Patents

Literature

93results about How to "Corrosion resistance has" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material, and preparation method and applications thereof

ActiveCN104961983AExcellent electrical and thermal conductivityExcellent mechanical properties and oil resistancePetroleumConductive rubber

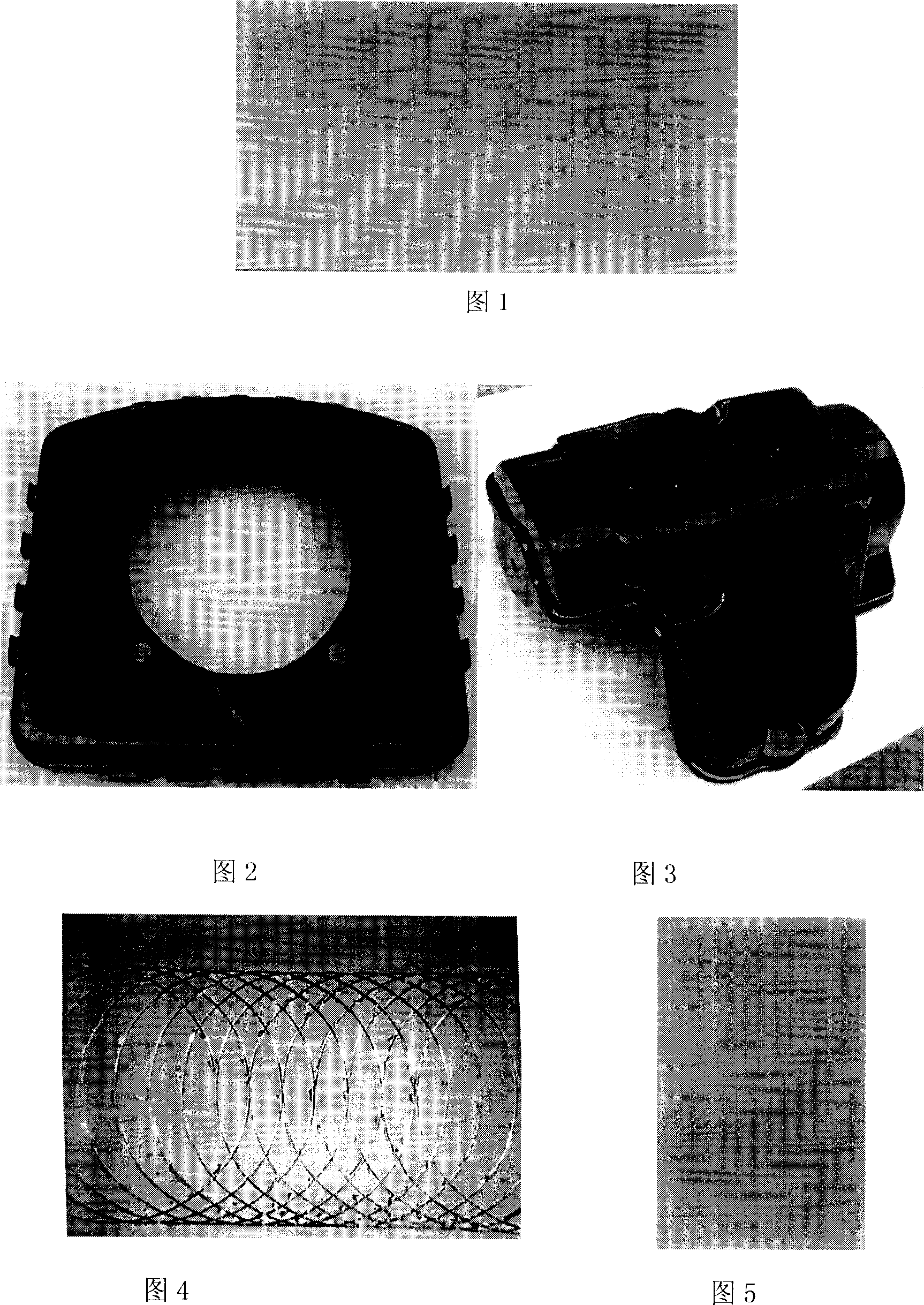

The invention relates to a high-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material. The high-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material is prepared from following ingredients, by weight, 50 to 100 parts of an electroconductive thermal conductive rubber master batch, 40 to 60 parts of an auxiliary rubber material, 30 to 50 parts of a reinforced material, 30 to 50 parts of a flexibilizer, 30 to 50 parts of a filling material, 8 to 10 parts of a stabilizing agent, 10 to 15 parts of a tackifier, 3 to 5 parts of a vulcanizing agent, and 2 to 3 parts of a vulcanizing assistant agent. The high-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material possesses excellent electrical conductivity and thermal conductivity; volume resistivity is as high as 102 omega.cm; heat conductivity coefficient is higher than 4W / (m.K); the high-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material can be applied to special fields such as petroleum, coal mine, and spaceflight; the high-electrical conductivity high-thermal conductivity oil-resistant aging-resistant rubber material possesses excellent mechanical properties, oil resistance, and air aging resistance, and can be used in oil medium or in outdoor environment.

Owner:青岛科凯达橡塑有限公司

Method for silane reinforcing magnesium alloy cathode electrophoretic corrosion-proof layer

InactiveCN1936101AGood adhesionImprove corrosion resistanceElectrophoretic coatingsMetallic material coating processesSilanesLacquer

The invention relates to a method of silence enhancing magnesium alloy cathode electrophoresis corrosion resistant coating layer. It takes silence enhancing process to the surface of magnesium alloy after cleaning. The silence solution adopts aqueous solution of 2-3 ethoxy, silicone base propyl tetrasulfide, propenyl-3-ethoxy silicane, gama- glycidol ether oxygen propyl-3-methoxyl silence or 2, 3 ethoxy silicone base ethane, and pH value is acidity. The method need not special device to heat, and combining with cathode electrophoresis, the binding power of cathode electrophoresis lacquer and magnesium alloy basal body would be enhanced.

Owner:重庆工学院

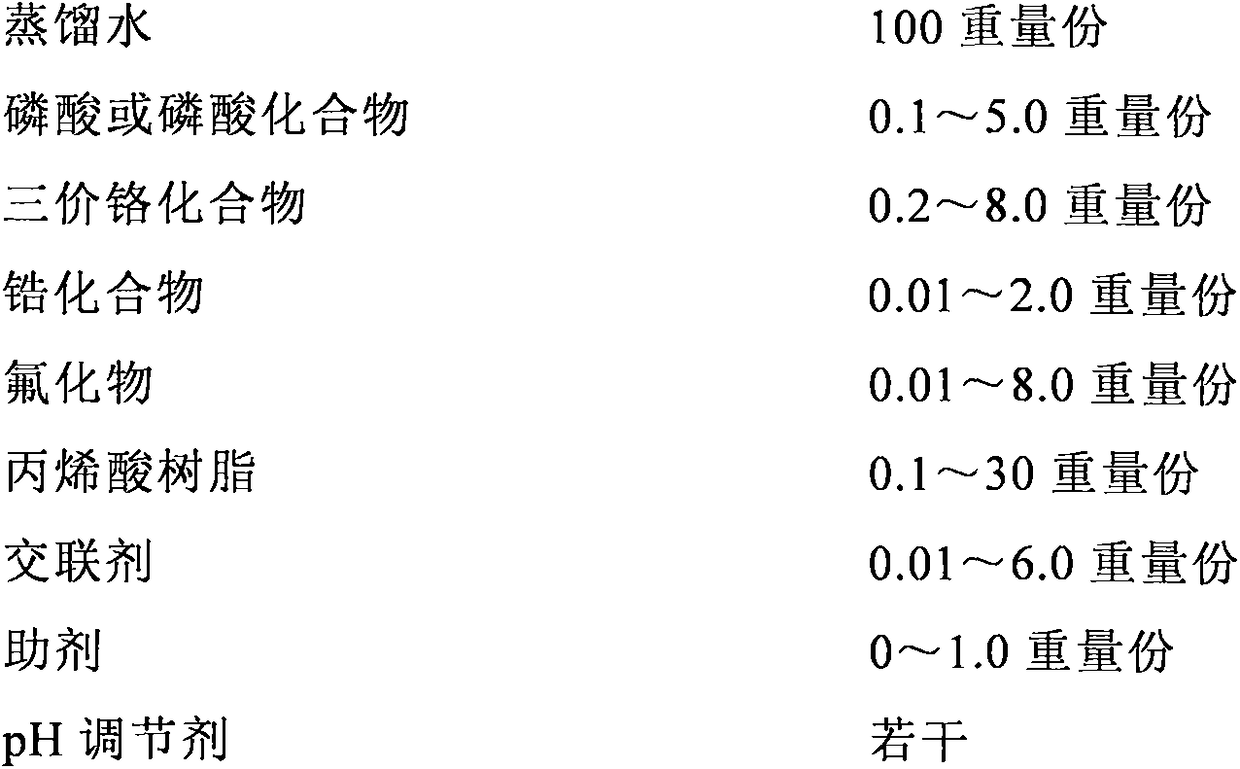

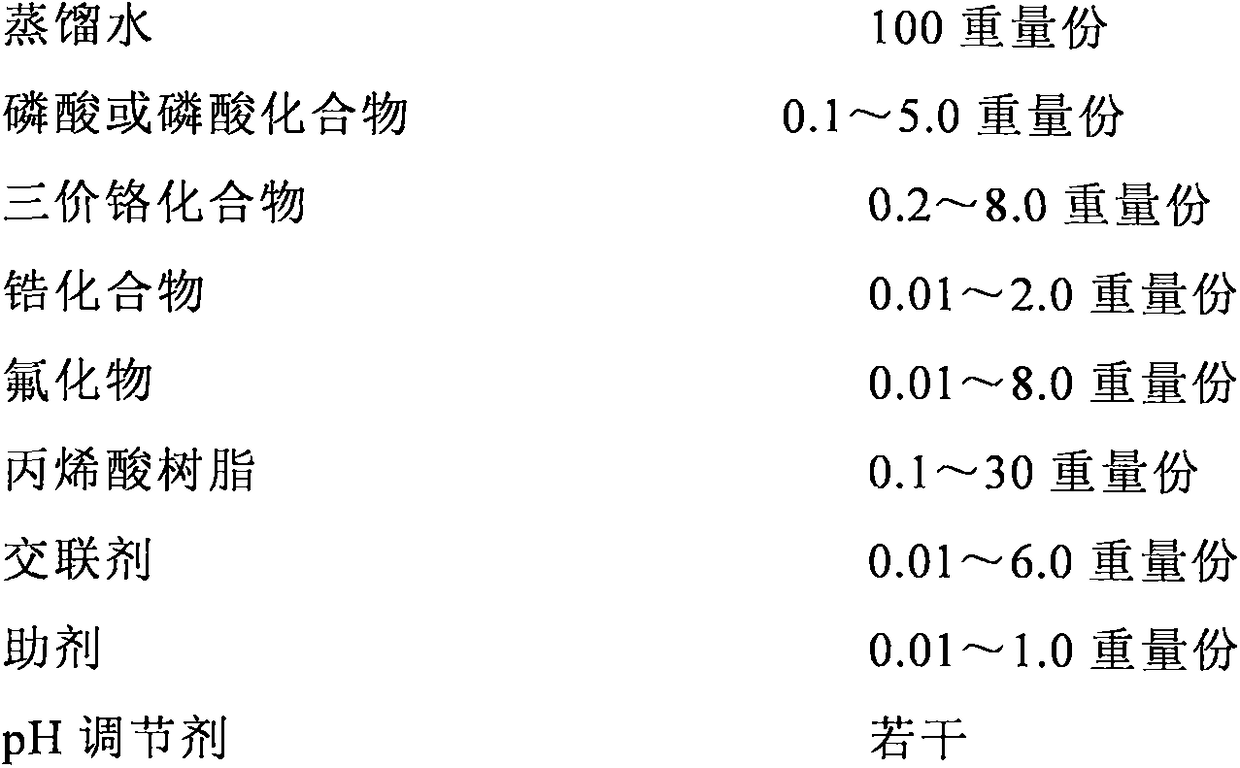

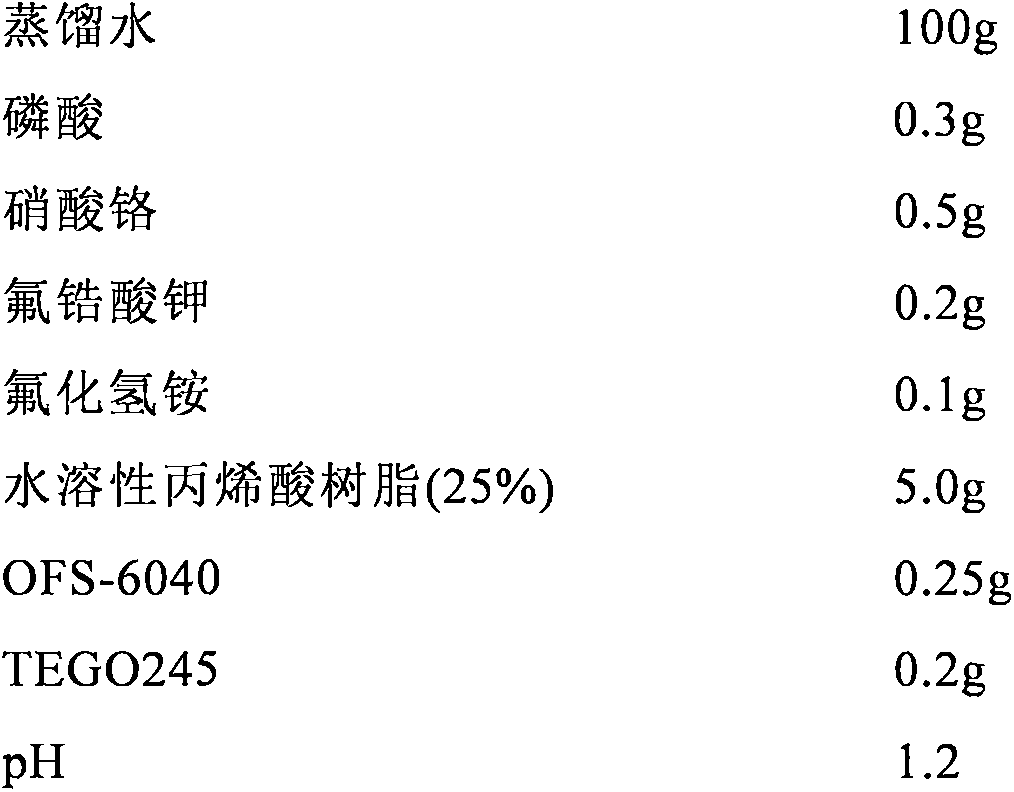

Passivation solution suitable for processing aluminum foil of aluminum-plastic film

InactiveCN108754472AImprove corrosion resistanceImprove bindingMetallic material coating processesChromium CompoundsPolyolefin

The invention relates to a passivation solution suitable for processing the aluminum foil of an aluminum-plastic film. The passivation solution comprises, by weight, 100 parts of distilled water, 0.1-5.0 parts of phosphoric acid or phosphate compound, 0.2-8.0 parts of trivalent chromium compound, 0.01-2.0 parts of zirconium compound, 0.01-8.0 parts of fluoride, 0.1-30 parts of acrylic resin, 0.01-6.0 parts of crosslinking agent, 0-1.0 part of auxiliary and a certain amount of pH regulator. 8021 aluminum foil processed by the passivation solution has excellent corrosion resistance, and the processed aluminum foil combined with CPP through modified polyolefin-based glue has excellent binding force, electrolyte resistance and water resistance.

Owner:惠州市广麟材耀科技有限公司

Butyl blending emulsion chemical protective glove and preparation method thereof

ActiveCN103965554AKeep airtightCorrosion resistance hasGlovesProtective garmentPolymer scienceVulcanization

The invention discloses a butyl blending emulsion chemical protective glove and a preparation method thereof. The butyl blending emulsion chemical protective glove comprises a glove liner and a macromolecule blending emulsion material outer gumming layer, wherein the macromolecule blending emulsion material outer gumming layer comprises the components of a macromolecule blending alloy material main body, a vulcanizer, a promoter and a vulcanization activator according to the mass ratio of 100 to 0.5-5 to 0-2 to 1-3; the macromolecule blending alloy material main body comprises 60 to 100 percent of butyl rubber and 0 to 40 percent of other high polymer materials; the high polymer materials are PVC, PE, phenolic aldehyde or nitrile rubber. The butyl blending emulsion chemical protective glove overcomes defects in binding power and tear resistance, has excellent performances of chemical corrosion prevention, solvent resistance and oil resistance, has an excellent water resisting property and an electrical insulating property, and also has wear resisting, cut preventing and puncture resisting properties and the like; the preparation process is accomplished through mechanized linkage and flow production; the production is feasible, the technology is reasonable, the cost is reasonable, and the butyl blending emulsion chemical protective glove and the preparation method are applicable to industrialized scale production.

Owner:ZHEJIANG KANG LONG DA SPECIAL PROTECTION TECH CO LTD

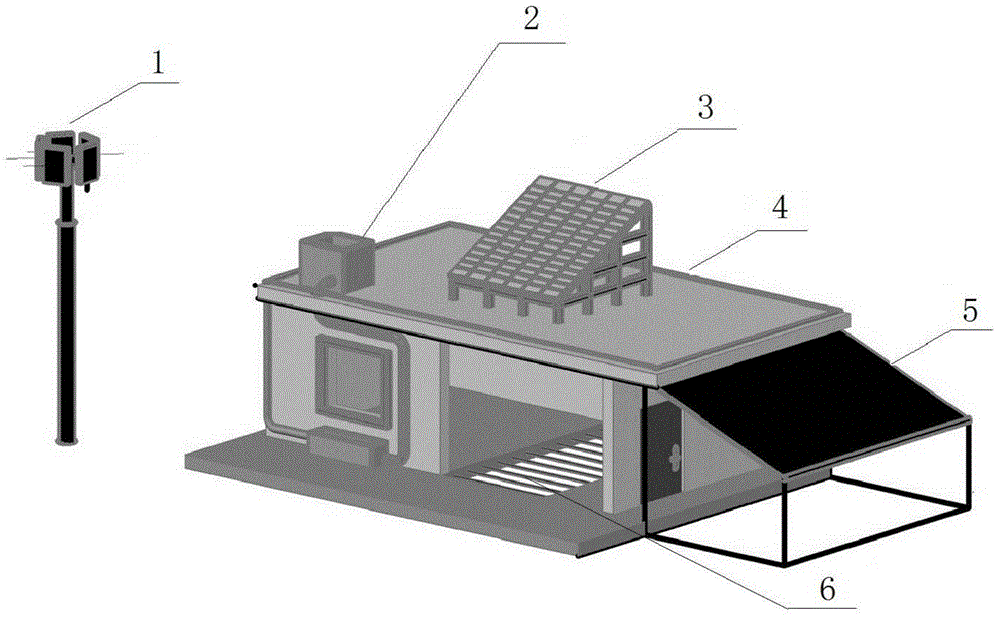

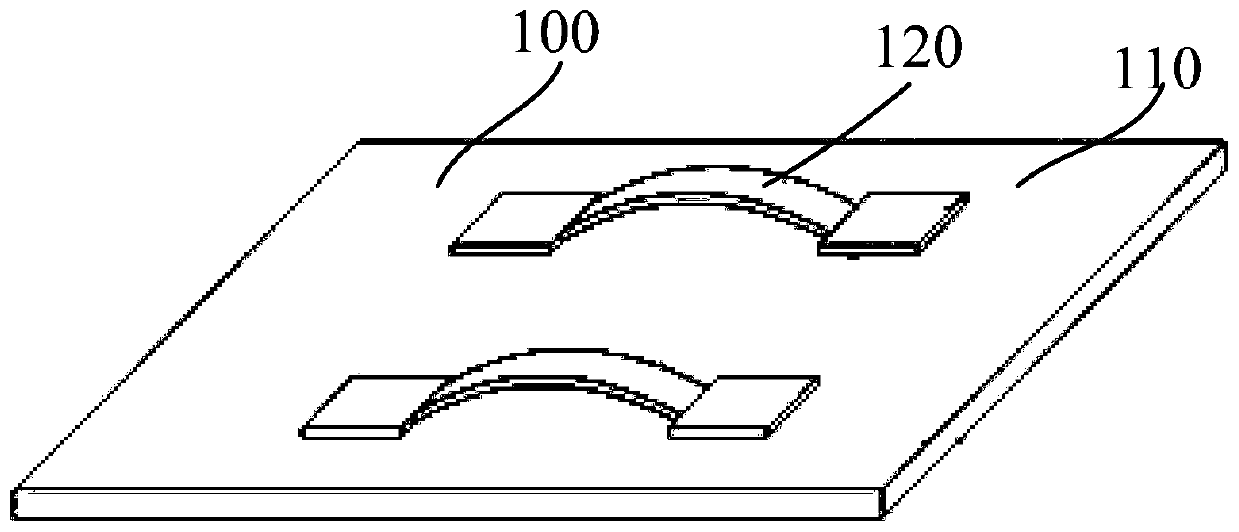

Environment self-adaptation modularized intelligent building system suitable for field

InactiveCN104947795ATo achieve the purpose of dry and wet separationHigh tensile strengthRoof covering using slabs/sheetsRoof improvementIntelligent lightingFiber

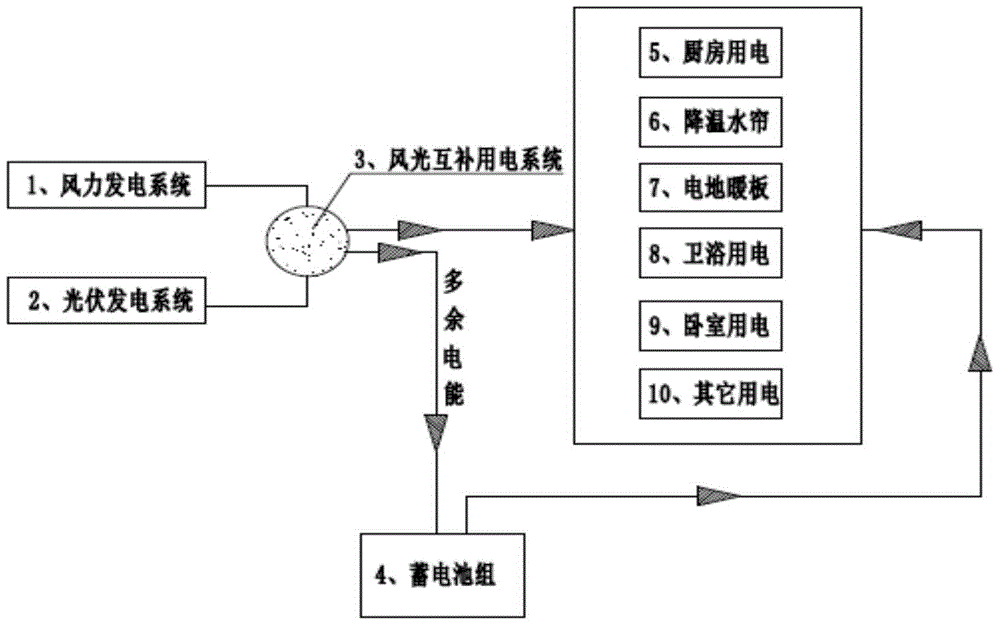

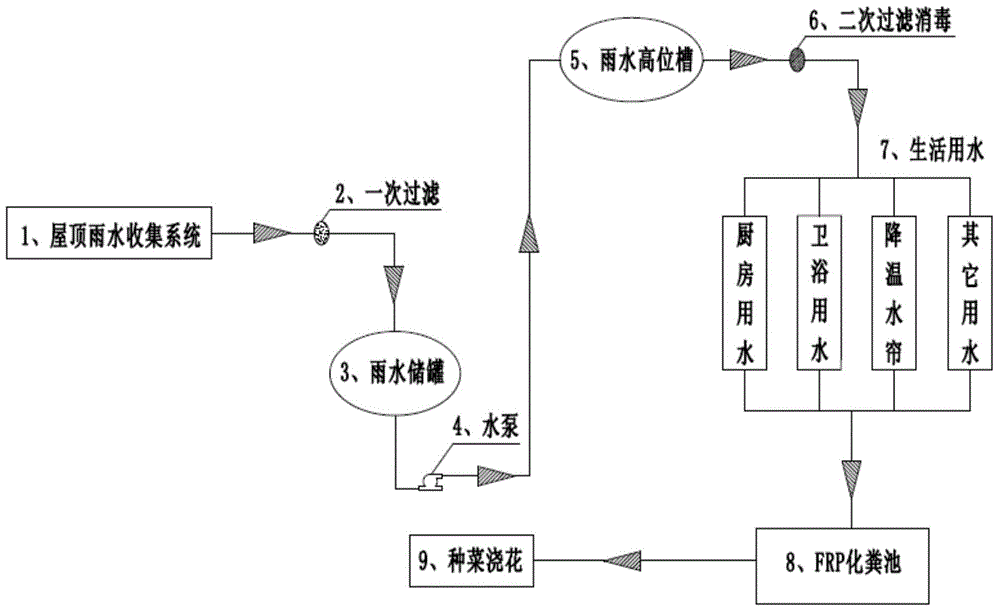

The invention discloses an environment self-adaptation modularized intelligent building system suitable for the field. The environment self-adaptation modularized intelligent building system comprises a modularized-assembled building body structure, an assembled house unit bathroom, an assembled house integrated kitchen, an assembled house carbon fiber electric heating floor heating plate, a solar photovoltaic power generation system, a wind power generation system, a wind-solar complementary power system, a roof rainwater collecting system, an FRP digestion tank, a soilless cultivation sunshine vegetable greenhouse, a cooling water curtain and the like, wherein the wind-solar complementary power system is composed of the solar photovoltaic power generation system and the wind power generation system. Solar photovoltaic power generation can be achieved through the building system, energy of power generation can be used for cooling in summer and heating in winter, water resources of the nature can be recycled, and the modularized movable building system can reduce the environment pollution and material waste and can also reduce power supply cost and the like.

Owner:镇江绿材谷新材料科技有限公司

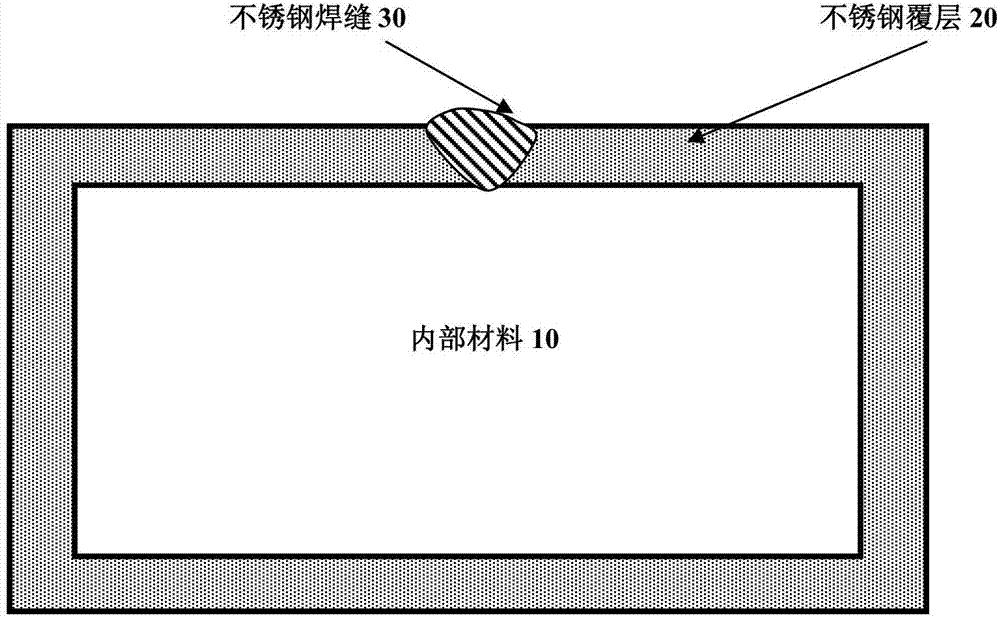

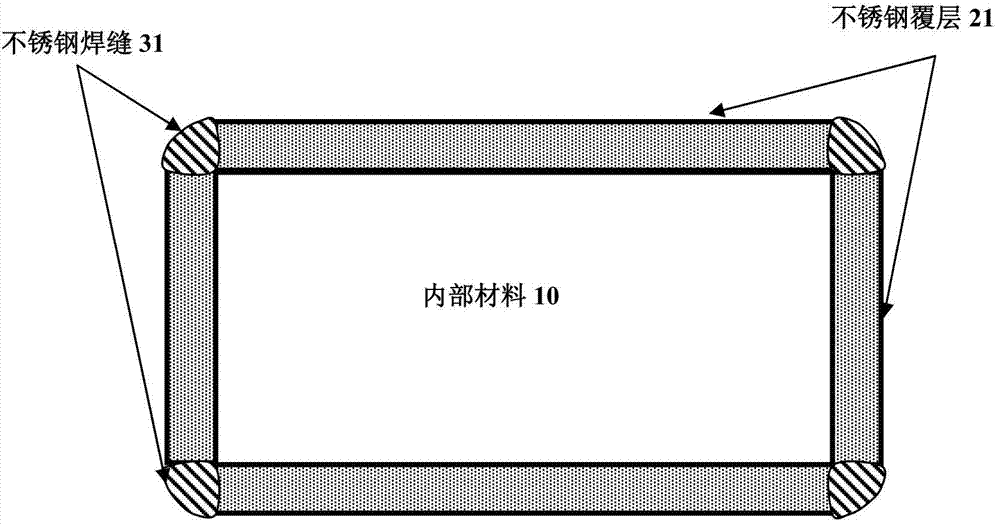

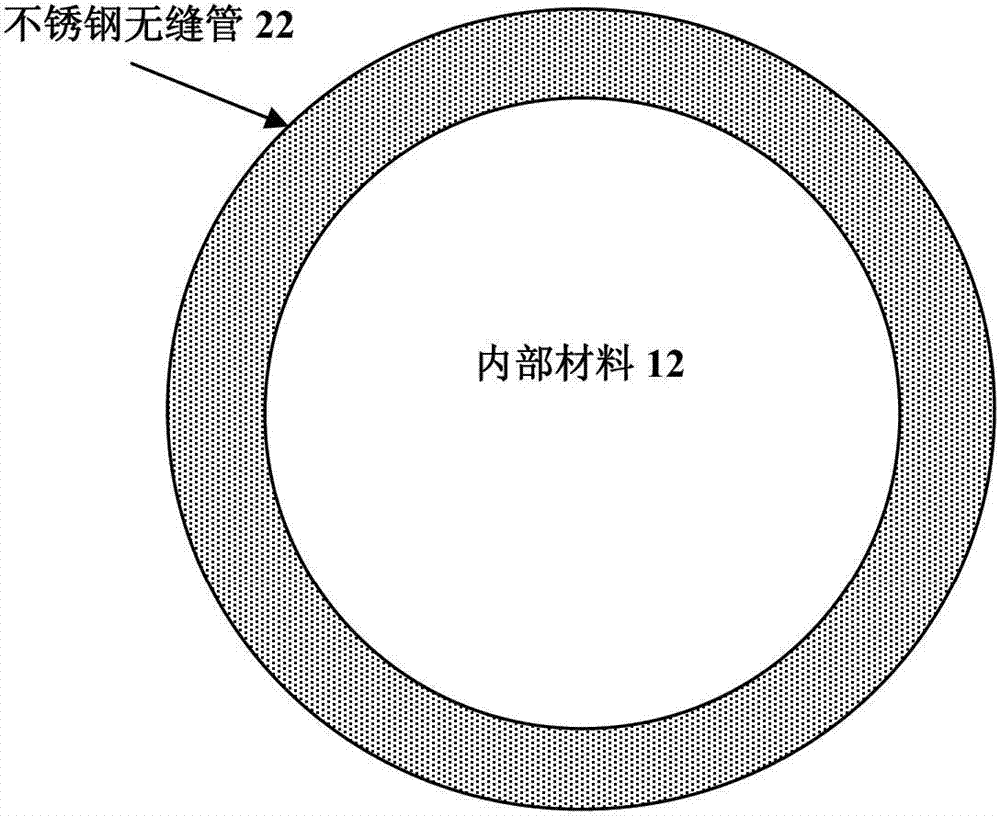

Corrosion-resistant composite section bar and preparation method thereof

ActiveCN104329560ALow costReduced corrosion resistanceConstructions elementsSocial benefitsMetallurgy

The invention discloses a corrosion-resistant composite section bar and a preparation method thereof. The corrosion-resistant composite section bar consists of an internal material, an external cladding layer and a chemical transition region, wherein the external cladding layer is attached to the internal material; the chemical transition region is sandwiched between the internal material and the external cladding layer; the internal material is a carbon steel material, a low alloy steel material or a micro alloy steel material; the external cladding layer is a stainless steel cladding layer; the chemical transition region is an element diffusion transition region between the internal material and the external cladding layer. According to the corrosion-resistant composite section bar, the manufacturing cost is low, the process is simple, and important social benefit and economic benefit are realized in development of low carbon and green economy.

Owner:CENT IRON & STEEL RES INST +1

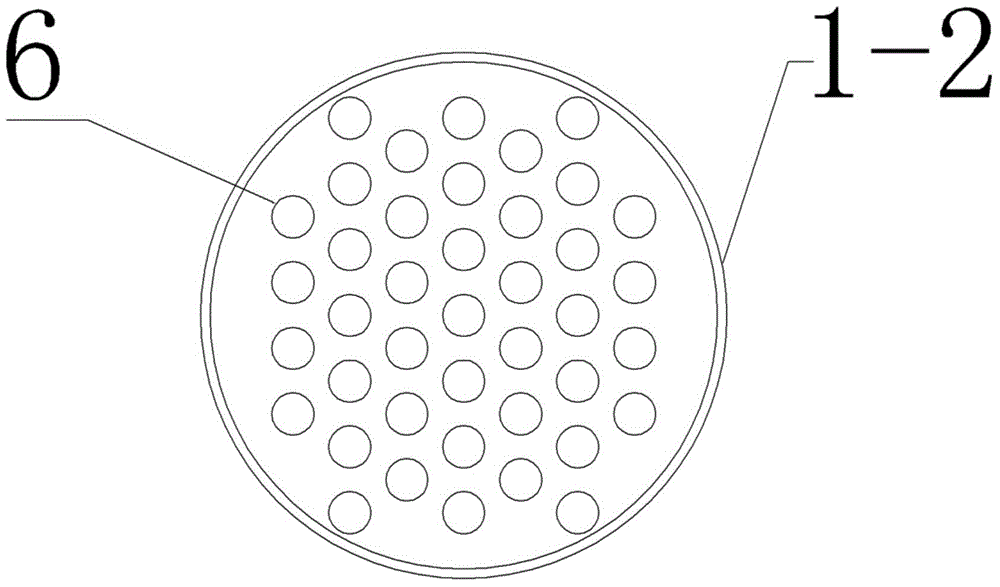

Ceramic material, ceramic heat exchange tube as well as preparation method thereof and ceramic reboiler

InactiveCN104529463AImprove corrosion resistanceCorrosion resistance hasHeat exchange apparatusHeating oilReboiler

The invention discloses a ceramic material, a ceramic heat exchange tube as well as a preparation method and a ceramic reboiler. The ceramic material comprises the following components in percentage by mass: 5-10% of metallic silicon, 60-70% of silicon carbide, 10-15% of silicon dioxide, 10-15% of binding clay and 0.2-1% of lignin. The ceramic heat exchange tube disclosed by the invention has normal temperature compression strength of 35-50MPa, can resist a pressure of 0.7-0.9MPa under the working condition that the temperature is lower than 300 DEG C and heating oil flows in the tube, cannot have a seepage condition, is strong in corrosion resistance, and has good corrosion resistance to high-temperature gases and liquid of hydrochloric acid, sulfuric acid and the like; silicon dioxide is used for forming an enamel layer to seal air holes, thereby solving the problem of seepage of a common SiC material; and the ceramic heat exchange tube has the advantages of high-temperature resistance, quick heat conduction, corrosion resistance and seepage resistance, is durable in various environments, and is long in service life and suitable for popularization and application.

Owner:GONGYI RONGHUA CERAMIC HEAT EXCHANGER

Modified meta-aramid, preparation method thereof and hollow fiber membrane

ActiveCN109456476AImprove stabilitySimple preparation processMembranesSemi-permeable membranesPolymer scienceChloride

The invention discloses a modified meta-aramid polymer and a preparation method thereof. Metaphenylene diamine, 2-(4-aminophenyl)-5-aminobenzimidazole and various diamine monomers such as halogenateddiamine monomers are poly-condensed with isophthalic chloride by a low-temperature solution polycondensation method to form the modified meta-aramid polymer, wherein the isophthalic chloride is repeatedly added into reaction solution. The invention further discloses a preparation method for preparing a hollow fiber membrane by the prepared meta-aramid polymer. The prepared modified meta-aramid polymer keeps original excellent performances, further has low intrinsic viscosity and good chlorine resistance and is more applicable to spinning of the hollow fiber membrane, the prepared membrane is more easily preserved in a dry state, and the preparation method is simple, easy to operate and suitable for industrial production and has an excellent market application prospect.

Owner:OCHEMATE MATERIAL TECH CO LTD

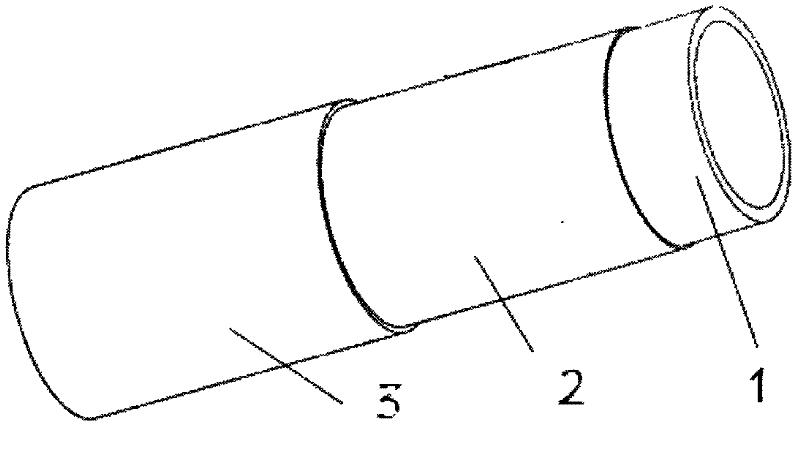

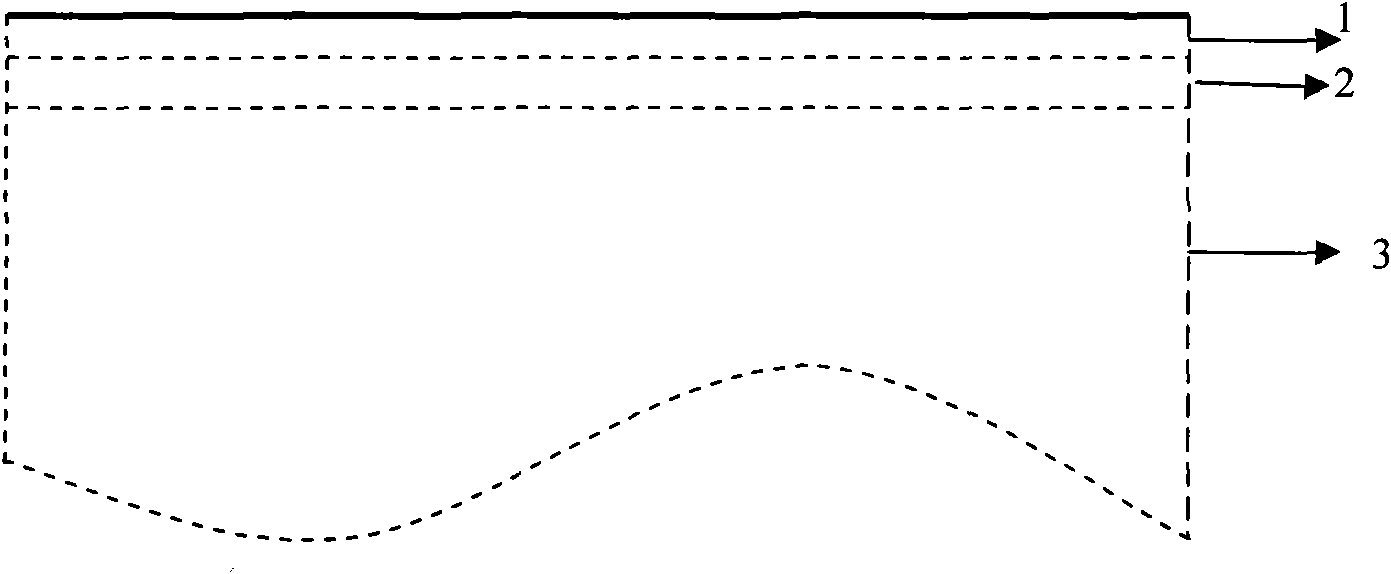

High-strength flame-retardant anti-static pipeline

InactiveCN102506240AHigh crystallinityHigh degree of interface adhesionSynthetic resin layered productsRigid pipesPolymer scienceAcrylonitrile

The invention provides a high-strength flame-retardant anti-static pipeline comprising an inner layer, a combined layer and an outer layer, wherein the inner layer contains the following proportional components: 600 to 800 parts of high-density polyethylene by weight, 5 to 15 parts of glass fibre by weight, 1 to 2 parts of wollastonite by weight, 1 to 6 parts of ethylene-propylene diene copolymer by weight, 4 to 9 parts of butadiene-acrylonitrile rubber by weight, 3 to 6 parts of styrene-butadiene-styrene terpolymer copolymer by weight, 9 to 13 parts of nano carbon tube by weight, 10 to 30 parts of polypropylene grafted maleic anhydride by weight, 15 to 25 parts of flame retardant by weight and 13 to 19 parts of graphitized carbon black by weight; the outer layer contains the following proportional components: 300 to 500 parts of medium-density polyethylene by weight, 12 to 21 parts of flame retardant by weight and 9 to 13 parts of graphitized carbon black by weight; and the main component of the combined layer is hot melting glue. The pipeline provided by the invention has favorable performances of heat insulation and flame retardant; meanwhile, the pipeline also has higher toughness; and furthermore, the erosion resistance, the high-pressure resistance and the rigidity performance are high.

Owner:ZHEJIANG NORMAL UNIVERSITY

Self-lubricating metallic material

InactiveCN101885250ACorrosion resistance hasImprove the lubrication effectVacuum evaporation coatingSputtering coatingCorrosion resistantMoving parts

The invention discloses a self-lubricating metallic material. The self-lubricating metallic material is prepared by the following steps of: coating a substrate layer on the surface of a metallic material by adopting an MEVVA source ion implantation technique; and then coating a WS2 lubricating layer on the surface of the processed metallic material by using an RF radio frequency sputtering process in PVD. The self-lubricating metallic material obtained by the invention is load resistant, corrosion resistant, abrasion resistant and high temperature resistant, and is suitable for manufacturing moving parts in various common and extreme environments.

Owner:BILL ANDA SHANGHAI LUBRICATING MATERIAL

Vacuum atomization suspension uniform sputtering coating method for spherical powder material

ActiveCN103436848ACorrosion resistance hasImprove performanceVacuum evaporation coatingSputtering coatingHigh energyMoisture resistance

The invention discloses a vacuum atomization suspension uniform sputtering coating method for a spherical powder material. Spherical powder is placed in a vacuum atomization tank; a cathode sputtering target and an anode body are arranged in the vacuum atomization tank; in the vacuum environment, when high-energy particles accelerated by an electric field or a magnetic field impact the surface of the cathode sputtering target, atomic molecules on the surface of the target carry out momentum exchange with the high-energy particles, so that atoms or molecules are splashed out of the surface of the target and have a certain energy; when the splashed atoms or molecules are collided with the spherical powder which is atomized and suspended in the vacuum, thin film deposition on the spherical powder is implemented. According to the invention, the high-performance spherical powder material which has functions of high and low temperature resistance, high-pressure resistance, moisture resistance, corrosion resistance, antioxidation and the like, has excellent performance, meets different requirements and has special functions can be produced; the antioxidant surface of the spherical metal powder can be subjected to functionalization processing.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

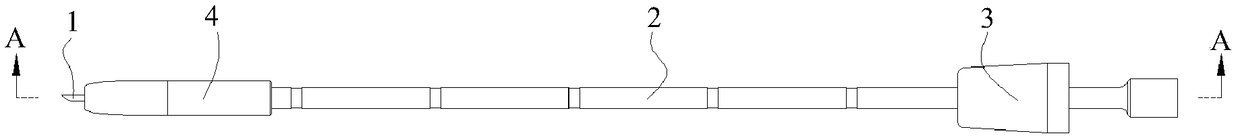

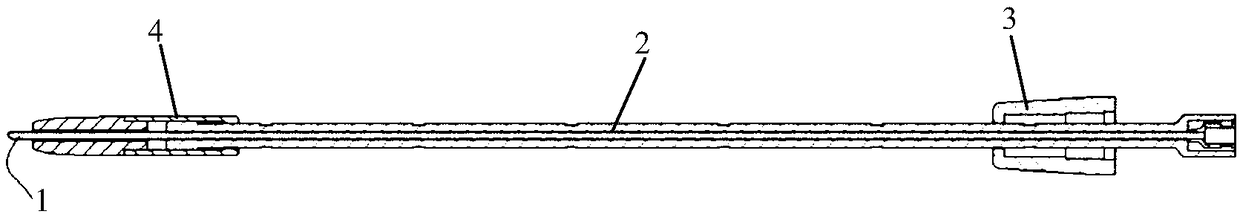

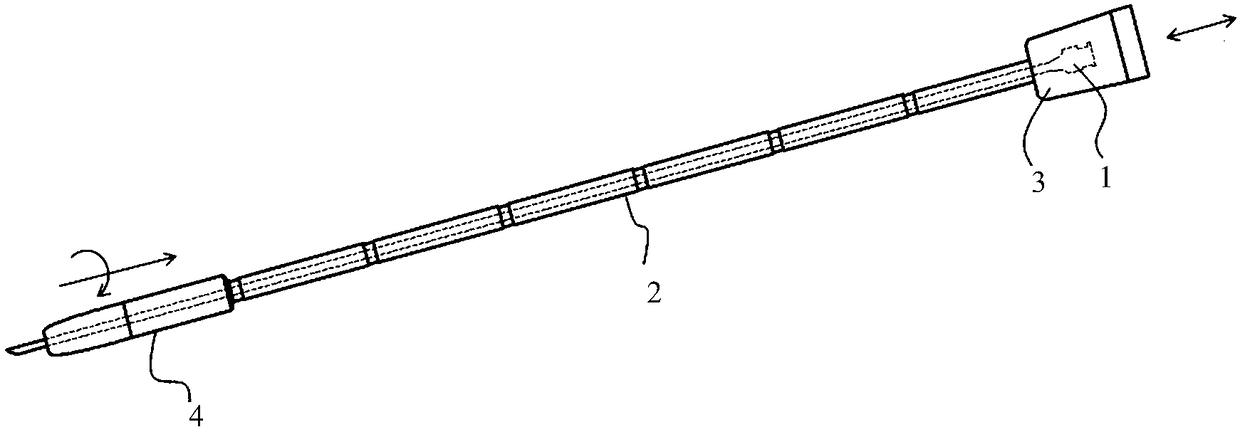

Multifunctional combined syringe needle for underwater application in coral reef areas

PendingCN109248004ACorrosion resistance hasHigh strengthVeterinary instrumentsUnderwater equipmentBiological bodyProtection KIT

A multifunctional combined syringe needle for underwater applications in coral reef areas relates to syringes. The syringe needle is provided with a needle body, a rod body, a locking sleeve and a protective sleeve, the needle body is used for directly penetrating a living body for injecting a medicament; the rod body is provided with a scale line, and the rod body is used for contrast measurement, tapping sounding, direction indicating and body securing; the locking sleeve locks the needle body to the tip of the injection gun; the protective sleeve is for receiving and protecting the needle body exposed outside the rod body. The syringe needle can be matched with most types of syringe tips on the market and has strong versatility; the syringe needle is simple in structure and convenient to operate, can be used immediately without professional training, and is conducive to promotion and popularization of coral protection activities from professional divers to amateurs, thereby promoting the coral protection activities; and the needle can be stored, is easy to operate and easy to carry, does not impose an additional burden on diving activities, helps to protect the safety of divers,and helps to efficiently complete a task of injecting Acanthaster planci.

Owner:THIRD INST OF OCEANOGRAPHY MINIST OF NATURAL RESOURCES

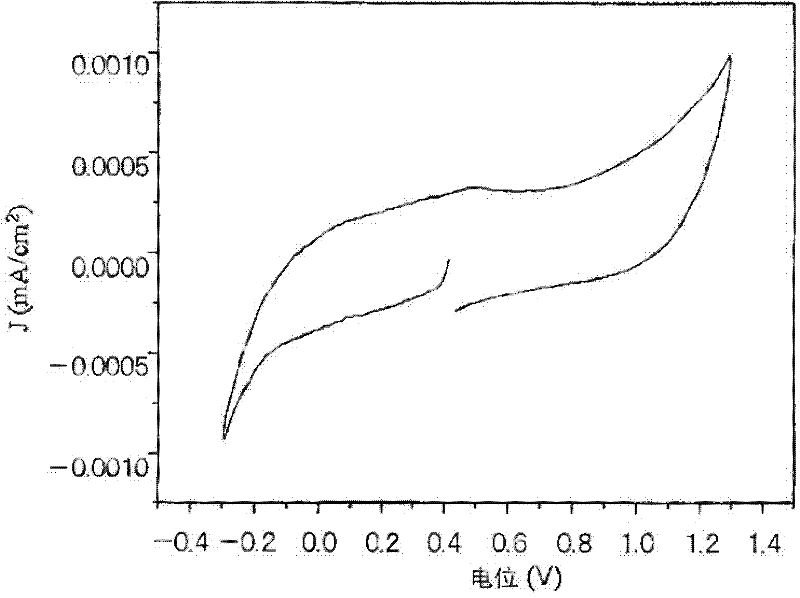

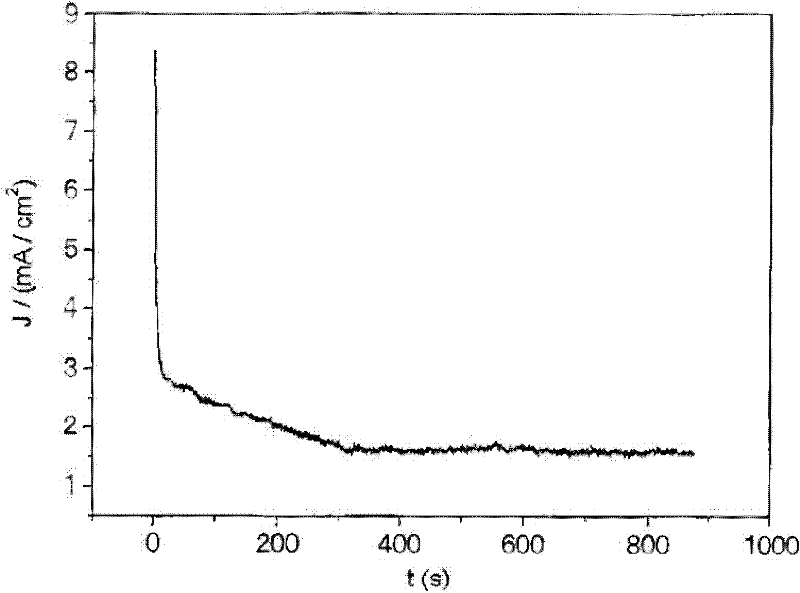

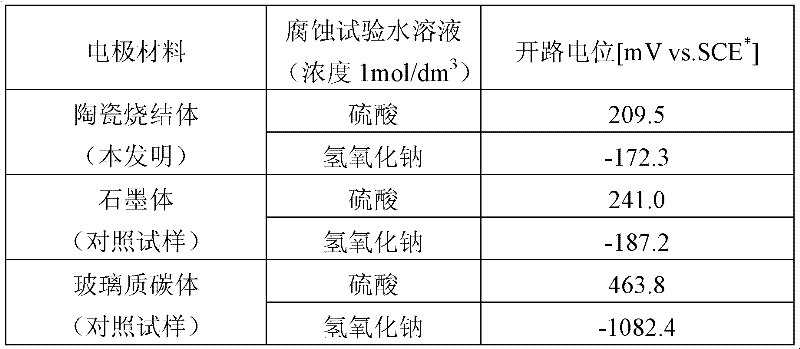

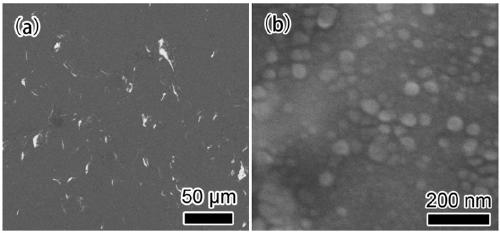

Ceramic electrode material and process for producing the ceramic electrode material

InactiveCN102197440AReduce exposureCorrosion resistance hasCell electrodesMultiple component coatingsSlurryReducing atmosphere

Disclosed is a ceramic material that has proper electrical conductivity and high corrosion resistance as an electrode material. Also disclosed is a process for producing the corrosion resistant ceramic electrode material in a good workable and economical manner. According to the process, a molded product gelled by polymerizing a polymerizable monomer, which has been previously added to a ceramic slurry, is fired in a reducing atmosphere after drying and degreasing thereof, whereby a corrosion resistant ceramic electrode material including three-dimensional net-like electrically-conducting paths that are formed of a reduction fired product of a polymer compound having carbon atoms among ceramic particles can be provided.

Owner:NAGOYA INSTITUTE OF TECHNOLOGY

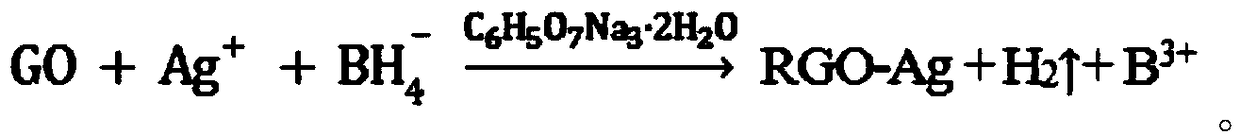

Preparation method of corrosion-resistant antibacterial and anti-biofouling multifunctional metal-based protective coating

ActiveCN109207984AChange distribution statusDoes not change the microstructurePressure inorganic powder coatingChemical reactionStress relief

The invention belongs to the field of composite coating preparation, and particularly relates to a preparation method of a corrosion-resistant antibacterial and anti-biofouling multifunctional metal-based protective coating. Through the method, firstly, nano-silver is formed on a graphene oxide-OH functional group through a chemical reaction in an in-situ synthesis mode, and graphene / nano-silver composite powder is obtained through reduction; secondly, the graphene / nano-silver composite powder and metal powder are ball-milled, metal / graphene / nano-silver composite powder is formed, and then stress relief annealing is conducted under inert gas protection; and finally, the composite powder is deposited into the protective coating through a cold spraying technology. Through the method, by adjusting the chemical reaction conditions, the particle size distribution of the metal powder, the weight ratio of metal / graphene / nano-silver and the ball-milling time, the distribution state of the graphene / nano-silver in the metal-based composite coating is changed, and thus the multifunctional metal-based protective coating with good corrosion resistance, antimicrobial property and biofouling property is prepared.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

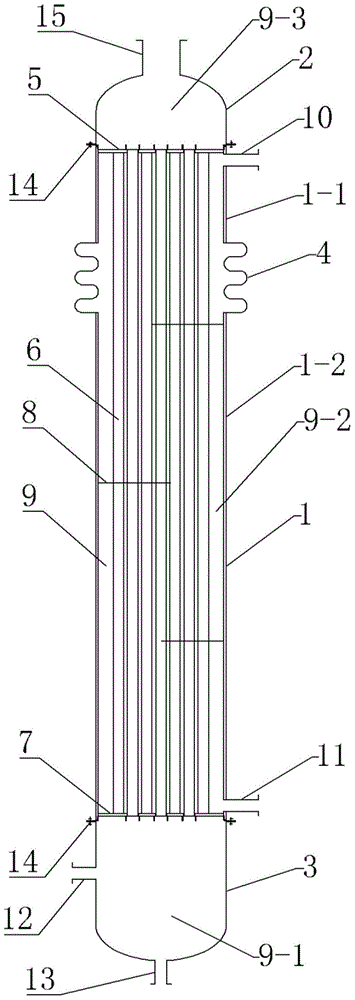

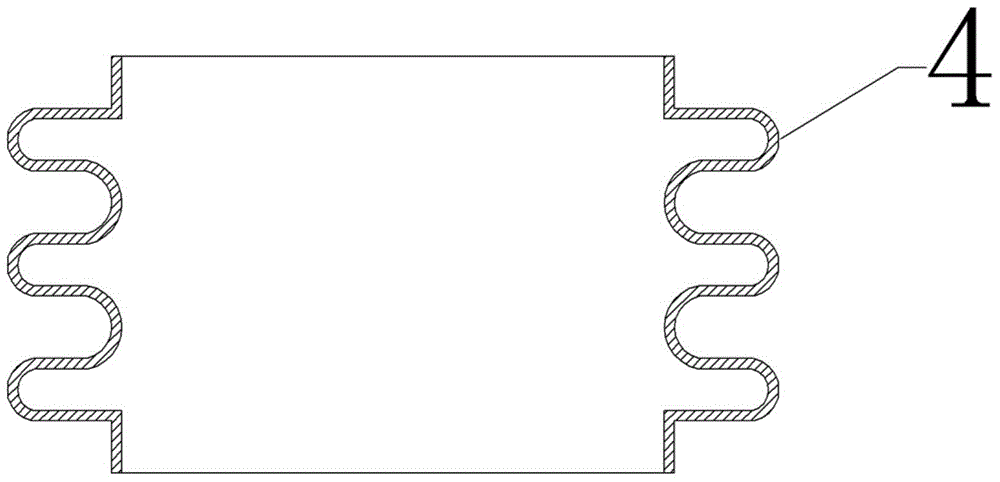

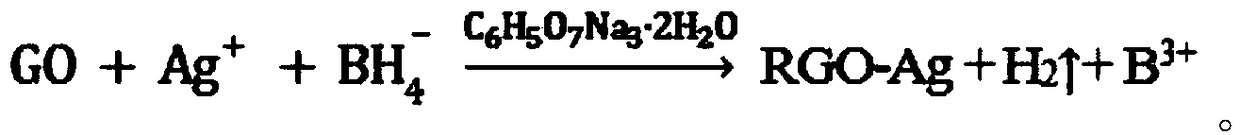

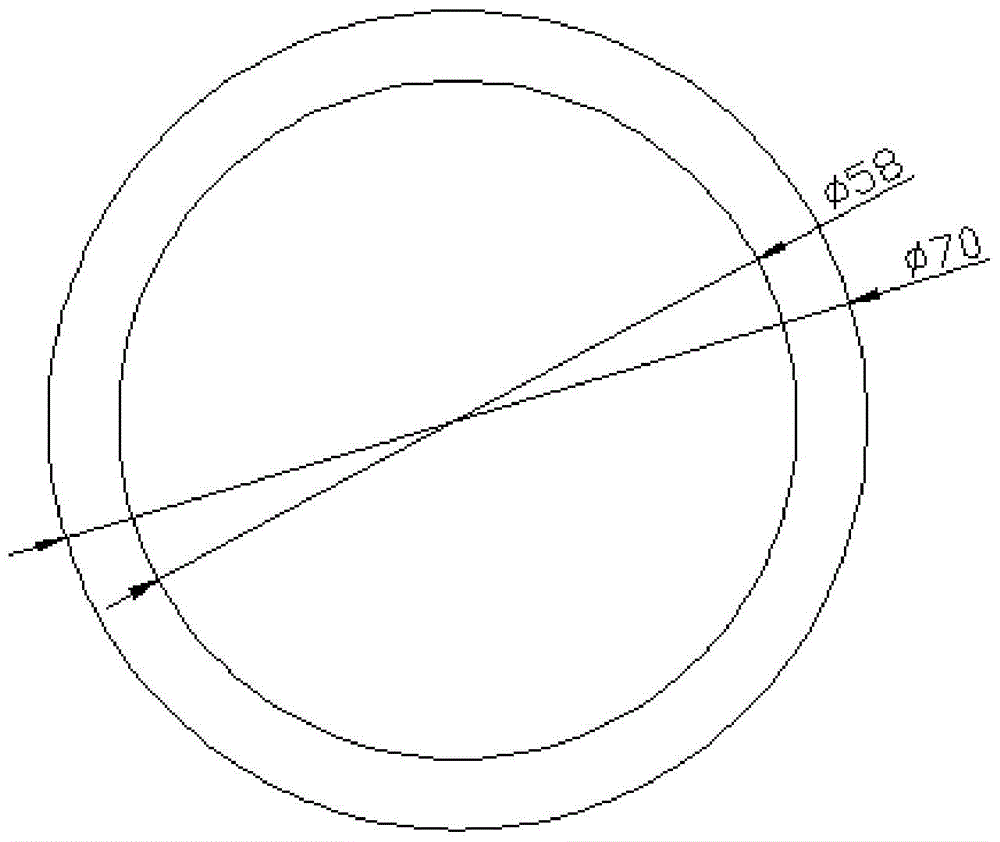

Gas turbine turbocharger suitable for coke oven gas internal combustion engine

InactiveCN103422976AHigh temperature and corrosion resistance withCorrosion resistance hasInternal combustion piston enginesBlade accessoriesExternal combustion engineTurbocharger

A gas turbine turbocharger suitable for a coke oven gas internal combustion engine is composed of an axial-flow turbine and a centrifugal-flow compressor, wherein the axial-flow turbine and the centrifugal-flow compressor are coaxial. The diameter of the turbine is phi 248mm, and the diameter of an impeller of the centrifugal-flow compressor is phi 258mm. The outer diameter of a thrust bearing work face is phi 72mm, and the inner hole diameter of the thrust bearing work face is phi 29mm. The work rotation speed of the gas turbine turbocharger is 32400 turns per minute, the pressure ratio is 3.25, the flow is 2.2 kilograms per second, and the allowable highest temperature of an inlet of the turbine is 690 DEG C. A gas inlet shell of the turbocharger is made of Chalco nodular cast iron; a gas outlet shell of the turbocharger is made of corrosion-resistant alloy cast iron; blades of the turbine are made of corrosion-resistant high-temperature alloy, and the surfaces of the blades undergo shot blasting processing and are provided with aluminide coatings; a nozzle ring is made of corrosion-resistant heat-resistant steel. The gas turbine turbocharger is used for being matched with the 16V 240-type coke oven (tail) gas internal combustion engine, and the rated power reaches 2000kW. Performance requirements and high-temperature-resistance and corrosion-resistance requirements of the coke oven gas internal combustion engine are met, and the gas turbine turbocharger can stably operate in a combined mode for a long time.

Owner:TIANJIN JL RAILWAY TRANSPORT EQUIP

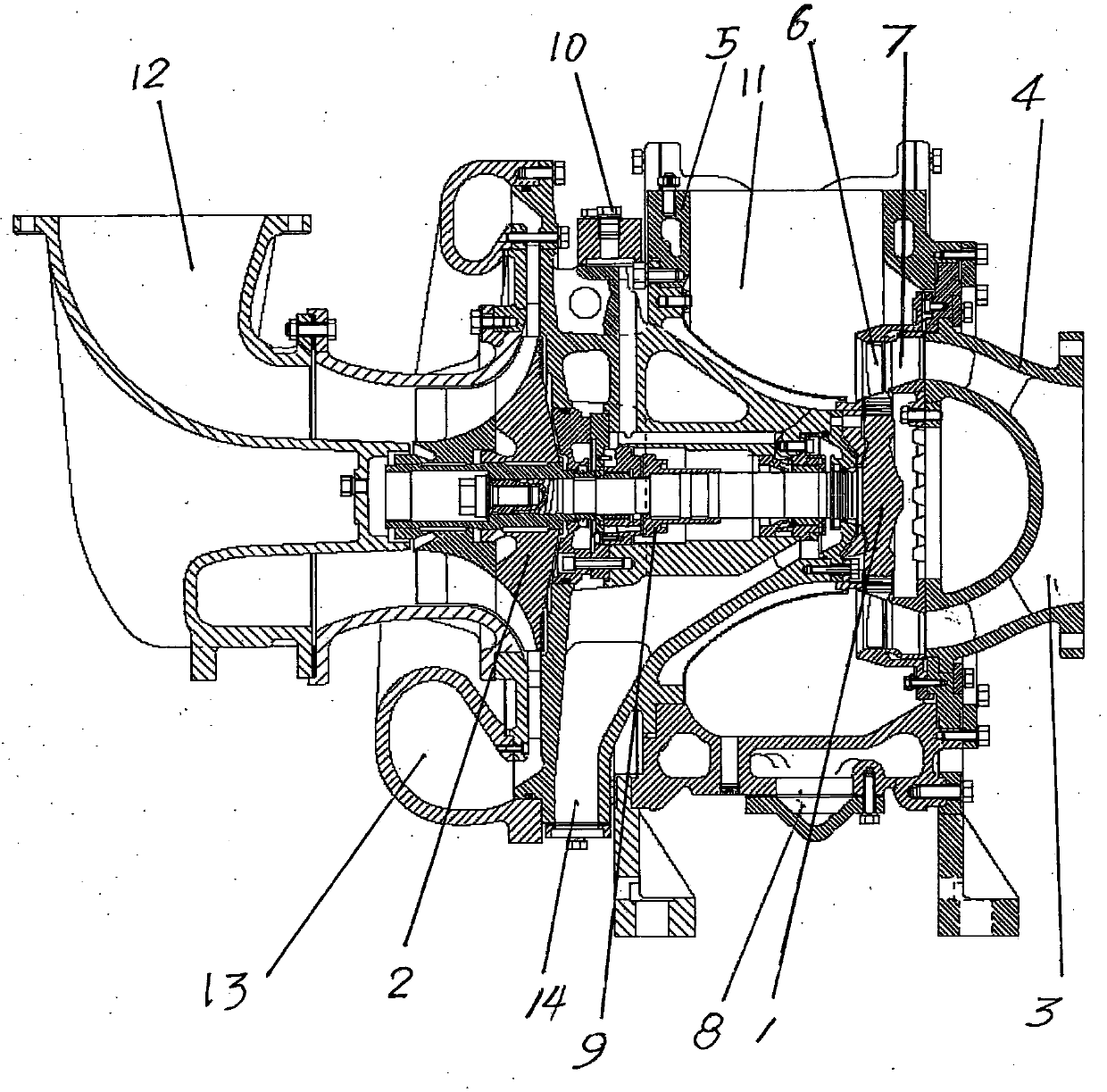

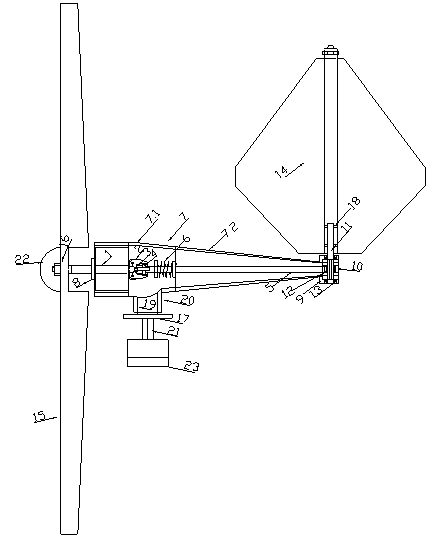

Centrifugal speed adjustment tail vane deflection yaw type wind generating set

InactiveCN103967705AAchieve forward and backward motionReduce spinWind motor controlMachines/enginesElectricityDrive shaft

The invention discloses a centrifugal speed adjustment tail vane deflection yaw type wind generating set. The wind generating set comprises fan blades (15), a transmission shaft (1), a tail vane (14), a tail vane push-pull rod (5) and a tail vane installation rack (9). The tail vane (14) is installed on the tail vane installation rack (9). The fan blades (15) are connected to the front end of the transmission shaft (1) in a rotating mode. The tail vane (14) can rotate under the pushing and pulling effects of the tail vane push-pull rod (5). The wind generating set further comprises a tail vane rotation gear shaft (11). A tail vane push-pull rack (12) matched with the tail vane rotation gear shaft (11) is arranged at the rear end of the tail vane push-pull rod (5). One end of the tail vane rotation gear shaft (11) is fixedly connected with the tail vane (14), and the other end of the tail vane rotation gear shaft (11) is provided with a gear shaft body and is installed on the tail vane installation rack (9) in a rotating mode. The wind generating set is protected and can work normally and generate electricity continuously in strong wind, and the product reliability is improved.

Owner:象山众用洁能设备厂

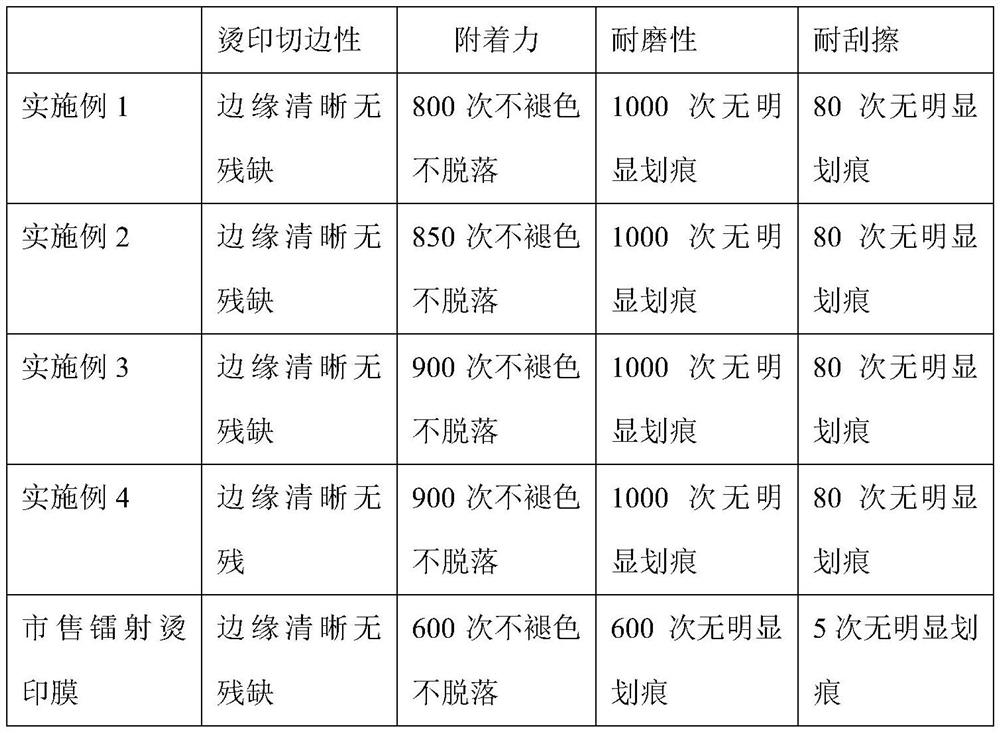

Preparation method of corrosion-resistant and friction-resistant holographic laser hot stamping film

InactiveCN112322202AExtended service lifeBrightness and anti-counterfeiting guaranteeNon-macromolecular adhesive additivesFilm/foil adhesive primer layersPolyurethane membraneHot stamping

The invention belongs to the technical field of package anti-counterfeiting, and relates to a preparation method of a holographic laser hot stamping film, in particular to a preparation method of a corrosion-resistant and friction-resistant holographic laser hot stamping film. The corrosion-resistant and friction-resistant holographic laser hot stamping film is characterized by sequentially comprising a base layer, a stripping layer, a color layer, an electroplated layer and a glue layer from bottom to top, wherein the base layer comprises the following components in parts by weight: 50-70 parts of modified acrylic resin, 30-40 parts of a polyurethane film and 5-13 parts of a covalent organic framework material. According to the preparation method of the corrosion-resistant and friction-resistant holographic laser hot stamping film provided by the invention, the prepared holographic laser hot stamping film has the advantages of wear resistance, acid and alkali corrosion resistance andlong service life, meanwhile, the brightness and the anti-counterfeiting strength of the color layer, containing holographic information patterns, of the hot stamping film in a high-temperature hot stamping process are guaranteed, the production is simple, and the construction is convenient.

Owner:JIANGSU XINGGUANG PACKAGING SCI & TECH CO LTD

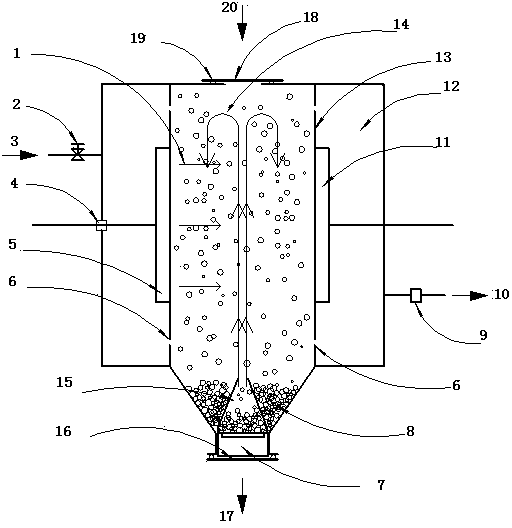

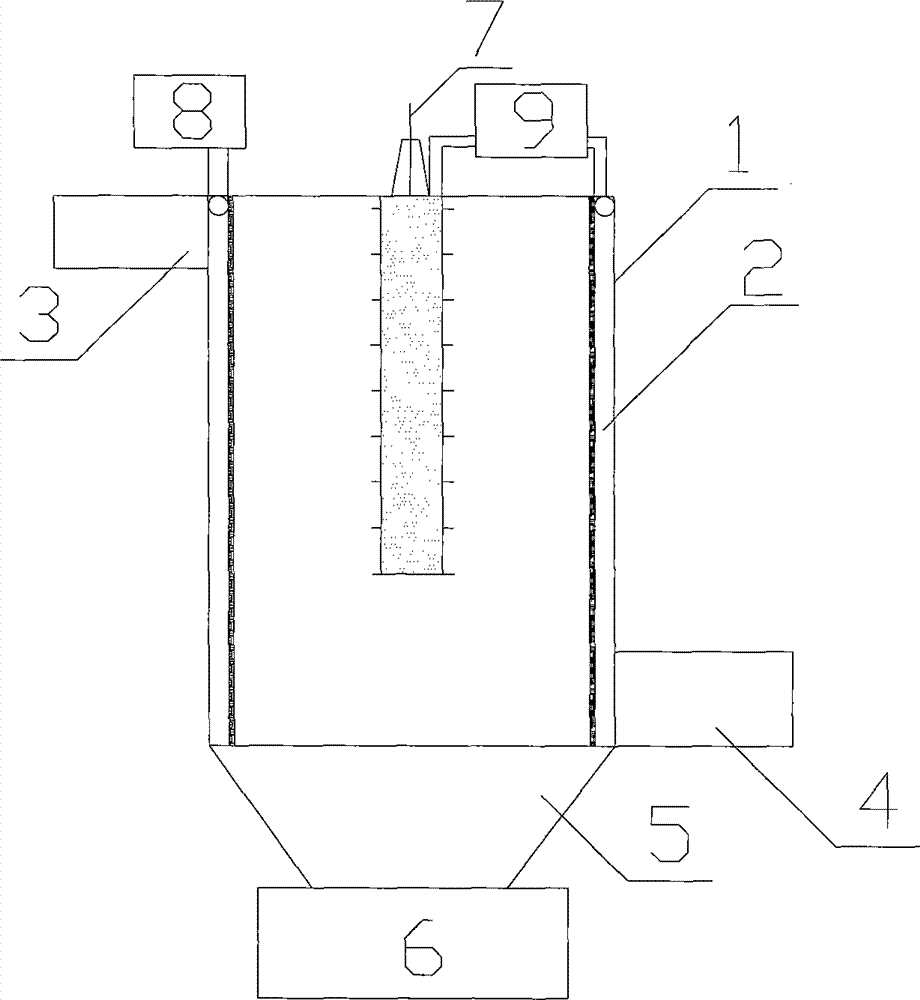

Wire-plate matching model of metal ceramic electric dust remover and ash removal mode

InactiveCN104492603ASolve the uniform distributionClear in timeExternal electric electrostatic seperatorElectrode constructionsElectricityMetallurgy

The invention provides a wire-plate matching model of a metal ceramic electric dust remover and an ash removal mode. The wire-plate matching model is characterized in that a dust collecting electrode and a corona electrode are made from a metal ceramic material which is high-temperature-resistant, corrosion-resistant, high in strength and good in conductivity; ventilating and permeable but dust retarding micropores are formed in the metal ceramic dust collecting electrode and the corona electrode for high-temperature and normal-temperature flue gas dust removal; the corona electrode is of a hollow structure inside and is reversely blown to remove ash by virtue of a pneumatic blowing device; the dust collecting electrode has two ash removal modes of dry type pneumatic blowing ash removal and wet microporous water-seepage ash removal. When the wet ash removal is adopted, the microporous structure of the dust collecting electrode has capillary action on ash removal water, so that ash removal water films on the surface of a polar plate are uniformly distributed, and meanwhile, the polar plate is prevented from being corroded.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Vehicle-mounted tank made of carbon fiber reinforced composite

InactiveCN106429060AImprove corrosion resistanceCorrosion resistance hasLarge containersGlass fiberEngineering

The invention provides a vehicle-mounted tank made of a carbon fiber reinforced composite. The vehicle-mounted tank is formed by combining three to six tank cavities. Each tank cavity is made of an inner liner layer. A rubber air-inflation inner container serves as a die of each inner linear layer, and each inner linear layer is made through a four-dimensional enveloping and winding formation process. The tank cavities are connected with one another through bolts and bonding. Each tank cavity is externally coated with a structural layer. Each structural layer is a glass fiber reinforced thermosetting composite layer and made through a four-dimensional enveloping and winding formation technology. Reinforcing ribs are arranged at the connection positions of the tank cavities. The reinforcing ribs are made of a glass fiber reinforced thermosetting composite and perform hoop winding reinforcing. Through holes are formed among the tank cavities. Supports are arranged at the bottoms of the tank cavities. The vehicle-mounted tank has the beneficial effects that by means of the vehicle-mounted tank made of the carbon fiber reinforced composite, the problem that a metal vehicle-mounted tank is poor in corrosion resistance can be solved; the wall thickness and design weight of a tank body can be remarkably lowered; fuel consumption of a vehicle is reduced; and the vehicle-mounted tank is small in weight, high in strength, resistant to corrosion and static electricity, capable of saving energy, environmentally friendly, good in comprehensive benefit and the like.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

Modified meta-aramid, preparation method thereof and hollow fiber membrane

ActiveCN109456477AImprove stabilitySimple preparation processSemi-permeable membranesMembranesHollow fibre membranePolymer science

The invention discloses a modified meta-aramid polymer and a preparation method thereof. Metaphenylene diamine, alkyl diamine H2N-M-NH2 and various diamine monomers such as halogenated diamine monomers are poly-condensed with isophthalic chloride by a low-temperature solution polycondensation method to form the modified meta-aramid polymer, wherein the isophthalic chloride is repeatedly added intoreaction solution. The invention further discloses a preparation method for preparing a hollow fiber membrane by the prepared meta-aramid polymer. The prepared modified meta-aramid polymer keeps original excellent performances, further has low intrinsic viscosity and good chlorine resistance and is more applicable to spinning of the hollow fiber membrane, the prepared membrane is more easily preserved in a dry state, and the preparation method is simple, easy to operate and suitable for industrial production and has an excellent market application prospect.

Owner:OCHEMATE MATERIAL TECH CO LTD

Anti-ionizing radiation container and preparation method thereof

The invention provides an anti-ionizing radiation container. The container includes an end cap and a container body, and the end cap is used for sealing the container body; and the container body includes a bottom wall and side walls fixedly connected with the bottom wall, the bottom wall and the side walls respectively comprise laminated plate bodies, each laminated plate body comprises an innerwall, a middle structure and an outer wall which are sequentially arranged from the interior to the exterior in an overlaid manner, the inner wall is a first fibrous resin material layer, the middle structure comprises second fibrous resin material layers and a metal layer alternately arranged from the interior to the exterior in an overlaid manner, and the outer wall is a third fibrous resin material layer. The invention also discloses a preparation method of the anti-ionizing radiation container.

Owner:CHINA GENERAL NUCLEAR POWER OPERATION +4

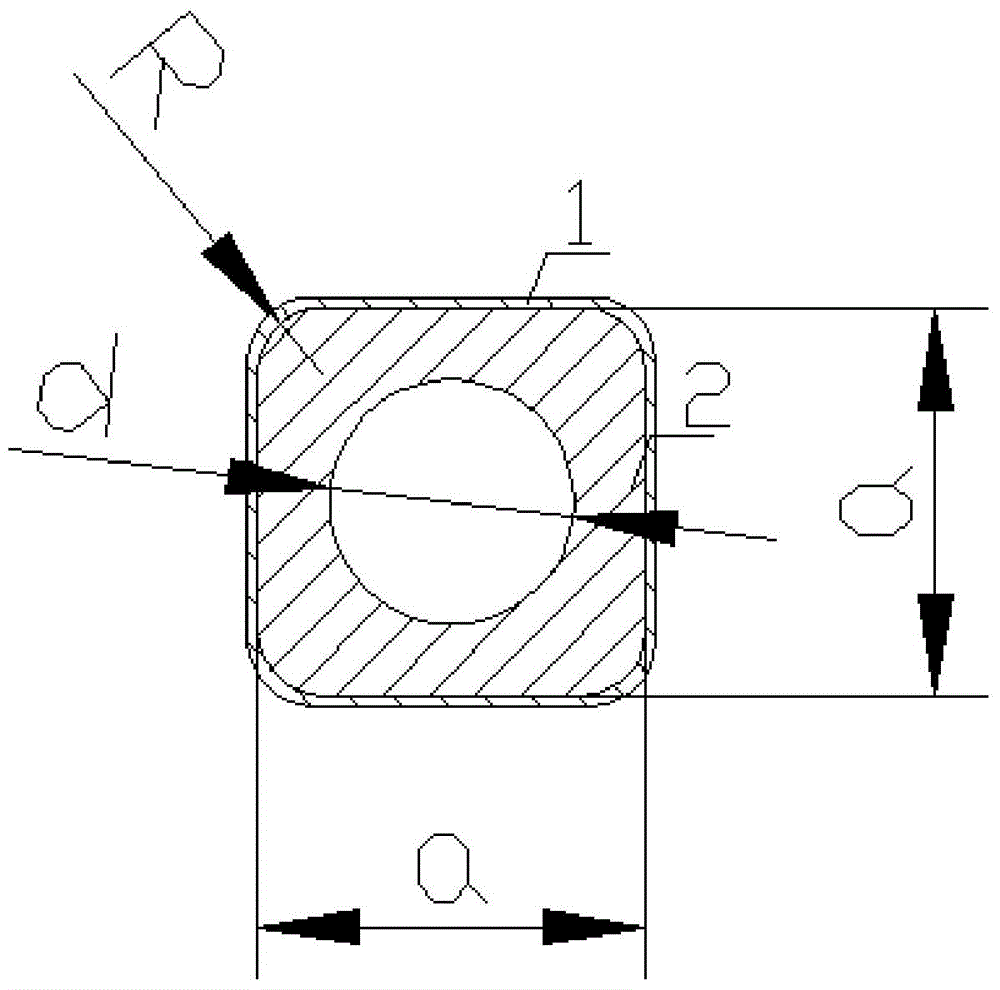

Electromagnetic wire and processing method thereof

InactiveCN104409157AIncrease the conductive areaIncrease the drawing sizeInsulated cablesPower cablesComposite filmSurface roughness

The invention discloses an electromagnetic wire and a processing method thereof. The electromagnetic wire comprises a body and an insulated body wrapping the body, wherein the inner contour line of the cross section of the body is square, and the outer contour line is round. In the processing, a moving core mark is matched with a moving outer mold to draw, so that the electromagnetic wire high in size precision, low in inner surface roughness, small in grain size and high in corrosion resistance is obtained. By continuously drawing a core ball on a coiling and pulling machine, a required long product is obtained, and the maximum length is at least up to 300m. A polyimide F46 composite film is adopted, and the advantages of high pressure resistance, high temperature resistance, high corrosion resistance and the like are achieved.

Owner:济南宝世达实业发展有限公司

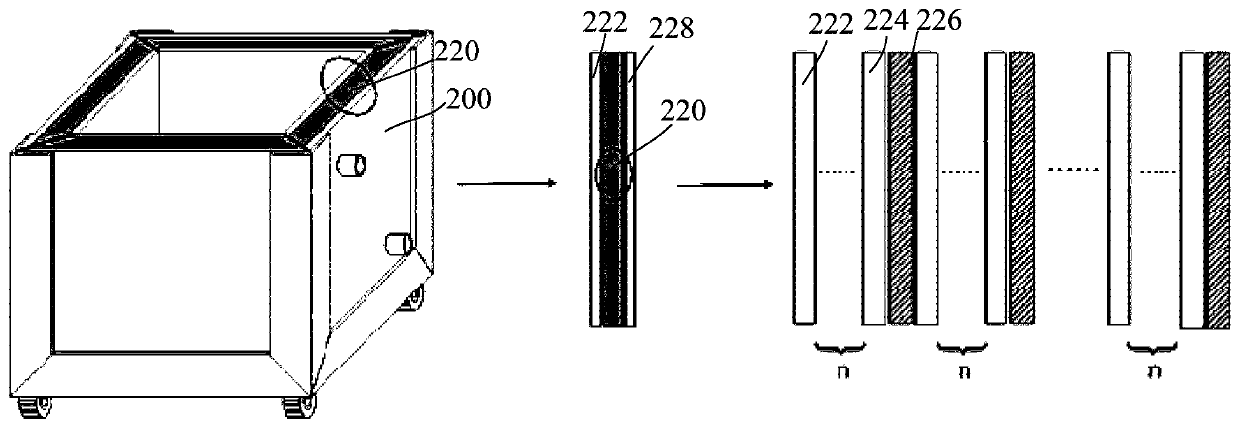

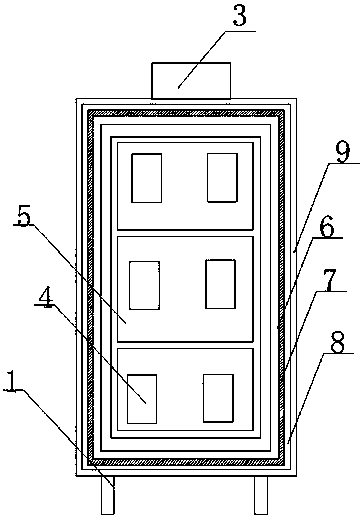

Anti-corrosion power cabinet with shielding layer

InactiveCN108054641AExtended service lifeCorrosion resistance hasSubstation/switching arrangement casingsNatural mineral layered productsElectrical elementDistortion

An anti-corrosion power cabinet with a shielding layer includes stand columns, a box body, a fan, an electrical element and a mounting plate, left and right ends of the bottom of the box body are equipped with the stand columns, the fan is mounted above the top of the box body, the mounting plate is mounted on the inner side of the box body through bolt connection, the electrical element is mounted on the mounting plate, and the box body includes an insulating layer, a shielding layer, a metal layer and an anti-corrosion layer in sequence from inside to outside. The anti-corrosion power cabinet with a shielding layer overcomes defects of the prior art, an original metal box body structure is improved, the insulating layer, shielding layer, metal layer and anti-corrosion layer are adopted and are glued to perform one-time extrusion molding, the formed box body has the characteristics of light mass, corrosion resistance and an anti-distortion capability, an effect of prolonging the service life of the power cabin, environment protection and energy conservation and the like, the performance is excellent, and thus the anti-corrosion power cabinet is suitable for popularization.

Owner:安徽星博电气科技有限公司

Supporting strip material for cold shrink cable accessories and preparation method thereof

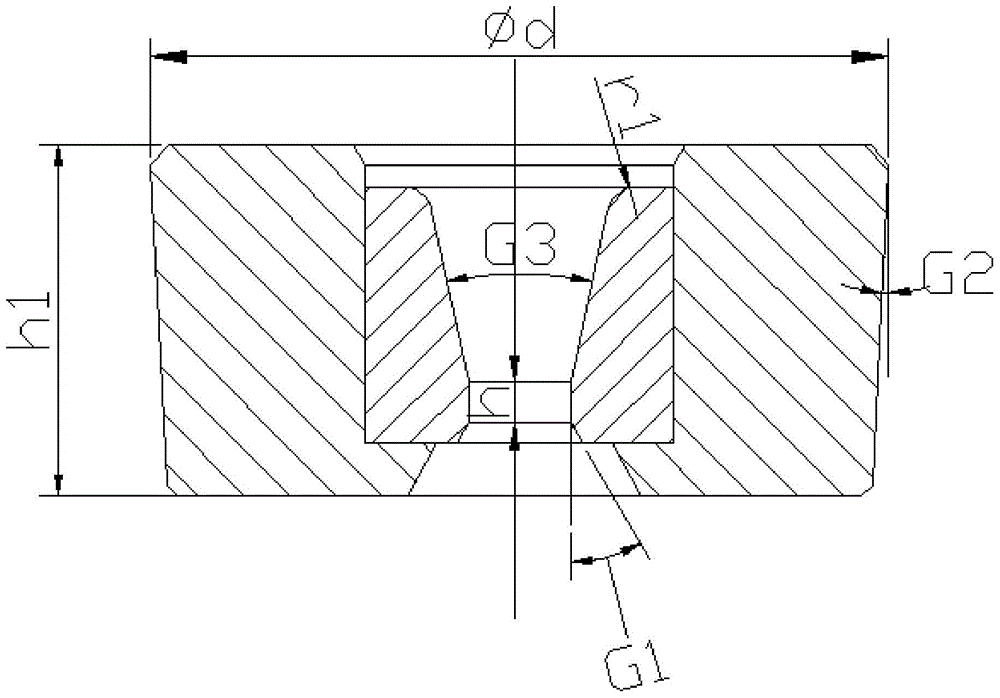

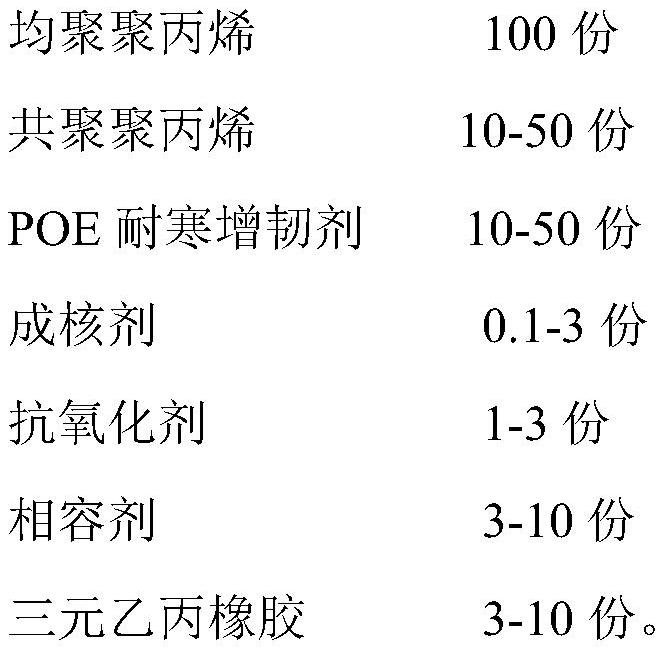

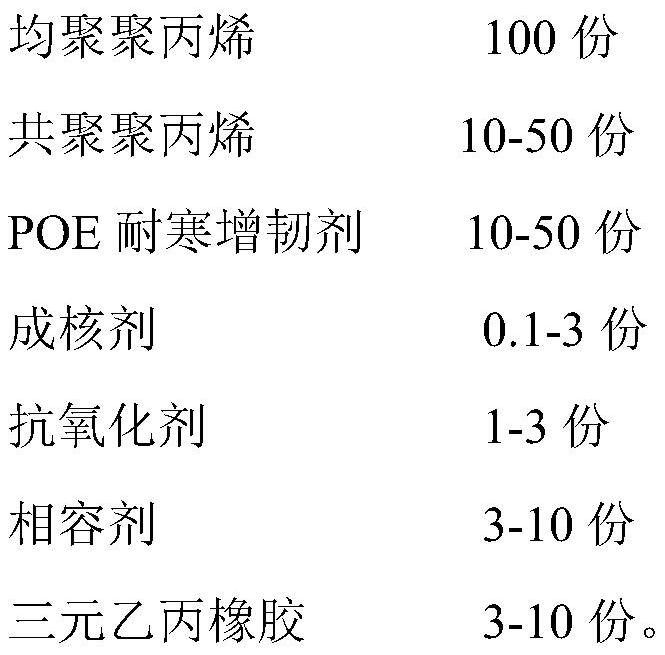

InactiveCN111647225AWide variety of sourcesScientific and reasonable formula designEthylene-propylene-diene-monomerPolypropylene

The invention relates to a supporting strip material for cold shrink cable accessories and a preparation method thereof, and belongs to the technical field of cable accessories. The supporting strip material for cold shrink cable accessories is prepared from the following raw materials by weight: 100 parts of homo-polypropylene, 10-50 parts of co-polypropylene, 10-50 parts of a POE cold-resistanttoughening agent, 0.1-3 parts of a nucleating agent, 1-3 parts of an oxidant, 3-10 parts of a compatilizer and 3-10 parts of ethylene propylene diene monomer. The supporting strip material for cold shrink cable accessories has the advantages of small density, light weight, heat resistance and corrosion resistance, but also has the characteristics of impact resistance and low-temperature embrittlement resistance; the invention also provides a simple and feasible preparation method which is beneficial to industrial production.

Owner:山东耐高电力器材有限公司

Method for preparing insulation board

The invention provides a method for preparing an insulation board. The method comprises the following steps: firstly, adding 4,4'-diaminodiphenyl ether into dimethyl fomamide to prepare mixed solution; mixing sepiolite powder and glass beads, adding the mixture into the mixed solution, uniformly stirring to obtain a mixture; respectively adding triethylamine and aceticanhydride into the mixture, and adding 3,3',4,4'-benzophenone tetracarboxylic dianhydride into the mixture for reaction to prepare a blend; and demolding the blend after the blend is extruded in a mould, and naturally cooling the blend to room temperature to obtain the insulation board. In the method, the sepiolite powder and the glass beads serving as inorganic phases and polyimide serving as an organic phase are adopted to prepare the insulation board which is high-temperature resistant and has long service life. Compared with common insulation materials, by sufficiently utilizing the advantages of corrosion resistance, light weight, low heat conductivity of the sepiolite powder and the glass beads, and high temperature resistance, water prevention, high adhesiveness and the like of the polyimide, the material has the advantages of low heat conductivity, light weight, acid and alkali resistance, corrosion resistance, wide application temperature range and the like, thereby having great market prospect.

Owner:SHAANXI UNIV OF SCI & TECH

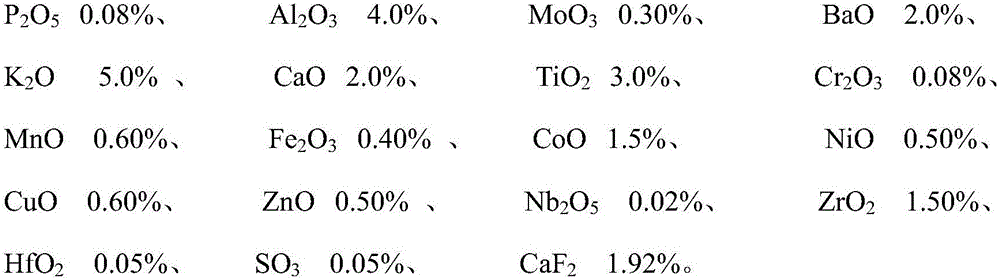

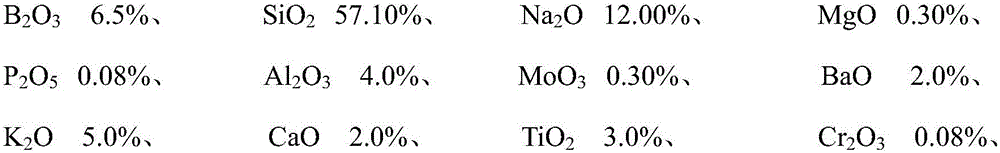

Preparation method of enamel plate for flue of thermal power plant

The invention relates to a preparation method of an enamel plate for a flue of a thermal power plant. The enamel plate prepared through the method has excellent chemical durability, corrosion resistance and thermal stability and is suitable for the inner wall, where a smoke wet desulphurization and dedusting treatment device is installed, of the flue the thermal power plant. The preparation method specifically comprises the following steps that enamel glaze is prepared, specifically, a, raw materials are mixed, the raw materials for preparing the enamel glaze are evenly mixed in solvent water, and the raw materials of the enamel glaze include glaze, quartz, borax, barium nitrate, clay and sodium nitrite; b, melting is conducted, the raw materials which are evenly mixed are placed in a crucible and melted for 1-3 hours at the temperature of 1200-1400 DEG C; c, chilling is conducted, the melted raw materials are placed in water and rapidly cooled to the room temperature and then fished out to be dried, and the raw materials are solidified, so that blocky frit is obtained; and d, ball milling is conducted, the frit, clay and water are added into a ball mill to be ground till the mixture can pass through a sieve with 40-80 meshes, and glaze slip is prepared.

Owner:ZHEJIANG KAIER NEW MATERIALS

Synthetic resin tile and preparation method thereof

PendingCN109591414ADelay resin agingExtended service lifeSynthetic resin layered productsConstructions elementsWeather resistanceChemistry

The invention discloses a synthetic resin tile and a preparation method thereof, belonging to the technical field of resin tiles. According to the preparation method, chopped alkali-free glass fibersare added into a polyvinyl chloride resin base material so as to form a network skeleton structure in the base material, so that the aging of the resin is delayed, and the service life of the synthetic resin tile is prolonged. Meanwhile, the synthetic resin tile is divided into three layers, namely an upper surface layer, a middle layer and a lower surface layer which have different effects, so that the resin tile has multiple properties of weather resistance, ultraviolet resistance and the like further has relatively high practicability and high product quality on the basis that basic properties (lightness, high strength, good tenacity, corrosion resistance and the like) of the resin tile are guaranteed.

Owner:LESHAN JIACHENG BUILDING MATERIAL

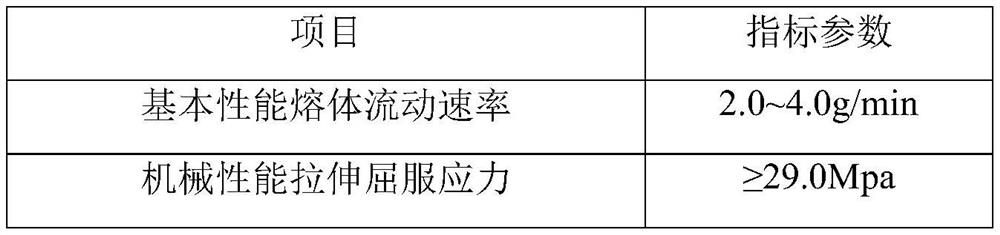

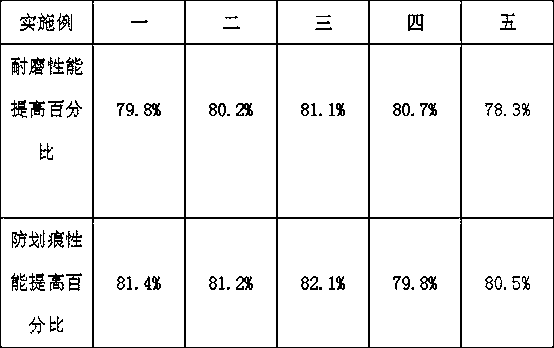

Wood-plastic composite floor and preparation method thereof

The invention belongs to the field of floors, in particular to a wood-plastic composite floor and a preparation method thereof. Aiming at solving the problems of relatively short service life caused by relatively poor wear resistance and scratch resistance of existing wood-plastic composite floors, the wood-plastic composite floor provided by the invention is characterized by being prepared from the following raw materials in parts by weight: 30 to 50 parts of PVC resin, 40 to 45 parts of wood flour, 5 to 10 parts of a binder, 5 to 10 parts of a modifier, 6 to 12 parts of a plasticizer, 7 to 12 parts of a flame retardant, 15 to 20 parts of composite fiber, 15 to 25 parts of polyester fiber, 20 to 25 parts of bamboo charcoal fiber, 20 to 25 parts of carbon rubber, 7 to 11 parts of hollow microspheres, 8 to 13 parts of polytetrafluoroethylene, 11 to 16 parts of wear-resistant rubber, and 9 to 14 parts of polypropylene fiber. According to the wood-plastic composite floor provided by the invention, relatively good wear resistance is realized, the strength is improved at the same time, the scratch-resisting effect is good, the flame-retarding effect is good, the service life can be prolonged, and the preparation method is simple.

Owner:江苏星和瑞塑木科技有限公司

Safe and stable novel vibrating screen supporting beam

InactiveCN104475335AGuaranteed positioning accuracyGuaranteed assembly qualitySievingScreeningStress distributionEngineering

The invention provides a safe and stable novel vibrating screen supporting beam. The safe and stable novel vibrating screen supporting beam comprises a supporting beam, butting bases and a flange, wherein the butting bases are respectively arranged on the left and right sides of the supporting beam; the flange is arranged at one end of the supporting beam; each butting base comprises a base plate, a vertical plat and an oblique supporting plate which are connected with one another sequentially; each vertical plate is provided with a bolt hole and is fixed together with the flange by the bolt hole; the supporting beam is provided with a bracket rack and a gasket; the gasket is arranged on the bracket rack; a scouring-corrosion-resisting layer is arranged on the surface of the supporting beam. The safe and stable novel vibrating screen supporting beam provided by the invention has the beneficial effect that the safe and stable novel vibrating screen supporting beam has the characteristics of being resistant to scouring and corrosion, large in structural rigidity, high in strength, reasonable and balanced in stress distribution, high in safety coefficient, compact in structure, light in weight and the like.

Owner:AURY TIANJIN IND TECH

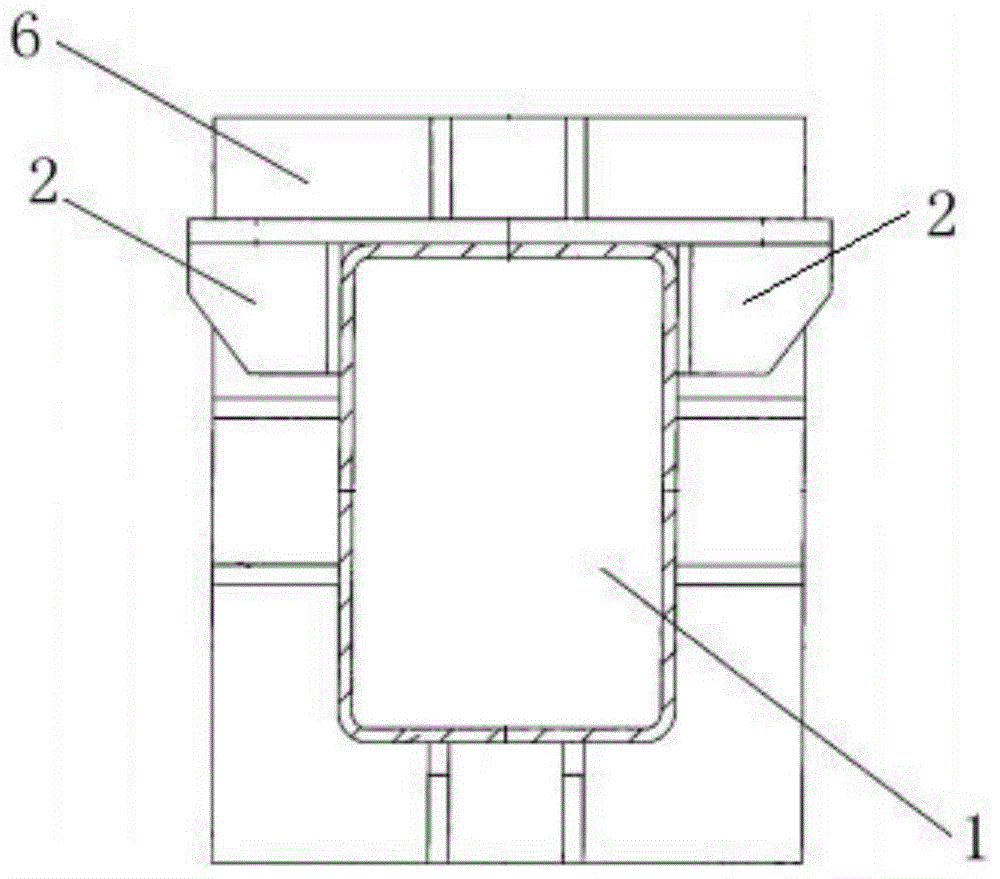

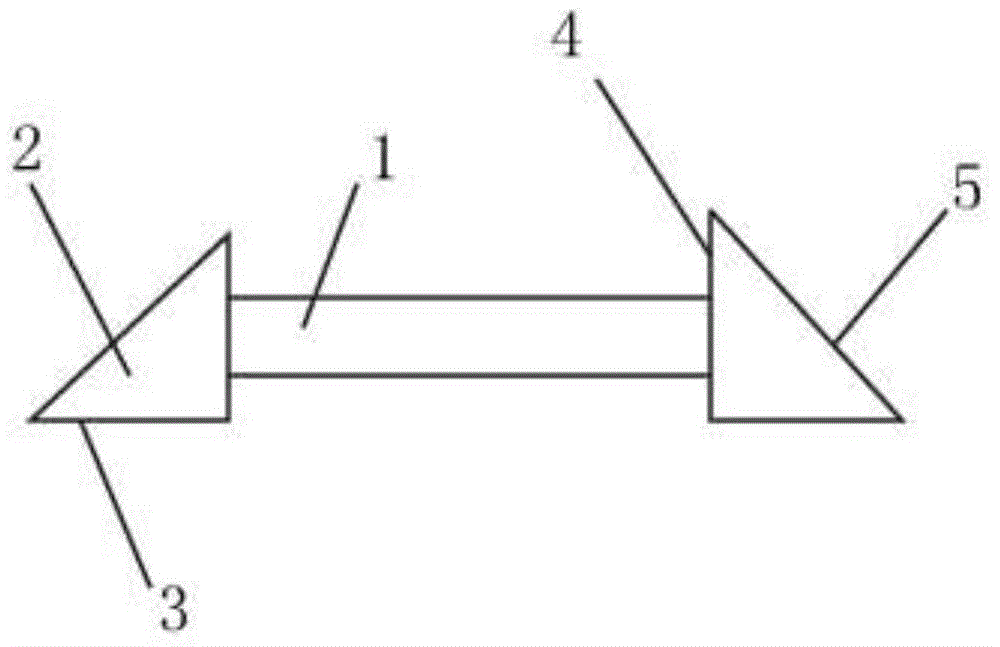

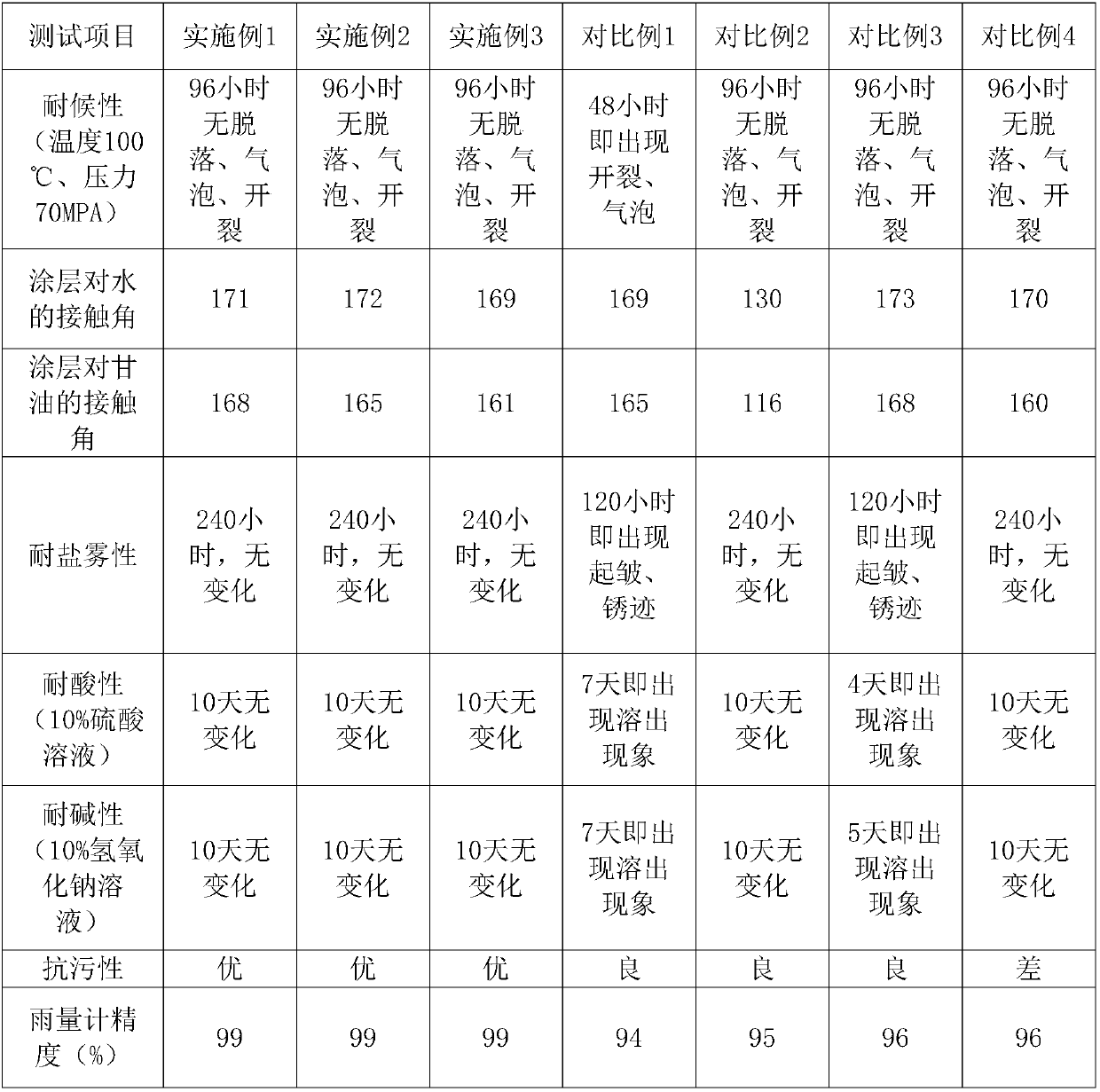

Super-amphiphobic corrosion resistant coating for rain gauge and preparation method thereof

ActiveCN108017977ACircumstances Affecting AccuracyCorrosion resistance hasFireproof paintsAntifouling/underwater paintsEpoxyStrong acids

The invention discloses a super-amphiphobic corrosion resistant coating for rain gauge and a preparation method thereof. The super-amphiphobic corrosion resistant coating is prepared from, by weight,40-60 parts of organosilicon epoxy resin, 5-10 parts of curing agent, 10-20 parts of polytetrafluoroethylene, 10-20 parts of polyether-ether-ketone, 20-25 parts of polydopamine, 20-25 parts of oxygenbased ferric chloride modified by nano polyaniline, 5-10 parts of aluminium triphosphate, 5-10 parts of talc powder, 5-10 parts of nano silver particles, 1-3 parts of silane coupling agent, 1-2 partsof wetting agent, 0.5-2 parts of defoamer, 0.5-2 parts of dispersant and 30-50 parts of n-butyl alcohol. The super-amphiphobic corrosion resistant coating not only has good properties of high temperature resistance, high pressure resistance, strong acid resistance, strong alkali resistance, corrosion resistance and the like, but also has an excellent hydrophobic and oileophobic property and an anti fouling property, can significantly prolong the service-life of the rain gauge, and significantly improve the measurement precision of the rain gauge.

Owner:BEIJING FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com