Novel sidewall for underground vehicle

A new type of vehicle technology, applied in the direction of railway car body, railway car body components, material-based railway technology, etc., can solve the problems of complex manufacturing process of the car body side wall, affecting the appearance of the vehicle, lack of light in the carriage, etc., and achieve smoothness. Good, simplified process, well-lit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below with reference to the accompanying drawings and examples. However, the invention is not limited to the examples given.

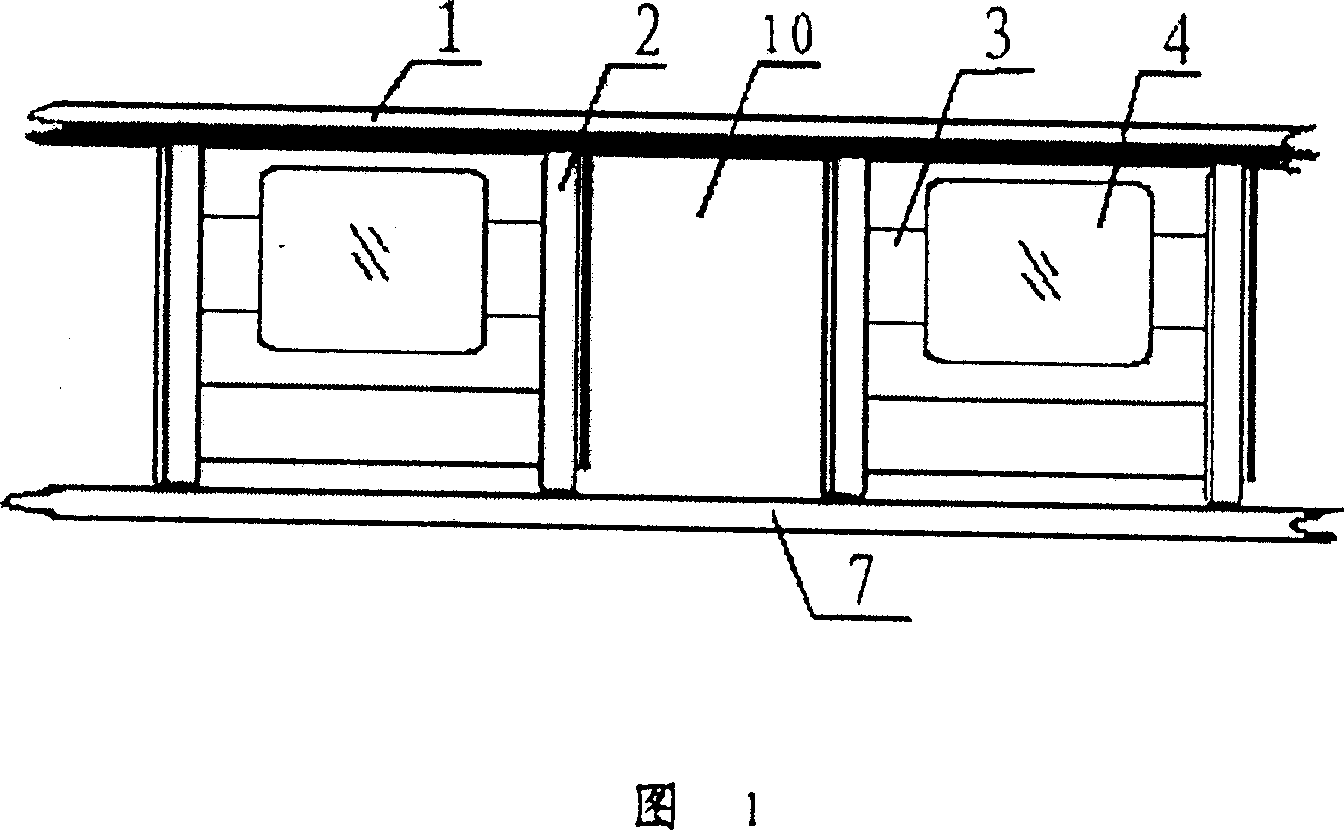

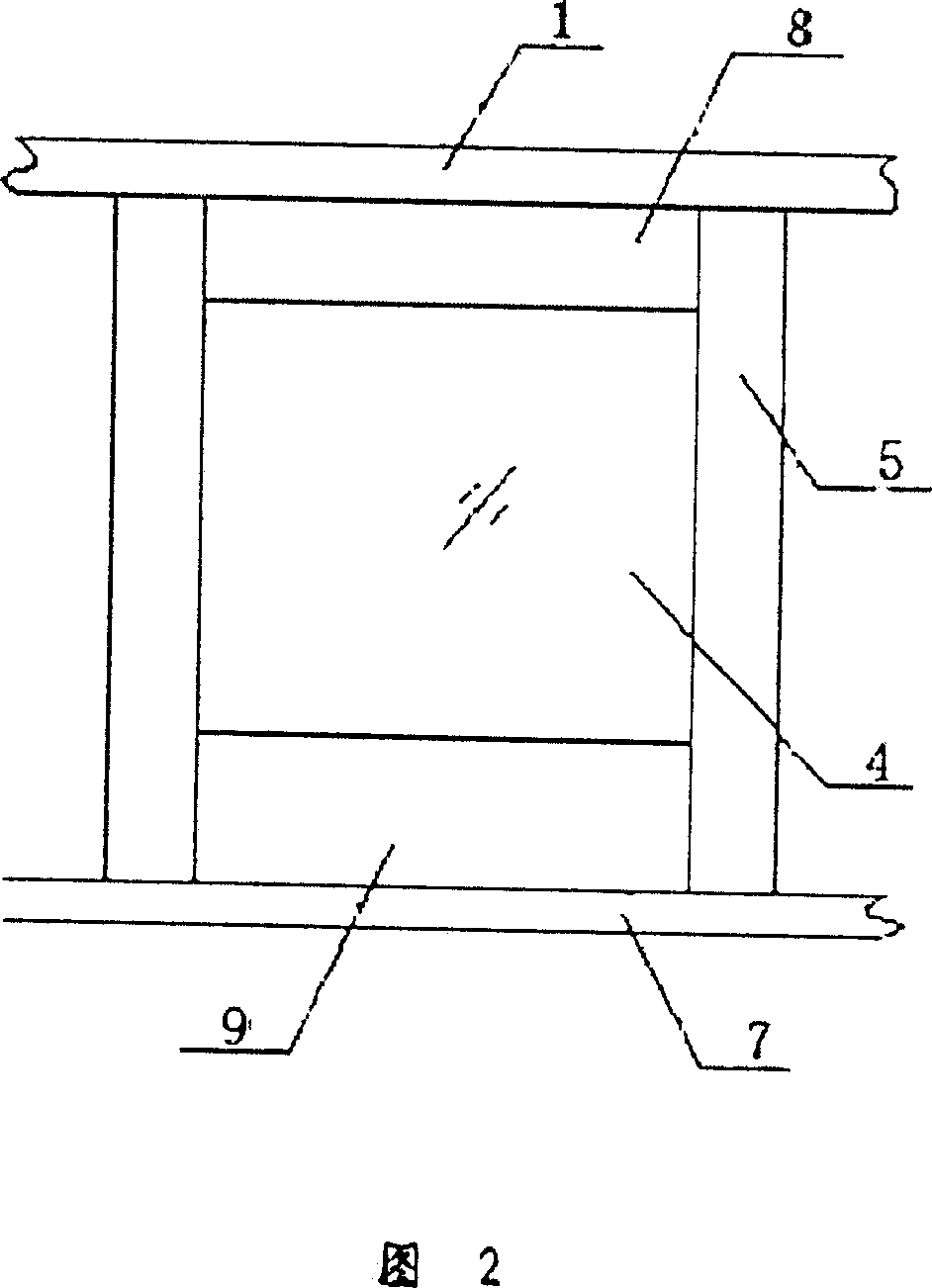

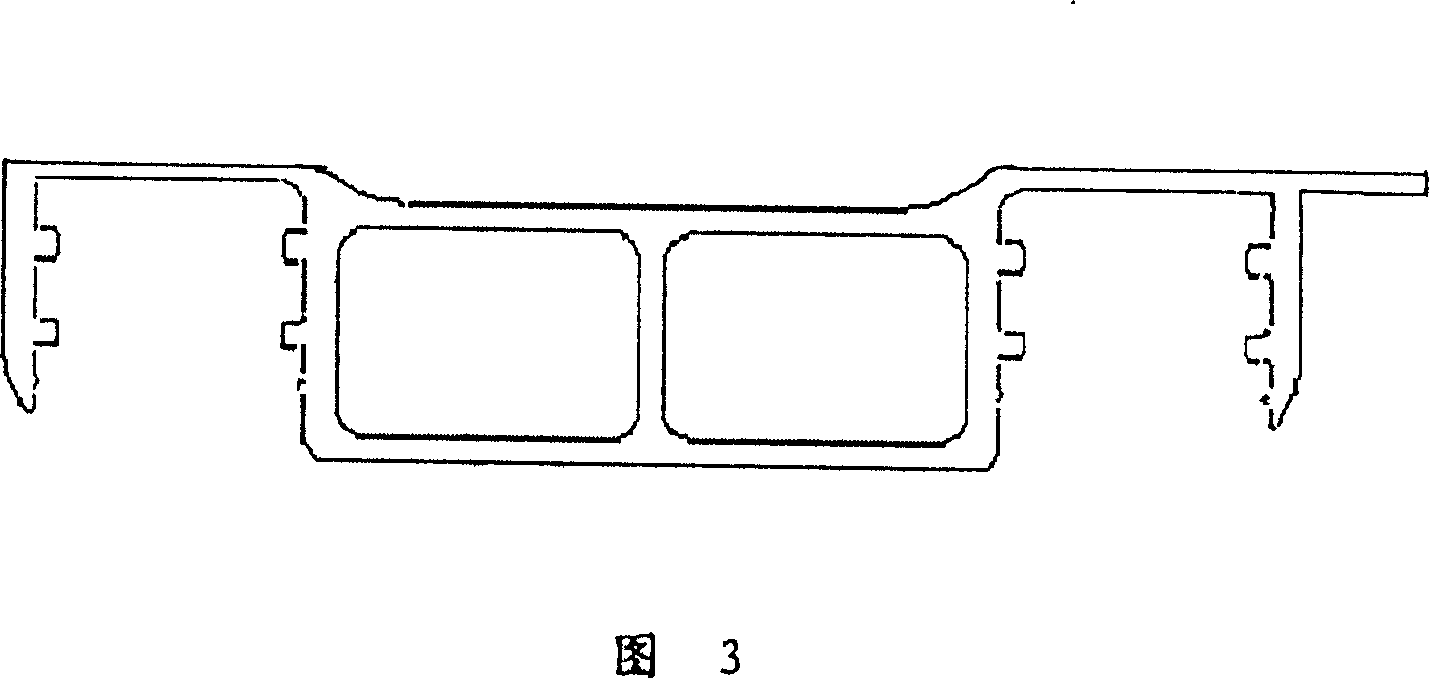

[0012] As shown in Fig. 2, the novel side wall of the subway vehicle of the present invention comprises upper side beam 1, lower side beam 7 and vehicle window 4, is characterized in that: have the profile column 5 that is distributed with the width of car door, vehicle window opening, this profile column The upper and lower ends of 5 are welded into one body with the upper side beam 1 and the lower side beam 7 respectively, and the window area between adjacent profile columns has a window upper plate 8 and a window lower plate 9 riveted and fixed with the upper side beam 1 and the lower side beam 7 respectively, The vehicle window 4 glass is located between the upper window plate 8 and the lower window plate 9 .

[0013] Since the force at both ends of the carriage is relatively small, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com