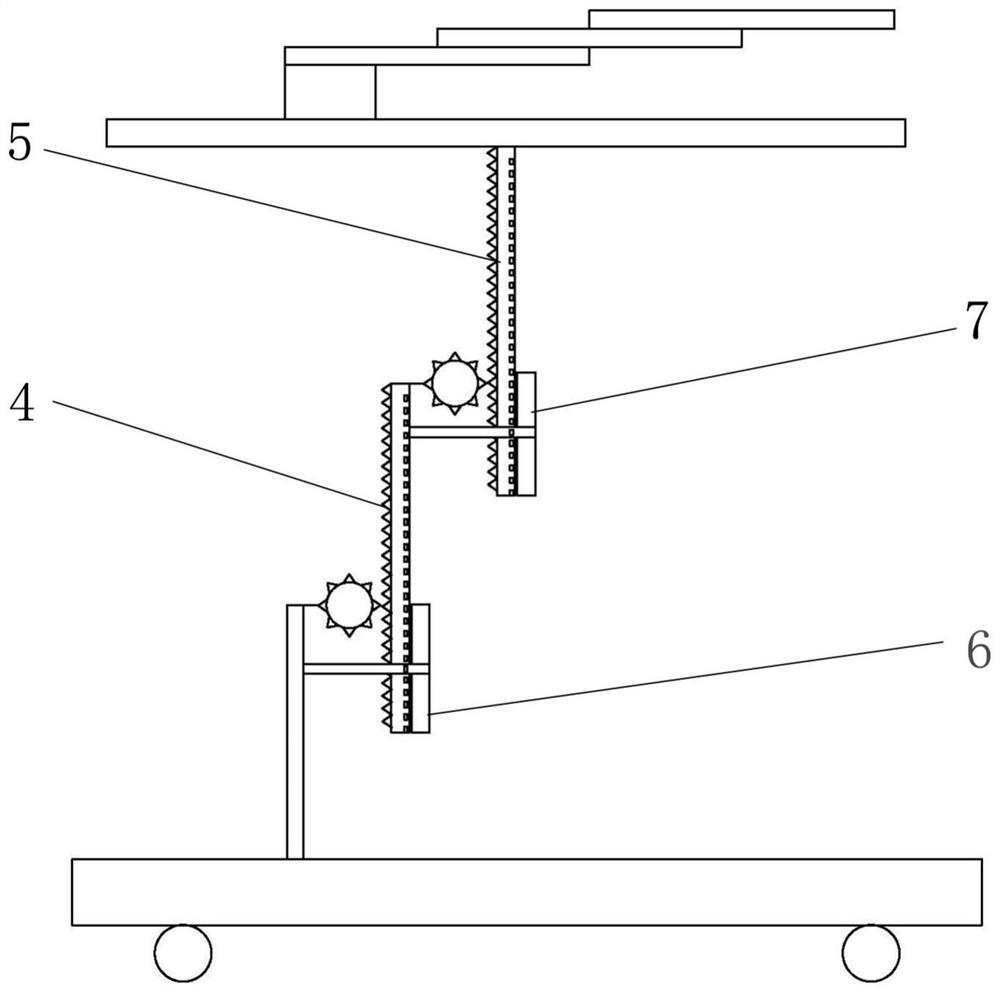

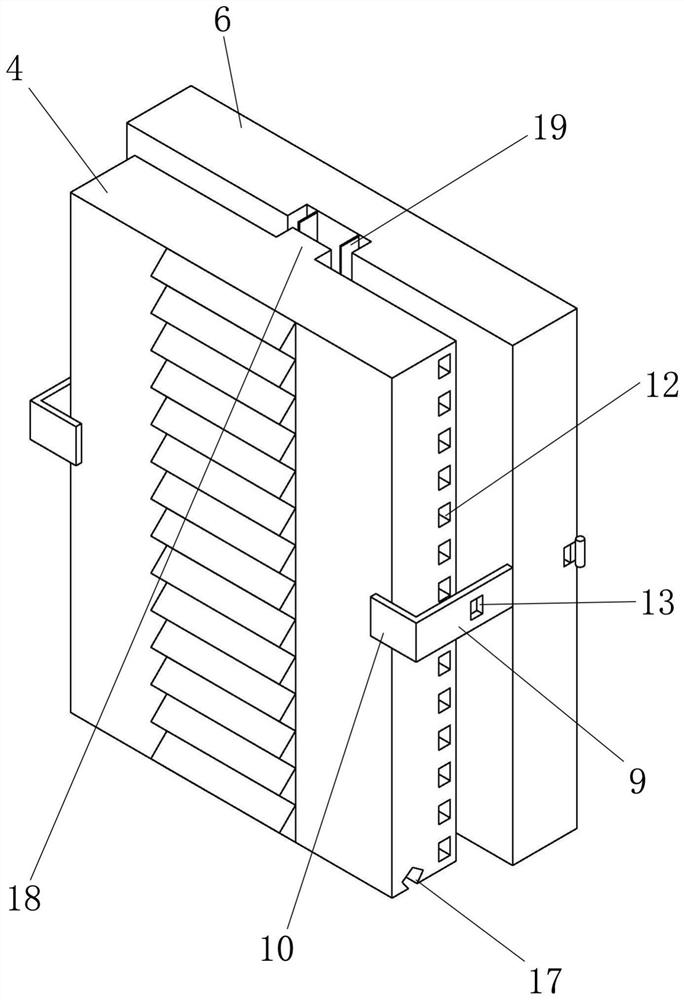

[0025] like Figure 1 to Figure 7 As shown, a stacking device includes an AGV trolley 1, a lifting device and a fork 2, wherein the lifting device includes a support rod 3, a first motor, a first lifting bar 4, a second motor, a second lifting bar 5, The first vertical guide plate 6, the second vertical guide plate 7 and the lifting plate 8, the support rod 3 is a straight rod extending upwards from the upper surface of the AGV trolley 1, the first motor is installed on the upper end of the support rod 3, the first motor The shaft end is connected with a gear, and the first vertical guide plate 6 is connected to the support rod 3 through the first horizontal straight plate 9. The first horizontal straight plate 9 has a limiting plate 10 extending inward, and the limiting plate 10 is the inner surface of the horizontal straight plate from both sides. Straight plates extending toward each other, the first lifting bar 4 is a straight plate embedded between the limiting plate 10 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com