Patents

Literature

167results about How to "Relieve welding stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Welding repair method for large-sized heat-resistant steel castings

ActiveCN103962791AEliminate Large Area DefectsRelieve welding stressArc welding apparatusShielded metal arc weldingCrazing

The invention relates to a welding repair method for large-sized heat-resistant steel castings, and solves the problems that the welding stress is difficultly removed, the defects of incomplete fusion, incomplete penetration, delayed crack and slag inclusion are easily caused in a repair process and the repair quality is difficultly guaranteed as the heat-resistant steel castings are poorer in welding performance, complicated in defect position and large in workpiece in an existing manual arc welding type surfacing welding mode for repairing large-sized castings. The method mainly comprises the following steps: 1, removing the defects; 2, performing heat treatment; 3, performing dye check; 4, performing statistics on the repair welding quantity; 5, preheating before welding; 6, performing repair welding on defect parts; 7, cleaning and repairing; 8, performing post-welding heat treatment; 9, performing nondestructive inspection. According to the method, the large-area defects of the castings can be effectively repaired, the repair quality is guaranteed, the processing and use requirements of the castings can be met after repair, and the economic loss of scrapped important or major castings is reduced. The method is used for repairing the large-area defects of the large-sized heat-resistant steel castings.

Owner:HARBIN JIANCHENG GRP

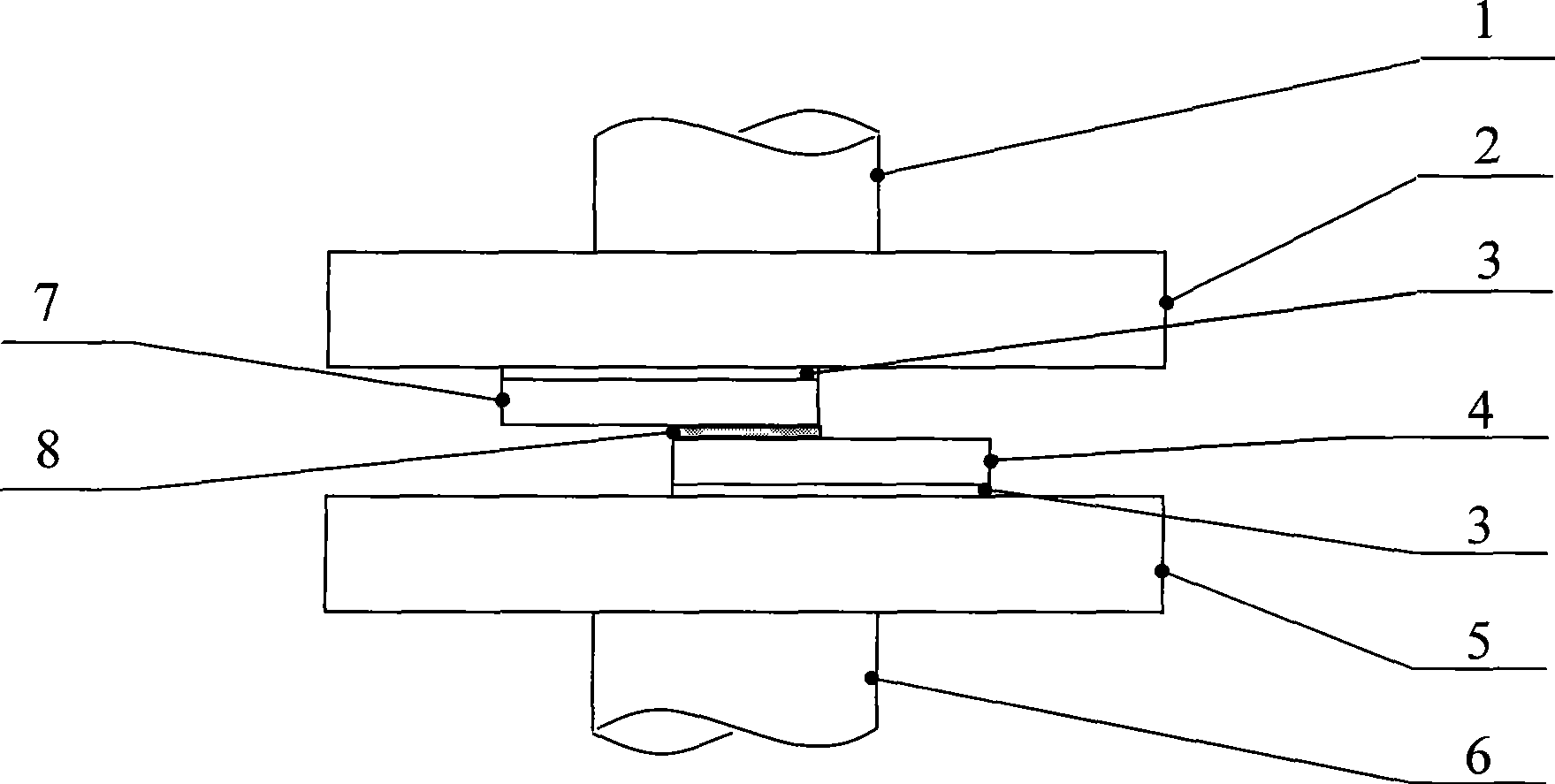

TiNi shape memory alloy and stainless steel instant liquid-phase diffusion welding connection method

InactiveCN101362253ALess loss of shape memory propertiesSmall organizationWelding/soldering/cutting articlesNon-electric welding apparatusHeat-affected zoneSurface cleaning

The invention relates to a method for transient liquid phase diffusion bonding between TiNi shape memory alloy and stainless steel, which belongs to the technical field of the connection of dissimilar materials. In the prior art, the technology of the connection between TiNi shape memory alloy and stainless steel has the problems of welding crack, large crystal grains in the heat affected zone and poor mechanical properties. The transient liquid phase diffusion bonding between TiNi shape memory alloy and stainless steel is realized through the following steps: after the surfaces of TiNi shape memory alloy and stainless steel to be welded and the surface of AgCuTi foil is cleaned and dried, a TiNi shape memory alloy / AgCuTi metallic foil / stainless steel structure is formed, fixed through a welding clip, and then positioned in a vacuum diffusion oven, and welding pressure and temperature are applied to the structure. The method has the advantages that the welding temperature is low (relative to fusion welding), the influence to the base material is small, the connector has no welding defect, the shearing strength of the connector in the room temperature reaches 250 MPa, and the microhardness of the area near the seam section can reach 670 Hv.

Owner:BEIJING UNIV OF TECH

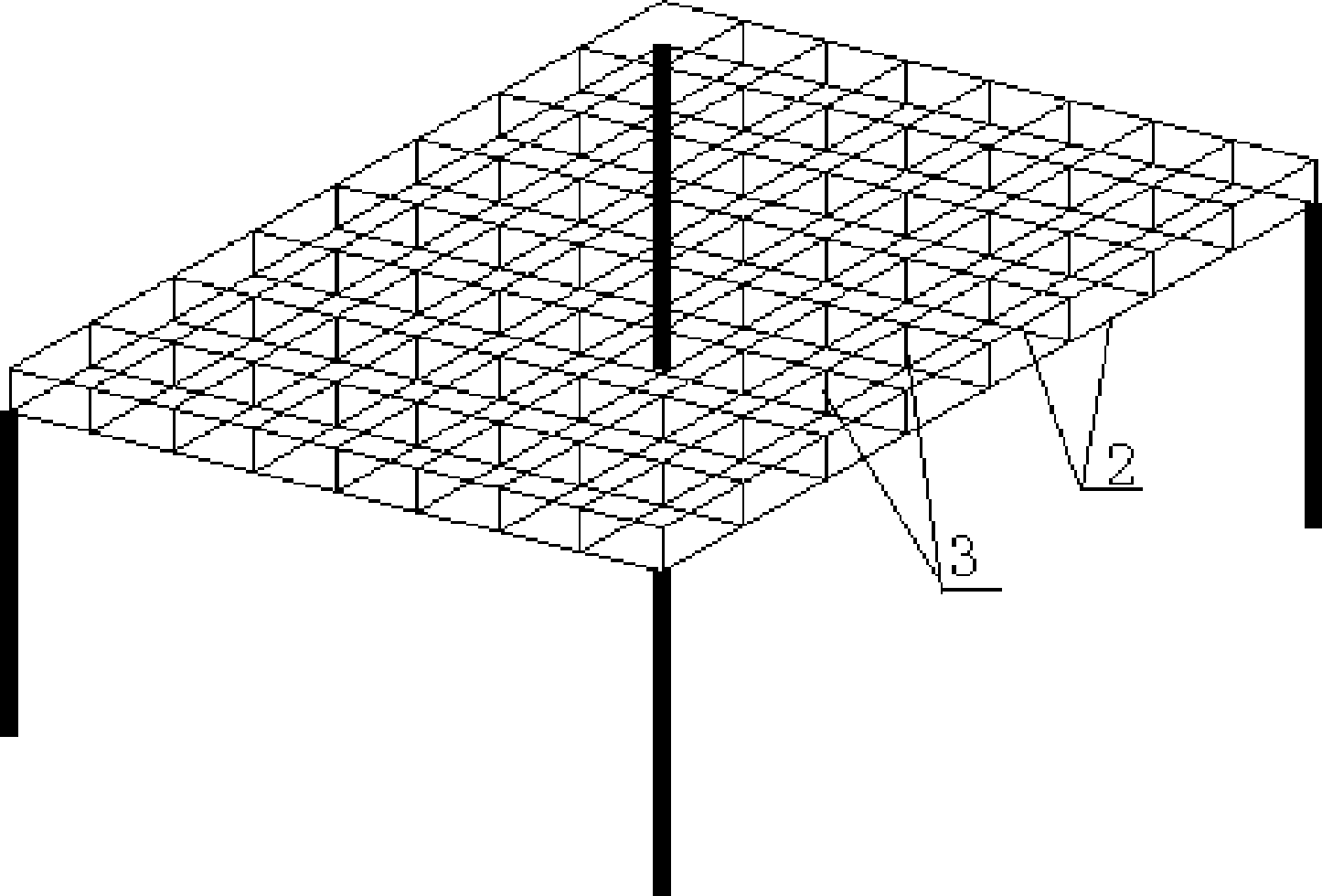

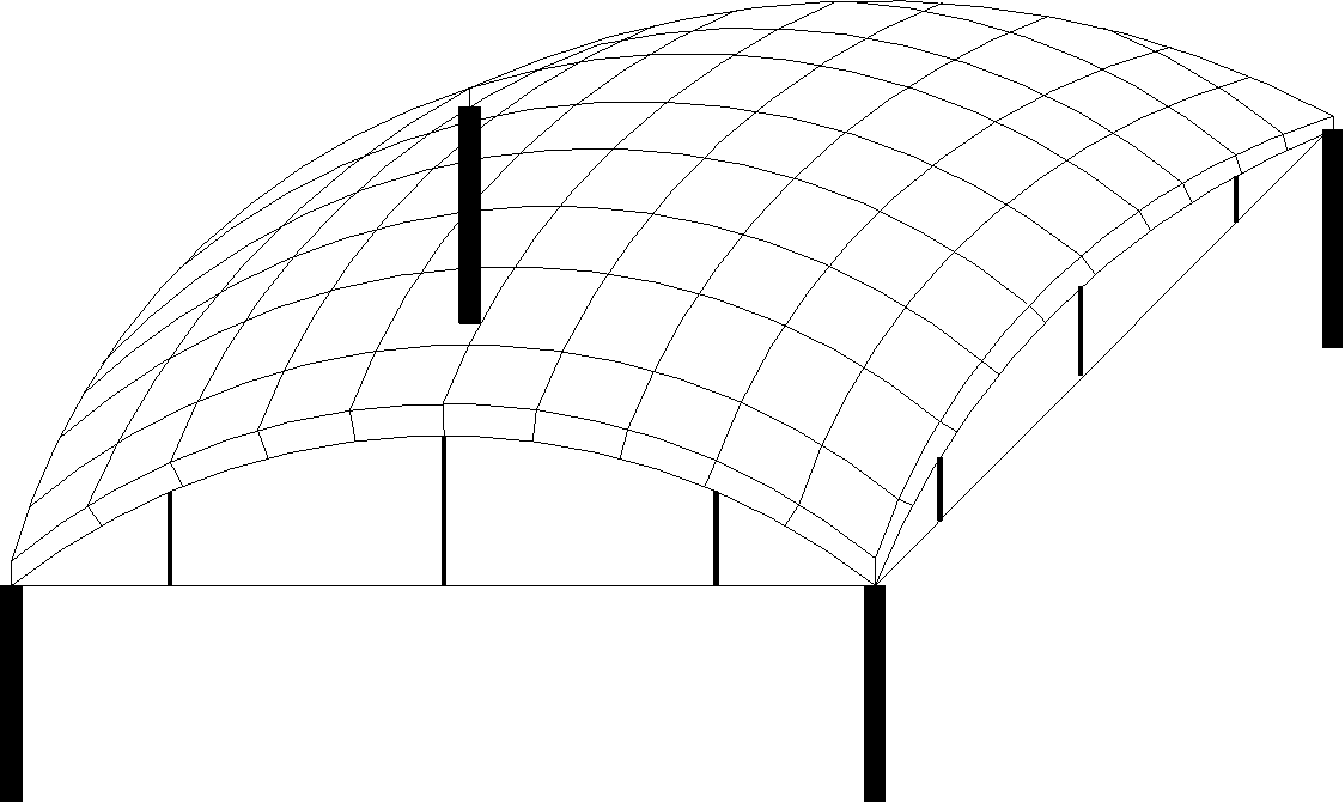

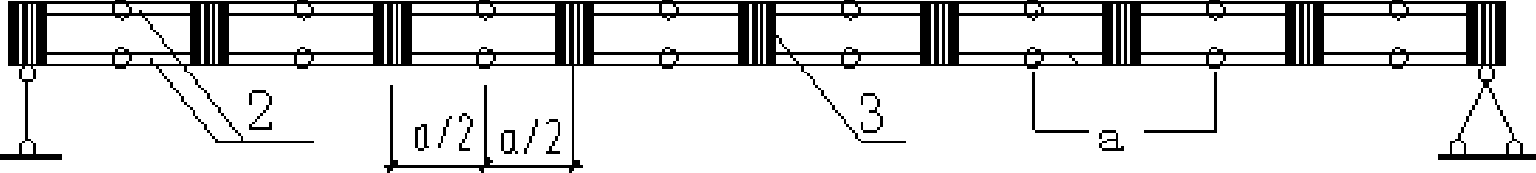

Assembly of integral flat-plate type or hood face section steel hollow lattice construction and production method

InactiveCN101397822AIncrease stiffnessReduce the height of the structureBuilding roofsFloorsRegular gridEngineering

The invention relates to a wholly assembled flat or curved steel vierendeel grid structure and a producing method thereof. The producing method comprises the steps: firstly, the two ends of a cylinder steel pipe are welded with a supporting plate respectively; the surface of the supporting plate and the pipe wall of the cylinder steel pipe are taken as welding points, 8 chords with T-shaped sections are respectively welded at the two ends of the cylinder steel pipe to form a double-layer assembling crisscross unit; chords of two or more double-layer assembling crisscross units are connected by a double spicing plate on the construction site so as to assemble the flat or curved grid structure. The flat or curved grid structure produced by the method has dexterous and firm structure; the welding technique is finished in factories, thus being capable of improving the precision and quality of production; the grid is formed by a vierendeel beam rather than a vierendeel truss rod so that water pipelines and electrical wires can go through the grids conveniently, takes regular grid shapes and plays a role of hanging floors and roofs.

Owner:贵州喀斯特钢结构有限公司 +2

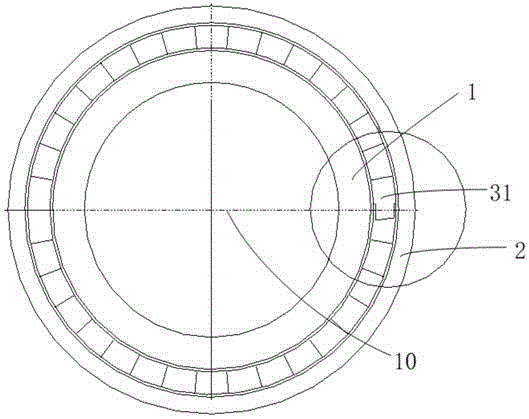

Accurate rounding method of large-diameter metal cylinder body

The invention relates to an accurate rounding method of a large-diameter metal cylinder body, which comprises the steps of: manufacturing rounding moulds in advance according to the requirements for the sizes and the precisions of a cylinder body by using physical characteristics of heat expansion and cold contraction of a metal material, connecting the rounding moulds by using a distance rod with threads at two ends to form a rounding mould set; and placing the cylinder body to be rounded on a support platform of a heating furnace (or thermal treatment furnace), then placing in the heating furnace (or thermal treatment furnace) for heating, heating to reach the final heating temperature, then taking the cylinder body out, loading in the rounding mould set, slowly cooling, when the cylinder body is cooled to the room temperature, ensuring that the inner surface of the cylinder body and the outer surface of the rounding mould are naturally jointed and the cylinder body can reach the required roundness. Compared with the traditional mechanical strength rounding method of the cylinder body, the accurate rounding method has remarkable advantages of high rounding precision and less residual stress after rounding, can be used for accurate rounding in the process of machining the large-diameter metal cylinder body, especially accurate rounding of the large-diameter metal cylinder body and a large-diameter rotary metal cylinder body with high strength and large wall thickness.

Owner:云南大为化工装备制造有限公司

Machining method of closed three-elemental impeller with small flow

The invention relates to a machining method of a closed three-elemental impeller with a small flow. The machining method comprises the following steps of: 1. mounting an impeller forging on a lathe machining center of a numerically-controlled machine tool, thereby carrying out semi-finishing treatment on the impeller forging; 2. machining a circular groove in an impeller cover and completing the machining of the whole flow channel of an impeller; and 3. welding a circular impeller cover shielding plate on the impeller cover and completing the contour finishing of the impeller cover and an impeller hub, wherein the semi-finishing treatment is performed by clamping the impeller forging on the lathe machining center of the numerically-controlled machine tool and carrying out the lathe machining on the impeller forging; the lathe machining in an axial feeding manner is performed until reaching an air inlet of an impeller blade; the outer contour of the impeller cover is formed by performing the lathe machining in a radial feeding manner; and the allowance of 4 to 6mm is left between the impeller cover and the impeller hub. The method has the characteristics of weldless flow channel forming surface, smooth flow channel, effective reduction in aerodynamic resistance, good aerodynamic performance and aerodynamic efficiency, good machining quality, high impeller strength, good corrosion resistance and the like.

Owner:杭州杭氧透平机械有限公司

65 Mn cold-rolled wide steel strip manufacturing process

ActiveCN107649512AShorten the timeImprove production efficiencyRoll force/gap control deviceMetal rolling stand detailsProduction lineWeld seam

The invention discloses a 65 Mn cold-rolled wide steel strip manufacturing process. The 65 Mn cold-rolled wide steel strip manufacturing process comprises the steps that 65 Mn raw materials are slow-cooled for 48 h and then sent to a cold rolling factory; an acid rolling combined unit production line is used, after heat cutting is conducted on the 65 Mn raw materials, welding is conducted, the speed of welding a steel strip is 3.3-3.6 m / min, the welding input power is 10.0-10.5 KW; a welding seam area of a joint is heated and annealed, the annealing temperature is 620-650 DEG C, the annealingtime is 50-60 s, and then dephosphorizing and acid pickling are conducted; the cold rolling total downward pressing amount is controlled to be 35-50%, the downward pressing rate of a first rack S1 is9-15%, and the rolling force is 10-18 MN; the downward pressing rate of a second rack S2 is 10-17%, and the rolling force is 10-18 MN; the downward pressing rate of a third rack S3 is 10-17%, and therolling force is 10-18 MN; the downward pressing rate of a fourth rack S4 is 8-13%, and the rolling force is 10-18 MN; the downward pressing rate of a fifth rack S5 is 1.5-5%, and the rolling force is4-7 MN; and after five times continuous rolling is conducted, the finished product thickness is formed by rolling, and coiling for warehousing is conducted after rolling is finished. By means of the65 Mn cold-rolled wide steel strip manufacturing process, continuous and steady rolling of the 65Mn cold-rolled wide steel strip on the acid rolling combined unit is achieved.

Owner:新余钢铁股份有限公司

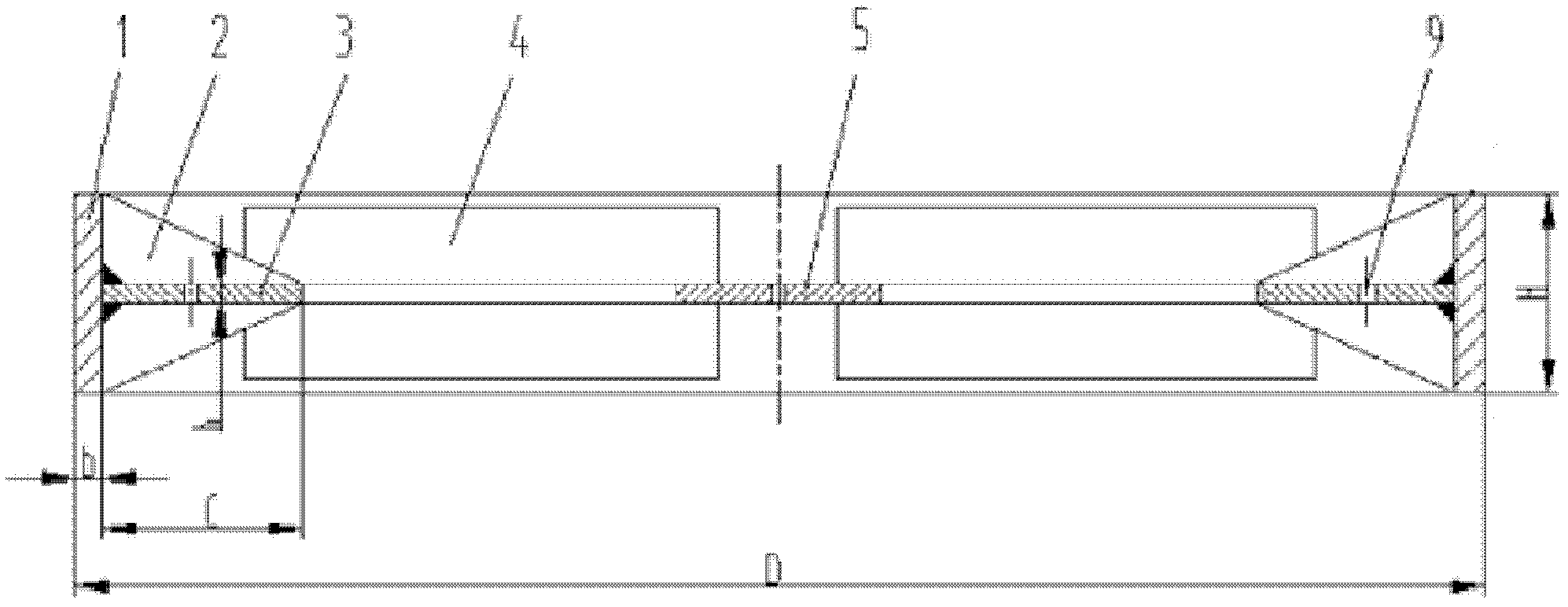

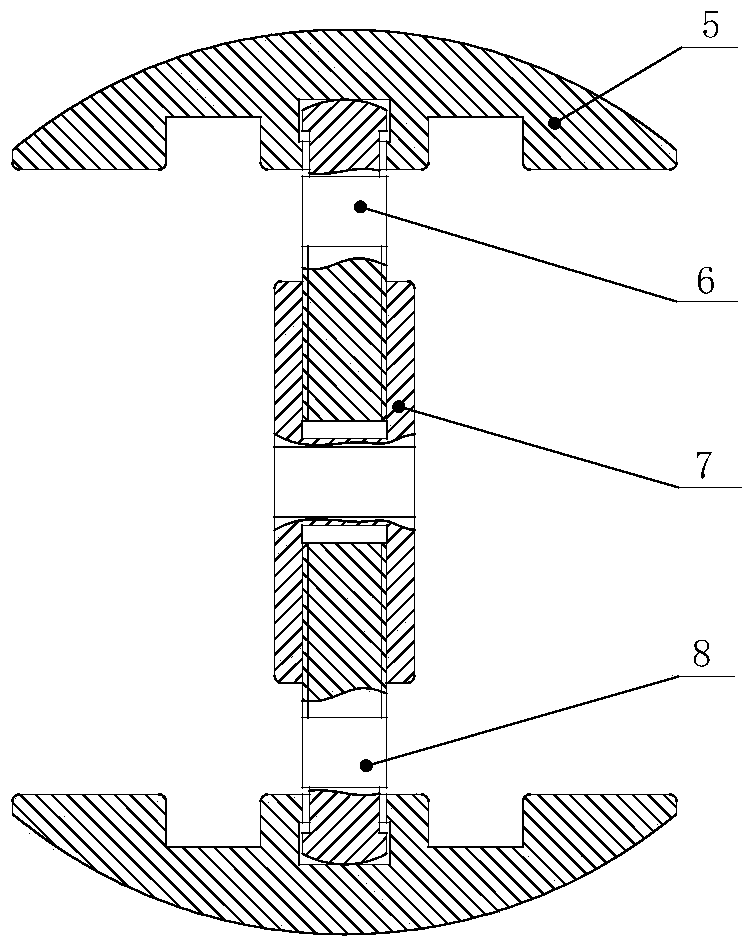

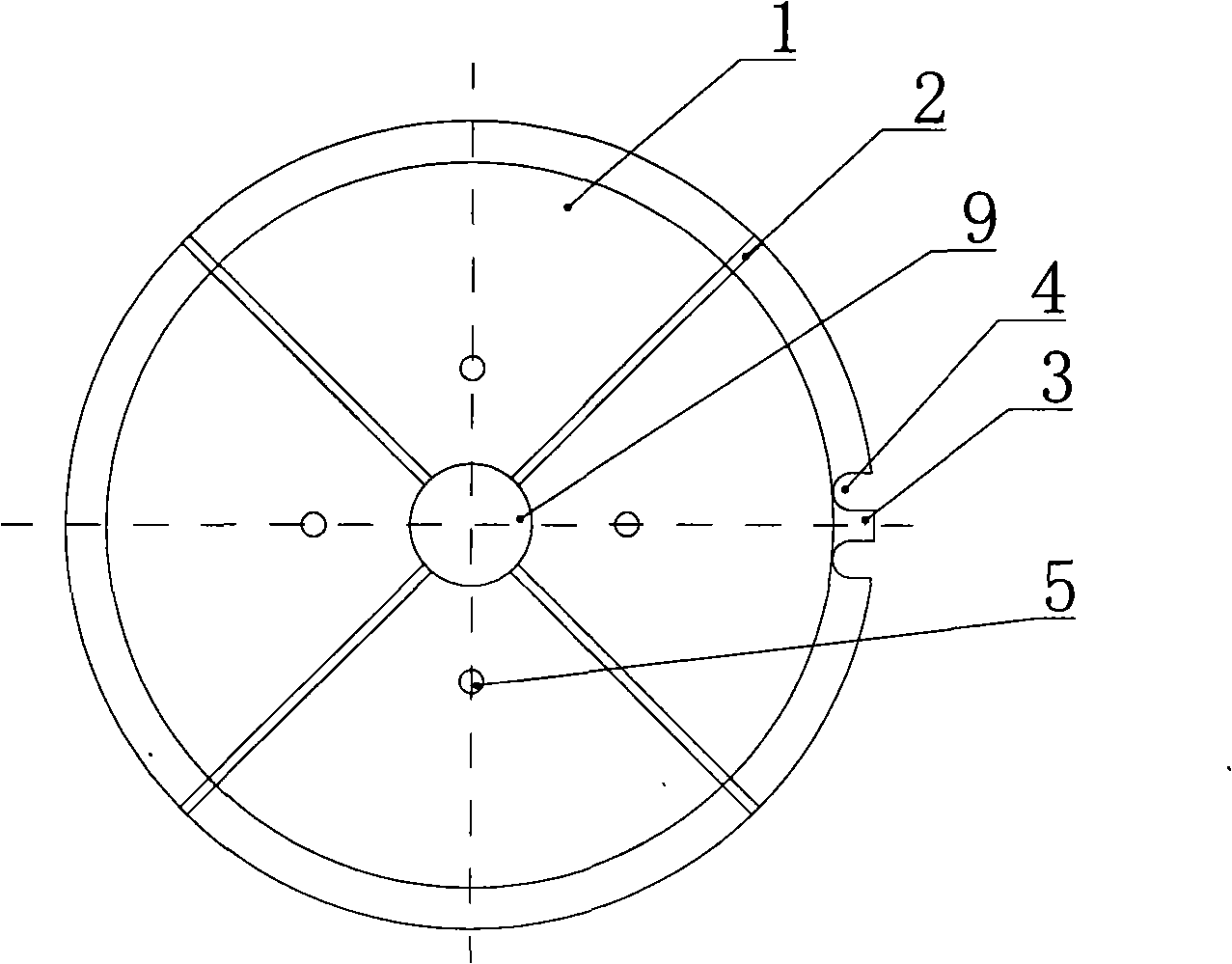

Extensible and retractable inner supporting tool

ActiveCN109366052ALarge stretchEasy accessWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStress relief

The invention discloses an extensible and retractable inner supporting tool. One end of a left-handed screw is installed in a screw installation hole in the plane geometric center of a supporting plate, and the left-handed screw is in rotating fit with the screw installation hole. A left-hand thread at the other end of the left-handed screw is installed in a threaded hole in the center at one endof a sleeve. One end of a right-handed screw is installed in a screw installation hole in the plane geometric center of the other supporting plate, and the right-handed screw is in rotating fit with the screw installation hole. A right-hand thread at the other end of the right-handed screw is loaded in a threaded hole in the center at the other end of the sleeve. The extensible and retractable inner supporting tool has extending and retracting functions; in a shortened state, the extensible and retractable inner supporting tool can be put into a shell and then extends to support a cylinder, rigid restraining to the cylinder is achieved, and the welding deformation is reduced; and by means of stress relief annealing heat treatment through the belt tool, deformation stress is eliminated, andtherefore the cylinder circular degree after welding is guaranteed, and the circular degree of the shell is reduced to 2.5 mm from 10 mm.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

Ultrasonic-impact-assisted laser cladding repairing method for ultra-high-strength steel member

InactiveCN107675167ALow costReduced tendency to crackMetallic material coating processesJet aeroplaneRoom temperature

The invention belongs to the technical field of laser machining and relates to an ultrasonic-impact-assisted laser cladding repairing method for an ultra-high-strength steel member. The ultrasonic-impact-assisted laser cladding repairing method is mainly used for repairing damage such as surface corrosion and micro cracks of the ultra-high-strength steel member of an airplane. In the earlier stage, same metal powder for repairing is adopted for conducting a direct laser cladding repairing test and an ultrasonic-impact-assisted laser cladding repairing test on a 30CrMnSiNi2A ultra-high-strengthsteel undercarriage half-shaft base body, wherein according to the metal powder, the cladding metal impact toughness is larger than or equal to 420 KJ / m<2>, the room-temperature ductility is larger than or equal to 10.8%, and the room-temperature tensile strength is larger than or equal to 1400 MPa; and the room-temperature tensile performance, the room-temperature impact performance and the microhardness performance of two repairing areas are tested. The results are obtained as follows: according to direct laser cladding repairing, the average tensile strength is 1428.6 MPa, the average elongation rate is 11.8%, the average impact toughness is 471 KJ / m<2>, and the average microhardness of repairing metal is 474.3 HV; and according to ultrasonic-impact-assisted laser cladding repairing, the average tensile strength is 1436.2 MPa, the average elongation rate is 14.8%, the average impact toughness is 643 KJ / m<2>, and the average microhardness of the repairing metal is 490.7 HV.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

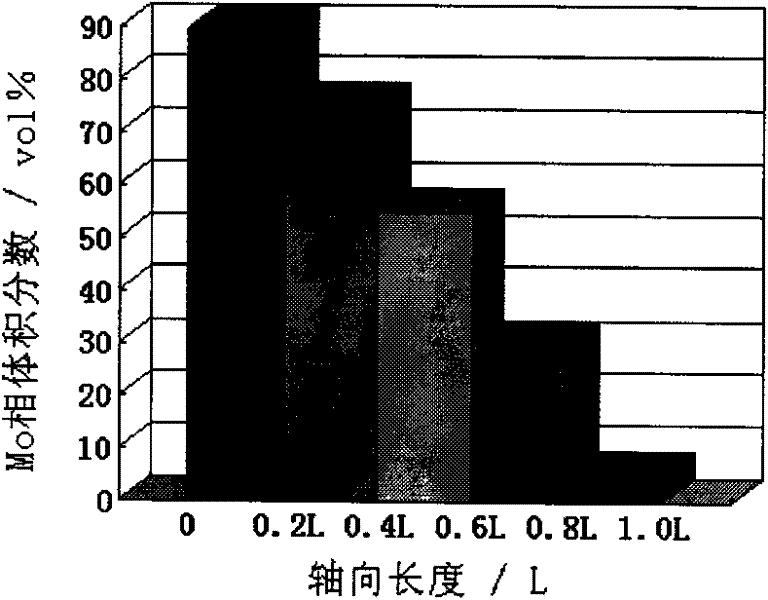

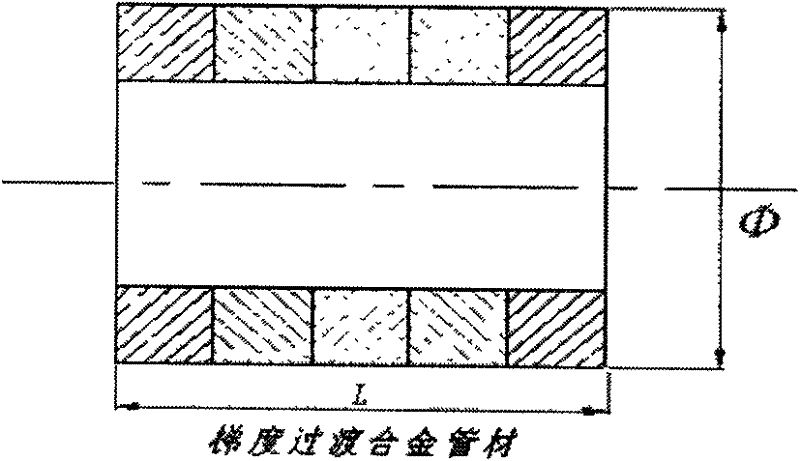

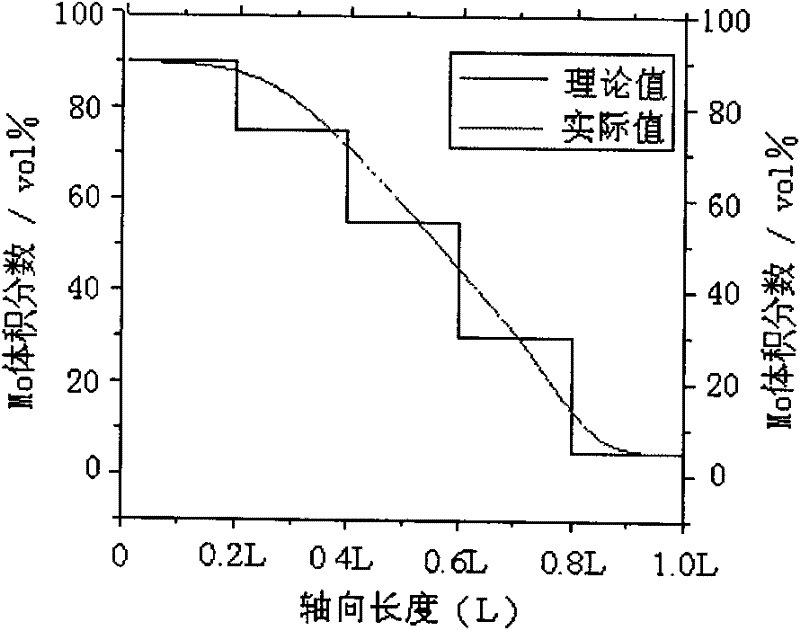

Alloy material with thermal expansion coefficient in gradient change and preparation method thereof

The invention relates to an alloy material with a thermal expansion coefficient in a gradient change and a preparation method of the alloy material. The alloy material comprises a substrate material component and a thermal expansion coefficient adjusting phase component, wherein the substrate material component is one or a mixture of several elements of Cu, Ni, Cr, Mn, Co and Fe in an optional ratio; the thermal expansion coefficient adjusting phase component is one or a mixture of several fibers of W, Mo, Al2O3, SiC and Si in an optional ratio; a gradient transition alloy is at least divided into two sections; and the distribution of the components of a thermal expansion coefficient adjusting phase in each section of the alloy changes in a gradient way. The method disclosed by the invention is suitable for preparing gradient transition alloy bars and pipes, the thermal expansion coefficient of the prepared alloy material changes in the gradient way, and the alloy material is well matched with welded ceramics and metals. The gradient transition alloy has important significance to release residual stresses generated in a ceramic and metal connecting process.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

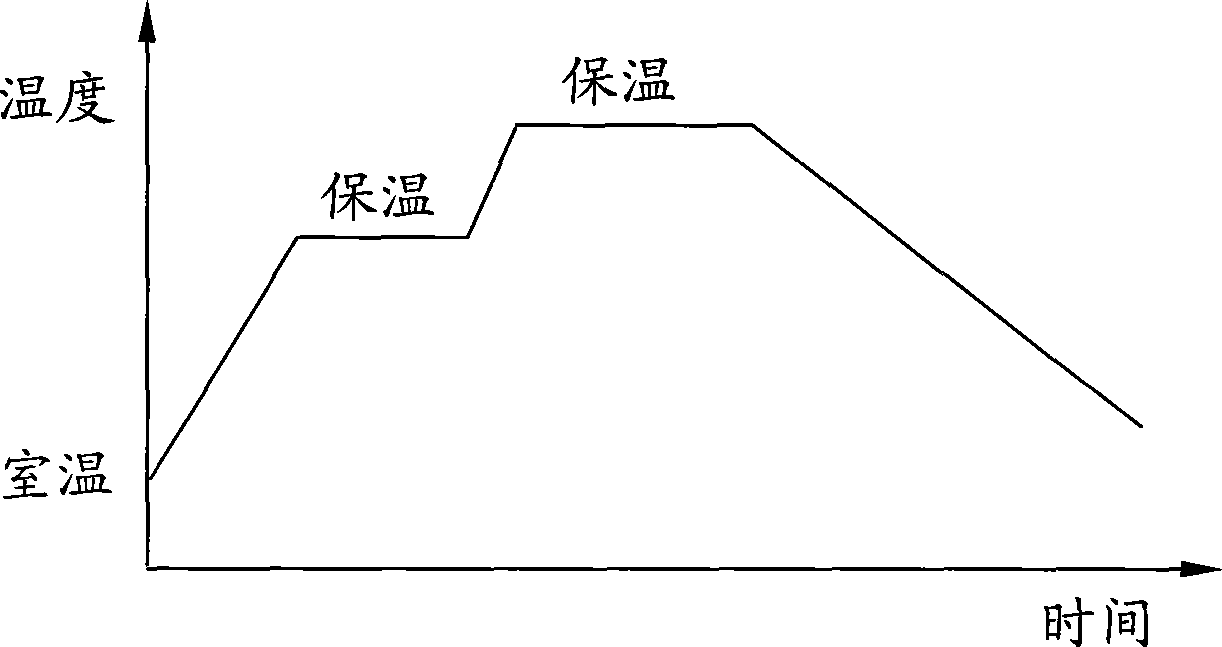

Method for assembling and welding ultrathin large-diameter saw blade

InactiveCN101347850AReasonable designAvoid hardened tissueMetal sawing tool makingArc welding apparatusTO-18Thermal insulation

The invention discloses an assembly welding method for an ultrathin saw blade with the large diameter, which comprises the processing steps of forming, preheating, welding, thermal insulation and slow cooling, etc. The invention relates to an assembly welding method of a saw, the selection of welding materials, an assembly welding structure of the saw, a way of preheating and slow cooling as well as the design content of parameters, welding process, and the technique. The diameter of carbon tool steel, alloy tool steel, and spring steel which are used in welding is between 2,800mm to 5,200mm, and the materials are used for producing the ultrathin saw blade with large diameter and the thickness of 11mm to 18mm. The invention has the following advantages of simple device, popular welding method and easy mastering for the operation process; the design of the assembly welding structure and the welding process of the saw is reasonable, the welding can be carried out without the need of spot welding and fixing for a welding seam, the welding stress is distributed uniformly, after welding, the whole saw blade is neat without deformation and the welding seam has no welding cracking; the reasonable selection of the welding materials meets the performance requirements that the welding seam can bear, and keeps the same color of the welding seam and substrate.

Owner:HARBIN INST OF TECH

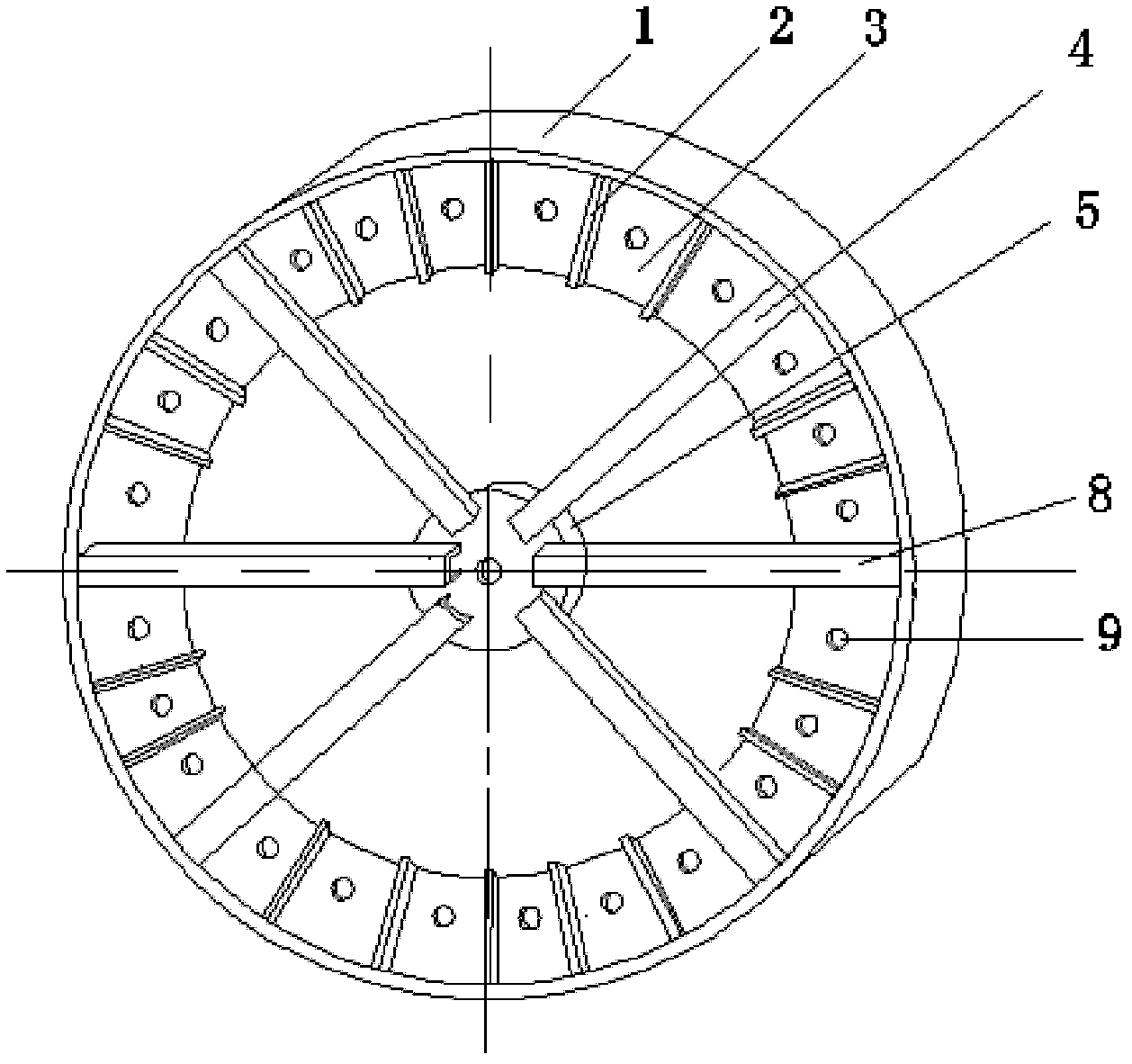

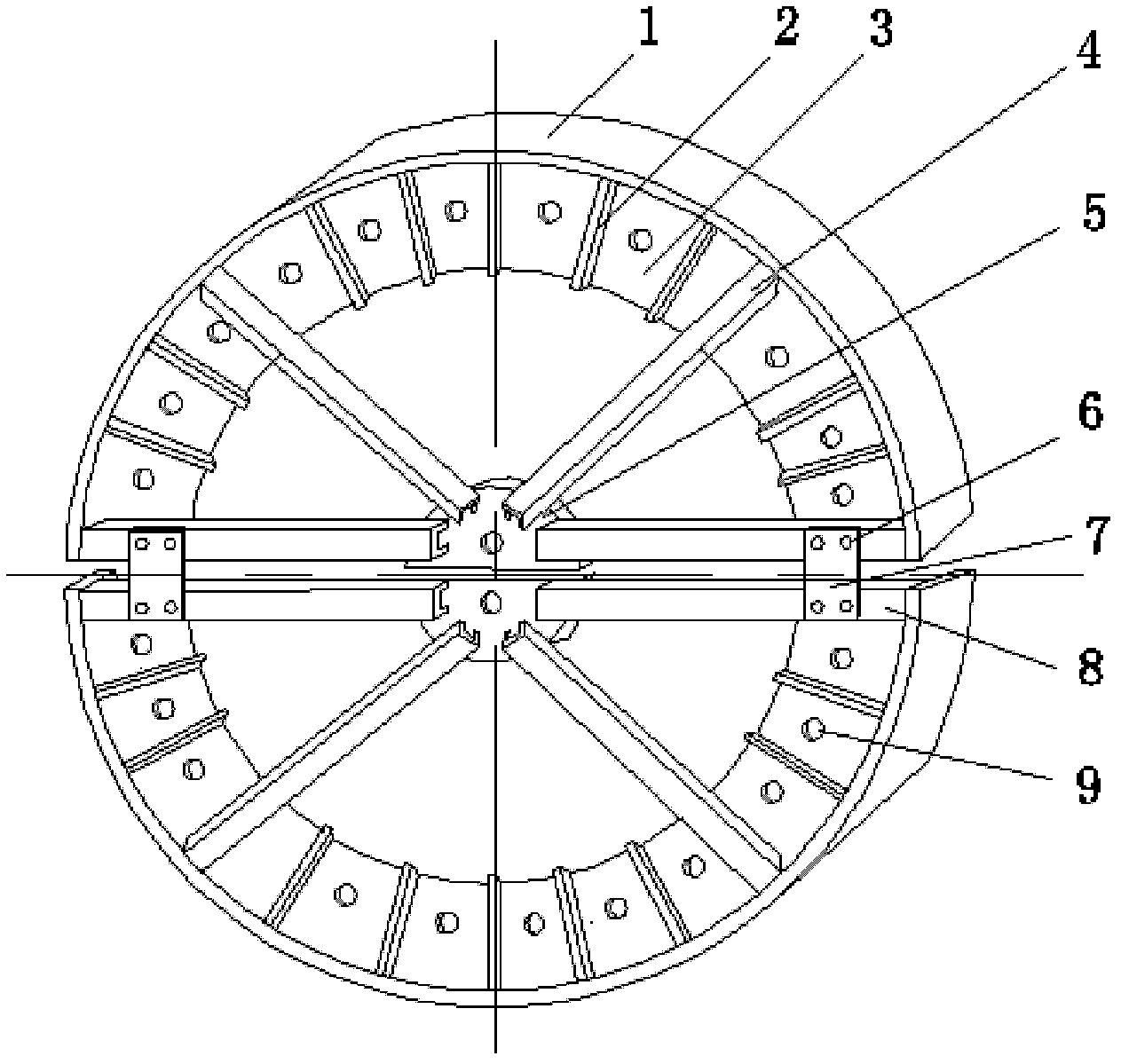

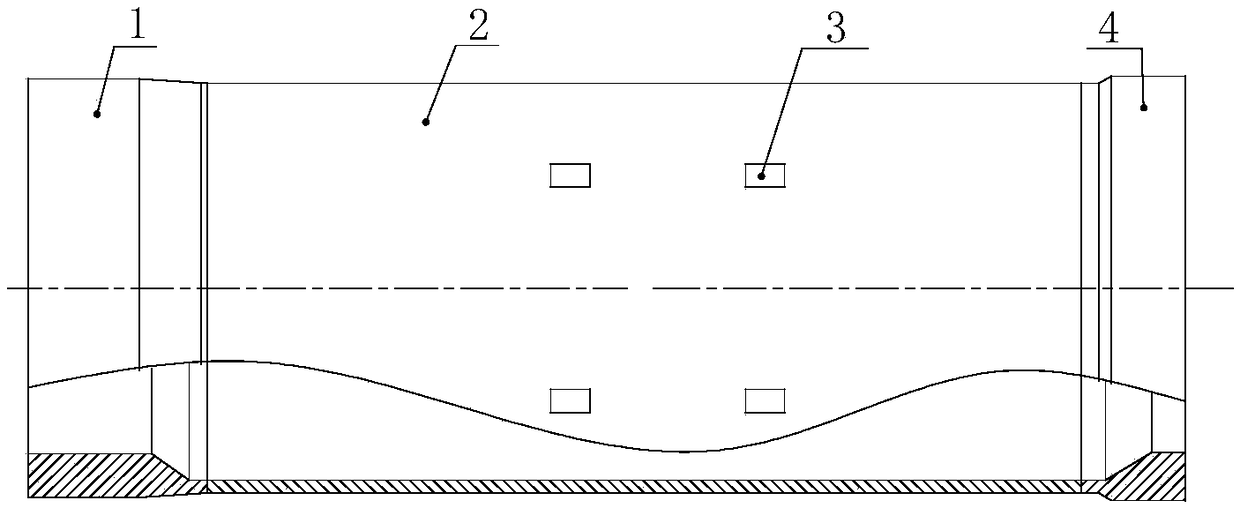

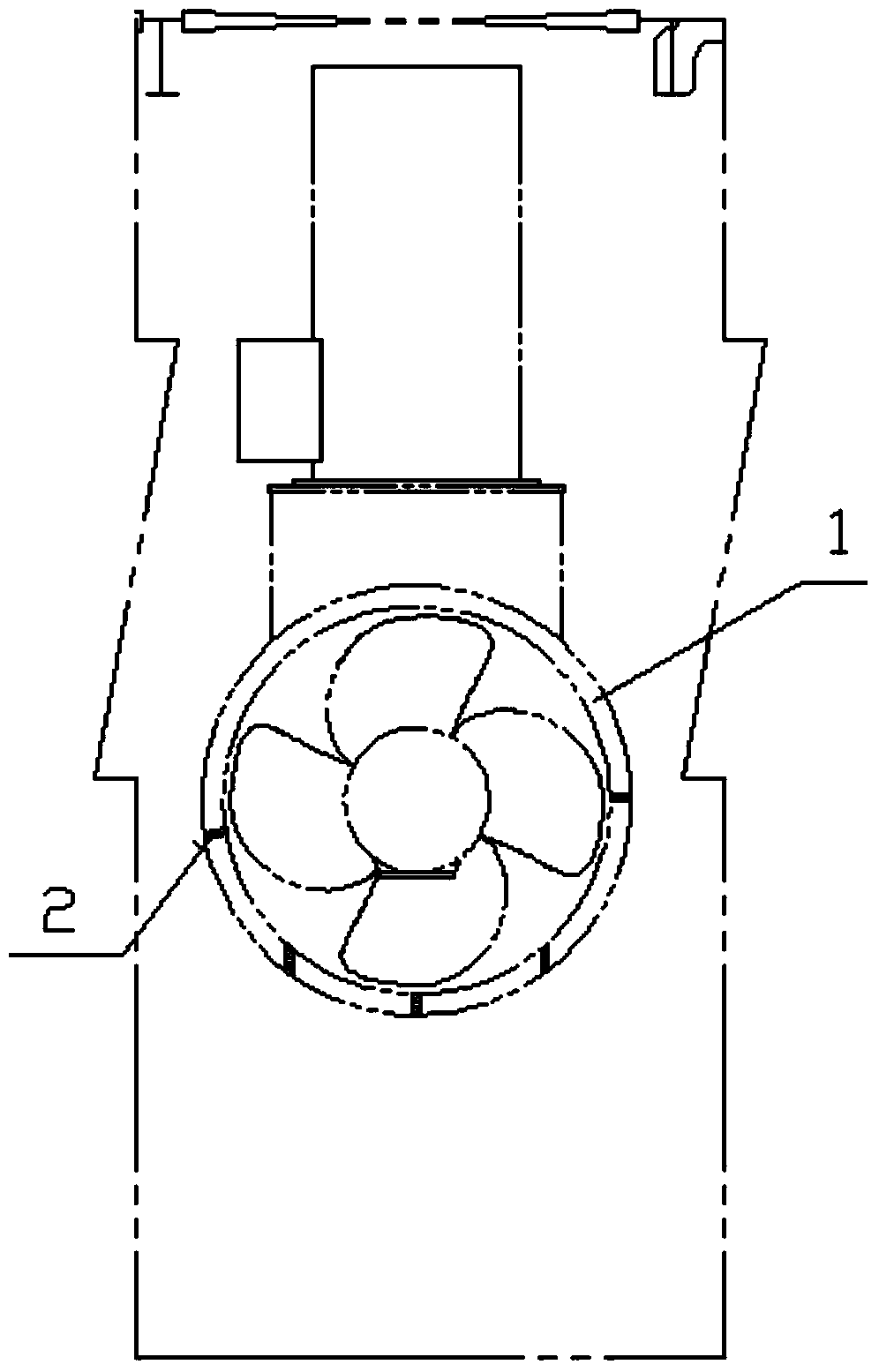

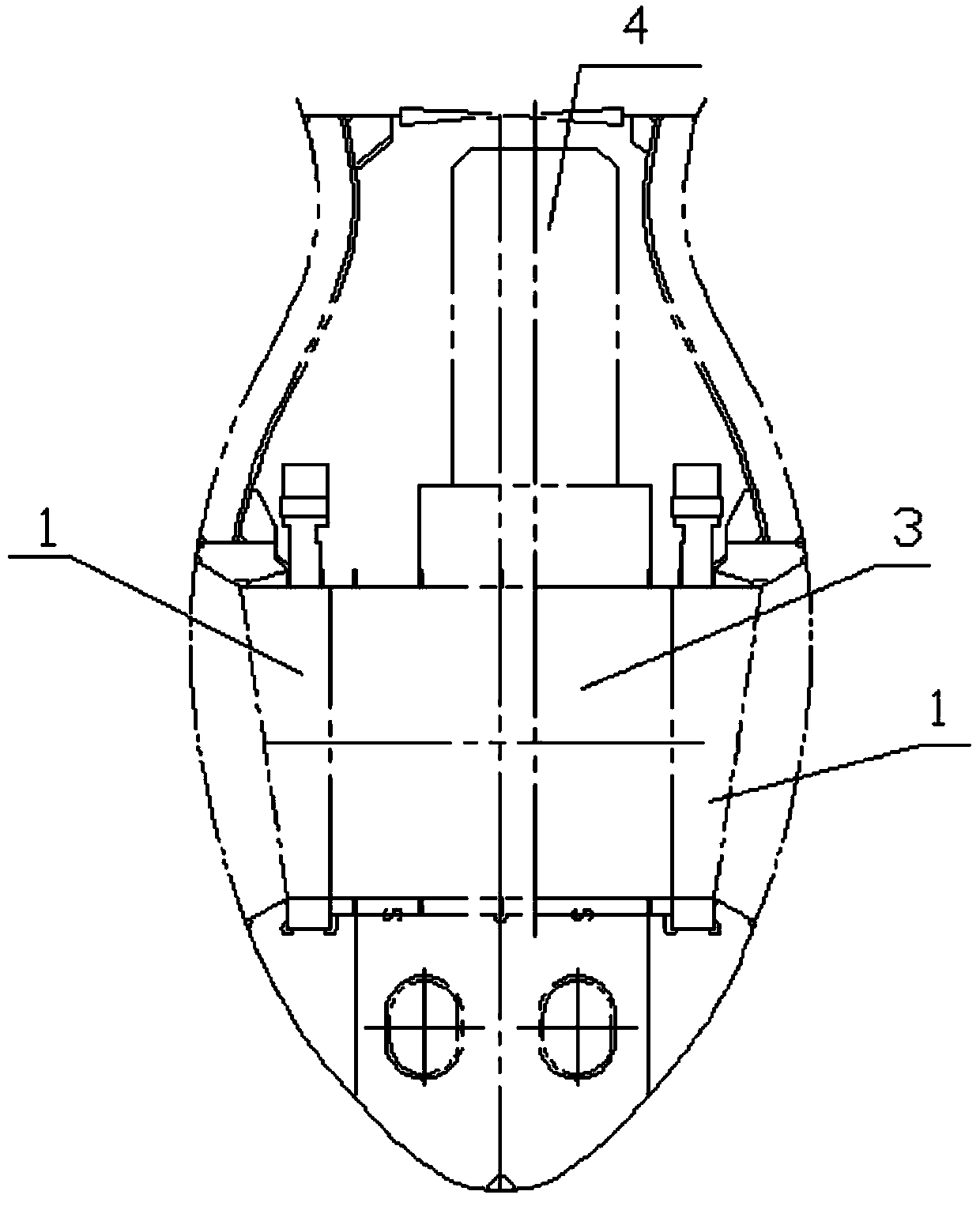

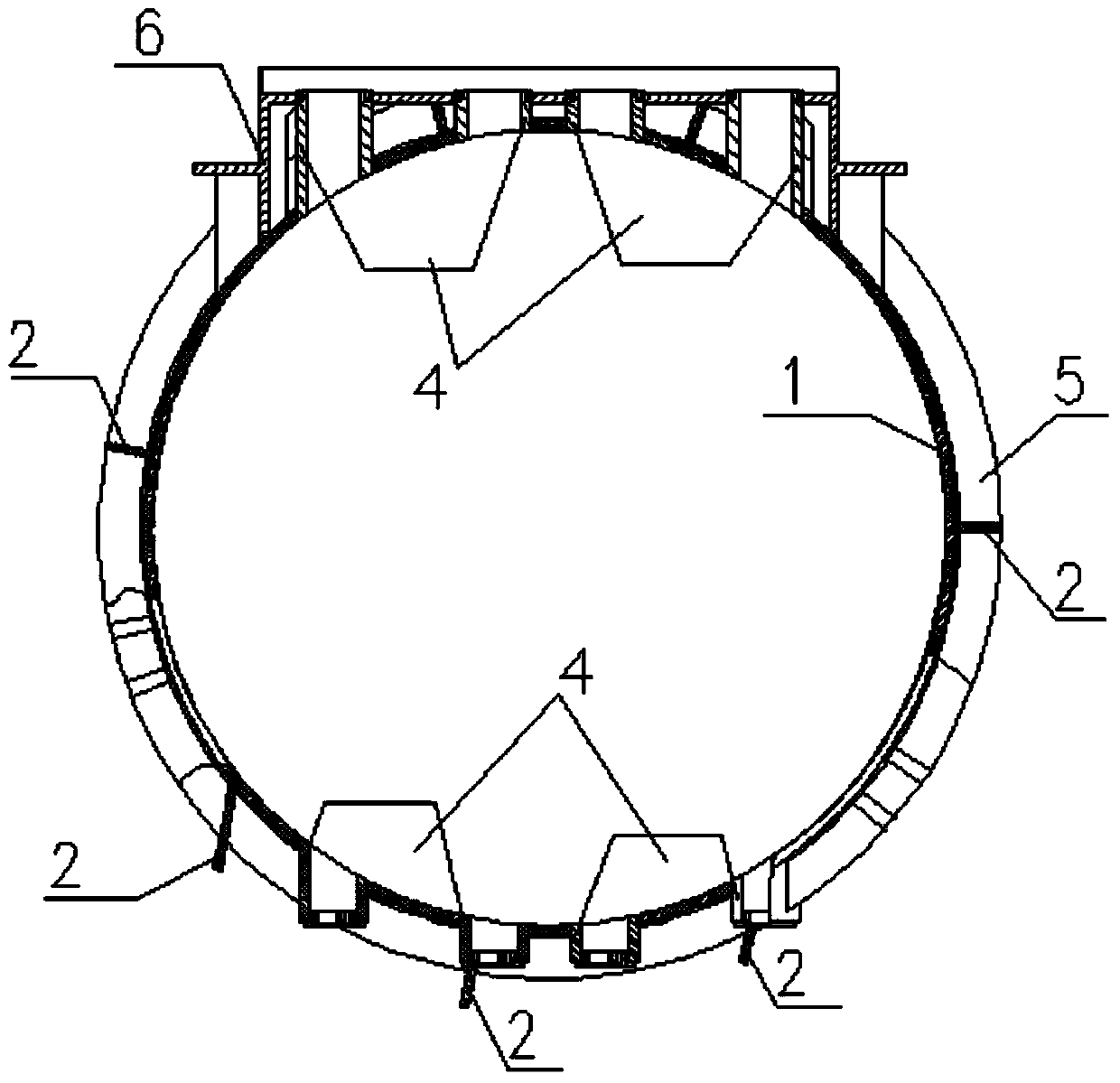

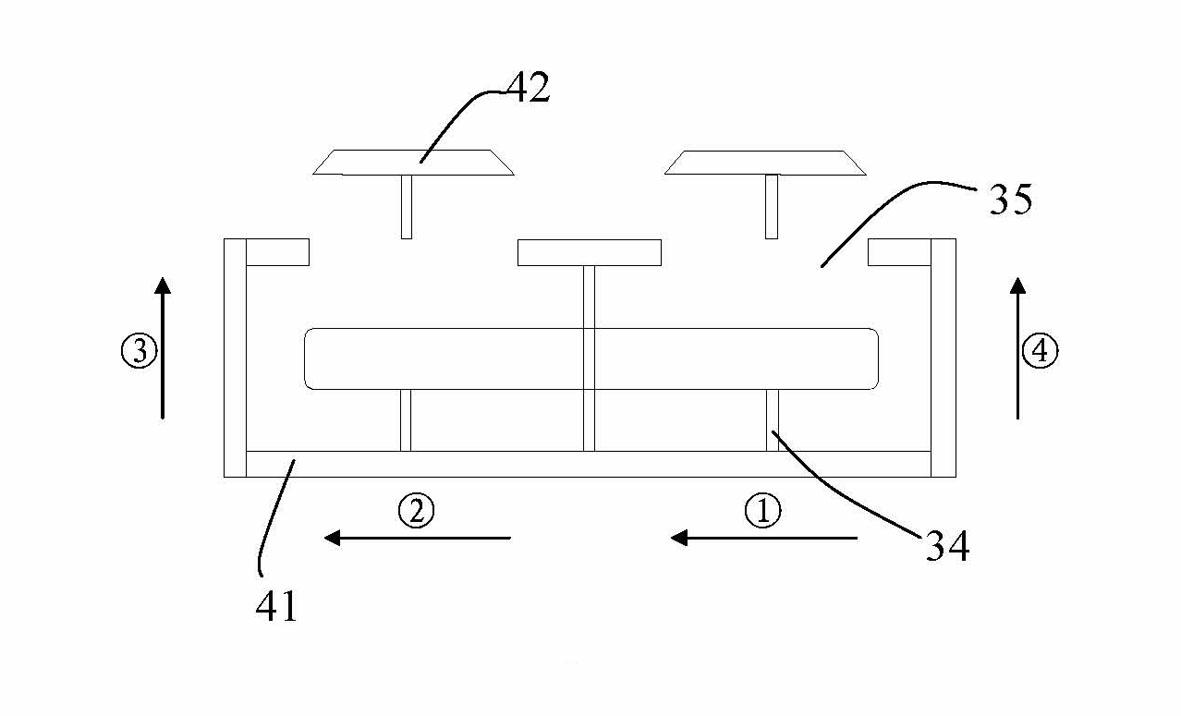

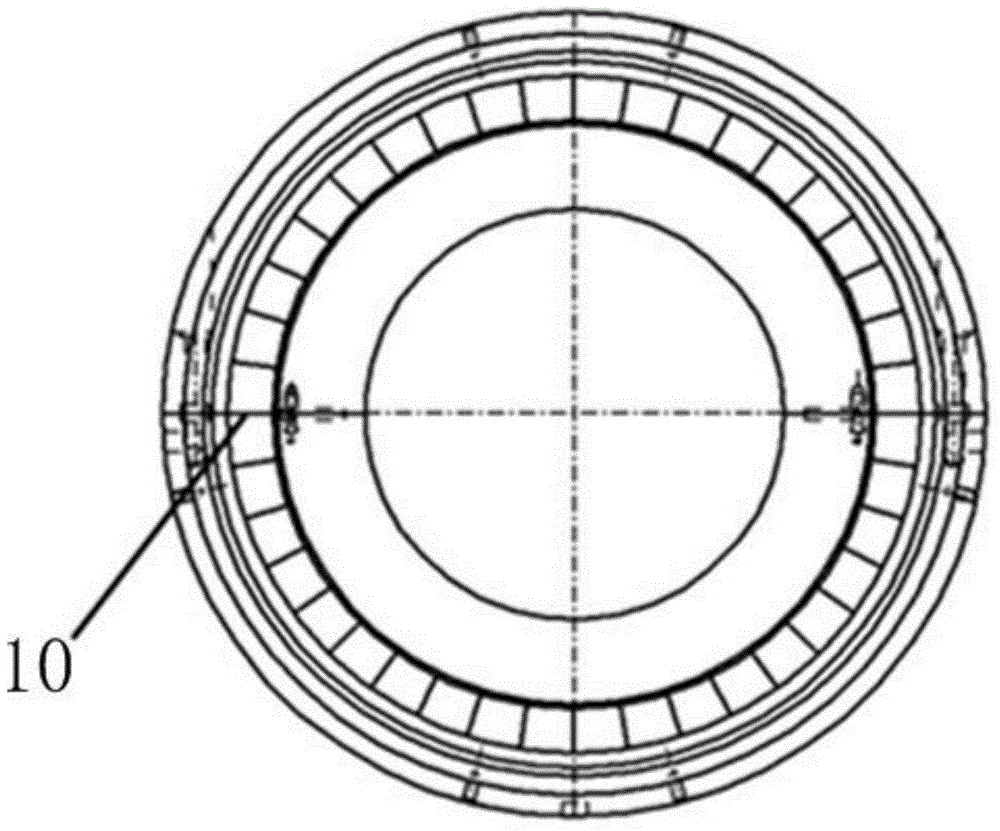

Assembling and welding method of side thrust device

ActiveCN103803018ARelieve welding stressControl deformationVessel partsClassical mechanicsElectric machinery

The invention relates to the technical field of ship construction, in particular to an assembling and welding method of a side thrust device. The assembling and welding method of the side thrust device comprises the steps that lofting is conducted so as to machine extension pipes, and four generatrices of each extension pipe are drawn; by making the four generatrices of each extension pipe as benchmarks, bearing blocks, annular reinforcing rib plates, longitudinal reinforcing rib plates and motor fixing bases are assembled and welded to constitute two side thrust seal cover modules; the side thrust seal cover modules are integrally annealed so as to eliminate welding stress, and the inner surfaces of the bearing blocks and the upper surfaces of the motor fixing bases are machined; the two side thrust seal cover modules are welded to two sides of a side thrust cylinder body respectively, and after welding is finished, the side thrust seal cover modules and the side thrust cylinder body are integrally assembled and welded in a segmented mode; after a slipway is folded, the integral segment comprising the side thrust seal cover modules and the side thrust cylinder body is provided with blades, a shaft, a bearing assembly, a seal part, a transmission mechanism and a driving mechanism. The assembling and welding method of the side thrust device can avoid welding deformation of the side thrust device, guarantee concentricity of bearings and shorten the period of ship construction.

Owner:WUCHANG SHIPBUILDING IND

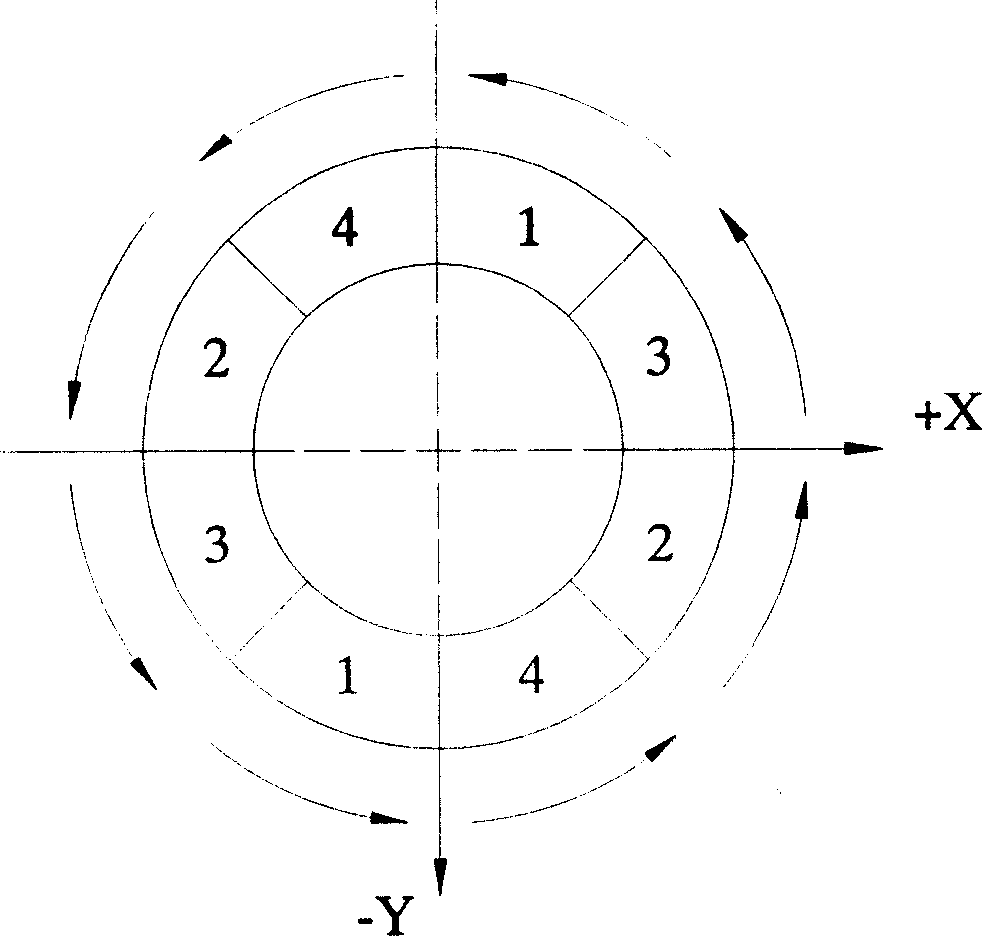

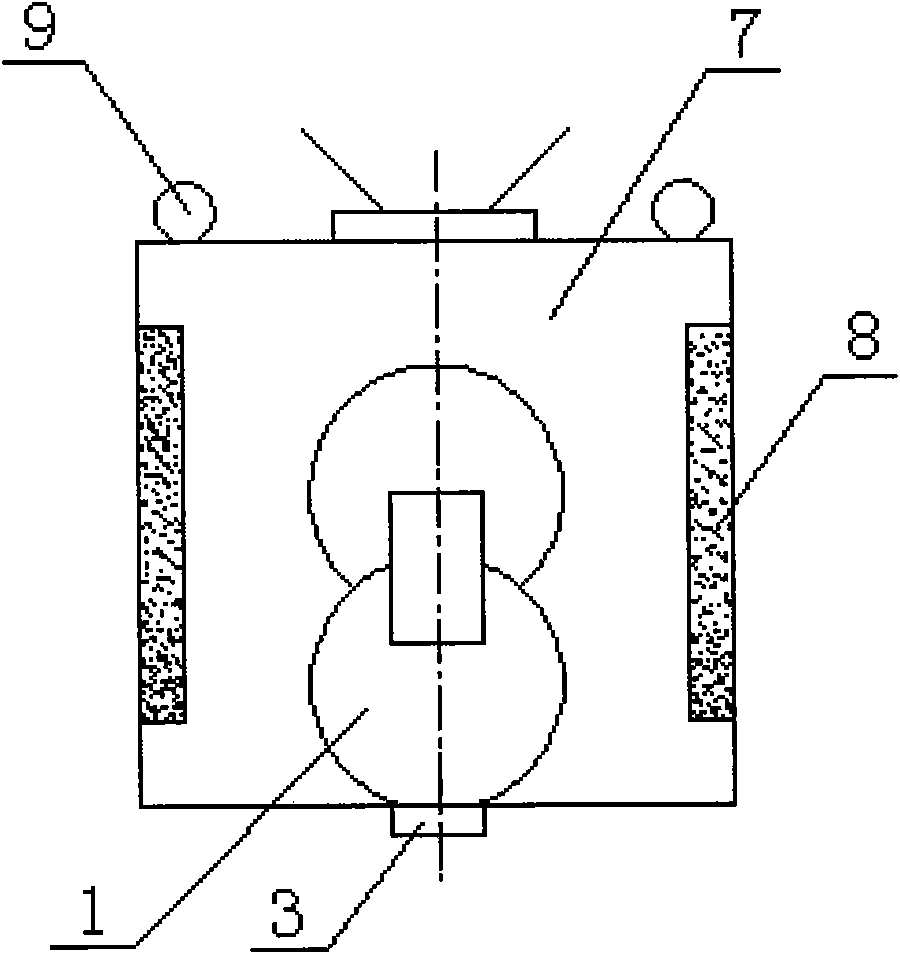

Method for controlling welding deformations of special type motor bedplate

InactiveCN1915573AAvoid controlRelieve welding stressWelding/cutting auxillary devicesAuxillary welding devicesTemperature controlSurface layer

A method for controlling the weld deformation of special motor base includes such steps as using supporter and technological flange to fix the base of motor, drawing crossed central lines X and Y on the external surface of top end ring, drawing eight-division lines at the weld seam, cleaning with acetone and silk fabric, argon arc welding, abrading the welded seam, color inspecting, and synchronously and symmetrically welding by two welding workers layer by layer while vibration beating for each layer except surface layer.

Owner:SICHUAN DONGFENG ELECTRIC MACHINARY WORKS CO LTD

Construction method for butt welding irregular space box-type steel members

InactiveCN102091877AGuaranteed flatnessGuarantee welding qualityWelding apparatusButt weldingStructural engineering

The invention provides a construction method for butt welding irregular space box-type steel members, comprising the following steps of: (1) mounting at least a fabrication hole at an upper wing plate at a welding position; (2) butting two sections of the steel members; (3) entering into the box of the steel box from the fabrication hole, and welding butting positions of a lower wing plate and ribs by means of sectional and symmetrical welding; (4) welding the butting positions of side plates at the external part of the box of the steel box by means of symmetrical welding; and (5) welding a cover plate on the fabrication hole. The construction method provided by the invention is convenient in operation, and capable of removing welding stress and improving welding quality.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

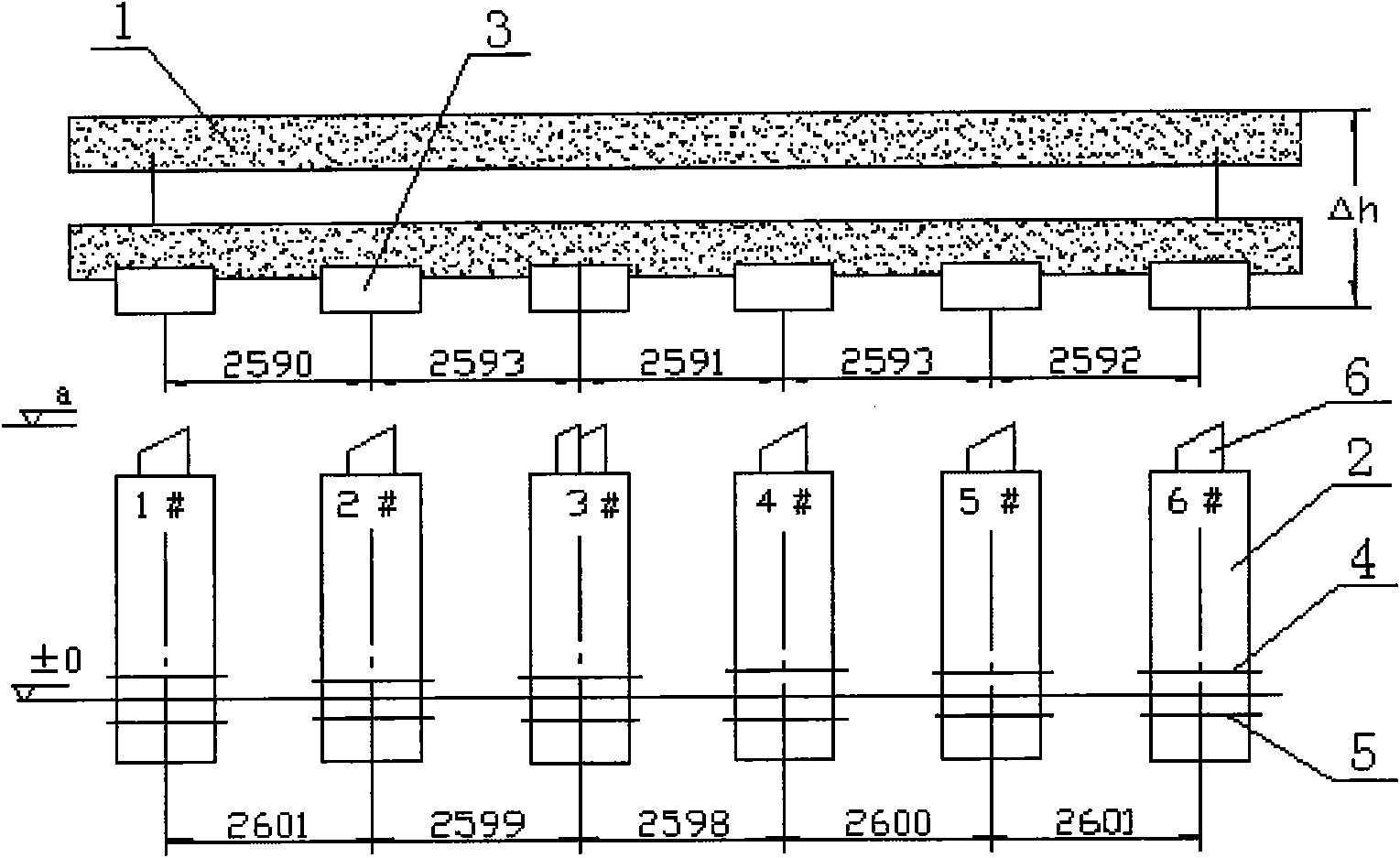

Method for mounting water beam of walking beam heating furnace in thermal state

InactiveCN102062532AEliminate manufacturing errorsGuaranteed verticalityCharge manipulationFurnace typesTemperature controlThermal state

The invention relates to a method for mounting a water beam of a walking beam heating furnace in a thermal state, namely a simulated working state. The method is characterized in that: an assembly welding method for the water beam and an upright post at the temperature of 273+ / -10 DEG C is completely simulated through a heating incubator and a temperature control system, and comprises the following operating steps of: 1) determining the verticality and elevation of a double-barreled upright post, and fixedly welding the double-barreled upright post; 2) calculating the heated elongation of the water beam; 3) taking the double-barreled upright post as a center, correspondingly determining center distance among other upright posts according to the elongation, and fixedly welding all the upright posts; 4) correcting out-of-tolerance dimension among the upright posts after finishing the welding; 5) arranging a heating box; 6) heating the water beam, and matching with welding; and 7) keeping the temperature and cooling, wherein the heating box is arranged and controlled in sections. The invention has the advantages that: the service life is obviously prolonged, the welding stress in a cold drawing state is eliminated, and the fabrication error of the water beam can be effectively eliminated in the construction process.

Owner:ANGANG CONSTR CONSORTIUM

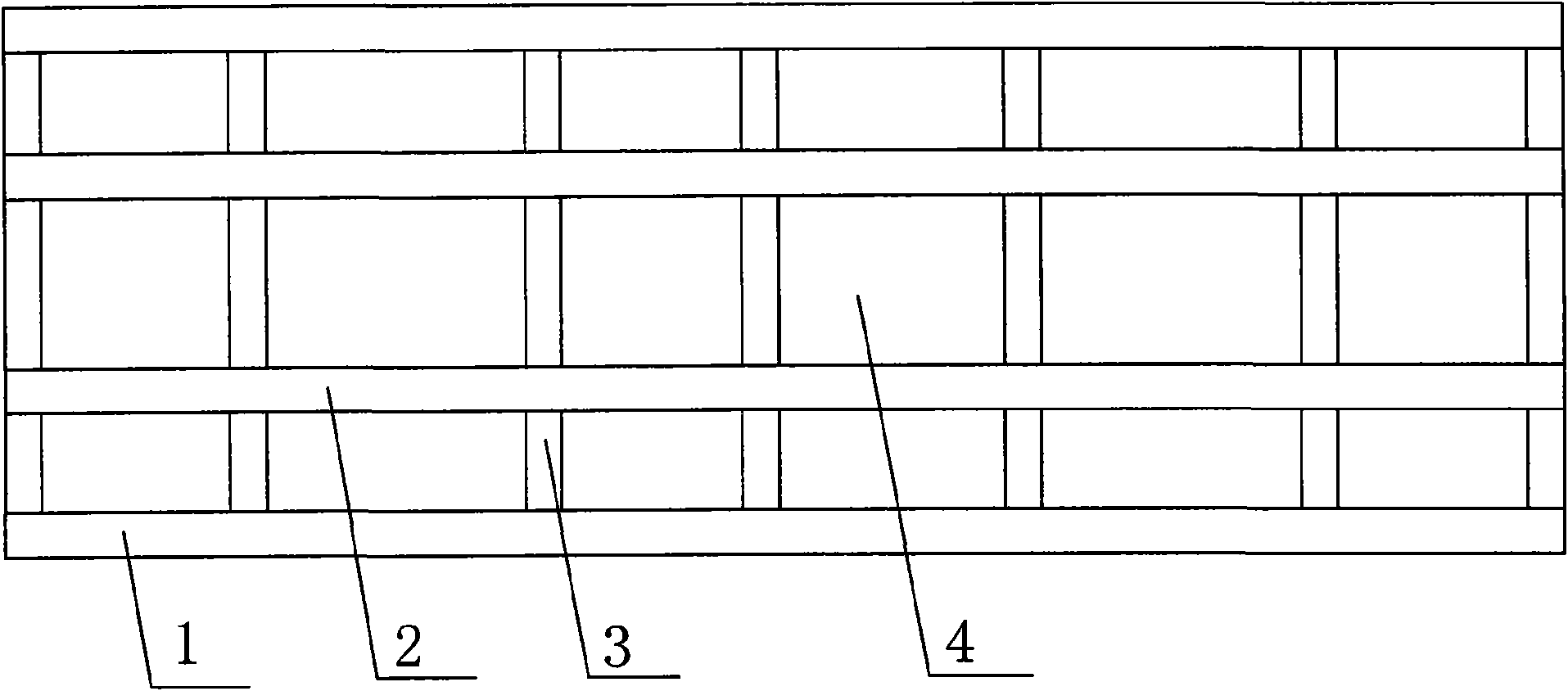

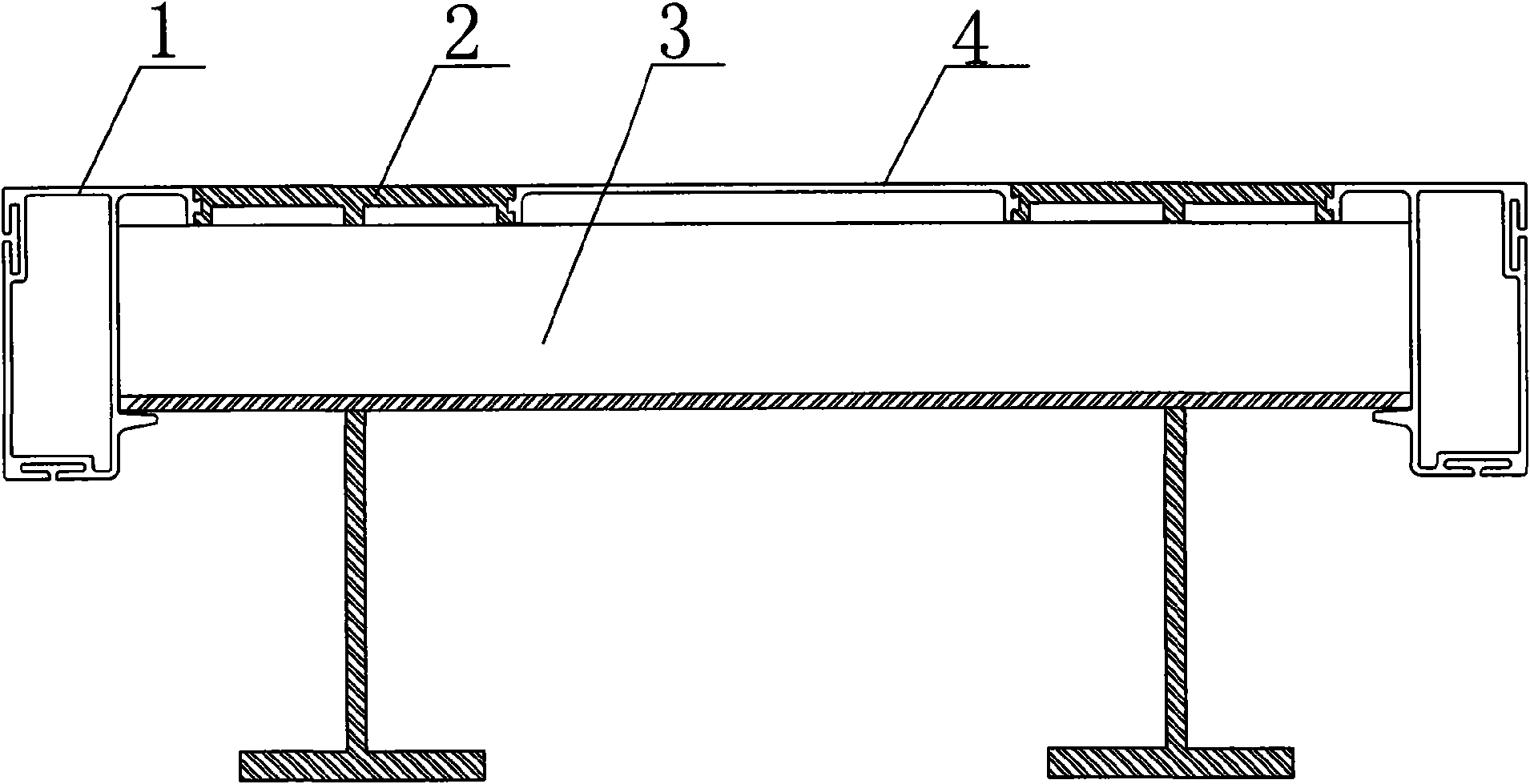

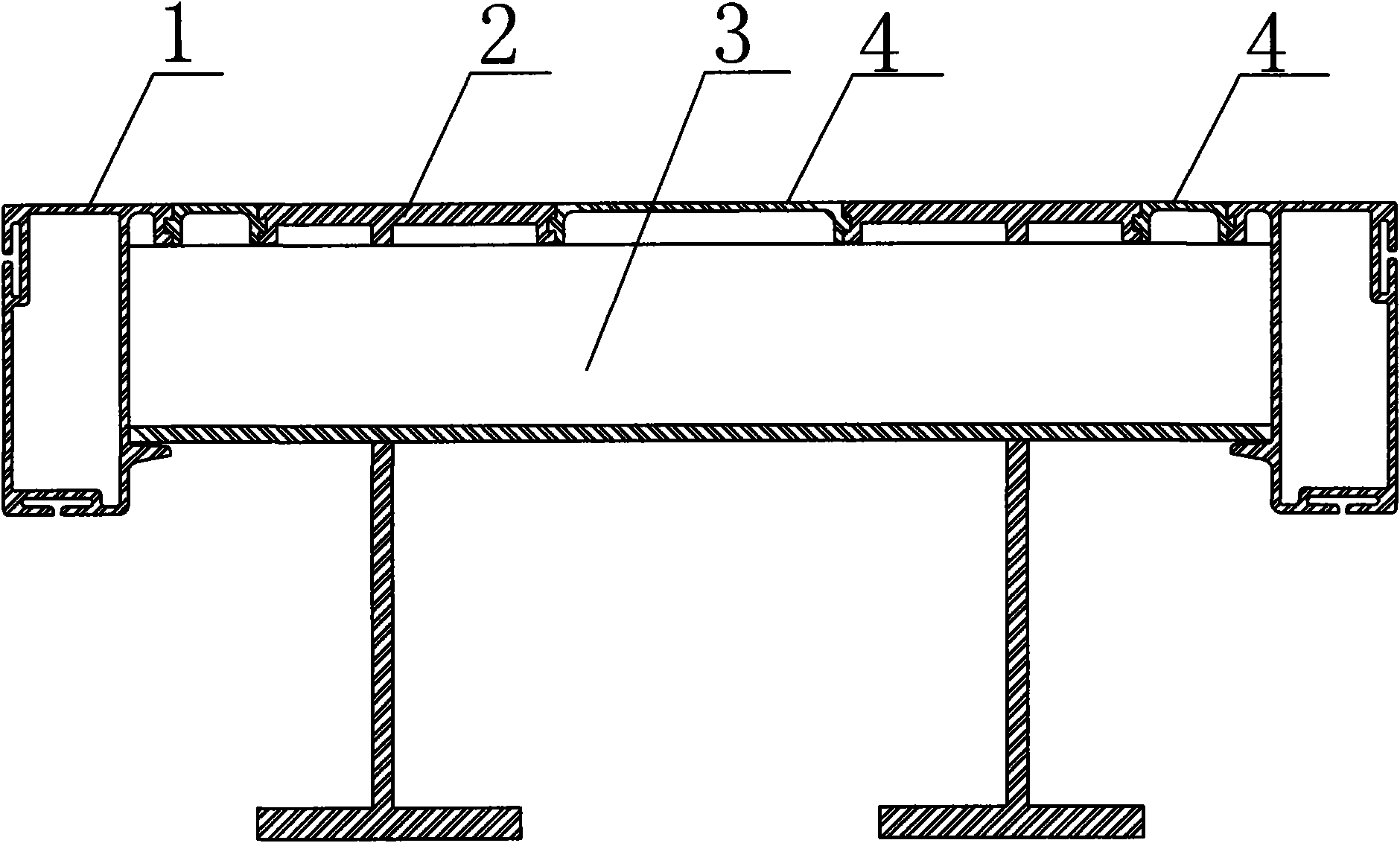

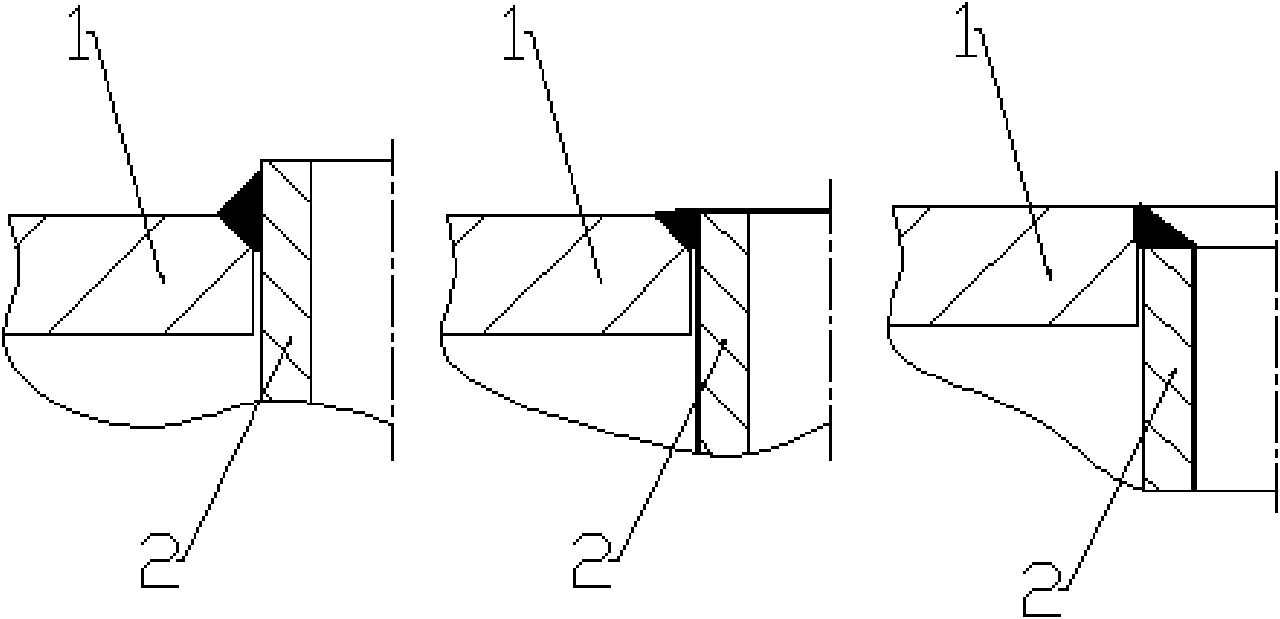

Joggling type vehicle bottom plate assembly

InactiveCN101628590AAvoid welding deformationWon't happenUnderstructuresSuperstructure subunitsEngineeringTongue and groove

The invention relates to a joggling type vehicle bottom plate assembly which comprises edge beams, longitudinal beams and transverse beams. The joggling type vehicle bottom plate assembly is characterized in that the upper parts of the edge beams and the longitudinal beams are provided with planes; one side edge of the edge beams is provided with a joggling groove structure along the length direction, and both side edges of each longitudinal beam are provided with joggling groove structures along the length direction; the edge beams are connected with the longitudinal beams by a joggling groove along the transverse direction of a vehicle body so as to form a plane on the upper surface or the edge beams are connected with the longitudinal beams and the longitudinal beam is connected with the longitudinal beam in such a way that both side edges are provided with transition connecting plates in the joggling groove structure by the joggling groove along the transverse direction of the vehicle body so as to form the plane on the surface; and the transverse beams are connected with the edge beams and the longitudinal beams. The invention prevents the welding deformation of the bottom plate assembly and eliminates welding stress, and the strength and the working reliability of the bottom plate assembly are not influenced by welding, particularly the vehicle bottom plate made of an aluminum magnesium alloy material has more obvious effect; no harmful gas is generated in the assembly process of the bottom plate assembly, thereby being beneficial to environmental protection; the assembly process is simple, the production efficiency is high, and the manufacture cost is reduced.

Owner:王景峰

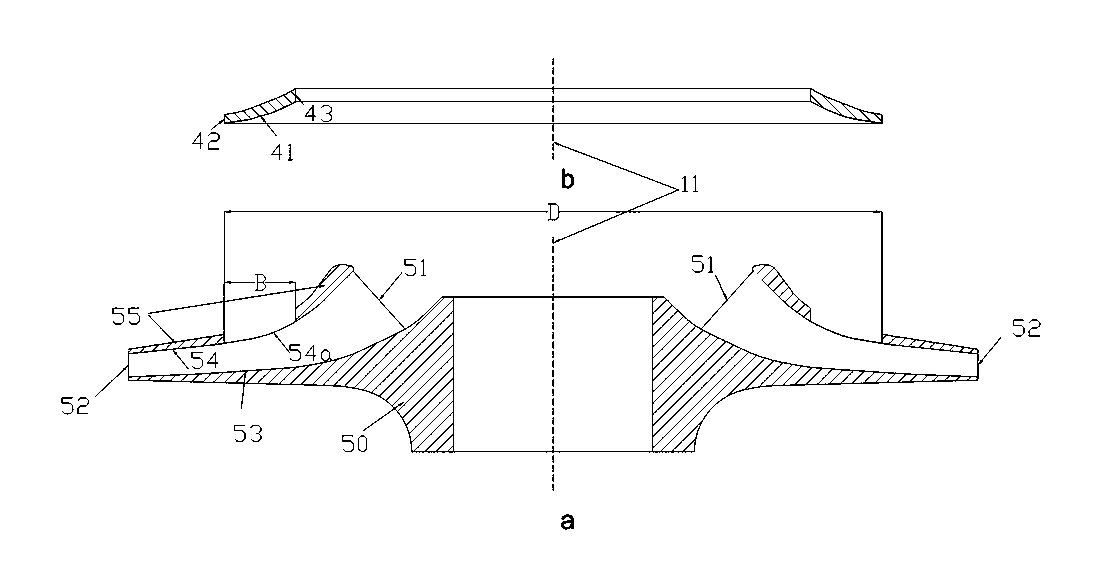

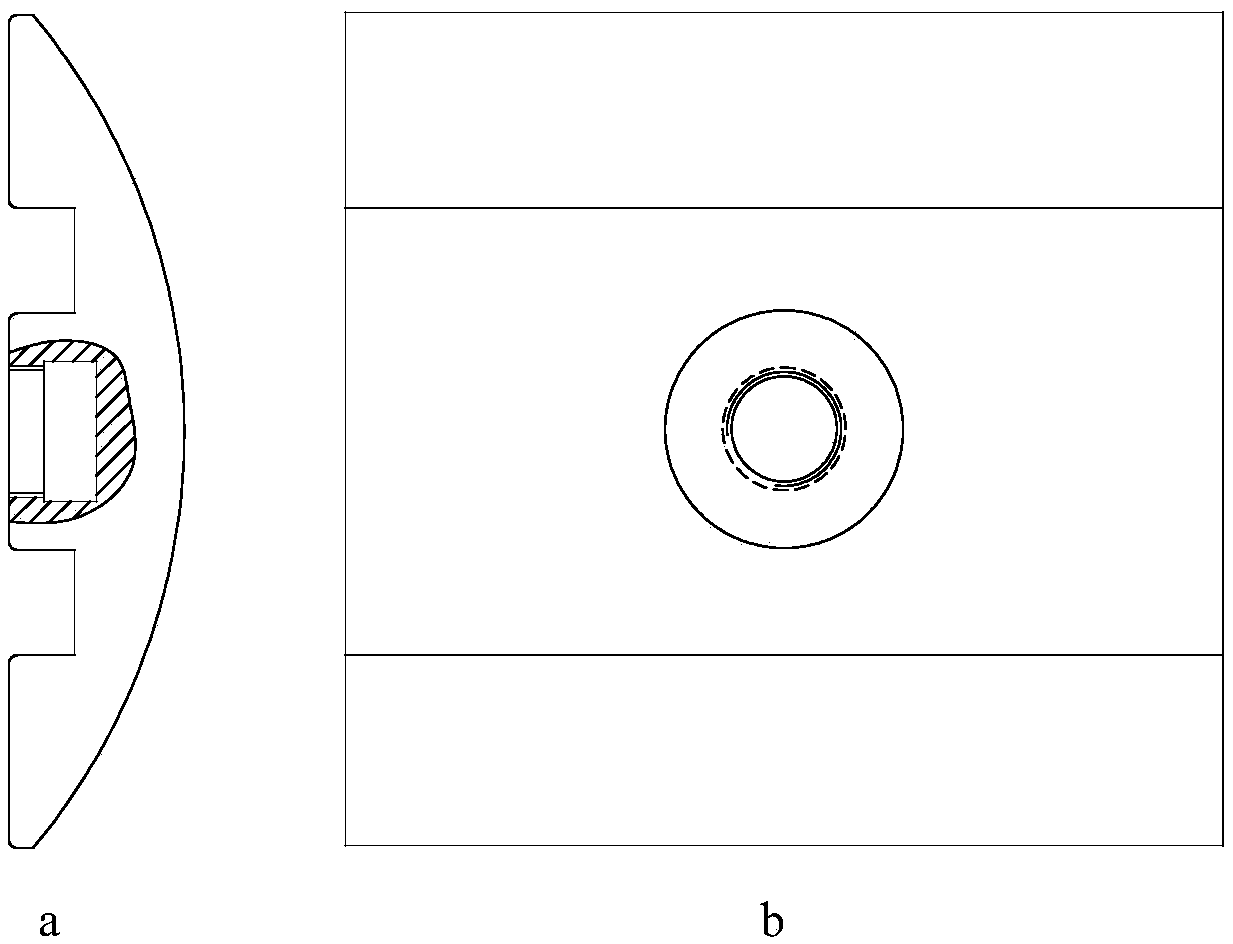

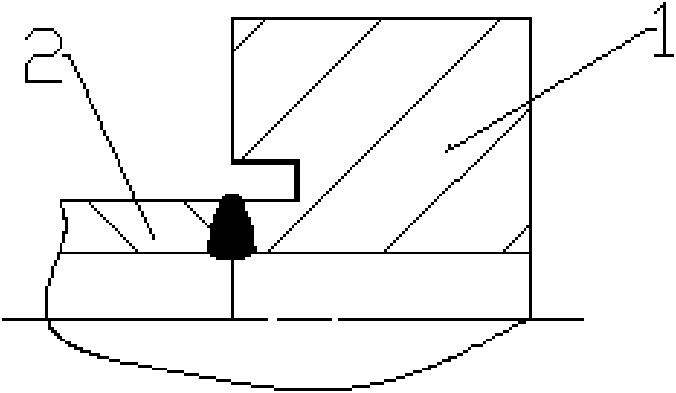

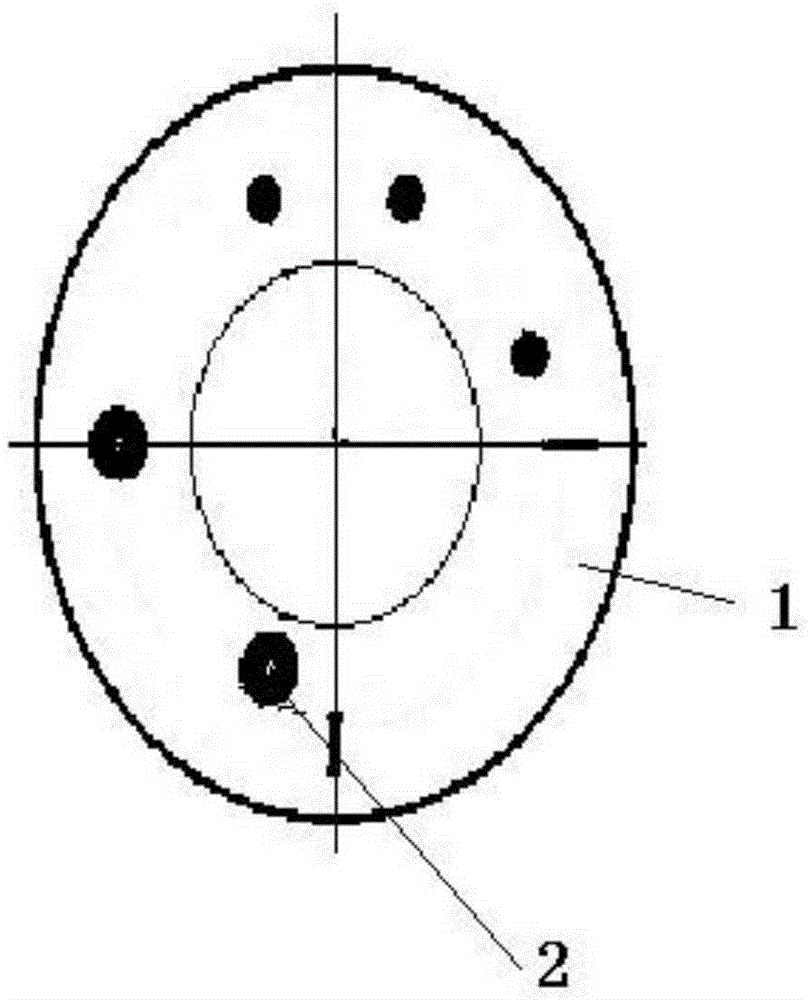

Bore welding method of heat exchange tube and tube plate in heat exchanger

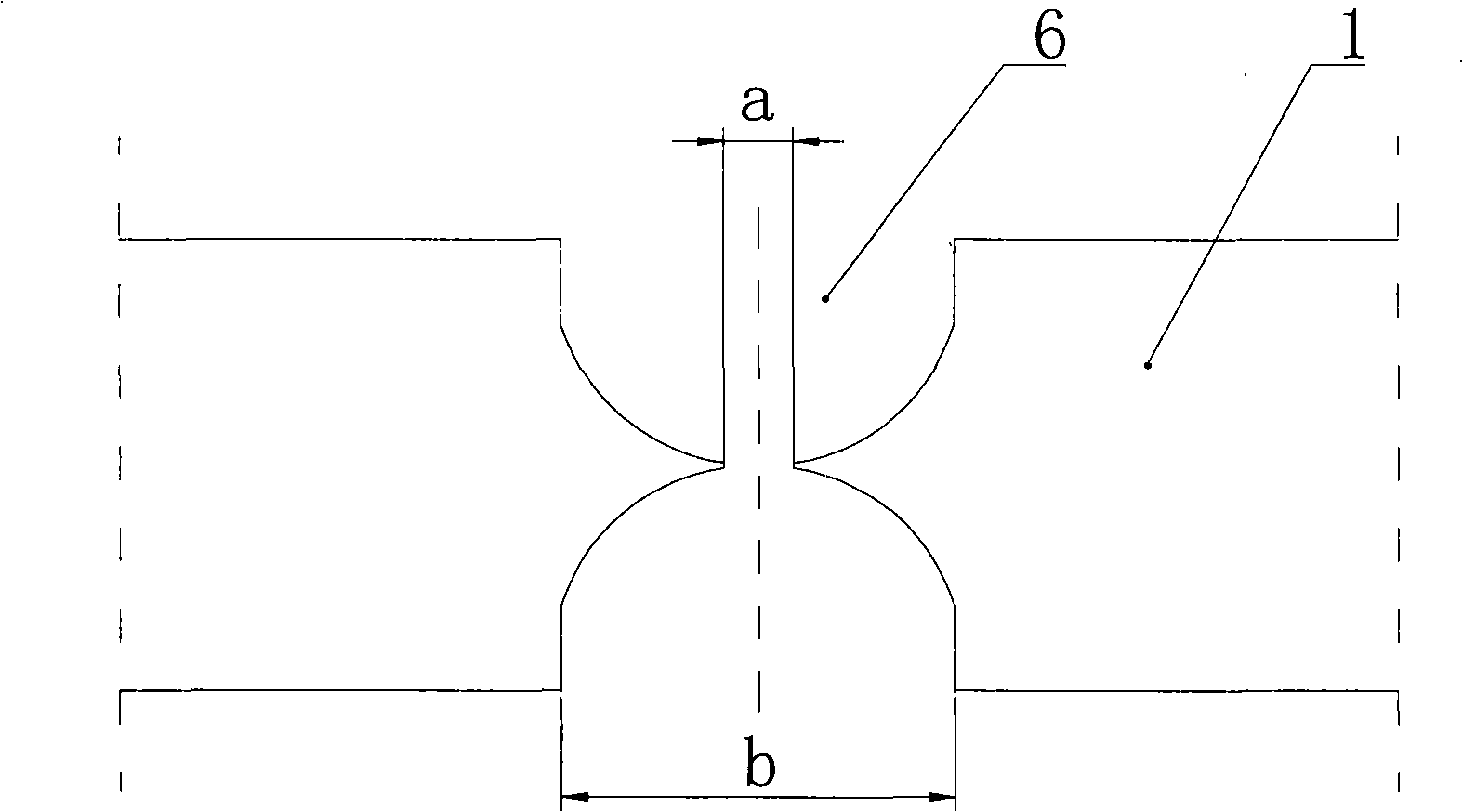

ActiveCN101628354AAvoid crevice corrosion problemsAvoid Effusion CorrosionArc welding apparatusHeat exchange apparatusPlate heat exchangerEngineering

The invention discloses a bore welding method of a heat exchange tube and a tube plate in a heat exchanger, comprising the following steps: processing a circular hole (2) on the tube plate (1), overlapping the welding end of the heat exchange tube (3) on the circular hole (2) of the tube plate (1) during the welding process, performing bore welding at the joint, and inserting the welding end of the heat exchange tube (3) into the circular hole (2) by 0.3-1.8 mm, wherein the diameter of the circular hole (2) on the tube plate (1) is 0.1-0.3 mm larger than the external diameter of the heat exchange tube (3). By welding the heat exchange tube and the tube plate with the method, the invention improves the welding quality and effectively avoids crevice corrosion and deposit fluid corrosion after welding. The bore welding method of a heat exchange tube and a tube plate in a heat exchanger has simple technological operation and excellent welding performance, greatly improves the quality of the heat exchanger and prolongs the service life.

Owner:SICHUAN BLUSR MACHINERY

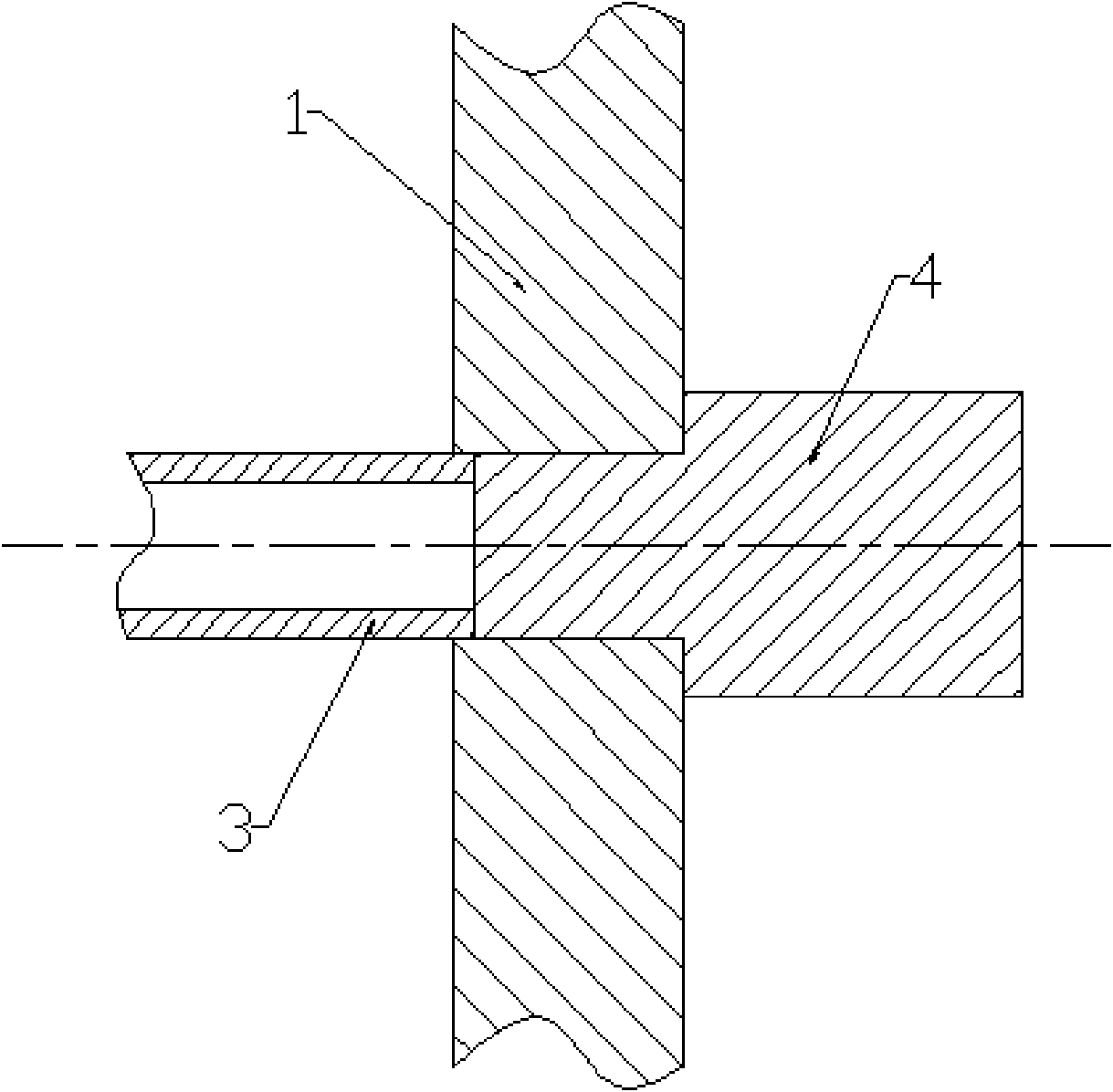

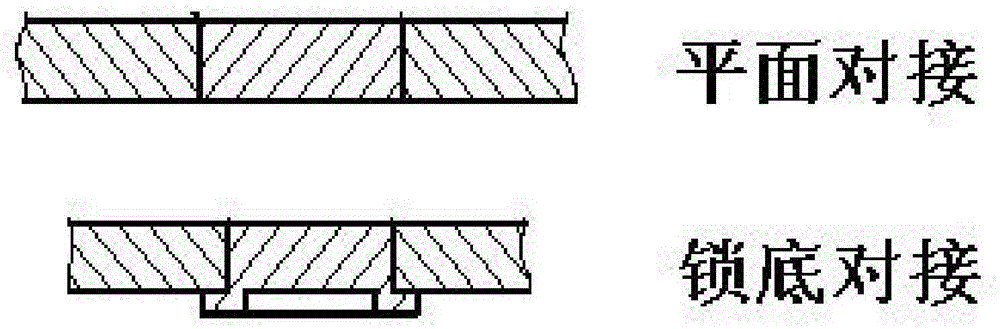

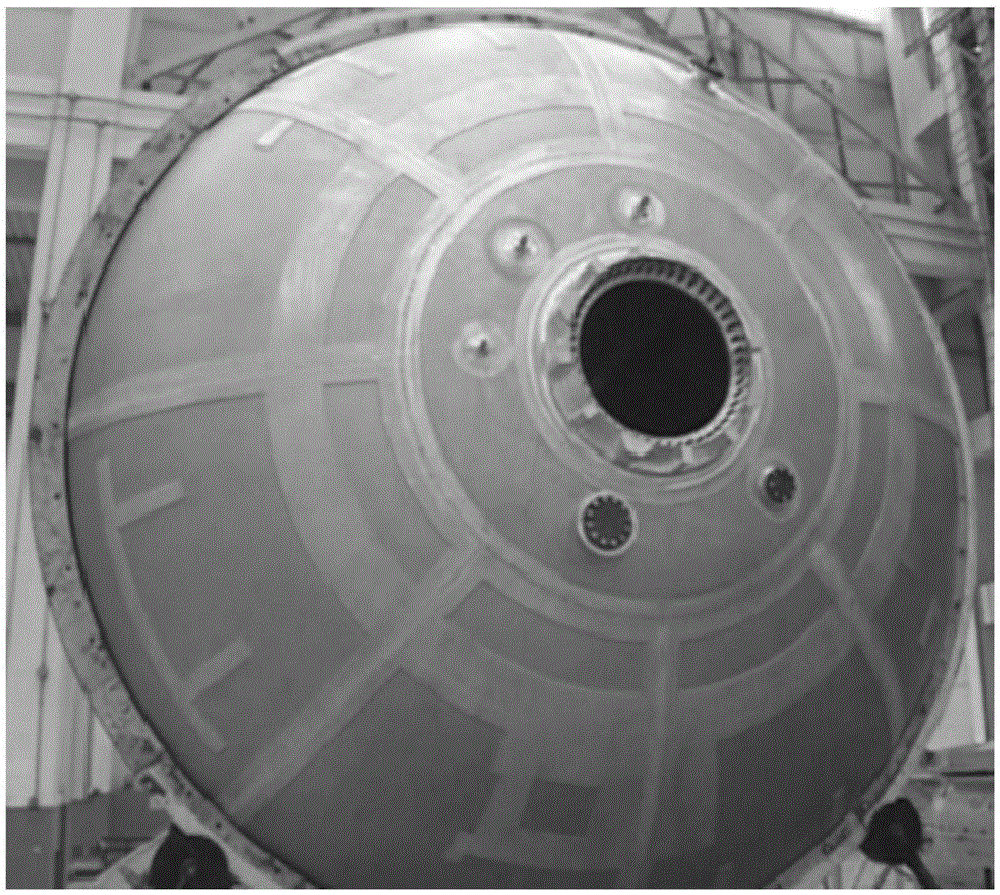

Electron beam welding method applicable to small-diameter flange plates on thin-wall top cover

ActiveCN106670640AIncrease foilPlay full without depressionElectron beam welding apparatusWorkpiece edge portionsButt jointEngineering

The invention belongs to the technical field of electron beam welding, and particularly relates to an electron beam welding method for multiple small-diameter flange plates at different circumferential positions of a large-size thin-wall space curved face top cover. A flange plate structure applicable to top cover flange plate electron beam welding is designed, a welding joint portion of each flange plate is of a butt joint lock bottom structure, and assembling precision and welding quality are effectively ensured. Meanwhile, according to the hole size in the position, to which each flange plate is assembled and welded, on the top cover, the diameter of the welding face of the corresponding flange plate is adjusted, and it is ensured that the assembling gap between the corresponding flange plate and the top cover meets welding requirements. By using a tool, by the adoption of elastic prestress deformation, welding stress is counteracted, deformation is reduced, electron beam welding for the flange plates distributed at different positions of the space curved face top cover is achieved, and satisfying welding quality is obtained.

Owner:CAPITAL AEROSPACE MACHINERY +1

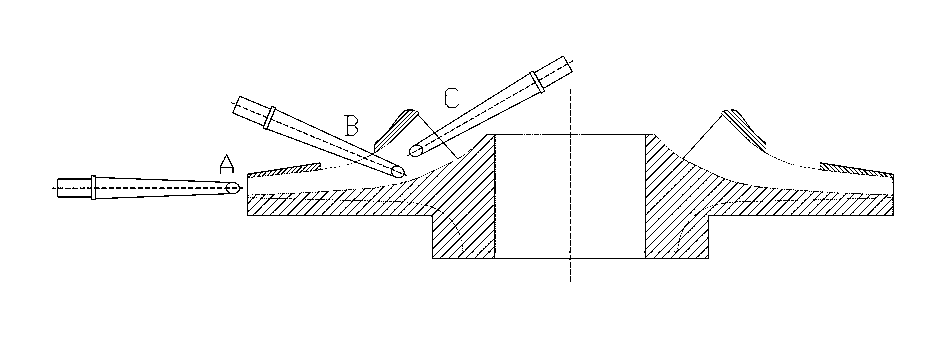

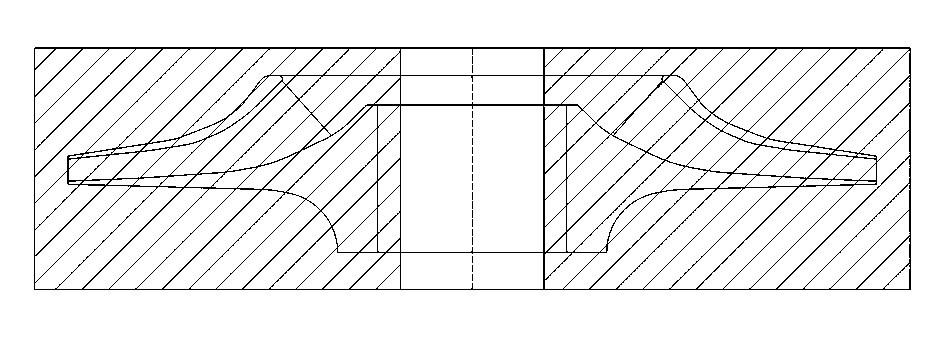

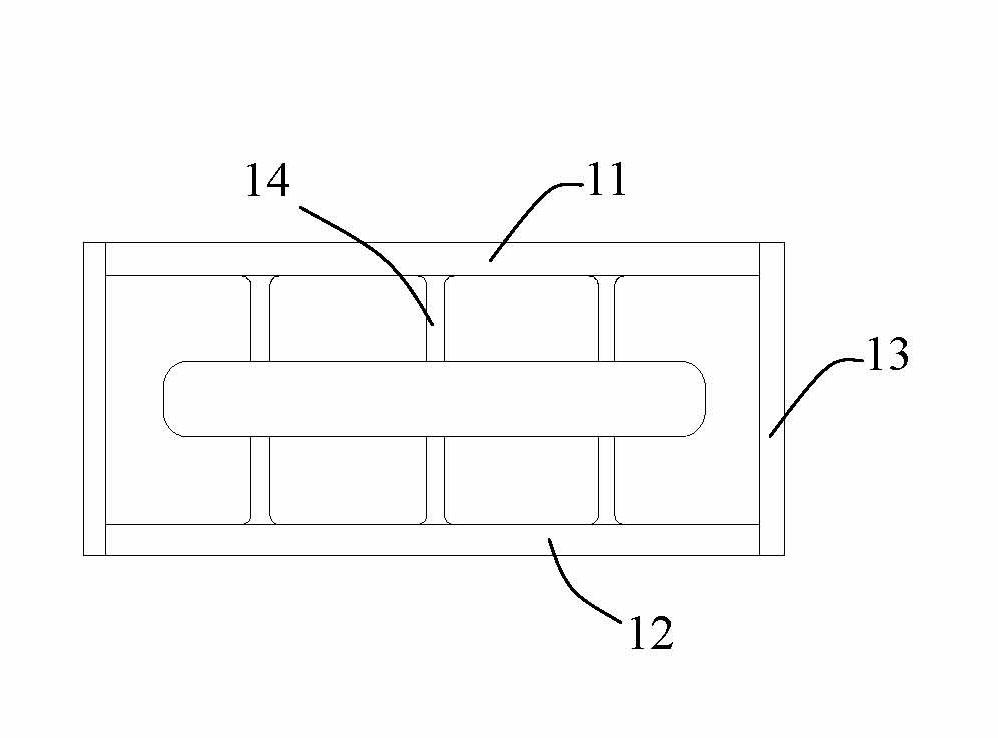

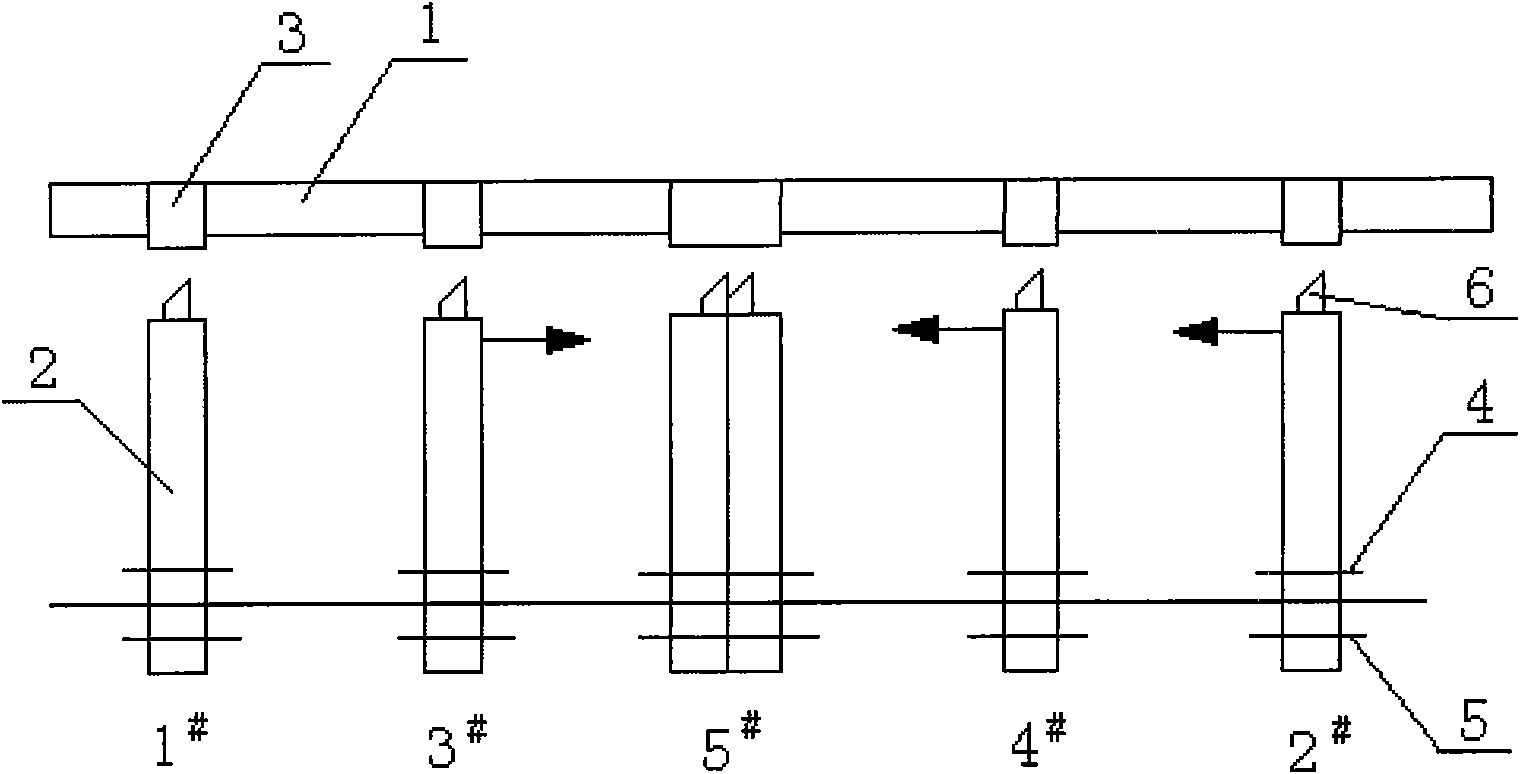

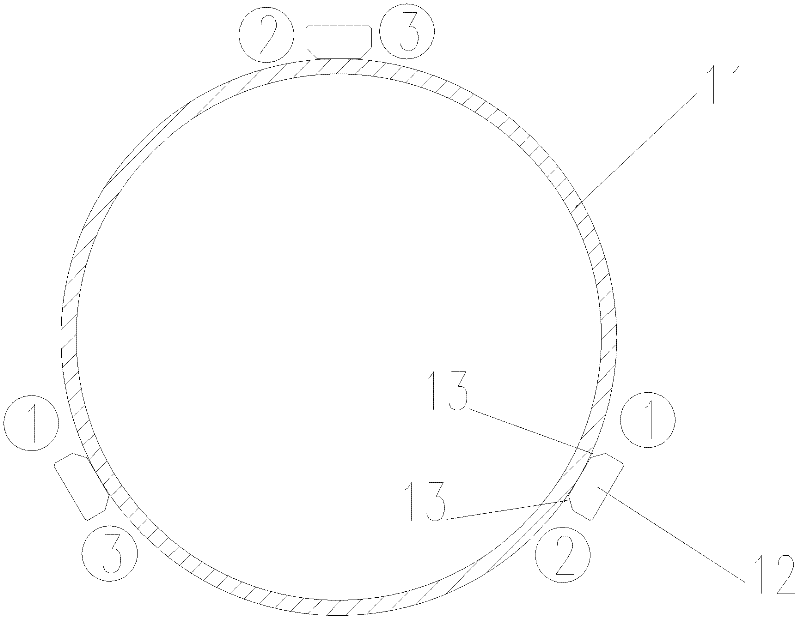

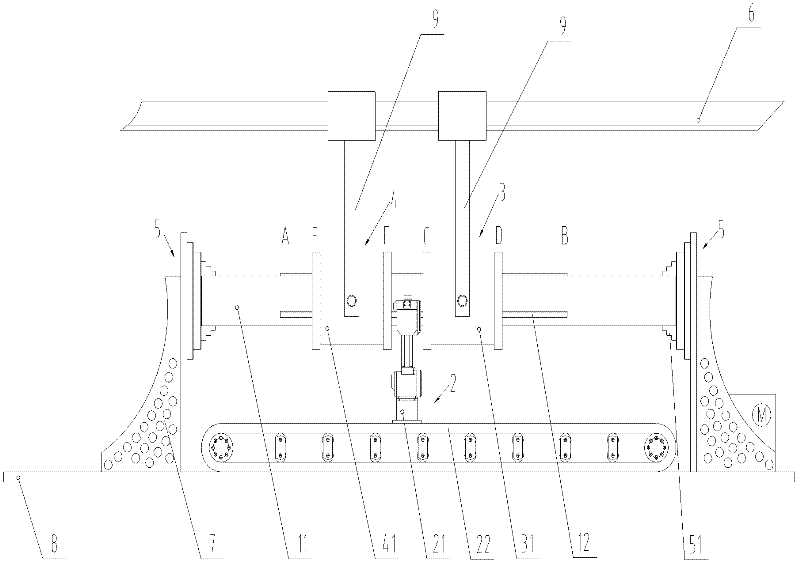

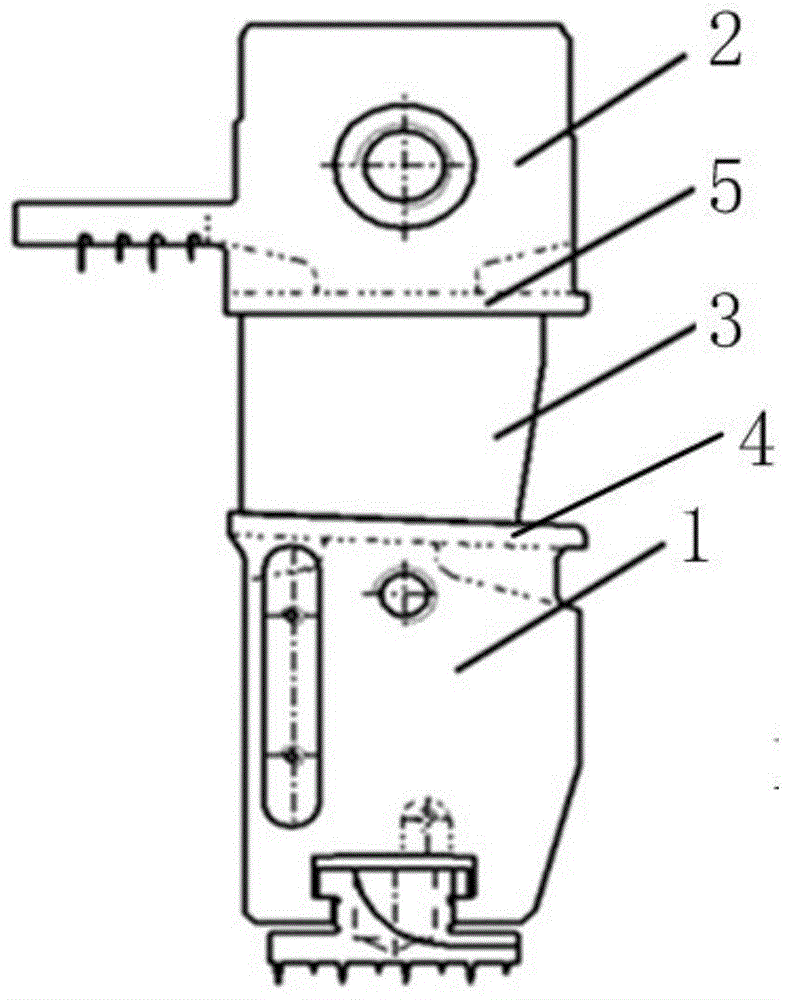

Method and device for welding drill pipe body for rotary drilling and outer keys

ActiveCN102500966AReduce local temperature variationsAvoid cold cracksWelding/cutting auxillary devicesAuxillary welding devicesWeld seamWelding deformation

The invention discloses a method and a device for welding a drill pipe body for rotary drilling and outer keys. The method comprises the following steps of: a preheating step: preheating a welding area (13) between the drill pipe body (11) and each outer key (12); a welding step: welding the welding area (13) between the drill pipe body (11) and each outer key (12) to form a welding seam; and a post-heating step: heating the welding seam formed between the drill pipe body (11) and each outer key (12) after the welding step. The invention also discloses a device for welding the drill pipe body for the rotary drilling and the outer keys, which comprises a preheating unit (3), a welding unit (2) and a post-heating unit (4). By the technical scheme, the cold breaking phenomenon during the welding process of the drill pipe body and the outer keys can be effectively avoided. In addition, the welding stress and the welding deformation of the drill pipe body and the outer keys, caused after the preheating step and the post-heating step, can be effectively eliminated.

Owner:SHANGHAI ZOOMLION HEAVY IND PILING MACHINERYCO +1

Laser repairing technology for aluminum foil roll crack

InactiveCN102677047AImprove tissue uniformityAvoid it happening againMetallic material coating processesLaser beam welding apparatusAlcladOptoelectronics

The invention relates to a laser repairing technology for an aluminum foil roll crack. The laser repairing technology for the aluminum foil roll crack comprises the following steps: A, cleaning up a roll; B, preheating the roll at a low temperature; C, optimizing technical parameters, and performing laser cladding on polished and cleaned pits on the roll, wherein in the process, the roll is vibrated, the temperature of the roll is kept to be 180-250 DEG C until the pits are filled, a cladding layer is higher than the roll surface, and used alloy powder comprises the following components by weight percent: 10-15% of Cr, 1-2% of B, 0.5-1.5% of Si and Fe in balancing amount; and D. detecting. The laser repairing technology for the aluminum foil roll crack can perform laser cladding on the roll crack and can effectively fill a very deep crack to making the deep crack meet a using requirement; the structural uniformity of the cladding layer is good; and the fusion rate of the cladding layer and a matrix is high.

Owner:DANYANG HONGTU LASER TECH

Method for repairing defects of pipe orifice of high-alloy hollow valve shell casting

The invention relates to a method for repairing crank defects of high-alloy steel castings, in particular to a method for repairing defects of a pipe orifice of a high-alloy hollow valve shell casting pipe orifice. The method comprises the steps that firstly, defects are gouged and removed from the inner side of the pipe orifice, and then the remaining defects are removed from the outer side of the pipe orifice; secondly, a heating device is used for preheating both the upper portion and the lower portion of the pipe orifice, and then welding is conducted according to the inside-to-outside welding principle in a multilayer multipass welding sequence through the welding method that the swing width of a welding rod is smaller than or equal to 20 mm; finally, postweld heat treatment is conducted. The method is unique, the defects can be minimized, internal stress caused by uneven preheating is effectively reduced, the defects caused by welding are reduced, and cost is lowered.

Owner:KOCEL STEEL

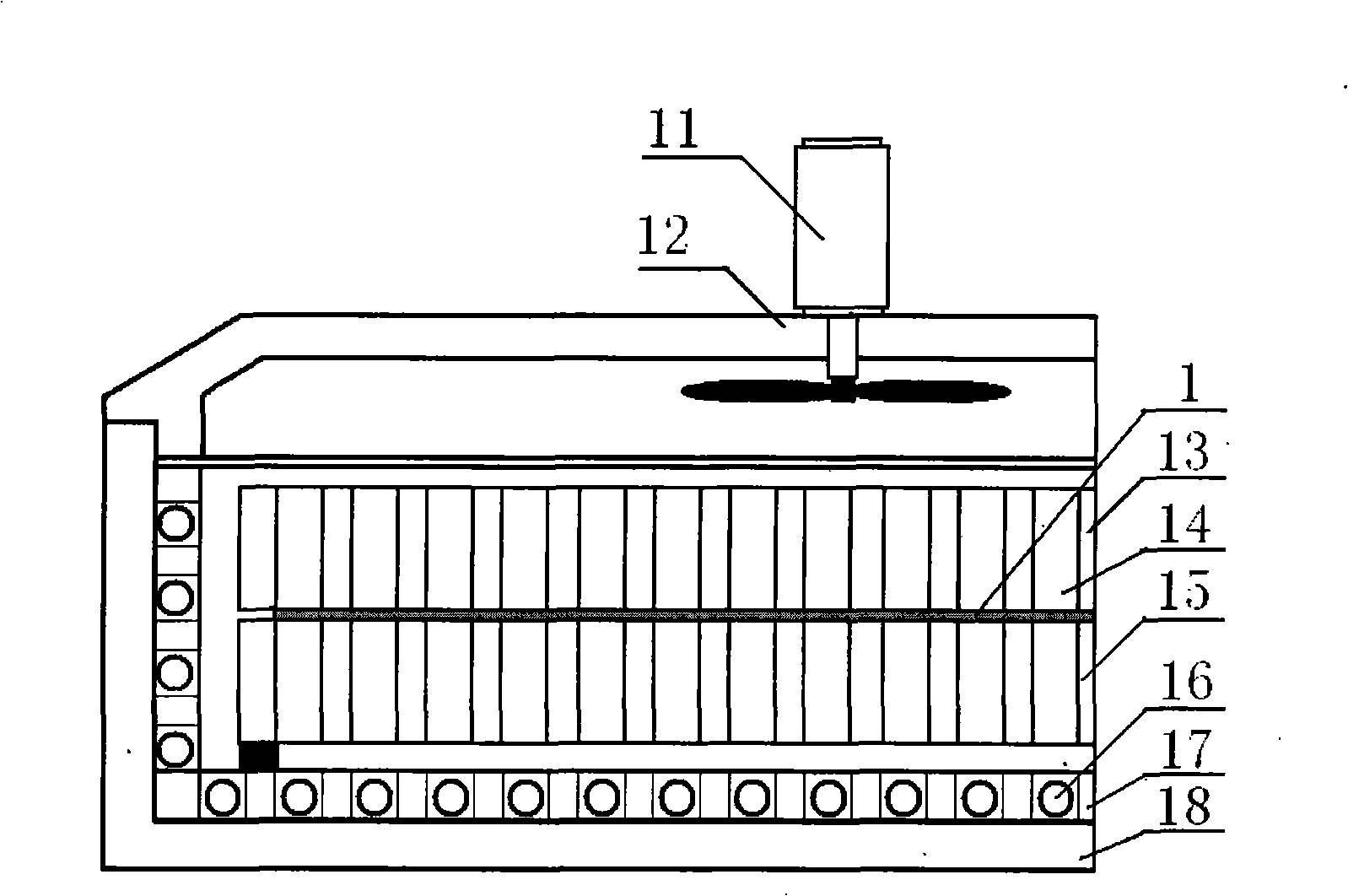

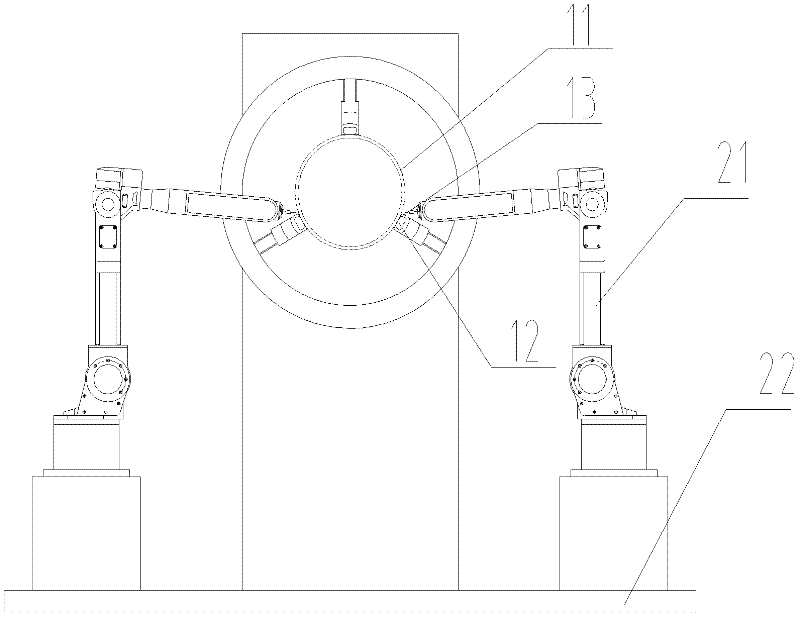

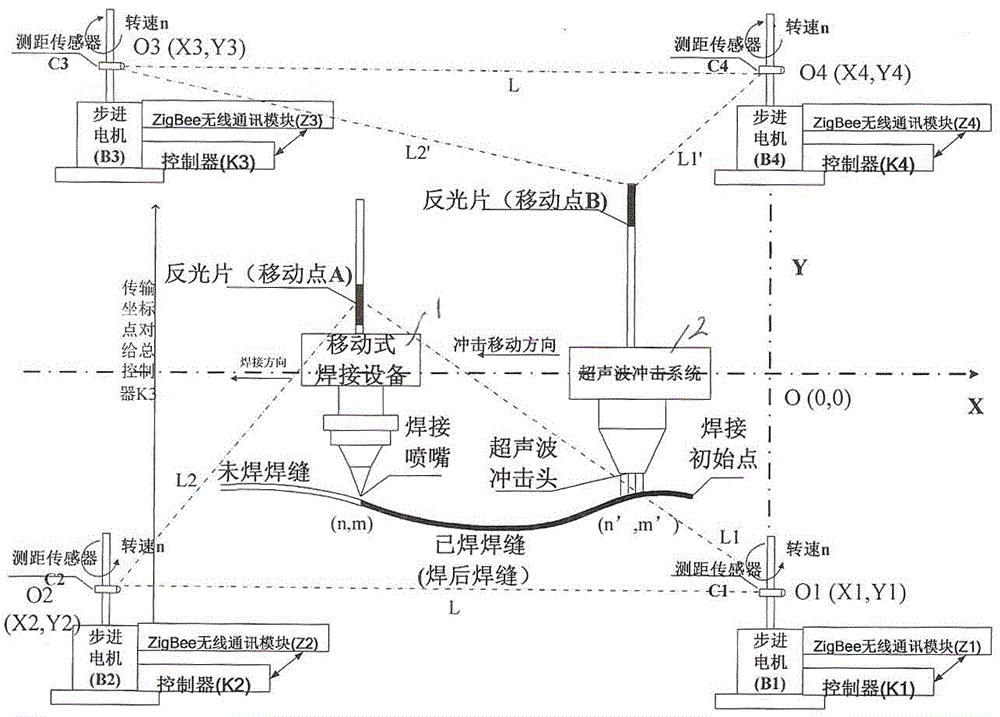

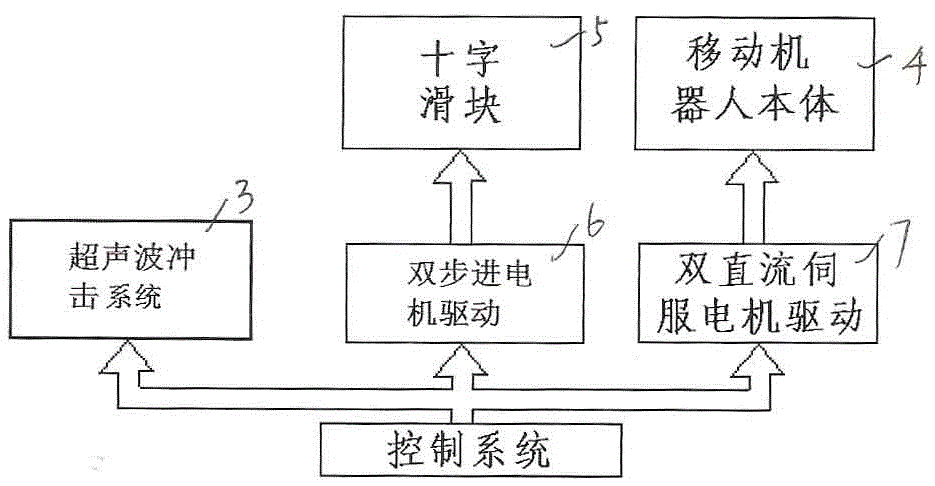

Automatic correcting and ultrasonic impacting system of post-welding seam tracking robot

ActiveCN105458483AImprove tracking accuracyNot affected by trackingFurnace typesHeat treatment process controlImpact systemBiomedical engineering

The invention discloses an automatic correcting and ultrasonic impacting system of a post-welding seam tracking robot. The automatic correcting and ultrasonic impacting system is composed of a mobile welding device, an ultrasonic impacting system, a step motor, a controller, a Zibee wireless communication module, a reflection sheet and a distance measurement sensor. According to the invention, the deviation between the operation tail end of the ultrasonic impacting system and post-welding seams can be sensed in real time and can be corrected in real time, and an ultrasonic impacting head can accurately impact the post-welding seams for removing the welding stress. The automatic correcting and ultrasonic impacting system has the advantages that the structure is simple, the automation degree is high, and the accuracy of tracking the post-welding seams is high.

Owner:NANTONG UNIVERSITY

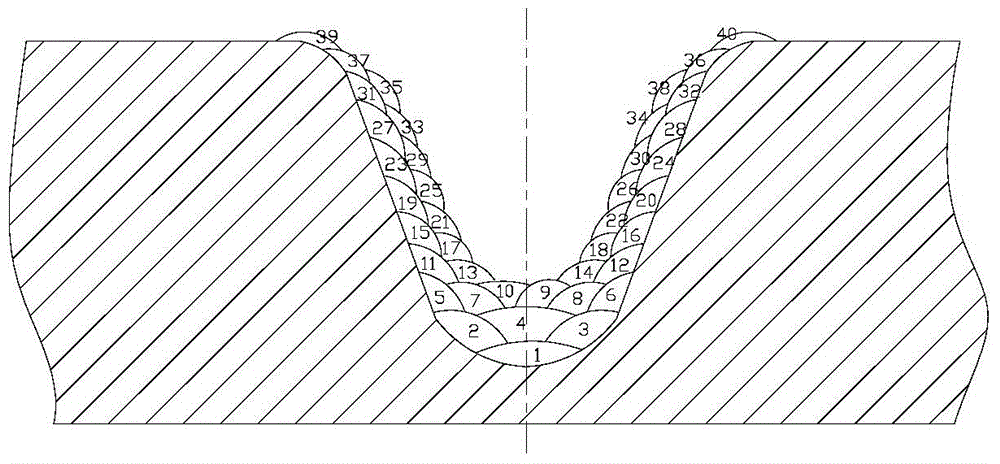

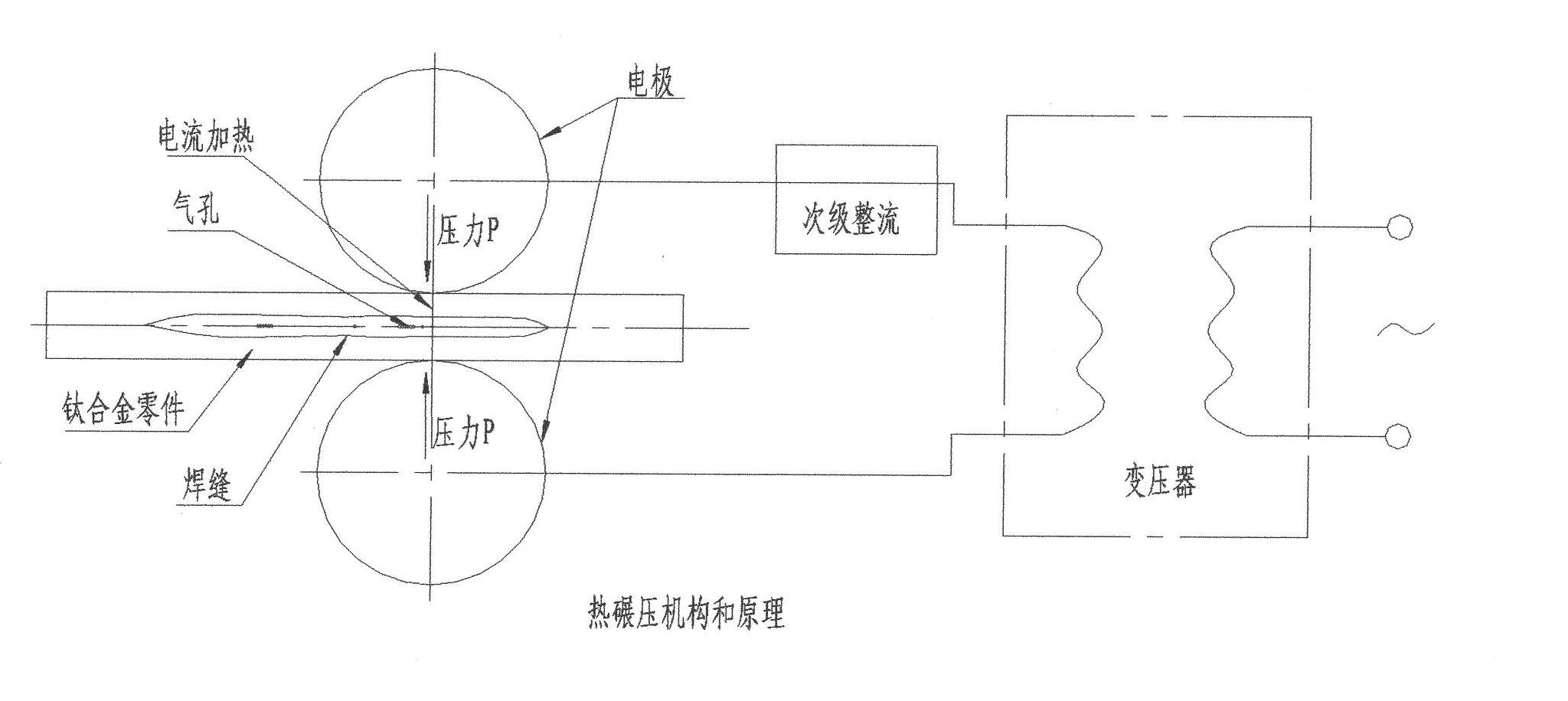

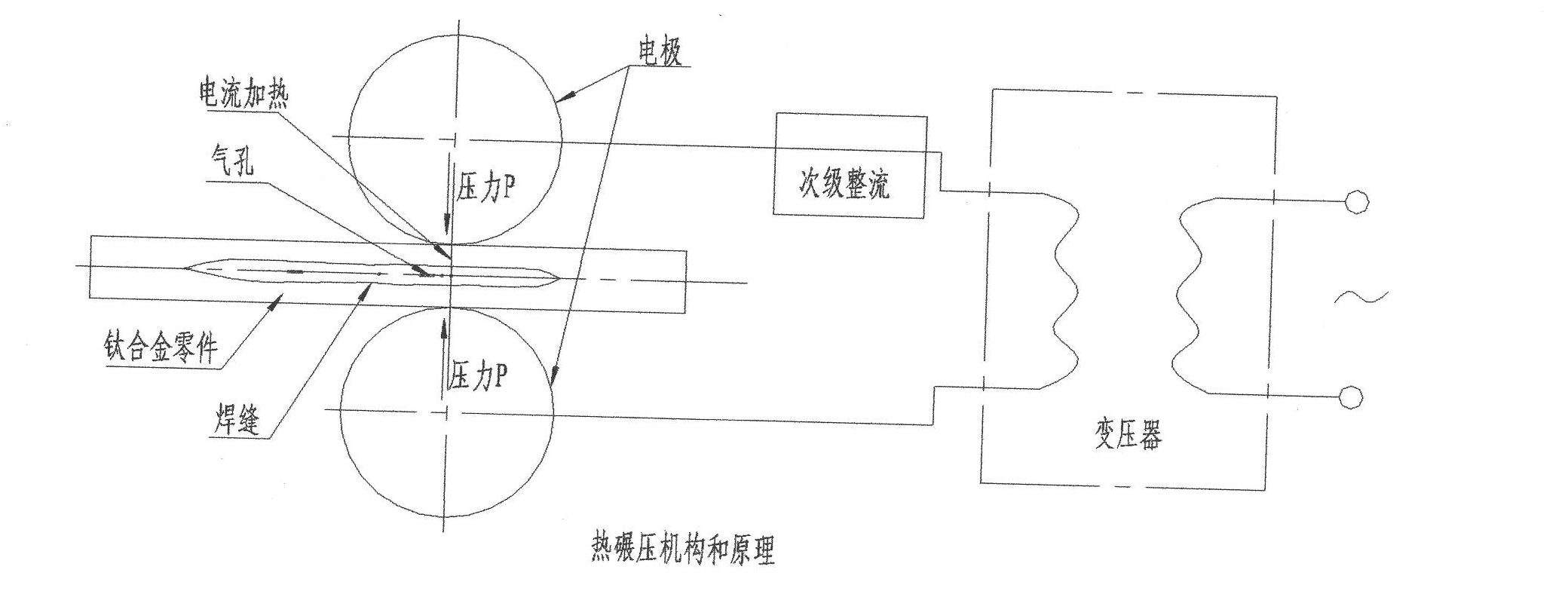

Method for repairing arc-seam weld porosity defects of titanium alloy sheets through hot rolling

InactiveCN102107319ASolve the problem of stomatal defectsAvoid defectsWelding electric supplyWelding with roller electrodesPorosityDefect repair

The invention discloses a method for repairing the arc-seam weld porosity defects of titanium alloy sheets through hot rolling, which is characterized in that the hot rolling operation is performed by using the resistance welding principle and the resistance welding properties of materials of parts, and specifically discloses a process method which is implemented through exerting a pressure on weld metals and carrying out ohmic-heating so as to eliminate porosities by using a roll welding method. By using the method disclosed by the invention, the problem that the insides of arc-seam welds have porosity defects in the process of processing titanium alloy plate-welding cases can be solved subtly, the quality repair on welds with small deformation or micro-deformation can be realized, and in the process of hot rolling, because the weld position is heated or pressurized, and subjected to trace form correction and welding stress elimination, the weld qualities, structure sizes and technical conditions of parts after construction meet the design requirements. If a repair welding part has an indentation with a depth exceeding process standards, the defect can be treated by using an argon arc welding surface-cladding process, and the qualification rate of defect repair implemented by using the method disclosed by the invention is 100%.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Ultrasonic peening assisted argon arc welding repair method for martensitic stainless steel engine casing

ActiveCN107498263AFlexible process operationLow costArc welding apparatusWelding/soldering/cutting articlesMartensitic stainless steelPeening

The invention relates to an ultrasonic peening assisted argon arc welding repair method for a martensitic stainless steel engine casing and belongs to the technical field of argon arc welding repair. Accoriding to the ultrasonic peening assisted argon arc welding repair method, in the early stage, the same base material welding wire is adopted for conducting argon arc welding repair and ultrasonic peening assisted argon arc welding repair tests on a 1Cr12Ni3Mo2Co2V martensitic stainless steel test plate, and the room-temperature tensile and impact toughness properties of a Z1Cr12Ni3Mo2Co2V martensitic stainless steel base material and two kinds of repair connectors are tested correspondingly. Test results shows that the average ductility of the sample repaired through ultrasonic peening assisted argon arc welding is 1.25 times that of the sample directly repaired through argon arc welding, and the impact toughness is improved by almost 35%. Therefore, martensitic stainless steel is repaired through ultrasonic peening assisted argon arc welding technology, the impact toughness and room-temperature plasticity of the connectors can be improved significantly, the recracking tendency in the service process can be reduced beneficially, and thus the service life after repair is prolonged.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

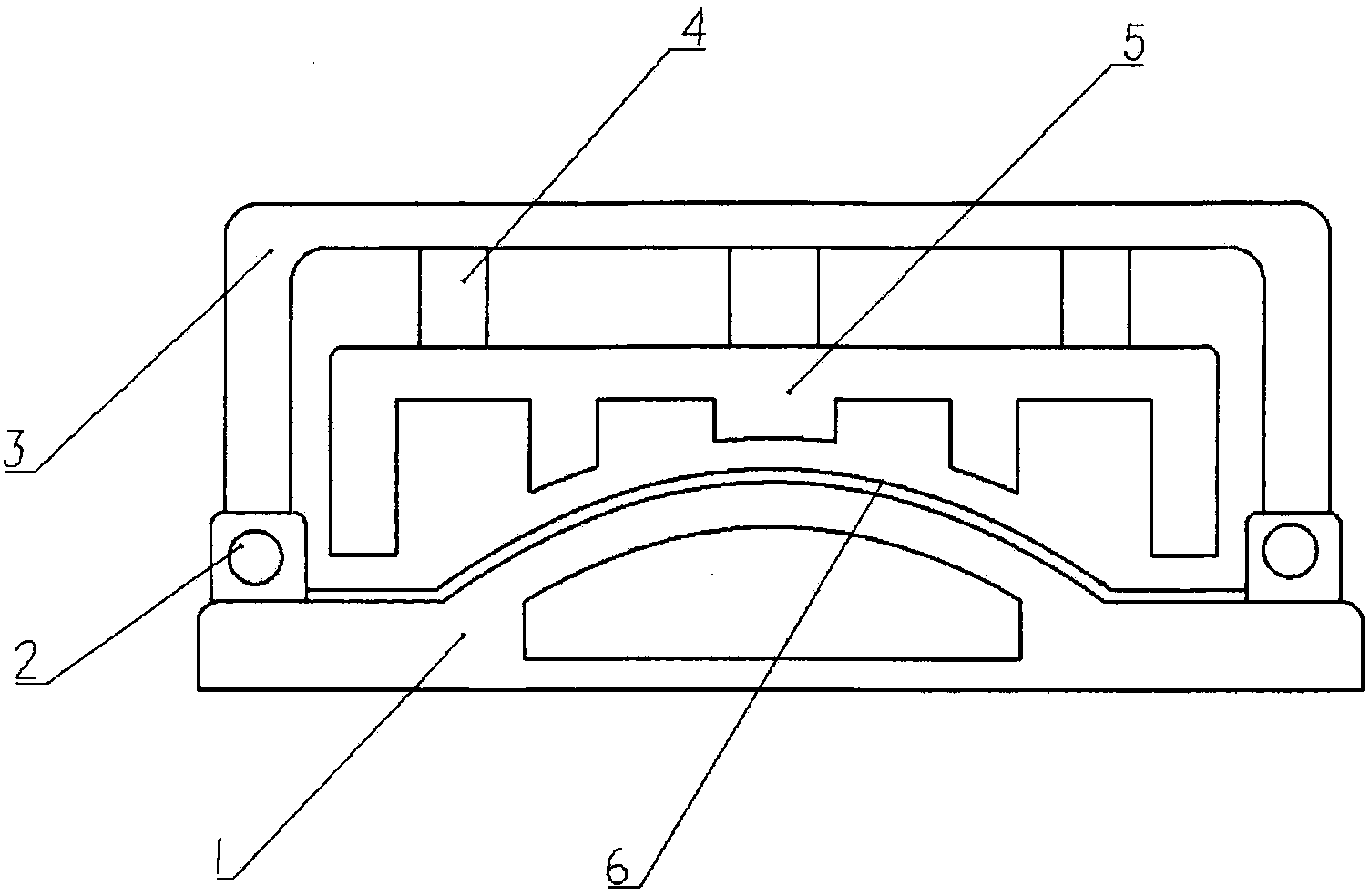

Stress-eliminating distortion-correcting thermal treatment tooling and process of titanium alloy at high temperature

ActiveCN103668025ARestoring the theoretical shapeGuaranteed manufacturing accuracyThermal dilatationStress relieving

The invention relates to stress-eliminating distortion-correcting thermal treatment tooling of titanium alloy at high temperature. According to the invention, the upper surface of a clamping board base is adhered to the lower surface of a part to be thermally treated; two ends of the clamping board base are provided with positioning blocks; an inverted U-shaped fixing frame is movably connected with the clamping board base through pins; a power supporting column is arranged below the fixing frame; a clamping board is connected below the power supporting column; the shape of the lower surface of the clamping board is consistent with the shape of the upper surface of the part to be thermally treated; the lower surface of the clamping board is in clearance fit with the upper surface of the part to be thermally treated; the thermal expansion coefficient of the power supporting column is greater than the expansion coefficient of other parts of the tooling. The invention further discloses a novel stress-eliminating thermal treatment process which is capable of effectively eliminating welding stress, correcting part shape and guaranteeing the theoretical shape of titanium alloy parts when being used for putting pressure on workpieces at high temperature.

Owner:SHENYANG AIRCRAFT CORP

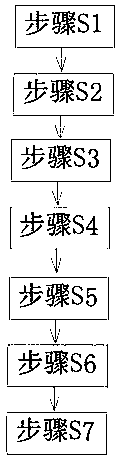

Welding method of super-thick steel casting

InactiveCN109108431AEliminate welding residual stressReduces the chance of weld cracksArc welding apparatusFurnace typesLayer removalWelding deformation

The invention discloses a welding method of a super-thick steel casting. Process steps include S1, preparing a joint: an asymmetric X-type groove is adopted; S2, preheating: the front side and the reverse side are uniformly heated, the preheating temperature is set within the range of 150-160 DEG C, and the heating rate does not exceed 100 DEG C / h; S3, back welding: gas shielded welding backingis carried out on flux-cored welding wires for three layers, and fire warming is carried out to remove stress after each weld seam is welded; S4, reverse side air gouging: air gouging back chipping and carburized layer removal are carried out; S5, reverse side back welding: back welding is carried out by three layers after the temperature of the steel casting reaches a preheating temperature according to the method described in the step 2, and fire warming is performed on each weld seam to remove stress; S6, filling and cover surface welding: the front side and the reverse side are welded respectively by one welder simultaneously and symmetrically, and hammering is carried out layer by layer after each layer of weld beads of each weld seam is welded; and S7, 550 DEG C *2h heat treatment after stress removal is carried out immediately after the completion of welding. By means of the method, welding stress and welding deformation can be significantly reduced, and the probability of generating steel casting welding cracks is greatly reduced.

Owner:CHINA MERCHANTS HEAVY IND JIANGSU

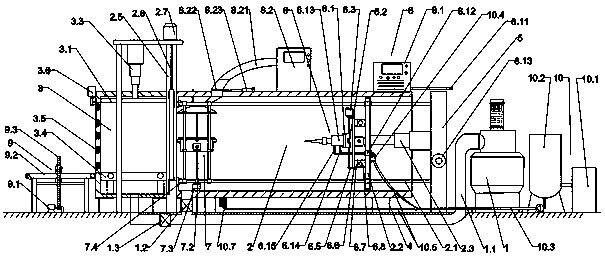

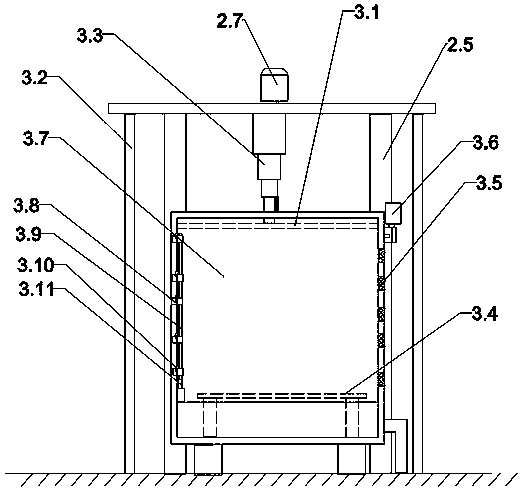

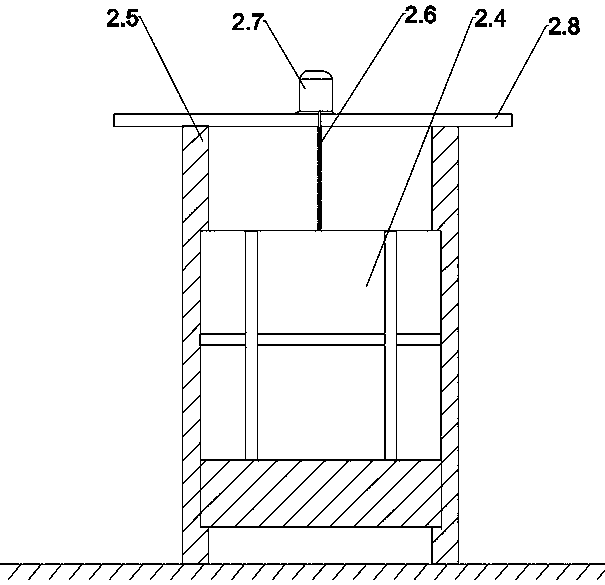

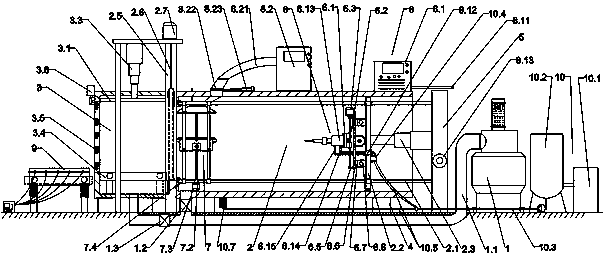

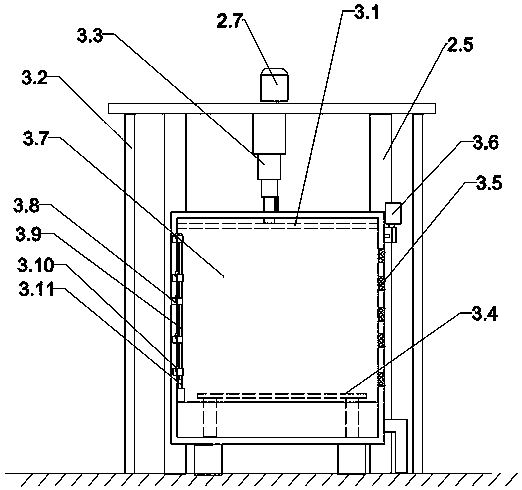

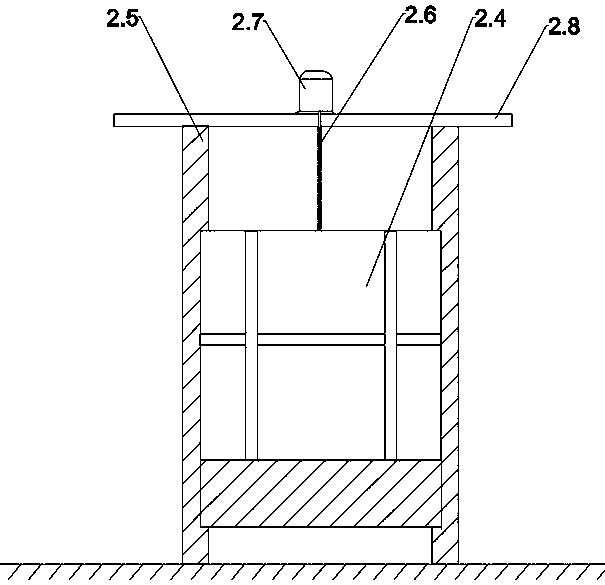

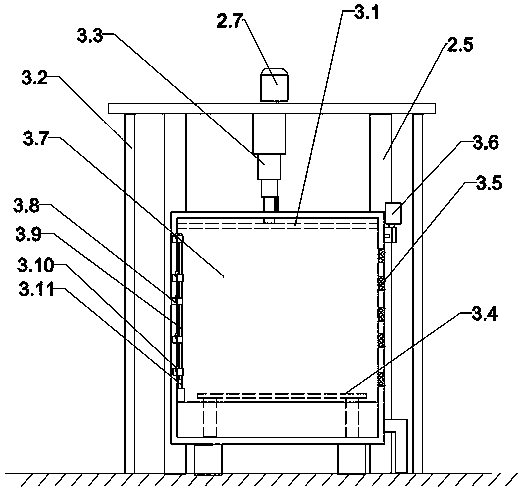

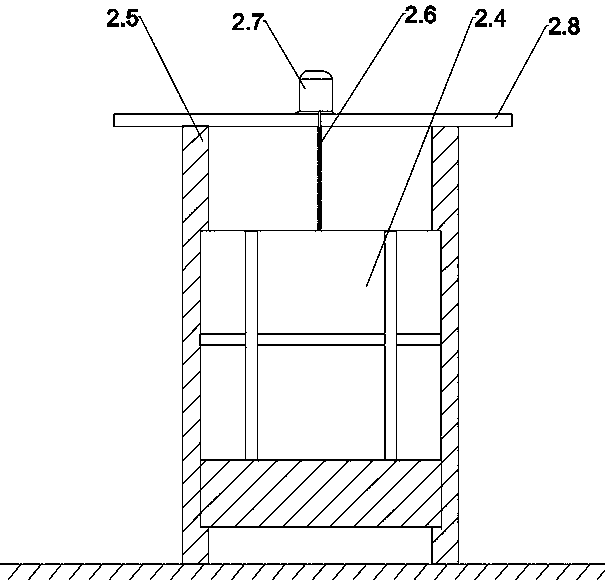

Vacuum welding equipment capable of automatically detecting weld joint and using method of vacuum welding equipment

InactiveCN109570725AReduce vacuum timeIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLiquid nitrogen

The invention provides vacuum welding equipment capable of automatically detecting a weld joint and a using method of the vacuum welding equipment. The vacuum welding equipment comprises a vacuum device, a welding vacuum chamber, a feeding vacuum chamber, an electron beam welding device, a welding worktable, an argon arc welding device, a nitrogen generation device and a weld joint detecting device; the welding vacuum chamber and the feeding vacuum chamber are provided with a piston sealing plate and a lifting sealing plate correspondingly; the electron beam welding device is arranged on the piston sealing plate, and the welding worktable can be overturned by 180 degrees and rotated by 360 degrees; the argon arc welding device is mounted on the piston sealing plate in a replaceable mode, and the nitrogen generation device can provide liquid nitrogen for a welding gun and a weldment for cooling; and the weld joint detecting device is arranged at the bottom of a feeding conveying belt. Adetecting frame is arranged to be of a semi-arc structure and can rotate, detection through a probe on the detecting frame is more thorough, when the weldment is transferred out from the equipment, the quality of the weld joint of the weldment can be quickly, conveniently and accurately detected, and the production efficiency is effectively improved.

Owner:GUANGXI NANNING SHENGQIAN TECH DEV CO LTD

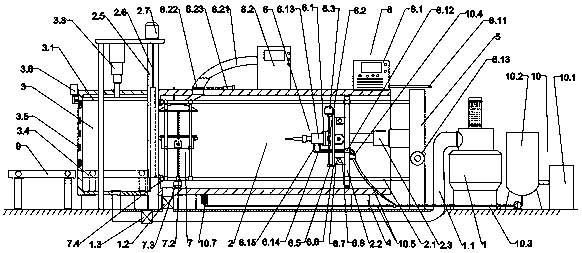

Vacuum welding equipment with supersonic aging function and application method of vacuum welding equipment

InactiveCN109570724AHeating evenlyUniform and stable air quenchingWelding/cutting auxillary devicesAuxillary welding devicesNitrogenLiquid nitrogen

The invention provides vacuum welding equipment with an supersonic aging function and an application method of the vacuum welding equipment. The vacuum welding equipment comprises a vacuum device, a welding vacuum chamber, a feeding vacuum chamber, an electron beam welding device, a welding working table, an argon arc welding device, a nitrogen making device, and an supersonic aging device. The welding vacuum chamber and the feeding vacuum chamber are separately provided with a piston sealing plate and a lifting sealing plate. The electron beam welding device is arranged on the piston sealingplate. The welding working table can rotate at 180 degrees and 360 degrees. The argon arc welding device is mounted on the piston sealing plate in a replacing mode. The nitrogen making device can provide liquid nitrogen for a welding gun and a weldment for cooling. The supersonic aging device is arranged on a conveying belt. Continuous production is achieved. The size of the vacuum chamber can beadjusted based on the size of the weldment. Impurities of the weldment can be shaken off before the weldment entering the vacuum chamber. The supersonic aging is adopted to remove welding stress afterwelding. The fatigue life of a welding structure is prolonged. The welding quality is guaranteed.

Owner:GUANGXI NANNING SHENGQIAN TECH DEV CO LTD

Vacuum welding equipment and using method thereof

ActiveCN109570722AReduce vacuum timeIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding fume

The invention provides vacuum welding equipment and a using method thereof. The vacuum welding equipment comprises a vacuum device, a welding vacuum chamber, a feeding vacuum chamber, an electron beamwelding device, a welding worktable, an argon arc welding device and a nitrogen generation device; the welding vacuum chamber and the feeding vacuum chamber are provided with a piston sealing plate and a lifting sealing plate correspondingly; the electron beam welding device is arranged on the piston sealing plate, and the welding worktable can be overturned by 180 degrees and rotated by 360 degrees; the argon arc welding device is mounted on the piston sealing plate in a replaceable mode, and the nitrogen generation device can provide liquid nitrogen for a welding gun and a weldment for cooling; and the vacuum device is connected to the welding vacuum chamber and the feeding vacuum chamber for vacuumizing. Continuous production can be conducted without interrupts, the volumes of the vacuum chambers can be adjusted according to the size of the weldment, welding processes can be switched, a welding fume treatment device is arranged, thus the very environment-friendly effect is achieved, and production requirements of the modern novel vacuum welding equipment are met.

Owner:GUANGXI NANNING SHENGQIAN TECH DEV CO LTD

Process for welding medium-high carbon steel without cracking and deformation

ActiveCN102463402AReduce internal stressReduce cooling rateArc welding apparatusWelding/cutting media/materialsCarbon steelInternal stress

The invention discloses a process for welding medium-high carbon steel without cracking and deformation. The process comprises the following steps of: preheating a welding part to 85-100 DEG C before welding; welding by using a NiCrFe-3 welding rod; controlling the temperature of the welding part between 90 and 110 DEG C during the welding process; indirectly welding with short arc by using the roasted NiCrFe-3 welding rod; and carrying out integral insulating and aging treatment to the welding part after welding, wherein the insulation temperature is 60-80 DEG C. Medium-high carbon steel parts are welded by adopting the above welding process and the welding materials, and the preheating of the medium-high carbon steel parts and the roasting of the welding rod are carried out before welding, so that the cooling speed of the welding part in the follow-up welding operations is reduced and the internal stress in the welding joint is reduced; through the hammering to the welding portion during the welding process, the process can be used for refining grains and eliminating partial welding stress, and is beneficial to the fusion of the welding material and a base material; the problem of eliminating welding internal stress of the medium-high carbon steel in the welding process is solved, the fusion of the welding material and the base material during the welding of the medium-high carbon steel parts is improved, and the various performances of the welded medium-high carbon steel parts are equivalent to that of the original parts.

Owner:成都植源机械科技有限公司

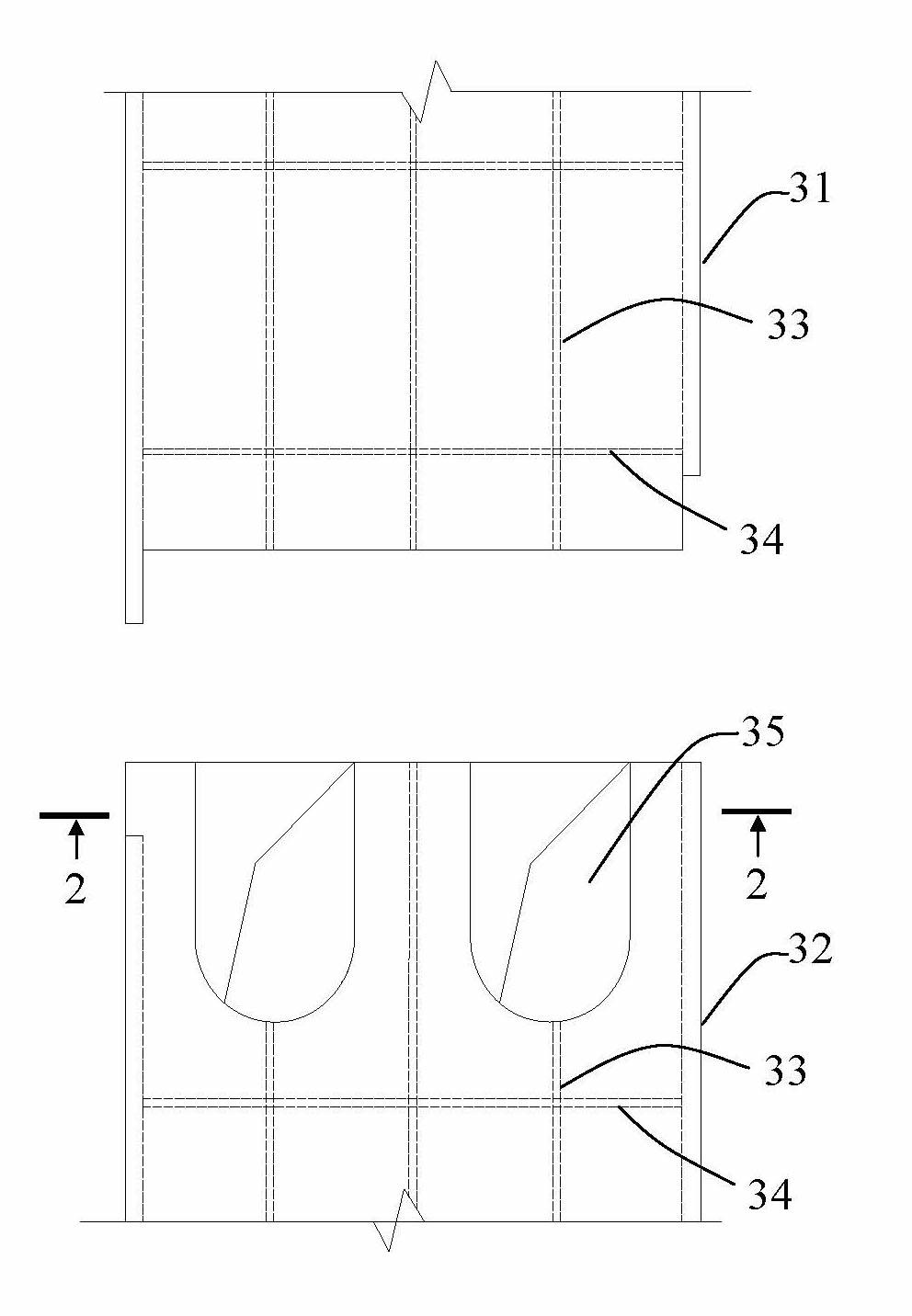

Partition of steam turbine and processing technology thereof

ActiveCN106150570AOvercome the difficult separation problemSolve these problems of wear and tearMachines/enginesEngine componentsStructural engineeringProcess engineering

The invention discloses a partition of a steam turbine and a processing technology thereof, and belongs to the field of manufacturing of partitions of steam turbines. The partition of the steam turbine comprises semicircular partitions, wherein the two sides of blades of the semicircular partitions are inner shrouds and outer shrouds respectively; the height of the single blade positioned on a midsplit surface is larger than the height of the midsplit surface; U-shaped notches are formed in the connection parts of the single blade and the corresponding inner shroud and the single blade and the corresponding outer shroud; and the height of the U-shaped notches exceeds the height of the midsplit surface. According to the processing technology of the partition of the steam turbine, full circle processing and full circle welding methods are adopted, and the U-shaped notches are cut in to-be-cut positions of the single blade on the midsplit surface in advance, so that the problem that during full circle processing of the partition, the midsplit surface is not liable to separate is overcome, the welding deformation is reduced, and the processing accuracy is improved.

Owner:北京北重汽轮电机有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com