Vacuum atomization suspension uniform sputtering coating method for spherical powder material

A technology of spherical powder and sputtering coating, which is applied in the fields of chemistry and metallurgy, can solve the problem of inability to produce high and low temperature resistance, high pressure resistance, humidity resistance, corrosion resistance and oxidation resistance, inability to solve spherical powder materials, and inability to complete spherical metal powder Anti-oxidation surface functional treatment and other issues to achieve excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

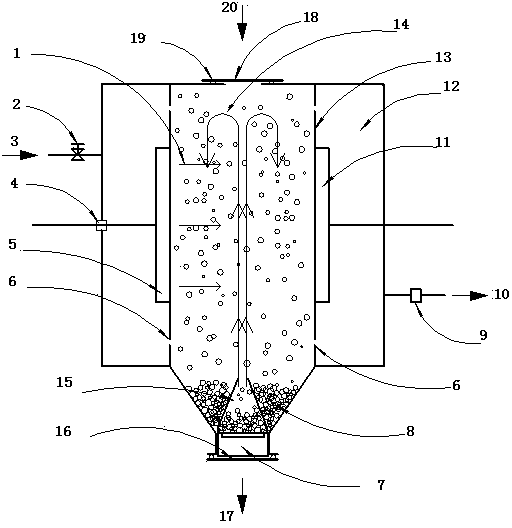

[0014] Such as figure 1 The vacuum atomization suspension uniform sputter coating method for spherical powder materials shown is characterized in that: the spherical powder 8 is placed in a vacuum atomization tank, and a cathode sputtering target 5 and an anode body are arranged in the vacuum atomization tank 11. In a vacuum environment, when the high-energy particles accelerated by the electric field or magnetic field hit the surface of the cathode sputtering target 5, the atoms and molecules on the target surface and the high-energy particles exchange momentum, so that the target atoms or molecules are splashed from the target surface Come out, and have a certain energy, collide with the spherical powder 8 that is atomized and suspended in the vacuum, so as to realize the thin film deposition on the spherical powder 8.

[0015] Further, the vacuum atomizing tank includes a tank body, a coating gas tube 3 installed on the tank body and a vacuum device 10, the tank body is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com