Patents

Literature

46results about How to "Flexible process operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sewage disposal system with biological phosphorus removal and chemical phosphorus removal bypass and disposal method

InactiveCN101381183ARealize recycling of resourcesSolving the Contradiction of Biological Phosphorus and Nitrogen RemovalTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentSludgeSewage

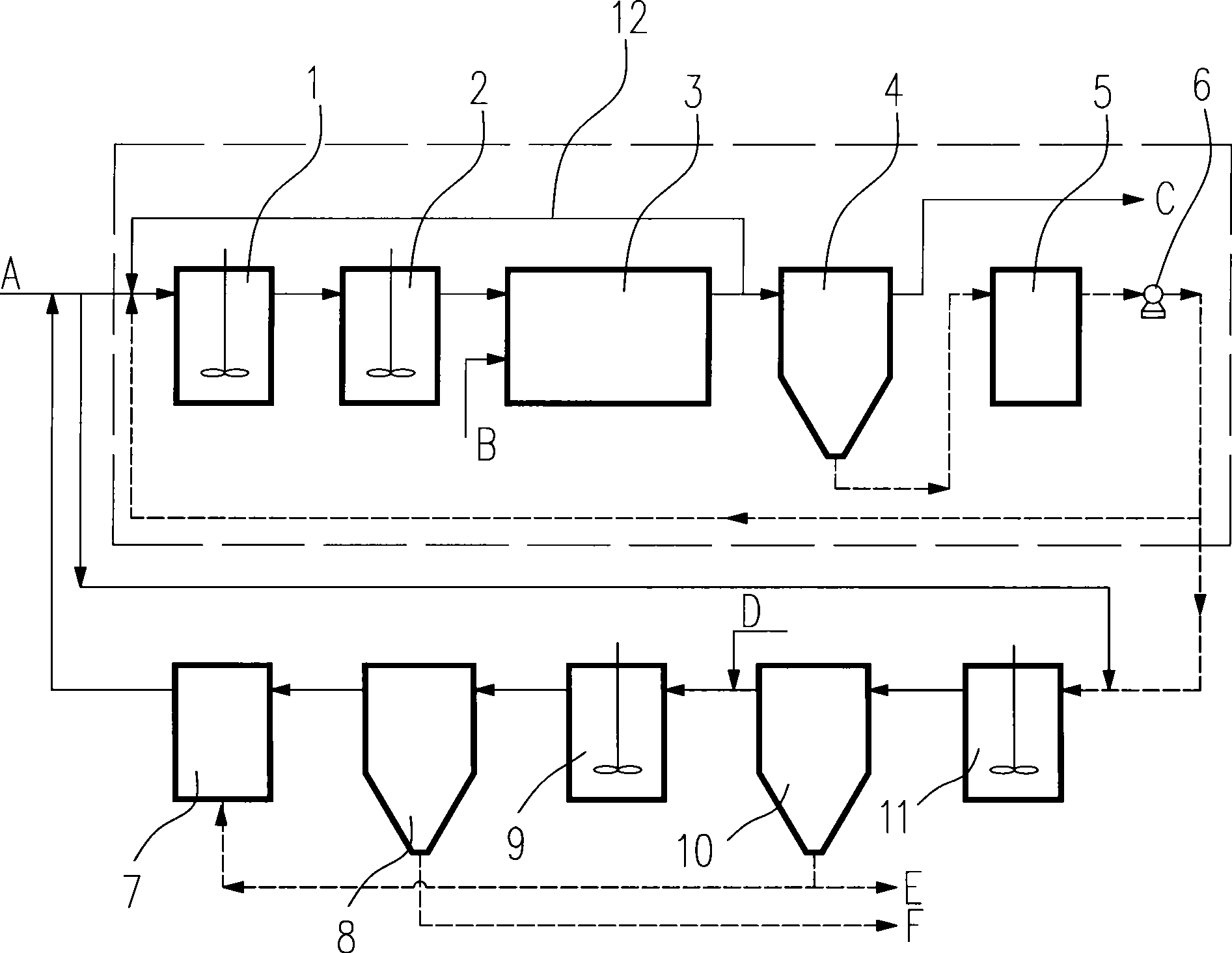

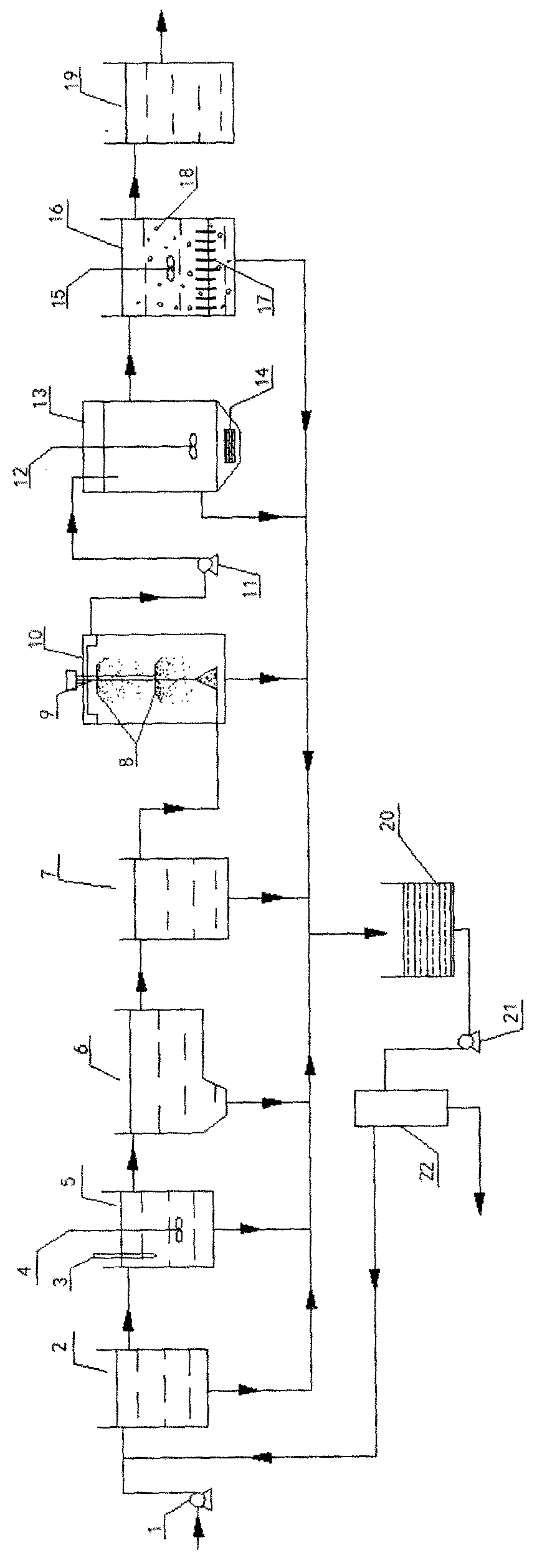

The invention discloses a system and a method for treating sewage with biological phosphorus removal and bypath chemical phosphorus removal. The system comprises a nitrogen-phosphorus removal subsystem and a bypath phosphorus removal subsystem, wherein the nitrogen-phosphorus removal subsystem is formed by connecting an anaerobic tank, an anoxic tank, an aeration tank, a sedimentation tank, a sludge return tank and a sludge return pump in turn, wherein the water outlet of the sludge return tank is connected to a sewage inlet of the anaerobic tank through a sludge return pump via pipelines; the bypath phosphorus removal subsystem is formed by connecting a mixing tank, an anaerobic phosphorus release sedimentation tank, a mixing reaction tank and a second sedimentation tank in turn; and the water outlet of the sludge return tank of the nitrogen-phosphorus removal subsystem is communicated with the water inlet of the mixing tank through the sludge return pump. The treatment system is simple in structure, organically combines the biological phosphorus removal with the chemical phosphorus removal, effectively solves the disadvantages that the biological phosphorus removal is low in efficiency and the pure chemical phosphorus removal remains high in operation cost, and has the advantages of good phosphorus removal effect and less medicament cost than the pure chemical phosphorus removal.

Owner:BEIJING YIPU INT WATER AFFAIRS

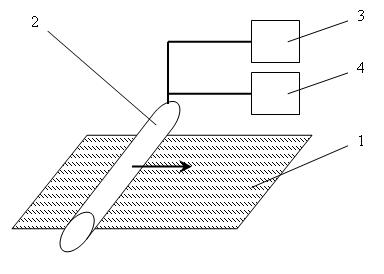

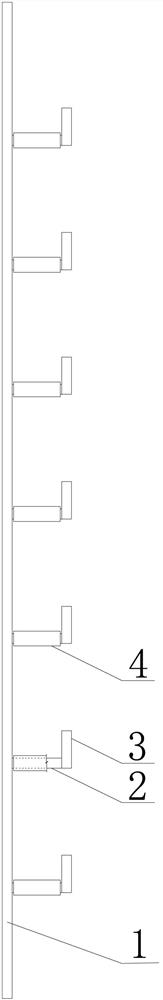

New-old concrete combining construction method at local repair section

The invention relates to a new-old concrete combining construction method at a local repair section. The construction method comprises the following steps of: (1) old concrete grooving: sawing joints on the old concrete on one side of a combination surface by a joint saw and uniformly arranging grooves at equal intervals; (2) groove cleaning: cleaning away the concrete within a grooving range in the step (1) by using impacting equipment and manually chiseling away edge-corner areas to form flat groove bottoms; (3) combination surface scabbling: scabbling the cutting surface of the middle and old concrete in the step (1); (4) interfacial agent spraying: spraying an interfacial binding agent on the combination surface of the new-old concrete; (5) steel bar laying: laying steel bars or steel bar supports in the grooves arranged in the step (1); and (6) new concrete pouring: pouring the new concrete inside the erected steel bar supports and the grooves. The new-old concrete combining construction method provided by the invention is simple in construction method and flexible in technological operation, can enable the new and old concrete at the local repair section to be closely combined, is durable and stable, and is widely applicable to new-old concrete engineering practice at the local repair section.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

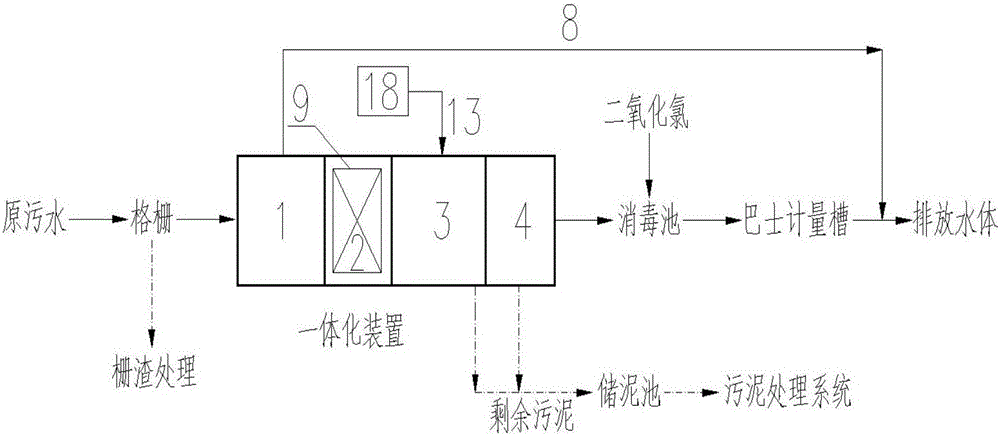

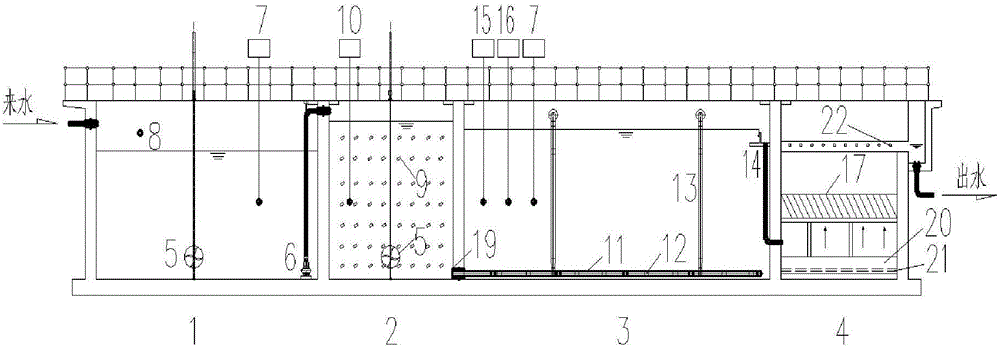

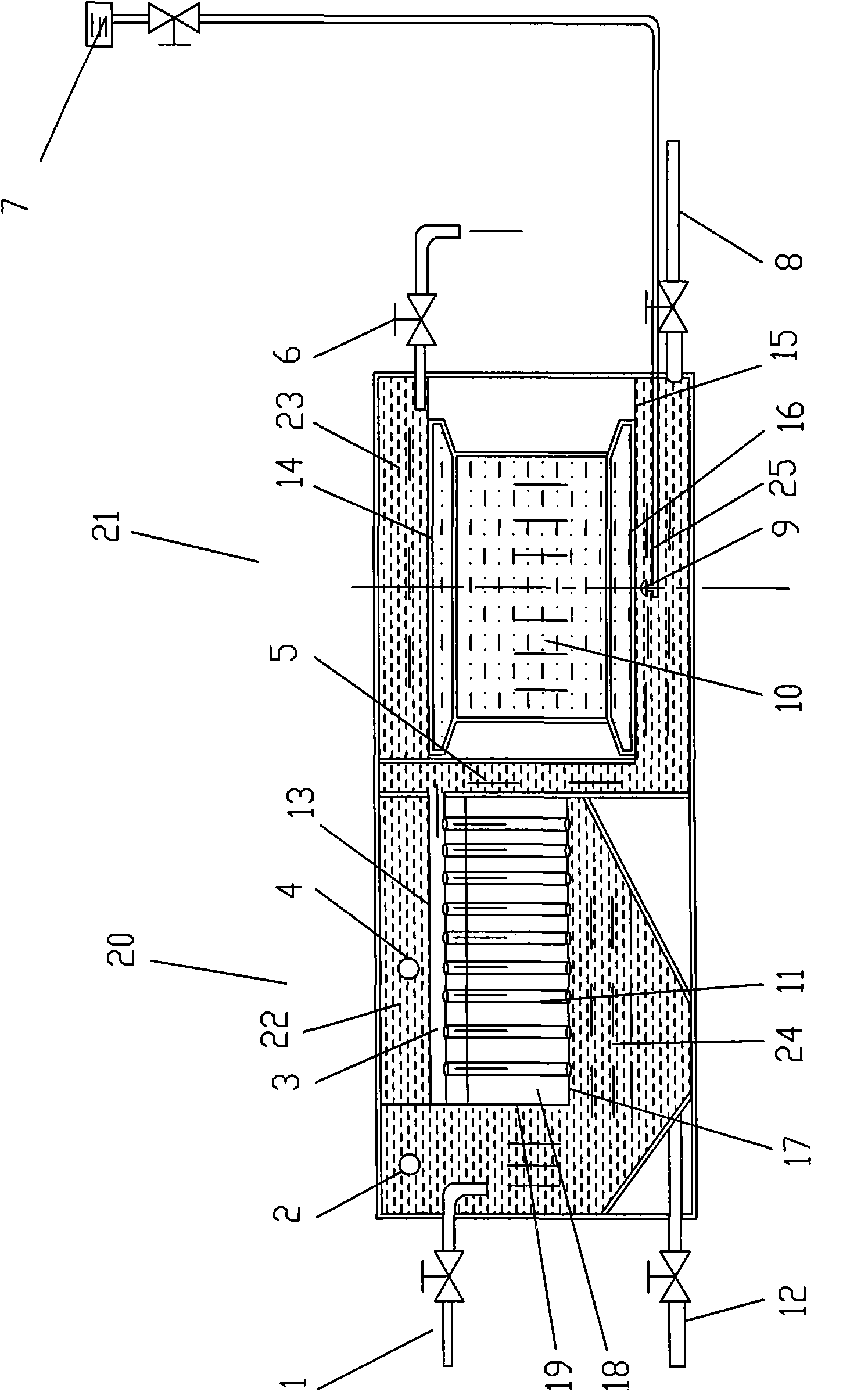

Integrated system and process for treating domestic sewage of villages and towns

InactiveCN105967438AGood pre-reaction treatment effectSimple structureWater treatment parameter controlTreatment with aerobic and anaerobic processesPolyvinyl chlorideEngineering

The invention provides an integrated system and process for treating domestic sewage of villages and towns and belongs to the technical field of environment protection and sewage treatment. Main body parts of the system comprise four space parts including an adjusting tank, an anaerobic pre-reaction tank, a main biochemical reaction tank and an inclined tube sedimentation basin; the four parts are combined and integrated into a process unit by adopting a separation plate; other parts of the system comprise a grid, a disinfection device and a PAP metering device. The adjusting tank is used for adjusting the water quantity of input water and homogenizing the water quality. Modified suspension packing is added into the anaerobic pre-reaction tank and the anti-impact load of the process is enhanced, so that the pre-reaction treatment effect is better. The main biochemical reaction tank has a simple structure and physical regions are not formed in the tank; a water input and water distribution pipe and a disc type micro-pore aeration device are crossly distributed at the bottom of the tank and an overflowing weir is used for discharging the water, so that the treatment efficiency on pollutants is high; and a sludge reflowing system is not arranged and a process is flexible to operate. The inclined tube sedimentation basin adopts a polyvinyl chloride plastic hexagonal inclined pipe, so that the occupied space is small, hydropower staying time is short and the sedimentation efficiency of the pollutants is high.

Owner:BEIJING SHOUGANG INT ENG TECH

Ultrasonic peening assisted argon arc welding repair method for martensitic stainless steel engine casing

ActiveCN107498263AFlexible process operationLow costArc welding apparatusWelding/soldering/cutting articlesMartensitic stainless steelPeening

The invention relates to an ultrasonic peening assisted argon arc welding repair method for a martensitic stainless steel engine casing and belongs to the technical field of argon arc welding repair. Accoriding to the ultrasonic peening assisted argon arc welding repair method, in the early stage, the same base material welding wire is adopted for conducting argon arc welding repair and ultrasonic peening assisted argon arc welding repair tests on a 1Cr12Ni3Mo2Co2V martensitic stainless steel test plate, and the room-temperature tensile and impact toughness properties of a Z1Cr12Ni3Mo2Co2V martensitic stainless steel base material and two kinds of repair connectors are tested correspondingly. Test results shows that the average ductility of the sample repaired through ultrasonic peening assisted argon arc welding is 1.25 times that of the sample directly repaired through argon arc welding, and the impact toughness is improved by almost 35%. Therefore, martensitic stainless steel is repaired through ultrasonic peening assisted argon arc welding technology, the impact toughness and room-temperature plasticity of the connectors can be improved significantly, the recracking tendency in the service process can be reduced beneficially, and thus the service life after repair is prolonged.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

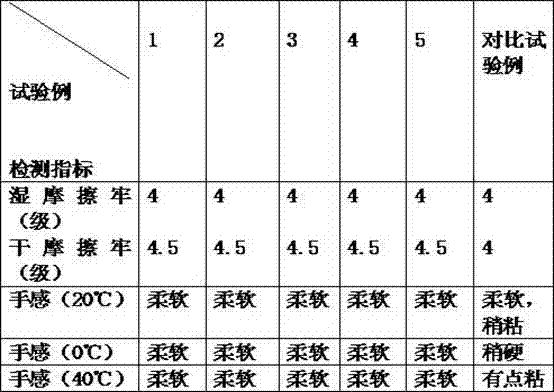

Process for producing hydrogen from natural gas by using calcium carbide tail gas

InactiveCN102745647AEasy to handleFlexible process operationHydrogen separationEnergy inputPressure stabilizationOperation mode

A process for producing hydrogen from natural gas by using calcium carbide tail gas comprises the following steps: firstly performing pressure stabilization and desulphurization of natural gas, converting the natural gas together with the calcium carbide tail gas, allowing the raw material of calcium carbide tail gas to enter from an inlet of an adsorption tower, performing neutralization and PSA for hydrogen extraction so as to obtain hydrogen with a desired purity at an outlet end; the basic working steps of the pressure swing adsorption comprise adsorption and regeneration; when compared with the prior art, the process of the invention is flexible in operation, can effectively treat calcium carbide tail gas, not only realizes reasonable utilization of the calcium carbide tail gas, but also cause no great environment pollution; meanwhile the invention can combine multiple operation modes; with program control by a computer control system, 6 adsorption towers can operate simultaneously; if needed (for example, if a valve fault or a control device fault occurs), 5 towers can be switched to operate simultaneously, and thus an on-line service function of the device is realized, which greatly improves the device operation reliability.

Owner:QINGHAI YIHUA CHEM

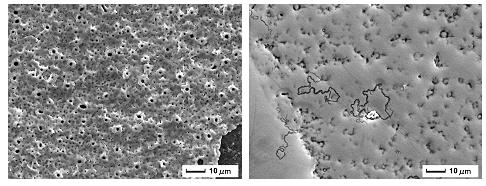

Method for manufacturing micronanostructure on surface of block amorphous alloy

The invention relates to a method for manufacturing a micronanostructure on the surface of a material, in particular to the method for manufacturing the micronanostructure on the surface of a block amorphous alloy. The method is characterized by comprising the following steps of: completely cleaning oxide, oils and fats from the surface of the block amorphous alloy in a conventional way; making the surface of the block amorphous alloy, required to be processed, in a vacuum or inert gas protection state in a proper way; and rolling the surface required to be processed under the action of a given pressure with a roller-shaped die which is heated to an enough high temperature so as to obtain the block amorphous alloy surface with the micronanostructure. The surface manufactured by the methodis high in quality, low in processing cost, high in processing efficiency and flexible in technical operation.

Owner:JIANGSU UNIV

Micro-aerated biological filter

InactiveCN101597120ASmall footprintSave land acquisition and foundation treatment costsTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentFilter materialSewage

The invention relates to an organic waste water treatment technology, in particular to a micro-aerated biological filter. According to the technical proposal provided by the invention, the micro-aerated biological filter comprises a first filter and a second filter, which is characterized in that: the first filter is thereon provided with a sewage import pipe and is internally provided with a filter chamber which is vertically provided with a plurality of bamboo tubes which are parallel to each other, the bottom end of each bamboo tube is communicated with the bottom of the first filter, and the top end of each bamboo tube is communicated with an overflow tank of the first filter; the second filter is internally provided with a biological bed which can be moved out or moved in, a massive filter material is placed in the biological bed, the second filter below the biological bed is internally provided with an aeration head, and the second filter above the biological bed is internally provided with a drain pipe; the second filter is internally provided with a flow guiding chamber which guides waste water to the bottom of the biological bed, and the flow guiding chamber is communicated with the overflow tank. The invention shortens biological reaction time, reduces equipment investment and simplifies operation process.

Owner:无锡强工机械工业有限公司

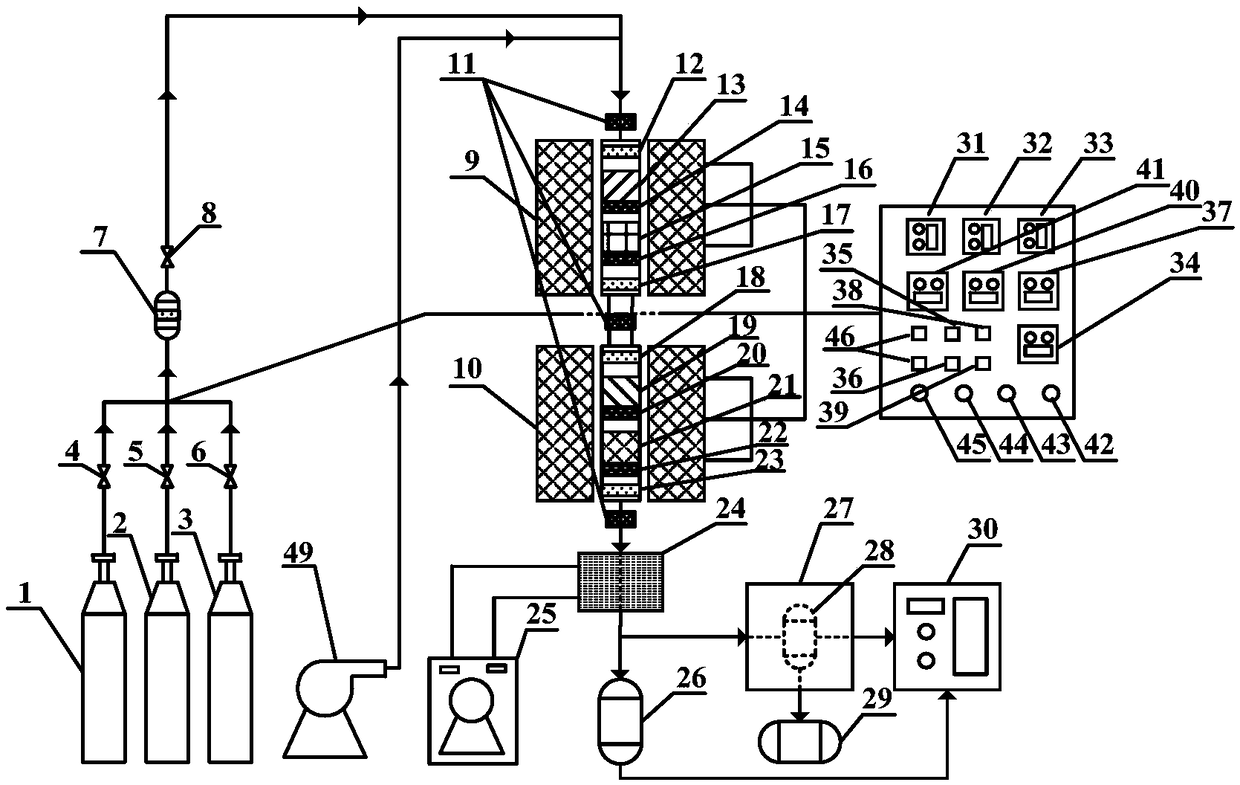

Directed catalytic cracking device and method

PendingCN108913179AHigh yieldImprove qualityBiofuelsLiquid hydrocarbon mixture productionTarDistributor

The invention discloses a directed catalytic cracking device and method. A reaction atmosphere in a reaction tube of an upper stage furnace is laid to a catalyst bed through a first gas distributor toactivate reaction gas, the reaction atmosphere generates free radicals under the action of a catalyst, the free radicals contact with free radicals produced by pyrolysis of the raw materials in a rawmaterial bed, a gaseous product is laid to a catalyst A bed through a third gas distributor, the catalyst A bed catalytically cracks the gaseous product of pyrolysis, the catalytic cracking product is fed into a catalyst B bed and is subjected to type-selective catalysis, and the type-selective catalysis product is fed into a condensation device and is condensed to form liquid tar. The device combines pyrolysis of coal, biomass and the like, a tar yield increasing process and orientation control of a product distribution process, simplifies the overall processes, is environmentally friendly,reduces the energy consumption cost, improves the production efficiency, is suitable for large-scale production and is suitable for industrial promotion and application.

Owner:NORTHWEST UNIV(CN)

UV/O3/H2O2 advanced oxidation reactor and process

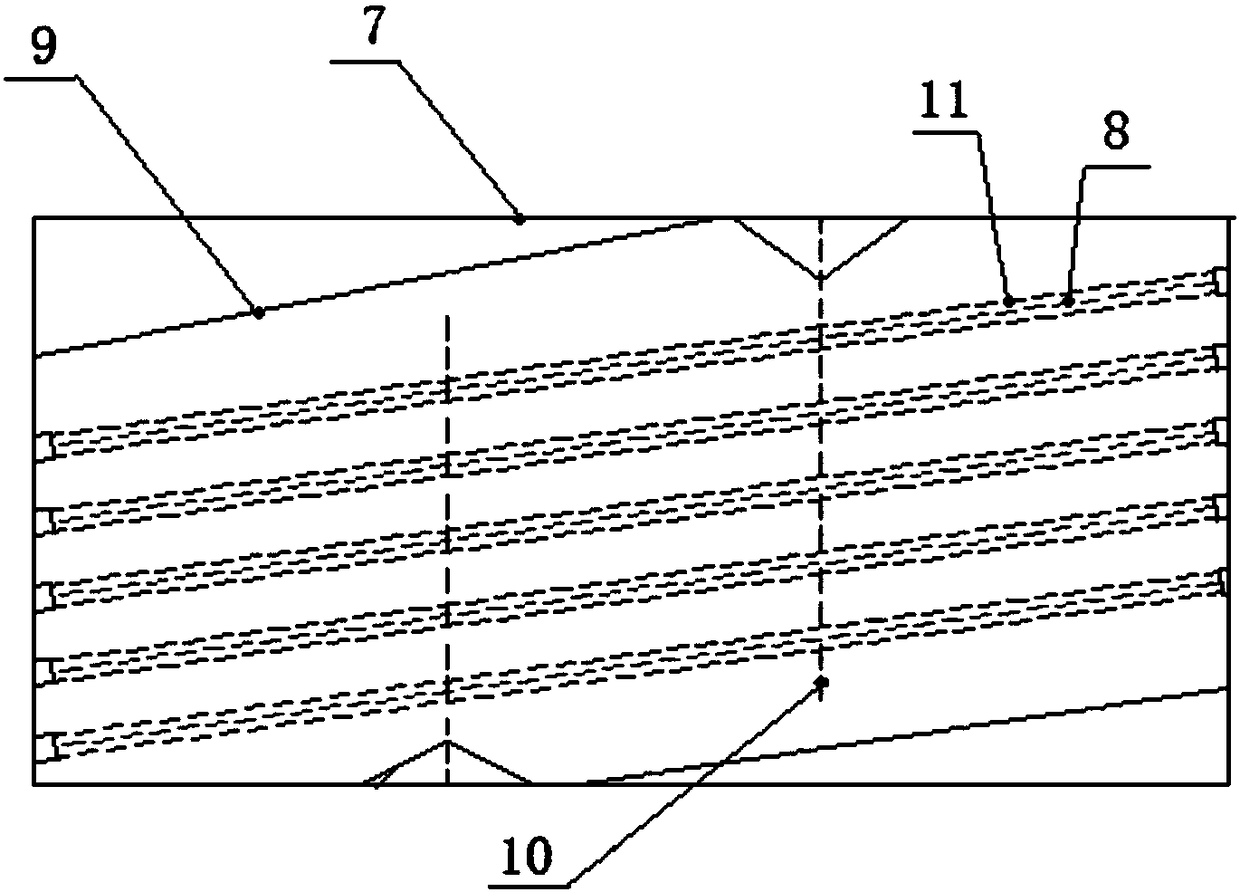

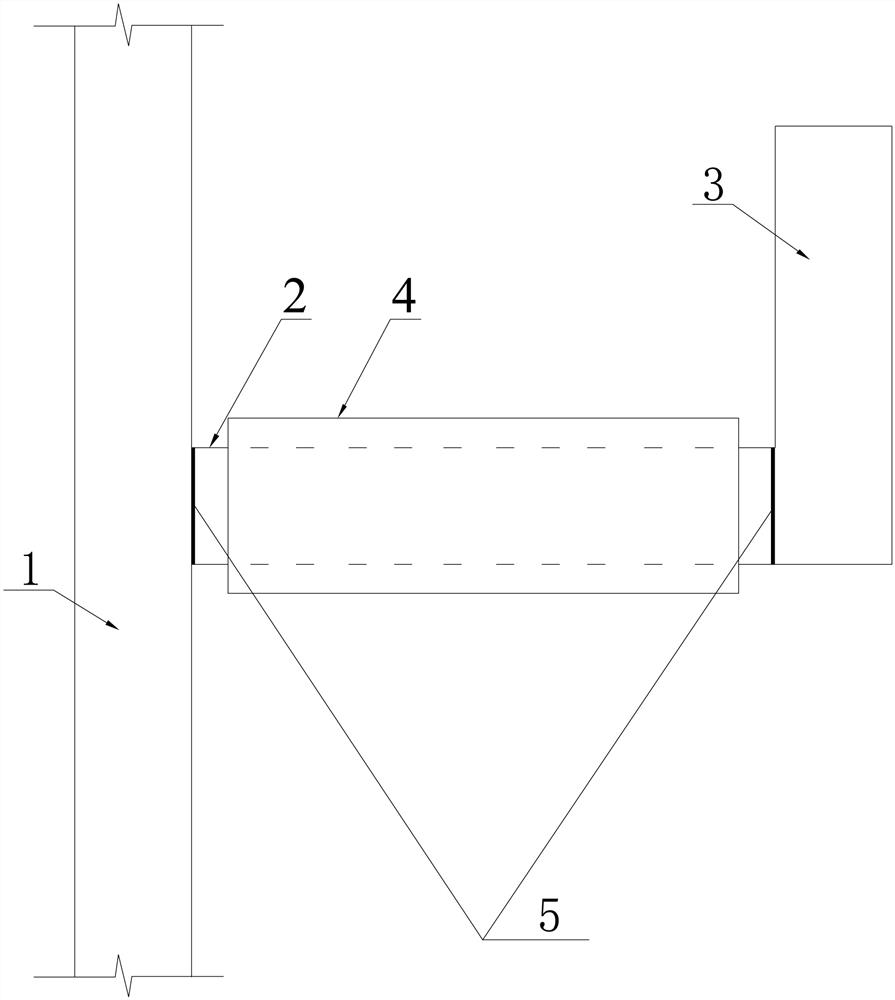

InactiveCN108585329AAvoid generatingOptimized structural formWater treatment parameter controlWater treatment compoundsOzone generatorUltraviolet

The invention discloses a UV / O3 / H2O2 advanced oxidation reactor and process. The UV / O3 / H2O2 advanced oxidation reactor comprises a water inlet pipe, a water outlet pipe, an ultraviolet reactor, an H2O2 adding facility and an O3 adding facility, wherein the ultraviolet reactor adopts a down-inlet up-outlet prancing type structure; a plurality of ultraviolet lamp groups are embedded in the ultraviolet reactor; the ultraviolet lamp groups and a partition plate are arranged at a certain angle; the water inlet pipe is connected with a water inlet formed in the lower part of the ultraviolet reactor;the water outlet pipe is connected with a water outlet is formed in the upper part of the ultraviolet reactor; a connection pipeline of the water inlet pipe is provided with the H2O2 adding facilityand the O3 adding facility; after raw water is pressurized, H2O2 with a certain concentration is added through the H2O2 adding facility, and ozone which is prepared by an ozone generator and has a certain concentration is added through a water injector and then enters into the ultraviolet reactor. According to the UV / O3 / H2O2 advanced oxidation reactor and the process disclosed by the invention, separate and united operations of three advanced oxidation ways including UV / O3, O3 / H2O2 and UV / H2O2 can be realized, the oxidation efficiency is improved, and a technological operation is more flexible.

Owner:SHANDONG WATER & WASTEWATER MONITORING CENT

Electromagnetic stirring auxiliary argon arc welding repairing method for cast magnesium alloy aviation component

InactiveCN107511569ALow melting pointReduce intensityWelding/soldering/cutting articlesWelding accessoriesElectromagnetic stirringArc welding

The invention relates to an electromagnetic stirring auxiliary argon arc welding repairing method for a cast magnesium alloy aviation component, and belongs to the technical field of argon arc welding. According to the method, for the cast magnesium alloy aviation component which is cracked and corroded and has other defects after servicing, a welding stick made of the same parent metal or similar components is selected, reasonable electromagnetic stirring and argon arc welding repairing technology parameters are adopted, and cracks and corrosive defects on the component are repaired, wherein the phi of the welding stick ranges from 1.0 mm to 1.6 mm. The repaired part deformation is in the tolerance range, the defects of cracks and incomplete fusion are avoided, and a repairing connector with few metallurgy defects and excellent performance is formed.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

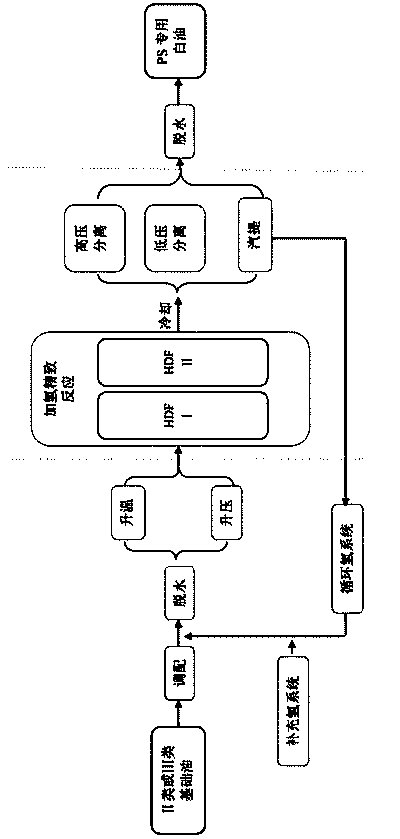

Production method of polyolefin white oil

ActiveCN104232159ALow viscosityGuaranteed hydrogenation effectTreatment with hydrotreatment processesPolyolefinFixed bed

The invention discloses a production method of polyolefin white oil. The production method comprises the following steps: (1) by taking paraffin and naphthene based lubricating base oil as raw material oil, blending the paraffin and naphthene based lubricating base oil, and dehydrating; (2) inputting the processed raw material oil into two tandem fixed bed reactors with noble metal catalysts, and performing two-section high-pressure hydrogenation treatment in the presence of a hydrorefining catalyst; and (3) dehydrating and refining to obtain the high-viscosity food-grade polyolefin white oil. The production method has the beneficial effects that the reaction temperature can be reduced, the degradation of the raw material viscosity during hydrorefining can be reduced, and the hydrogenation effect of the high-viscosity white oil can be ensured; the change of pour points and flash points can be reduced; the requirements of saturated aromatic hydrocarbons can be met; the strict requirements of the polyolefin white oil on the water content can be met; a process is flexible to perform and the polyolefin white oil is strong in market adaptability.

Owner:BEIJING YOUGONG SCI & TECH

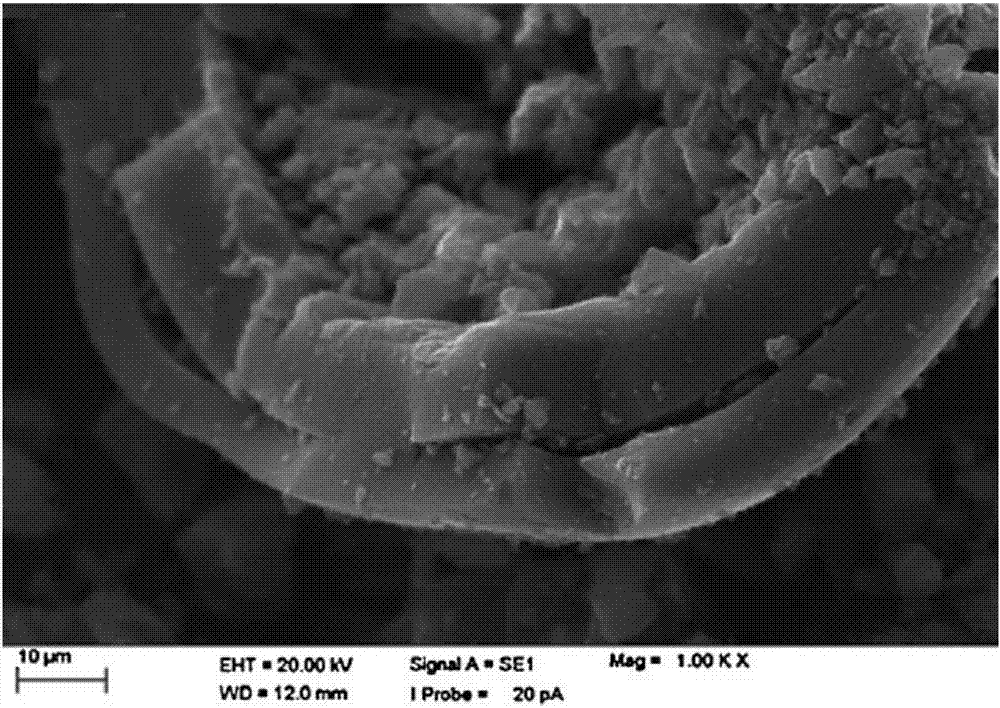

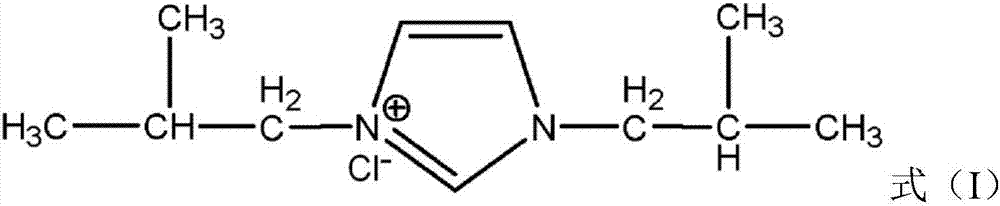

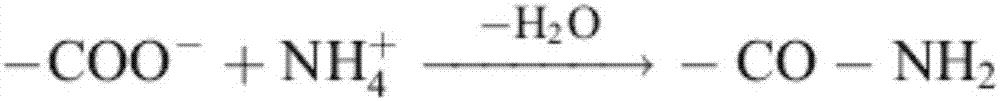

Oxygen-free steam carbonization method for cotton straws

InactiveCN106865543ARich pore structureImprove fertilizer efficiencyCarbon compoundsOrganic fertilisersWater vaporCarbonization

The invention provides an oxygen-free steam carbonization method for cotton straws. The method comprises the following steps: cutting the cotton straws into section materials, immersing the cotton straw section materials in an NH4Cl solution, taking out the immersed cotton straw section materials, draining off the section materials, putting the drained-off cotton straw section materials into a container, carrying out steam heating for carbonization, cooling to room temperature, washing and drying, thus obtaining biomass charcoal. The biomass charcoal obtained through the method is large in specific surface area, good in pore structure and high in organic carbon content, and has a good improvement effect when used for soil improvement.

Owner:北京联绿生态环境有限公司

Method for preparing chrome tanning agent from waste chrome tanning liquid

ActiveCN104498648AImprove performanceContribute to resource utilizationTanning treatmentSodium acetateSolid content

The invention discloses a method for preparing a chrome tanning agent from a waste chrome tanning liquid. The method is characterized by comprising the following steps: collecting the waste chrome tanning liquid after tanning is completed, precipitating chrome by using alkali, and performing plate-frame pressure filtration to obtain chrome cakes; performing acidolysis on the chrome cakes by using sulfuric acid, cooling, filtering to obtain filtrate, adjusting the pH value to 2.0-2.5, separating by using a cation-exchange chromatography, measuring the content of the component chrome, adding corresponding parts of sodium formate and sodium acetate according to the contents of negative and neutral components, dissolving, boiling to concentrate until the final solid content is up to 50%, cooling for one hour, separating by using the cation-exchange chromatography, measuring the content of the component chrome, performing aging reaction for 4-7 days according to the contents of the negative and neutral components until the contents of the negative and neutral components are up to 75-84%, diluting for 6 times with water, adjusting the pH value to be 3.8-4.0, placing to stand for 6 hours until the contents of the negative and neutral components are 40-50%, and the content of a high electric charge component with the valence greater than +4 is 17-22%. The method for preparing the chrome tanning agent from the waste chrome tanning liquid is simple and flexible to operate, high in yield, excellent in property of the tanning agent, and applicable to tanning of first-layer high-class leather and second-layer leather of cattle, sheep, pigs and the like.

Owner:SICHUAN UNIV

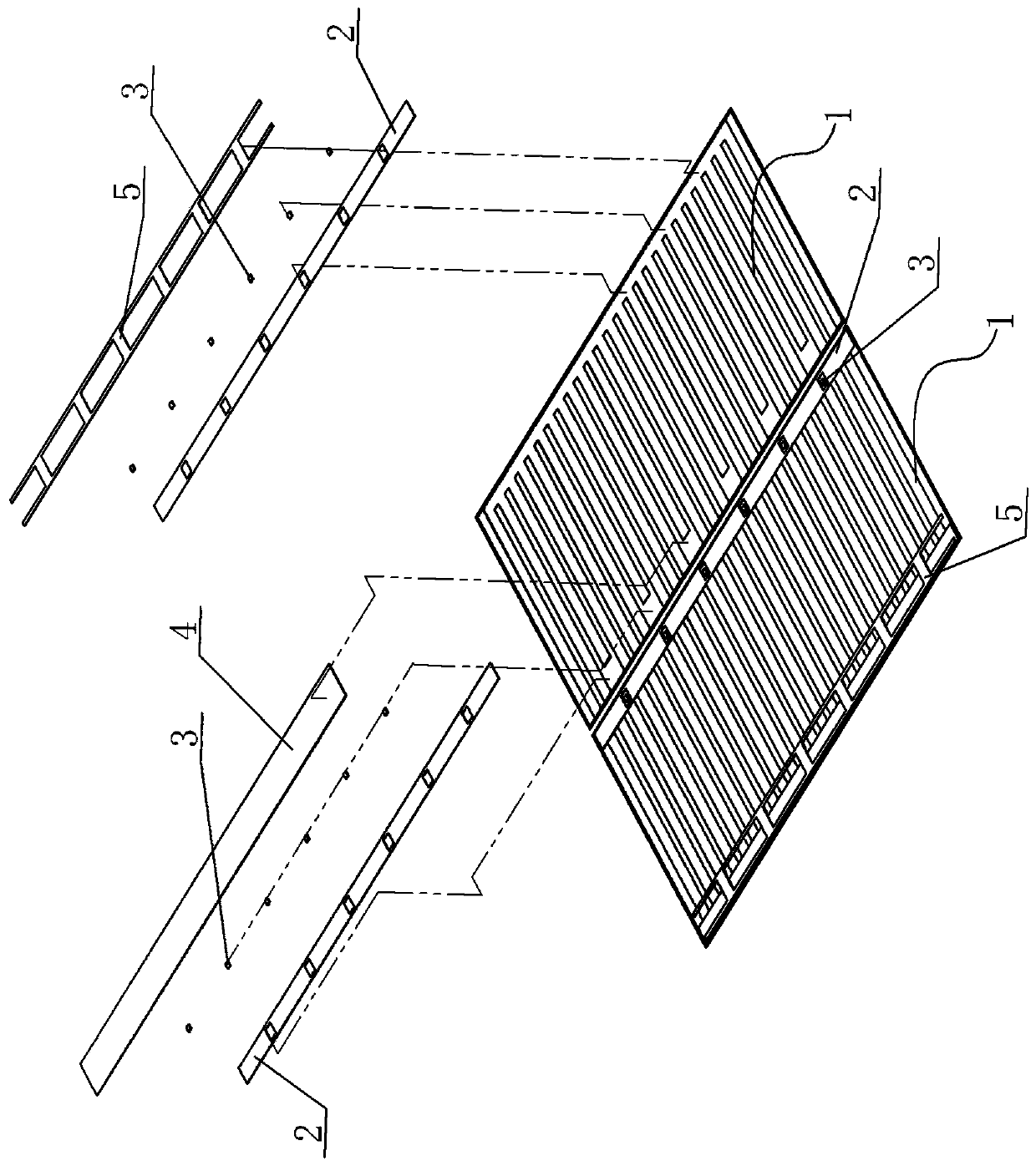

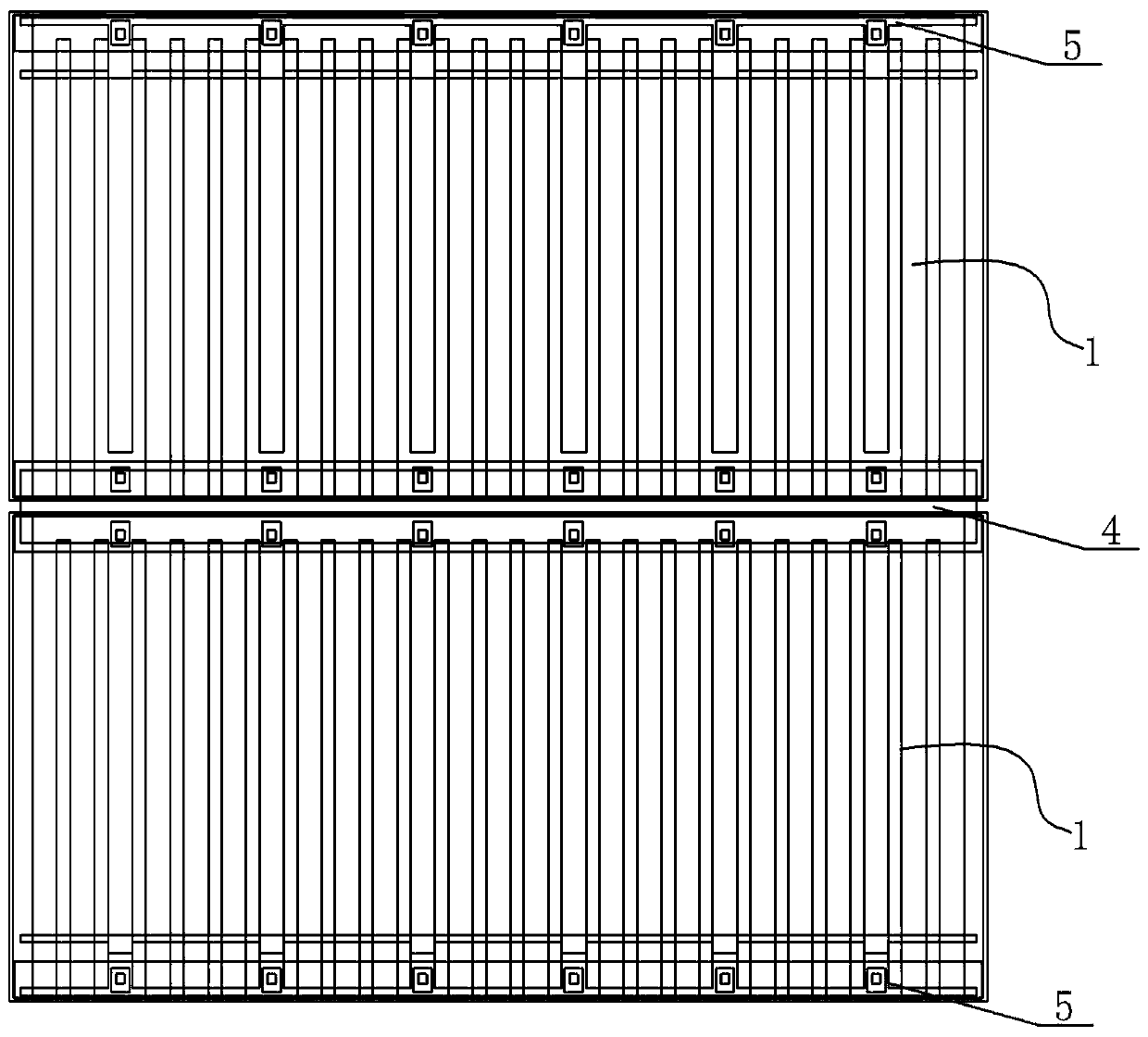

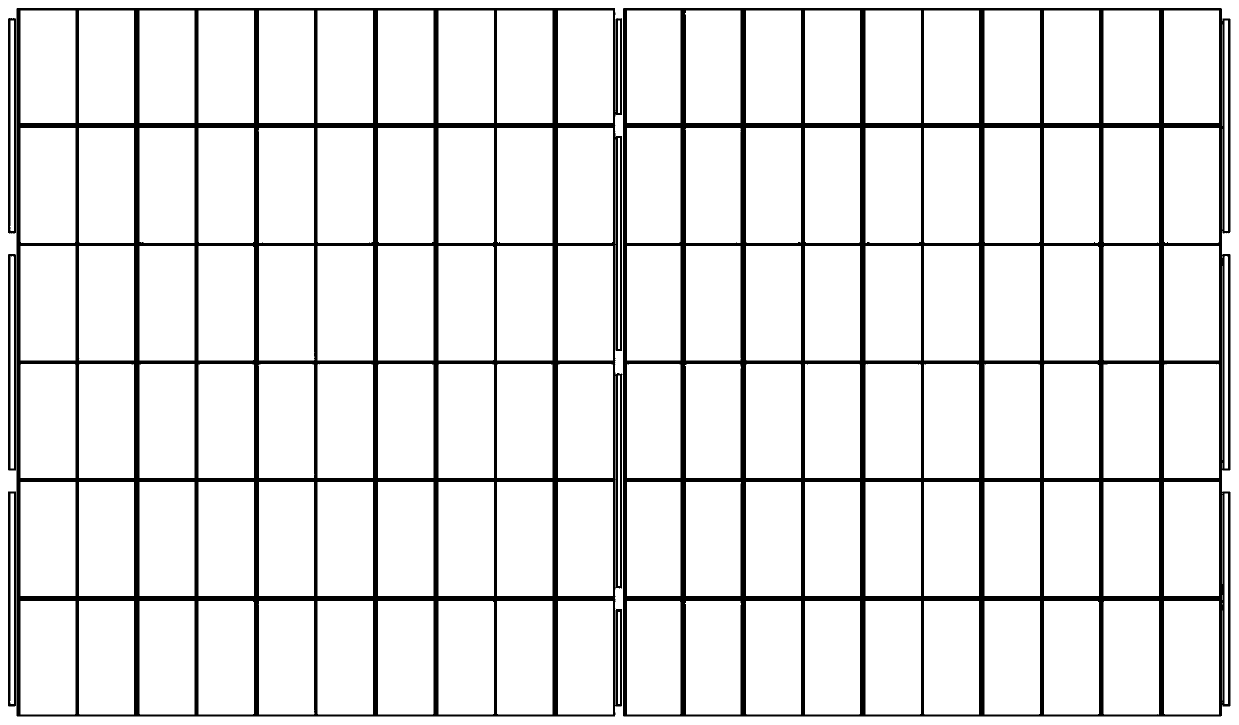

Manufacturing process of IBC battery assembly

ActiveCN110676336AGuaranteed power generation efficiencyStable productionPhotovoltaic energy generationSemiconductor devicesElectrical batteryEngineering

The invention provides a manufacturing process of an IBC battery assembly. The manufacturing process improves the assembly efficiency of the battery assembly, ensures the yield and further ensures thepower generation efficiency of IBC battery pieces. The process comprises the following specific steps: S1,carrying out laser cutting: firstly, carrying out laser cutting on a whole battery piece, andforming (n-1) laser scratches on the battery piece to make the battery piece divided into n small battery pieces; S2, coating insulating glue : presetting a certain number of extraction electrodes onareas arranged along the length direction at the two sides of each of the n small battery pieces, and meanwhile, coating the peripheries of the extraction electrodes with insulating glue; S3, curingthe insulating glue: curing the battery pieces coated with the insulating glue; S4, coating solder paste: coating the solder paste at the positions of the corresponding preset extraction electrodes onthe small battery pieces; S5, arranging the battery pieces: arranging the small battery pieces in a positive-negative series connection manner; S6, placing a series solder strip; and S7, welding thesolder strip: welding the solder strip and the solder paste at the corresponding positions to conduct the solder strip and the solder paste.

Owner:SUZHOU AUTOWAY SYST

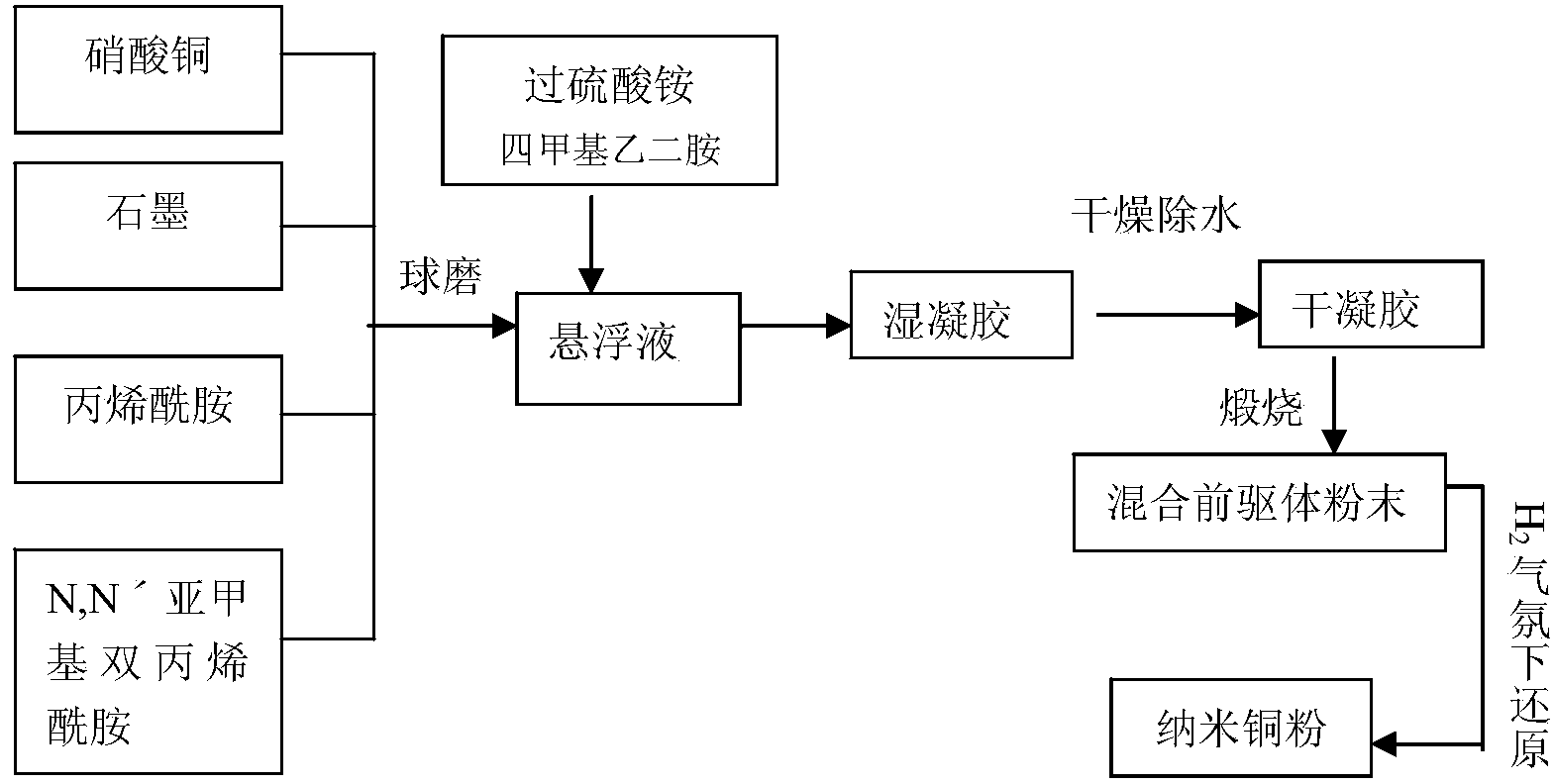

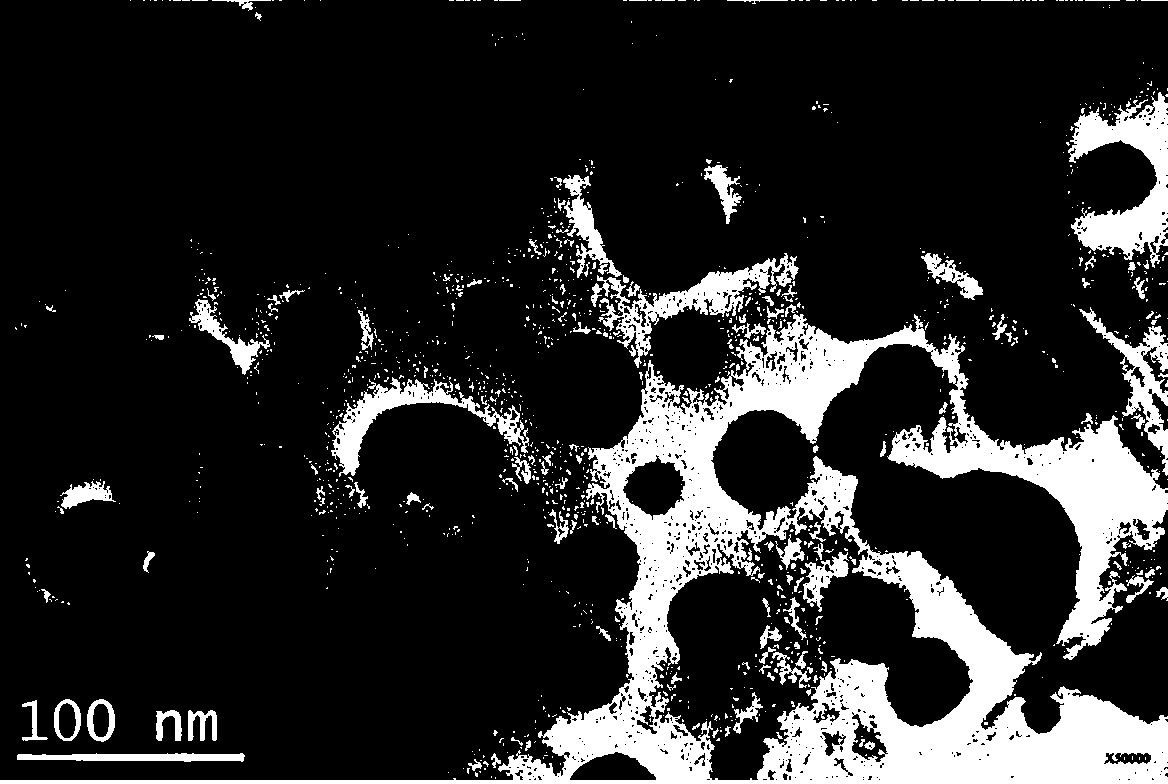

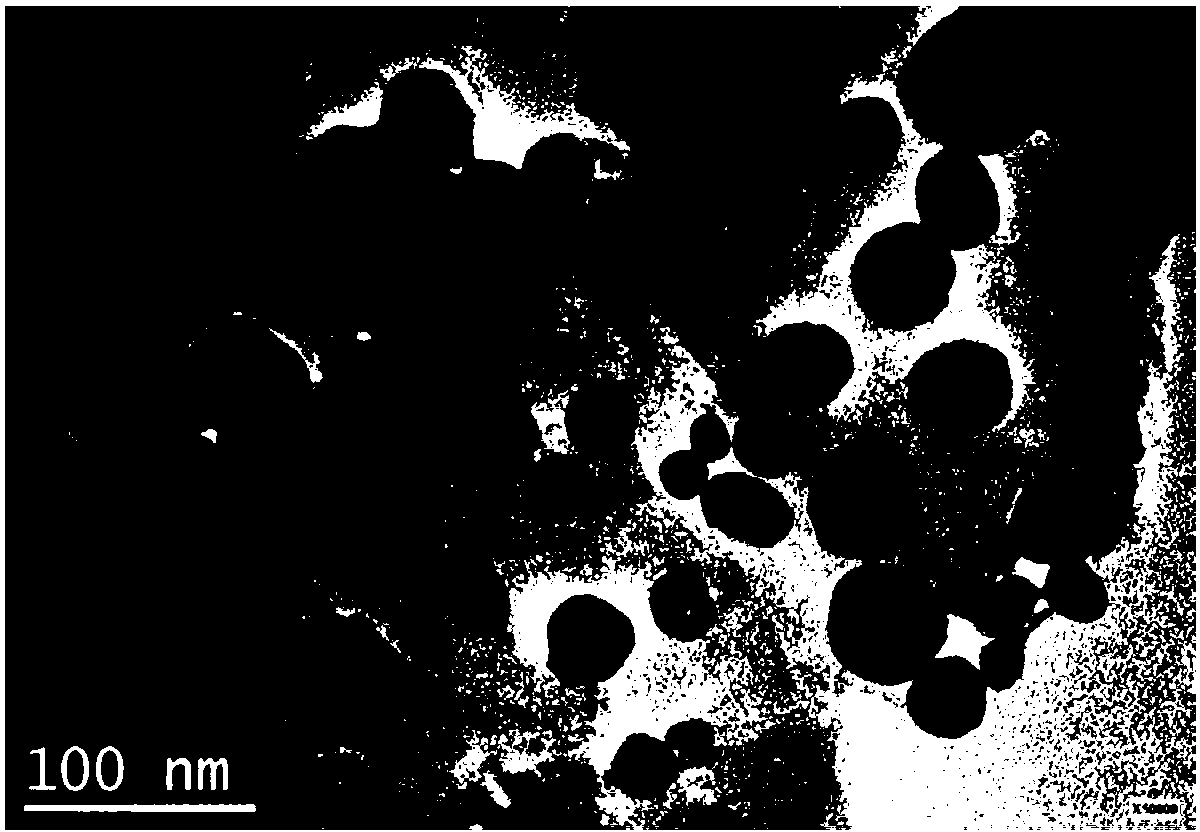

Preparing method for nano-copper powder

ActiveCN103752841ARaw materials are cheap and easy to obtainFlexible process operationChemistryGraphite

The invention discloses a preparing method for nano-copper powder. The preparing method for the nano-copper powder is characterized by comprising the following steps that a mixture composed of copper nitrate and graphite serves as a raw material, the raw material is added into an organic monomer solution, suspension liquid is obtained through ball milling, and then the suspension liquid is gelatinized under the action of an initiating agent and a catalyst to obtain wet gel; the wet gel is dried to obtain dried gel; the dried gel is calcined to obtain hybrid precursor powder composed of copper dioxide and copper; reduction is performed on the hybrid precursor powder in a hydrogen gas atmosphere to obtain the nano-copper powder. According to the preparing method for the nano-copper powder, required raw materials are low in price and easy to obtain, the process is simple, the protection condition of high pressure or inert atmosphere in the reaction process is not required, the method does not have special requirements for a reaction device, production cost is greatly lowered, and therefore the method is applicable to industrial production. The productive rate of the nano-copper powder manufactured through the method is high and can reach more than 96 percent, and the obtained product is of a similar spherical shape and has the advantages that the degree of purity is high, the range of particle size distribution is narrow, agglomeration does not exist, and dispersity is good.

Owner:HEFEI UNIV OF TECH

Preparation method of moderately-dried solid microbial fermented livestock fodder

The invention discloses a preparation method of a moderately-dried solid microbial fermented livestock fodder. The preparation method of the moderately-dried solid microbial fermented livestock fodder provided by the invention comprises the following steps: drying a fodder directly prepared by solid microbial fermentation to enable the water content of the fodder to be 16%-22% so as to obtain the solid microbial fermented livestock fodder, wherein a fluidized drying mode is adopted preferably. The invention also discloses the solid microbial fermented livestock fodder produced according to the method. According to the method disclosed by the invention, the technological operation is simple, convenient and flexible, the equipment investment is low, and the produced solid microbial fermented livestock fodder can satisfy the requirements on market circulation time, also can adapt to changes of various storage environment conditions, and especially can adapt to the changes of seasons and site environments, so that the solid microbial fermented livestock fodder is suitable for popularization and application in the vast rural areas of China.

Owner:CHINA AGRI UNIV

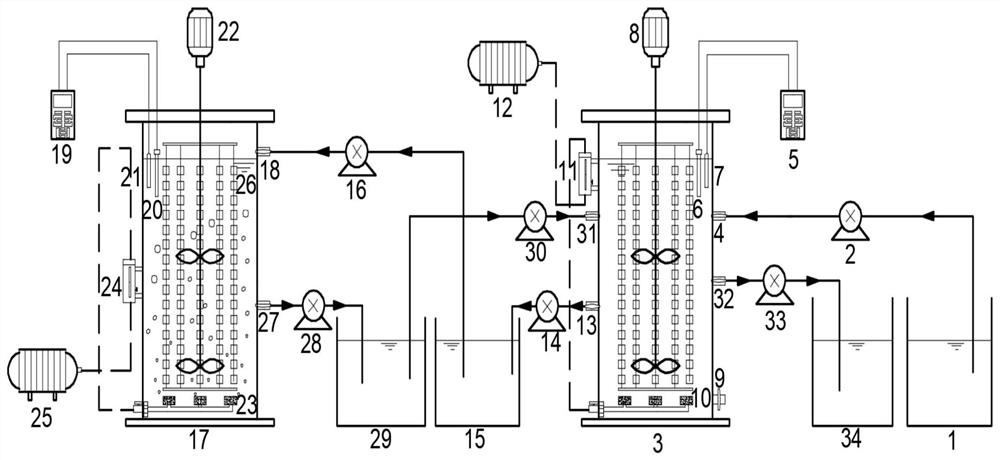

Short-cut nitrification and anaerobic ammonia oxidation integrated-endogenous short-cut denitrification and anaerobic ammonia oxidation integrated domestic sewage treatment process

PendingCN112250181AFlexible process operationEasy to operateWater treatment compoundsWater contaminantsEnvironmental chemistryCarbon source

The invention discloses a short-cut nitrification and anaerobic ammonia oxidation integrated-endogenous short-cut denitrification and anaerobic ammonia oxidation integrated domestic sewage treatment process and belongs to the field of biological sewage treatment. Involved devices mainly comprise a water inlet tank, a first SBBR, a second SBBR, two middle water tanks and a water outlet tank. Domestic sewage firstly enters the first No.1 SBBR for anaerobic stirring to store an internal carbon source; an effluent enters a the second SBBR for synchronous short-cut nitrification anaerobic ammonia oxidation reaction, most ammonia nitrogen is removed, and nitrate nitrogen and nitrogen are generated; and then the effluent enters the first SBBR again for synchronous endogenous short-cut denitrification anaerobic ammonia oxidation reaction to generate a small amount of nitrate nitrogen and nitrogen. Advantages of organic matters in the domestic sewage and the anaerobic ammonia oxidation reactionare fully utilized, high efficiency and energy saving are realized, and deep denitrification of the domestic sewage can be realized.

Owner:BEIJING UNIV OF TECH

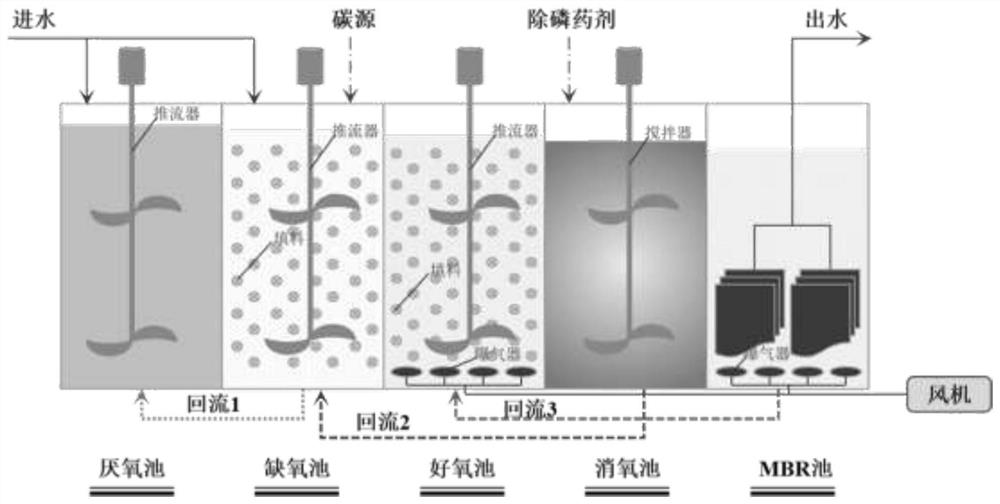

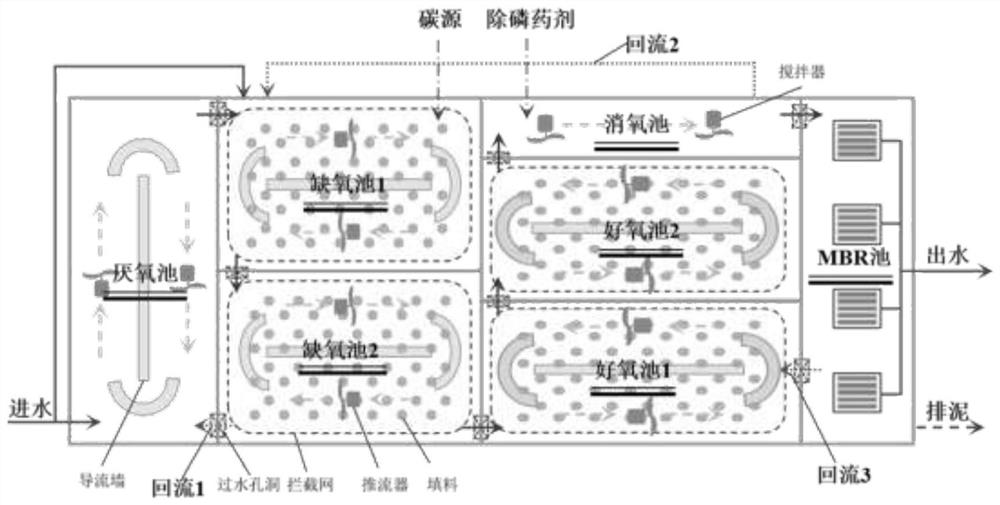

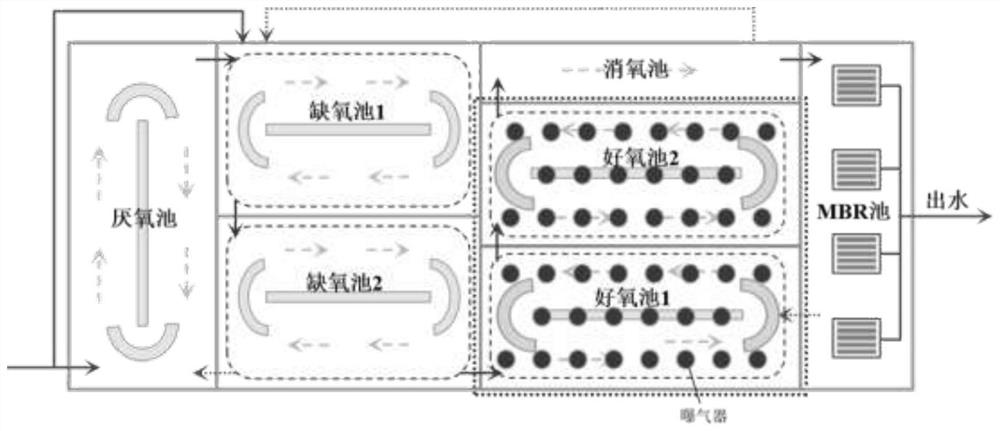

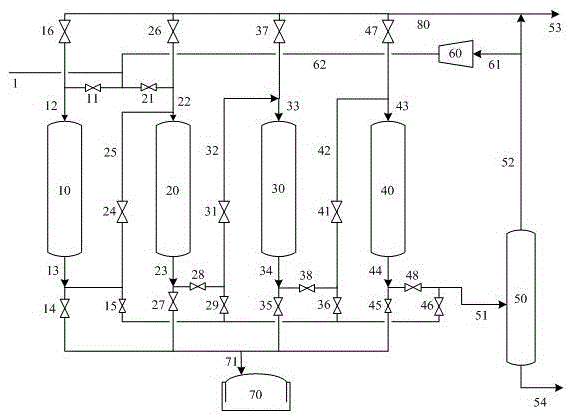

Urban sewage plant upgrading and reconstruction treatment process and system

PendingCN112110615AFlexible process operationImprove stabilityWater treatment parameter controlTreatment with aerobic and anaerobic processesEnvironmental chemistryCarbon source

The invention discloses an urban sewage plant upgrading and reconstruction treatment process and system, and belongs to the technical field of sewage treatment. The system consists of an anaerobic tank, an anoxic tank, an aerobic tank, an oxygen elimination tank and an MBR tank, an internal carbon source in inlet water can be fully utilized for denitrification through sectional water inlet, and reflux liquid obtained after oxygen elimination of the oxygen elimination tank does not contain dissolved oxygen so that the carbon source in the anoxic tank only supplies denitrifying bacteria for denitrification; the tail end of the anoxic tank flows back to the anaerobic tank so that a single anaerobic phosphorus release reaction is carried out in the anaerobic zone, and denitrifying bacteria andphosphorus-accumulating bacteria do not compete for organic matters. Phosphorus release in the anaerobic zone and denitrification in the anoxic zone are carried out respectively and do not influenceeach other. The process can stably reach the standard IV water standards (COD is less than 30mg / L, BOD is less than 6mg / L, NH4 + -N is less than 1.5 (2.5) mg / L, TN is less than 15mg / L, TP is less than0.3 mg / L and SS is less than 5mg / L).

Owner:北京安国水道自控工程技术有限公司

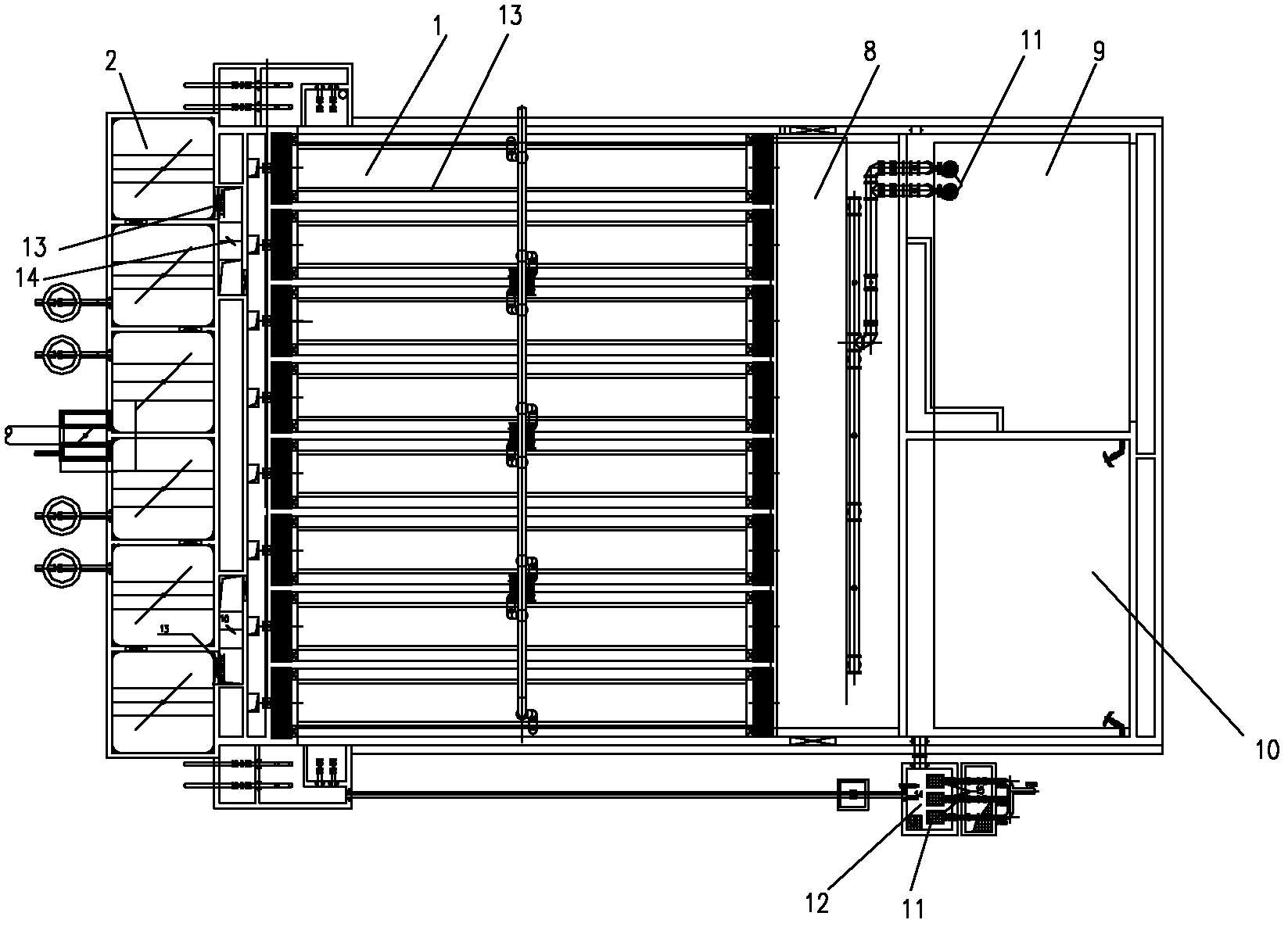

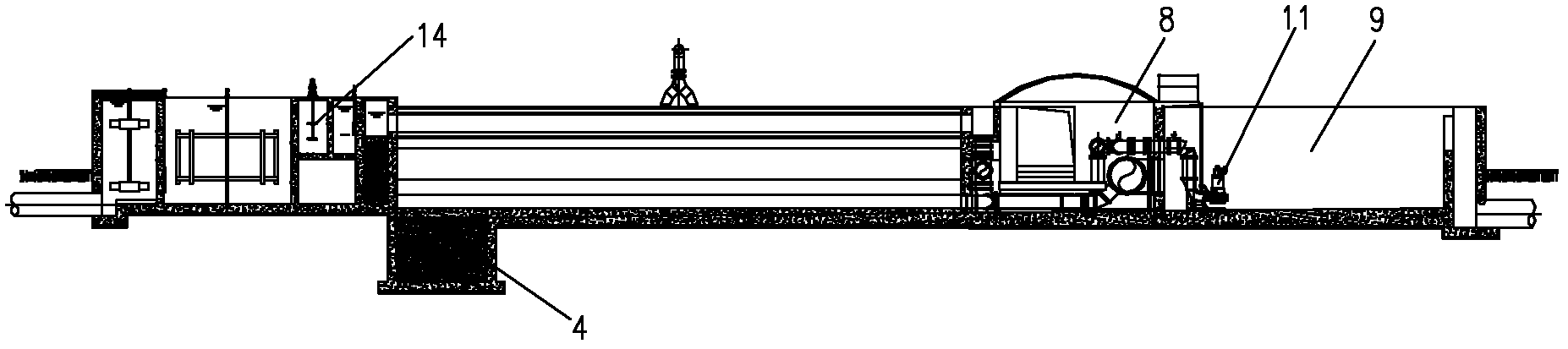

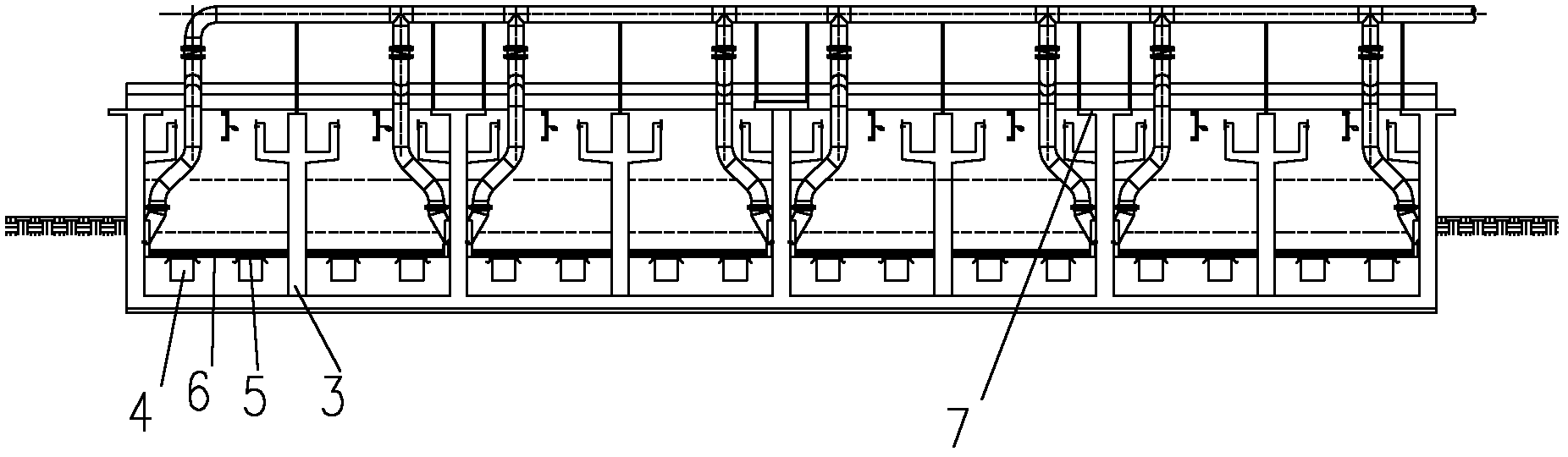

Denitrified deep bed biological filter tank

ActiveCN102491512BIncrease lossPrevents affecting backwash frequencyWaste based fuelTreatment with anaerobic digestion processesFlocculationWater volume

The invention relates to a denitrified deep bed biological filter tank, which comprises a tank body of a flocculation sedimentation tank which is divided into four groups of sedimentation tanks. The invention is characterized in that tank walls are additionally installed at the central position of the front part of each group of the sedimentation tank to form eight groups of filter tanks, a collecting tank is provided at the bottom of the filter tank, a cover plate is provided on the collecting tank, an interval part capable of penetrating water is provided between the cover plate and the collecting tank, an aeration head and an aeration pipe are uniformly distributed on the cover plate, a gas and water distribution block is additionally installed on the aeration pipe, a distribution tank is additionally installed at the upper part of each group of the filter tank. The invention has the advantages that the land occupation is less, the filter tank can be taken as the deep bed filter tank or the denitrified deep bed biological filter tank for removing SS, TN and TP. According to the invention, the gas and water distribution is employed; the water distribution and the gas distribution are uniform, maintenance-free for lifetime in the filter tank is provided. The water volume for backwashing is little with 4% and no exceeding of 2% generally. The filling material uses quartz sand which possesses hard quality, no loss or damage can be generated, no replacement is required. The standard of urban reclaimed water can be reached, and the water from the filter tank of the invention can be reused as wash water for plant area greening and road flushing.

Owner:天津泰达新水源科技开发有限公司

Water-based paint wastewater treatment device

PendingCN109422413AReduce loadImprove biodegradabilitySludge treatment by de-watering/drying/thickeningWater treatment compoundsSequencing batch reactorMoving bed biofilm reactor

The invention discloses a water-based paint wastewater treatment device which is characterized in that a pipeline is sequentially connected with a water collecting tank, a pH adjusting tank, a coagulating sedimentation tank, an advanced oxidation tank, an UASB (upflow anaerobic sludge blanket), a SBR (sequencing batch reactor), a MBBR (moving bed biofilm reactor) and a water production tank; aftersludge generated in each stage is treated, filtrate flows back, and mud cakes are transported outwards. By adopting the technical scheme, the water-based paint wastewater treatment device disclosed by the invention, after water-based paint wastewater is subjected to pH adjustment, coagulating sedimentation and advanced oxidation, and is sequentially treated by the UASB, the SBR and the MBBR, discharged water can be discharged or recycled, the production cost is reduced, the environmental pollution is reduced, and water resources are saved.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Device and method for continuously synthesizing sulfolene

The invention relates to a device and a method for continuously synthesizing sulfolene. The process comprises the following steps: continuously putting a butadiene raw material, a polymerization inhibitor and a sulfur dioxide raw material into a reaction kettle A and a reaction kettle B according to a proportion to carry out a synthesis reaction, controlling a reaction mixture through a back pressure valve, and putting a sulfolene product into a blow-off tank after primary flash evaporation and secondary flash evaporation; introducing synthesis tail gas into a condenser and a freezing tank through a buffer tank for cryogenic recovery and then recycling. The continuous synthesis process of sulfolene, provided by the invention, has the advantages of low equipment investment, flexible processoperation, high product yield, effective recycling of raw materials, and reduced production cost. In addition, the exhaust emission is reduced and clean production is realized.

Owner:PETROCHINA CO LTD

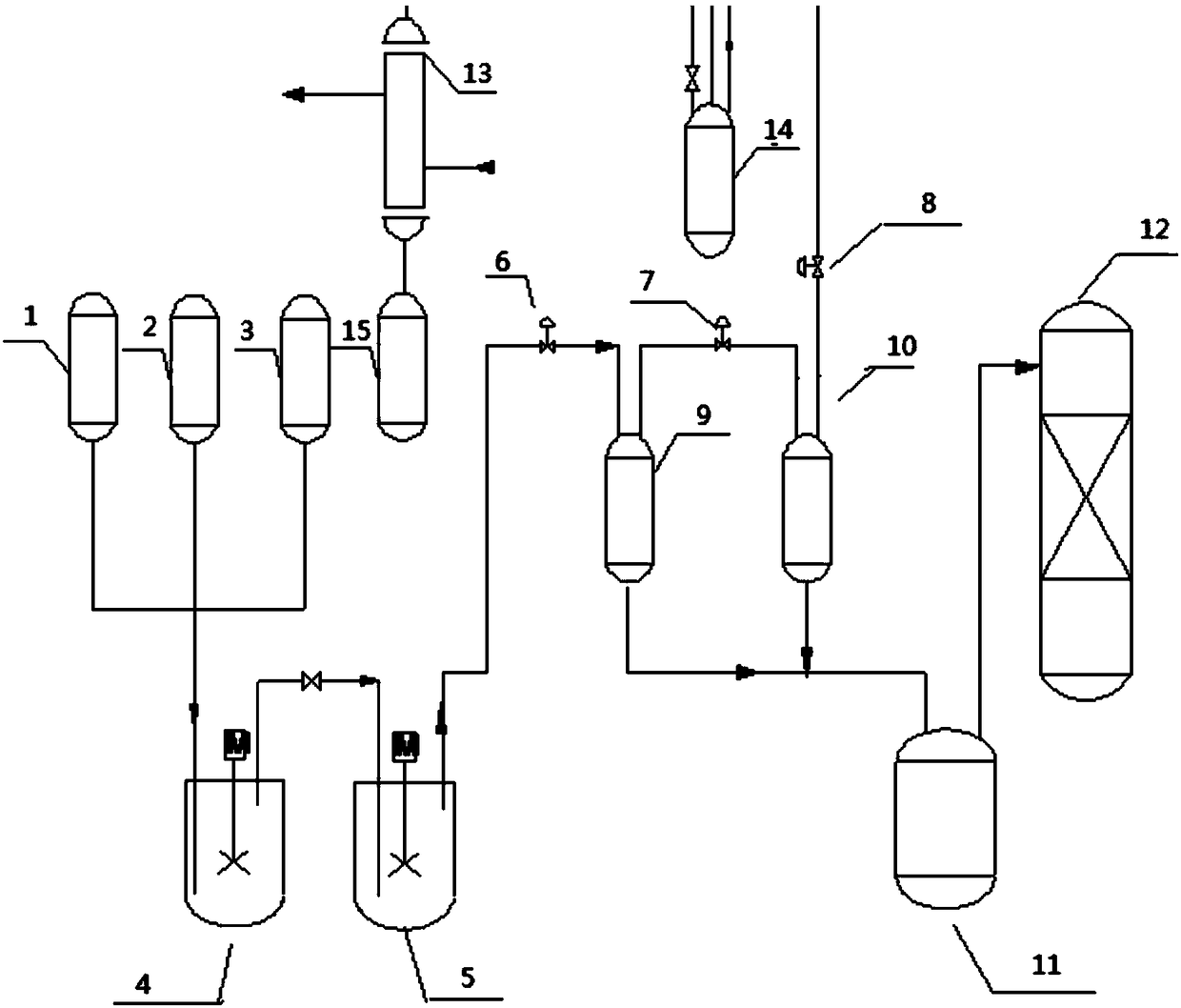

Leather printing paste and preparation method thereof

The invention relates to a leather printing paste and its preparation method. The leather printing paste is a combined two-component polyurethane resin printing paste containing epoxy polyurethane resin and amino-polyurethane resin. The epoxy polyurethane resin and the amino-polyurethane resin are mixed and heated to react so as to form a good network structure. The prepared leather printing paste has good heat resistance and cold resistance. In addition, the leather printing paste has good elasticity and feels soft and smooth. The leather printing paste is water-tolerant and solvent resistant, and has excellent dry and wet rubbing fastness.

Owner:LIAONING FIXED STAR FINE CHEM

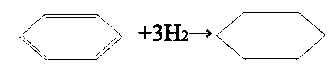

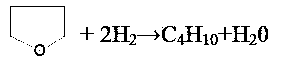

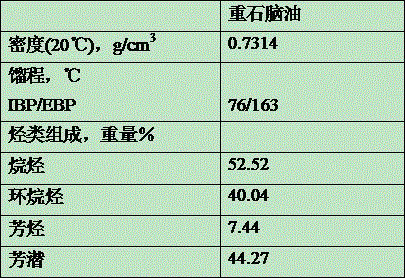

Naphtha catalytic reforming method of by-product reduction hydrogen

ActiveCN106753548AHigh hydrogenolysis activityMeet the needs of starting workNaphtha treatmentHydrocarbon oils treatment productsRheniumCatalytic reforming

The invention discloses a naphtha catalytic reforming method of by-product reduction hydrogen. When a reforming apparatus is normally operated, a random reforming reactor is cut, a platinum rhenium catalyst in the reactor is subjected to regeneration processing; then the reduced reforming catalyst has high hydrogenolysis activity, the reforming hydrogen obtained by the other reactor is processed, the contained C2<+> hydrocarbon is subjected to hydrogenolysis to carbon and methane, volume content of C2<+> in hydrogen storage is greatly reduced, and the requirement of commencement of works of the reforming catalyst is satisfied. Compared with the prior art, disadvantages of the low octane number of the gasoline obtained by catalytic reforming due to low temperature hydrogen storage, usage amount of C2<+> hydrocarbon used for active carbon adsorption, and low equipment utilization rate are overcome, and the method has the characteristic of flexible process operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

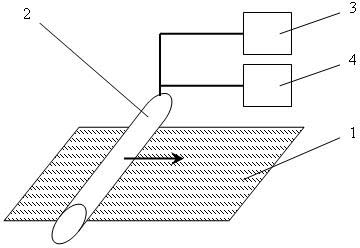

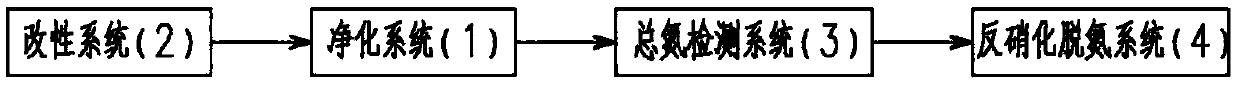

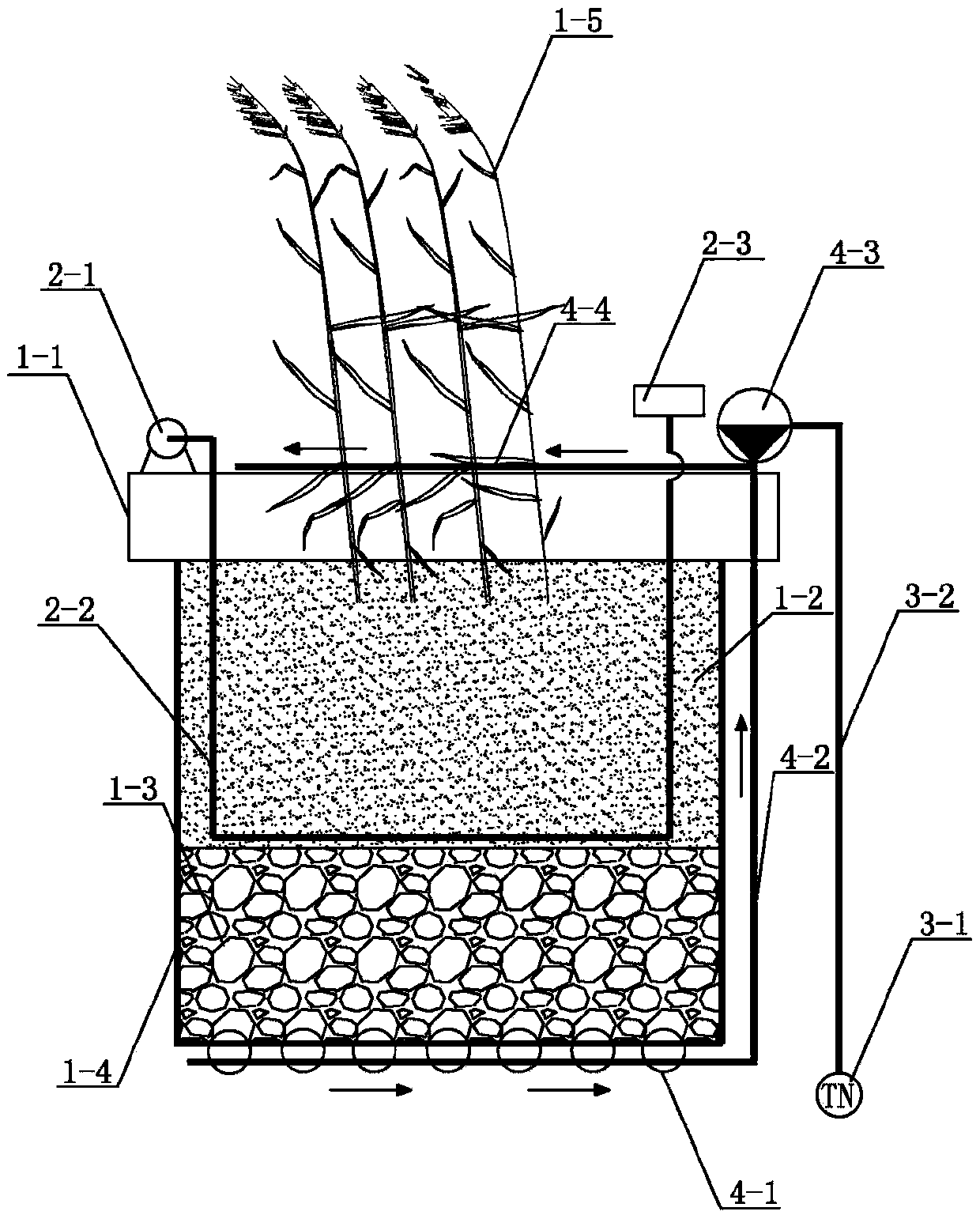

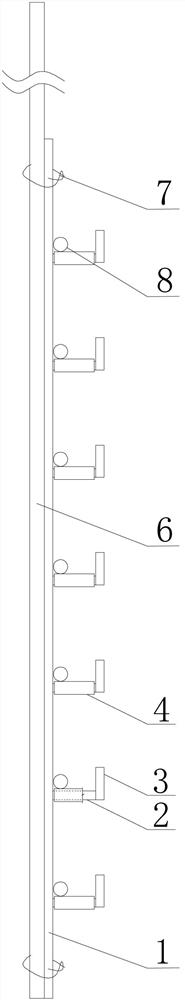

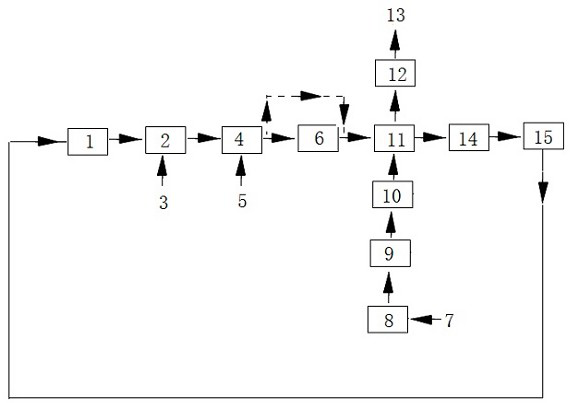

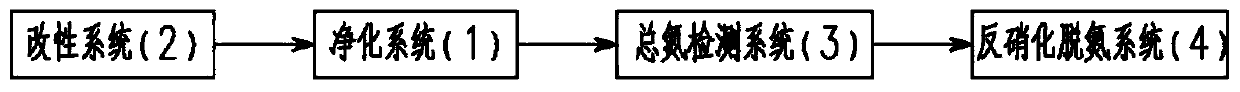

Automatic efficient purification system for total nitrogen of water and method of automatic efficient purification system

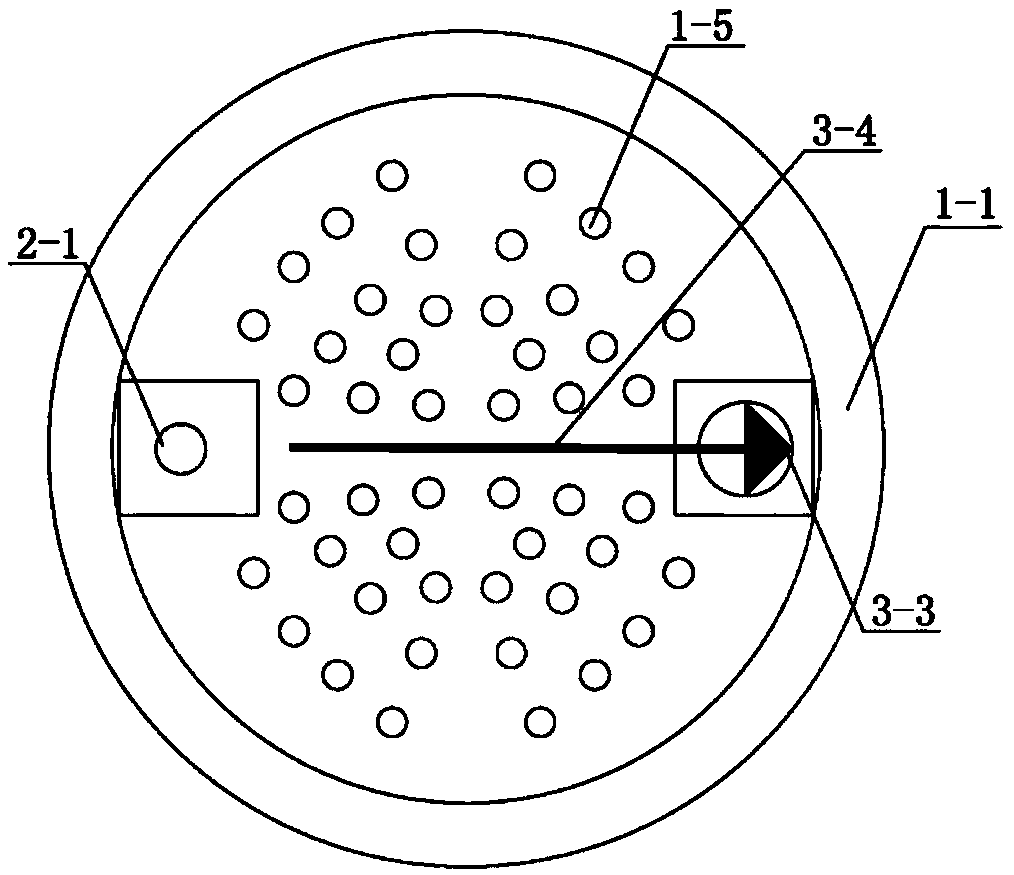

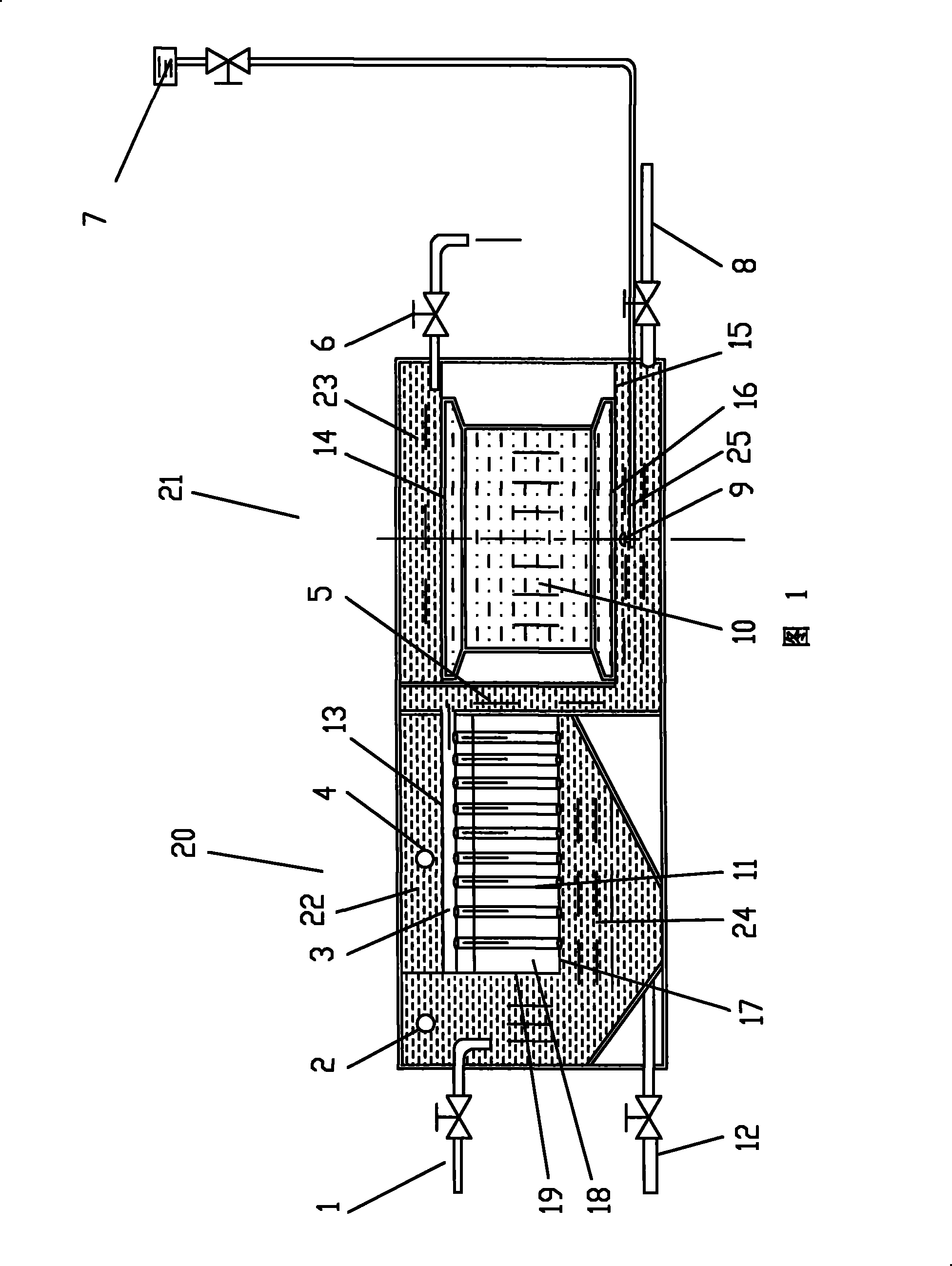

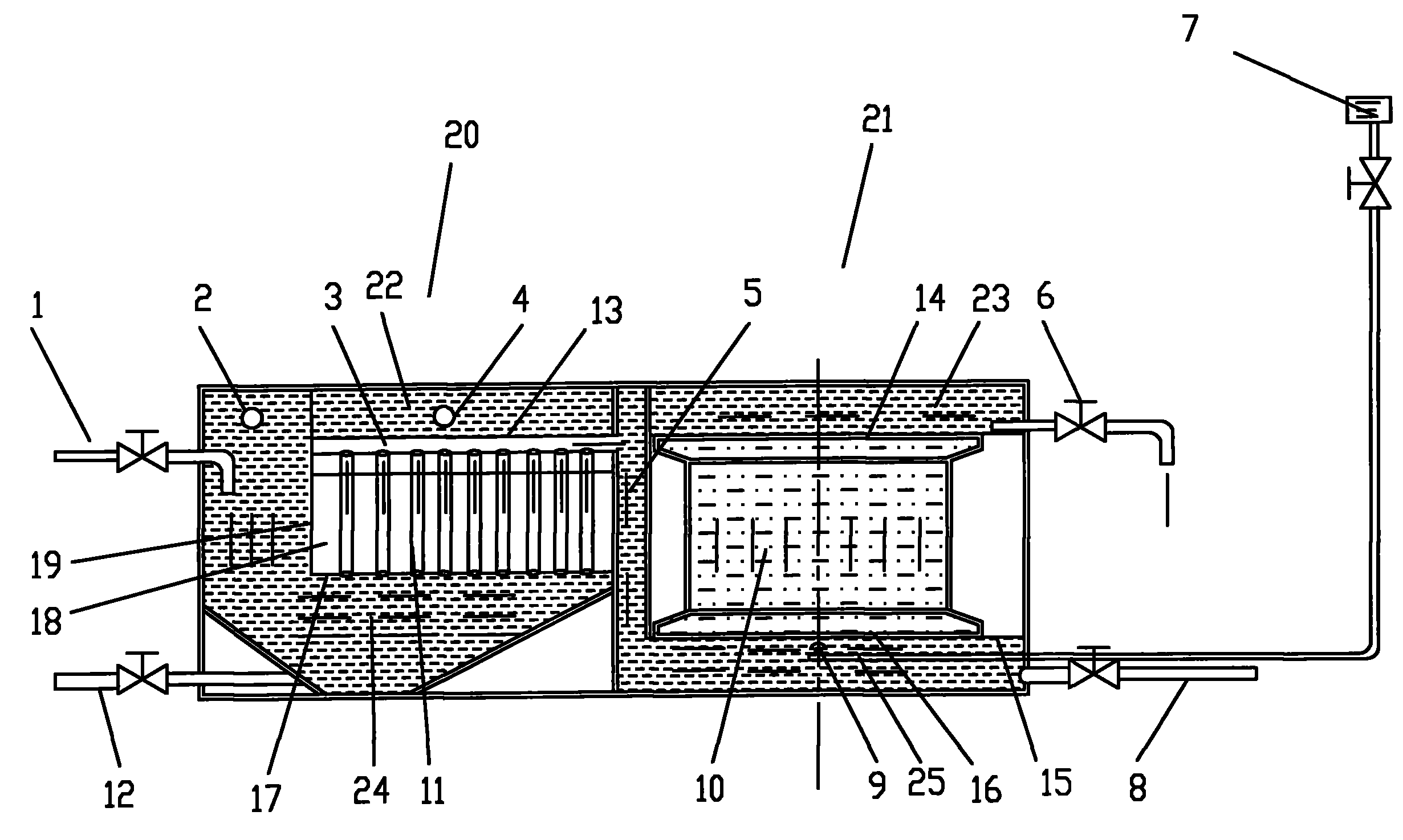

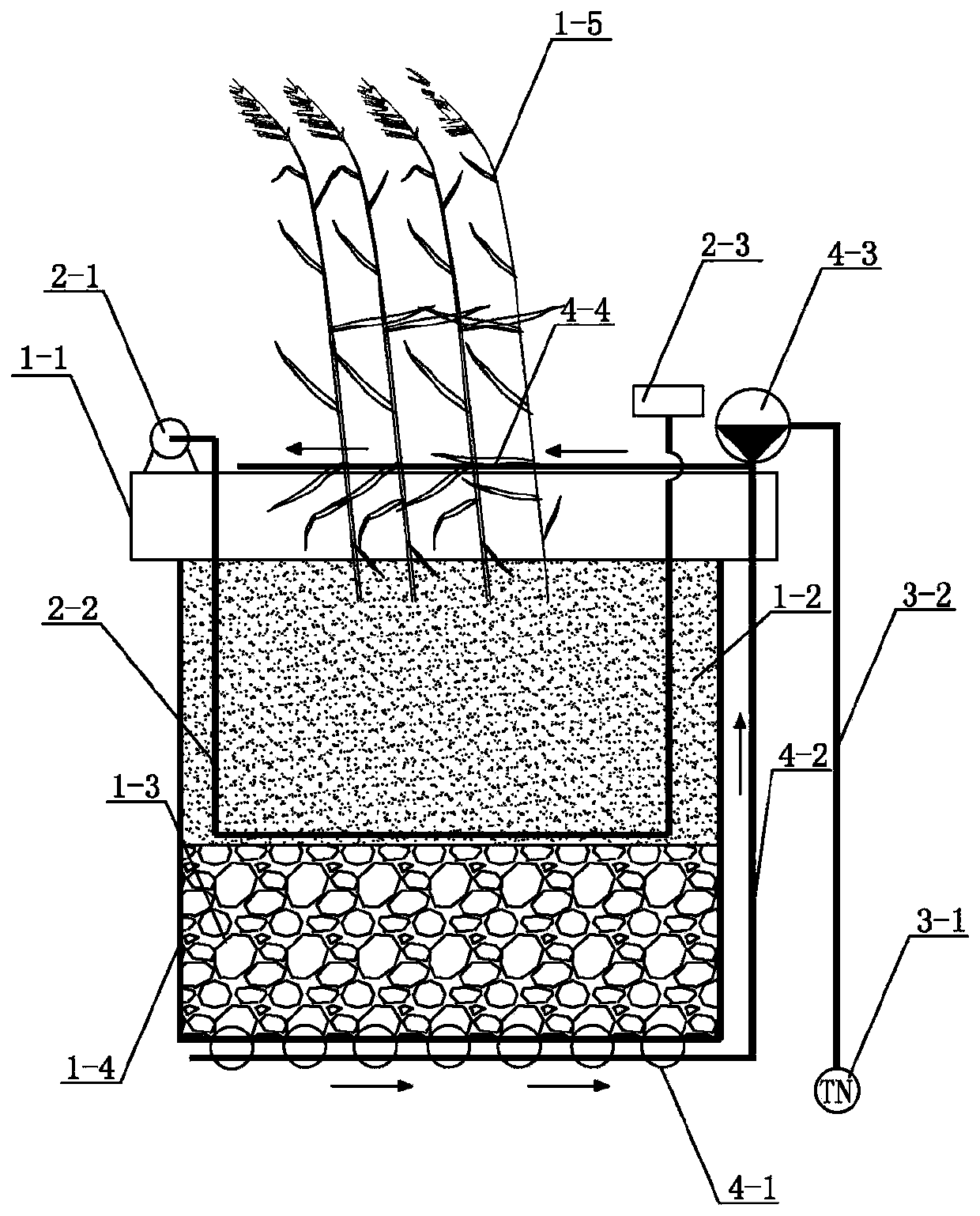

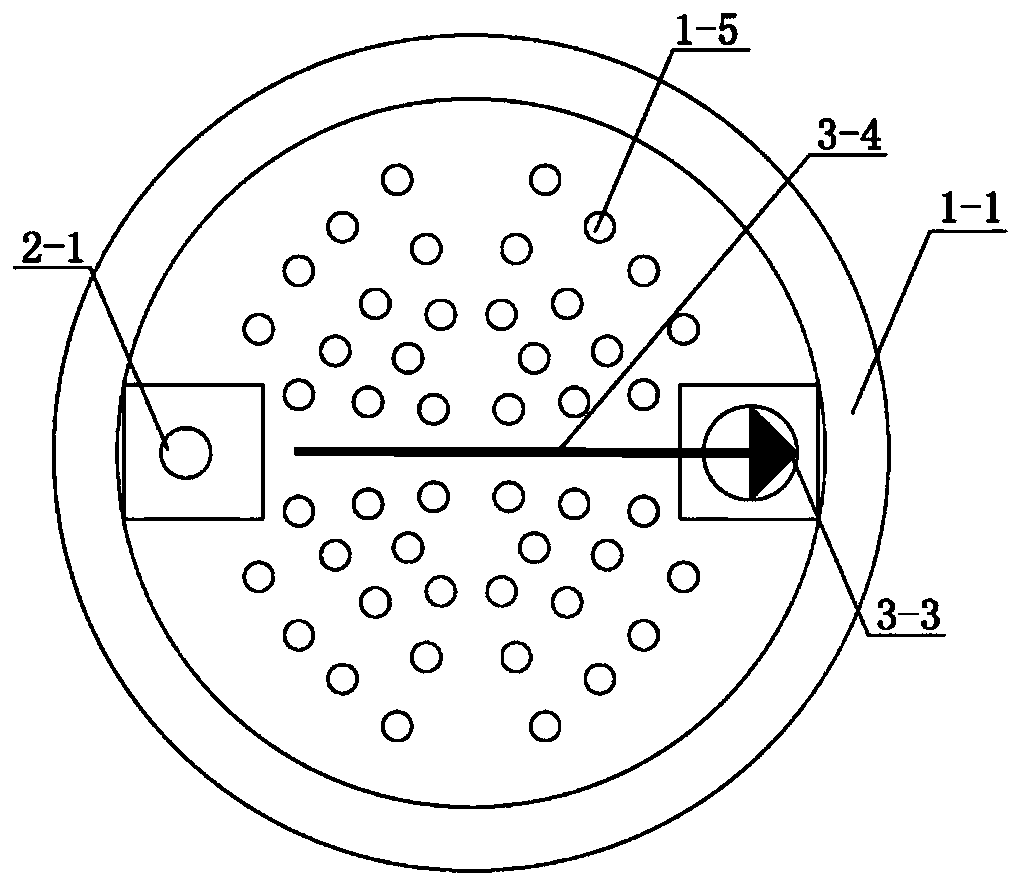

ActiveCN109250822AImprove nitrogen removal efficiencyPromote nitrificationWater treatment parameter controlBiological treatment apparatusTotal nitrogenTherapeutic effect

The invention discloses an automatic efficient purification system for total nitrogen of water and a method of the automatic efficient purification system. The system comprises a purification system (1), a modification system (2), a total nitrogen detection system (3) and a denitrification system (4), wherein the purification system (1), the total nitrogen detection system (3) and the denitrification system (4) are sequentially connected, and the modification system (2) is connected to the purification system (1); the purification system (1) is used for supplying oxygen to microbes on a biochar matrix by using plant root system action and improving nitrification. The modification system (2) is used for carrying out aeration modification on the biochar matrix (1-2) through an aeration pump(2-1), so as to improve the microbial activity of the biochar matrix (1-2). The total nitrogen detection system (3) is used for monitoring total nitrogen in water, and the denitrification system (4) is started up to perform refluxing when the total nitrogen exceeds a set standard value, so as to improve hydraulic conditions and improve a denitrification effect. The system and the method are high in denitrification efficiency, good in treatment effect, small in investment and low in operating cost, biochar is subjected to resource-converting utilization, and in-situ purification does not need afloor area.

Owner:HOHAI UNIV

Micro-aerated biological filter

InactiveCN101597120BAvoid easy cloggingSmall footprintTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentDraining tubeBiological filter

The invention relates to an organic waste water treatment technology, in particular to a micro-aerated biological filter. According to the technical proposal provided by the invention, the micro-aerated biological filter comprises a first filter and a second filter, which is characterized in that: the first filter is thereon provided with a sewage import pipe and is internally provided with a filter chamber which is vertically provided with a plurality of bamboo tubes which are parallel to each other, the bottom end of each bamboo tube is communicated with the bottom of the first filter, and the top end of each bamboo tube is communicated with an overflow tank of the first filter; the second filter is internally provided with a biological bed which can be moved out or moved in, a massive filter material is placed in the biological bed, the second filter below the biological bed is internally provided with an aeration head, and the second filter above the biological bed is internally provided with a drain pipe; the second filter is internally provided with a flow guiding chamber which guides waste water to the bottom of the biological bed, and the flow guiding chamber is communicated with the overflow tank. The invention shortens biological reaction time, reduces equipment investment and simplifies operation process.

Owner:无锡强工机械工业有限公司

A method for preparing chrome tanning agent from chrome tanning waste liquor

ActiveCN104498648BImprove performancePromote resource utilizationTanning treatmentSodium acetateLiquid waste

The invention discloses a method for preparing a chrome tanning agent from a waste chrome tanning liquid. The method is characterized by comprising the following steps: collecting the waste chrome tanning liquid after tanning is completed, precipitating chrome by using alkali, and performing plate-frame pressure filtration to obtain chrome cakes; performing acidolysis on the chrome cakes by using sulfuric acid, cooling, filtering to obtain filtrate, adjusting the pH value to 2.0-2.5, separating by using a cation-exchange chromatography, measuring the content of the component chrome, adding corresponding parts of sodium formate and sodium acetate according to the contents of negative and neutral components, dissolving, boiling to concentrate until the final solid content is up to 50%, cooling for one hour, separating by using the cation-exchange chromatography, measuring the content of the component chrome, performing aging reaction for 4-7 days according to the contents of the negative and neutral components until the contents of the negative and neutral components are up to 75-84%, diluting for 6 times with water, adjusting the pH value to be 3.8-4.0, placing to stand for 6 hours until the contents of the negative and neutral components are 40-50%, and the content of a high electric charge component with the valence greater than +4 is 17-22%. The method for preparing the chrome tanning agent from the waste chrome tanning liquid is simple and flexible to operate, high in yield, excellent in property of the tanning agent, and applicable to tanning of first-layer high-class leather and second-layer leather of cattle, sheep, pigs and the like.

Owner:SICHUAN UNIV

Shear wall horizontal rib installation positioning rod and construction method

PendingCN111636692AEasy to makeCost controlBuilding material handlingArchitectural engineeringShear wall

The invention provides a shear wall horizontal rib installation positioning rod and a construction method. The shear wall horizontal rib installation positioning rod comprises a main rod, wherein a plurality of positioning cross rods are welded and fixed to the side wall of the main rod at equal intervals in the height direction of the main rod, and a limiting vertical rod is vertically welded andfixed to the top of the tail end of each positioning cross rod; and the positioning cross rods are sleeved with rotating sleeves. The positioning rod can be used for auxiliary installation of a shearwall horizontal rib, the position precision and levelness of horizontal rib installation are guaranteed, meanwhile, the installation difficulty is effectively reduced, the installation of the horizontal rib can be completed by a single person, and the labor cost of operation is reduced.

Owner:CHINA NUCLEAR IND 22ND CONSTR

Production process of vulcanization-free gas hydrogenation catalyst

ActiveCN113694940ATroubleshoot restore issuesMeet the needs of hydrogen consumptionGas treatmentDispersed particle separationPtru catalystExhaust fumes

The invention discloses a production process of a vulcanization-free gas hydrogenation catalyst. The preparation method comprises the following steps: preparing FeMo / Al2O3, CoMo / Al2O3 and NiMo / Al2O3 gas hydrogenation catalysts by an equivalent-volume impregnation method, carrying out ex-situ prevulcanization on the catalysts by adopting a limited hydrogen control circulating vulcanization process, removing H2S from sulfur discharge tail gas through Cu / C or Cu / Al2O3, emptying, and passivating after sulfur discharge is finished. The process is flexible to operate, low in hydrogen consumption, high in utilization rate of the vulcanizing agent, short in vulcanizing time and good in vulcanizing effect. In the whole ex-situ prevulcanization process, the waste gas emission amount is small, and the waste gas component is simpler than that of coke-oven gas and is easy to purify; Cu / C or Cu / Al2O3 is used as a gas mercury removal agent after being desulfurized, so that the method is green and economical.

Owner:WUHAN KELIN FINE CHEM

A system and method for automatic and efficient purification of total nitrogen in water body

ActiveCN109250822BPromote nitrificationImprove hydraulic conditionsWater treatment parameter controlBiological treatment apparatusMicroorganismPlant roots

The invention discloses an automatic efficient purification system for total nitrogen of water and a method of the automatic efficient purification system. The system comprises a purification system (1), a modification system (2), a total nitrogen detection system (3) and a denitrification system (4), wherein the purification system (1), the total nitrogen detection system (3) and the denitrification system (4) are sequentially connected, and the modification system (2) is connected to the purification system (1); the purification system (1) is used for supplying oxygen to microbes on a biochar matrix by using plant root system action and improving nitrification. The modification system (2) is used for carrying out aeration modification on the biochar matrix (1-2) through an aeration pump(2-1), so as to improve the microbial activity of the biochar matrix (1-2). The total nitrogen detection system (3) is used for monitoring total nitrogen in water, and the denitrification system (4) is started up to perform refluxing when the total nitrogen exceeds a set standard value, so as to improve hydraulic conditions and improve a denitrification effect. The system and the method are high in denitrification efficiency, good in treatment effect, small in investment and low in operating cost, biochar is subjected to resource-converting utilization, and in-situ purification does not need afloor area.

Owner:HOHAI UNIV

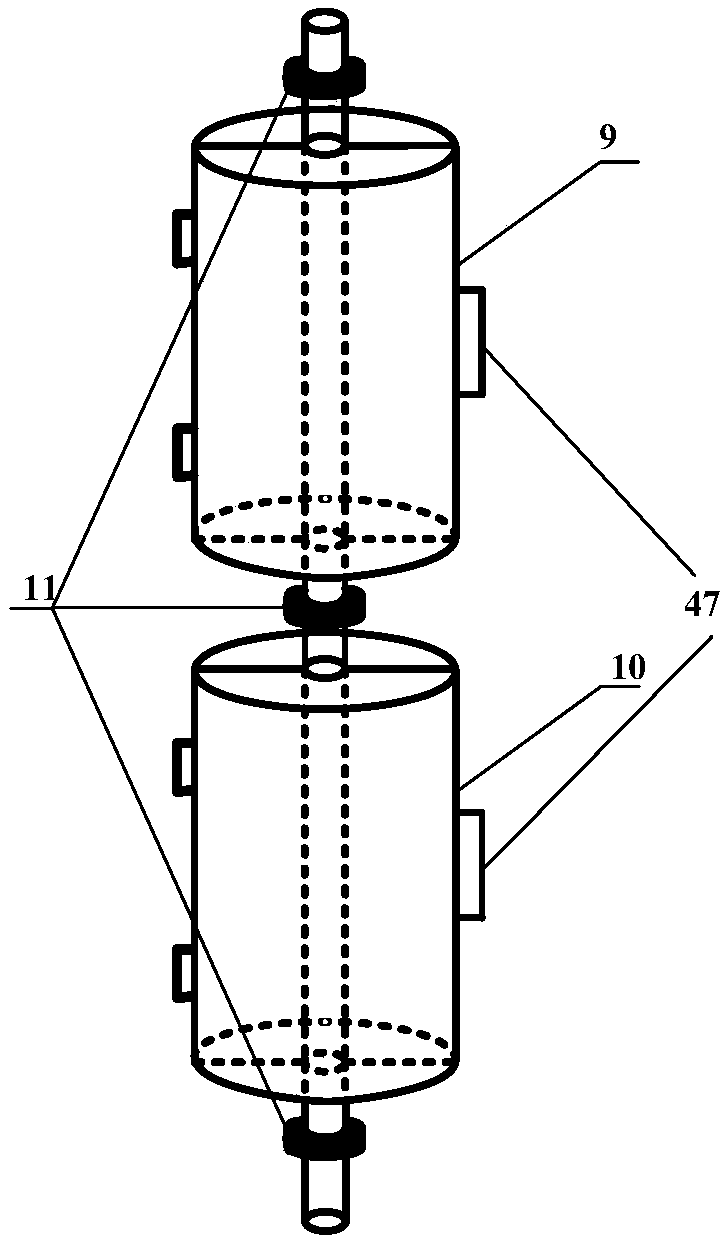

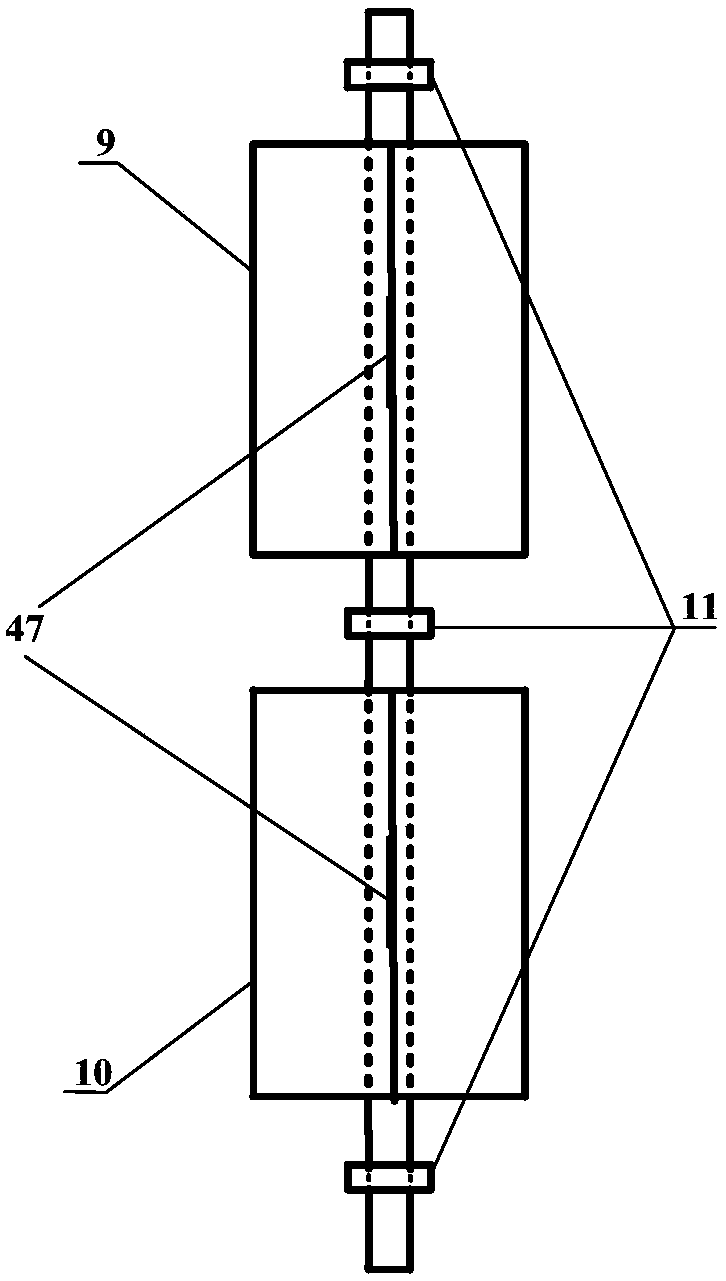

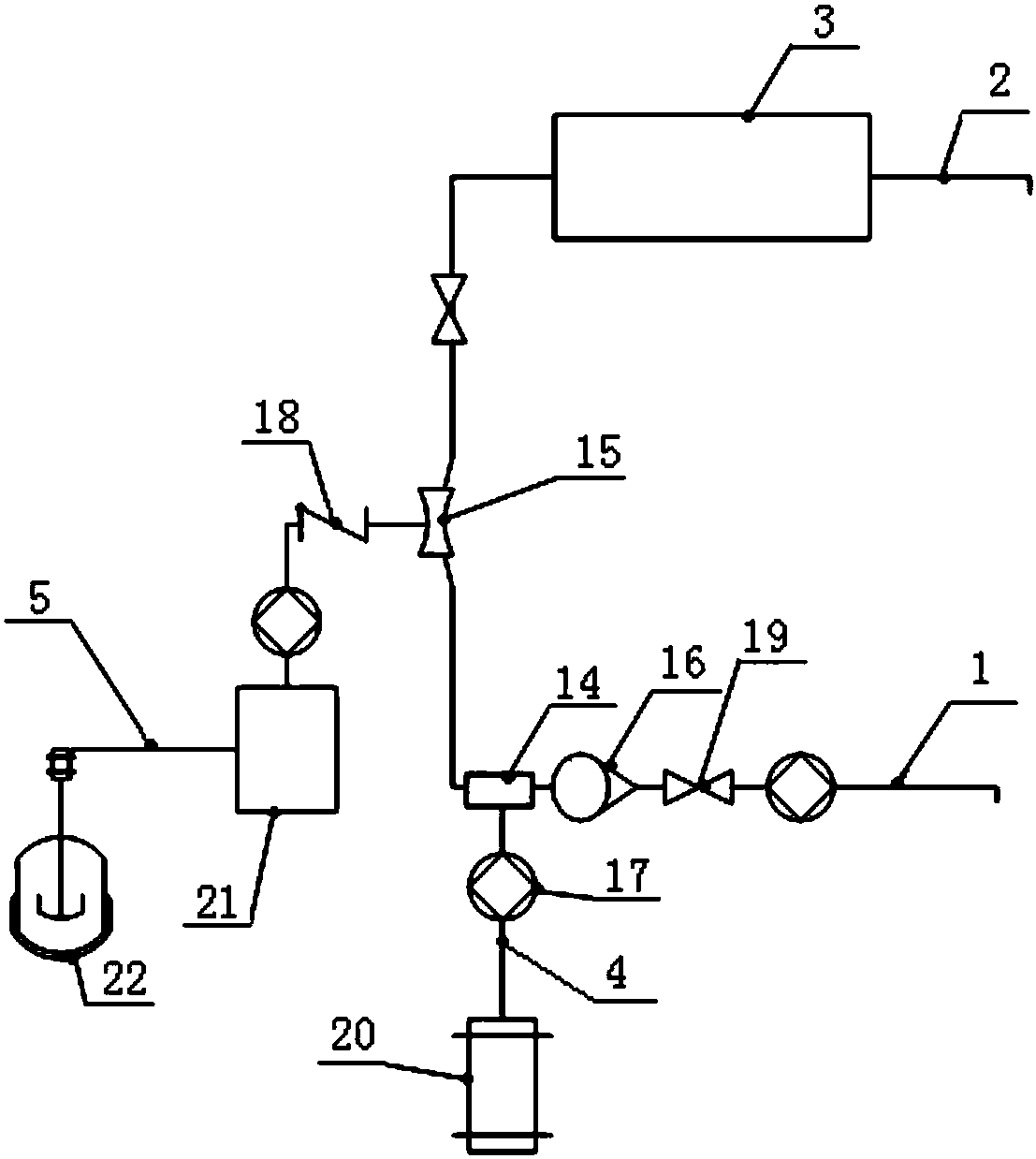

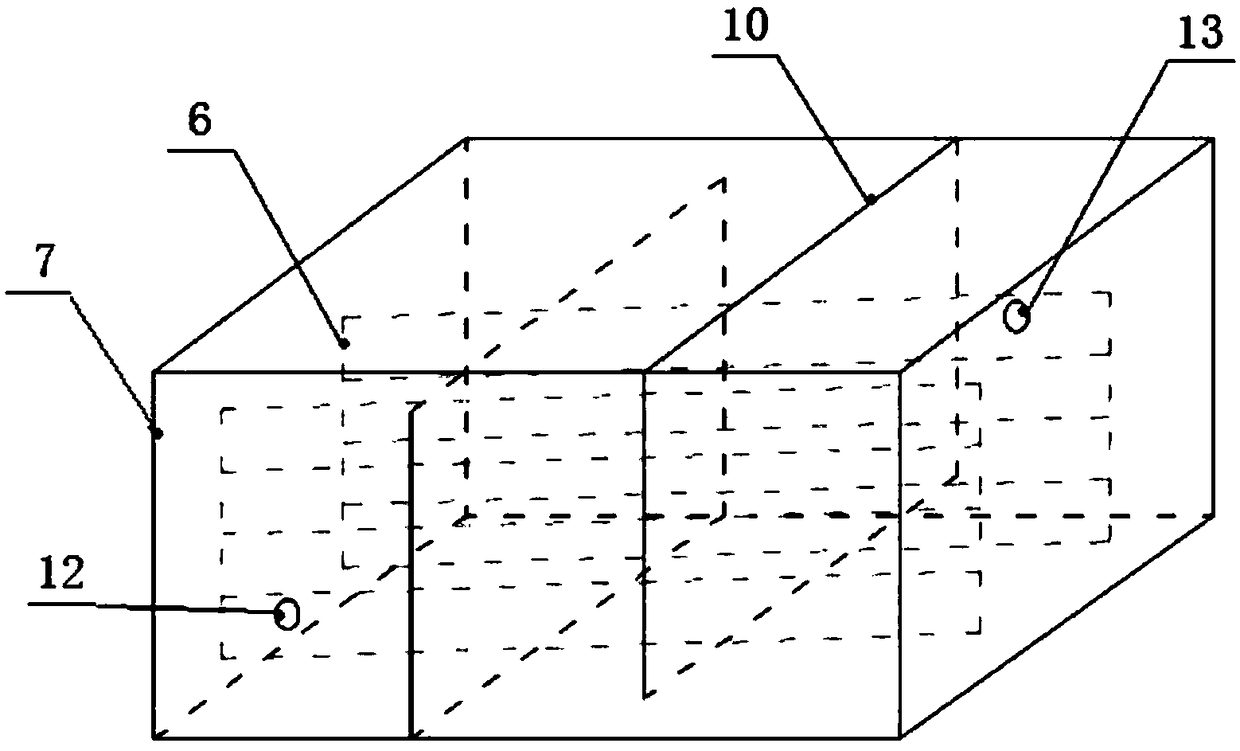

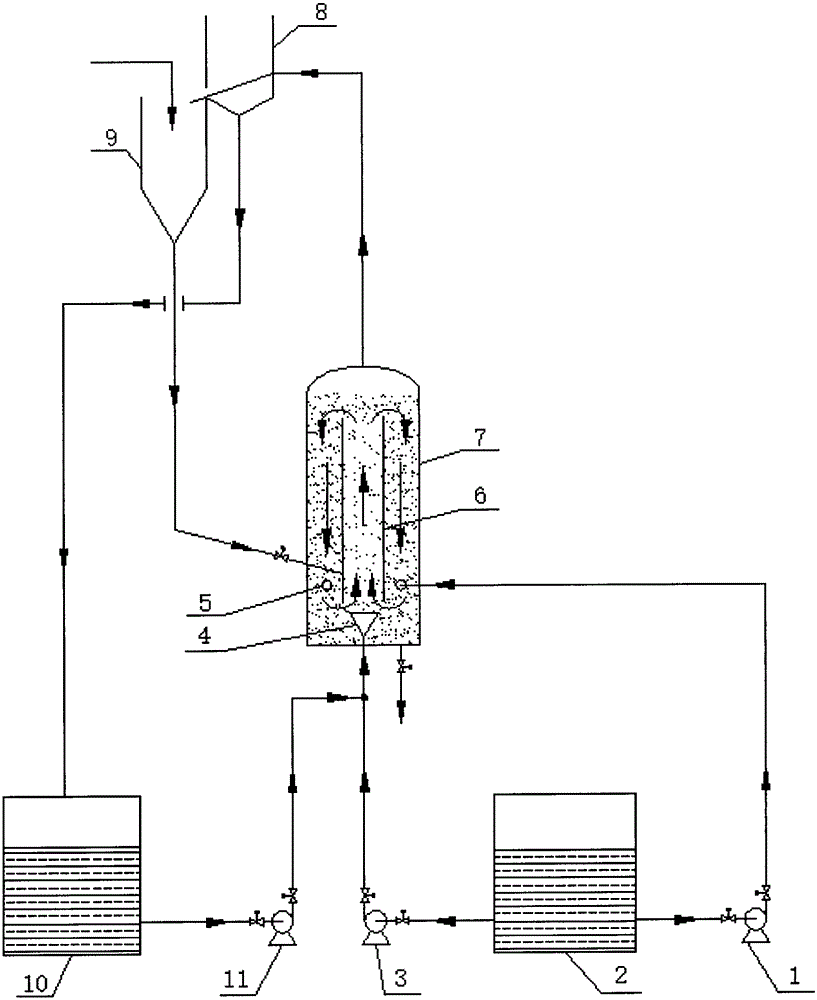

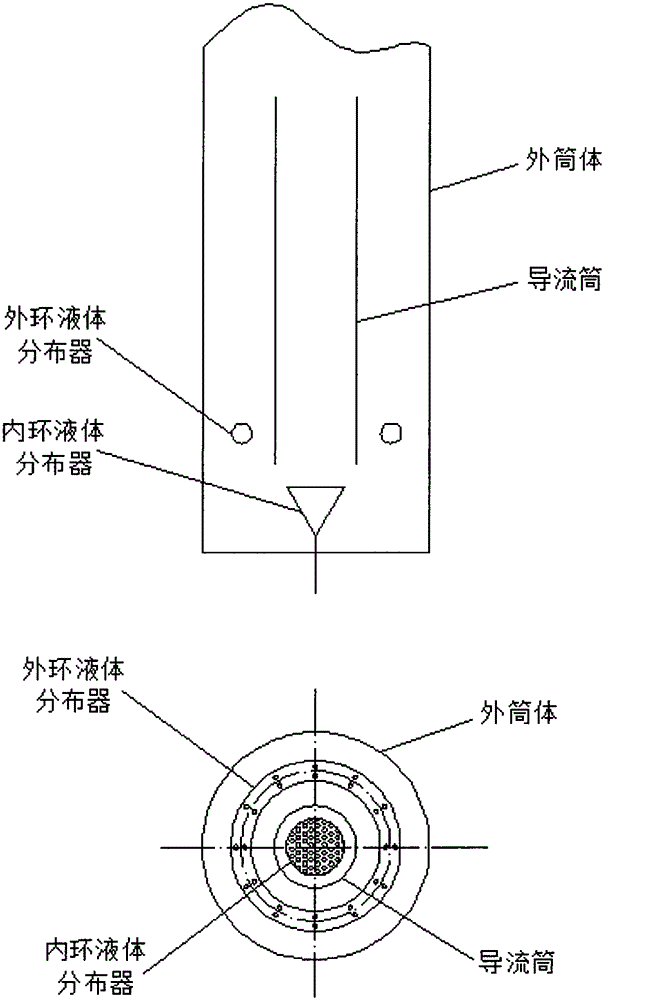

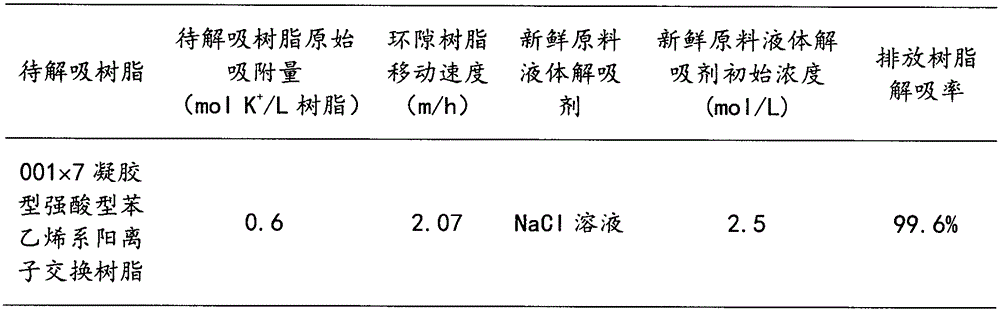

Ion desorption device and operating method thereof

InactiveCN105126939AControl desorption efficiencyHigh desorption rateIon-exchanger regenerationDesorptionWastewater

The invention provides an ion desorption device and an operating method thereof. The ion desorption device at least comprises an ion desorption system, a liquid-solid separation system, a resin transportation system and a liquid transportation system; the ion desorption system mainly comprises an inner annular liquid distributor, an outer annular liquid distributor, a guide barrel and an outer barrel. A first circuit of liquid desorption agent enters the guide barrel by virtue of the inner annular liquid distributor to contact resin to be desorbed in the guide barrel at a bubbling bed and turbulent bed state; a second circuit of liquid desorption agent enters an annular gap between the outer barrel and the guide barrel by virtue of the outer annular liquid distributor to contact the resin to be desorbed at a moving bed state, and the resin to be desorbed circumferentially flows between the annular gap and the guide barrel. The first circuit of liquid desorption agent is used as fresh raw material liquid desorption agent or desorption liquid already discharged into a desorption liquid storage trough, so that a purpose of high desorption rate and high emission liquid concentration can be realized. The ion desorption device is simple, efficient, continuous in operation, flexible to control and widely applied to the fields such as separation and recovery of metal elements and salt-containing waste water treatment.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com