Modifying treating device for corona discharge low temperature plasma fabric surface

A low-temperature plasma and surface modification technology, which is applied in the direction of ultrasonic/sonic fiber treatment, etc., can solve problems such as difficult industrial application, difficult large-scale uniform plasma, complex device structure, etc., and achieves efficient continuous surface modification treatment , simple process, no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

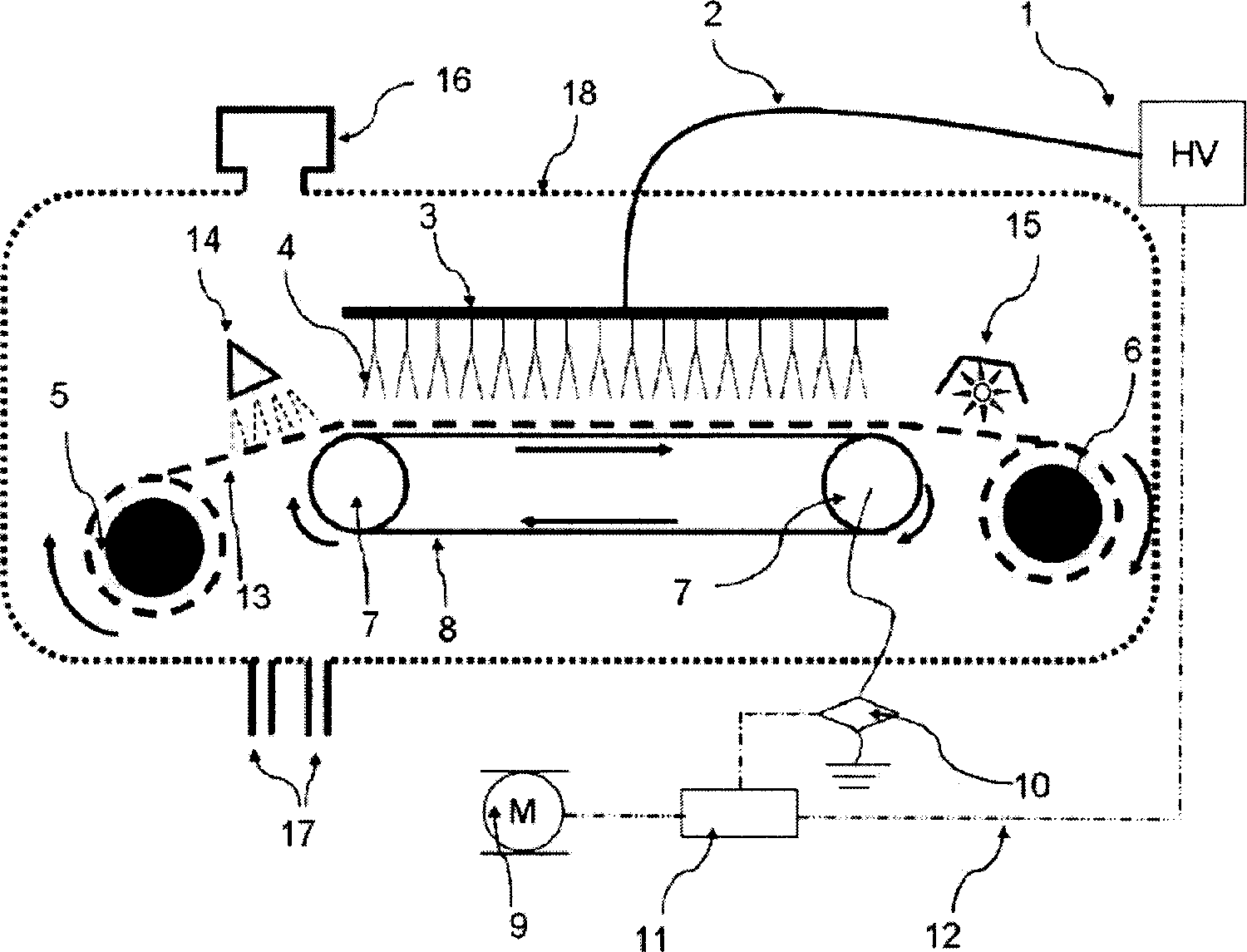

[0017] A corona discharge low-temperature plasma fabric surface modification treatment device for enhancing the dyeability of polypropylene fabrics, consisting of an electrode system, a material delivery system, a humidity adjustment device 14, a drying device 15 and corresponding automatic The control device and the power supply 1 constitute. The airtight chamber is equipped with an air pump to balance the internal and external pressure and to evacuate the air before injecting the working gas. Oxygen and argon are injected into the airtight chamber from the working gas injection port 17 as the working gas. The ultra-thin sheet electrode array 3 is composed of platinum-plated stainless steel sheets, and its size is determined by the area of the fabric. The ground electrode is composed of a stainless steel conveyor belt s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com