Safe and stable novel vibrating screen supporting beam

A technology of supporting beam and vibrating screen, which is applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of large machining allowance, poor manufacturing level, large material used for supporting beam flange, etc., and achieve a reasonable and balanced force distribution and reduce The effect of small noise volume and guaranteed position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

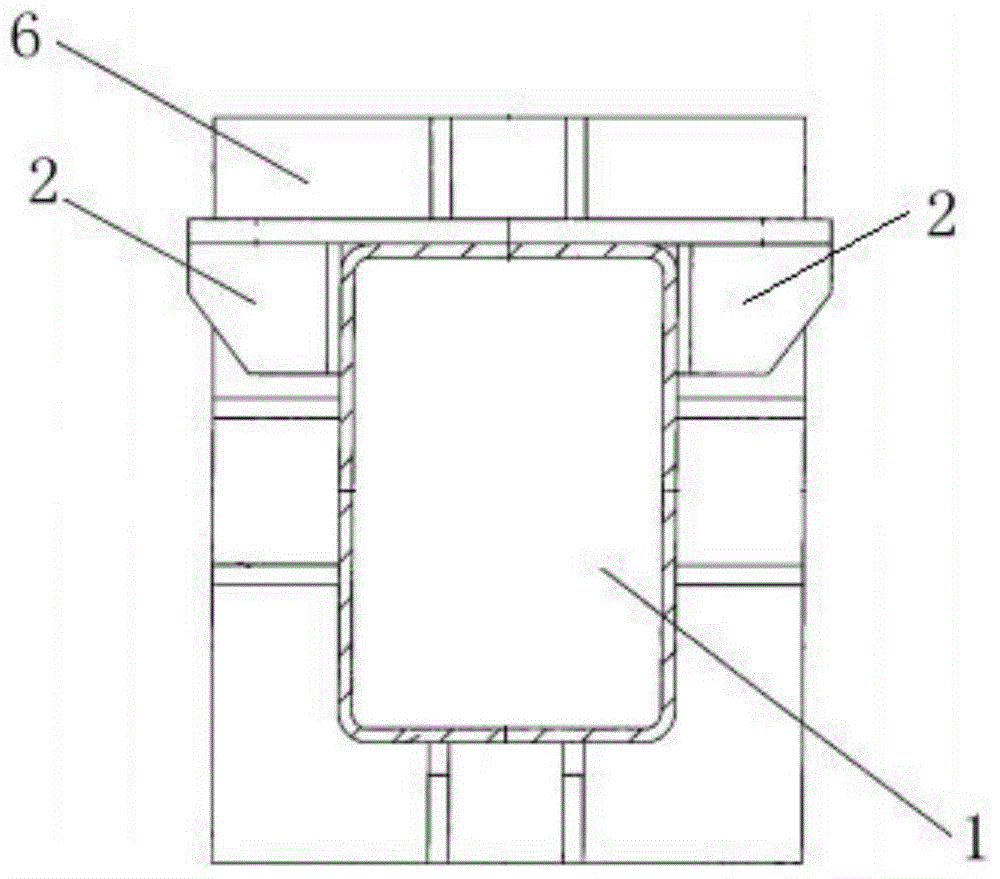

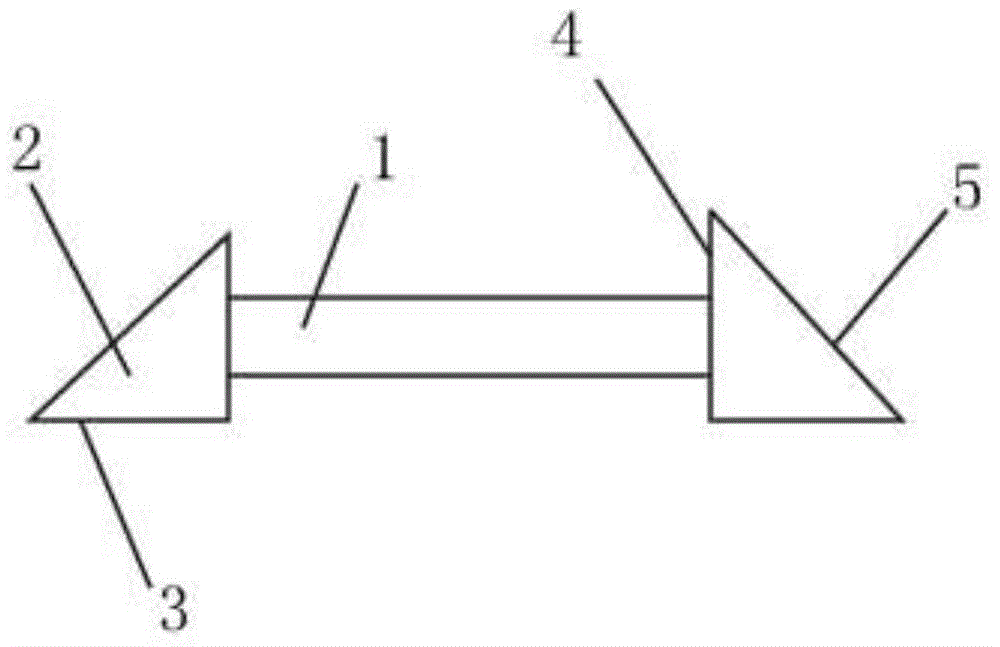

[0018] A new type of safe and stable vibrating screen support beam, including a support beam 1, a docking seat 2, and a flange 6, the left and right sides of the support beam 1 are provided with a docking seat 2, one end of the support beam 1 is provided with a flange 6, and the docking seat 2 Including the bottom plate 3, the vertical plate 4 and the inclined support plate 5, the bottom plate 3, the vertical plate 4, and the inclined support plate 5 are connected in sequence, the vertical plate 4 is provided with bolt holes, and the vertical plate 4 is fixed to the flange 6 through the bolt holes Together, the support beam 1 is provided with a support bracket and a washer, the support bracket is provided with the washer, and the surface of the support beam 1 is provided with an erosion-resistant corrosion layer.

Embodiment 2

[0020] A safe and stable new vibrating screen support beam, comprising a circular tube hollow support beam, a docking seat 2, and a flange 6. The left and right sides of the circular tube hollow support beam are provided with a docking seat 2, and one end of the support beam 1 is provided with a flange. Lan 6, the docking seat 2 includes a base plate 3, a vertical plate 4 and an inclined support plate 5, the base plate 3, the vertical plate 4, and the inclined support plate 5 are connected in sequence, the vertical plate 4 is provided with bolt holes, and the vertical plate 4 passes through the bolts The hole and the flange 6 are fixed together, the support beam 1 is provided with a support bracket and a gasket, the support bracket is provided with the gasket, and the surface of the support beam 1 is provided with an erosion-resistant corrosion layer.

Embodiment 3

[0022] A safe and stable new vibrating screen support beam, comprising a circular tube hollow support beam, a docking seat 2, and a flange 6. The left and right sides of the circular tube hollow support beam are provided with a docking seat 2, and one end of the support beam 1 is provided with a flange. Lan 6, the docking seat 2 includes a base plate 3, a vertical plate 4 and an inclined support plate 5, the base plate 3, the vertical plate 4, and the inclined support plate 5 are connected in sequence, the vertical plate 4 is provided with bolt holes, and the vertical plate 4 passes through the bolts The hole is fixed with the flange 6, and the flange 6 is provided with an air vent, and the bracket bracket and the gasket are fixed on the hollow support beam of the round tube through a rivet, and the bracket bracket is provided with the The washer, the surface of the hollow support beam of the round tube is provided with an erosion-resistant corrosion layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com