UV/O3/H2O2 advanced oxidation reactor and process

A H2O2, advanced oxidation technology, applied in the field of reaction systems, can solve the problems of low ozone utilization rate, short hydraulic retention time, lack of technology and research, etc., and achieve the effect of improving oxidation efficiency, reducing hydraulic retention time, and flexible process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

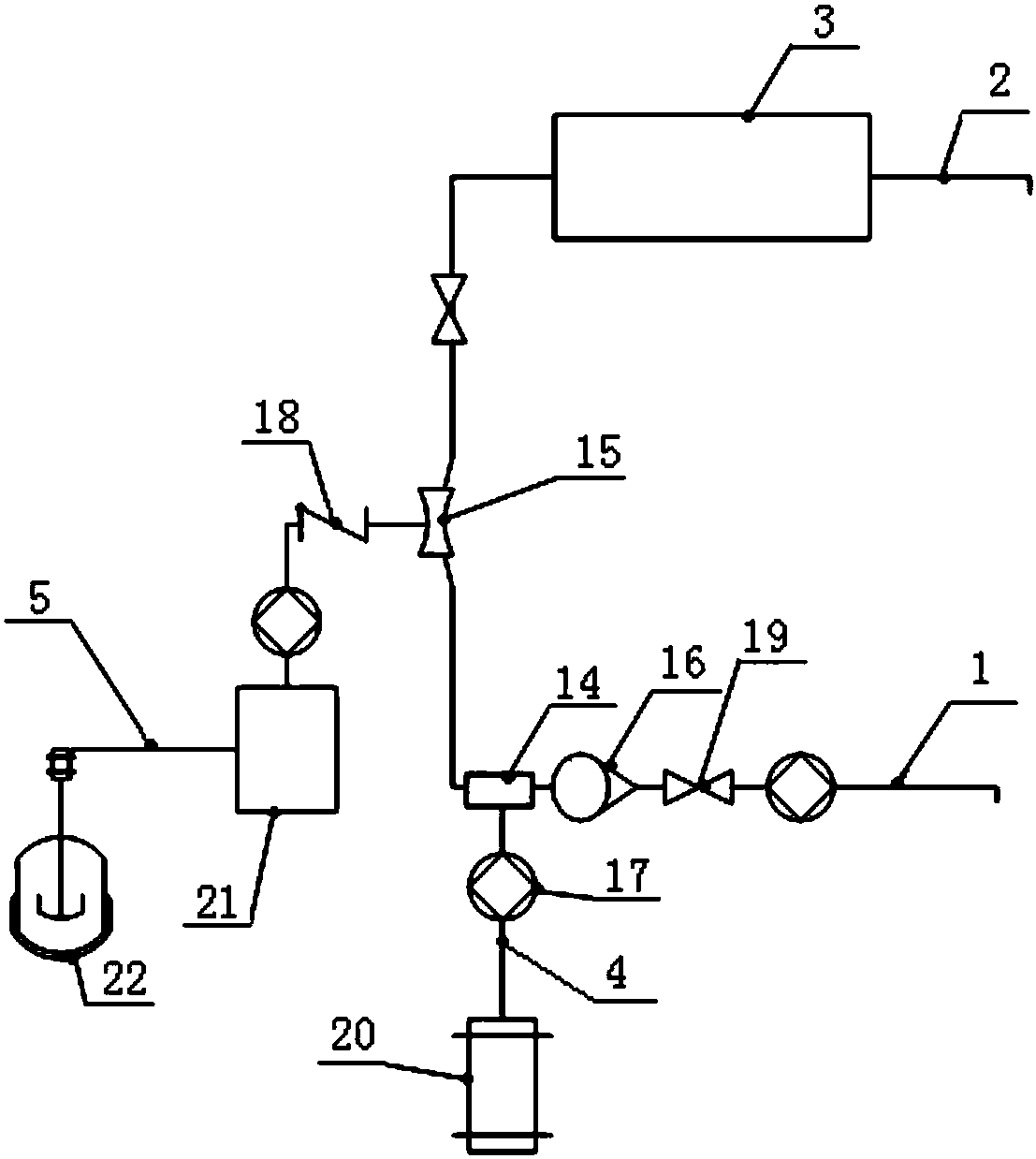

[0023] figure 1 Shown is the process flow diagram of the present invention.

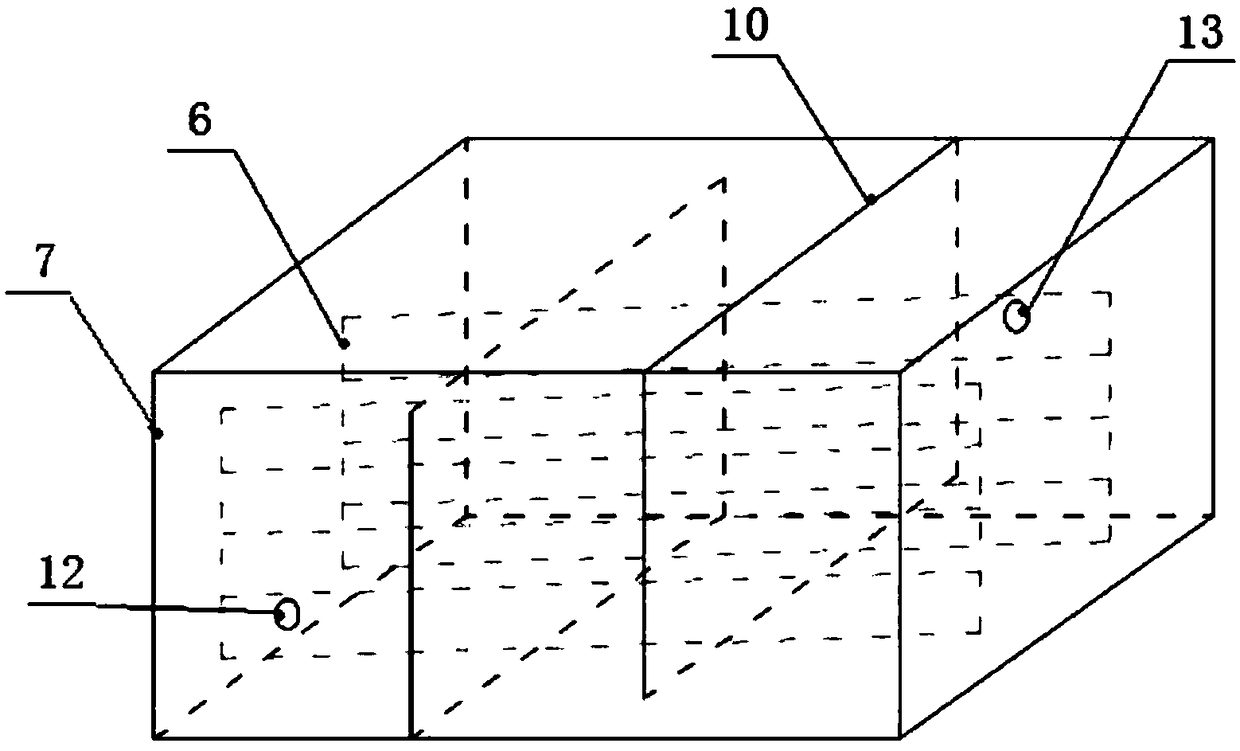

[0024] The invention provides a UV / O 3 / H 2 o 2 Advanced oxidation reactor, including water inlet pipe 1, water outlet pipe 2, ultraviolet reactor 3, H 2 o 2 Dosing facility 4 and O 3 Dosing facility 5.

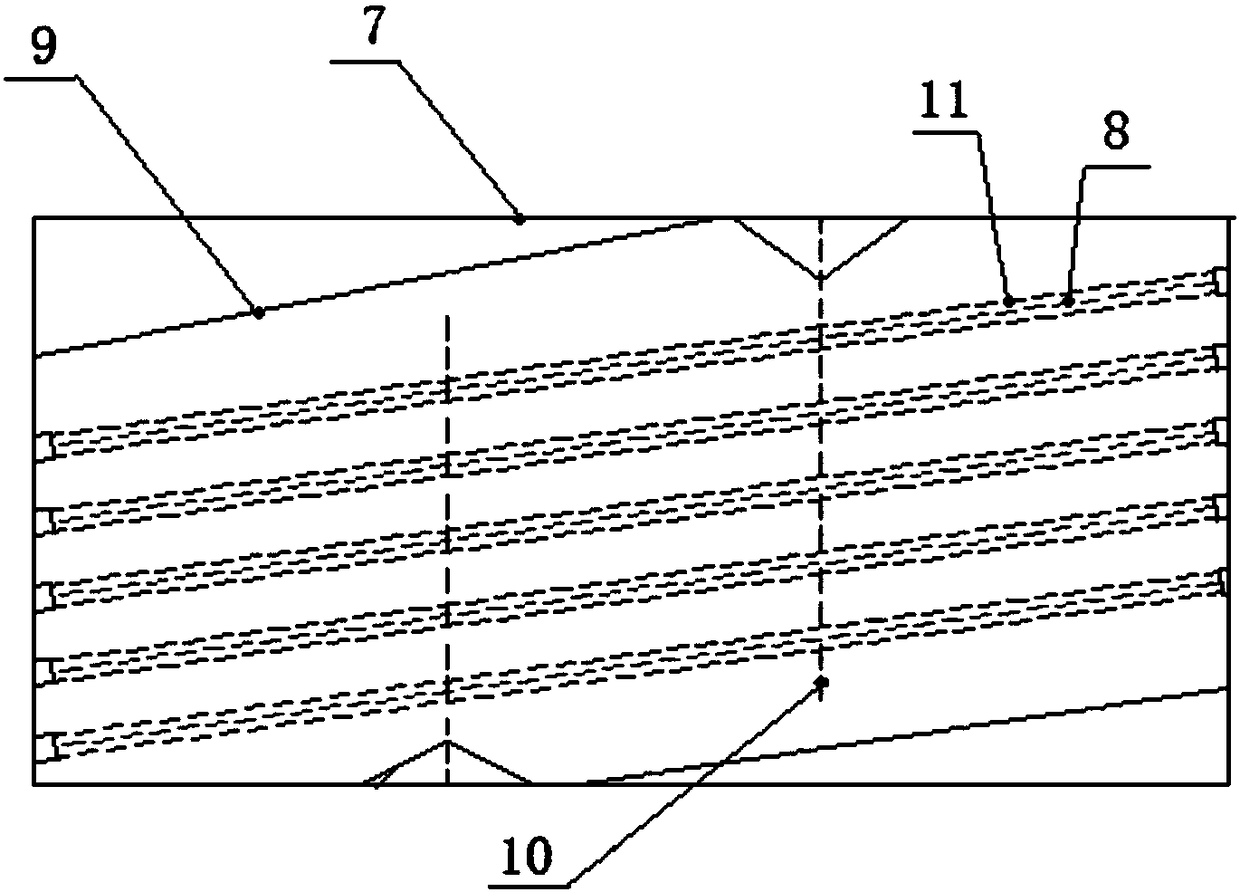

[0025] The ultraviolet reactor 3 adopts a prancing structure in which the bottom enters and the top exits, and several ultraviolet lamp groups 6 are embedded, and the ultraviolet lamp group 6 and the partition 9 are arranged at a certain angle; the hydraulic retention time is not greater than 5min, and the flow rate is not greater than 0.15m / s; UV dose is 200-300mJ / cm 2 .

[0026] The water inlet pipe 1 is connected to the water inlet 12 below the ultraviolet reactor, and the water outlet pipe 2 is connected to the water outlet 13 above the ultraviolet reactor. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com